Starch/nanometer SiO2 composite gel, and preparation method and application thereof

A composite gel and nanotechnology, applied in chemical instruments and methods, drilling compositions, etc., can solve problems such as poor viscoelasticity, low compressive strength, and difficulty in meeting requirements, and achieve high compressive strength, thermal Good stability, strong adhesion and sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

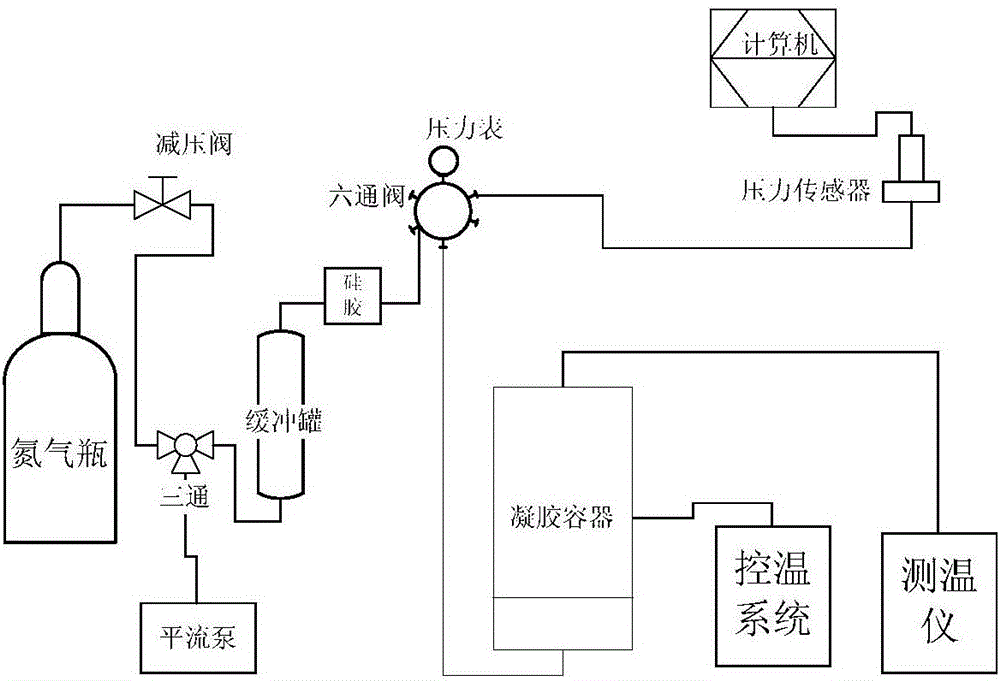

Method used

Image

Examples

Embodiment 1

[0040] Use a balance to weigh an appropriate amount of tap water and add it to the beaker. Place the beaker under the stirrer, and the bottom of the stirring rod is about 1 cm from the bottom of the beaker. Turn on the DW-3 digital display electric stirrer switch, adjust the stirring speed to about 400r / min, make the water form a vortex, and then weigh a certain amount of thiourea and nano-SiO with an analytical balance 2 , cornstarch and partially hydrolyzed polyacrylamide were added to the beaker at a constant speed. Continue to stir until the polymer is completely dissolved (generally take 4h of stirring). Then add a certain amount of cross-linking agent chromium acetate, stir and mix evenly, and place it in a constant temperature oven at 70°C for reaction to form a gel.

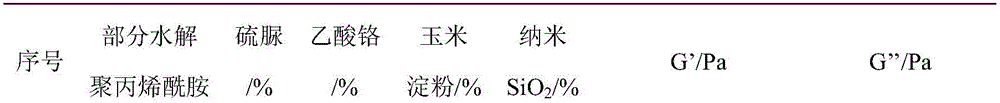

[0041] Among them, starch / nano-SiO 2 The formulation of the composite gel and its elastic modulus and viscous modulus are shown in Table 1.

[0042] Table 1 Starch / nano-SiO 2 Formulation of composite...

Embodiment 2

[0051] Its preparation method is with embodiment 1; Difference is starch / nano-SiO 2 In the formula of the composite gel, the mass percent of cornstarch is 5%. Table 3 and Table 4 are respectively starch / nanometer SiO 2 Viscoelasticity and compressive strength data of the composite gel.

[0052] Table 3 Starch / nano-SiO 2 Formulation of composite gel and its elastic modulus and viscous modulus

[0053]

[0054] Among them, G' represents the elastic modulus, and G" represents the viscous modulus.

[0055] It can be seen from Table 3 that when the amount of corn starch is 5%, SiO 2 The dosage of 3% is the critical value, and the viscoelastic modulus of the composite gel does not increase significantly above this dosage.

[0056] Table 4 Starch / nano-SiO 2 Pressure resistance of composite gel

[0057]

[0058] As can be seen from Table 4, the composite gel prepared by formula C0 (SiO 2 = 0%, corn starch = 5%) has the highest pressure bearing capacity, up to 0.4028MPa m...

Embodiment 3

[0060] Its preparation method is with embodiment 1; Difference is starch / nano-SiO 2 In the formula of composite gel, the mass percent of cornstarch is 0%, 0.5%, 1% and 7%; Nano-SiO 2 The mass percentage is 3%. Table 5 and Table 6 are respectively starch / nanometer SiO 2 Viscoelasticity and compressive strength data of the composite gel.

[0061] Table 5 Starch / nano-SiO 2 Viscoelasticity of composite gels

[0062]

[0063] Among them, G' represents the elastic modulus, and G" represents the viscous modulus.

[0064] Table 6 Starch / nano-SiO 2 Pressure resistance of composite gel

[0065]

[0066] The starch / nanometer SiO that the embodiment of the present invention 1-3 prepares 2 The composite gel has the characteristics of high strength, good elasticity, good toughness, good adhesion, and good air tightness. Therefore, in the process of drilling, completion and workover, it can play a lot of well killing and sealing functions, can effectively isolate the killing fl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com