Patents

Literature

71results about How to "Reduce cutting action" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

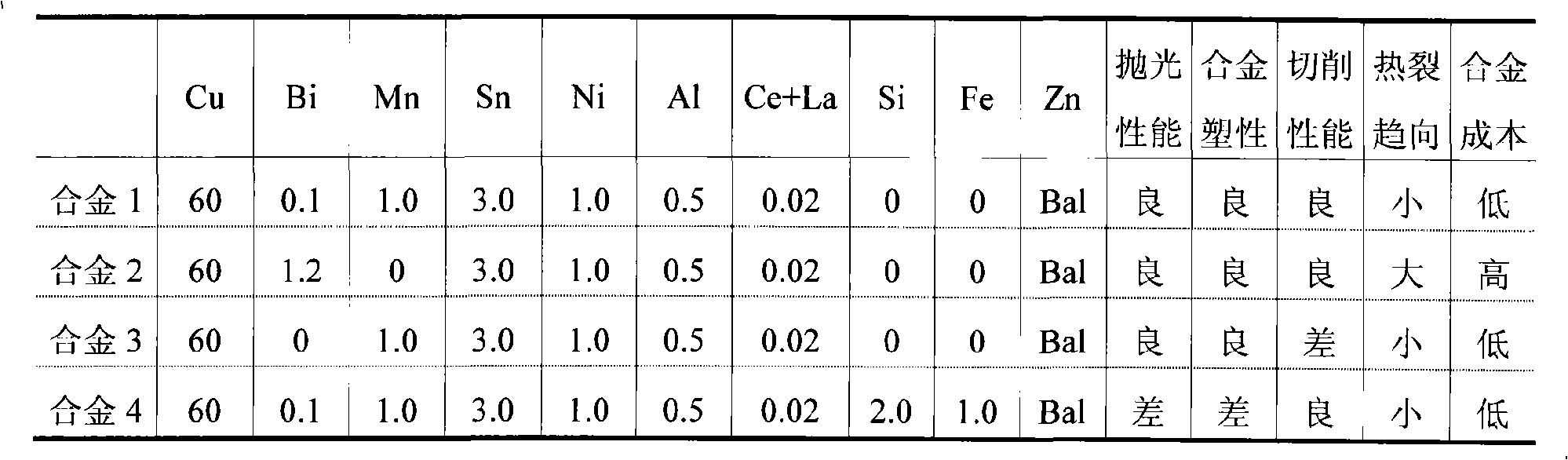

Rare earth manganese brass alloy and producing process thereof

The invention relates to a rare earth brass alloy with environment protection and easy cutting, which achieves the purpose of improving the easy cutting of the alloy by adding Bi and Mn to replace the lead in Pb brass. The alloy has the components of 55.0-65wt percent of Cu, 0.1-2.5wt percent of Bi, 0.1-1.0wt percent of Mn, 0-3.0wt percent of Sn, 0-1.0wt percent of Ni, 0.1-1.0wt percent of Al, 0.01-0.05wt percent of one or two of Ce and La, the rest of Zn and other inevitable impurities, wherein Bi, Si, Ce, La and Ce+La are added respectively in the form of master alloys of Cu-Bi, Cu-Si, Cu-Ce, Cu-La and Cu-Ce-La. The alloy has the advantages of favorable cutting performance, cold and hot working performances and cast performance, little thermal fragment trend, simple production process of supporting preparation in the existing Pb brass production equipment, low alloy cost, good polishing performance and welding performance, etc.

Owner:XIAMEN LOTA INT CO LTD

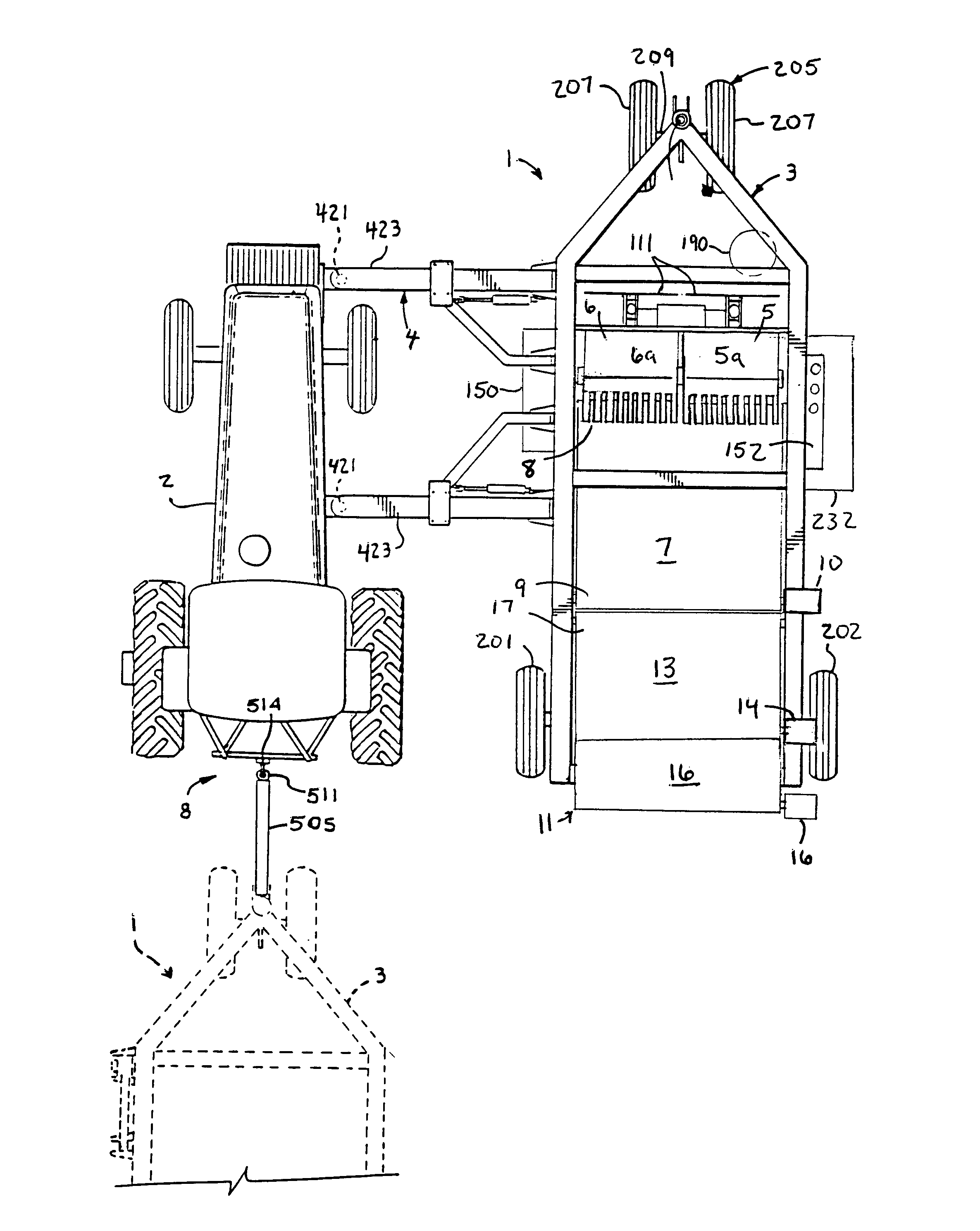

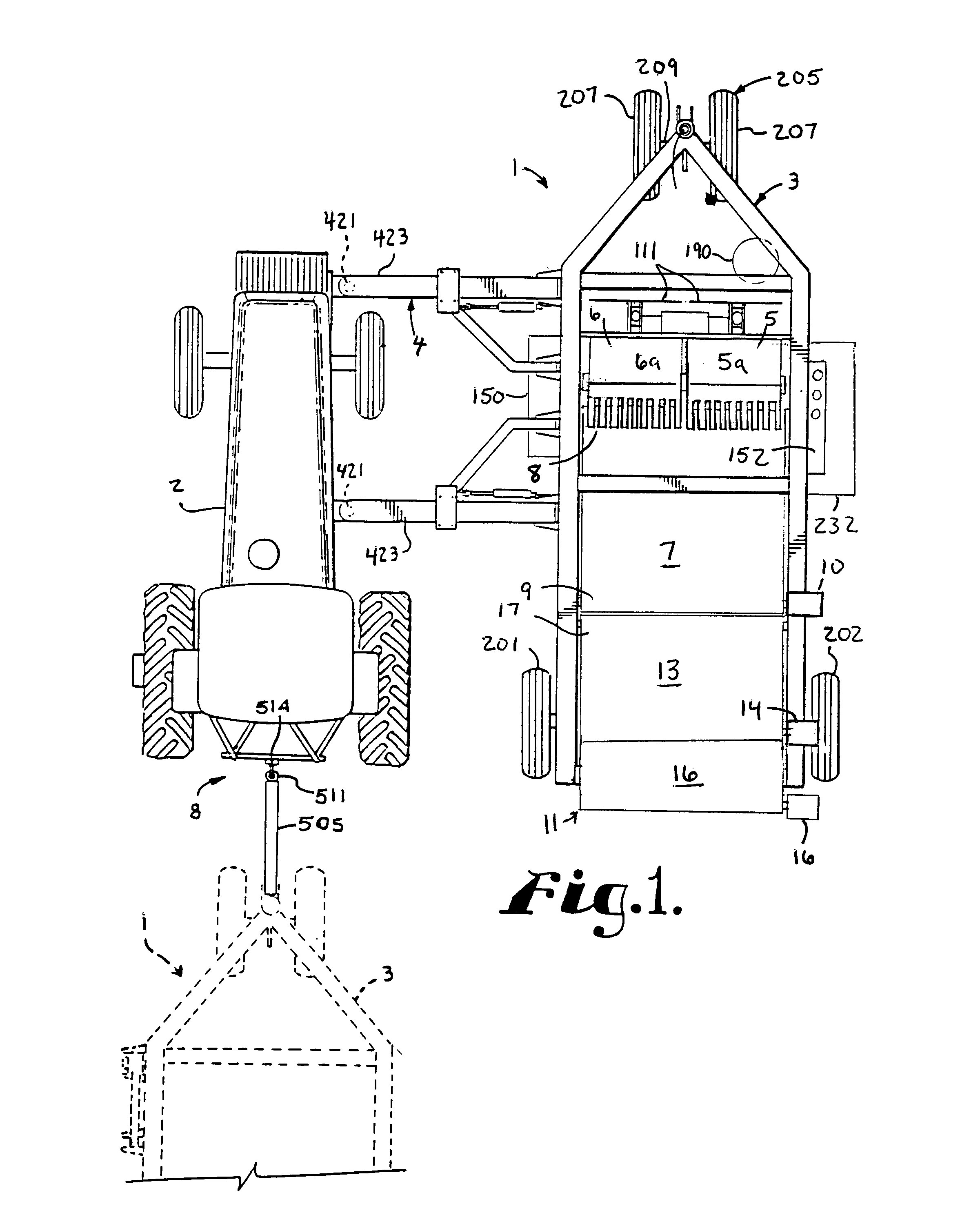

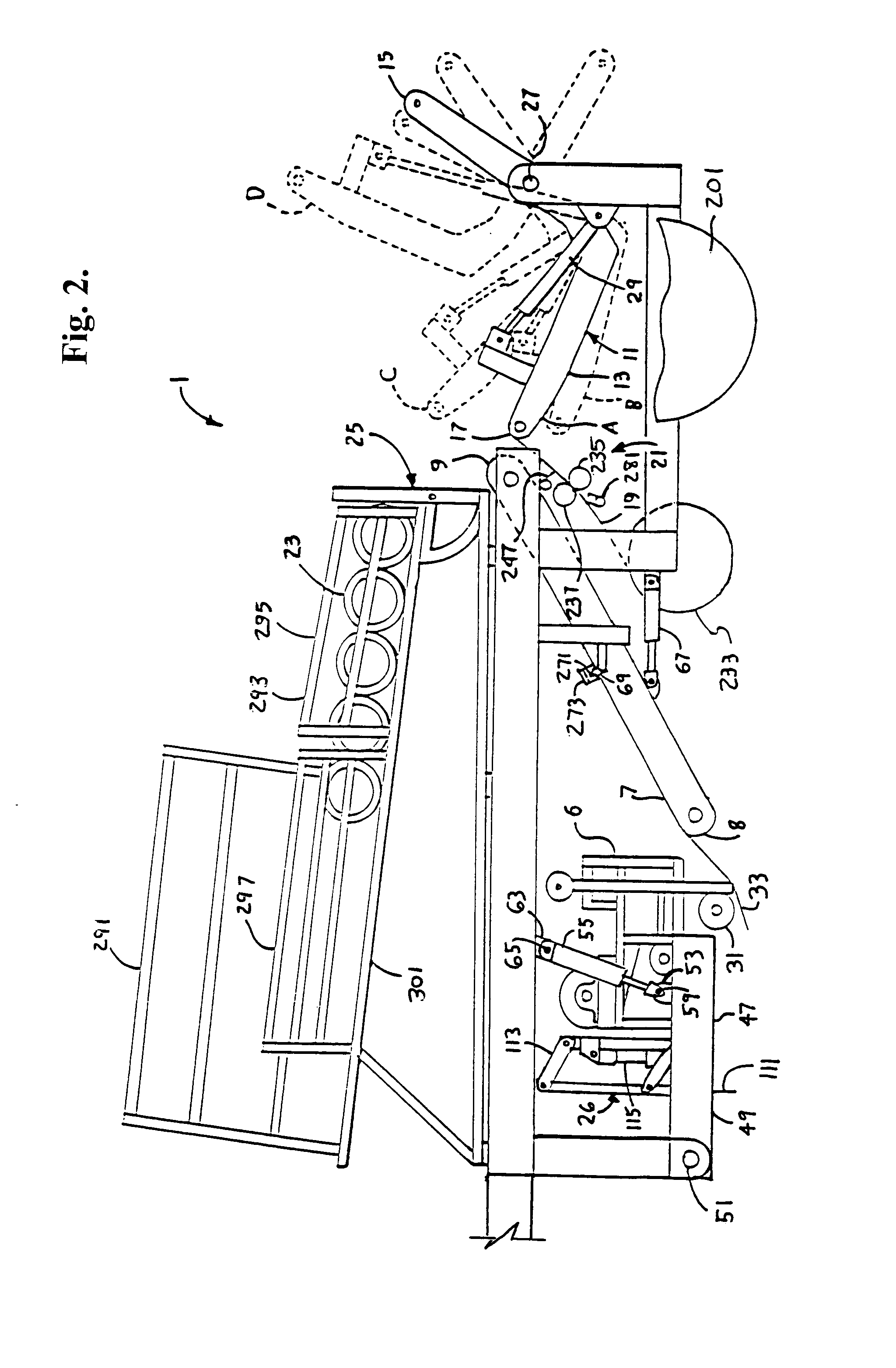

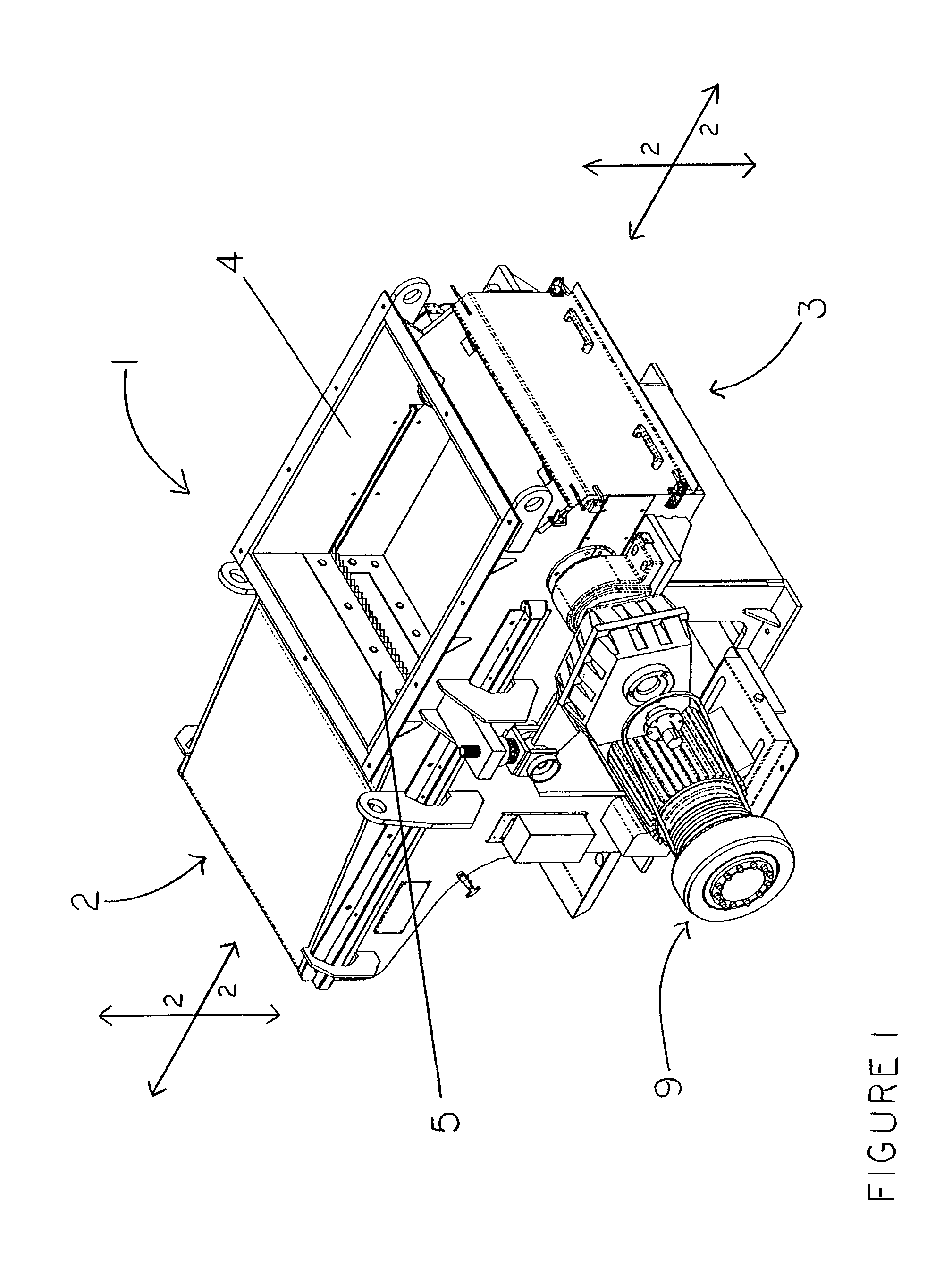

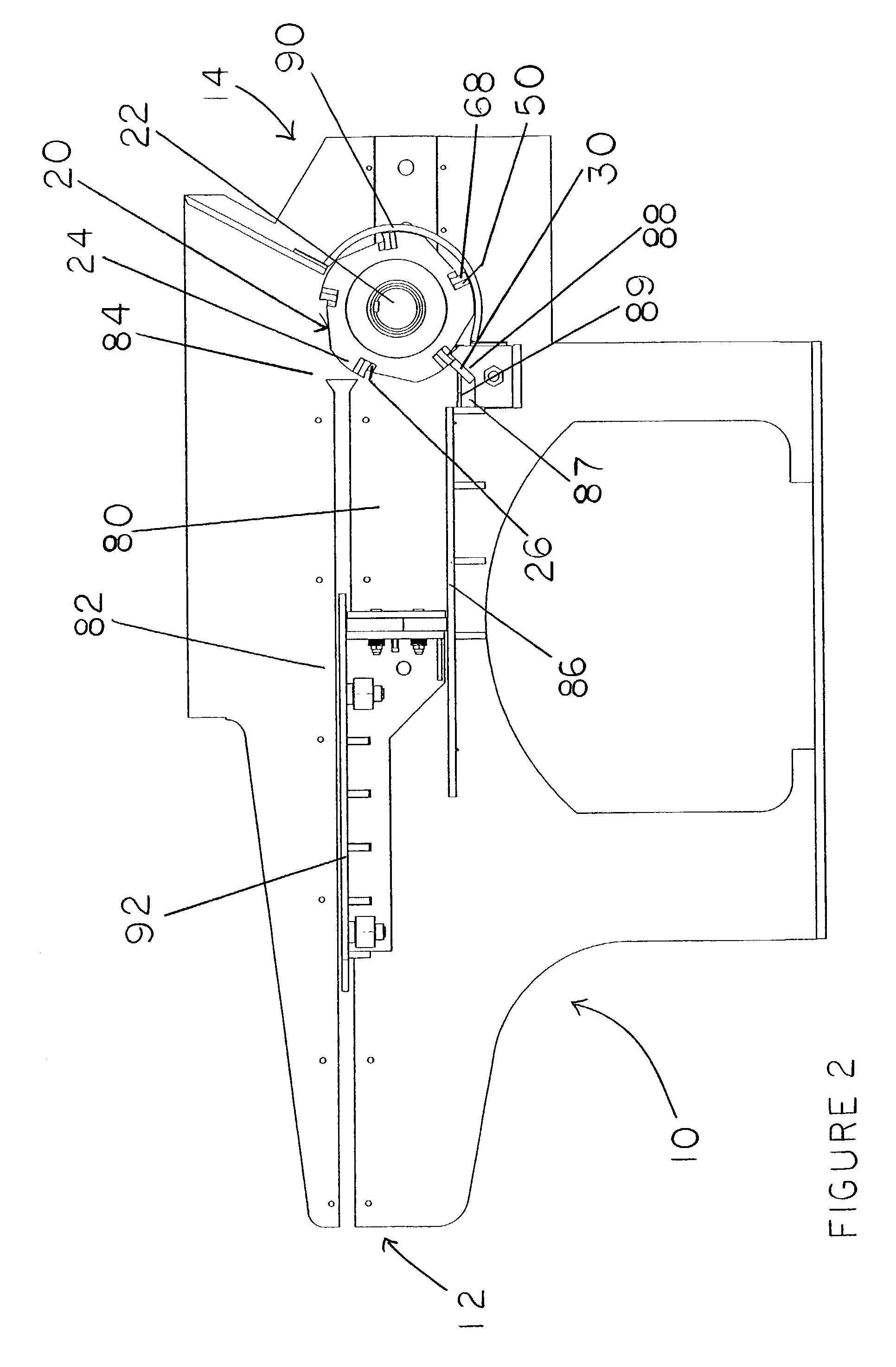

Sod harvester with controlled sod cut-off and conveying system

ActiveUS7264063B1Reduce cutting actionFast actionHops/wine cultivationTurf growingHydraulic motorControl valves

A sod harvester includes a sod cut-off system driven by a hydraulic actuator controlled by a processor in response to signals from a ground speed sensor to cut a strip of sod to a desired length. The controller also operating to control the speed of conveyors used to roll the sod into a roll. The sensor measures the rotations of a ground wheel and produces a signal which is used by a processor on the harvester to determine the distance traveled by the harvester. A control valve assembly and a high pressure hydraulic fluid accumulator provide for rapid extension of the actuators to produce a rapid downward cutting action of the cutting blades. A hydraulic motor connected in driving relationship to an outer rear wheel of the harvester provides power thereto to overcome the tendency of the tractor to drift to that side.

Owner:BUCYRUS EQUIP

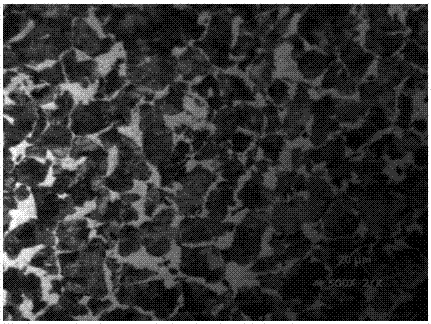

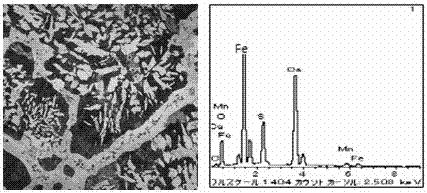

Steel and manufacturing method for Ca microalloying free-cutting high-strength expansion-breaking connecting rod

InactiveCN106939391AImprove breaking performanceReduce cutting actionChemical compositionHigh intensity

The invention relates to steel for a Ca microalloying free-cutting high-strength expansion-breaking connecting rod. The steel is prepared from, by mass percent, 0.25%-0.60% of C, 0.10%-1.20% of Si, 0.40%-1.50% of Mn, 0.05%-0.50% of Cr, 0.02%-0.15% of S, 0.02%-0.15% of P, 0.03%-0.55% of V, 0.0005%-0.0080% of Ca, 0.002%-0.035% of N, 0.002%-0.080% of Al, not larger than 0.02% of Ti and the balance Fe and inevitable impurity elements. The steel is subjected to smelting, continuous casting, heating, hot rolling and cooling, and the structure characteristic is uniform ferrite and pearlite. According to the steel, key elements in the steel are optimized, Ca microalloying is especially adopted, and the steel for the expansion-breaking connecting rod with high strength, good cutting machinability, good expansion-breaking performance and excellent comprehensive performance is obtained, and the design requirements for engine light weight, economical efficiency and driving comfort are met.

