Patents

Literature

81results about How to "Floating fully" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Production method of ultra-low-carbon steel for sedan car cortical plate

InactiveCN101096034AReduce manufacturing costLower recrystallization temperatureTemperature control deviceWork treatment devicesHigh energyHeating furnace

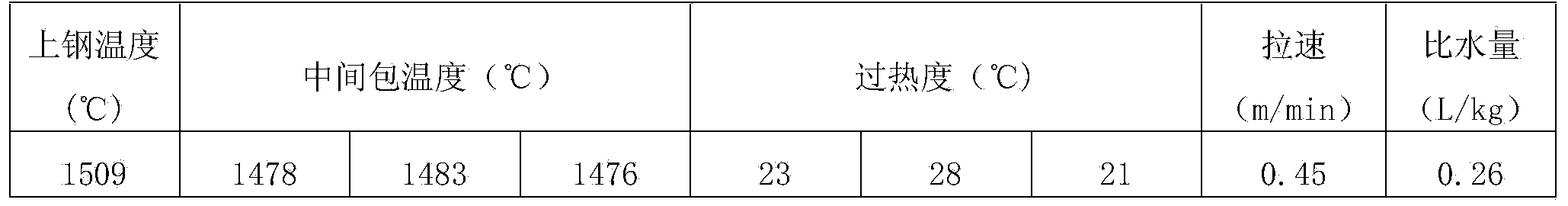

The invention provides a producing method for ultra low steel carbon used in car outer plate, characterized in that liquid steel is cast into plate slab in the pulling speed of 1.5-4m / min; the thickness of plate slab is 100-170mm; casting machine adopts dynamic light pressure and crystallizer electromagnetic braking technology and tundish superheat is 20-45deg.C; the plate slab is installed in heat directly and the charging temperature is more than 800deg.C; the plate slab is heated to 1150-1250deg.C in heating furnace; after the temperature is maintained for 30-90min rough rolling cogging is carried out. By adopting continuous rolling and casting short-flow process of medium-thin plate slab and collocating casting machine and heating furnace compactly quick charging is realized; charging material temperature is improved; problems of large investment and high energy consumption in conventional process are solved; inner limitation generated in continuous casting process of thin plate is eliminated; it is guaranteed that product is provided with good surface quality and stable mechanical property.

Owner:ANGANG STEEL CO LTD

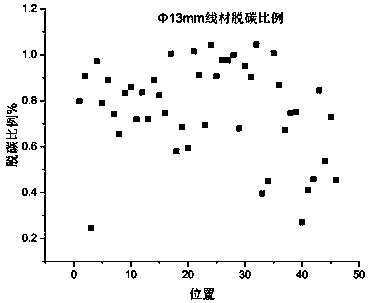

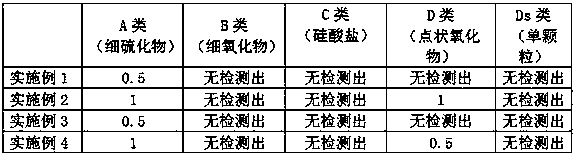

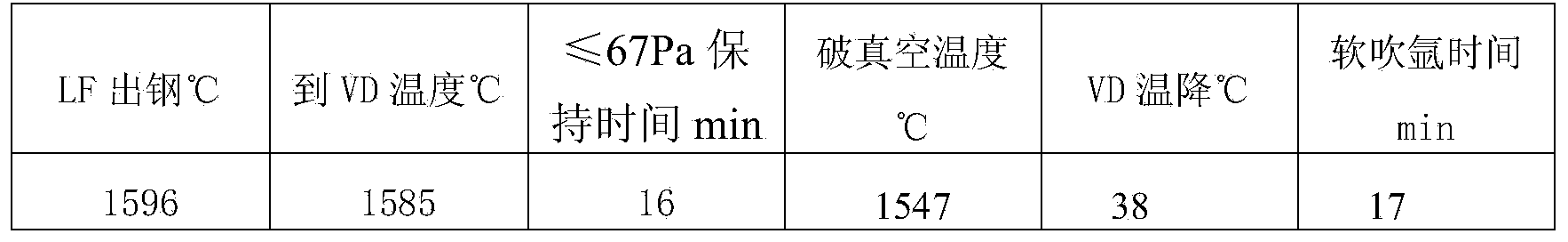

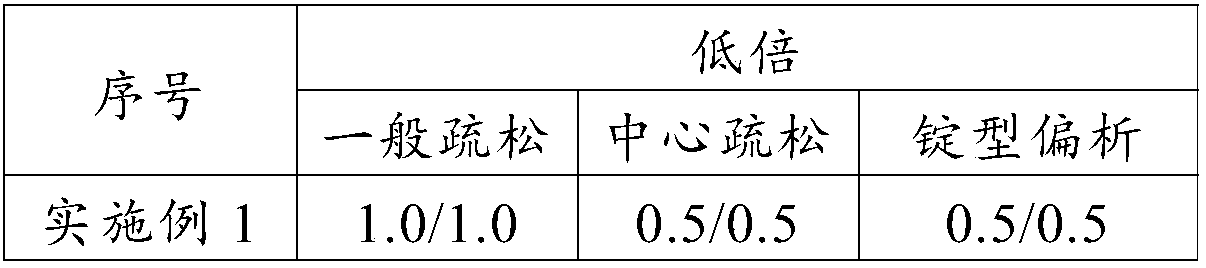

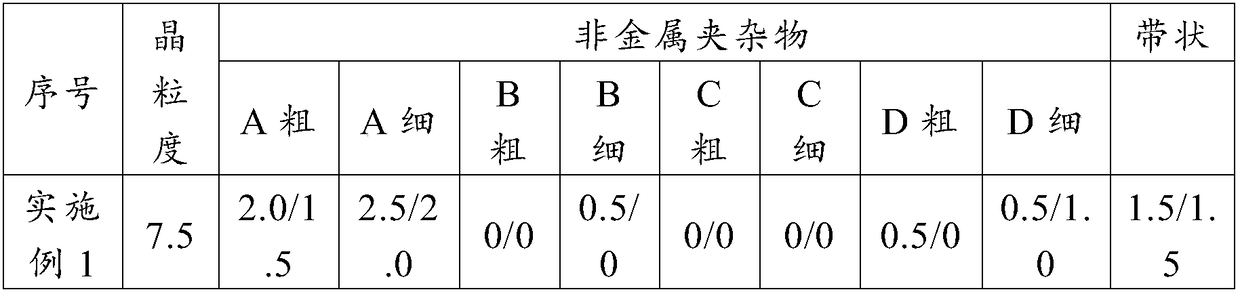

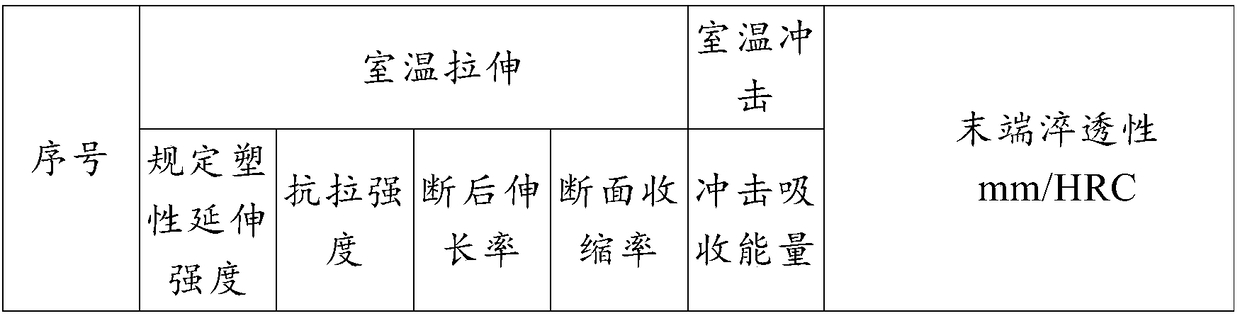

Production technology of spring steel 60Si2Mn hot-rolled wire rod for automotive suspension

ActiveCN109023059AGuarantee organizationGuaranteed performanceProcess efficiency improvementSlagDeoxygenation

The invention discloses a production technology of a spring steel 60Si2Mn hot-rolled wire rod for an automotive suspension. The production technology comprises the steps of a hot metal pretreatment working procedure, a converter smelting working procedure, an LF refining working procedure, an RH vacuum treatment working procedure, a continuous casting working procedure, a cogging working procedure, an ingot blank polishing working procedure and a wire rod rolling working procedure. According to the production technology, the generation of AL2O3 inclusion is controlled from the source by meansof hot metal pretreatment desulfurization, silicon iron deoxygenation, silicon carbide diffusion deoxygenation and wollastonite and active lime slag formation; by the adoption of special carburant andspecial silicon iron, the content of nitrogen and the content of titanium in steel are controlled, argon protection in the whole process and the sufficient standing time are adopted, the situation that the inclusion fully and upwards floats is guaranteed, and D and Ds inclusion in the molten steel is controlled; by means of large ladle slag detection and special covering slag, the phenomenon thatthe molten steel is subjected to secondary pollution can be completely eradicated, and a good effect of thermal-insulating adsorption of the inclusion can be achieved; by means of the stir and soft press operation of a large rectangular blank crystallizer, the internal quality of an ingot blank is ensured; and in the rolling process, due to the optimization of the rolling speed and the control over the rolling temperature, the structure and the performance of a finished product are guaranteed.

Owner:HANDAN IRON & STEEL GROUP +1

Method for preparing bearing steel

ActiveCN104178698AHarm reductionInhibit peroxidationProcess efficiency improvementElectric furnaceNon-metallic inclusionsOxygen content

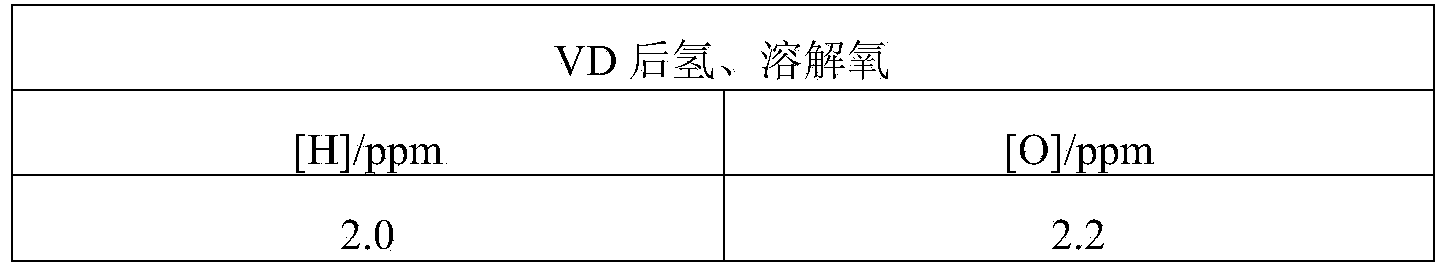

The invention relates to a method for preparing bearing steel. The method comprises the following steps of smelting, and alloying; carrying out continuous casting; rolling; carrying out slow cooling, and the like. The chemical components in the bearing steel are controlled in percentage by weight as follows: 0.95%-1.05% of C, 0.20%-0.30% of Si, 0.30%-0.35% of Mn, 0.02%-0.05% of Mo, 1.45%-1.48% of Cr, 0.015%-0.035% of AlS, less than or equal to 0.05% of Cu, less than or equal to 0.025% of S, less than or equal to 0.025% of P, less than or equal to 0.05% of Ni, less than or equal to 12*10<-6> of [O], less than or equal to 2*10<-6> of [H] and the balance of Fe and inevitable impurities. According to the bearing steel produced through the method disclosed by the invention, the total oxygen content of a steel product can be stably controlled below 8 ppm, non-metallic inclusions are low in content and uniformly distributed, and good casting blank structure homogeneity, steel quality stability and anti-fatigue property and casting blank segregation grade reduction are achieved.

