Rare earth manganese brass alloy and producing process thereof

A manganese brass and alloy technology, applied in the field of lead-free environment-friendly free-cutting rare earth manganese brass alloy, can solve the problems of soaring production cost of selenium brass, poor plasticity and cutting performance, low production efficiency, etc. Polished surface quality, increased hardness and strength, high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

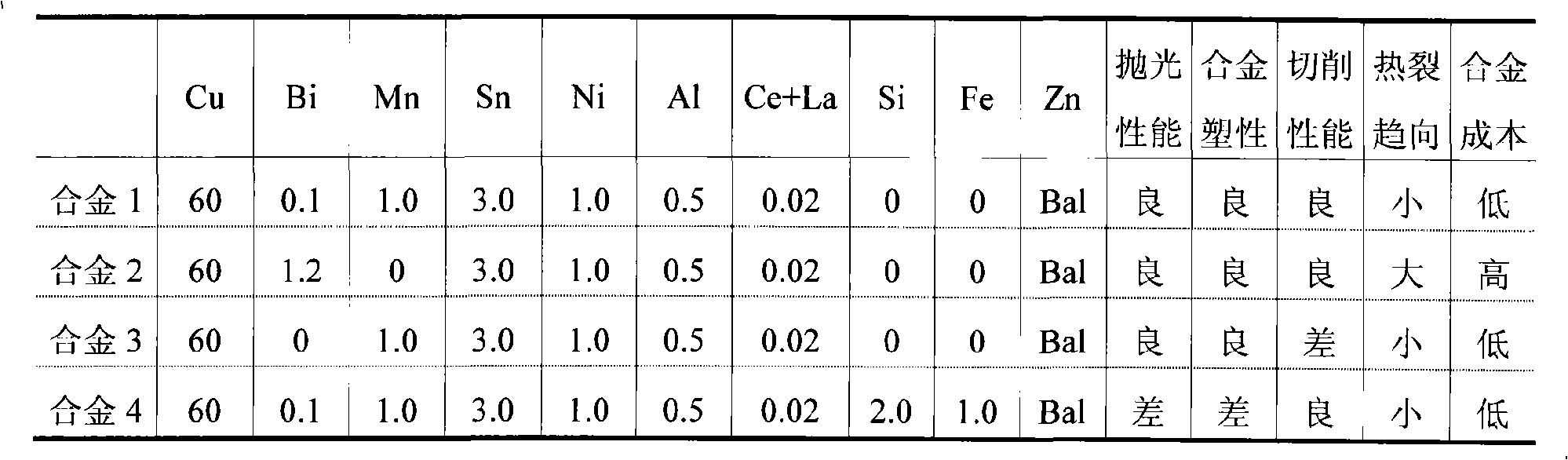

Examples

Embodiment 1

[0026] Using a power frequency induction furnace, after the copper is melted, add a covering agent to prevent the copper from being oxidized by direct contact with the atmosphere. Raise the temperature to about 1200°C, add zinc, aluminum, copper-manganese master alloy, copper-bismuth master alloy, and copper-cerium-lanthanum master alloy to the copper melt in sequence according to the composition ratio, add refining agent and refine, spray fire several times, and let stand Cast after 15 minutes. Its components are respectively by weight percentage: 60wt% Cu, 1.0wt% Mn, 0.1wt% Bi, 0.5wt% Al, 0.02wt% Ce+La, and the rest are Zn and unavoidable impurities.

[0027] The mechanical properties of the rare earth manganese brass alloy produced by the above production process after being extruded and drawn into a round bar are:

[0028]

[0029] Other performance indicators are as follows:

[0030] 1. Thermal processing performance: equivalent to HPb59-1;

[0031] 2. Cutting perform...

Embodiment 2

[0036] Using a power frequency induction furnace, after the copper is melted, add a covering agent to prevent the copper from being oxidized by direct contact with the atmosphere. Raise the temperature to about 1200°C, add zinc, aluminum, tin, copper-silicon master alloy, copper-bismuth master alloy, and copper-cerium-lanthanum master alloy to the copper melt in sequence according to the proportion of the ingredients, add refining agent and refine, spray fire several times, Let stand for 15 minutes before pouring. Its components by weight percentage are: 60wt% Cu, 3.0wt% Sn, 1.0wt% Mn, 0.1wt% Bi, 0.5wt% Al, 0.02wt% Ce+La, and the rest are Zn and unavoidable impurities.

[0037] The mechanical properties of the rare earth manganese brass alloy produced by the above production process after being extruded and drawn into a round bar are:

[0038]

[0039] Other performance indicators are as follows:

[0040] 1. Thermal processing performance: equivalent to HPb59-1;

[0041]...

Embodiment 3

[0047] Using a power frequency induction furnace, after the copper is melted, add a covering agent to prevent the copper from being oxidized by direct contact with the atmosphere. Raise the temperature to about 1200°C, add zinc, nickel, aluminum, tin, copper-silicon master alloy, copper-bismuth master alloy, copper-cerium-lanthanum master alloy in turn to the copper melt according to the proportion of the ingredients, add refining agent and refine and then spray fire The first time, cast after standing for 15 minutes. Its components by weight percentage are: 60wt% Cu, 1.0wt% Ni, 3.0wt% Sn, 1.0wt% Mn, 0.1wt% Bi, 0.5wt% Al, 0.02wt% Ce+La, and the rest are Zn and Unavoidable impurities.

[0048] The mechanical properties of the rare earth manganese brass alloy produced by the above production process after being extruded and drawn into a round bar are:

[0049]

[0050] Other performance indicators are as follows:

[0051] 1. Thermal processing performance: equivalent to HP...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com