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

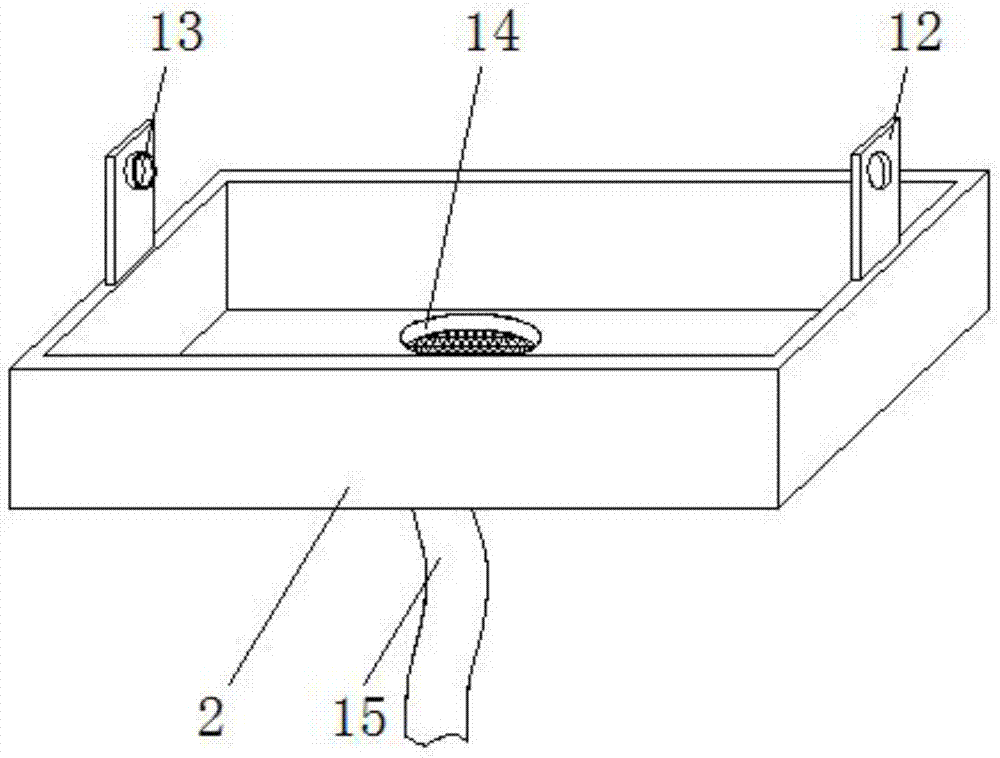

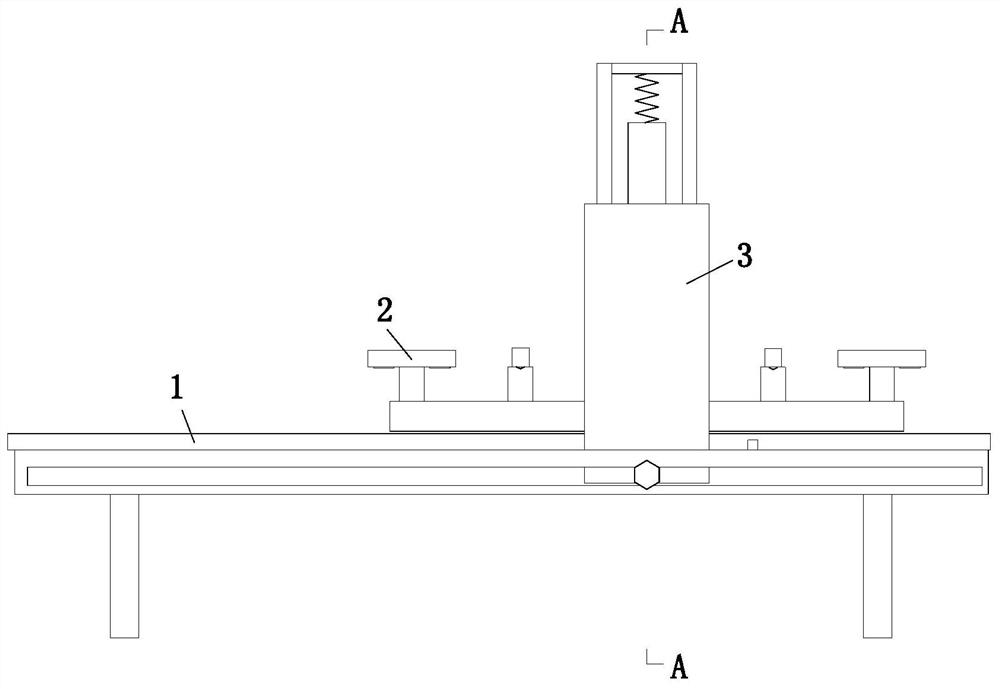

Cutting device for vehicle rubber pipe production

InactiveCN107283480ARealize the heat dissipation functionRealize left and right sliding adjustmentMetal working apparatusRotational axisHydraulic cylinder

The invention discloses a cutting device for the production of automobile rubber tubes, which comprises a machine body and a frame. A sliding track is horizontally arranged on the top of the frame, and a sliding block is slidably installed on the sliding track. There is a hydraulic cylinder, the bottom end of the hydraulic cylinder is connected with the rotary motor through the piston rod, the bottom end of the rotary motor is connected with the cutting head through the rotating shaft, and a cooling liquid nozzle is arranged on one side of the cutting head, so A coolant tank is installed on the top of one side of the frame, and a cutting groove is arranged on the top of the body. The invention can realize the precise cutting of the pipe material, and the cutting effect is good. Through the cooling liquid nozzle provided on one side of the cutting head, the heat dissipation function of the cutting head can be realized, so as to avoid the overheating of the cutting head after working for a long time. Cutting effect, can reduce the dust generated in the cutting process, reduce pollution, and simple structure, easy to use, strong practicability.

Owner:枞阳县金源汽车零部件有限公司

Magnetic-driven axial-flow auxiliary pump for heart

The invention discloses a magnetic dive axial-flow heart assistant pump, composed of stator, rotor, and DC voltage-stabilized power supply. The stator comprises stator winding and stator casing and the rotor composed of tube high-energy level magnet and propelling equipment. The propelling equipment integrated composed of internal sleeve, central shaft and two impeller blades to develop a spiral sealed blood propelling channel; the rotor is placed in the subulate shaft sleeve of stator cantilever. The stator winding generates magnetic field to drive the rotor to put the blades in motion, makes the blood one-way flow and assists or completely replaces the heart to pump blood. The stator winding is connected with the power supply.

Owner:张杰民 +1

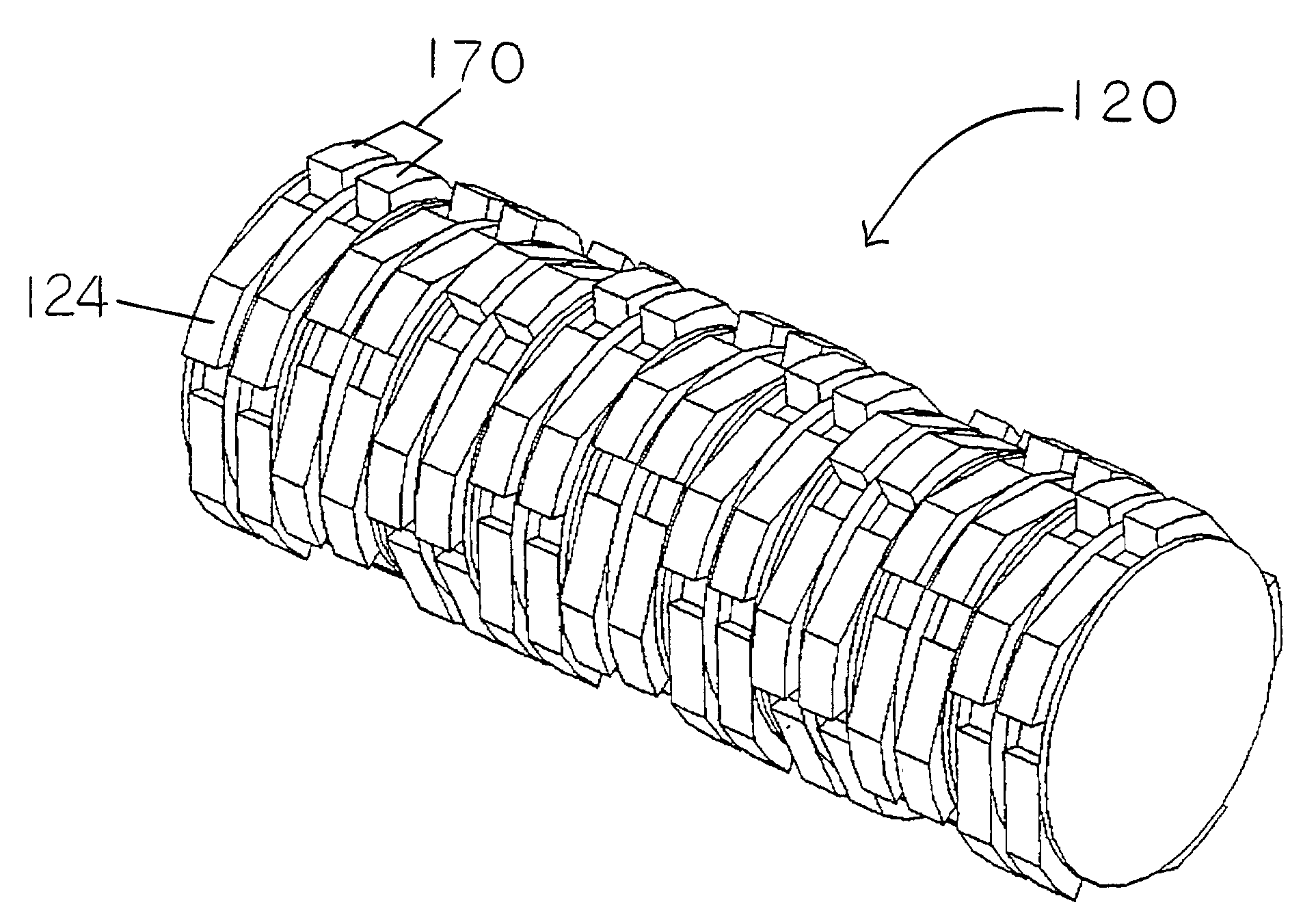

Rotor and counter knife for a rotary grinder

The present invention relates to a single shaft rotary grinder with an improved cutter and combination “comb” rotor and counter knife configuration for reducing film, fibrous material and other material which has a tendency to wrap around the rotor, rubber, solid plastics and wood. Reducing this type of material, such as plastic film, into small pieces has been problematic. This invention provides one or more comb shaped counter knives and a rotor having a plurality of geometrically shaped cutters mounted in a plurality of partial or full rows longitudinally along the rotor. The comb shaped counter knives and the rows of cutters work in cooperation to reduce film and other material into small pieces.

Owner:RAPID GRANULATOR INC

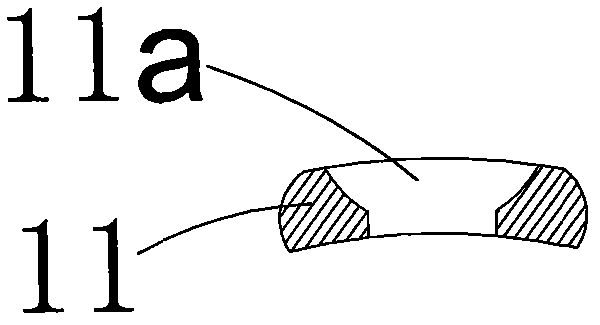

Semi-self-locking acetabulum posterior wall and posterior column anatomical plate

The invention discloses a semi-self-locking acetabulum posterior wall and posterior column anatomical plate which comprises a steel plate main body, a self-locking sleeve and self-locking screws, wherein the steel plate main body is sequentially provided with a first fixing region, a first location region, a main fixing region, a second location region and a second fixing region, the main fixing region is provided with self-locking screw holes, the first fixing region and the second fixing region are provided with non-self-locking screw holes, and the first location region and the second location region are provided with location holes. The invention can be properly twisted and bended and is in convenient moulding so as to be better jointed to a skeleton to bear joint motion load, enable the fracture to be normally healed and reduce complications such as loosening, displacement, pains, bone stress shielding and the like at a later stage of fracture. The invention has the advantages ofhaving less internal stress and relatively according with acetabulum anatomy and biomechanics, enhances the success rate of a fracture internal fixation operation, avoids moulding in the operation, saves the operation time, reduces the blood loss in the operation, reduces the anesthetic time and lowers the operation risks.

Owner:李明

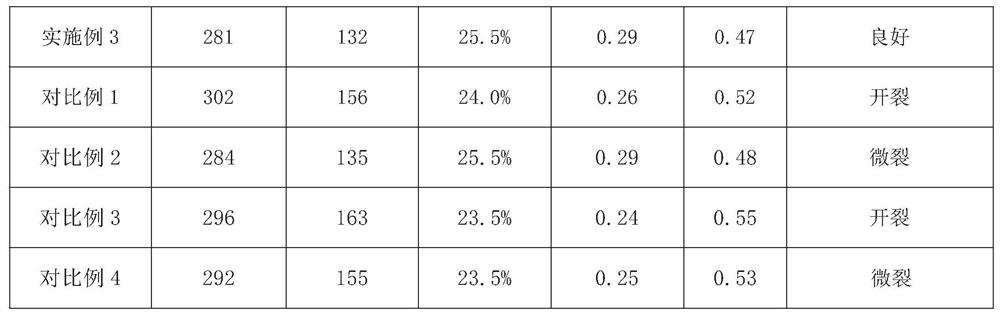

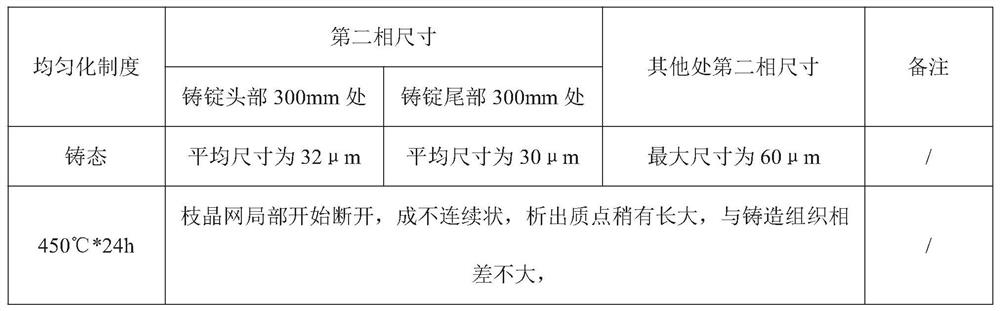

Method for improving O-state bending performance of 5083 alloy

The invention belongs to the technical field of aluminum alloy, and particularly discloses a method for improving the O-state bending performance of 5083 alloy. The method comprises the following steps of: adding prepared raw materials into a smelting furnace for smelting, and standing for refining, degassing, slagging-off and filtering to obtain molten aluminum, wherein the refining temperature is 730-740 DEG C; in the degassing process, controlling the hydrogen content measured by a launder to be less than or equal to 0.1 mL / 100g Al, and controlling the inclusion content of melt in an online launder to be less than 0.04 mm < 2 > / kg; casting the molten aluminum into an aluminum alloy cast ingot at the casting temperature of 710-720 DEG C and the casting speed of 45-55 mm / min; carrying out homogenization heat treatment on the aluminum alloy cast ingot; after preheating, sequentially carrying out multi-pass hot rough rolling and single-pass hot finish rolling to obtain a hot-rolled blank with the thickness of 10.0-12.0 mm; carrying out cold rolling on the hot-rolled blank at the high reduction rate to obtain a cold-rolled coiled material with the thickness of 3.0-5.0mm; and carrying out high-temperature rapid annealing, transverse shearing, straightening and slitting on the cold-rolled coiled material to obtain an aluminum alloy plate. The minimum relative bending radius of 90-degree bending of the 5083 alloy O-state plate can reach 0.5 t, and the surface is uniform, smooth and fine after bending.

Owner:河南明晟新材料科技有限公司

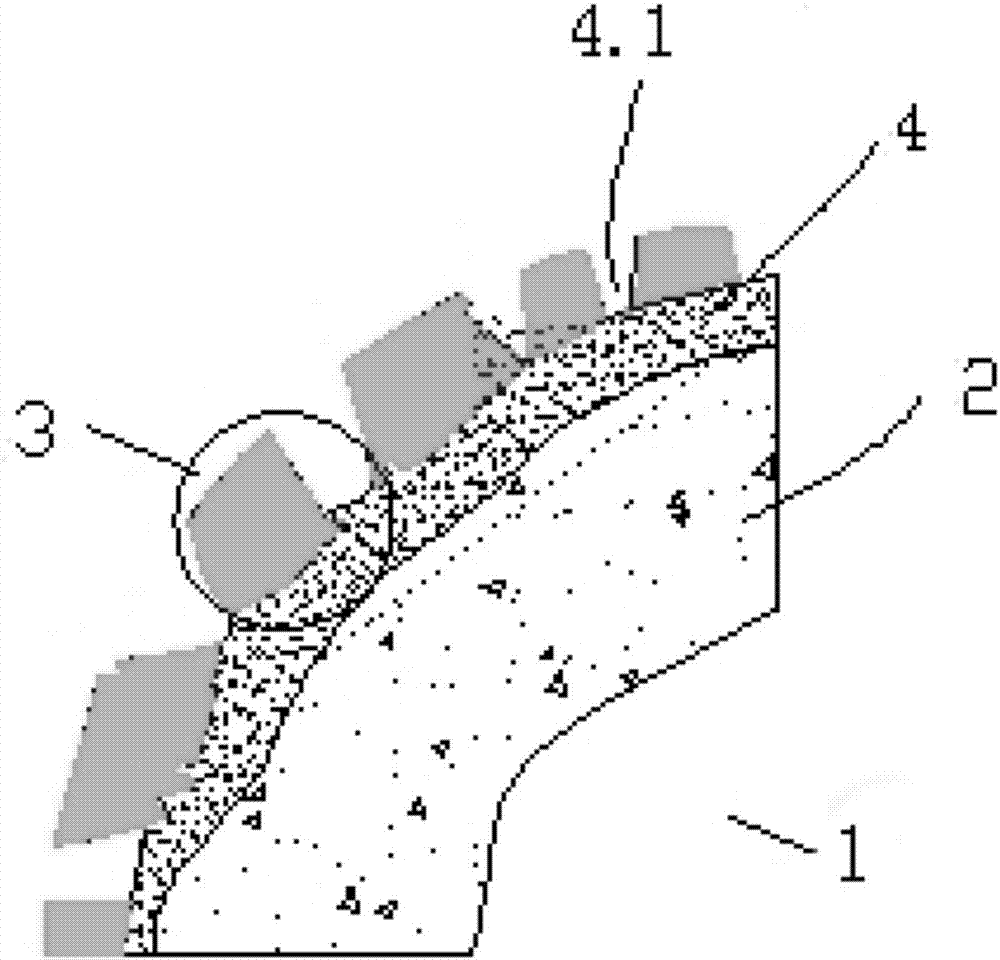

Fracturing equipment for coal bed gas exploiting

The invention discloses fracturing equipment for coal bed gas exploiting. A special pressurizing mixing mechanism is arranged to fully mix and pressurize high pressure water and sand grains fed by a sand grain supply mechanism and the mixture is sprayed through a fracturing pipe. Therefore, the sand grains are not sprayed by a high pressure pump, so that the problem that the sand grains damage blades of the high pressure pump can be solved effectively. Meanwhile, before the sand grains enter into the pressurizing mixing mechanism, the sand grains are mixed by using a lubricant, so that the condition that the cutting action to coal bed fractures is reduced as the sharp edges of the sand grains are damaged is prevented, and the fracturing and crack-increasing effects are achieved. By arranging a filter base, the sand grains can be prevented from entering a piston end, so that the piston end is prevented from being damaged. Meanwhile, increase of the pressure and the mixing action of thesand grains and the high pressure water can be also guaranteed.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

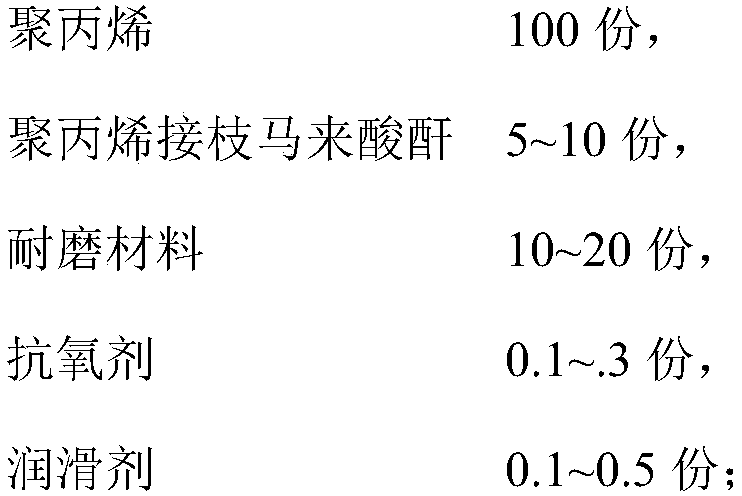

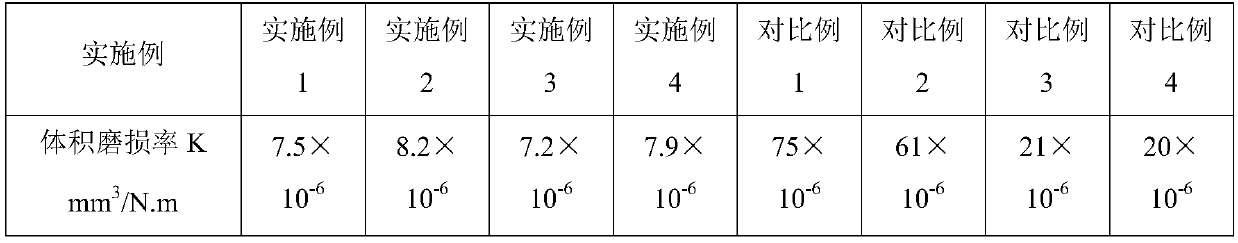

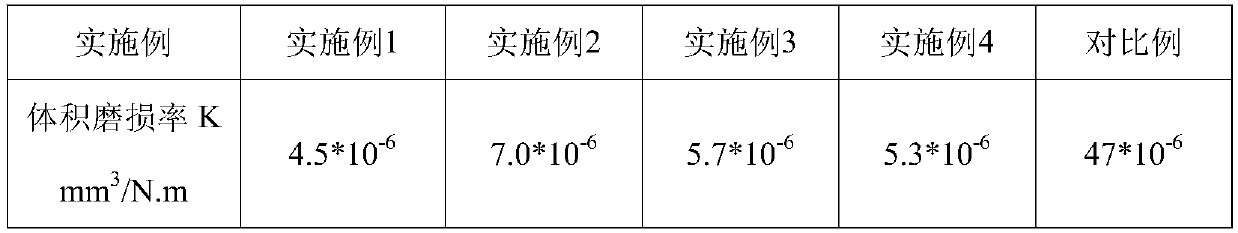

Wear-resistant polypropylene composite material and preparation method thereof

The invention discloses a wear-resistant polypropylene composite material and a preparation method thereof. The wear-resistant polypropylene composite material is composed of polypropylene, polypropylene grafted maleic anhydride, a wear-resistant material, an antioxidant and a lubricant, nano molybdenum disulfide, polytetrafluoroethylene, coupling agent A-172 and mica powder are mixed to prepare the wear-resistant material, and the wear-resistant material is added into the polypropylene composite material, so that the friction coefficient of the polypropylene composite material can be greatlyreduced, and the wear resistance of the polypropylene composite material is obviously improved.