Owner:SHANDONG IRON & STEEL CO LTD

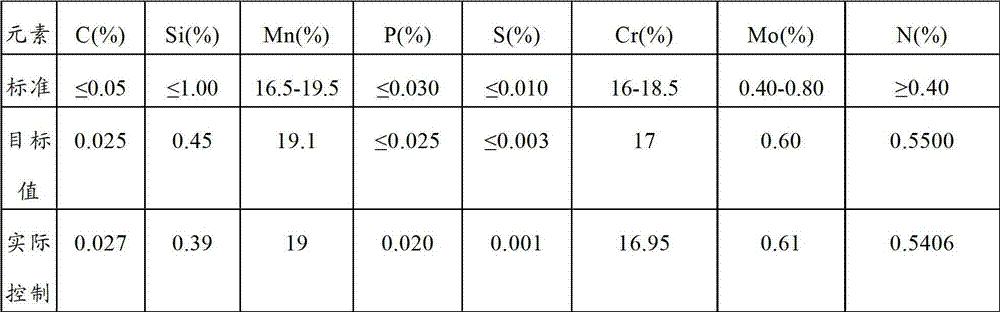

High-nitrogen high-manganese stainless steel and smelting method thereof

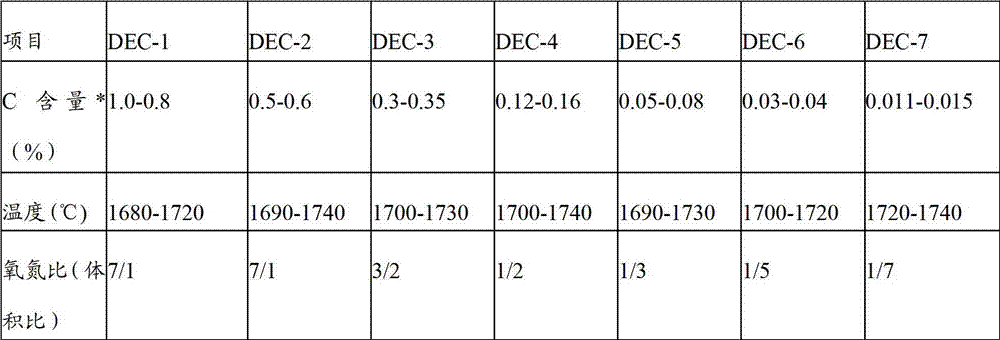

The invention discloses a smelting method of stainless steel. The smelting method comprises the following steps: (1) an electric furnace smelting process: adding chromium-containing waste steel and manganese-containing waste steel into an electric furnace for smelting, and tapping after waste steel is molten completely in the electric furnace, wherein the content of manganese is controlled to be 3-6%, and the content of chromium is controlled to be 24-28%; (2) a nitrogen-oxygen decarbonization refining process: transferring molten steel into a refining station of a nitrogen-oxygen refining furnace for refining under the condition that nitrogen is introduced at the flow rate of 2000-2200Nm<3> / h in the whole refining course, decarbonizing at first, adding metal Mn after decarbonizing is completed, raising the temperature, then, reducing, slagging after reducing, adding manganese alloy after slagging under the condition that the flow rate of nitrogen is 900-1100Nm<3> / h at the moment, stirring, and then tapping molten steel into a die casting ladle; (3) a ladle refining process, wherein nitrogen-manganese alloy is added stepwise in a refining process, and then argon blowing treatment is carried out; and (4) a die casting process. The invention further provides stainless steel obtained by using the smelting method. The smelting method disclosed by the invention has the advantages of shortening smelting time, improving nitrogen adding efficiency, reducing nitrogen adding cost and improving the purity degree of the molten steel.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

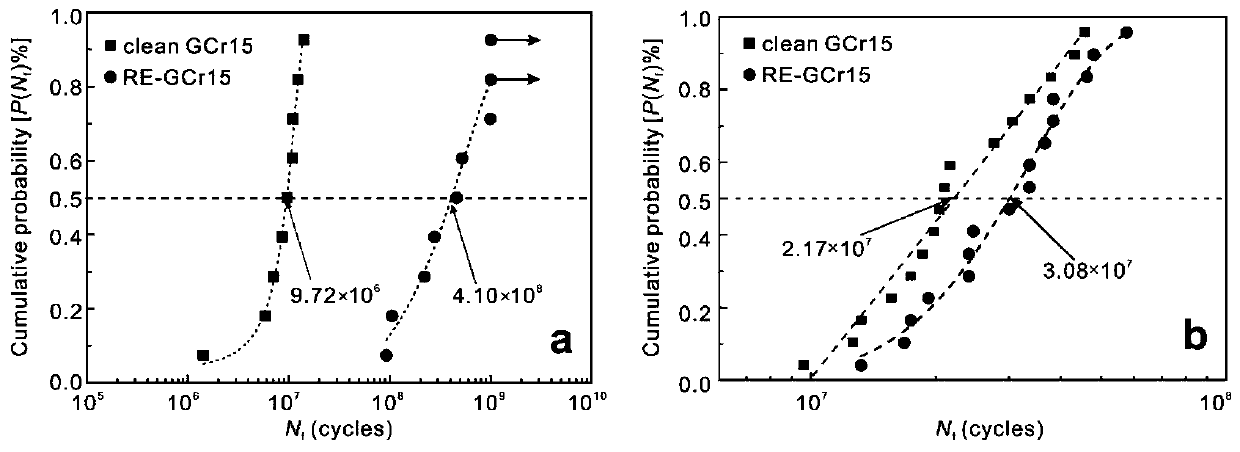

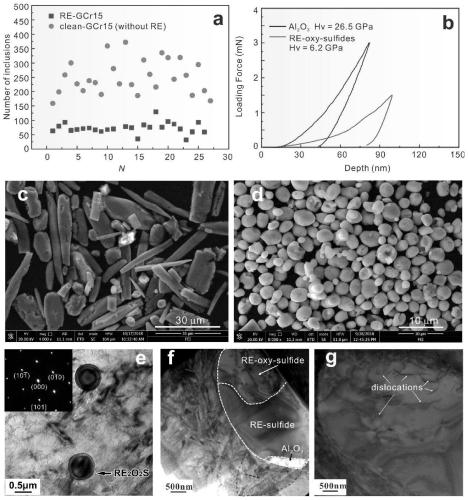

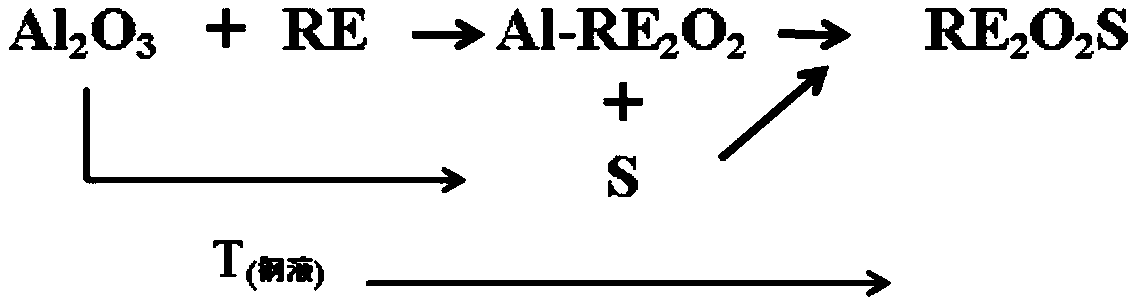

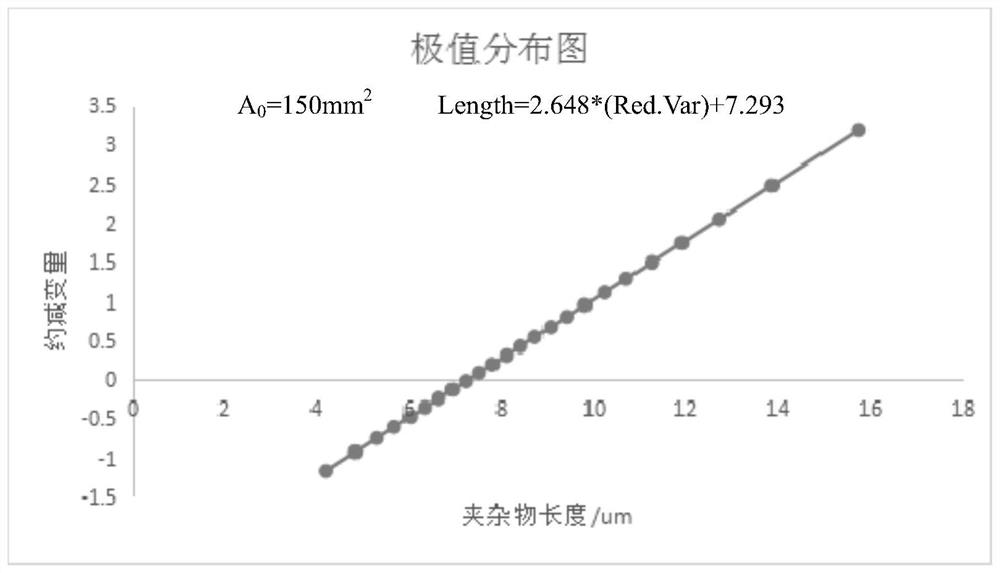

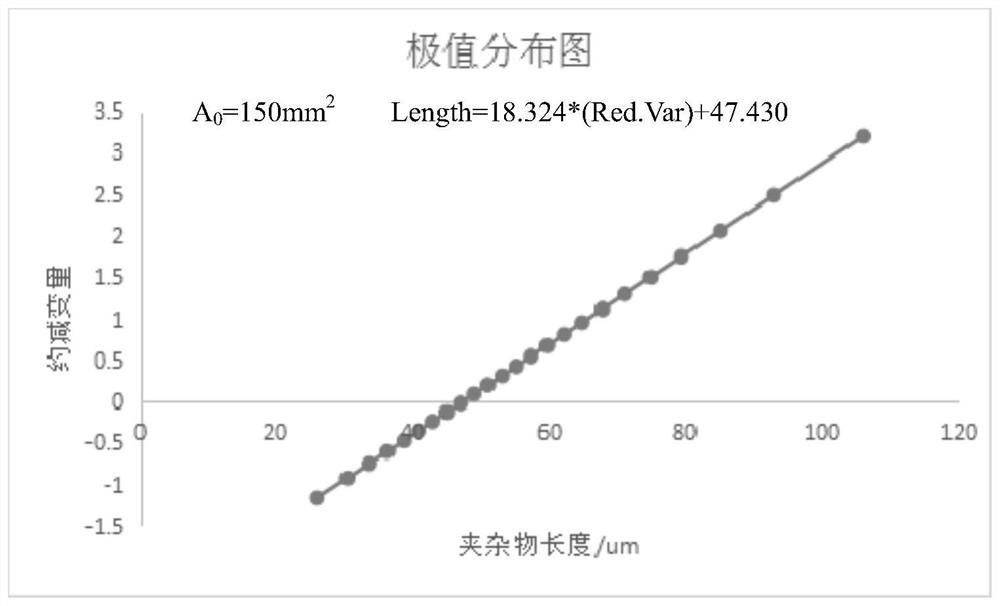

Ultra-clean rare earth steel and occluded foreign substance modification control method

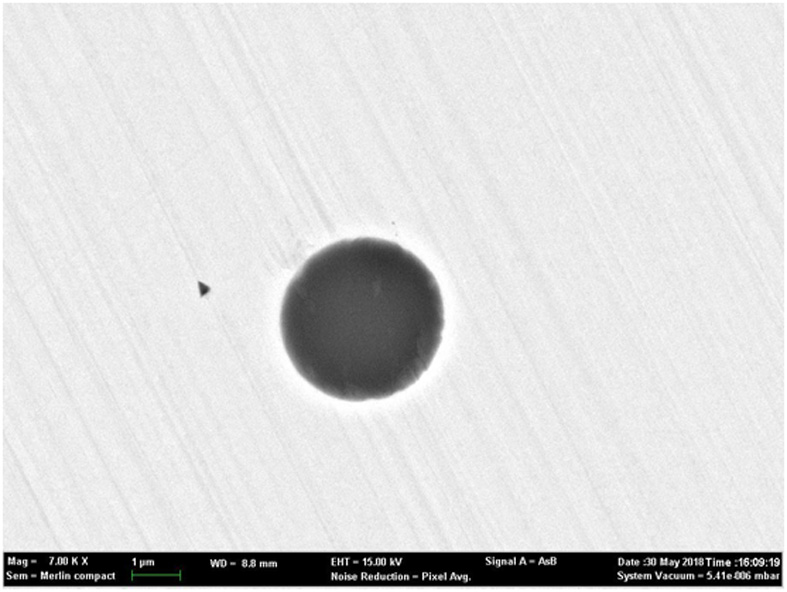

ActiveCN110484811AReduce hardnessImprove fatigue lifeProcess efficiency improvementRare-earth elementMicrometer

