Steel and manufacturing method for Ca microalloying free-cutting high-strength expansion-breaking connecting rod

A technology of micro-alloying and expanding connecting rod, applied in the field of Ca micro-alloyed steel material and its manufacturing, can solve the problems of reduced material fatigue performance, material strength, difficult to solve the machinability and crackability and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

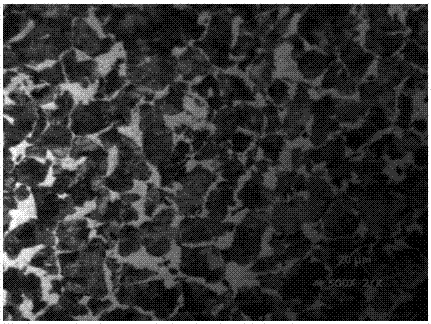

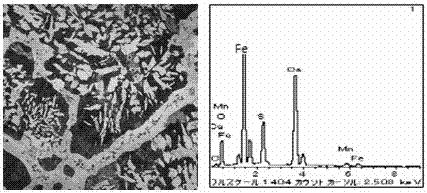

Image

Examples

Embodiment 1-3

[0040] Manufacture the Ca microalloyed free-cutting high-strength bursting connecting rod steel in Examples 1-3 of the present invention according to the following procedures:

[0041] 1) Smelting: After smelting in a 100-ton steelmaking furnace, refining outside the furnace is carried out, and the molten steel is then subjected to vacuum degassing treatment, and the mass percentage of each chemical element is strictly controlled according to the requirements.

[0042] 2) Continuous casting: continuous casting into a billet of 200mm×200mm, and the superheating degree of the tundish is controlled at 10-40°C. In order to control the segregation of materials, advanced end electromagnetic stirring and continuous casting light reduction advanced equipment and technology are used in continuous casting. Gained continuous casting slab chemical composition percentage is shown in the following table 1:

[0043] Table 1. (wt.%, the balance is Fe and other unavoidable impurity elements) ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com