Owner:HEFEI GENIUS NEW MATERIALS

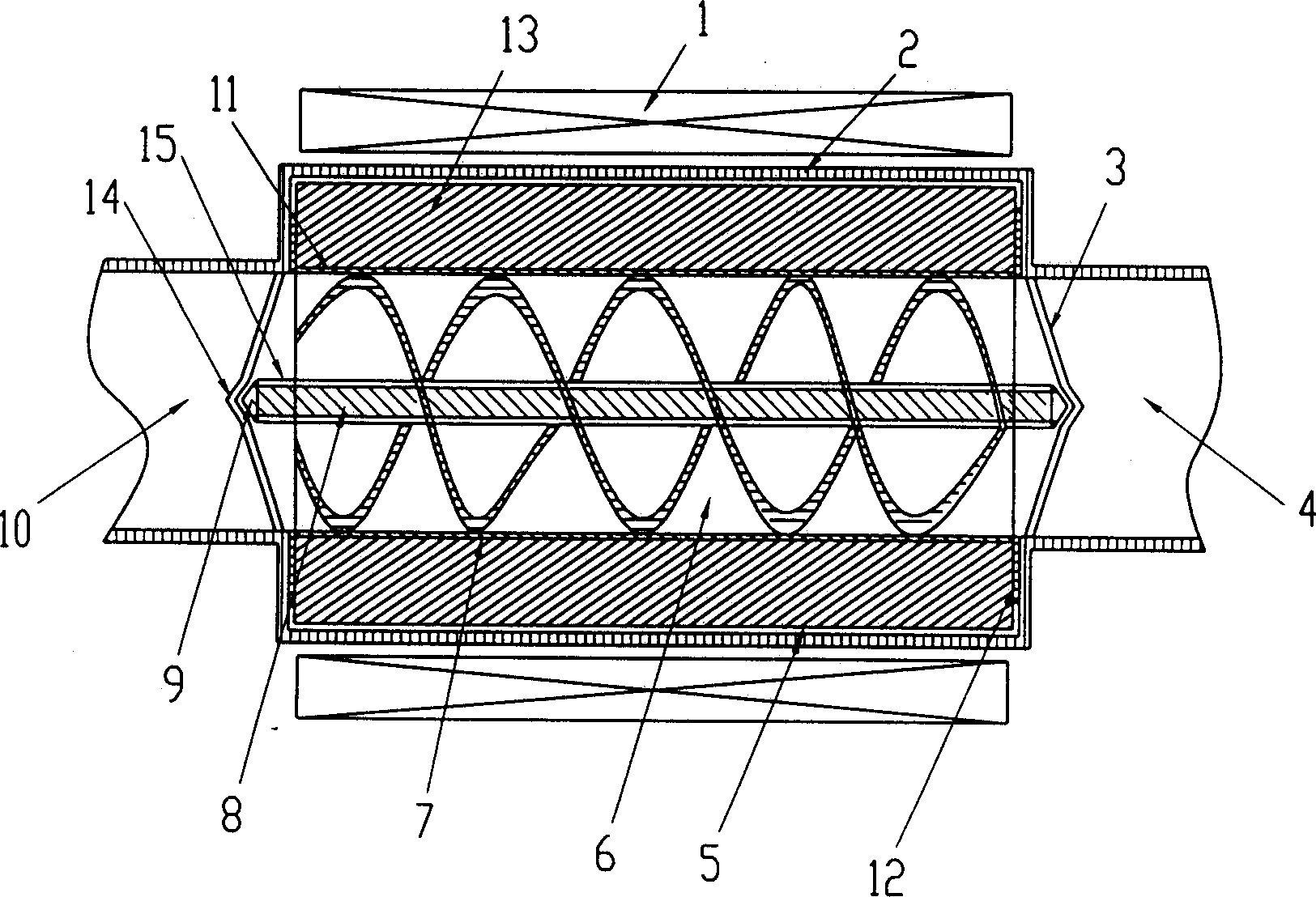

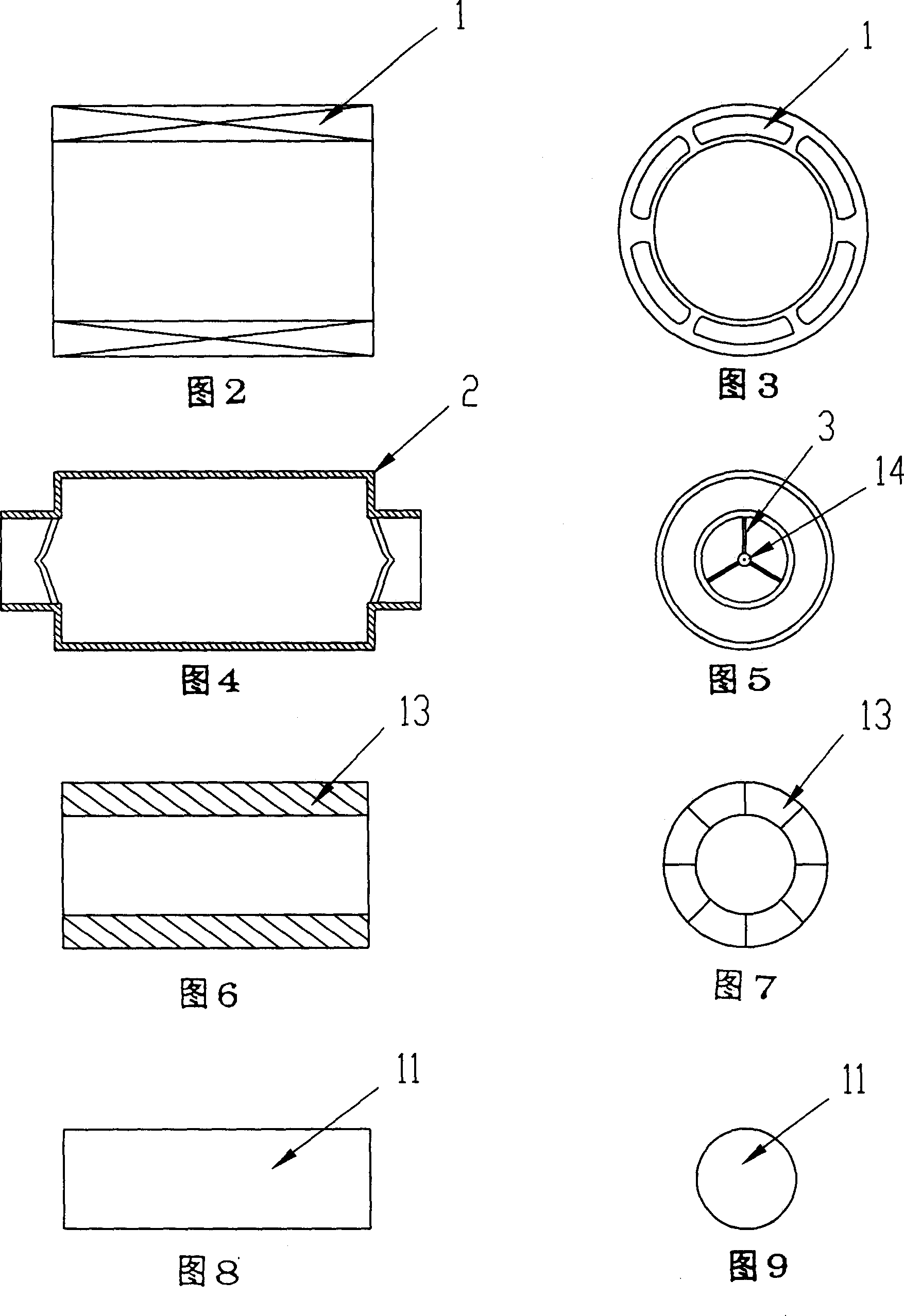

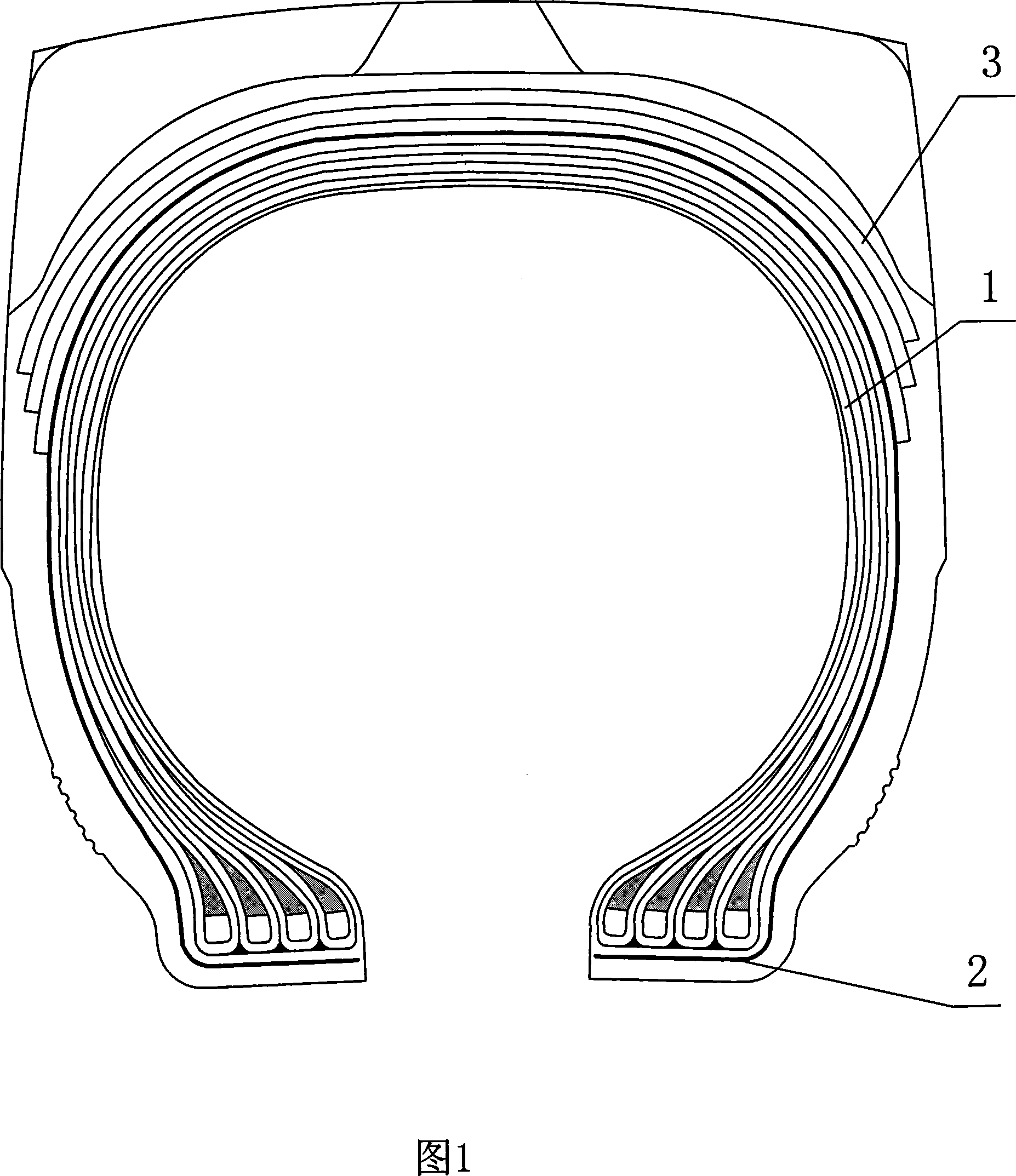

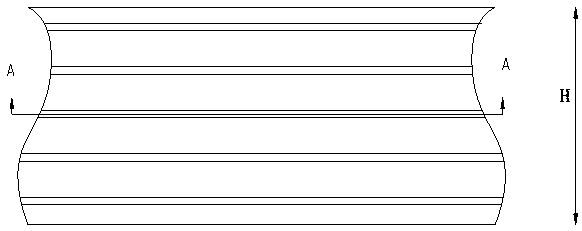

Oblique giant-scale engineering tyre

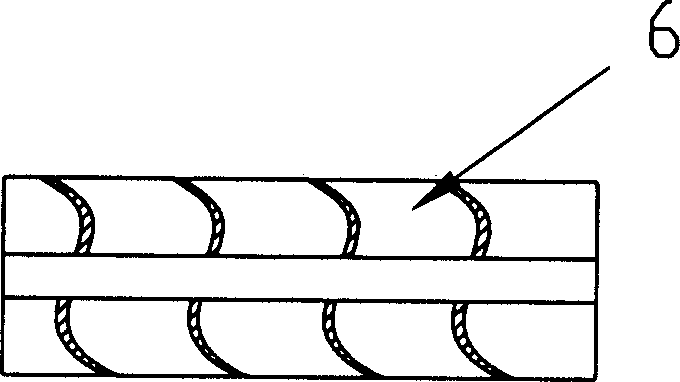

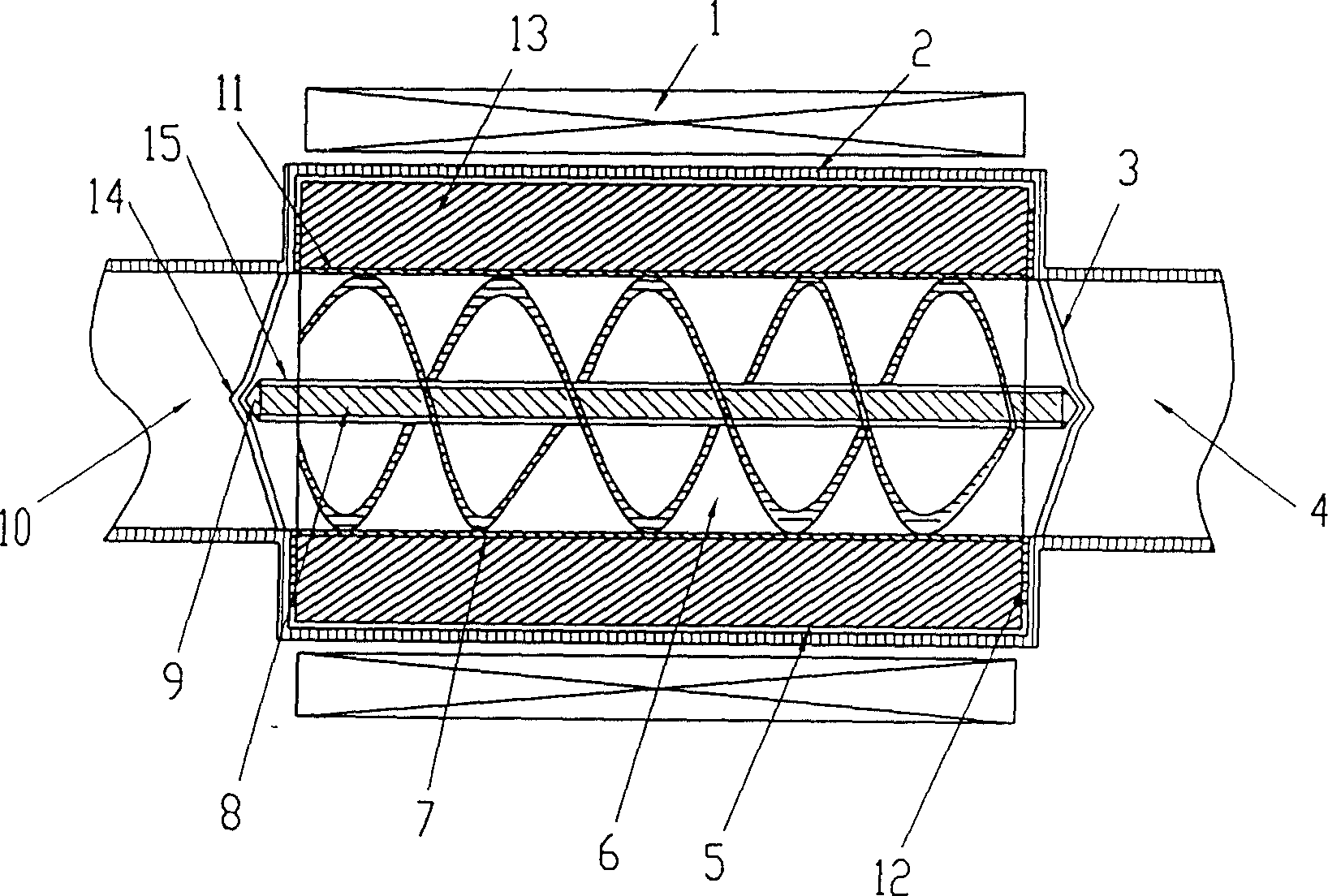

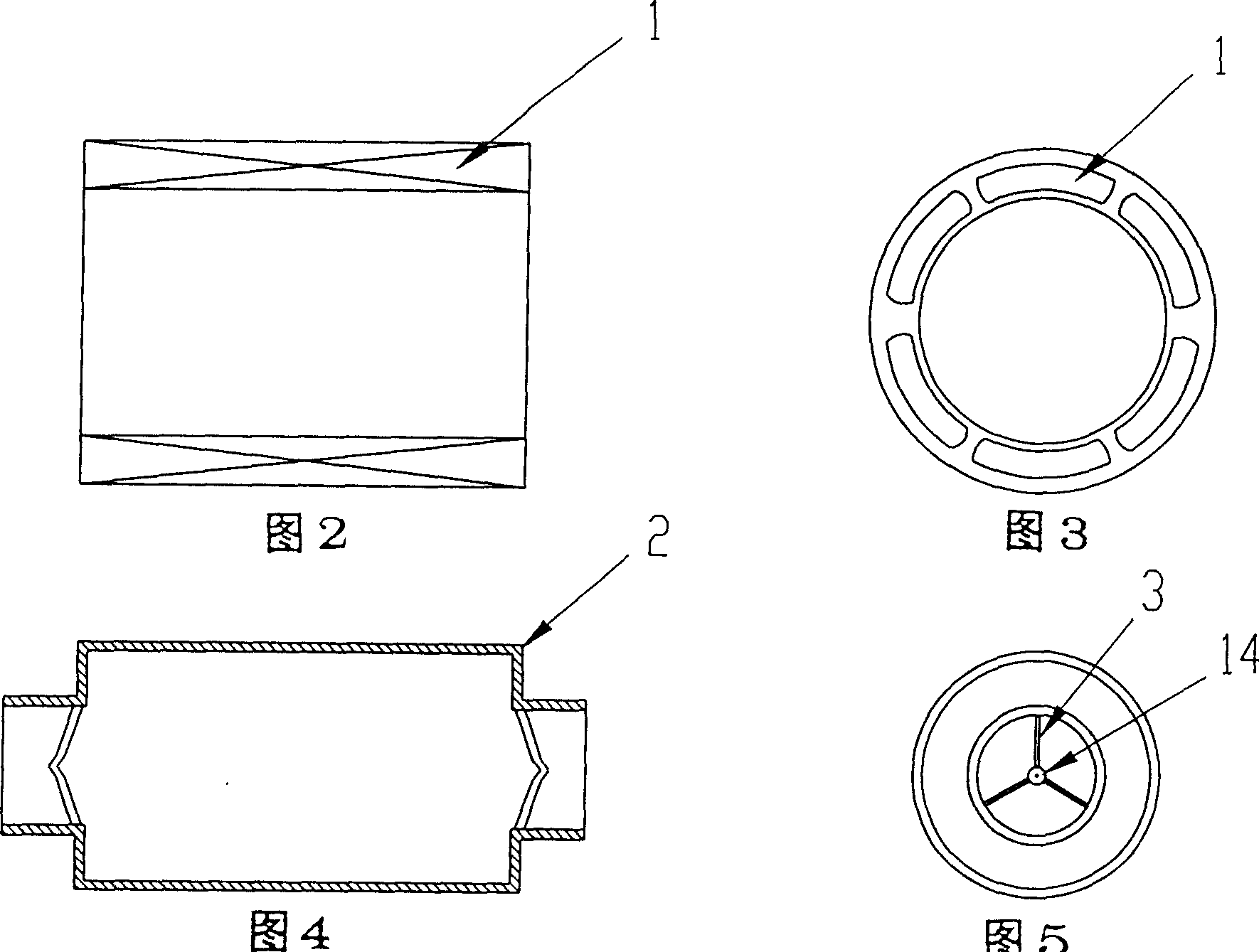

InactiveCN101229760AImprove puncture resistanceEnhanced tear resistance and other propertiesPneumatic tyre reinforcementsRolling resistanceEngineering

The invention relates to a skew giant engineering tire, which comprises a buffer layer, a matrix cord fabric layer manufactured by a cord fabric cylinder; the matrix cord fabric layer comprises a matrix cord fabric inner layer, a matrix cord fabric middle layer and a matrix cord fabric outer layer; the matrix cord fabric outer layer comprises a matrix cord fabric outer layer wrapped on an obverse side and a matrix cord fabric outer layer with travelers wrapped on a reverse side; the matrix cord fabric outer layer wrapped on the obverse side is provided at least a strengthened layer in which elastic modulus of cord threads is greater than the elastic modulus of the cord threads of the cord fabric cylinder of the cord fabric outer layer of the tire body in which travelers are wrapped on the reverse side and the cord threads of the matrix cord fabric inner layer as well as the cord threads of the matrix cord fabric middle layer; furthermore, at least one layer of the cord thread in the buffer layer is aramid material and the buffer layer is a strengthened buffer layer. The crown of the tire provided by the invention has the capability of prickling resistance and cutting resistance; service life of the tire is greatly prolonged; rolling resistance of the tire is greatly reduced; compared with the present tire adopting nylon materials as the matrix cord threads of the cord fabric outer layer, safe driving distance of the tire can be increased by over 50 percent.