The invention provides ultra-clean earth steel and an occluded foreign substance modification control method. 10-200 ppm of rare earth elements are included in the steel, and 50% or more occluded foreign substances in the steel are dispersed RE-oxygen-sulfide with the average equivalent diameter Dmean ranging from 1 micrometer to 5 micrometers in a spherical shape or a spheroidal shape or a granular shape. According to the method, at least 80%, preferably at least 90%, of Al2O3 occluded foreign substances in the steel are modified into RE-oxygen-sulfide, compared with steel with the same components without rare earth, the total amount of the occluded foreign substances in the steel is reduced by 18% or higher, the cracking probability caused by occluded foreign substances such as Al2O3 intraditional pure steel is reduced, the mechanical and chemical performance such as the fatigue life of the steel is remarkably improved, precise control over the modification type, distribution and dimension of the occluded foreign substances in the steel is achieved, and the method is suitable for researching and producing of high-performance steel in more varieties.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Method for preparing tropism silicon steel

InactiveCN101210297ALow heating temperatureShorten heating timeTemperature control deviceHeat treatment process controlMultiple frameThermal treatment

The invention discloses a manufacture method of an oriented silicon steel, which adopts smelting, continuous casting, heating, rough rolling, finish rolling, normalizing, cold rolling and heat treatment processes. The method is characterized in that continuous bending, continuous straightening, low-head vertical-bending medium-thin slab caster is adopted, the tundish superheat is 15 to 45 DEG C, the drawing speed is 2 to 4 m / min, the temperature gradient of a cast strand is 80 to 200 DEG C / mm, the surface temperature is 850 to 1,150 DEG C, the slab thickness is 100 to 170 mm, the surface charging temperature of a section cast strand and a continuous cast strand is not less than 800 DEG C, and the heating speed is larger than 5 DEG C / min; and a hot coil box is adopted after rough rolling, the cold rolling is achieved by single-frame rolling or multi-frame once or twice cold rolling, the temperature of a steel strip entering a finishing mill is 1,100 to 1,250 DEG C, the output temperature of the finishing mill is larger than 800 DEG C, and laminar cooling is adopted after rolling to reach a final cooling temperature of 400 to 800 DEG C. By controlling the state of a depressant in continuous casting and by adopting high-temperature, short-time and rapid hot rolling process, etc, the invention can achieve uniform product performance, high quality, reduced energy consumption as well as high efficiency.

Owner:ANGANG STEEL CO LTD

Steel and manufacturing method for Ca microalloying free-cutting high-strength expansion-breaking connecting rod

InactiveCN106939391AImprove breaking performanceReduce cutting actionChemical compositionHigh intensity

The invention relates to steel for a Ca microalloying free-cutting high-strength expansion-breaking connecting rod. The steel is prepared from, by mass percent, 0.25%-0.60% of C, 0.10%-1.20% of Si, 0.40%-1.50% of Mn, 0.05%-0.50% of Cr, 0.02%-0.15% of S, 0.02%-0.15% of P, 0.03%-0.55% of V, 0.0005%-0.0080% of Ca, 0.002%-0.035% of N, 0.002%-0.080% of Al, not larger than 0.02% of Ti and the balance Fe and inevitable impurity elements. The steel is subjected to smelting, continuous casting, heating, hot rolling and cooling, and the structure characteristic is uniform ferrite and pearlite. According to the steel, key elements in the steel are optimized, Ca microalloying is especially adopted, and the steel for the expansion-breaking connecting rod with high strength, good cutting machinability, good expansion-breaking performance and excellent comprehensive performance is obtained, and the design requirements for engine light weight, economical efficiency and driving comfort are met.

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

Steel for linear guide rail and hot-rolling production method for steel

ActiveCN109182901ALow content of harmful elementsPrevention of large-scale generation of inclusionsProcess efficiency improvementNon-metallic inclusionsWear resistance

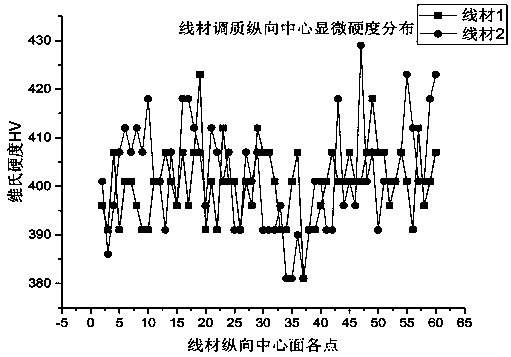

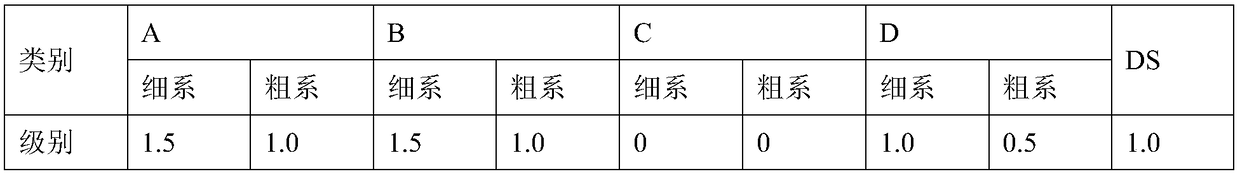

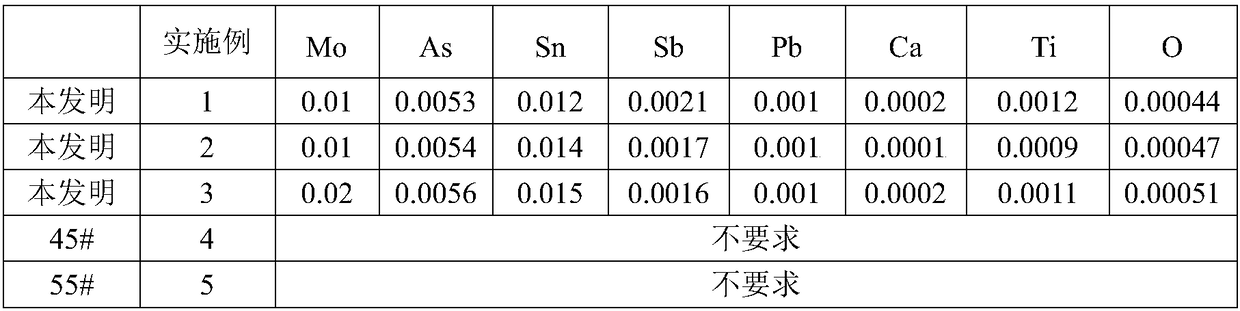

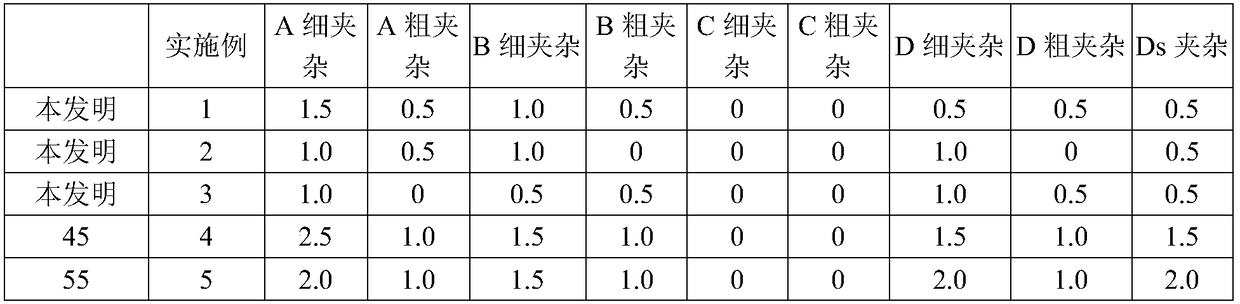

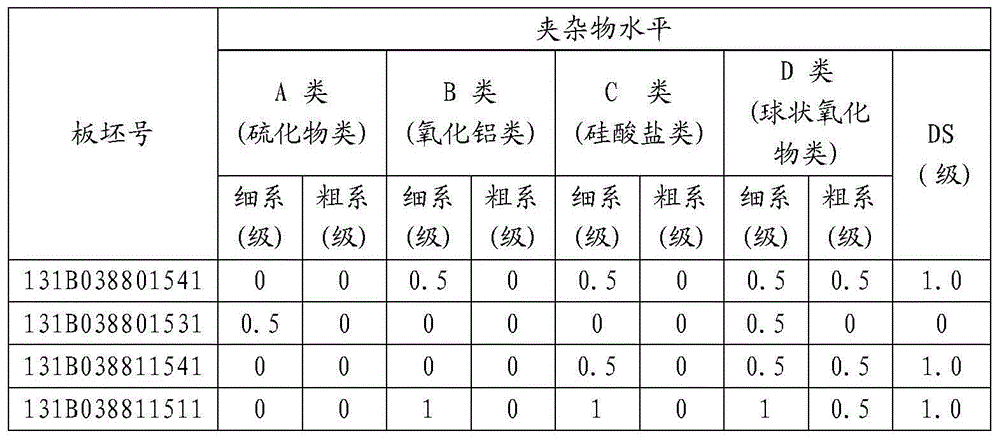

The invention relates to steel for a linear guide rail. The steel is prepared from the following chemical components in percentage by weight: 0.40-0.70% of C, 0.15-0.40% of Si, 1.30-1.80% of Mn, 0.30-0.60% of Cr, 0.005-0.030% of S, less than or equal to 0.025% of P, less than or equal to 0.25% of Ni, less than or equal to 0.30% of Cu, less than or equal to 0.10% of Mo, less than or equal to 0.05%of Al, less than or equal to 0.0010% of Ca, less than or equal to 0.003% of Ti, less than or equal to 0.0010% of O, less than or equal to 0.04% of As, less than or equal to 0.03% of Sn, less than or equal to 0.005% of Sb, less than or equal to 0.002% of Pb, and the balance of Fe and inevitable impurities. After being subjected to quenching and tempering, the steel has yield strength higher than orequal to 785 MPa, tensile strength higher than or equal to 930 MPa, ductility higher than or equal to 12%, and Charpy impact work AKU higher than or equal to 50 J at the normal temperature. Non-metalimpurities meet the following relationship: A-series fine system less than or equal to 1.5, A-series rough system less than or equal to 1.0, B-series fine system less than or equal to 1.5, B-series rough system less than or equal to 1.0, C-series fine system equal to 0, C-series rough system equal to 0, D-series fine system less than or equal to 1.0, D-series rough system less than or equal to 0.5, Ds-series less than or equal to 1.0. Main process comprises electric furnace or converter-external refining-VD or RH vacuum degassing-continuous casting-continuous rolling-stack cooling. By optimizing chemical components of a steel plate, hardenability, strength and wear resistance of the steel are remarkably improved.

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

Method for producing wheel steel by adopting LF-RH refining process

ActiveCN103556050AGuaranteed sedation timeConducive to full buoyancyManufacturing convertersRotary furnaceMaterials science

The invention belongs to the technical field of steel making, and provides a method for producing wheel steel by adopting an LF-RH refining process. The wheel steel produced through the method comprises the following chemical components in percentage by weight: 0.08%-0.10% of C, less than or equal to 0.05% of Si, 0.80%-1.00% of Mn, less than or equal to 0.020% of P, less than or equal to 0.006% of S, 0.020%-0.050% of Als, less than or equal to 0.0060% of N and the balance of Fe and inevitable impurities. The adopted process flow comprises the following steps of molten iron KR desulfurization, dephosphorizing rotary furnace smelting, decarburizing rotary furnace smelting, LF refining, RH refining and continuous casting. The wheel steel produced by adopting the method disclosed by the invention has the advantage that various impurities of more than 98% of steel coil can be controlled to be 1.0 grade or below under the condition of ensuring that the components of molten steel are qualified.

