Semi-self-locking acetabulum posterior wall and posterior column anatomical plate

A self-locking, steel plate technology, applied in the field of medical devices, can solve the problems of occupying hospitalization expenses, limiting the size and strength of implants, and more soft tissue stripping, so as to reduce the occupied space, prevent bone loss, and facilitate wound closure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

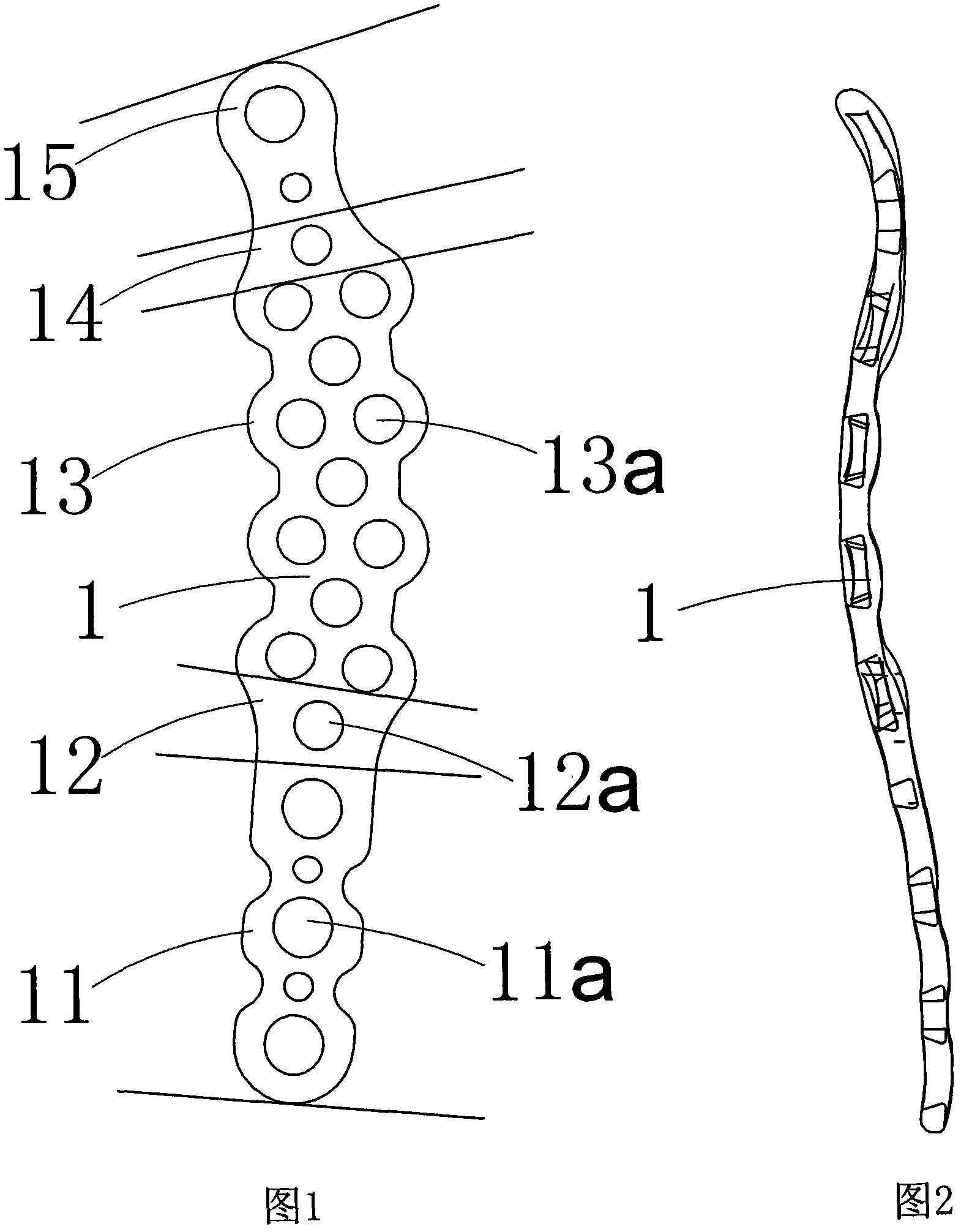

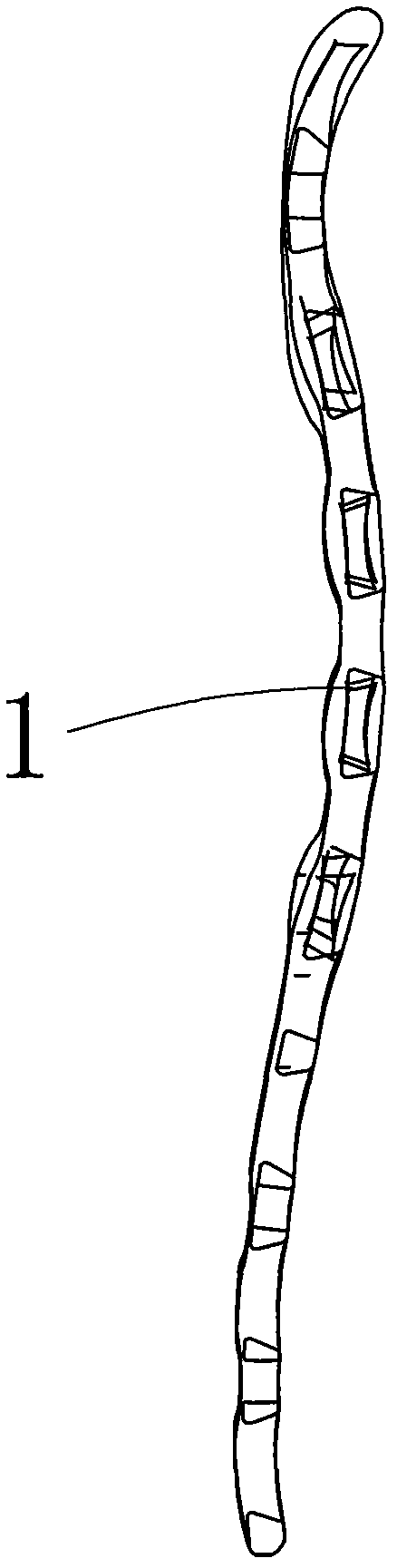

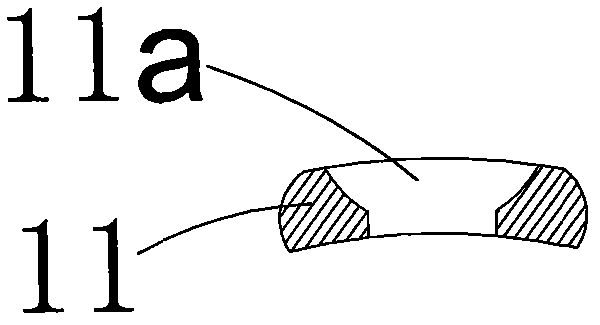

[0046] Such as Figure 1 to Figure 22 As shown, the reference numbers are as follows: steel plate main body 1, first fixing area 11, non-self-locking screw hole 11a, first positioning area 12, positioning hole 12a, main fixing area 13, self-locking screw hole 13a, second positioning area 14. Second fixing area 15, self-locking sleeve 2, working head 21, second external thread 22, handle 23, through hole 24, self-locking screw 3, connector 31, first external thread 32, guide hole 33, Inner pentagon counterbore 34.

[0047] The semi-self-locking acetabular posterior wall anatomical steel plate of the present invention comprises a steel plate main body 1, a self-locking sleeve 2 and a self-locking screw 3, and the steel plate main body 1 is sequentially formed with a first fixing area 11, a first positioning area 12, Main fixing area 13, second...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com