Owner:HAOHUA SOUTH CHINAGUILIN RUBBER

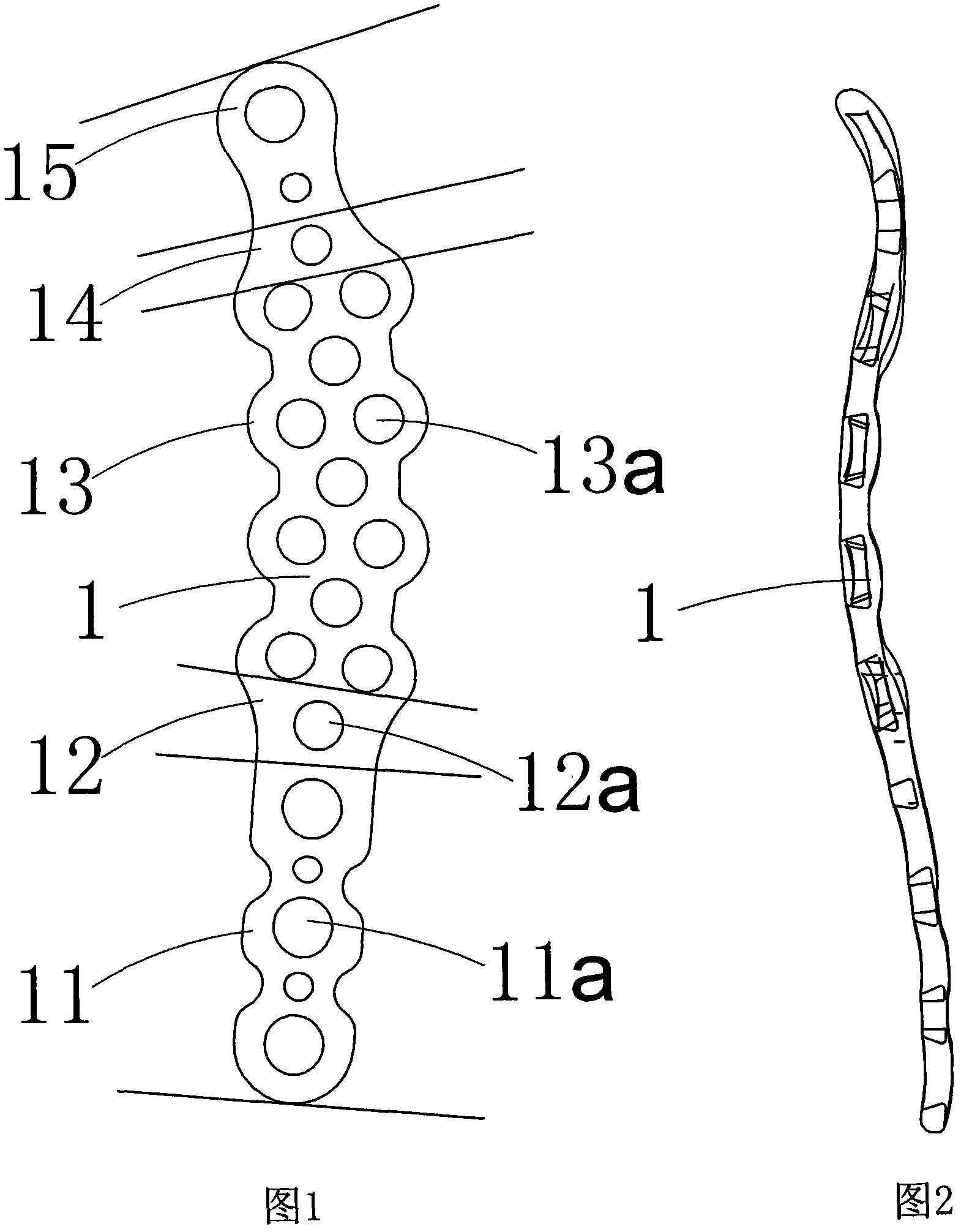

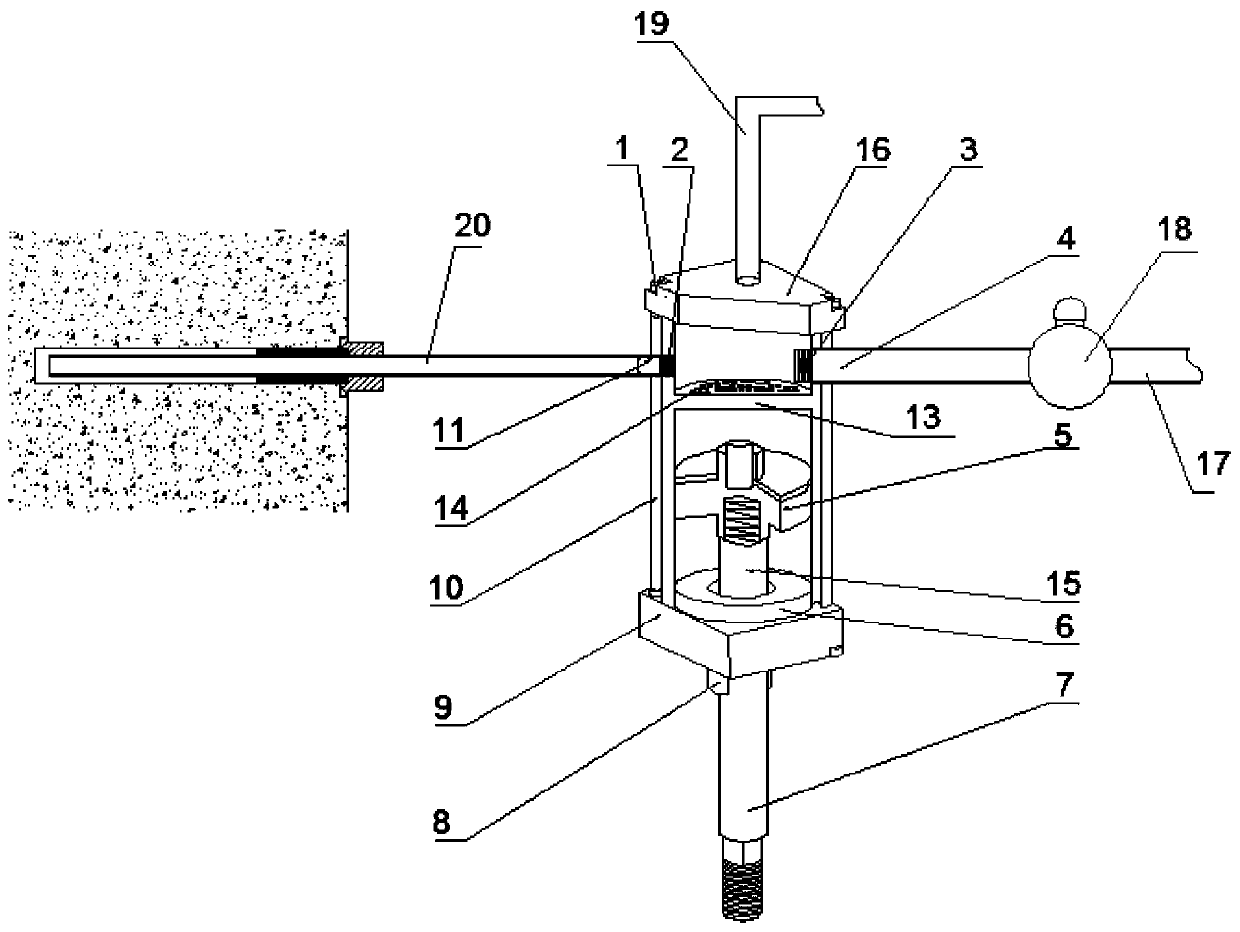

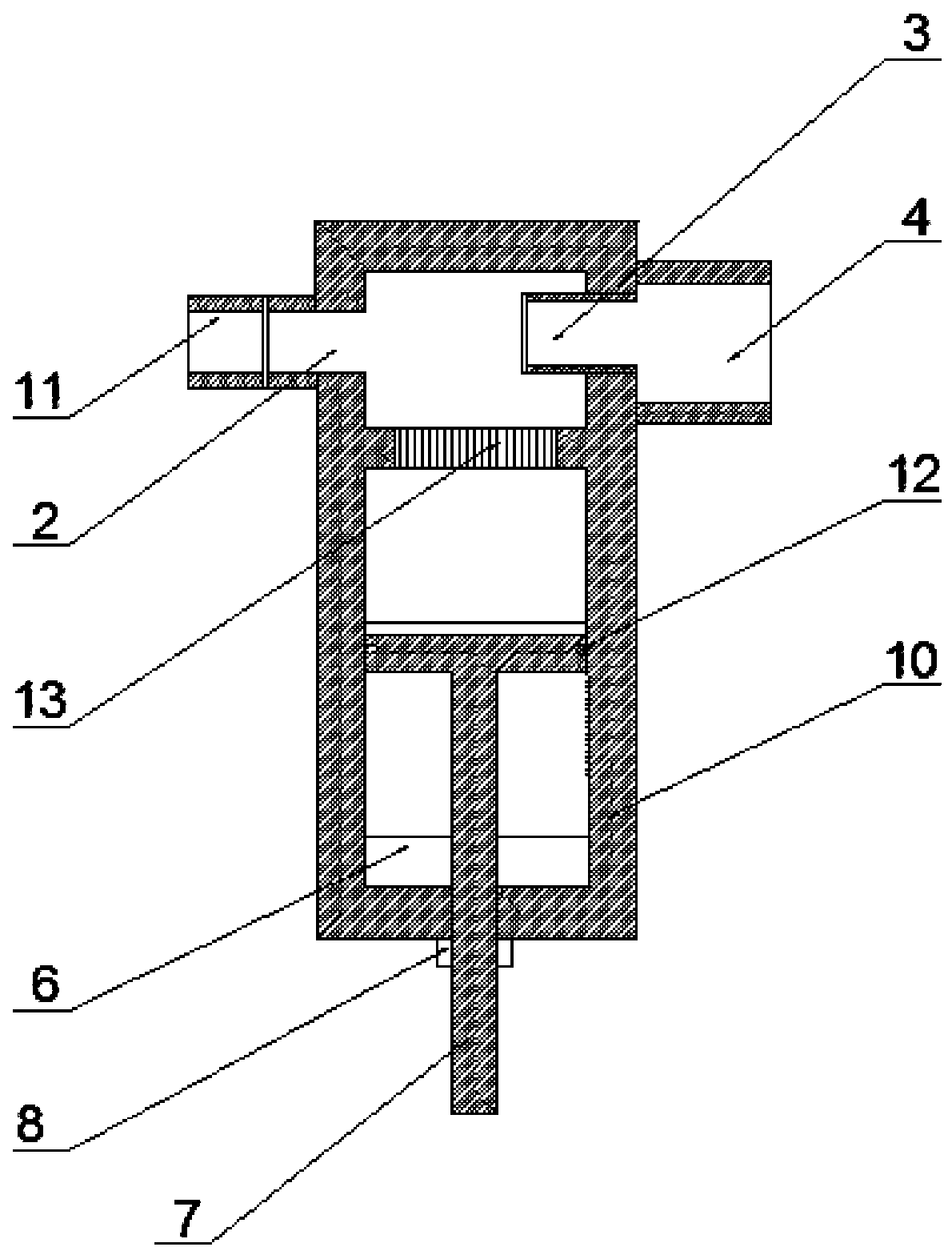

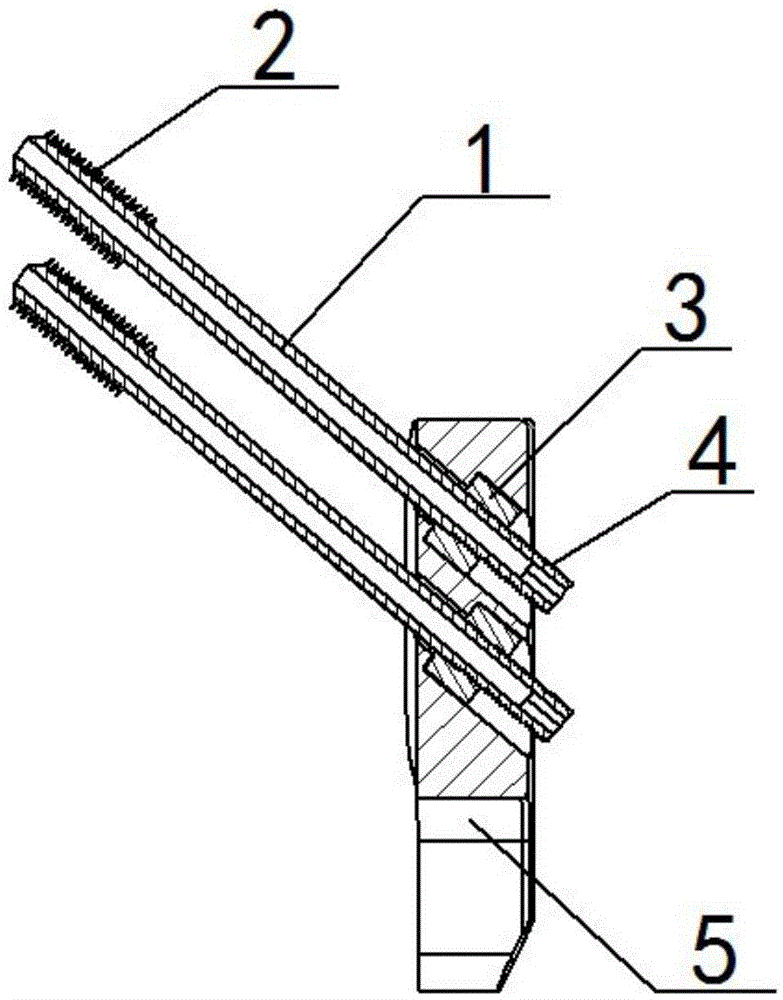

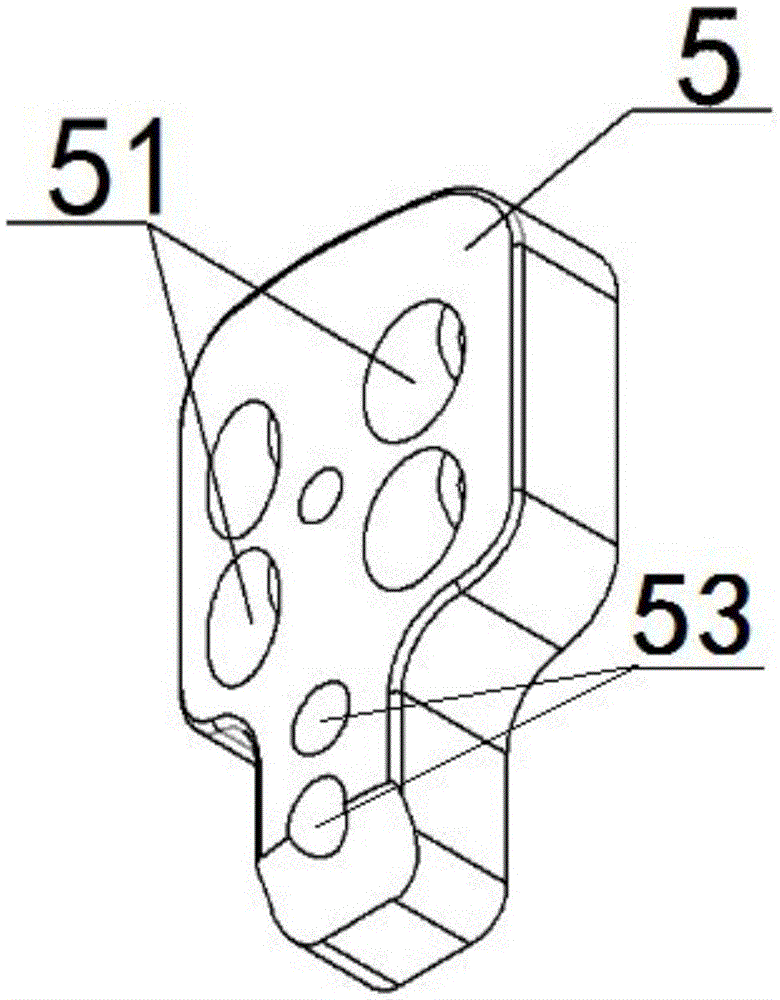

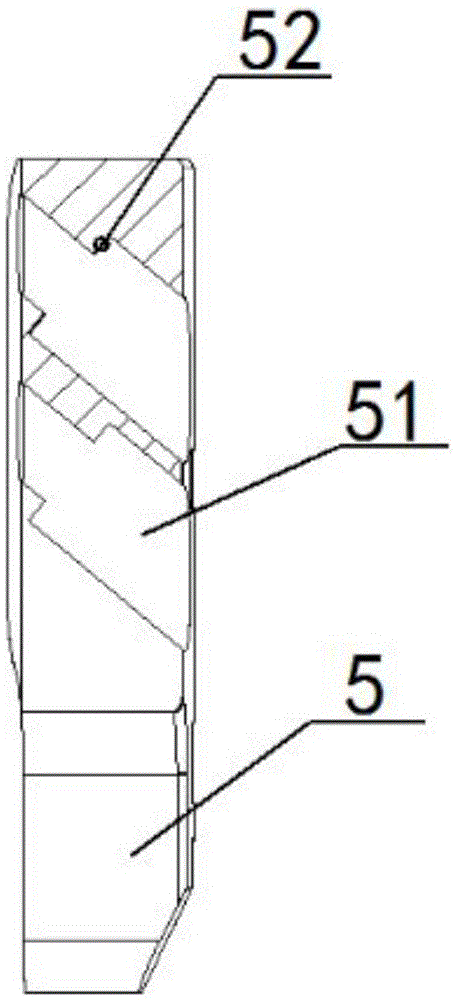

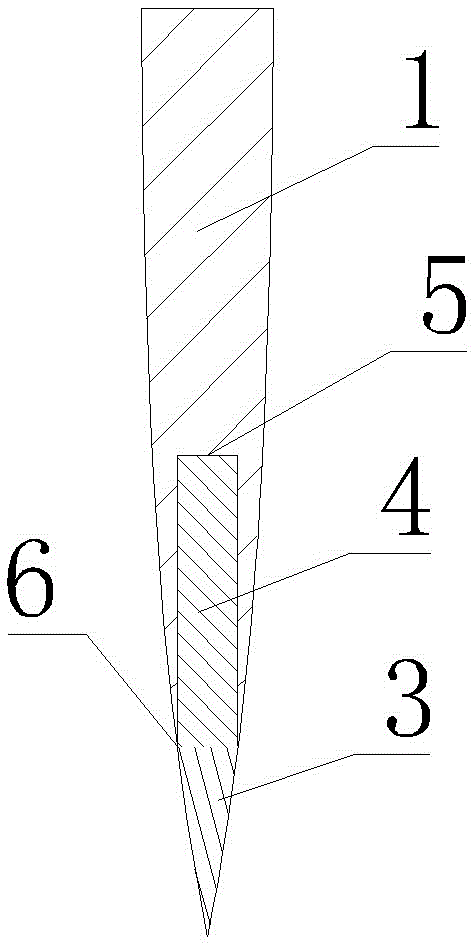

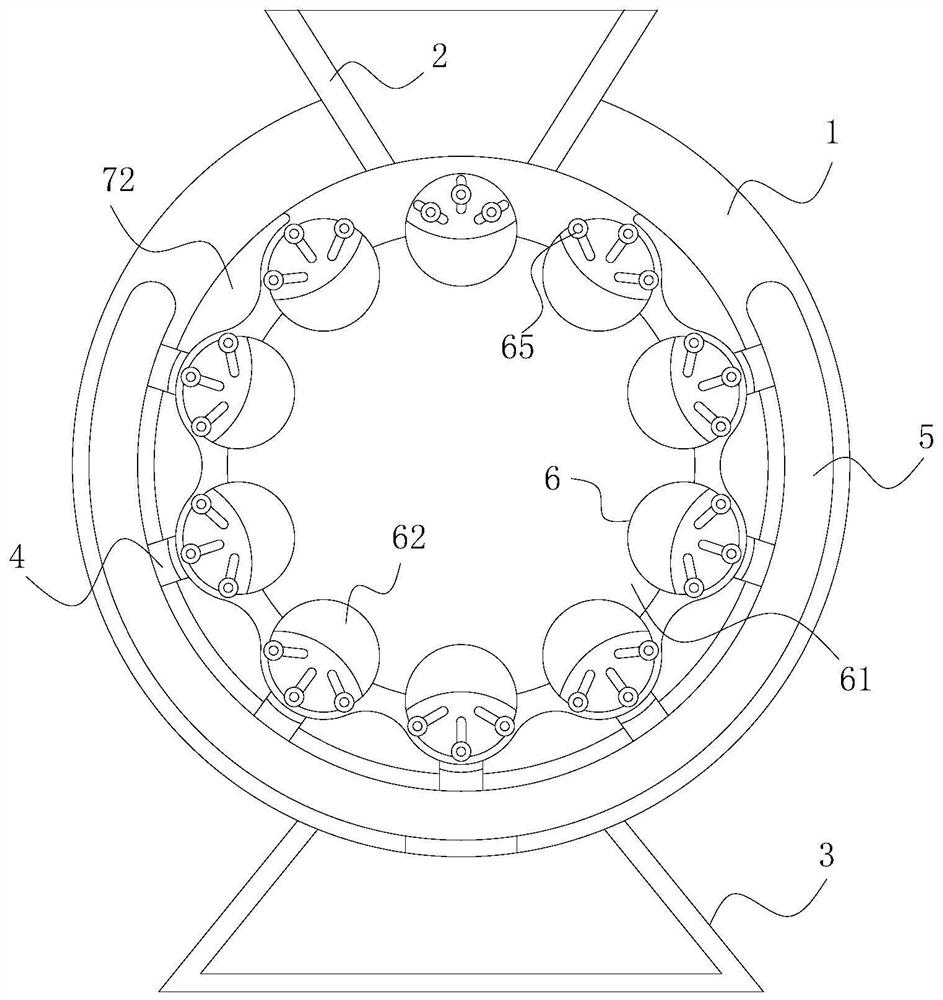

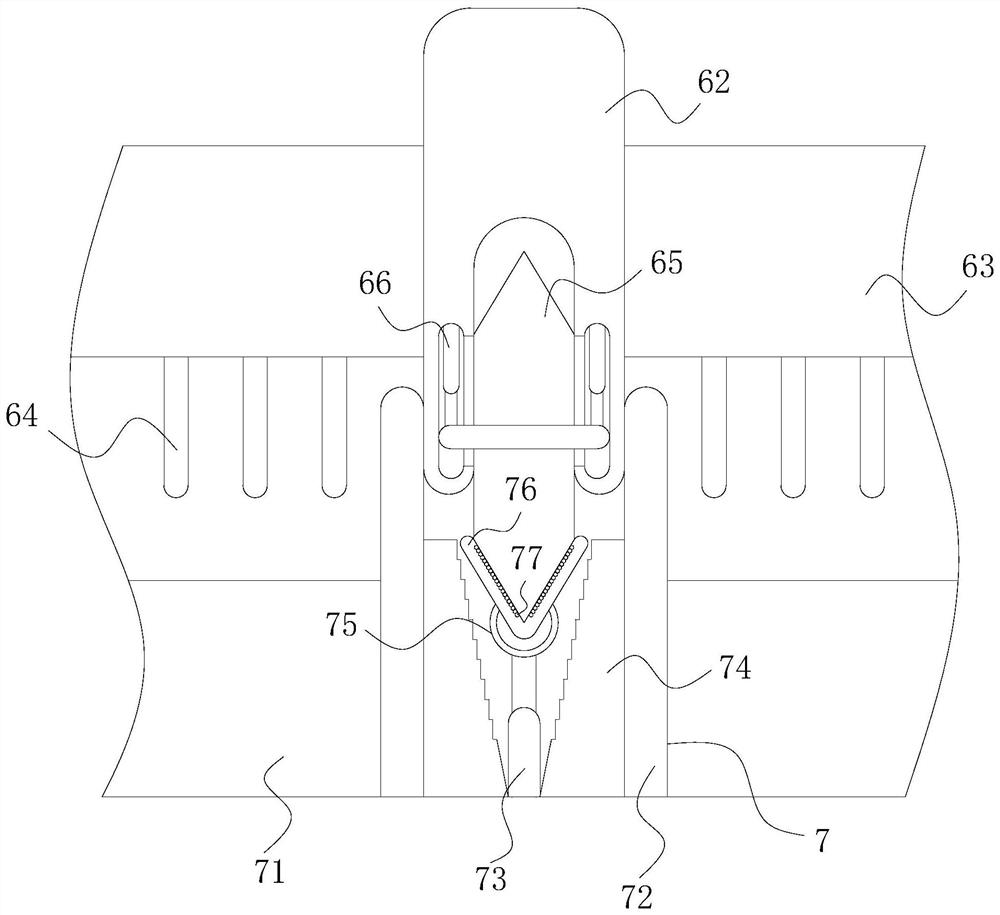

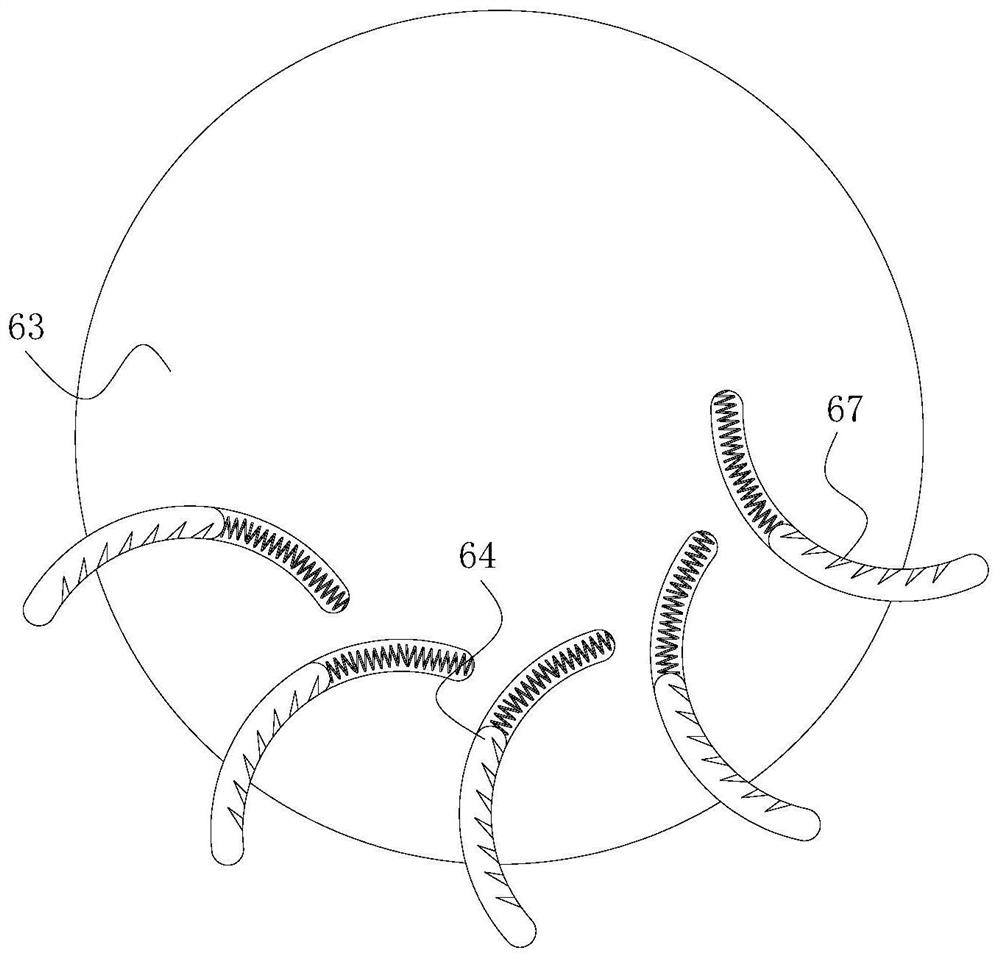

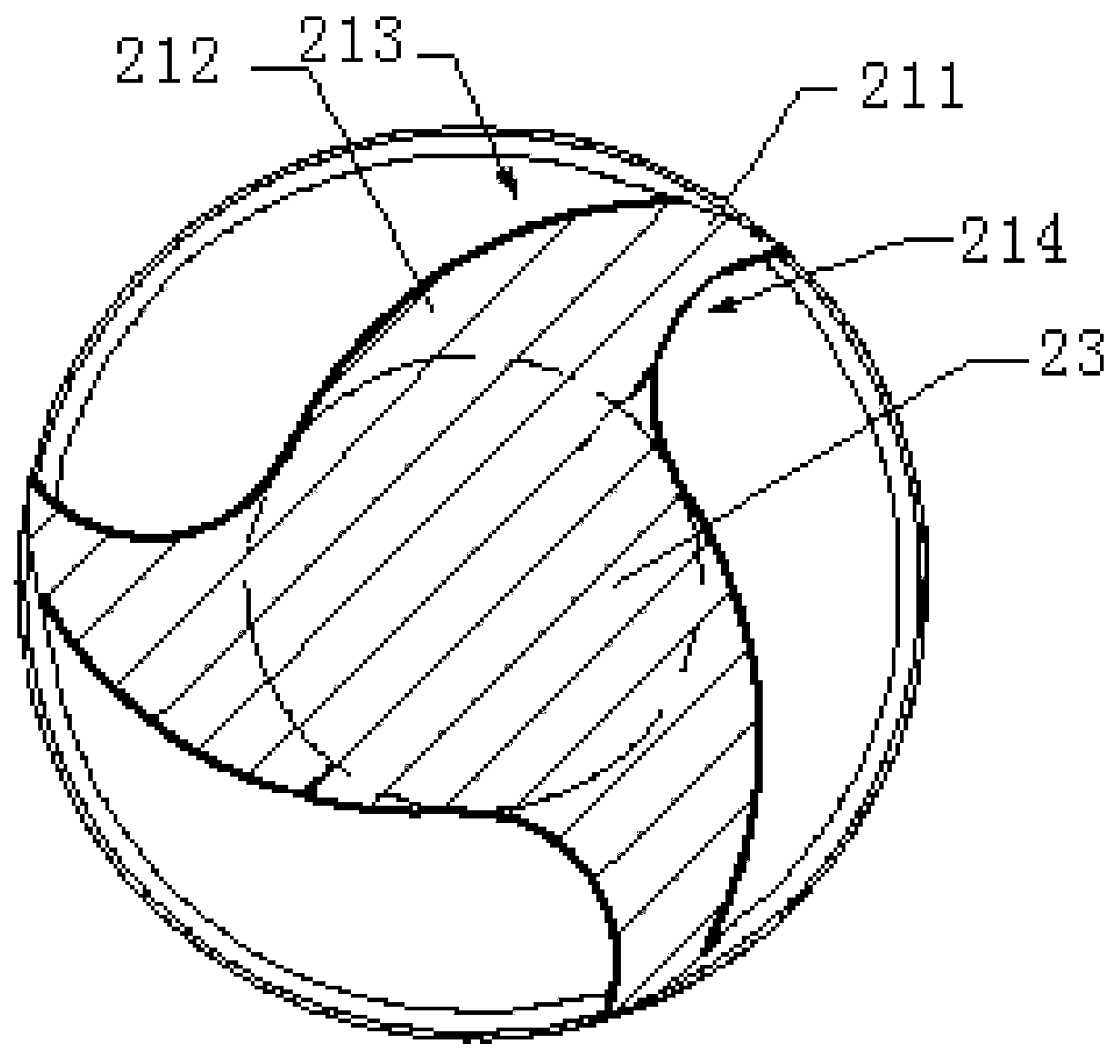

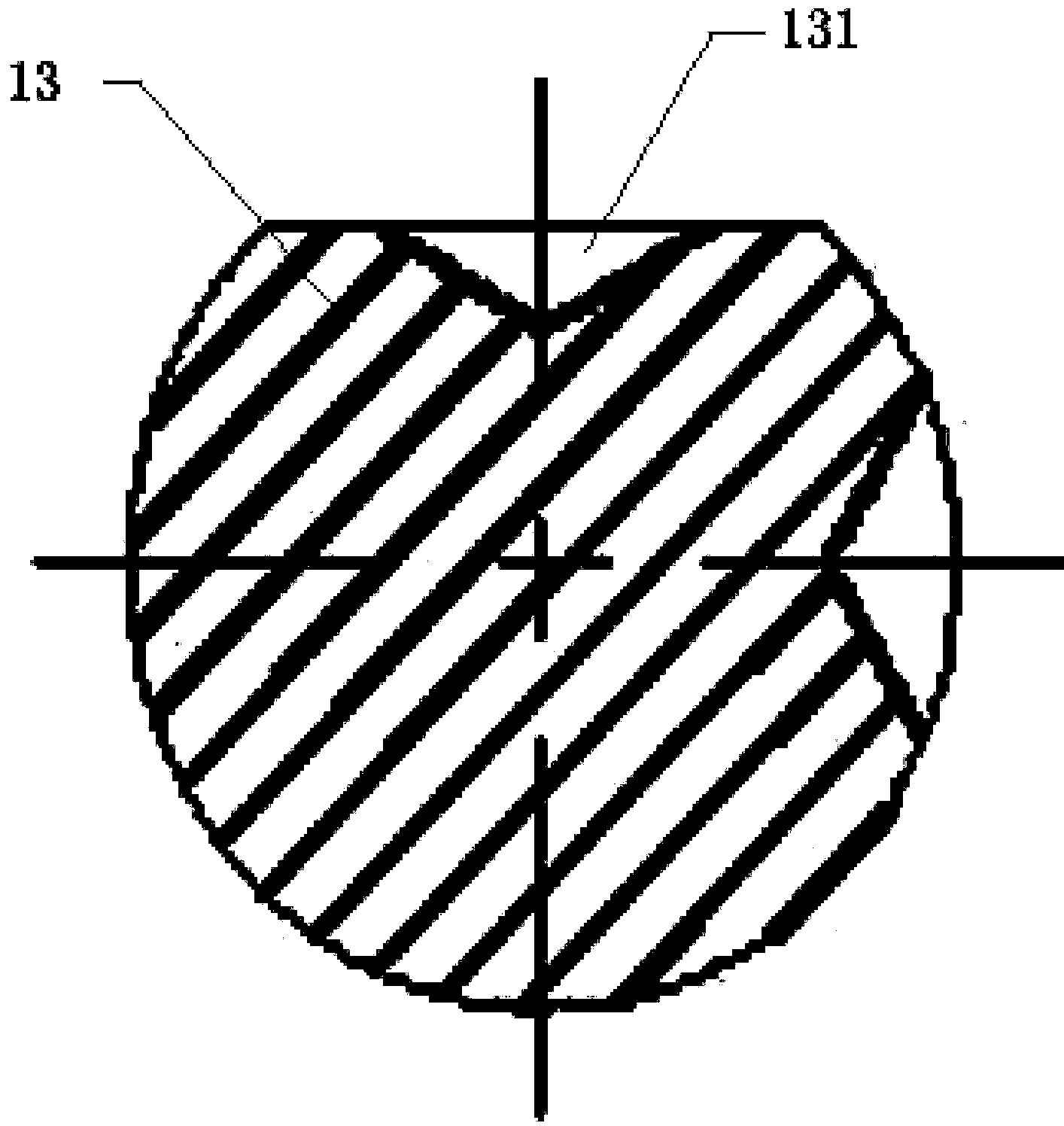

Internal fixing device for treating femoral neck fracture

ActiveCN105596069APressurization is effectiveReduce cutting actionInternal osteosythesisFastenersRight femoral headScrew thread