Owner:SHOUGANG CORPORATION

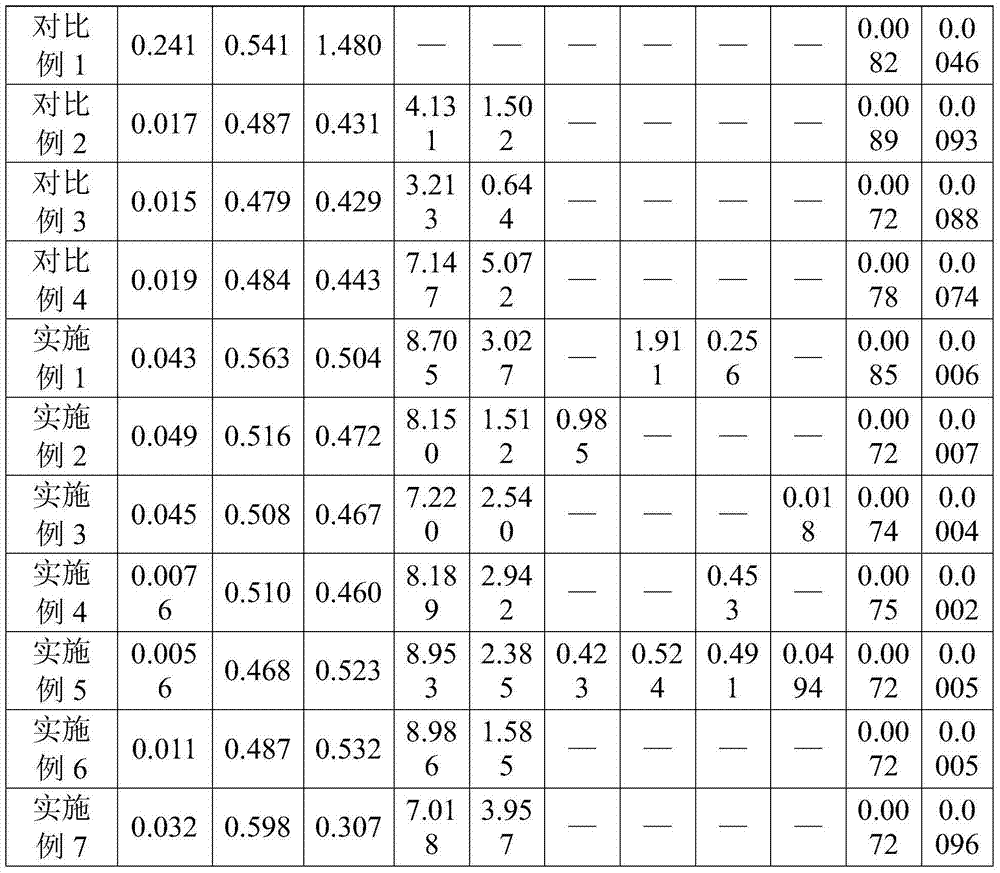

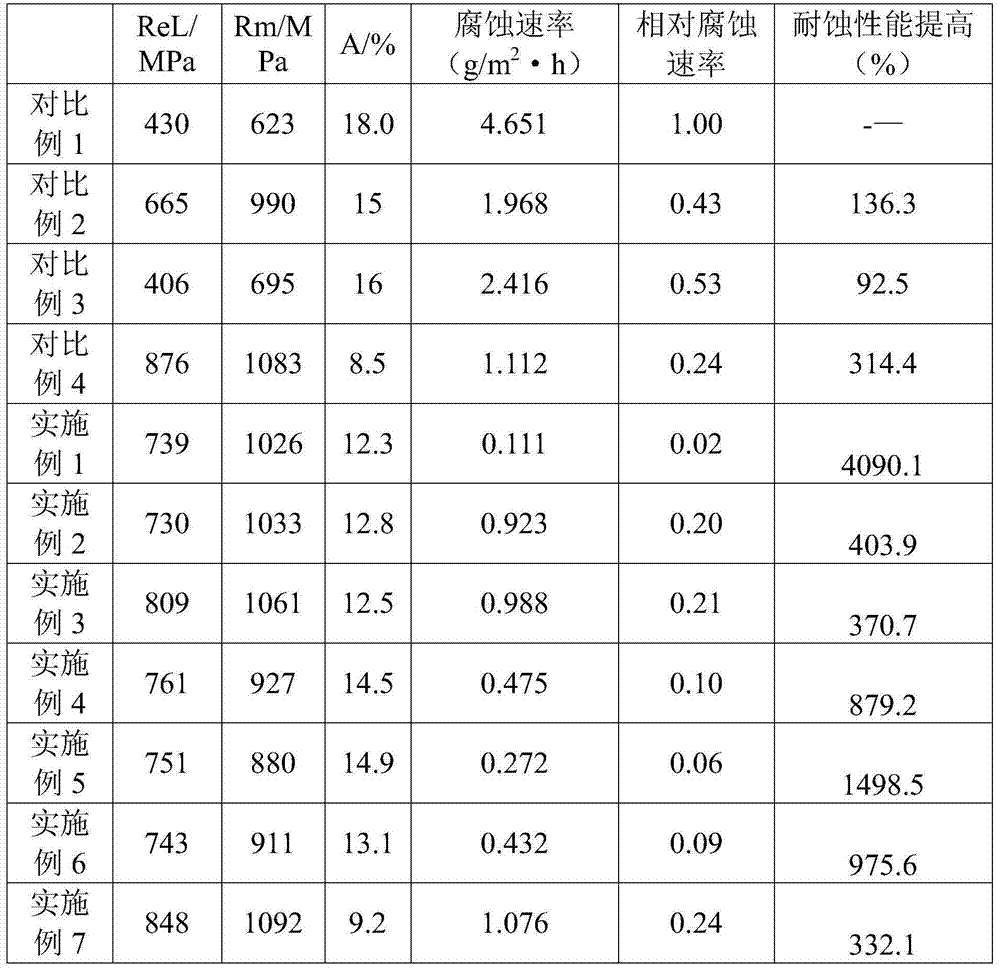

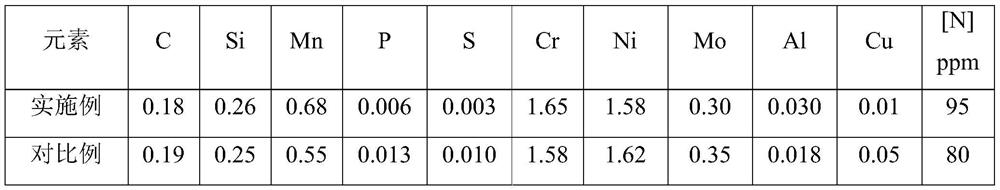

High-strength steel bar with high corrosion resistance and preparation method thereof

The invention discloses a high-strength steel bar with high corrosion resistance. The high-strength steel bar comprises the components of C, Si, Mn, P, S, Cr, Ni, Al, Cu, Mo, Ti and Fe. The invention further provides a preparation method of the high-strength steel bar with high corrosion resistance. The steel bar is stable in performance, has excellent corrosion resistance and high mechanical property, and can be widely applied to building engineering of coast and salt lake areas.

Owner:INST OF RES OF IRON & STEEL JIANGSU PROVINCE

High speed steel finishing roll of wire bar mill and manufacturing method of high speed steel finishing roll

ActiveCN104384193AEvenly distributedImprove bindingRollsMetal rolling arrangementsCrack resistanceChemical composition

The invention discloses a high speed steel finishing roll of a wire bar mill and a manufacturing method of the high speed steel finishing roll, belonging to the technical field of machining and casting. The finishing roll consists of a roll neck and a roll body comprising a working layer, a primary core and a core part; the working layer comprises the following chemical components: 1.50-2.50 percent of C, 0.40-1.00 percent of Si, 0.40-0.80 percent of Mn, less than or equal to 0.03 percent of P, less than or equal to 0.03 percent of S, 4.0-8.0 percent of Cr, 0.50-1.00 percent of Ni, 5.00-8.00 percent of Mo and 5.00-8.00 percent of V. In the casting process, the casting temperature and the rotating speed of a centrifuge can be controlled by adopting manners of high-temperature discharge from a furnace, low-temperature casting, high-speed mold filling and slow-down solidification. According to the high speed steel finishing roll and the manufacturing method of the high speed steel finishing roll, the adaptability of high speed steel materials on bar rolling can be effectively solved by reasonable design of alloy components and the processing technology, and the wear resistance and the millimeter rolling quantity of the roll are improved; in addition, the high speed steel finishing roll has favorable thermal crack resistance, and the working efficiency of a heavy and medium plate mill can be greatly improved.

Owner:SINOSTEEL XINGTAI MACHINERY & MILL ROLL

Manufacturing method of low-oxygen low-inclusion bearing steel

The invention discloses a manufacturing method of low-oxygen low-inclusion bearing steel. The manufacturing method comprises the steps of preparing of raw materials, converter smelting and alloying, LF+VD refining, continuous casting, rolling and slow cooling, wherein the mass percent of chemical components of the bearing steel in content is controlled to reach the standards of 1.06-1.1% of C, 0.7-0.75% of Si, 1.30-1.35% of Mn, 0.02-0.05% of Mo, 0.06-0.08% of Ni, 1.85-1.9% of Cr, 0.02-0.04% of Co, 0.02-0.03% of V, 0.01-0.03% of Als, 0.02-0.03% of Hf, 0.01-0.02% of Ta, 0.005-0.008% of Te, 0.05-0.1% of Cu, less than or equal to 0.025% of S, less than or equal to 0.025 of P, less than or equal to 10*10<-6> of O, less than or equal to 2*10<-6> of H and the balance Fe and inevitable impurities.According to the manufacturing method of the low-oxygen low-inclusion bearing steel smelting, the raw materials, the refining process, refining slag, crystallizer casting powder and the continuous casting process are controlled, so that the content of the obtained non-metal impurities of the bearing steel is low, and the content of the Ti is low; the phenomenon of nozzle nodulation is avoided inthe continuous casting process of square billets, blank throwing is smooth, the solidification speed of a blank shell is high, and safety of continuous casting is ensured, so that a final product is uniform in component, stable in performance and good in strength; and after heat treatment, the yield strength reaches 700 MPa, the tensile strength reaches 910 MPa, and the elongation at the cross section reaches 35%.

Owner:温州市赢创新材料技术有限公司

Low temperature decrease steel ladle pouring method

InactiveCN1640579AReduce consumptionOvercome defects such as loose segregationMelt-holding vesselsRefractoryMaterial consumption

The present invention relates to a two temperature drop ladle pouring method. It is characterized by that in the ladel pouring process said invention utilizes gas to heat molten steel by means of high-effective nozzle mounted on the ladel cover, and utilizes bottom blowing argon to stir the molten steel. Said method can stabilize pouring basket temperature and can implement stable low overheat molten steel pouring operation.

Owner:SHOUGANG CORPORATION

Process for smelting low-cost X70 pipeline steel moderate-thickness plate blanks

The invention discloses a process for smelting low-cost X70 pipeline steel moderate-thickness plate blanks. The process comprises the steps of molten iron pretreatment, converter smelting, LF furnace refining and plate blank continuous casting. In the process, C is 0.04%-0.08%, Mn is 1.40%-1.80%, Nb is 0.04%-0.08%, Cr is 0.2%-0.3%, P <= 0.015%, S <= 0.002%, N <= 60ppm, H <= 3.0ppm, and precious alloys Ni and Mo are not added. An RH (VD) vacuum treatment process is omitted, calcium treatment is performed after LF treatment, and inclusions are ensured to fully float upwards. The plate blank continuous casting step adopts a dynamitic soft-reduction process, and the center segregation of continuous casting blanks is controlled to be B-grade 1.0 or lower. The process for smelting the low-cost X70 pipeline steel moderate-thickness plate blanks is low in molten alloy cost and process cost and capable of achieving batch and industrial production of low-cost X70 pipeline steel moderate-thickness plates.

