Oil-water separating device for separation and recovery of thin oil film

An oil-water separation device, separation and recovery technology, which can be used in oil/oily substance/float removal devices, liquid separation, separation methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

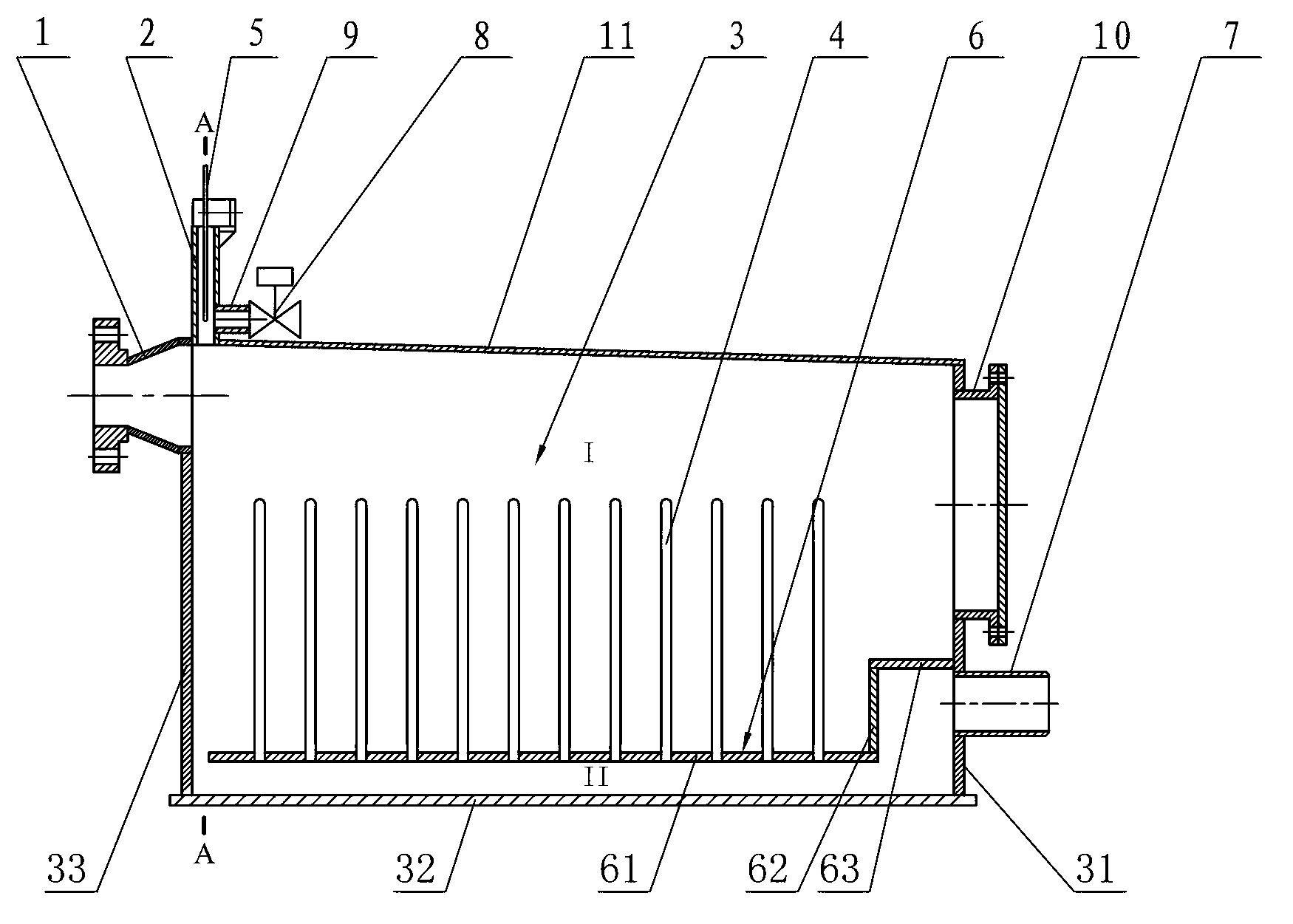

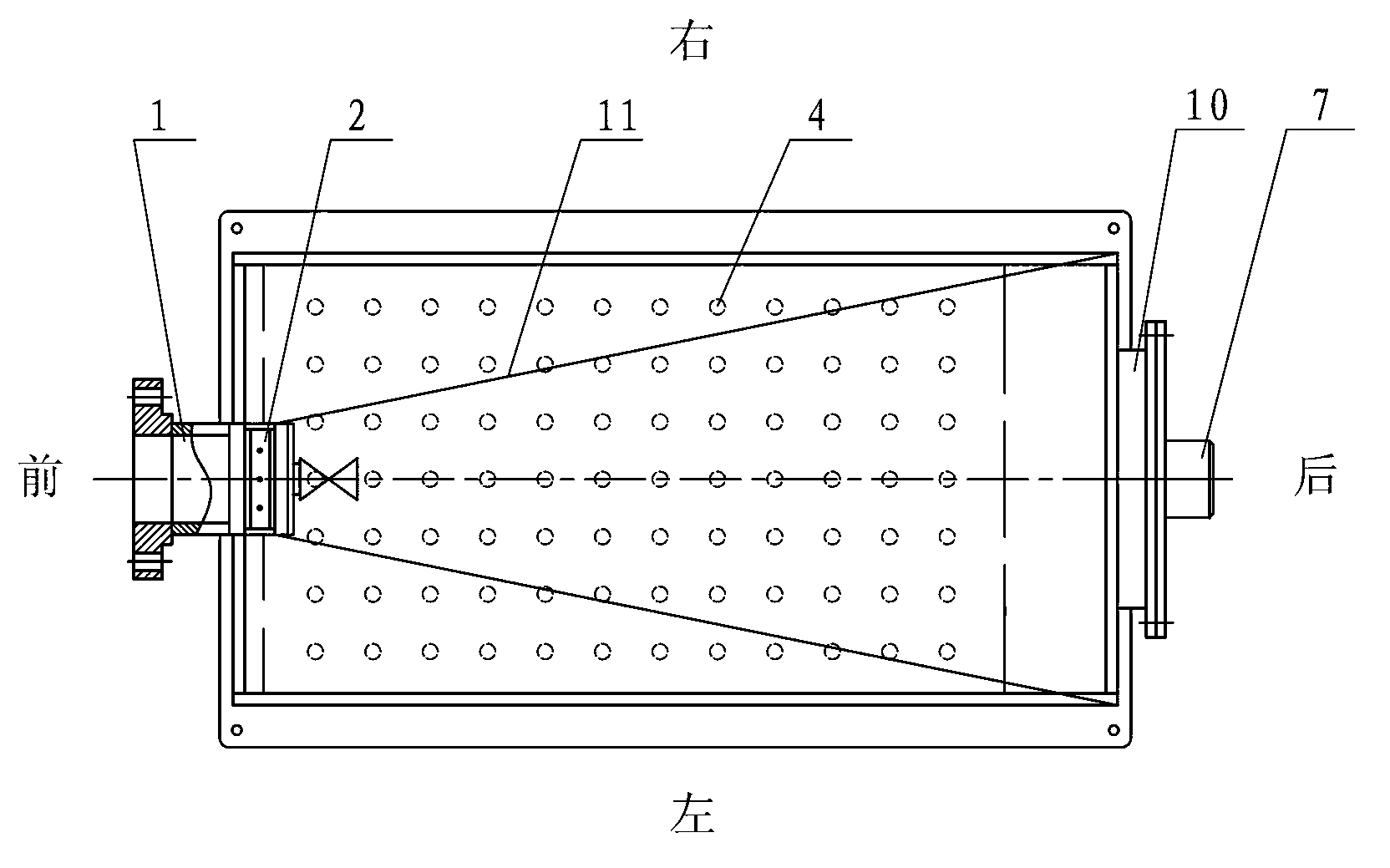

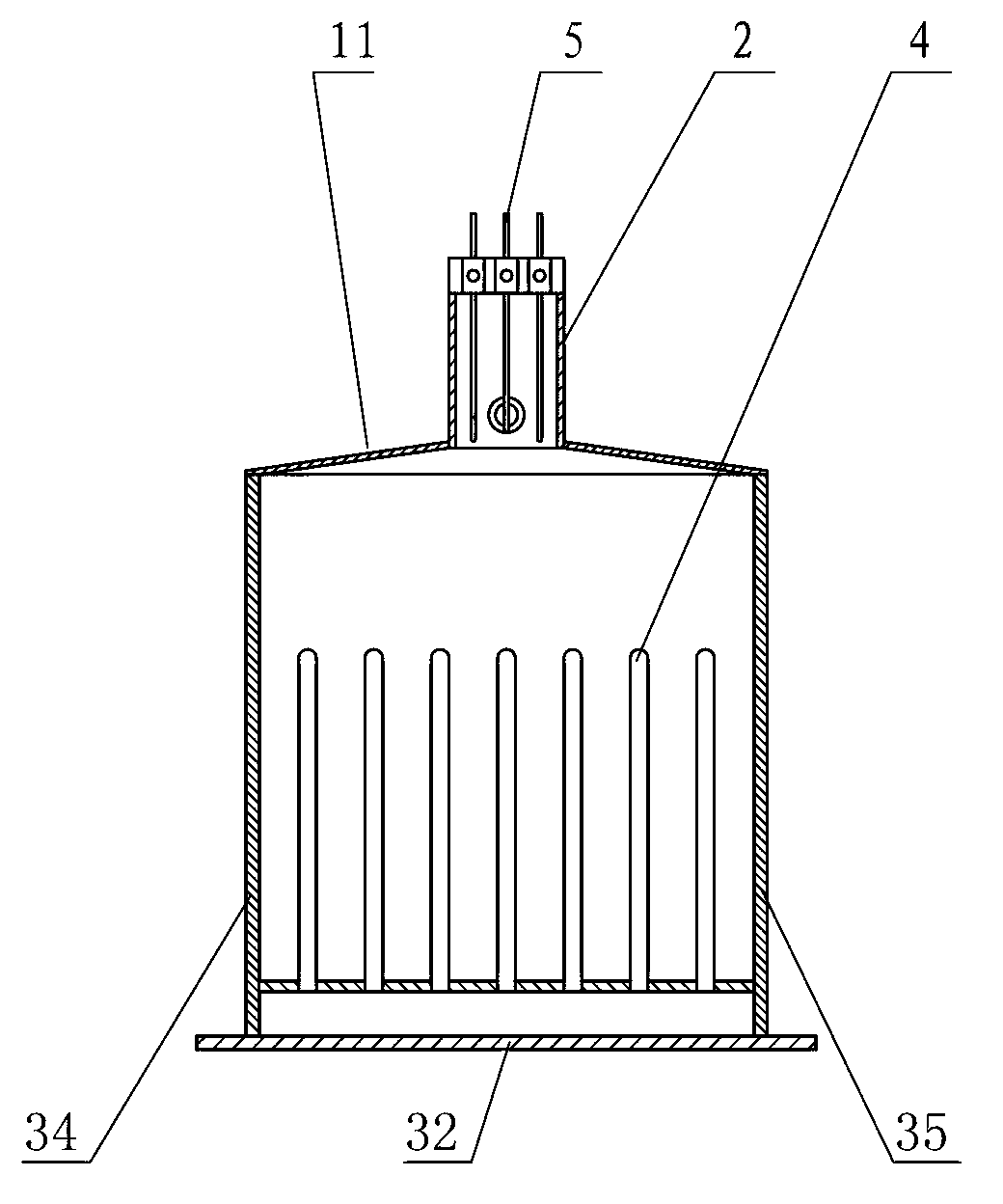

[0025] Such as figure 1 , figure 2 and image 3 Commonly shown is an oil-water separation device for thin oil film separation and recovery according to Embodiment 1 of the present invention, wherein the front, back, left and right directions are defined according to figure 2 As shown, the oil-water separation device of the present embodiment comprises:

[0026] Casing 3, this casing 3 is surrounded by bottom panel 32, front panel 33, rear panel 31, left panel 35 and right panel 34 jointly, and casing 3 is the cuboid shape of top opening; There is an inlet 1, an outlet 7 is provided at the lower part of the outer wall of the rear panel 31, and a layer of flow blocking device is provided at the lower part of the box body 3. The flow blocking device includes a horizontally arranged flow blocking separation plate 6, and the flow blocking separation plate 6 There are several columns perpendicular to it densely and uniformly distributed on it, and several columns form a square ...

Embodiment 2

[0035] Such as Figure 5 and Figure 6 As shown together, it is an oil-water separation device for thin oil film separation and recovery in Embodiment 2 of the present invention. Embodiment 2 is basically the same as Embodiment 1, except that the flow blocking device is provided with two layers up and down, from bottom to top number, there is a front gap between the flow-blocking separation plate 6 of the first layer and the front panel 33 of the box body 3, and between the flow-blocking separation plate 6 of the second layer and the rear panel 31 of the box body 3 The rear gap is left, and the upper and lower layers of flow-blocking separation plates divide the interior of the box body 3 into connected upper space I, middle space III and lower space II. Decrease can prolong the residence time of the fluid in the tank, make the oil fully float, and further improve the effect of oil-water separation.

[0036] Of course, the flow blocking device is not limited to one or two la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com