Owner:陆海波 +1

Preparation method of abrasive wheel for cutting of blue glass infrared cut-off optical filter

ActiveCN106002650AEasy to controlPromote sheddingAbrasion apparatusGrinding devicesBoron carbideHardness

The invention belongs to a preparation method of an abrasive wheel for cutting of a blue glass infrared cut-off optical filter. Ultrafine-grain-size powder is adopted as raw materials of a metallic bond, better holding force on diamonds is achieved, the service life of the abrasive wheel can be prolonged, and the cutting speed of the abrasive wheel can be increased. By means of the composite mixing process adopting a three-dimensional mixer for premixing and ultrasonic wet mixing, the quality stability of the abrasive wheel and consistency of the cutting performance of the abrasive wheel are guaranteed. A certain amount of boron carbide and a certain amount of titanium diboride are added into the bond, do not participate in sintering and can fall off from the bond in time in the cutting process, and therefore keenness of the abrasive wheel is improved, the stable cutting capacity of the abrasive wheel is improved, and tool repair is avoided in the cutting process; and meanwhile due to the fact that the hardness of the two kinds of matter is high, the cutting assisting effect is achieved, and the cutting capacity of the diamond abrasive wheel is improved. The re-pressing process is adopted, an abrasive wheel blank obtained through hot-pressing sintering is strengthened, and therefore the density, rigidity and strength of the abrasive wheel are improved, and the mechanical performance of the abrasive wheel is further guaranteed.

Owner:ZHENGZHOU RES INST FOR ABRASIVES & GRINDING CO LTD

Composite kitchen knife and assembling method thereof

InactiveCN106142144AEasy to processEasy to use and effectiveMetal working apparatusMetal-working hand toolsTool steelSpring steel

The invention provides a composite kitchen knife. The composite kitchen knife is simple in structure, low in manufacturing cost, excellent in performance, capable of processing food materials conveniently and convenient and effective to use. The composite kitchen knife comprises a knife body and a knife shank connected with the knife body and arranged on the back side of the knife body; the composite kitchen knife is characterized by further comprising a knife edge; the knife edge comprises a cutting edge and a connecting part; a groove matched with the connecting part is formed in the lower end of the knife body; the connecting part can be embedded in the groove; the knife edge is connected with the knife body through welding; the knife body is made of spring steel or tool steel; and the knife edge is made of tungsten steel or powder steel. The invention further provides an assembling method of the composite kitchen knife.

Owner:谢振华

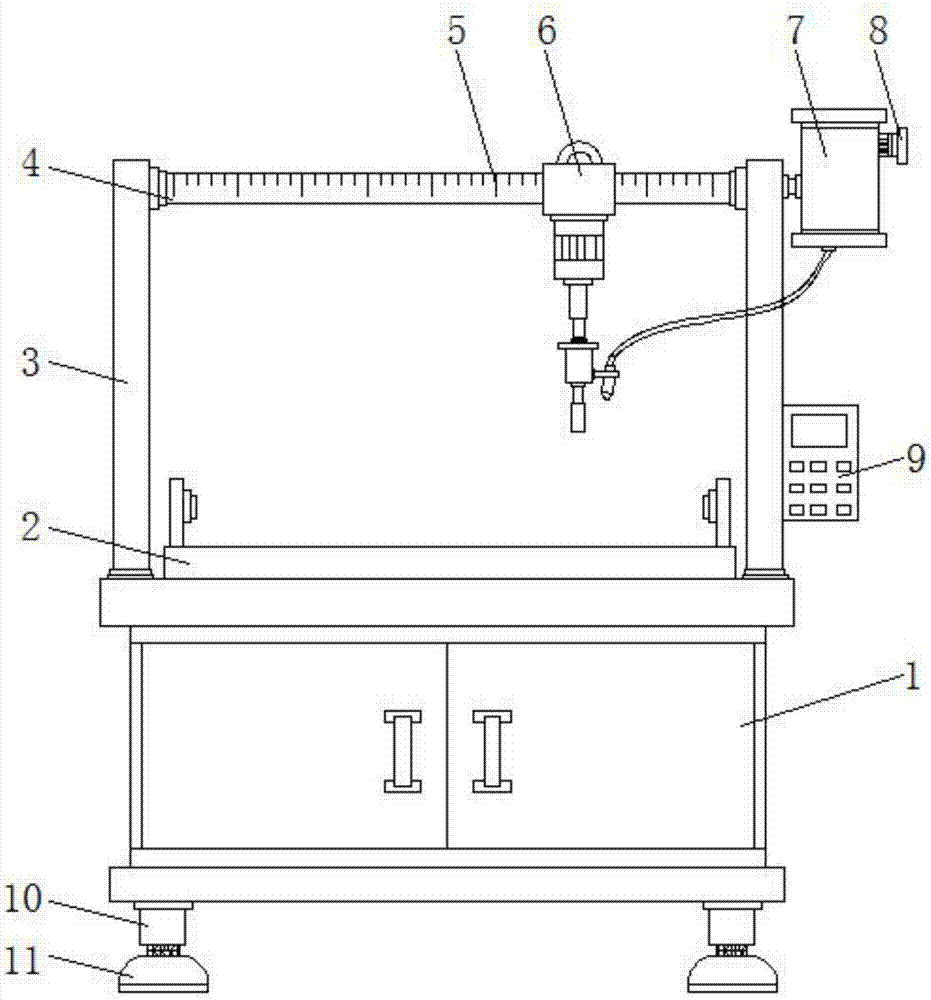

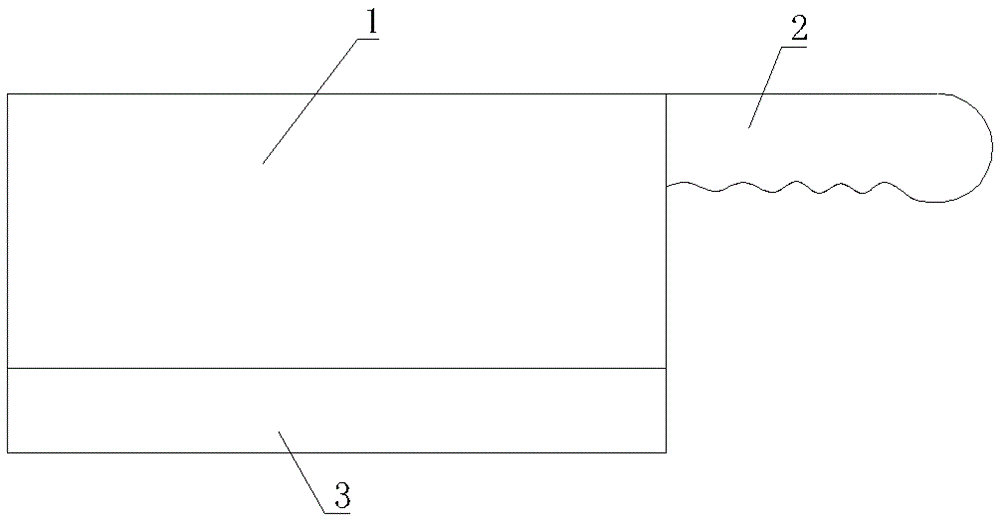

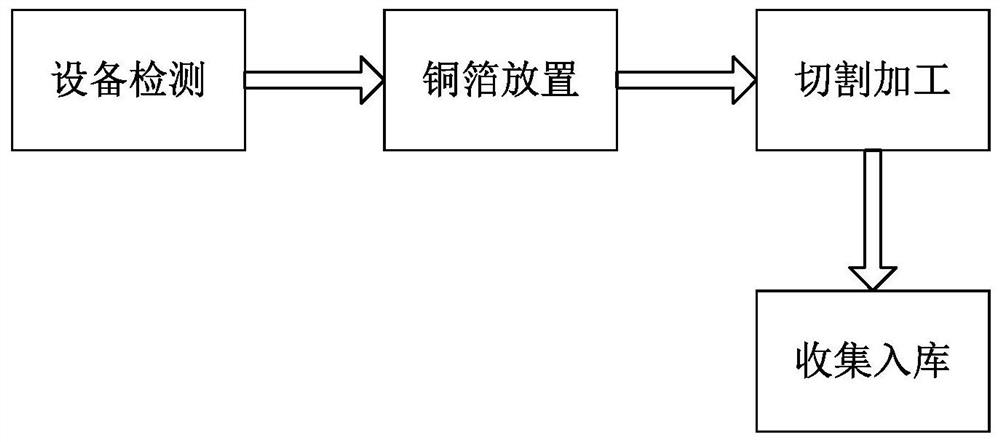

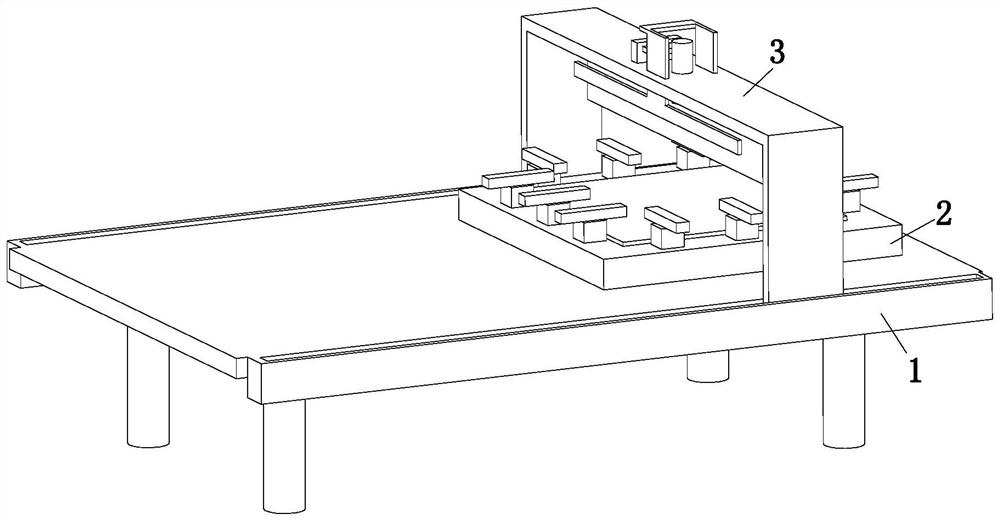

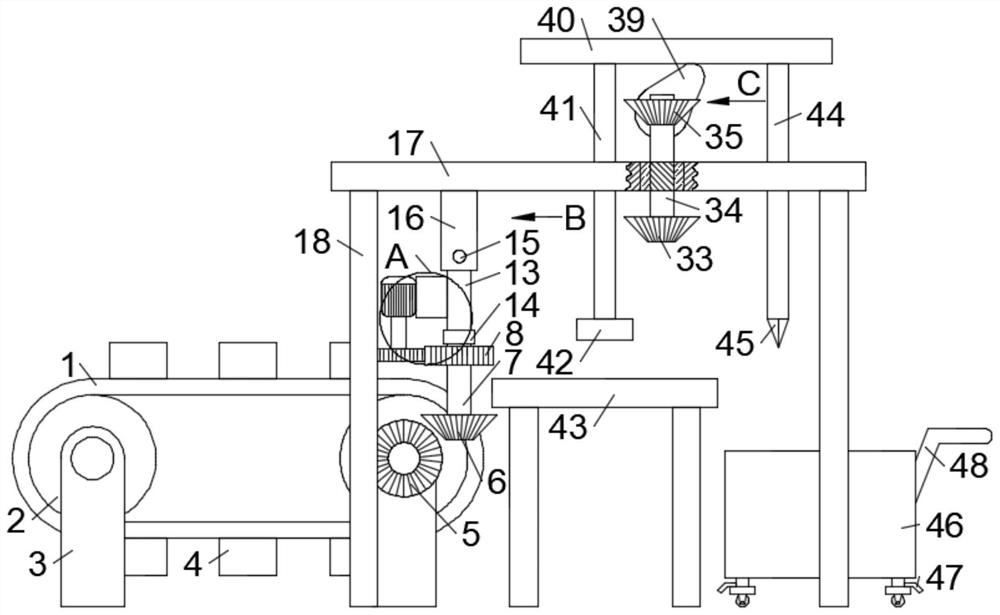

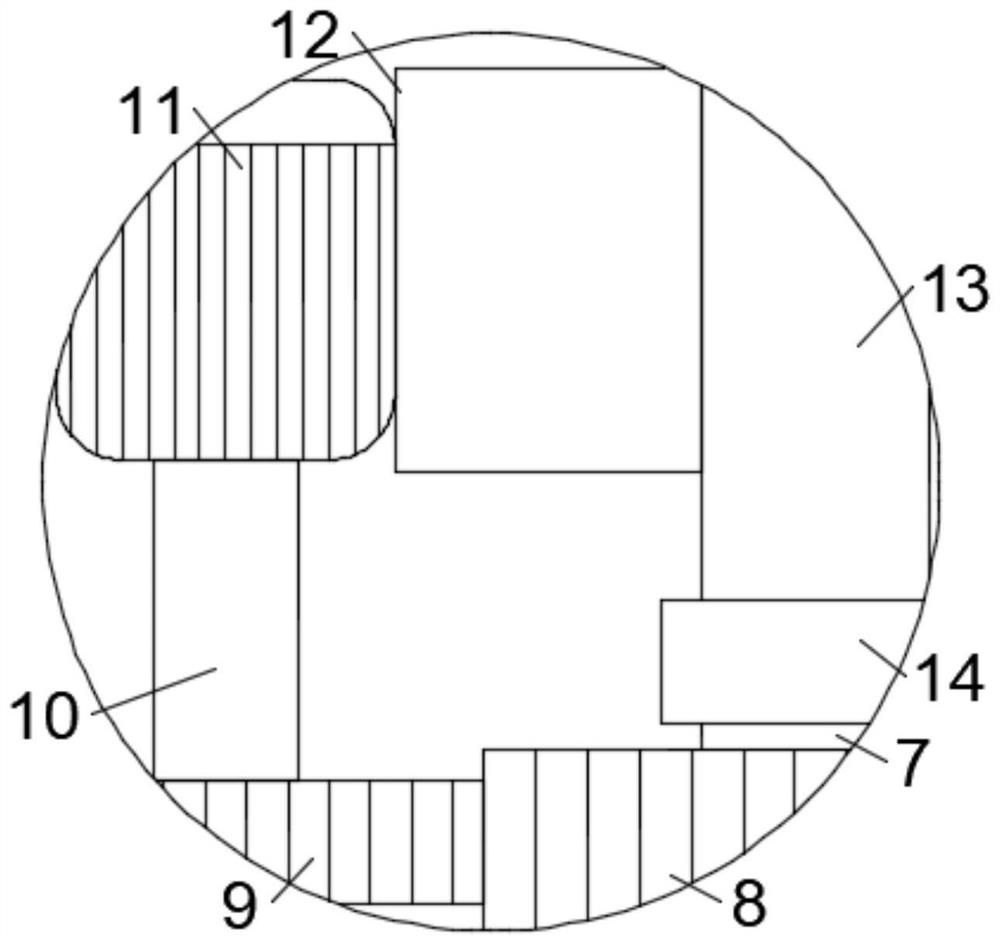

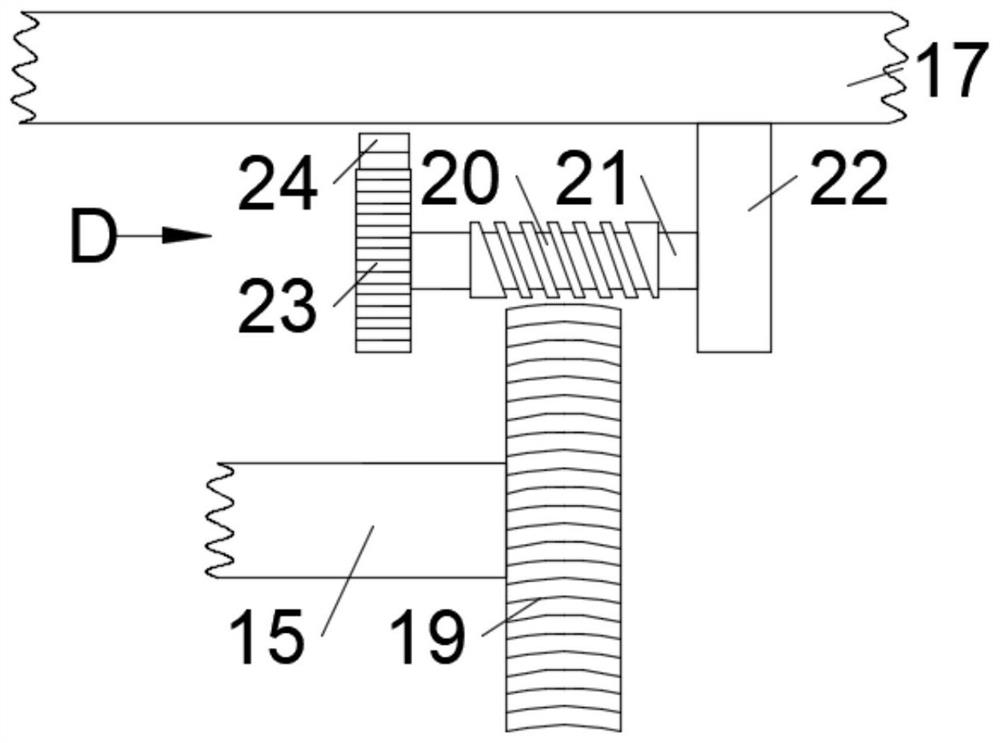

Copper-clad plate surface copper foil forming processing technology

InactiveCN112476503AReduce cutting actionReduce smoothness and other problemsMetal working apparatusCopper foilMetallurgy

The invention relates to a copper-clad plate surface copper foil forming processing technology. A supporting table, a bearing device and a cutting device are included, the upper end of the supportingtable is connected with the bearing device through a bearing, and the cutting device is arranged above the bearing device. According to the technology, the problems that when existing equipment is used for cutting copper foil on the surface of a copper-clad plate, the side wall of the placed copper foil cannot be leveled, and the copper foil is prone to suffering from beveling after being cut, consequently, the copper foil cutting effect is reduced, the copper foil cannot be driven to rotate, the copper foil cannot be cut from different angles, consequently, equipment adaptability is reduced,meanwhile, the equipment cannot move according to the required cutting size of the copper foil, consequently, the flexibility of the equipment is reduced, the cut position cannot be scraped and pressed during copper foil cutting, the copper foil is prone to displacement during cutting, consequently, the copper foil cutting effect is reduced, and smoothness of the cut opening of the copper foil isreduced can be solved.

Owner:张小闯

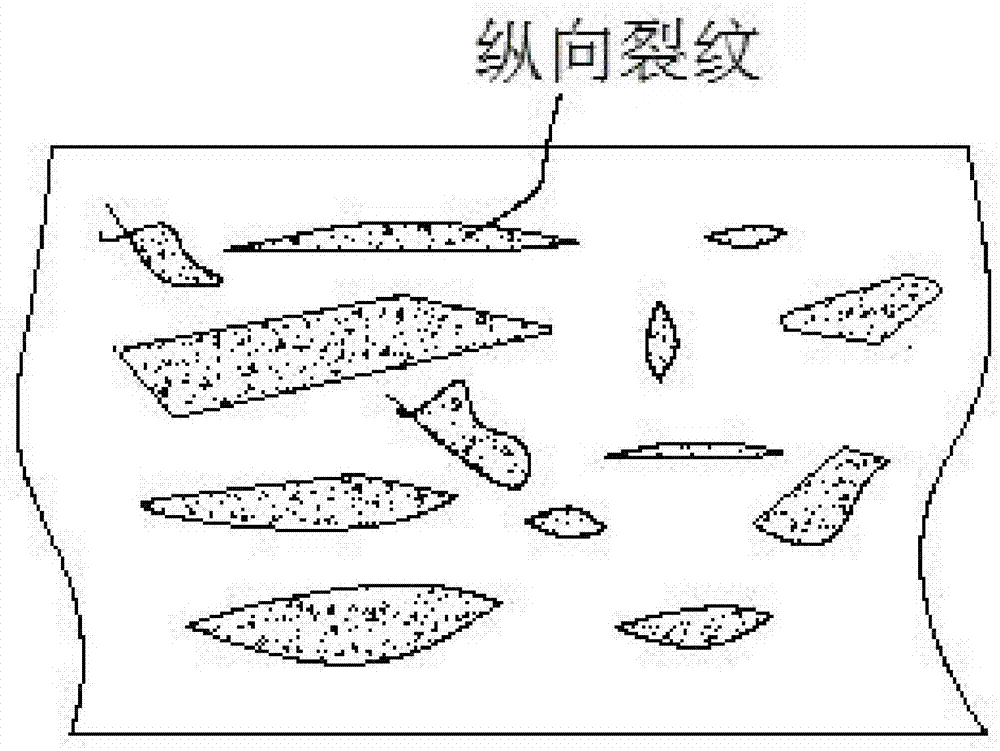

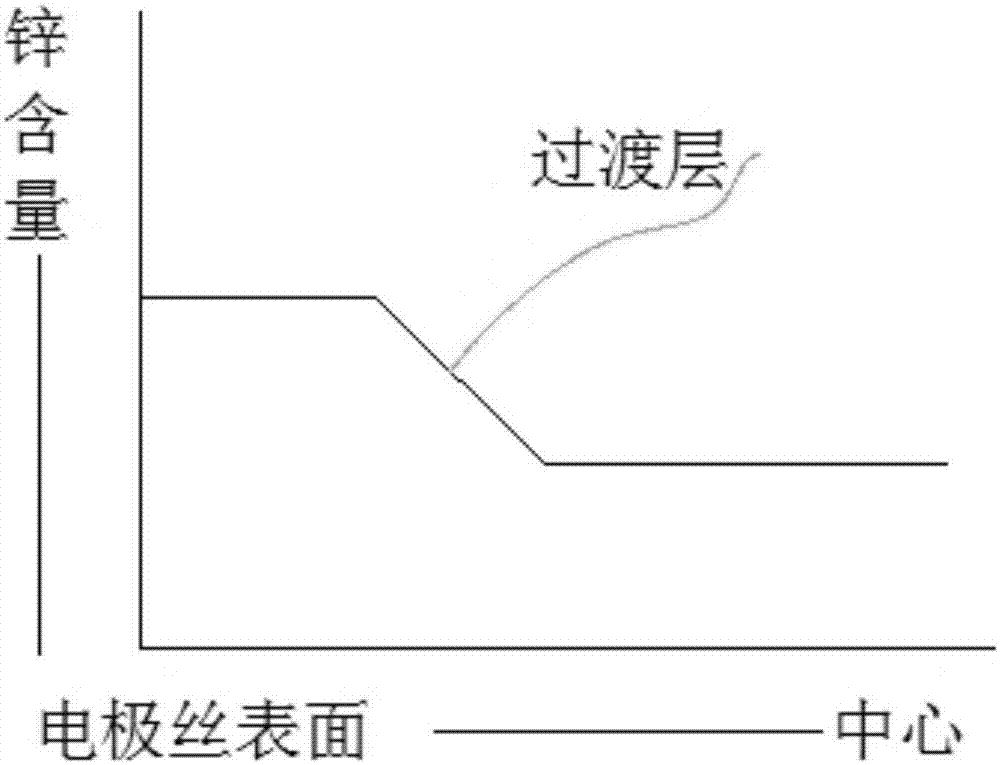

Electrode wire for slow wire EDM cutting

ActiveCN105834533BHigh cutting surface qualityLow cut surface qualityElectrical-based machining electrodesLow speedWire cutting

An electrode wire used for spark cutting of low-speed wire cutting comprises an electrode wire body. The electrode wire body is composed of a core material and a surface metal layer, wherein the core material is made of an alloying brass material, and the surface metal layer covers the core material. A transition layer is arranged between the core material and the surface metal layer. The alloying brass material is composed of, by weight, 58.0-65.0% of copper and the balance zinc, a small quantity of adding elements and inevitable impurities. The surface metal layer is composed of copper, zinc, adding elements and inevitable impurities, wherein the zinc content is larger than 52 wt% and smaller than 68 wt%, and the surface metal layer is distributed in a fracture shape longitudinally. Compared with the prior art, the electrode wire has the advantages that the manufactured electrode wire is stable in discharge performance, the cutting speed is increased, a wire feeding part and a guiding device of low-speed wire cutting equipment are prevented from being damaged, a machining technique of the electrode wire is simple, the application range is wide, the cost is low, and broad market prospects are achieved.