Owner:NANJING IRON & STEEL CO LTD

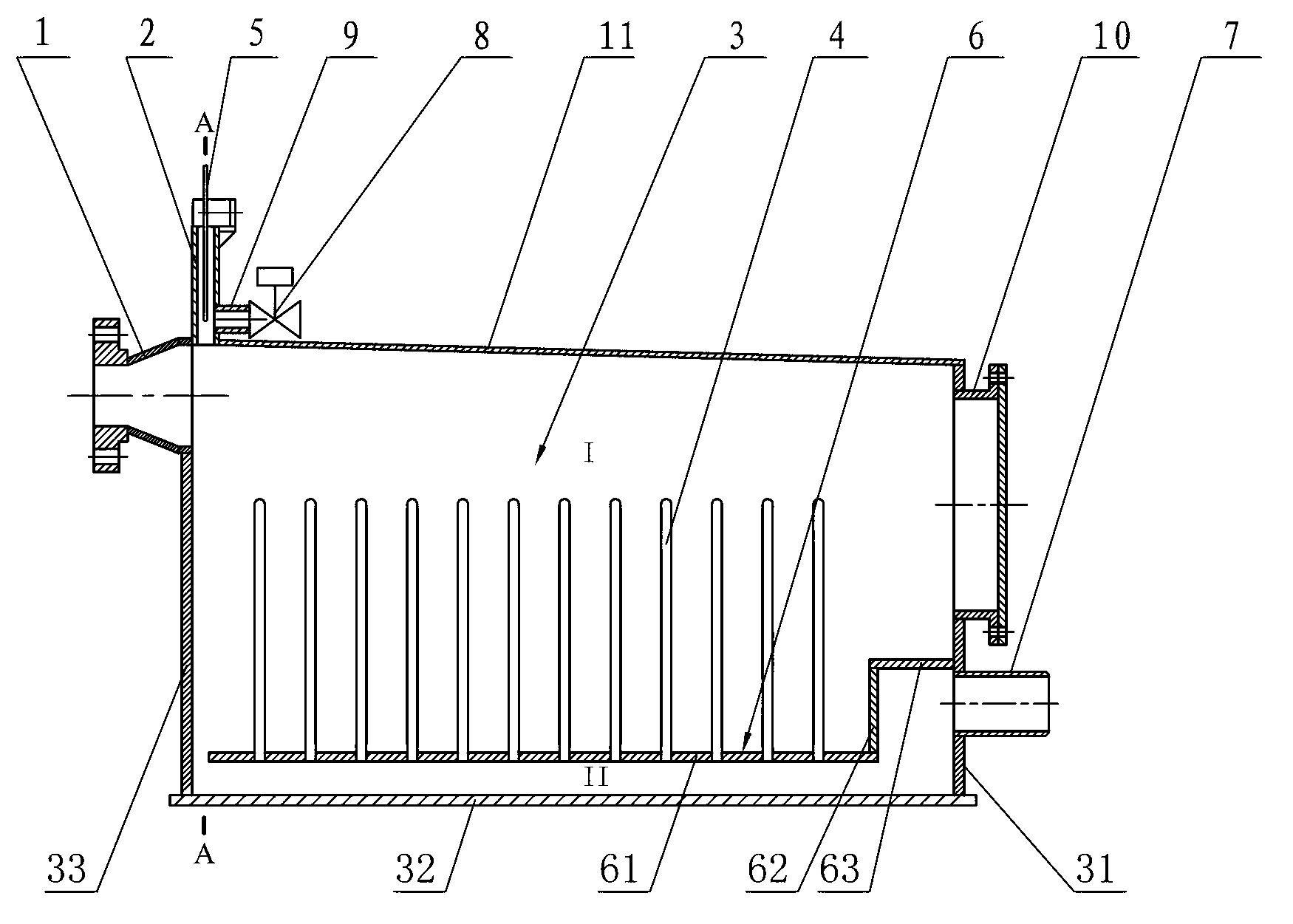

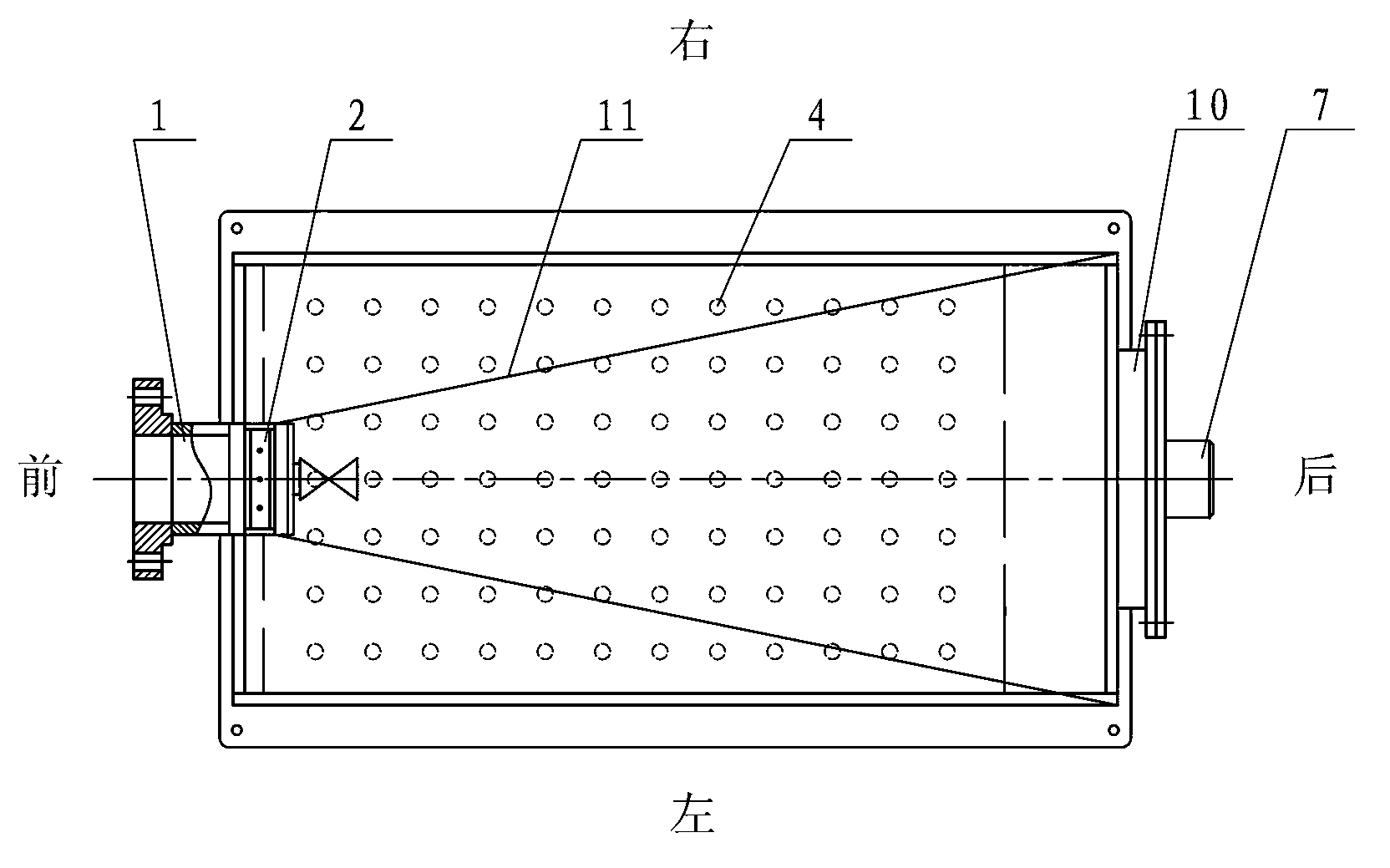

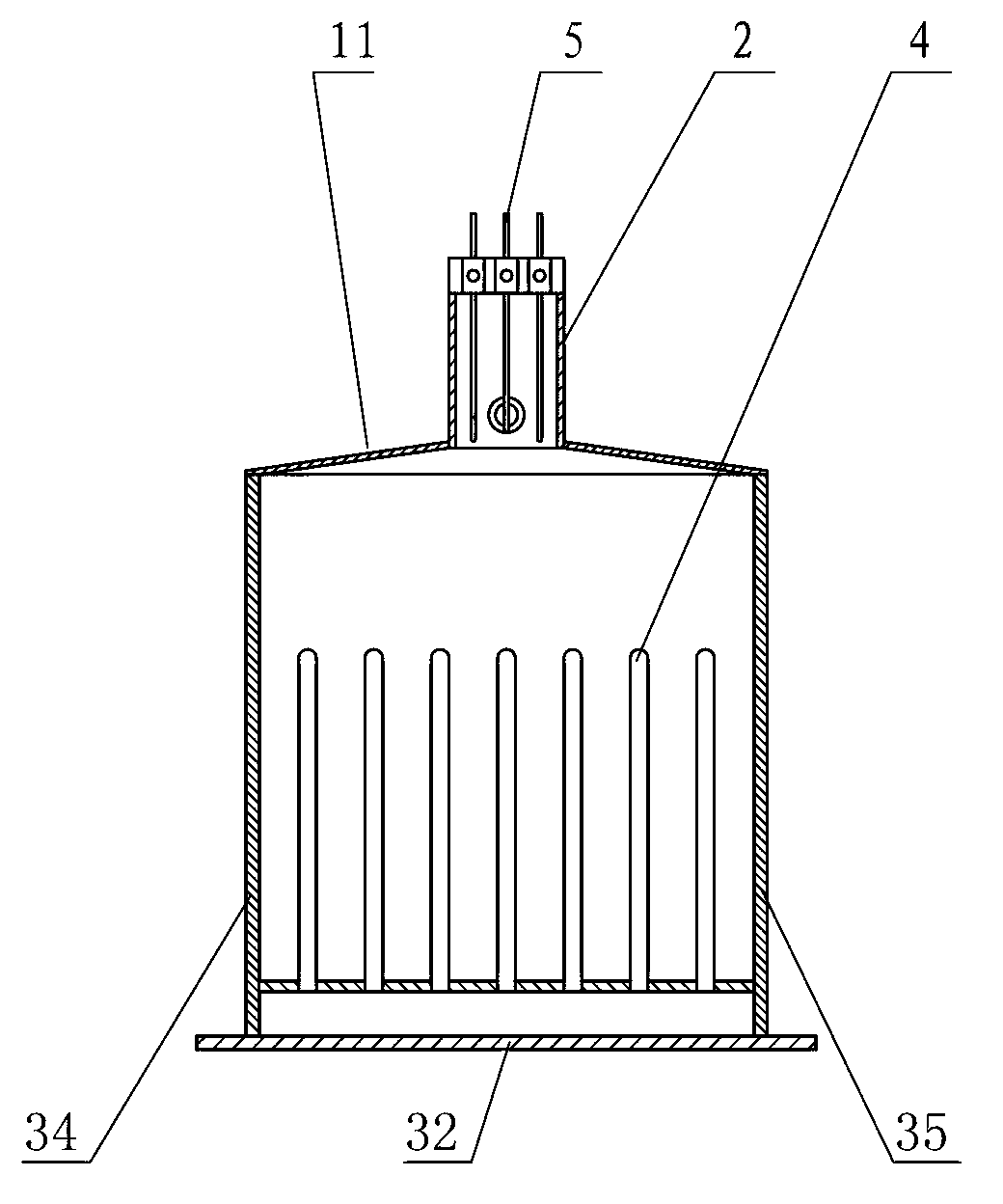

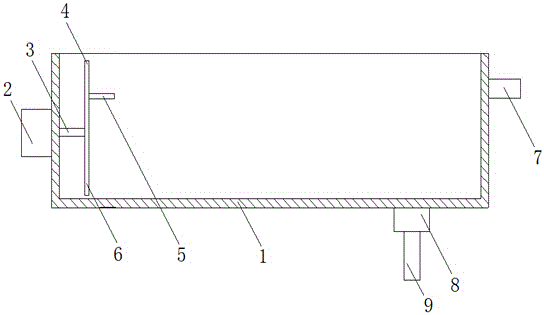

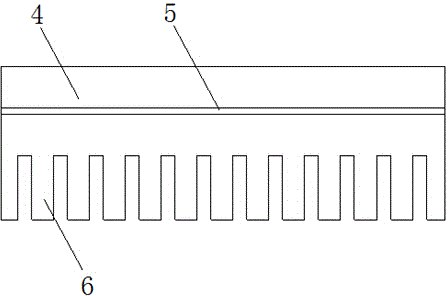

Oil-water separating device for separation and recovery of thin oil film

ActiveCN103073091AReduce flow rateFloating fullyFatty/oily/floating substances removal devicesLiquid separationAtmospheric airOil water

The invention discloses an oil-water separating device for separation and recovery of a thin oil film. The oil-water separating device comprises a tank body, a tank cover and an oil collecting well, wherein an inlet is formed in front of the tank body, an outlet is formed in the rear part of the tank body, and at least one layer of choked flow device consisting of a choked flow separating plate and a comb column array is arranged at the lower part in the tank body; the tank cover which gradually rises from rear to front and from left and right to middle to form a conical structure is connected to the upper side of the tank body in a sealing manner; and the oil collecting well is vertically arranged at the highest part of the conical structure on the outer wall of the tank cover, the oil collecting well is respectively communicated with the inside of the tank body and external atmosphere, an oil-level detector is arranged in the oil collecting well, a connecting side pipe is arranged on the pipe wall of the oil collecting well, and an electromagnetic valve is arranged on the connecting side pipe. The oil-water separating device disclosed by the invention is in a structure of bilateral symmetry with regard to the central line of the tank body. The oil-water separating device for separation and recovery of the thin oil film is especially suitable for oil-water separation and recovery of a micron-order thin oil film.

