Gas-insulated circuit breaker

一种气体绝缘、断路器的技术,应用在高压空气断路器、电路、电气元件等方向,能够解决调整作业及组装作业花费时间、制造成本高等问题,达到实现紧凑化及低成本化、制造成本低价、避免高电场的发生的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 2 Embodiment approach

[0101] (constitute)

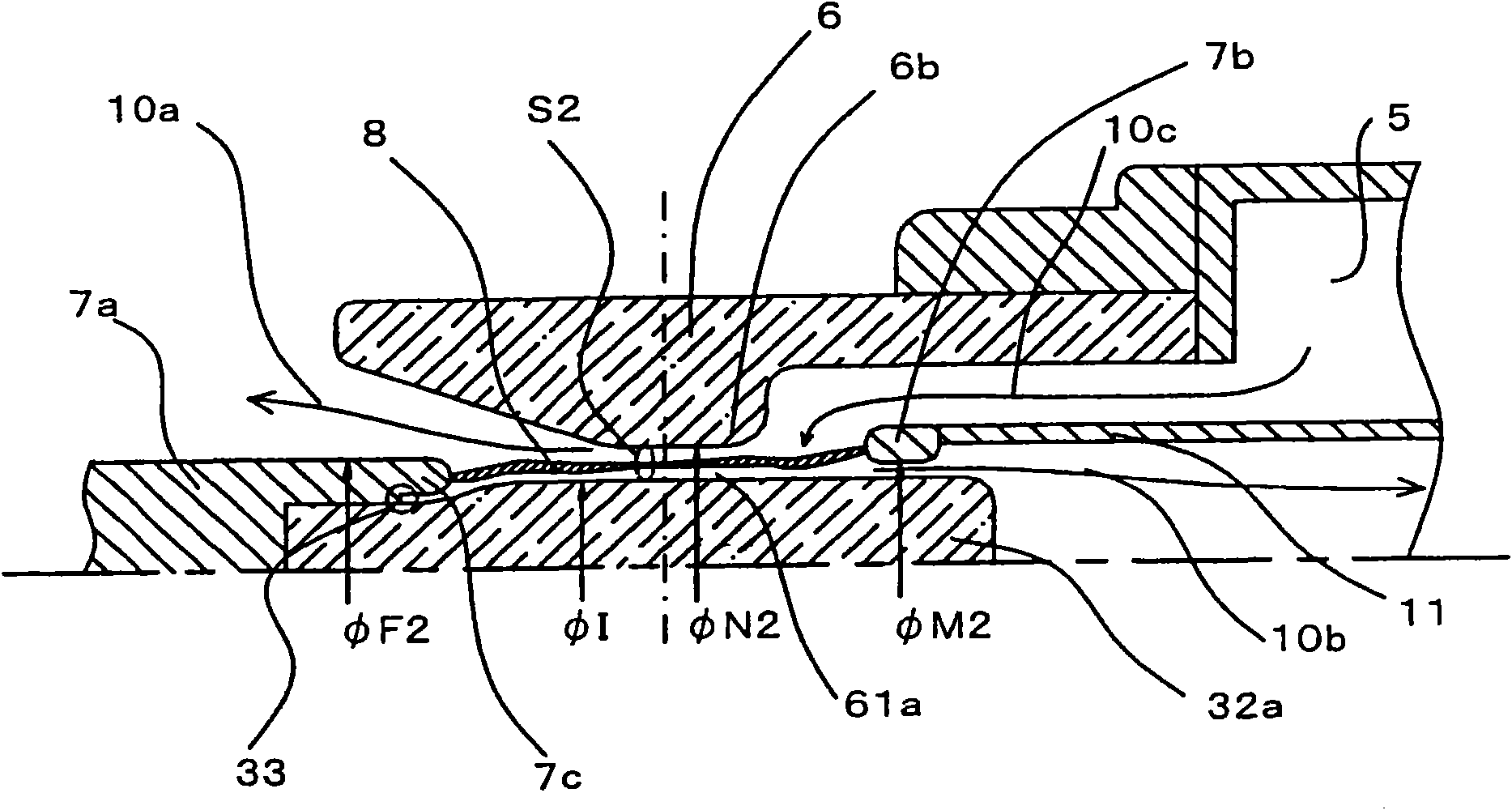

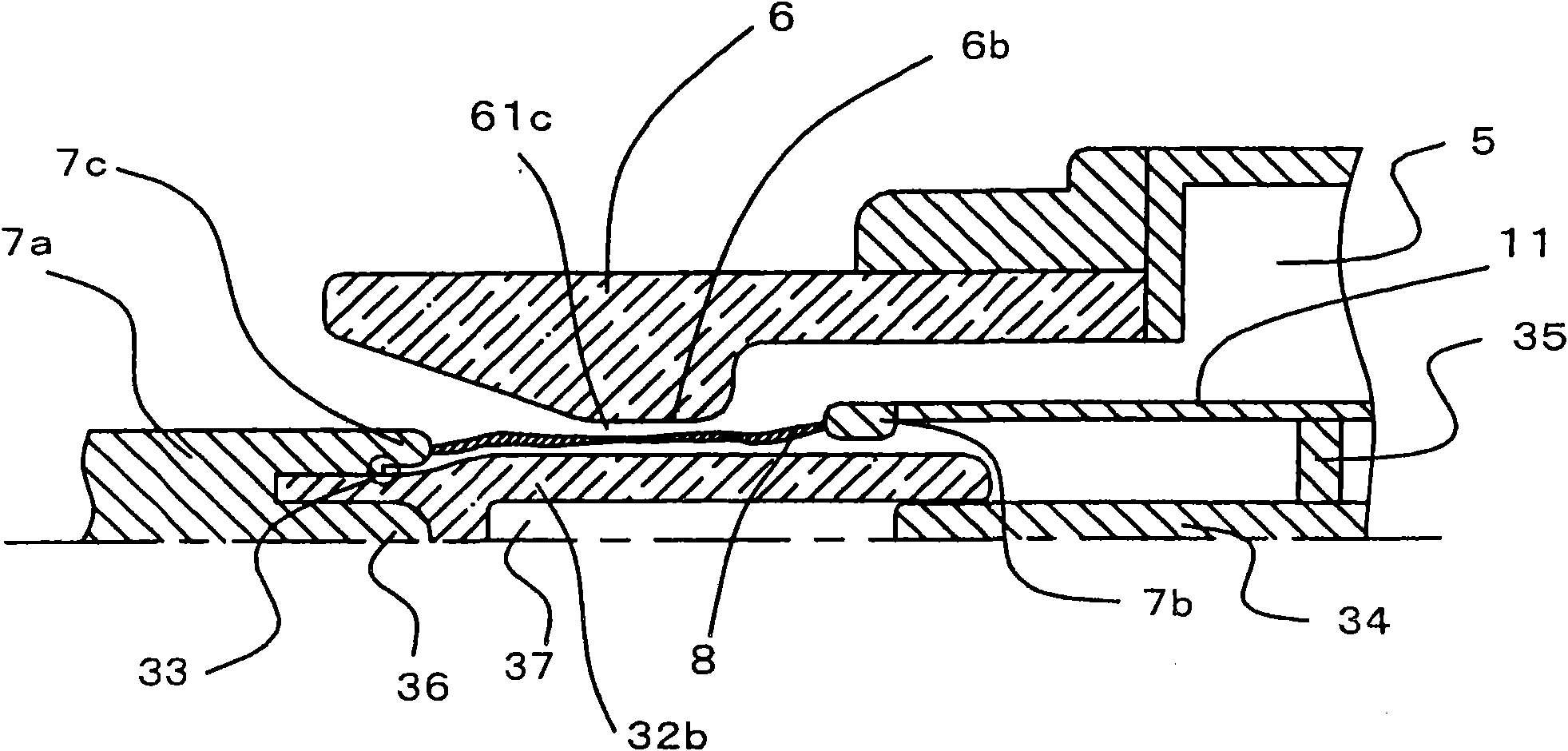

[0102] Next, use image 3 A second embodiment of the present invention will be specifically described. image 3 It shows the state near the arc during the breaking operation of the gas insulated circuit breaker. Since each component has a rotationally symmetrical shape, only the upper half of the center line is drawn.

[0103] The basic configuration of the second embodiment is the same as that of the first embodiment, but is characterized by the following points. That is, if image 3 As shown in the figure, an electric field relaxation shield 36 is provided at the center of the front end portion of the fixed arc contact 7a. The electric field relaxation shield 36 is embedded in the inner-nozzle insulating member 32b. In addition, reference numeral 35 is a rod support mounted on the hollow rod 11 .

[0104] The inner nozzle insulating member 32b of the second embodiment has a hollow structure in which a hole 37 is formed, and a guide rod 34 fixed to ...

no. 3 Embodiment approach

[0120] (constitute)

[0121] Next, use Figure 4 A third embodiment of the present invention will be described. Figure 4 It shows the state near the arc during the breaking operation of the gas insulated circuit breaker. Since each component has a shape symmetrical to the rotation axis, only the upper half of the center line is drawn.

[0122] The characteristic configuration of the third embodiment resides in the point of including the nozzle inner insulating member 32 c having the tapered surface 38 . The tapered surface 38 is formed by drawing a curve such that the diameter near the center of the nozzle inner insulating member 32c is large, and the diameter becomes smaller toward the vicinity of the ends.

[0123] That is, the diameter of the inner nozzle insulating member 32c formed with the tapered surface 38 becomes uneven along the axial direction. Therefore, the size of the gas flow path 61c of the insulating nozzle 6 according to the third embodiment changes with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com