Owner:NINGBO BODE HIGHTECH CO LTD

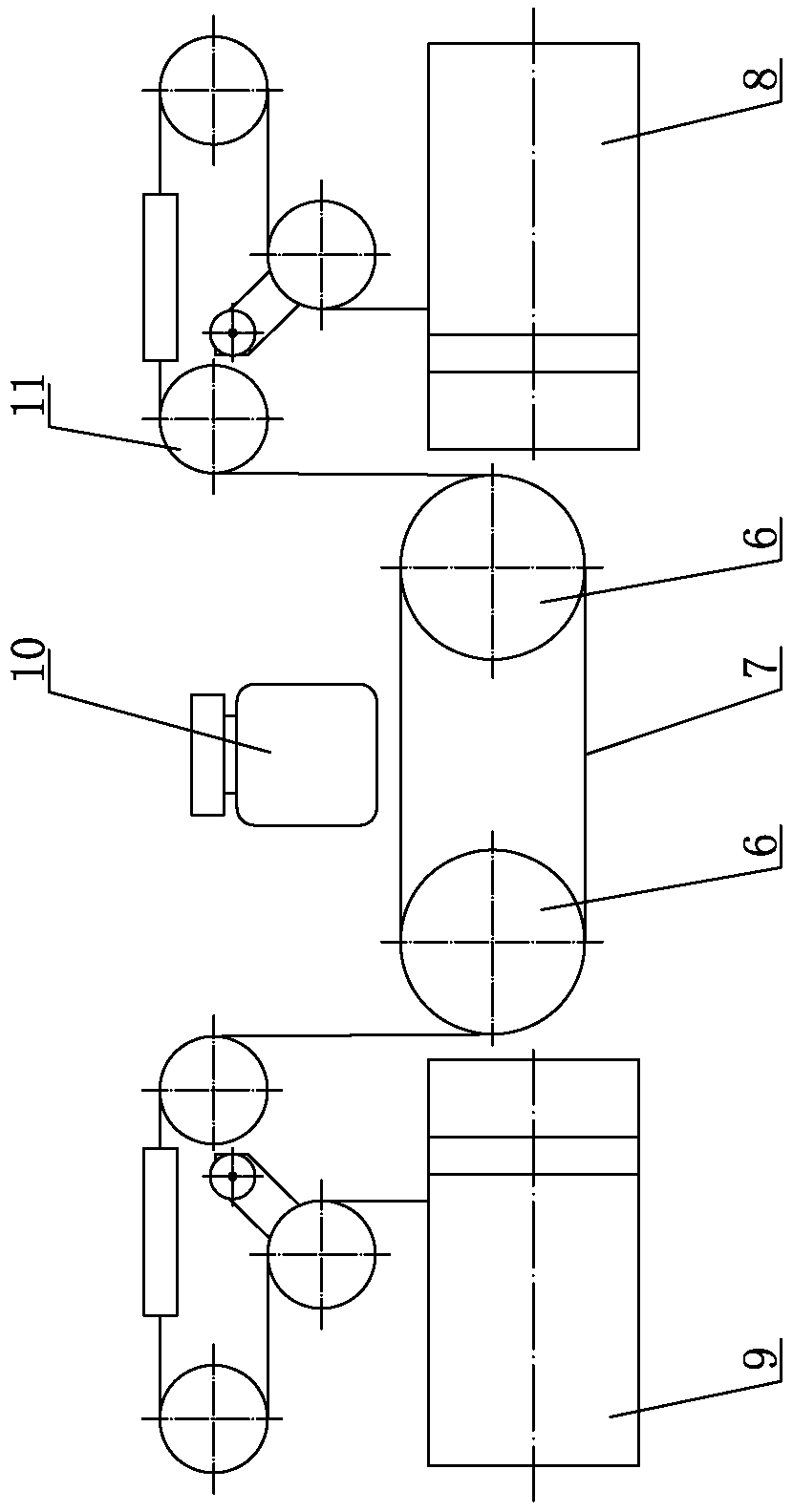

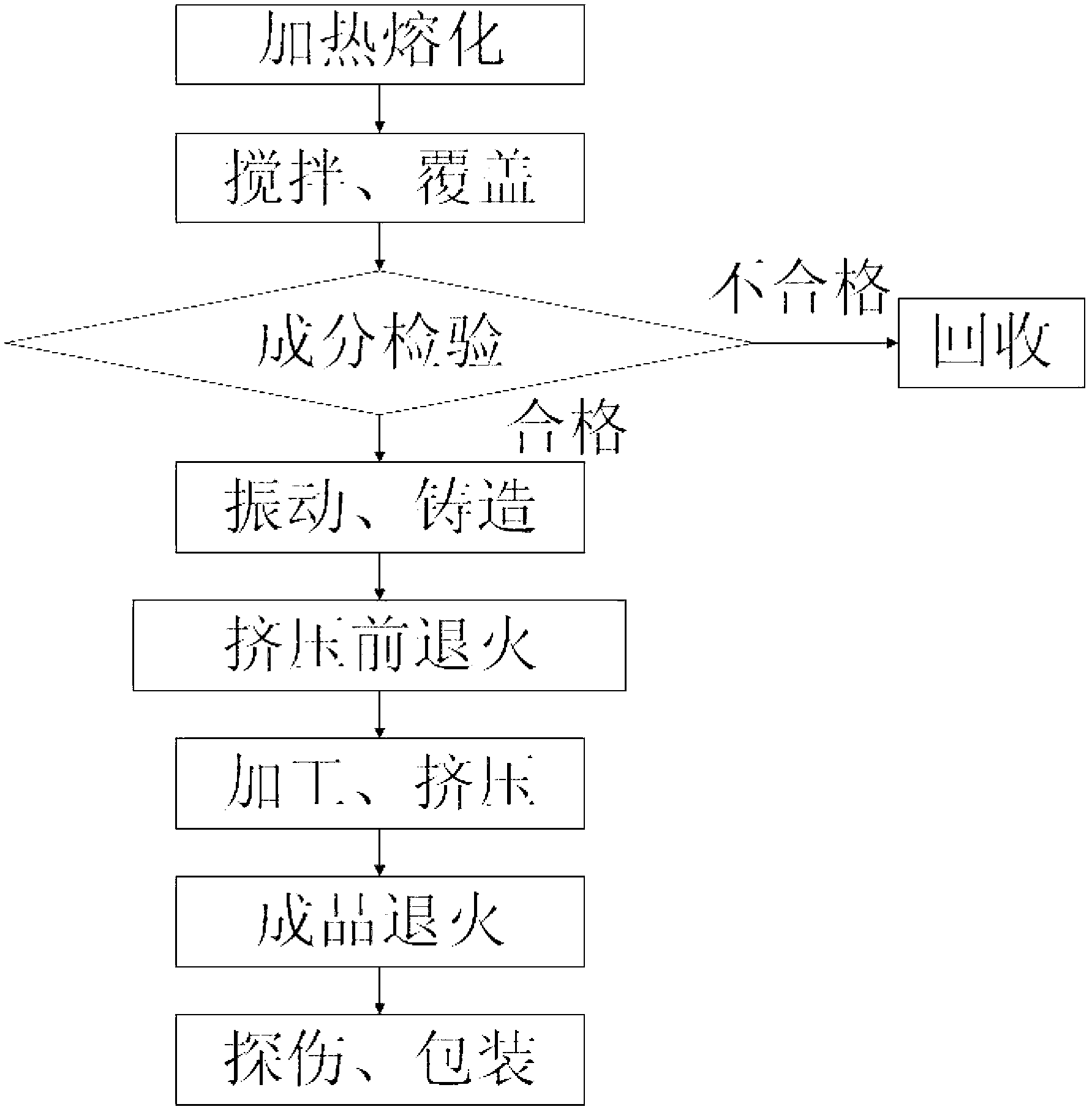

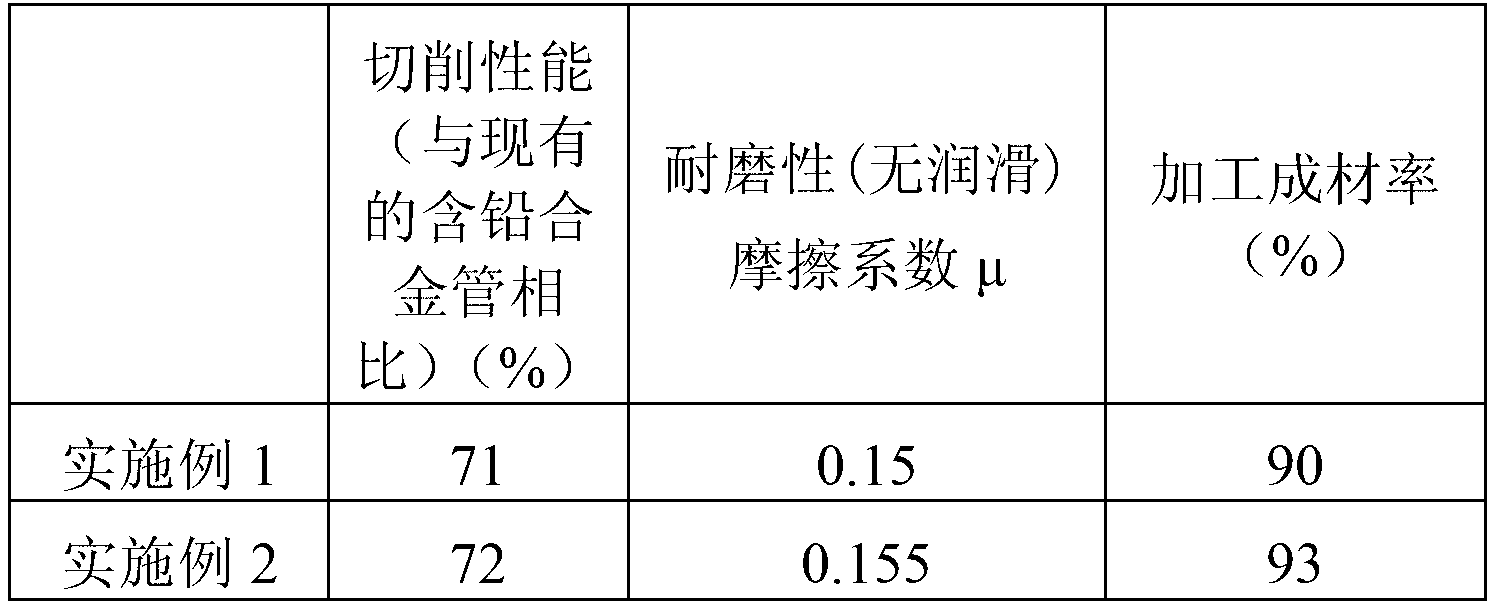

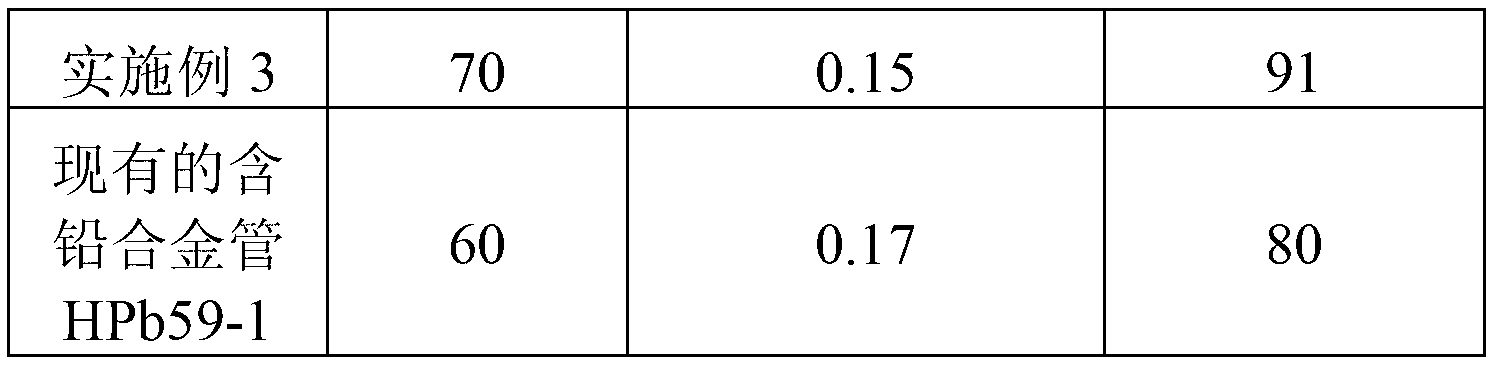

Novel copper-based alloy pipe for high speed railway and preparation method of alloy pipe

The invention provides a novel copper-based alloy pipe for a high speed railway and a preparation method of the alloy pipe. The novel copper-based alloy pipe for the high speed railway comprises the following components based on the total weight of the alloy pipe: 0.1-0.8 percent of aluminum, 0.05-0.5 percent of phosphorus, 0.5-1.5 percent of antimony, 0.2-0.5 percent of magnesium, 1-3 percent of silicon, 10-13 percent of tin, 4-6 percent of zinc and the balance of copper. Due to the addition of magnesium element, addition of lead is avoided on the basis that the machinability and wear resistance and antifriction property of the original lead-containing tin bronze are maintained or are not obviously reduced. According to the added magnesium element, single phases in diffuse distribution are formed in the copper alloy and achieve the chip breaking effects during cutting, so that the machinability of the copper alloy is improved.

Owner:SUZHOU JINCANG ALLOY NEW MATERIAL

Feed processing device

The invention belongs to the technical field of feed production equipment, and particularly relates to a feed processing device. The device comprises a mounting frame, a feeding hole, a base, filter holes, a gathering tank, a cutting mechanism and a heating mechanism, wherein the base is placed on the ground; the upper end of the base is fixedly connected with the mounting frame; the feeding hole is fixedly formed in the upper end of the mounting frame; the cross section of the mounting frame is circular; the cutting mechanism is arranged in the mounting frame; the cutting mechanism comprises a rotating roller, a mounting disc, a connecting rod, a scraping plate, a cutting wheel, a telescopic rod and an equal division opening; and when moving outwards under the magnetic action, the cutting wheel can make contact with the inner wall of a heating plate and generate friction with the heating plate along with rotation of the cutting wheel, so that residual water on the outer surface of the cutting wheel is evaporated, the situation that too many straws which are not completely dried causes mutual accumulation of chippings generated by cutting to block rotation of the mounting disc and the connecting rod is avoided, and meanwhile, the reduction of the cutting effect due to the influence on cutting is avoided.

Owner:佛山市果实生物科技股份有限公司

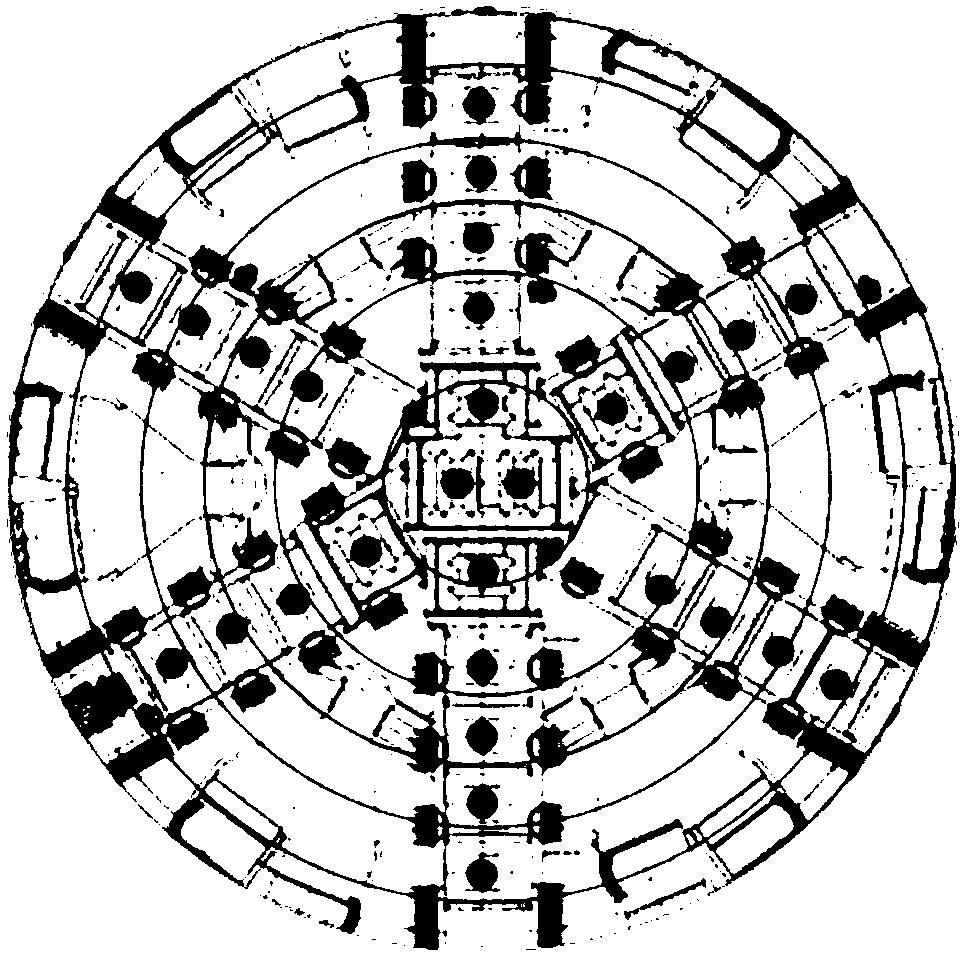

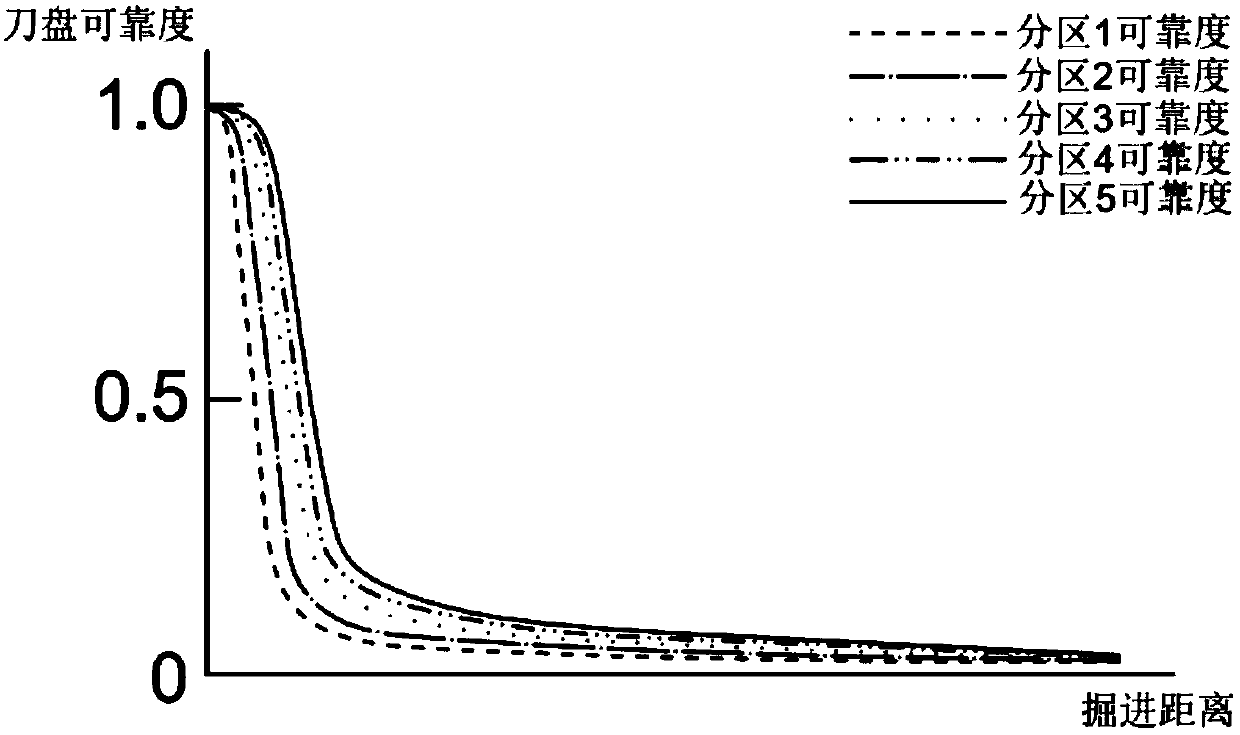

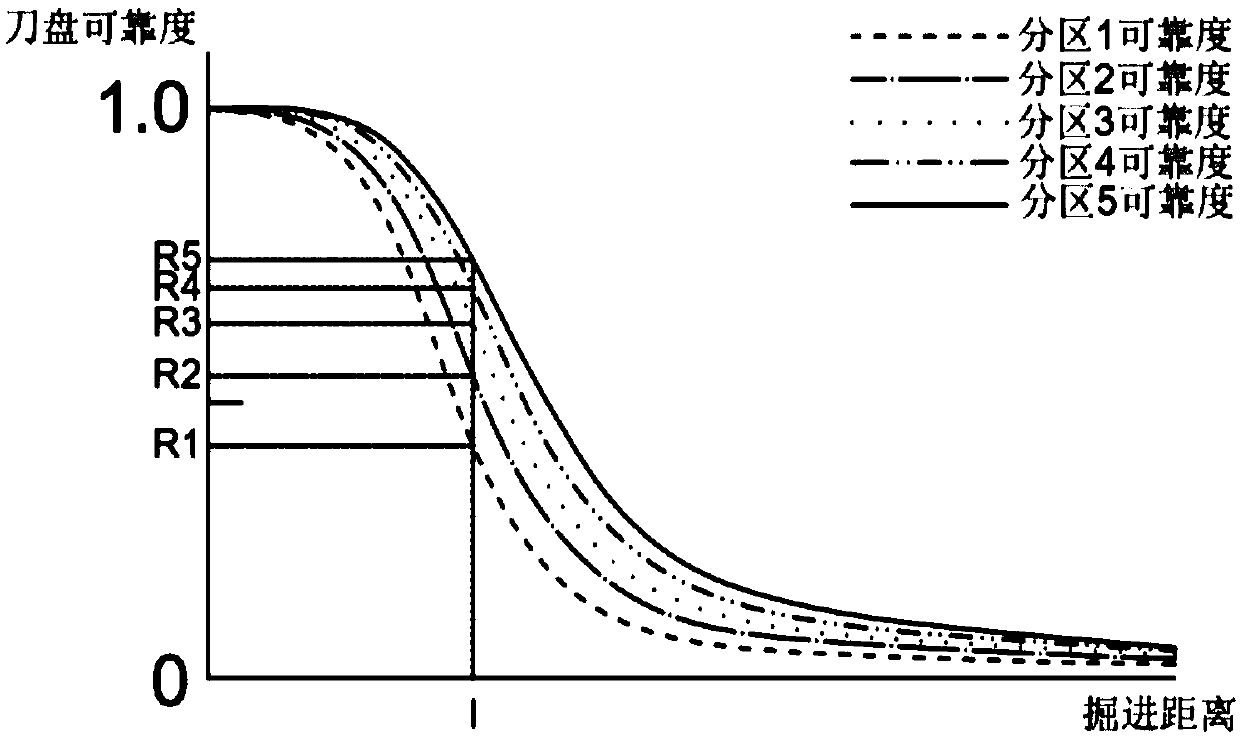

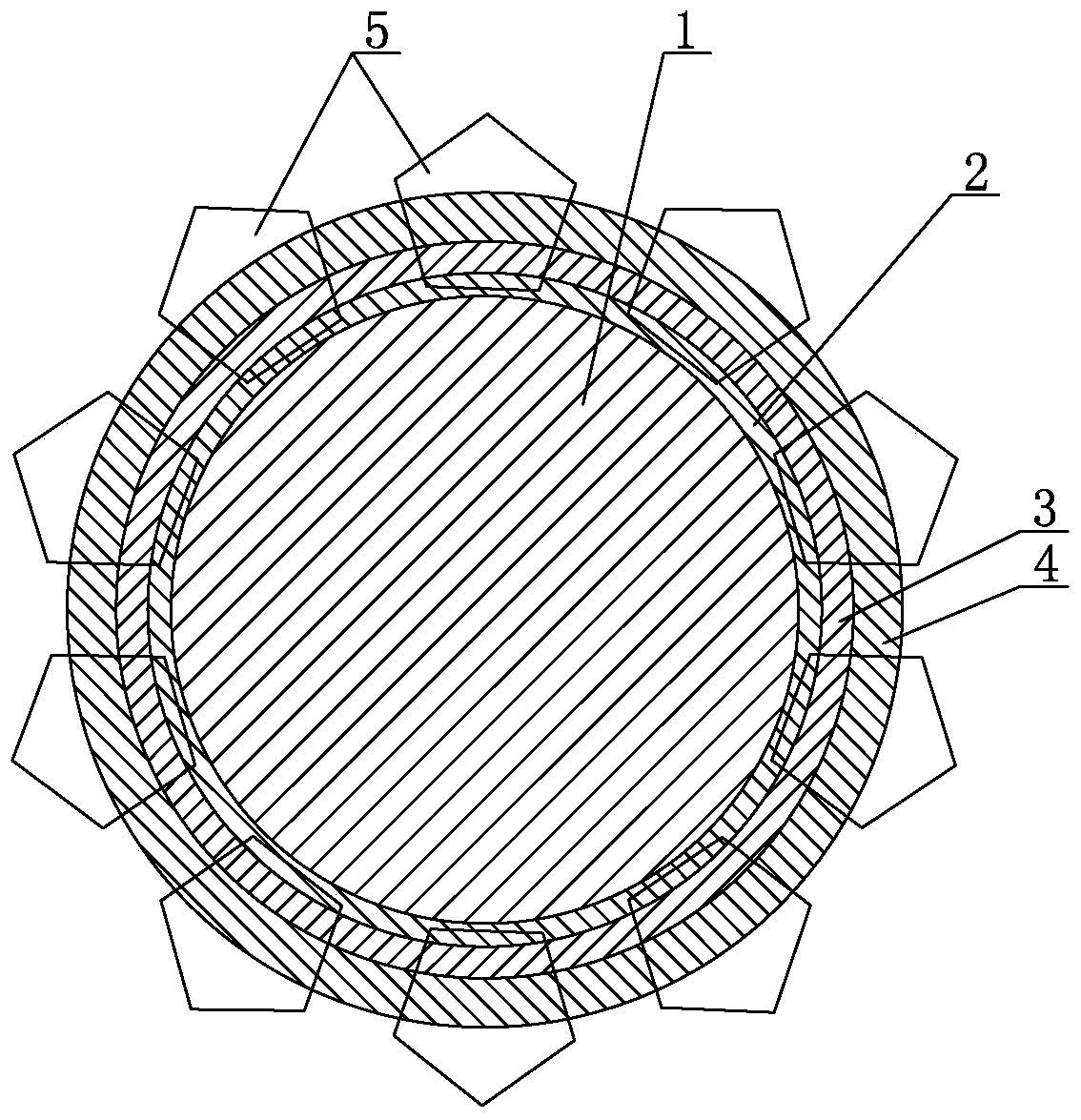

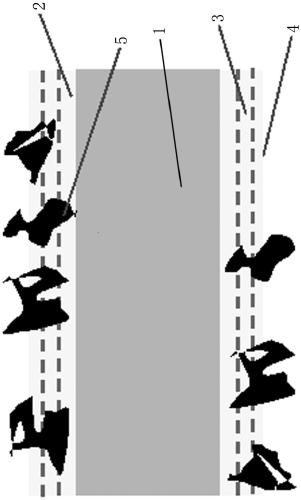

Method for predicting the cutting performance of shield cutter by dividing the cutter into sections

ActiveCN109063354AAvoid the downsides of machinabilityRealize partition monitoringDesign optimisation/simulationSpecial data processing applicationsRectangular coordinatesEngineering

The invention discloses a method for predicting the cutting performance of a shield cutter by dividing the cutter into sections, The reduction of cutting performance reliability of cutter system is used to characterize the reduction of cutting performance of cutter head section, Based on the reliability theory combined with degeneration thought, Using a reasonable mathematical statistical model, considering the propulsion environment of shield, the function of cutting performance reliability with shield advancing distance is put forward, Combined with engineering practice, the reference surface group in space rectangular coordinate system considering shield propulsion environment, cutter subarea system reliability and shield propulsion distance is drawn, which provides prediction and reference for the relationship between shield cutter subarea cutting performance and shield propulsion distance in all kinds of environments. This patent can provide a scientific method for the active prediction and selection of the position of shield tunneling in the process of shield tunneling scheme preparation. Considering the environmental factors of shield tunneling propulsion, the prediction ofthe final cutting performance of the tool system is more true and effective.