Owner:SHANDONG HUATE MAGNET TECH +1

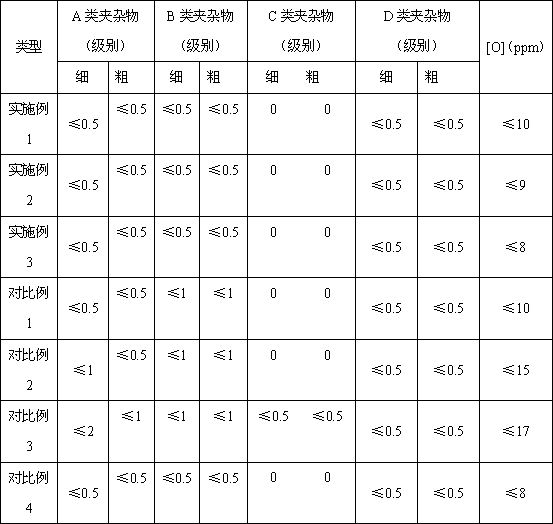

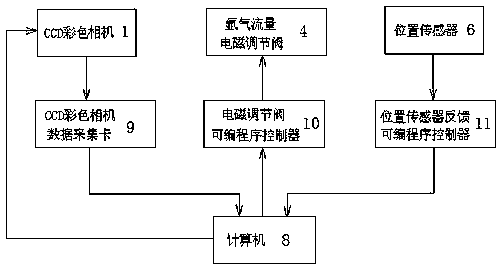

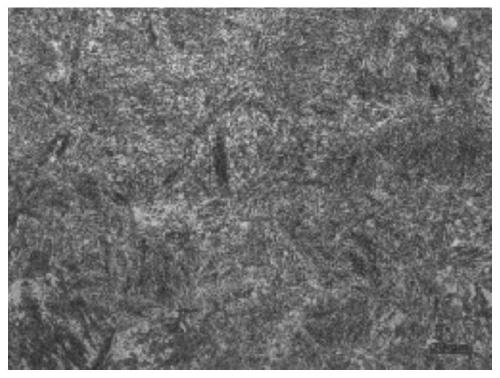

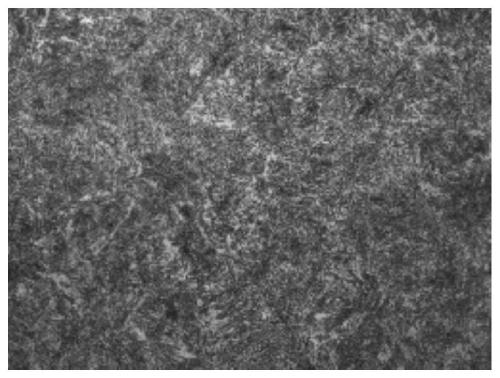

Device and method for adjusting argon flow of bottom blowing for steel ladle during LF refining and standing period

ActiveCN107608397AImprove the cleanliness of molten steelGood economic benefitsFlow control using electric meansArgon flowStreamflow

A device and a method for adjusting argon flow of bottom blowing for a steel ladle during an LF refining and standing period belong to the technical field of LF refining equipment and methods, and areused for automatically adjusting argon flow of bottom blowing for a steel ladle during an LF refining and standing period. The technical scheme is that an image acquisition apparatus is arranged above a standing position of a steel ladle, a signal output end of the image acquisition apparatus is connected with a computer, an argon flow solenoid valve is arranged a steel ladle bottom blowing argonconveying pipeline, and a control end of the argon flow solenoid valve is connected with the computer through a solenoid valve programmable controller. The device and the method are pioneers of a steel ladle bottom flowing technology, solve the long-existing problem that the bottom flowing argon flow for the steel ladle cannot be adjusted automatically, are capable of automatically adjusting flowof bottom blowing argon on the basis of actual situations of molten steel in the steel ladle, play an extremely important role in improving cleanliness of molten steel after LF refining and stably improving the quality of molten steel and subsequent final rolled products, and have substantial economic benefits.

Owner:HBIS COMPANY LIMITED HANDAN BRANCH COMPANY

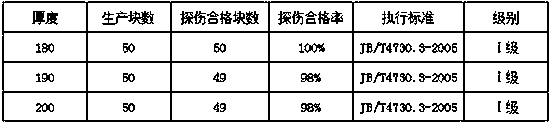

Steel for ball screws and manufacturing method thereof

PendingCN110484837ALow content of harmful elementsGuaranteed amount of residual aluminumBall screwWater immersion

The invention relates to steel for ball screws. The steel for ball screws comprises, by mass: 0.45%-0.60% of C, 0.15-0.40% of Si, 0.90-1.10% of Mn, 0.70-1.20% of Cr, less than or equal to 0.015% of S,less than or equal to 0.025% of P, less than or equal to 0.25% of Ni, 0.15-0.40% of Mo, less than or equal to 0.30% of Cu, less than or equal to 0.05% of Al, less than or equal to 0.0010% of Ca, lessthan or equal to 0.003% of Ti, less than or equal to 0.0010% of O, 0.0050-0.0090% of N, less than or equal to 0.04% of As, less than or equal to 0.03% of Sn, less than or equal to 0.005% of Sb, lessthan or equal to 0.002% of Pb, and the balance Fe and inevitable impurities. The delivery state of the steel is as follows: high-temperature quenching and tempering are carried out, and the hardness meets 220-280 HBW, and the microscopic structure is of a sorbite and bainite structure, and is subjected to SEP 1927 water immersion high-frequency flaw detection, so that the defect length is requirednot to exceed 5 mm. The manufacturing process comprises the steps of electric furnace or converter, external refining, VD or RH vacuum degassing, continuous casting, continuous casting blank squaringto form an intermediate billet (a square billet), intermediate billet heating and rolling, finishing, quenched-tempered heat treatment (including high temperature quenching and tempering), surface lathing and warehousing.

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

16 MnCrS5 gear steel and production method thereof

The invention discloses 16 MnCrS5 gear steel and a production method thereof. The gear steel comprises the following elements of, by weight, 0.14%-0.19% of C, 1.00%-1.30% of Mn, 1.00%-1.20% of Cr, less than or equal to 0.25% of Si, 0.10%-0.40% of Ni, 0.0060%-0.0150% of N, 0.020%-0.045% of Al and the balance iron and unavoidable impurity elements, wherein the unavoidable impurity elements compriseless than or equal to 0.020% of P, 0.020%-0.040% of S, less than or equal to 0.04% of As, less than or equal to 0.02% of Sn, less than or equal to 0.010% of Sb, less than or equal to 0.008% of Pb, less than or equal to 0.010% of Bi, less than or equal to 0.0003% of B, less than or equal to 0.01% of Nb, less than or equal to 0.01% of Ti and less than or equal to 15*10<-6> of [O]. The gear steel hasthe following effective effects of being low in cost, high in purity, narrow in hardenability, high in fatigue strength and stable in performance.

Owner:宝钢特钢长材有限公司

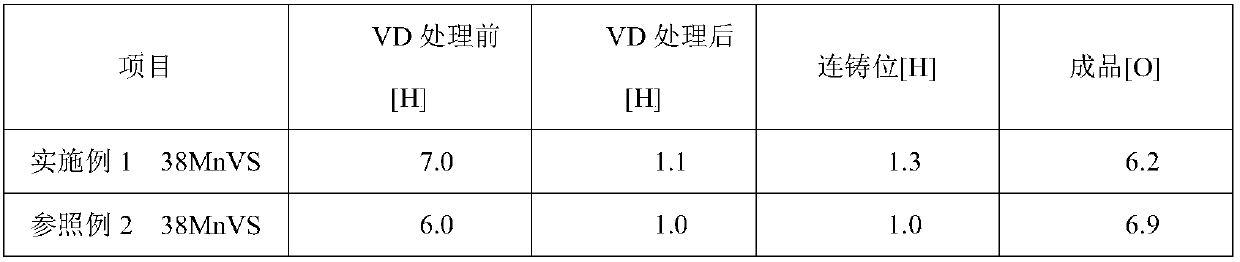

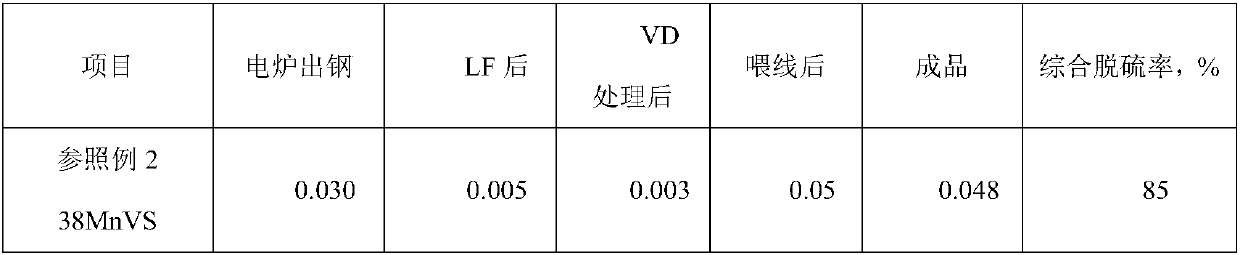

Smelting process for reducing desulfurization rate of molten sulfur bearing steel

InactiveCN107760822AGuaranteed purityHigh yieldElectric furnaceProcess efficiency improvementSulfurSmelting process

The invention relates to a smelting process for reducing the desulfurization rate of molten sulfur bearing steel. The smelting process comprises the following steps: performing primary smelting in anelectric furnace, feeding a sulfur line, performing vacuum degassing in a VD (Vacuum Degassing) furnace, performing refining in an LF (Ladle Furnace), and performing continuous casting. According to the smelting process, the VD furnace is arranged before LF treatment, molten steel is subjected to vacuum treatment of the VD furnace firstly, then effective dehydrogenation is achieved, and the oxygencontent and occluded foreign substances in the steel are reduced under beneficial vacuum conditions; and the operation of sulfur line feeding is implemented before vacuum treatment of the VD furnace,the comprehensive sulfur removal rate can be reduced by 53% or greater by further setting the operation modes of the VD furnace, the content of sulfur in the steel is effectively stabilized, and desulfurization because of molten steel smelting is reduced.

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

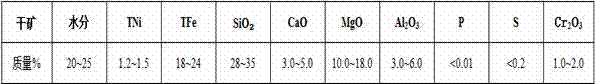

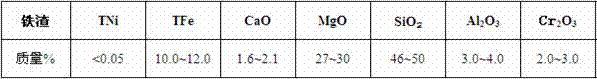

Austenitic stainless steel smelted through laterite-nickle ore and production process of austenitic stainless steel

InactiveCN107130168AStable slag melting point temperature and conductivityReduce energy consumptionAustenitic stainless steelSmelting process

The invention discloses austenitic stainless steel smelted through laterite-nickle ore and a production process of the austenitic stainless steel and belongs to a stainless steel smelting process. The stainless steel comprises, by mass percent, 0.030%-0.060% of C, 0.35%-0.60% of Si, 1.0%-1.3% of Mn, 18.00%-18.50% of Cr, 8.00%-8.10% of Ni, 0.025%-0.050% of N, 0%-0.5% of Cu, 0%-0.045% of P, 0%-0.0060% of S, 0%-0.0050% of O and the like. A homogenizing process is adopted, SiO2 / MgO and the like and slag composition operation of other process parameters are introduced for a first time, a stable slag melting temperature and electrical conductivity are achieved, and the energy consumption is greatly reduced. Laterite-nickel ore is subjected to double smelting of a rotary kiln, a submerged arc furnace and AOD, compared with traditional smelting, two middle working procedures of nickel and molten iron coasting and electric furnace remelting are reduced, the equipment and labor investment is reduced, the environment pollution caused by a storage area can be avoided, the process procedures are greatly shortened, the material forming time is shortened, and the stainless steel capacity is improved.