Owner:CENT SOUTH UNIV

Self-sharpening diamond wire for silicon wafer cutting and manufacturing method and using method thereof

ActiveCN110480530AEffectively fixedReduce risk of sheddingElectrolytic coatingsGrinding devicesCutting forceSilicon

The invention discloses a self-sharpening diamond wire for silicon wafer cutting and a manufacturing method and using method thereof, and belongs to the field of diamond wires for photovoltaic products. The diamond wire comprises a steel bus, the outer surface of the steel bus is plated with a first pre-growing layer, a second composite positioning layer and a third reinforcing layer, and diamondparticles are fixed by all the plated layers. The manufacturing method comprises the steps: surface pretreatment, nickel pre-plating, first-time nickel plating, second-time nickel plating, third-timenickel plating and treatment after plating. The using method comprises the following steps: the diamond wire after use for cutting is immersed into the lower part of etching liquid, a NaOH solution with the mass concentration being 15%-20% is adopted as the etching liquid, the third reinforcing layer is corroded by the etching liquid, and thus the diamond particles are exposed out of the second composite positioning layer to from a cutting blade. The diamond particles are fixed through the three plated layers, the risk of falling-off of the diamond particles is lowered, and the diamond wire maintains cutting force through treatment.

Owner:扬州六如新能源科技有限公司

Copper base alloy pipe containing silicon and aluminium and preparation method thereof

The invention discloses a copper base alloy pipe containing silicon and aluminium and a preparation method thereof. The copper base alloy pipe comprises the following ingredients by weight percent: 72-76% of copper, 0.05-0.5% of silicon, 1-1.8% of aluminium and the balance of zinc. On the basis of maintaining or not obviously reducing the cutability, wear resistance and antifriction property of original lead and tin containing bronze, the copper base alloy puts an end to addition of lead and inhibits dissolution of lead by adding elements such as silicon and aluminium, thus effectively reducing the pollution.

Owner:SUZHOU JINCANG ALLOY NEW MATERIAL

Wear-resistant nylon composite material and preparation method thereof

The invention discloses a wear-resistant nylon composite material and a preparation method thereof. The wear-resistant nylon composite material is prepared from the following components in parts by weight: 79-89 parts of nylon, 10-20 parts of a wear-resistant material, 0.1-0.3 part of an antioxidant and 0.1-0.5 part of a lubricant, wherein the wear-resistant material is formed by mixing nanometersilicon carbide, polytetrafluoroethylene, a coupling agent and mica powder. By utilizing the high hardness of the nanometer silicon carbide and the self-lubricating property, the high-temperature resistance and the like of the polytetrafluoroethylene, the wear resistance of the composite material is improved, a wear-resistant nylon product with excellent comprehensive performance is finally obtained, and the service life of the material is prolonged.

Owner:HEFEI GENIUS NEW MATERIALS

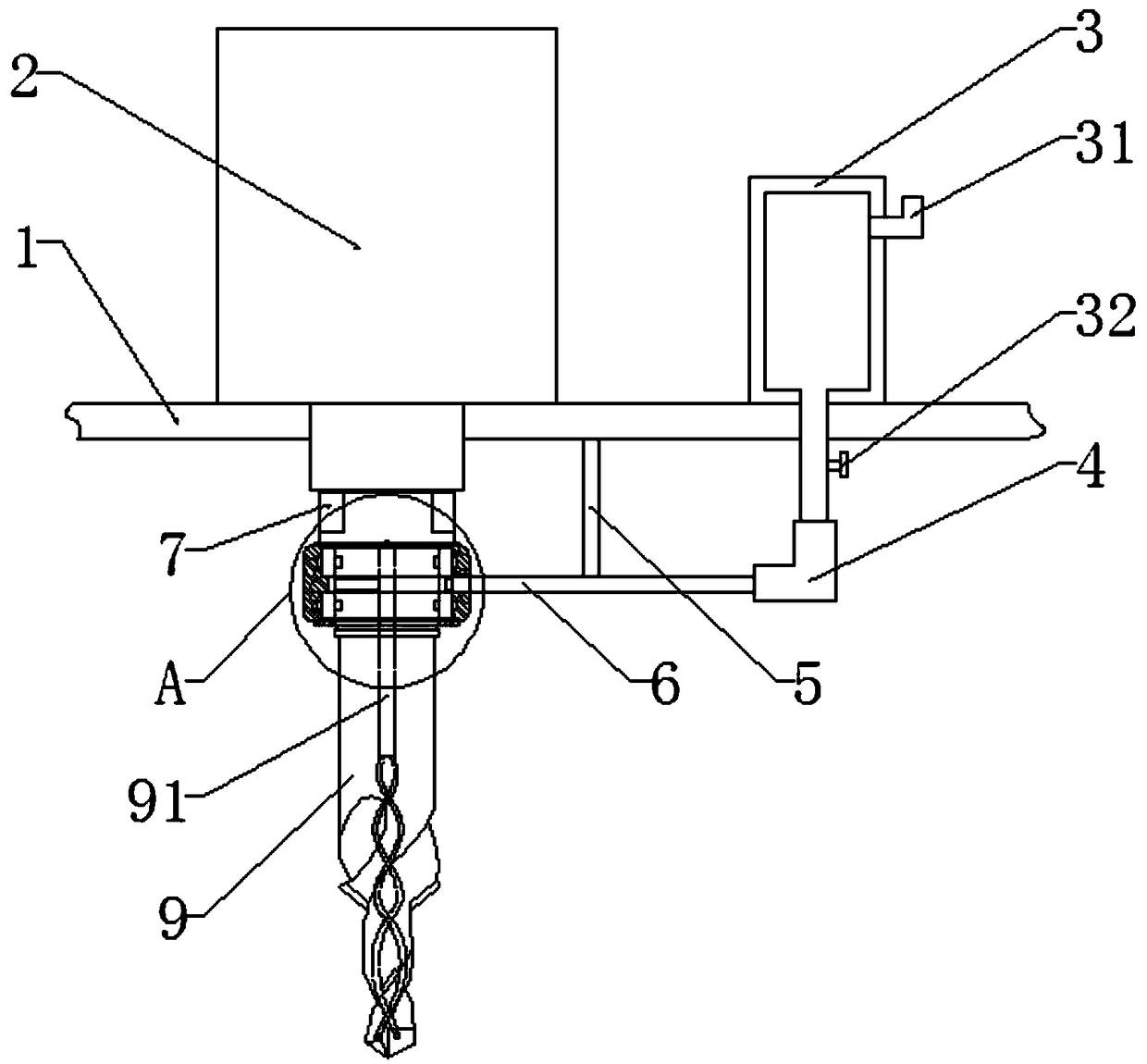

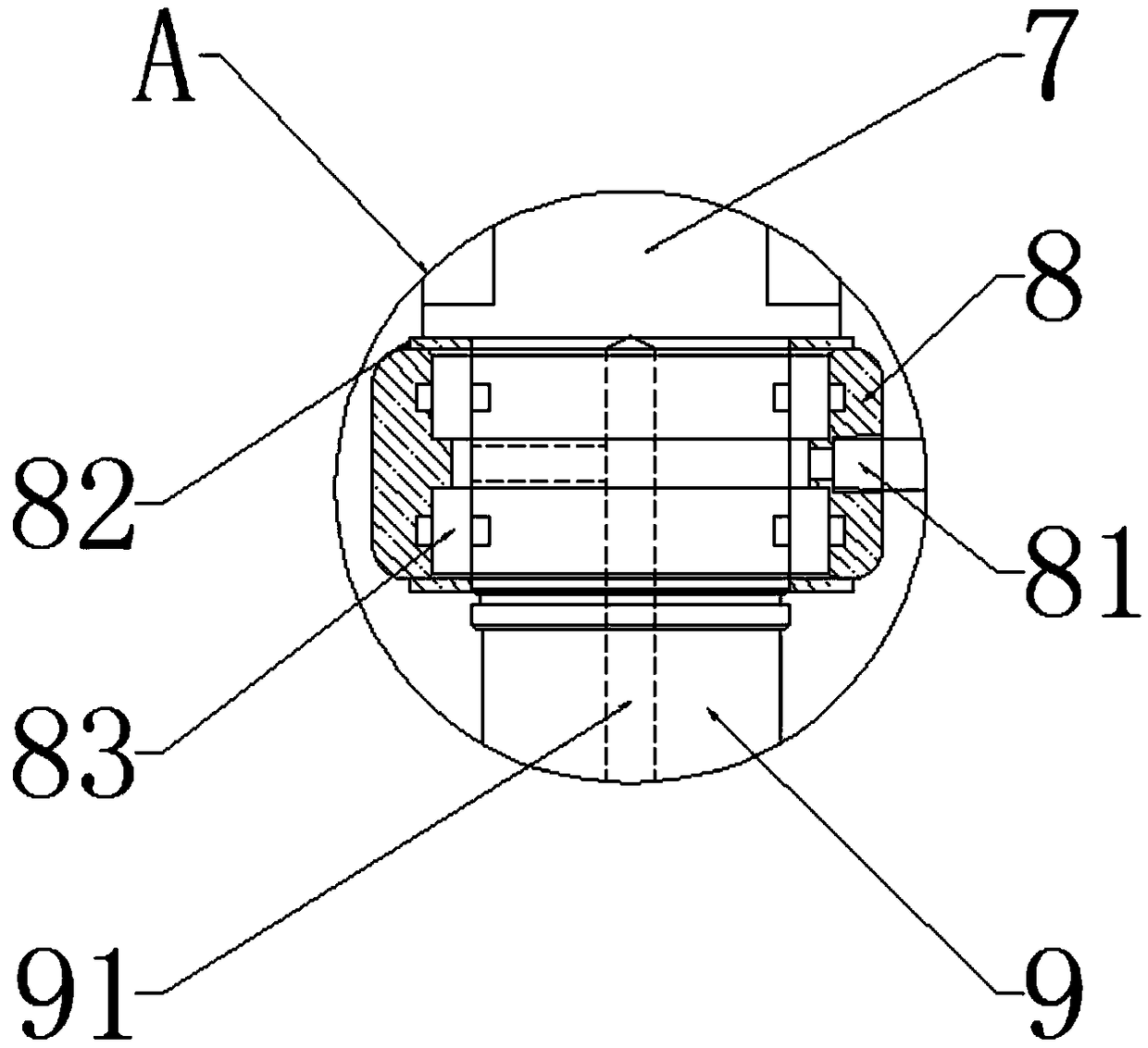

Inner cooling drilling, reaming and countersinking integrated tool and system comprising tool

PendingCN109352038AReduce the temperatureImprove fan heating effectTransportation and packagingTrepanning drillsEngineeringCooling pipe

The invention discloses an inner cooling drilling, reaming and countersinking integrated tool and a system comprising the tool. The tool comprises a tool handle and a tool bit. The tool bit part is provided with a drilling part, a reaming part and a countersinking part. An inner cooling way is arranged in the tool handle and the tool bit part. The part, located at the tool bit part, of the inner cooling way is spirally distributed in the spiral direction of a spiral groove of the tool bit part or / and the direction opposite to the spiral direction. The system further comprises a cooling device.The cooling device comprises a liquid storage barrel, a cooling pipe and a ring sleeve sleeving the tool handle part. An annular cooling liquid channel is formed by the inner circle of the ring sleeve and the outer circle of the tool handle and communicates with a radial inner cooling way, the ring sleeve is provided with a liquid inlet, and the liquid storage barrel is connected with the liquidinlet in the ring sleeve through the cooling pipe.

Owner:SHANDONG UNIV

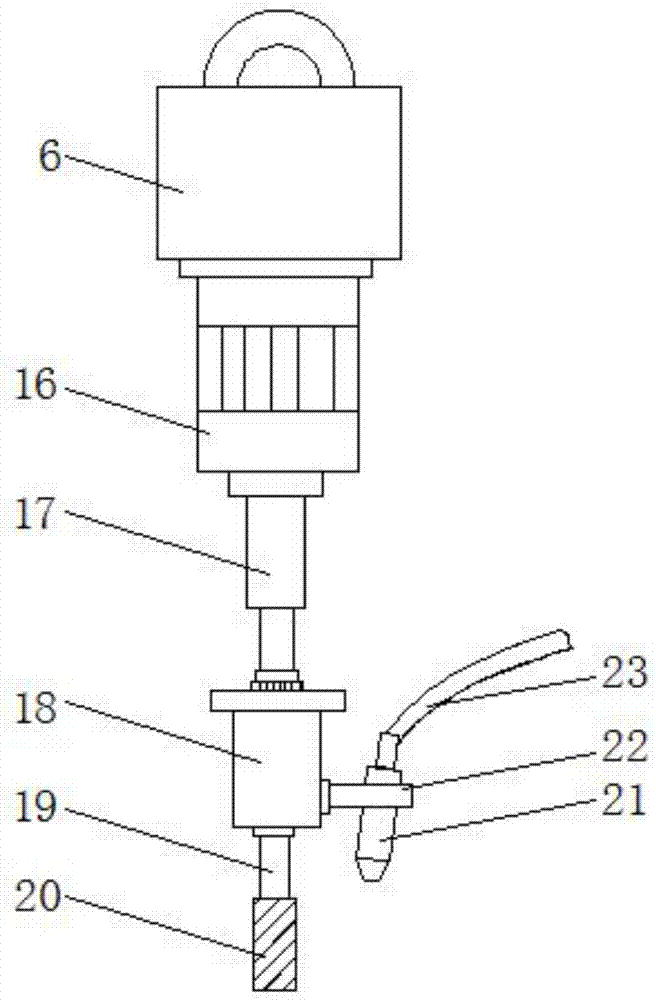

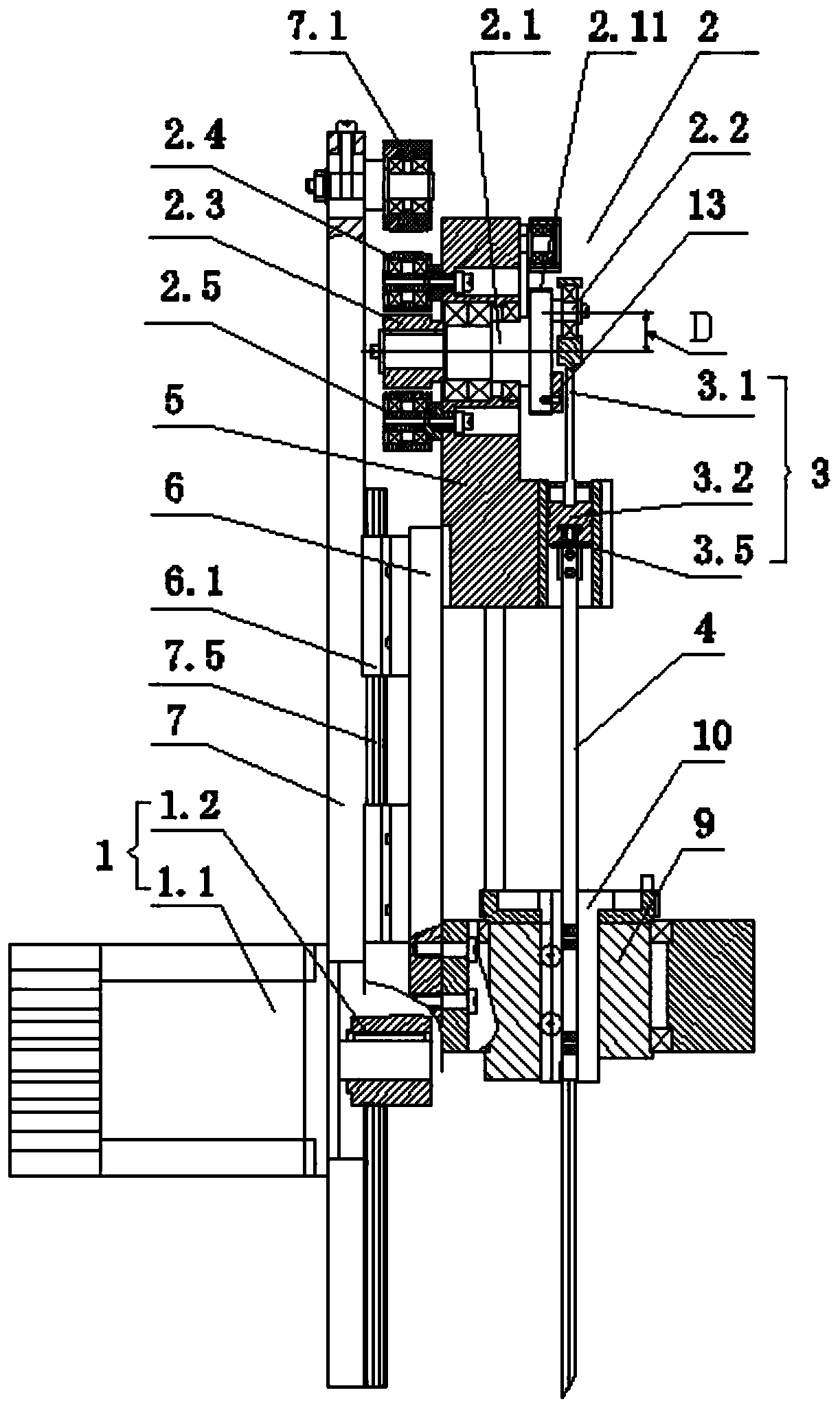

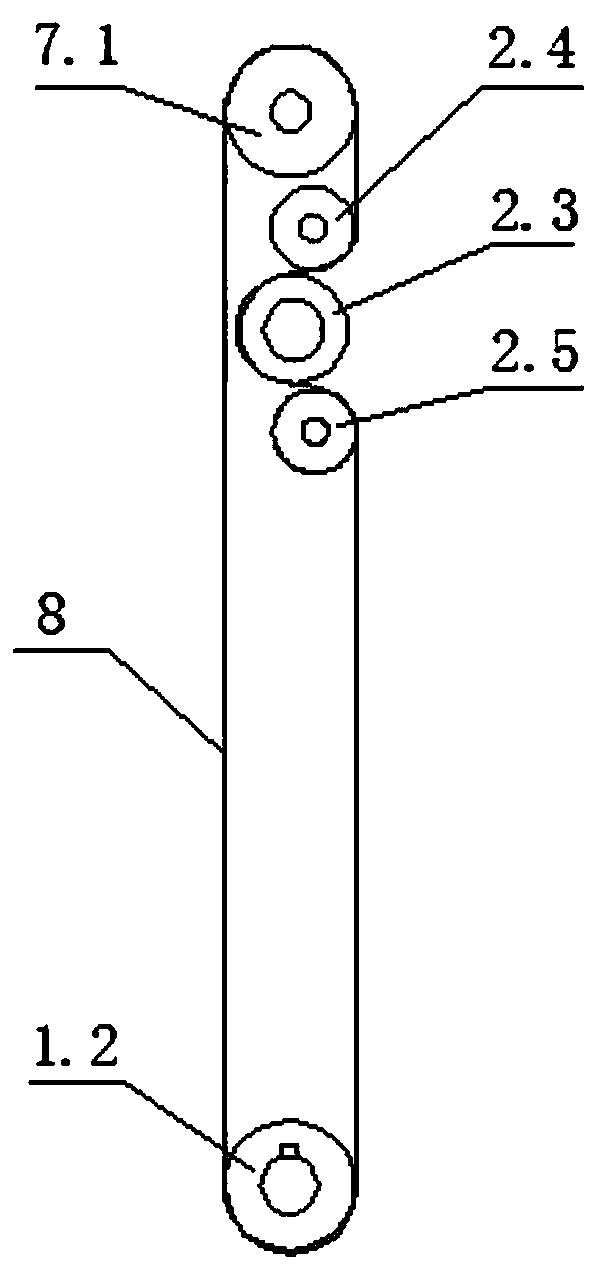

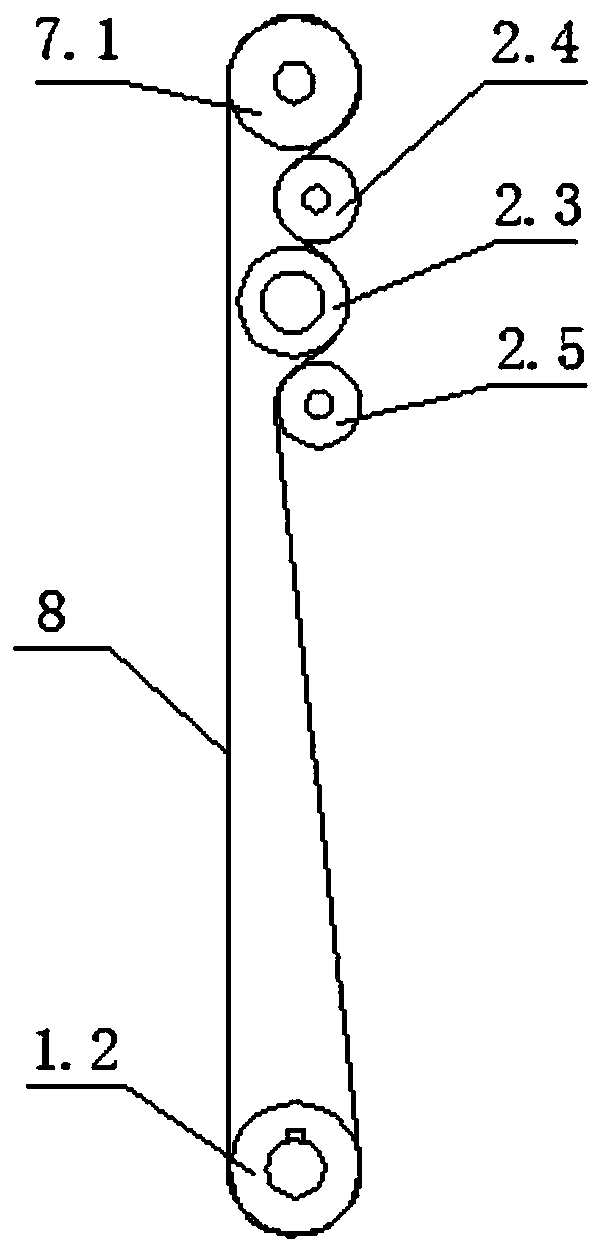

Cutting tool device with eccentric balance mechanism

PendingCN110815318ANot easy to dissolveIncrease productivitySevering textilesMetal working apparatusBalancing machineReciprocating motion

The invention discloses a cutting tool device with an eccentric balance mechanism. The cutting tool device with the eccentric balance mechanism comprises a power mechanism, an eccentric wheel mechanism, a connecting rod assembly and a cutting tool. The power mechanism is in transmission connection with the eccentric wheel mechanism, the eccentric wheel mechanism is connected with the cutting toolthrough the connecting rod assembly, and the eccentric wheel mechanism is provided with the balance mechanism. In the cutting tool device with the eccentric balance mechanism, a spindle motor transmits rotation motion through a gear or a synchronous belt, the eccentric wheel mechanism converts the rotation motion into reciprocating motion through the connecting rod assembly, large-stroke reciprocating motion is realized, and thud the production efficiency is improved. As the eccentric wheel mechanism is provided with the balance mechanism, the resultant force gravity center point C of a firstbalance gravity center A which is composed of the connecting rod assembly in cup joint with an eccentric inertia shaft and a first balancing weight block and a second balance gravity center B which iscomposed of the first balance gravity center A and a balance wheel device is always located on the circle center of an eccentric spindle, the unbalanced force on the eccentric inertia shaft is eliminated, and the vibration and noise caused by centrifugal force during high-speed rotation are reduced.

Owner:WUHAN KEPUYINENG TECH CO LTD

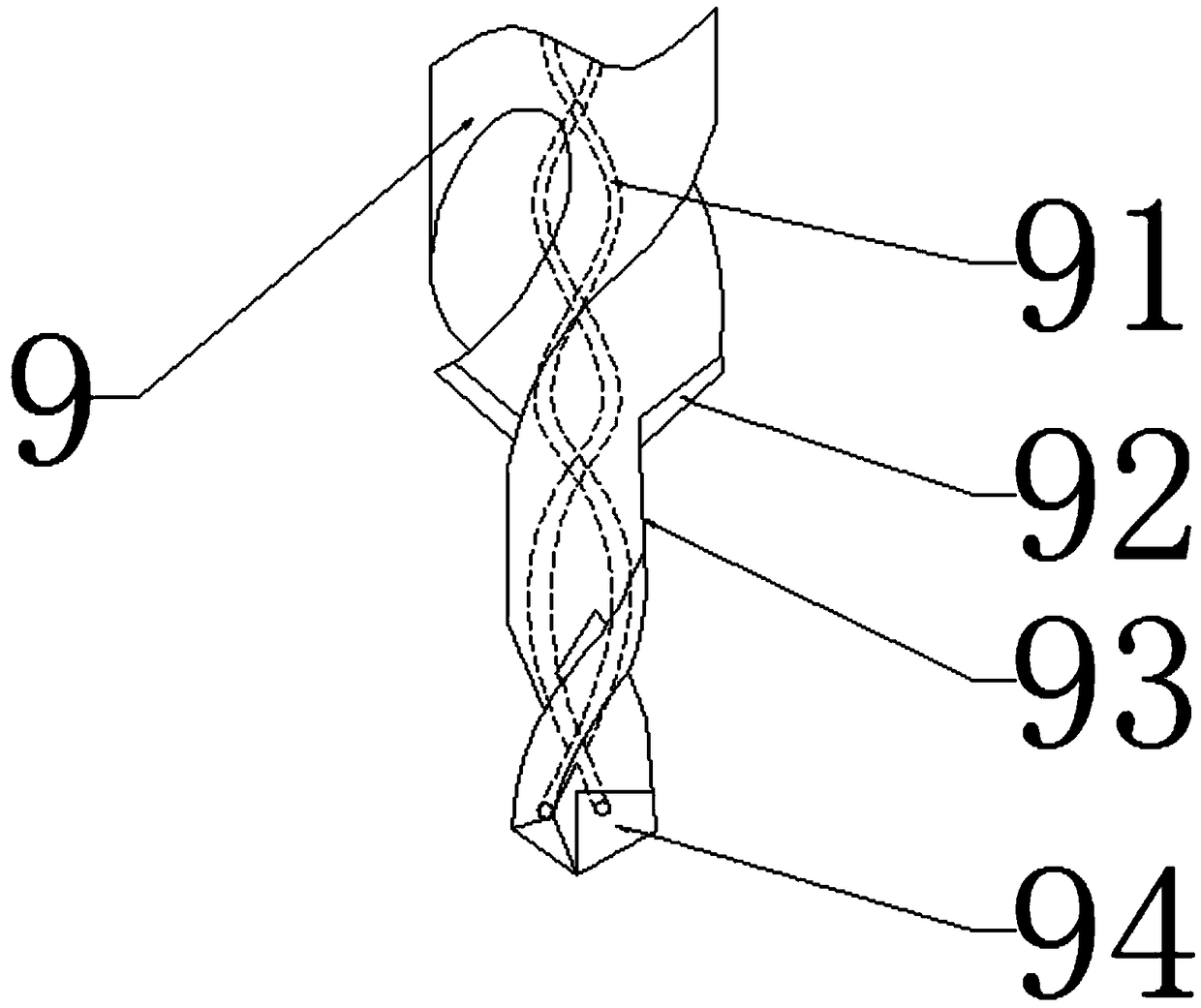

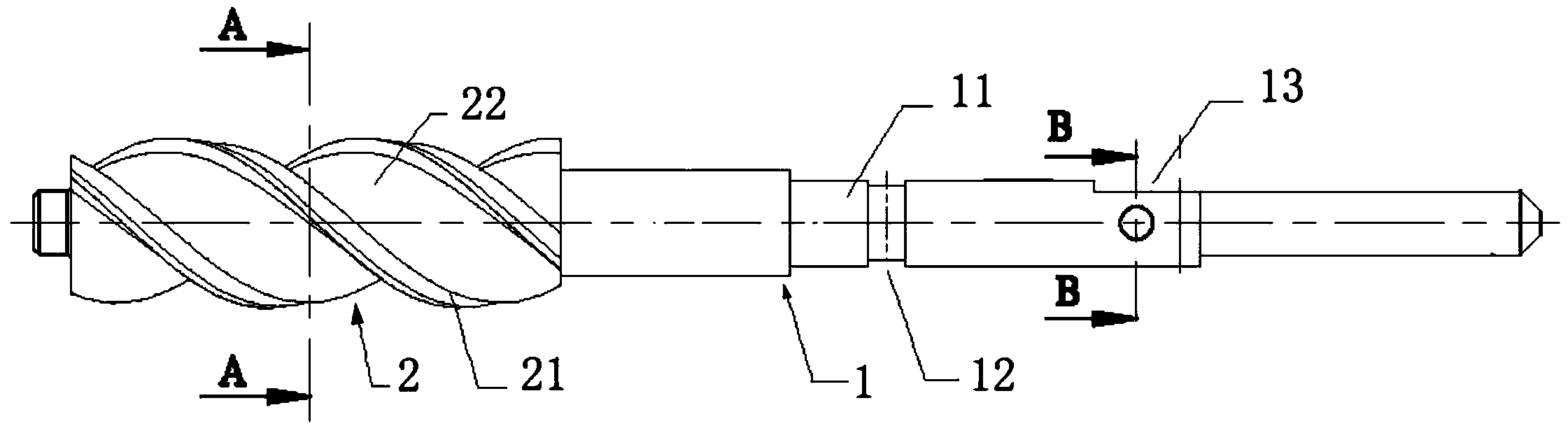

Cutting tool for hard gelatin traditional Chinese medicine processing machine

The invention discloses a cutting tool for a hard gelatin traditional Chinese medicine processing machine. The cutting tool comprises a cutting handle and a cutting head, wherein the cutting head is columnar and comprises a cutting core and three or four cutting edges uniformly and spirally arranged at the outer edge of the cutting core; scrap containing space is formed between each two adjacent cutting edges; each cutting edge comprises an edge point and an edge root, the edge point comprises a cutting side face and a non-cutting side face, the direction of the cutting side face is opposite to the spiral direction of the cutting edge, and the direction of the non-cutting side face is as the same as the spiral direction of the cutting edge; a first edge belt and a second edge belt are arranged on the cutting side face of each edge point, a first relief angle formed by the intersecting of the first edge belt and the horizontal plane is 11-13 degrees, a second relief angle formed by the intersecting of the second edge belt and the horizontal plane is 27-29 degrees, a front angle formed by the intersecting of the non-cutting side face and a vertical face at an outer point of the edge point is 9-11 degrees, and a bearing mounting section and a transmission part mounting section are mounted in the middle of the cutting handle. By utilizing the cutting tool, the powder of the cut hard gelatin traditional Chinese medicine is in a flocculent flake shape, is immediately dissolved into water and is smoothly discharged under the premises that the rigidity and strength are sufficient.

Owner:HARBIN YIWEN DINGSHENG INVESTMENT MANAGEMENT ENTERPRISE LLP

Production method of composite slide plate for bridge bearing, and friction pair for bridge bearing

ActiveCN108504050AHinder deformationImprove carrying capacityBridge structural detailsResin matrixMetallic materials

The invention discloses a production method of a composite slide plate for a bridge bearing, and a friction pair for the bridge bearing. The composite slide plate is formed through lamination and hot-press molding of a resin matrix infiltrated and modified with a reinforced fiber cloth made by braiding at least one material, the thickness of the produced composite slide plate is 4.5-20 mm, and atleast one oil storage groove is formed in one side surface of the nonmetal slide plate. The friction pair is composed of a metal slide plate and the composite slide plate, and the metal slide plate islaminated to the one side surface, with the oil storage groove, of the composite slide plate. The friction pair has the characteristics of good mechanical properties, high mechanical strength, strongbearing capacity, good self-lubricating performance, excellent wear resistance and outstanding heat resistance, and the composite slide plate has a good bonding performance and can well bond a composite material to a metal material in the production process of the bearing. The above fiber reinforced composite material optimizes the structure of the bearing on the premise of ensuring the sliding and rotating functions of the bearing, improves the bearing capacity, reduces the vertical deformation of the bearing and reduces the wearing capacity of the slide plate.

Owner:LUOYANG SUNRUI SPECIAL EQUIP

Isatis root slicing device

ActiveCN113021475AMeet the needs of useReduce cutting actionMetal working apparatusKnife bladesBevel gear

The invention relates to the technical field of isatis root processing, in particular to an isatis root slicing device. The isatis root slicing device comprises a conveying belt, wherein rotating wheels are connected to the two ends of the conveying belt; supporting frames are fixedly connected to the two ends of rotating shafts of the two rotating wheels through bearings; one end of the rotating shaft of each rotating wheel is fixedly connected with a first bevel gear; each first bevel gear is meshed with a second bevel gear; each second bevel gear is connected with a driving assembly; and each driving assembly is connected with a gap rotating assembly. The device solves the problems that the cutting effect is reduced and a user cannot use the device conveniently due to the fact that isatis root is still conveyed during blade cutting in an existing isatis root slicing device. The isatis root slicing device is reasonable in structural design and convenient to use; and the conveying belt stops conveying during blade cutting, and continues conveying after cutting is completed, so that the slicing effect and the working efficiency are improved, the use requirements of the user are met, the good market prospect is achieved, and popularization is facilitated.

Owner:邓银常

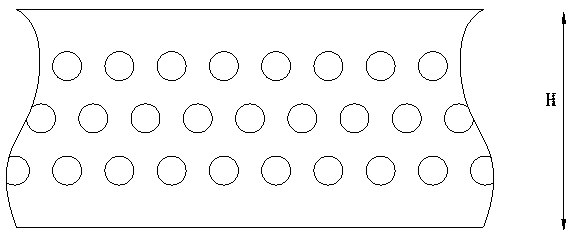

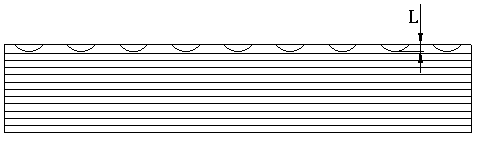

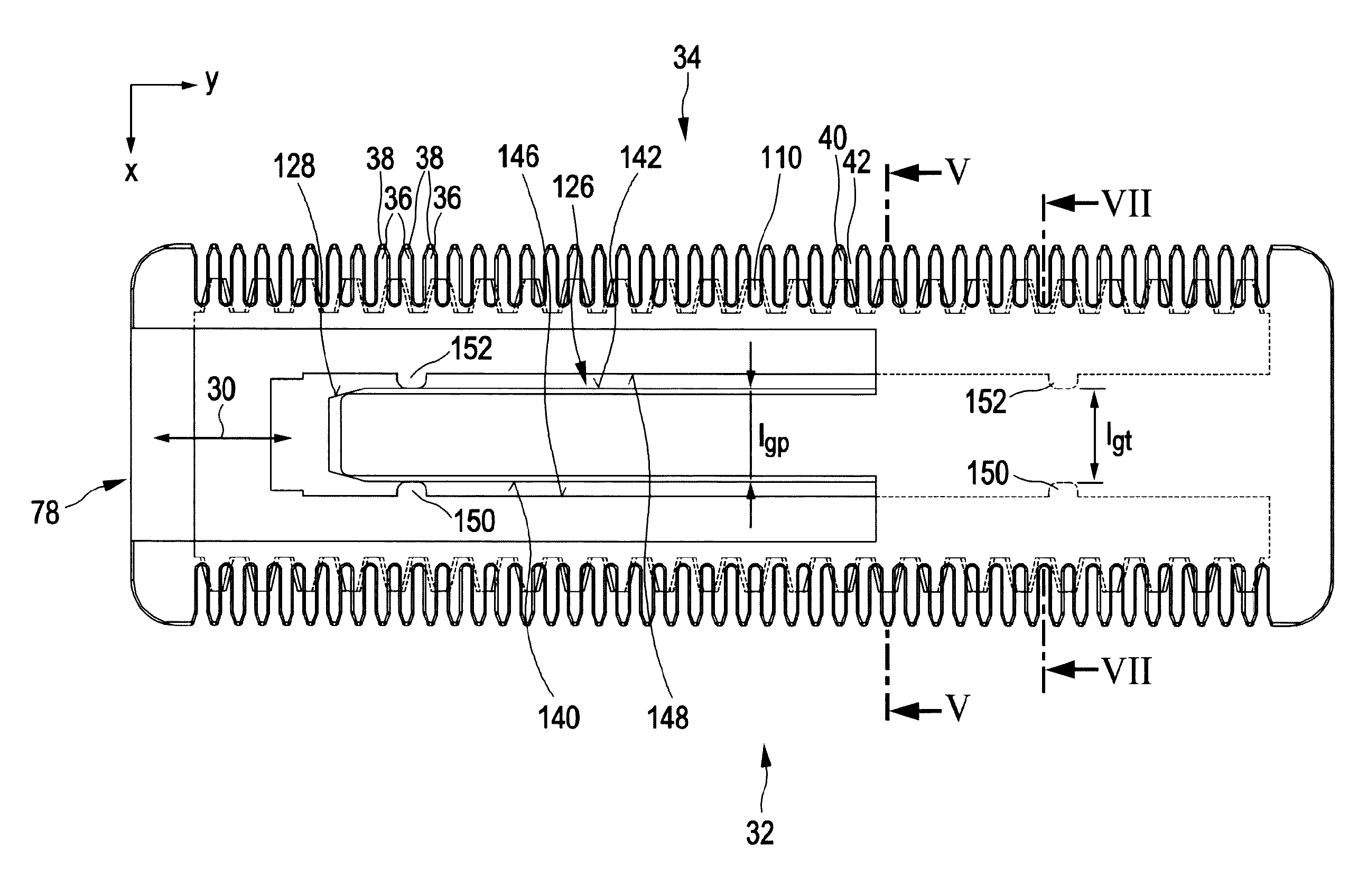

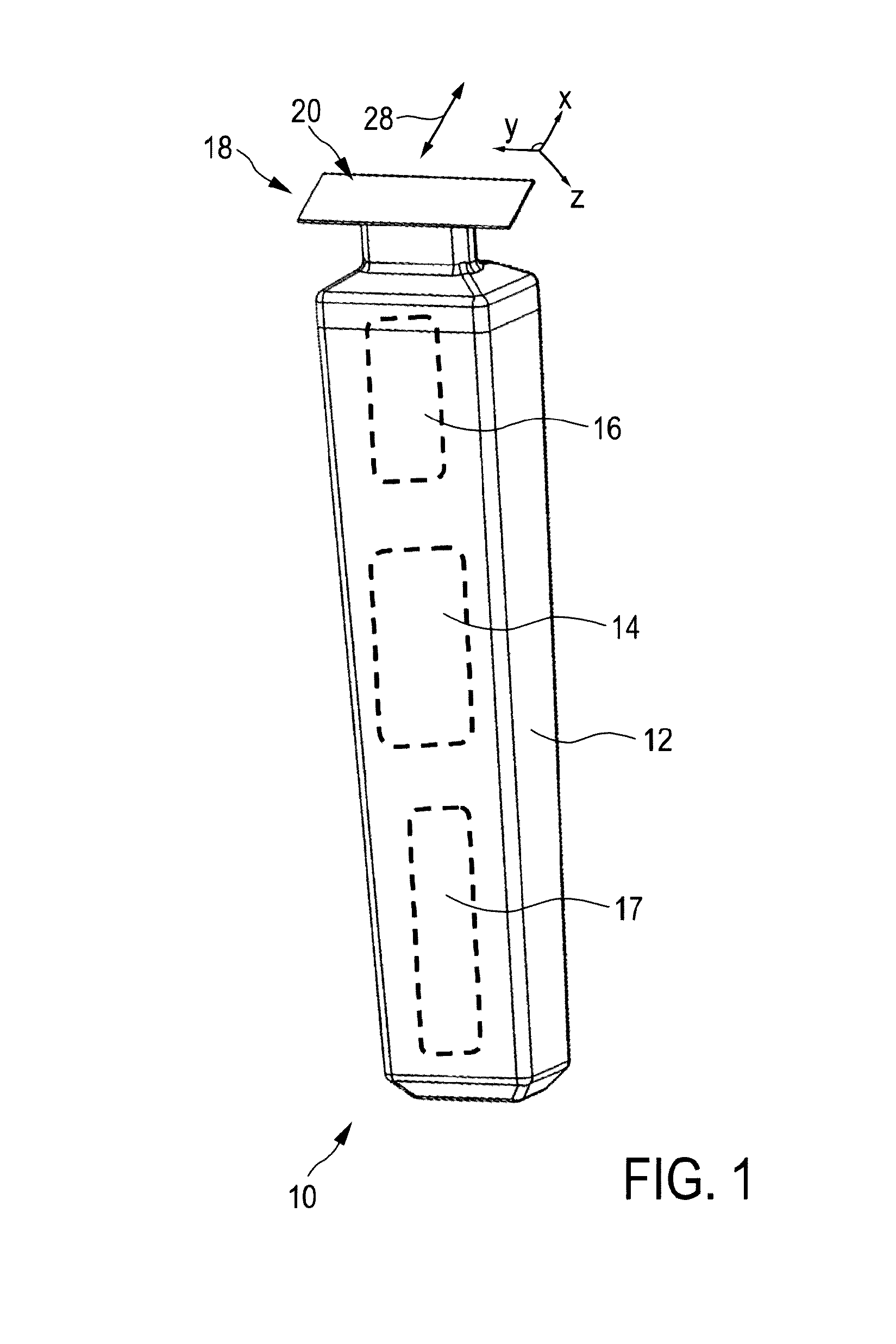

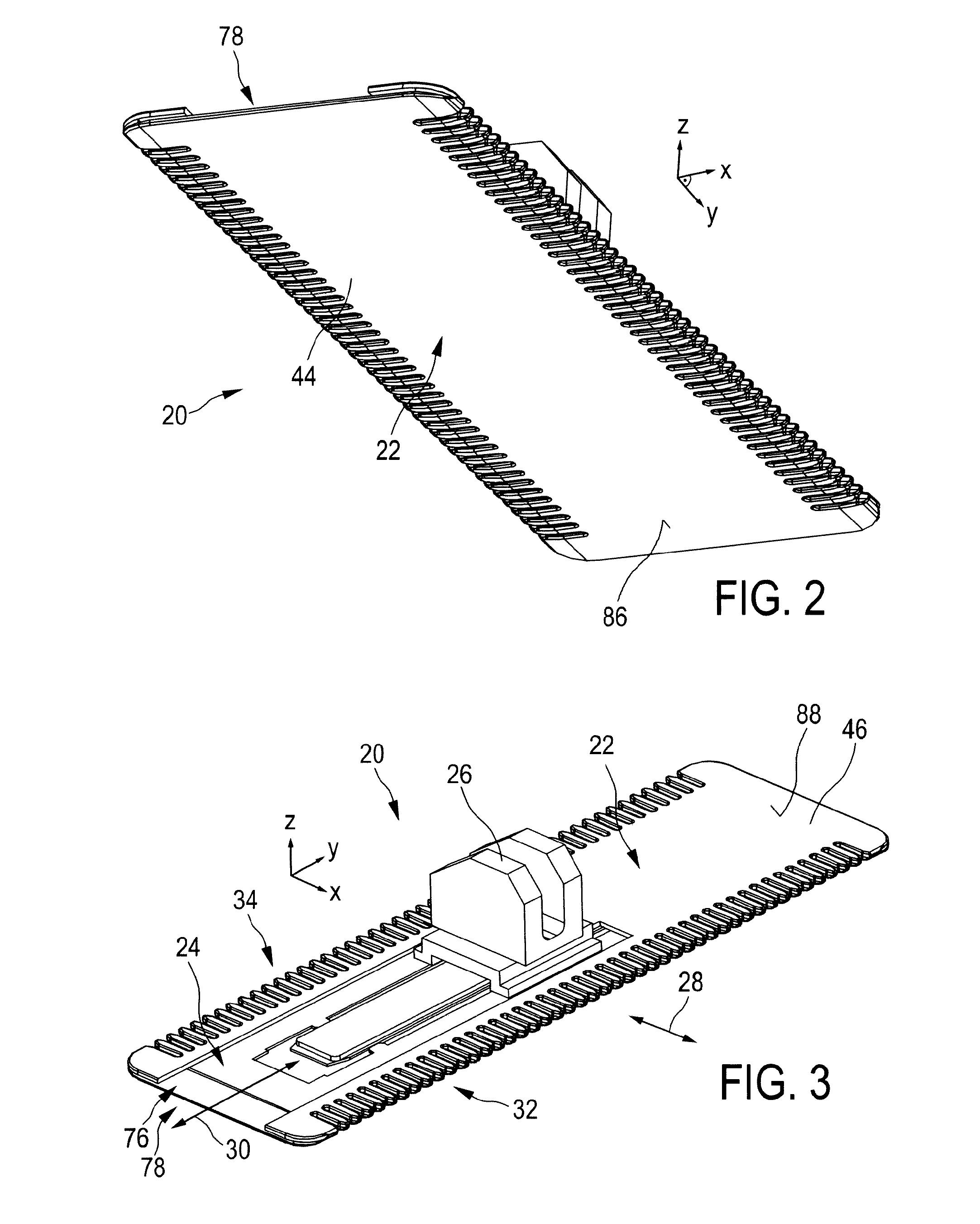

Blade set and hair cutting appliance

ActiveUS20160229071A1Simple structureImprove structural strengthMetal working apparatusLeading edgeEngineering

The present invention relates to a hair cutting appliance (10) and a blade set (20) for a hair cutting appliance (10), said blade set (20) being arranged to be moved through hair in a moving direction (28) to cut hair, said blade set (20) comprising a stationary blade (22), comprising a first wall portion (44), and a second wall portion (46), each wall portion defining a first surface (80, 82, 84), a second surface (86, 88, 90), and at least one toothed leading edge (32, 34) comprising a plurality of mutually spaced apart projections (36), wherein the toothed leading edge (32, 34) at least partially extends in a transverse direction (Y, t) relative to the moving direction (28), wherein the mutually spaced apart projections (36) at least partially extend forwardly in a longitudinal direction (X, r) approximately perpendicular to the transverse direction (Y, t), wherein the first surfaces (80, 82) of the first wall portion (44) and the second wall portion (46) face each other, at least at their leading edges (32, 34), wherein, in a filled region (58), facing projections (36) along the leading edges (32, 34) of the first and second wall portions (46) are mutually connected at their tips (38) to define a plurality of teeth (40), a movable blade (24) comprising at least one toothed leading edge (106, 106), said movable blade (24) being movably arranged within a guide slot (76) defined by the stationary blade (22), wherein the guide slot (76), at least partially extends into the forwardly extending projections (36) to an inwardly facing end face (114) of the filled region (58), and wherein the toothed leading edge (106, 108) of the movable blade (24) is spaced apart from the end face (114) of the filled region (58), thereby defining a clearance portion (118), and wherein the movable blade (24) leading edge (106, 108) and the end face (114) are longitudinally spaced apart by a clearance longitudinal dimension (lcl) of less than 0.5 mm, preferably less than 0.2 mm, more preferably less than 0.1 mm.

Owner:KONINKLJIJKE PHILIPS NV

Flaxseed formula food

The invention relates to a flaxseed formula food, and belongs to the technical field of foods. The flaxseed formula food is prepared from main components including detoxified flaxseed powder and tartary buckwheat powder. The particle size distribution range of the detoxified flaxseed powder is 10-80 meshes, and the content of the detoxified flaxseed powder is 2-10 parts by mass; and the particle size distribution range of the tartary buckwheat powder is 30-120 meshes, and the content of the tartary buckwheat powder is 5-15 parts by mass. The invention adopts the compounding of the flaxseed powder and the tartary buckwheat powder to realize the effect of defect complementation and effect improvement. The flaxseed powder can avoid the caking of the tartary buckwheat powder, and the tartary buckwheat powder helps to improve the mouth feel of the flaxseed powder, so that the flaxseed formula food can achieve good performance on appearance characters and customer acceptance.

Owner:浙江中科中创健康科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com