Owner:GUANGDONG GUANGQING METAL TECH

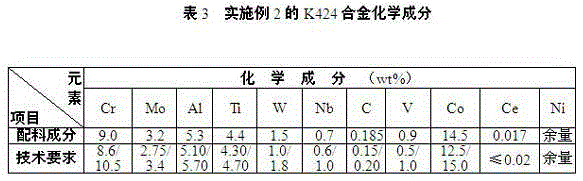

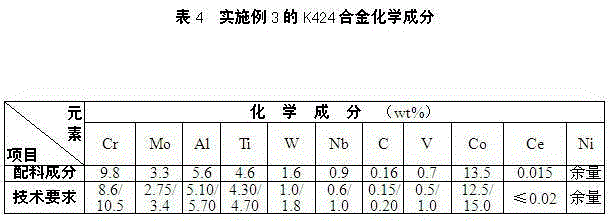

Method for preparing K424 cast superalloy through K417G and DZ417G alloy returns

The invention belongs to the technical field of superalloy preparation and particularly relates to a method for preparing K424 cast superalloy through K417G and DZ417G alloy returns. The method includes the steps that firstly, the K417G and DZ417G alloy returns are remelted and refined respectively, and then 14%-22% of the K417G alloy returns, 50%-42% of the DZ417G alloy returns and 36% of metal elements are adopted to be refined under high vacuum and high temperature conditions to be prepared into the K424 cast superalloy meeting product using requirements. According to the method, the K417G and DZ417G alloy returns are used reasonably, and the precious metal elements such as Co, Ni and Mo are reused, so that waste of resources is reduced, the ecological environment is improved, and the production cost of castings is lowered; about 150 thousand yuan is saved in production of one ton of the superalloy, and the annular benefit can reach 1.5 million yuan if ten tons of the K424 cast superalloy is produced every year according to the method.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

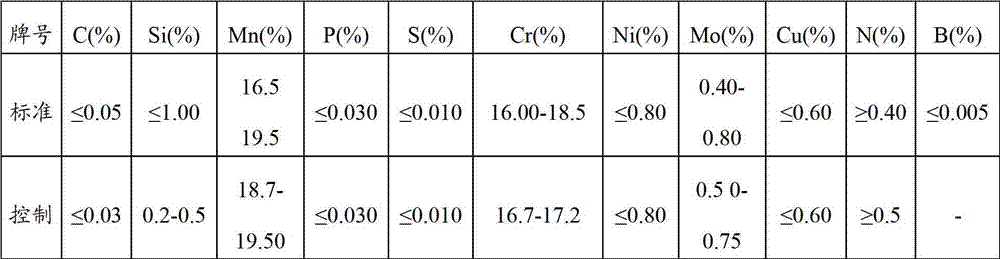

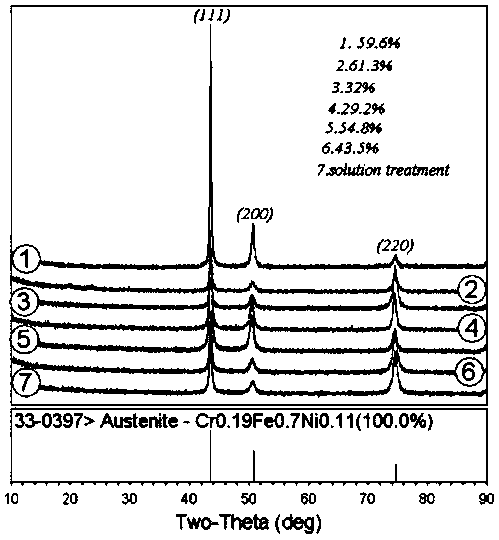

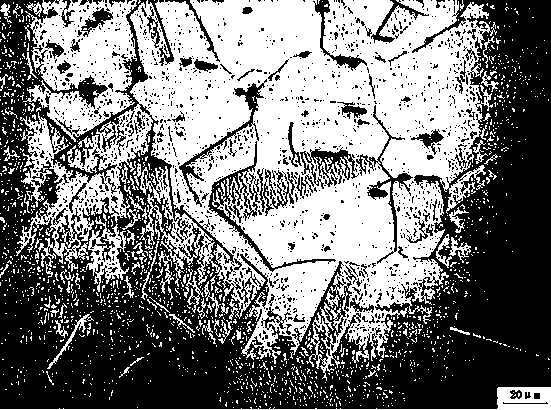

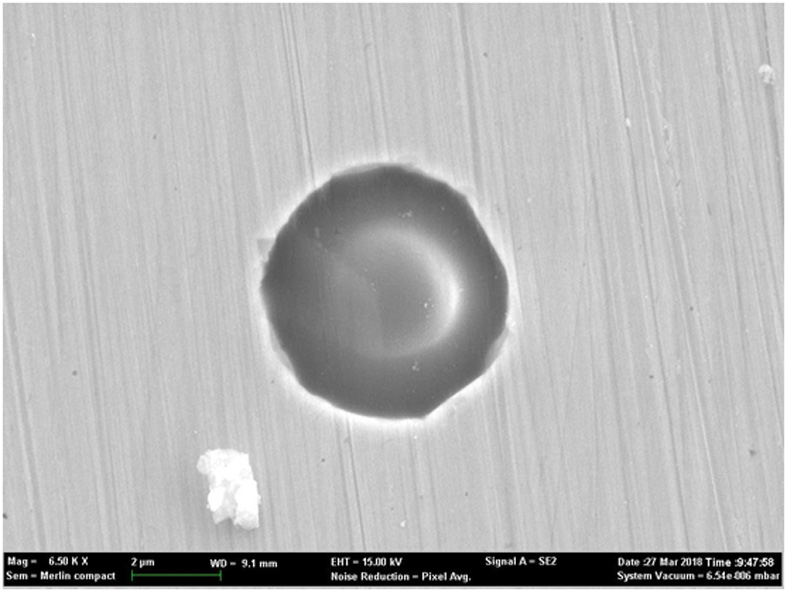

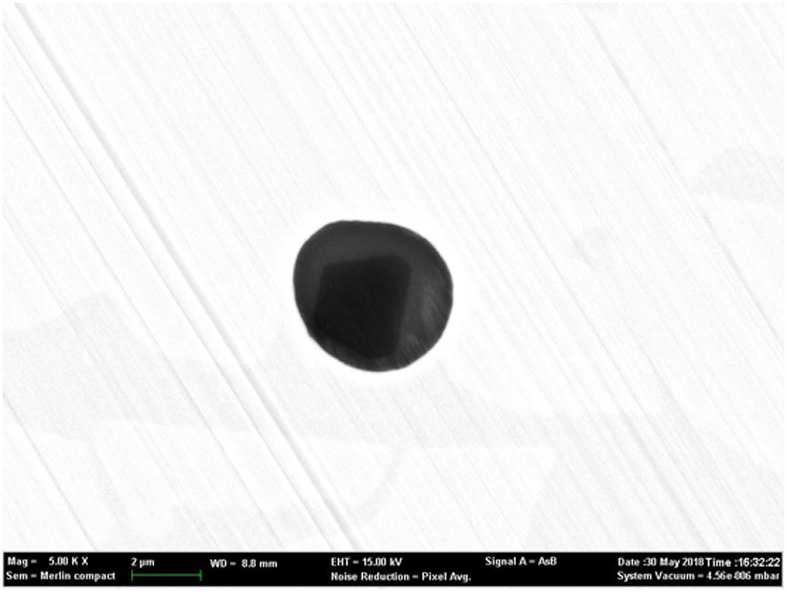

Austenitic stainless steel for electronic products and preparation method of austenitic stainless steel

InactiveCN110819893AThe second phase is proportionally reducedIncrease contentSolution treatmentCalcium handling

The invention discloses austenitic stainless steel for electronic products and a preparation method of the austenitic stainless steel, and belongs to the field of stainless steel smelting. The problems that existing austenitic stainless steel is high in chromated nickel equivalent and poor in corrosion resistance are solved. The stainless steel comprises smaller than 0.03% of C, 0.5%-1.5% of Mn, smaller than 0.75% of Si, smaller than 0.04% of P, smaller than 0.01% of S, 15.0%-19.0% of Cr, 9.0%-15.0% of Ni, 2.0%-3.0% of Mo, smaller than 0.5% of Cu, smaller than 0.1% of N, smaller than 0.01% ofO and the balance Fe and other uncontrollable elements. The preparation method comprises the steps of smelting and casting, wherein a Si-Ca-Ba line is utilized for calcium treatment; hot rolling; hotline solution treatment and acid pickling; cold rolling; and degreasing. The stainless steel prepared through the method is low in chromated nickel equivalent, good in corrosion resistance, low in magnetic conductivity and high in hardness.

Owner:GANSU JIU STEEL GRP HONGXING IRON & STEEL CO LTD

Smelting method of high-purity austenitic stainless steel

The invention discloses a smelting method of high-purity austenitic stainless steel. The smelting method comprises the following steps that (1), molten steel is subjected to decarburization, reductionand desulfurization treatment in an AOD converter; (2), silicon-calcium alloy balls are added along with the steel flow during tapping; (3), slagging off is conducted after tapping; (4), a silicon-calcium wire is fed into an LF; (5), VD improves the basicity of slag, and slag washing is carried out under a high vacuum degree; and (6), an air curtain retaining wall is used for continuous casting tundish. According to the method, the silicon-calcium alloy balls are added in the AOD tapping process, the silicon-calcium wire is fed into the LF so that aluminum-magnesium spinel inclusions can be fully denatured, the melting point of the aluminum-magnesium spinel is reduced, meanwhile, the basicity of slag is improved, molten steel is subjected to VD slag washing, and CaO-SiO2-Al2O3-MgO inclusions are fully adsorbed by the slag at the high temperature; and in addition, the air curtain retaining wall is used in the continuous casting tundish, small-size inclusions are promoted to fully floatupwards, it is ensured that the size of the inclusions in an austenitic stainless steel casting blank is smaller than 10 micrometers, and the purity of austenitic stainless steel molten steel is improved.

Owner:GANSU JIU STEEL GRP HONGXING IRON & STEEL CO LTD

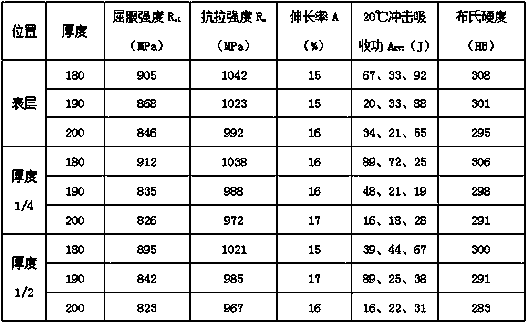

Alloy constructional steel 27SiMn with 180-200mm thickness and manufacturing technology thereof

ActiveCN109609840AImprove hardenabilityHigh strengthProcess efficiency improvementSmeltingHeat treated

The invention discloses alloy constructional steel 27SiMn with 180-200mm thickness and a manufacturing technology thereof. The alloy constructional steel 27SiMn is prepared from the chemical raw materials in percentage by mass: 0.27-0.30% of C, 1.2-1.4% of Si, 1.2-1.3% of Mn, no more than 0.030% of P, no more than 0.030% of S, 0.0008-0.001% of B, 0.020-0.030% of Ti, and the balance of Fe and residual elements. The manufacturing technology comprises the following steps of converter smelting, LF refining, VD vacuum degassing, die casting, heating, rolling, stacking cooling, and heat processing.The components of the alloy constructional steel 27SiMn are rationally designed, the manufacturing technology is improved, and parameters are accurately controlled, so that the alloy constructional steel 27SiMn with 180-200mm thickness and with a good combination property is obtained, and requirements of customers are better met.

Owner:NANYANG HANYE SPECIAL STEEL CO LTD

Low-carbon CrNiMo gear steel and preparation method thereof

The invention provides low-carbon CrNiMo gear steel and a preparation method thereof. The low-carbon CrNiMo gear steel comprises the following chemical components in percentage by weight: 0.15 to 0.21 percent of C, 0.15 to 0.30 percent of Si, 0.60 to 0.90 percent of Mn, 1.55 to 1.80 percent of Cr, 1.50 to 1.70 percent of Ni, 0.25 to 0.35 percent of Mo, 0.025 to 0.038 percent of Al, less than or equal to 0.20 percent of Cu, less than or equal to 0.020 percent of P, less than or equal to 0.010 percent of S, 0.0075 to 0.0130 percent of N and the balance being iron and other inevitable impurities. The preparation method comprises the steps of electric furnace smelting, LF refining, VD vacuum treatment and continuous casting. According to the invention, total oxygen content in molten steel is controlled by controlling tapping carbon; alloy components are basically controlled in place in an electric furnace tapping process, and LF fine adjustment is conducted; a proper amount of slag is added during tapping, an Al wire is fed in place in an early stage of LF, soft blowing is only conducted in the middle and later stages, and the components are not adjusted any more; and weak calcium treatment before VD vacuumizing denatures inclusions, nitrogen is increased through bottom blowing of the nitrogen in a vacuum state, and soft blowing time after VD vacuum breaking is reasonably controlled to ensure that the inclusions fully float upwards and are adsorbed by the slag, so that cleanliness of the molten steel is improved, and quality of the inclusions of a product is improved.

Owner:JIANGSU LIANFENG ENERGY EQUIP

Plant seed screening device

The invention discloses a plant seed screening device. The plant seed screening device comprises a screen pond, a telescopic device, a telescopic rod, a push plate, a separation plate, a stirring plate, a collector, a water outlet valve and a water outlet pipe, and is characterized in that: the telescopic device and the collector are symmetrically arranged on the outer wall of the screen pond, one end of the telescopic rod runs through the telescopic device to be arranged on the telescopic device, the other end is connected with the push plate, the separation plate and the stirring plate are arranged on the push plate, the water outlet valve is arranged on the bottom of the screen pond, and the water outlet pipe is arranged on the water outlet valve. The push plate is arranged in the screen pond, the outer wall of the screen pond is provided with the telescopic device and the collector, the telescopic device pushes the push plate to go forward through the telescopic rod, the push plate and a baffle plate push the floated incomplete seeds into the collector, the stirring plate below the push plate can stir the seeds, the incomplete seeds can be adequately floated, the screening rate of the seeds can be increased, and the working efficiency can be improved.

Owner:鲁蓉蓉

C110 steel graded petroleum casing pipe containing rare earth and production method thereof

The invention discloses a C110 steel graded petroleum casing pipe containing rare earth. The petroleum casing pipe is prepared from the following components in percentage by weight: 0.27 to 0.30 percent of C, 0.15 to 0.30 percent of Si, 0.35 to 0.50 percent of Mn, 1.35 to 1.45 percent of Cr, 0.60 to 0.70 percent of Mo, 0.02 to 0.04 percent of V, 0.10 to 0.20 percent of Ni, 0.02 to 0.05 percent ofAl, 0.02 percent of Re, less than or equal to 0.020 percent of P and less than or equal to 0.005 percent of S. The invention further discloses a production method of the petroleum casing pipe. According to the petroleum casing pipe and the production method thereof, inner tissues of the petroleum casing pipe are uniform and chemical components are not segregated; the SSC resistance of the petroleum casing pipe is improved; the obtained petroleum casing pipe has good quality, the service life is prolonged, the transportation safety of a pipeline is increased and requirements on social development are easy to met.

Owner:BAOTOU IRON & STEEL GRP

Magnesium-containing steel 45 and preparation process thereof

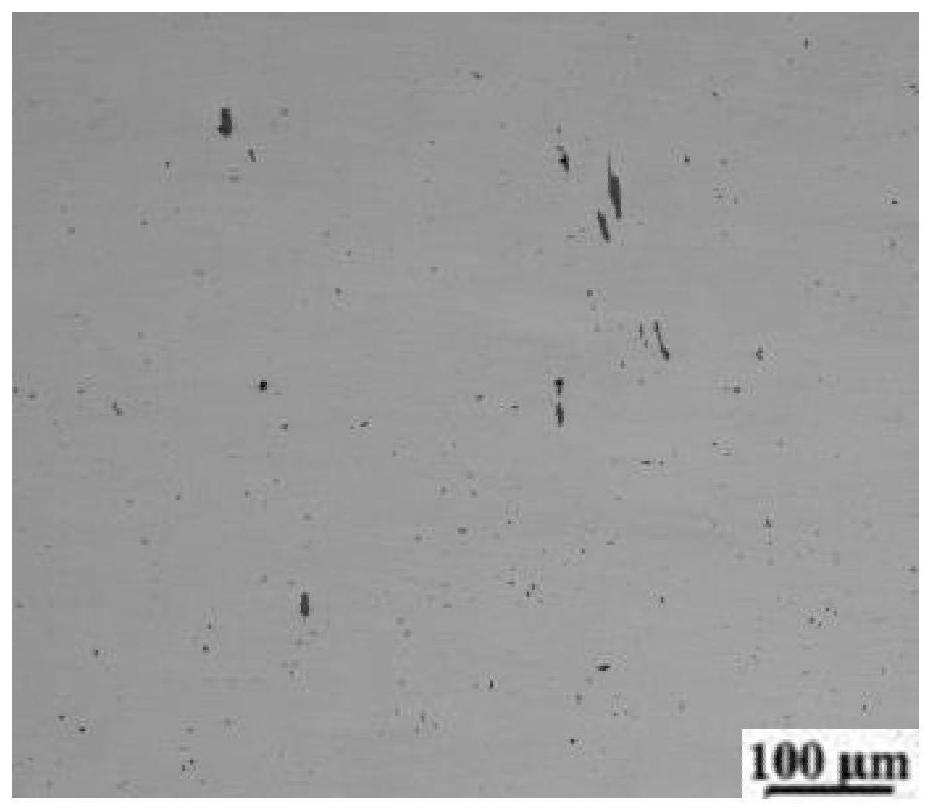

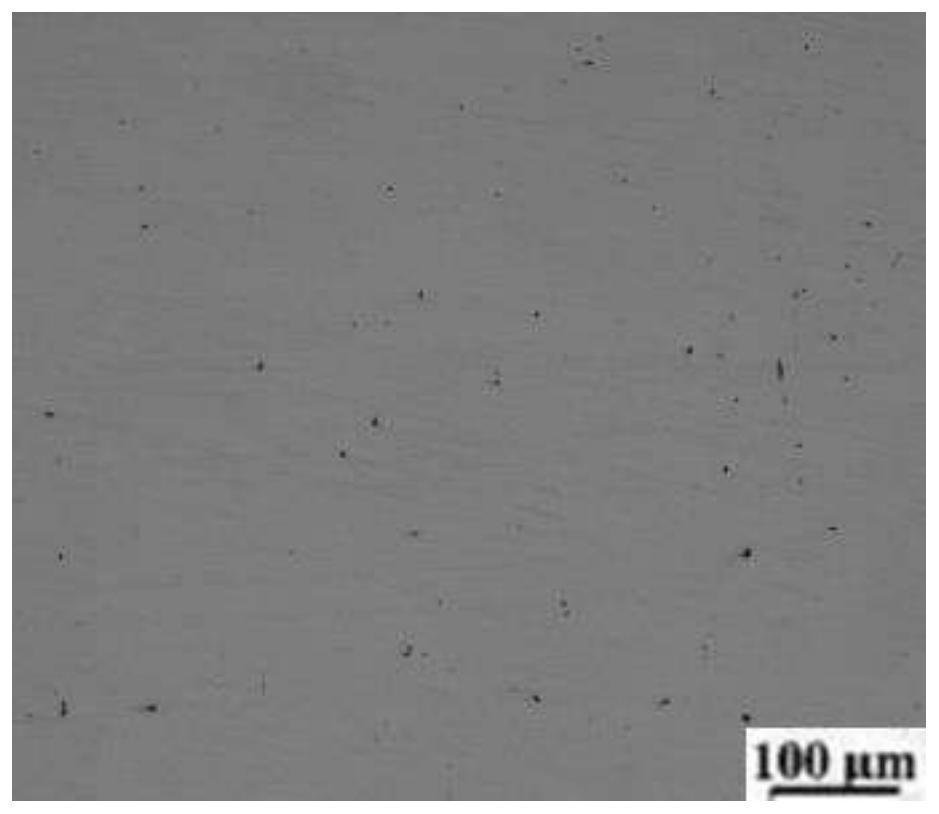

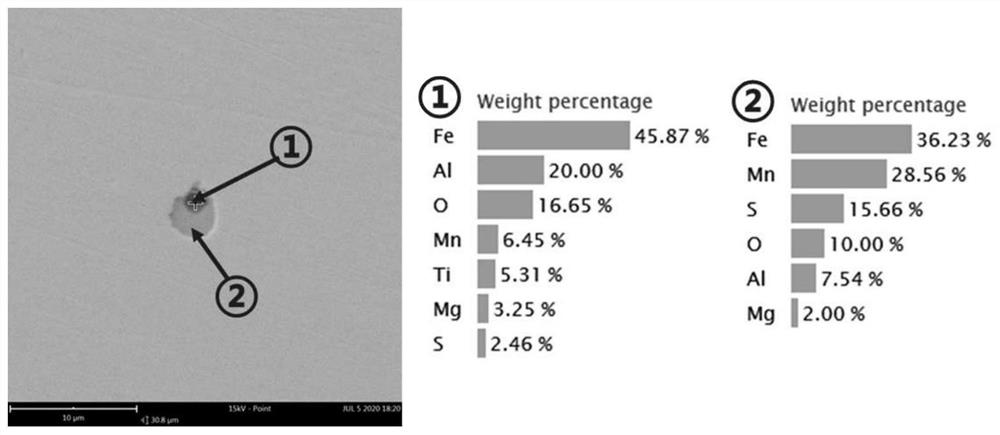

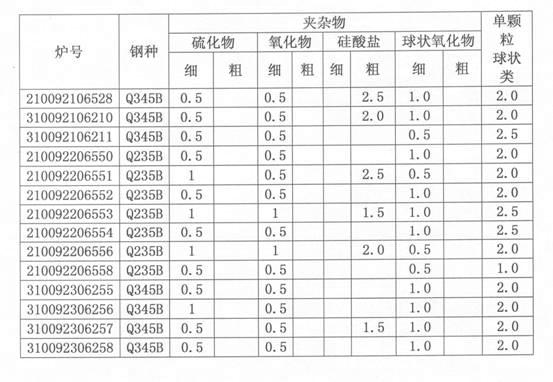

PendingCN113957338AIncreased level of controlIncrease ratingsTemperature control deviceProcess efficiency improvementOxide compositeMolten steel

The invention discloses magnesium-containing steel 45 and a preparation process thereof, and relates to the technical field of steel production. The steel 45 comprises the following chemical components of, in percentage by mass, 0.45%-0.48% of C, 0.17%-0.37% of Si, 0.65%-0.80% of Mn, less than or equal to 0.035% of P, less than or equal to 0.035% of S, 0.0005%-0.0020% of Mg, and the balance iron and inevitable impurities. On the basis of ensuring the safe production of the steel 45, the inclusion in the steel is modified by feeding a magnesium-silicon cored wire into molten steel at the final stage of refining, so that the inclusion in the steel is converted into the fine and dispersively distributed sulfide-oxide composite inclusion, the rating of the inclusion is optimized, and the comprehensive mechanical property of the steel 45 is improved.

Owner:NANJING IRON & STEEL CO LTD

Method for improving purity of molten steel in argon station

The invention discloses a method for improving purity of molten steel in an argon station, which comprises the following steps of: (1) adding 30 to 60kg of lime, 20 to 40kg of calcium carbide and 130 to 160kg of premelted refining slag into a steel ladle before argon blowing, and increasing argon quantity for strongly blowing argon, wherein the strong argon blow standard is that the sum of the diameters of blown open holes of the molten steel is controlled to be between 400 and 600mm; (2) after strongly blowing argon for 1 to 3 minutes, adding aluminum wires into the steel ladle; (3) after strongly blowing argon for 6 minutes together, reducing argon quantity for softly blowing argon, wherein the soft argon blow standard is that the sum of the diameters of blown open holes of the molten steel is controlled to be between 200 and 400mm, and the soft argon blow time is ensured to be more than or equal to 6 minutes; and (4) making the total argon blow time for the molten steel in the argon station more than or equal to 12 minutes, closing the argon when the temperature accords with the liquidus temperature of between 50 and 65 DEG C, and adding an alkaline covering agent and carbonized rice husks into the steel ladle. The premelted refining slag is added into the argon station, the process is easy to operate and the purity of the molten steel can be effectively improved.

Owner:NANYANG HANYE SPECIAL STEEL CO LTD

Smelting process capable of lowering TiN inclusion content in high-titanium microalloyed high-strength steel

The invention relates to a smelting process capable of lowering TiN inclusion content in high-titanium microalloyed high-strength steel. According to a molten iron pre-desulfuration process, it is required that the S content of molten iron is controlled below 0.010 wt% after the process is finished; according to a converter process, it is required that molten steel is deoxidized in tapping, and Als of the molten steel is controlled to be 0.0050-0.0150 wt%; according to an LF refining process, firstly, slagging desulfuration is carried out, the S content is lowered to below the required S content of the steel grade within 10 minutes, and the treatment period is controlled to be 25-30 minutes; according to an RH refining process, the vacuum degree reaches 1 mbar or below within 1.5 minutes of molten steel circulation, and composition regulation is completed within in 3 minutes; according to a continuous casting process, the superheat degree of tundish molten steel is controlled to be 13-23 DEG C, and the billet pulling rate is 1.10-1.20 m / min; and dynamic soft reduction is adopted in the course. The smelting process can effectively lower the quantity and dimension of TiN inclusions in molten steel of the high-titanium microalloyed high-strength steel, so that the purity of molten steel and the casting blank quality are improved.

Owner:HANDAN IRON & STEEL GROUP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com