High-nitrogen high-manganese stainless steel and smelting method thereof

A smelting method and stainless steel technology, which is applied in the field of smelting high-nitrogen and high-manganese stainless steel, can solve the problems of low production efficiency, high smelting cost, and long smelting time, and achieve short nitrogen addition time, fast decarburization speed, and the lowest raw material cost. Excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0089] 1. Batching and electric furnace smelting

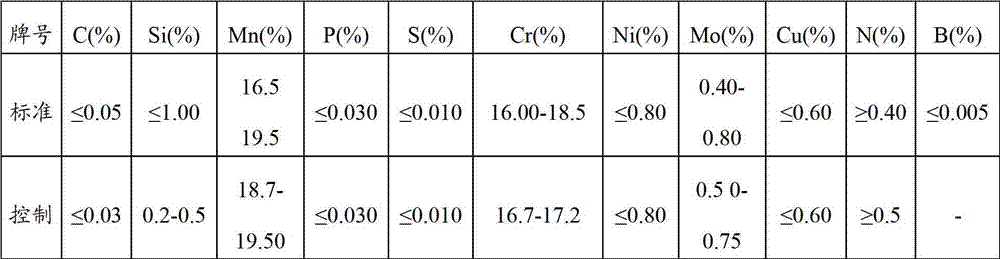

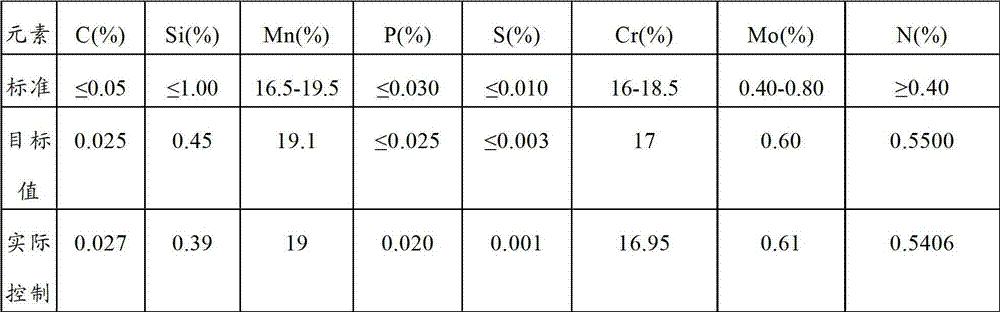

[0090] Mix 16t of 20Mn23Al steel scrap, 40t of Cr13 steel scrap and 20t of high-carbon ferrochromium, add them into a 90t electric furnace, and remove the steel from the electric furnace; the composition of the steel at this time is determined to be: C 1.86%, Si 0.76% , Cr 23.95%, Mn 4.89%, P 0.02%. Pour the above molten steel into two 45t AOD ladles for AOD smelting;

[0091] 2. AOD smelting

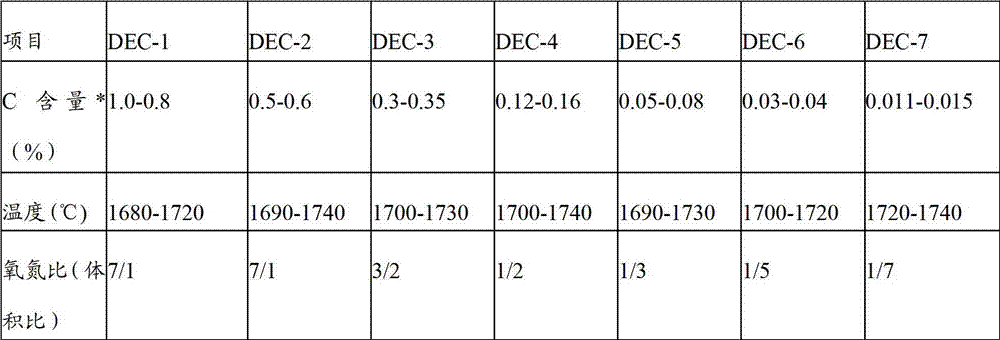

[0092] (1) Decarburization process: Transfer the above two ladles with molten steel to the AOD station for smelting. Nitrogen is blown throughout the AOD smelting process, and the nitrogen flow rate is 2100Nm 3 / h, the temperature at which AOD starts nitrogen blowing is 1500°C, and the decarburization process is carried out. During the decarburization process, lime and high-carbon ferrochrome are continuously added to each ladle. The total amount is 1t; during the smelting process, the oxygen-nitrogen ratio is adjusted according to t...

Embodiment 2

[0109] 1. Ingredients and electric furnace smelting

[0110] Mix 16t of 20Mn23Al steel scrap, 28t of Cr13 steel scrap and 32t of high-carbon ferrochromium, add them into a 90t electric furnace, and remove the steel from the electric furnace; the composition of the steel at this time is determined to be: C 2.56%, Si 0.86% , Cr 25.95%, Mn 4.6%, P 0.02%. Pour the above molten steel into two 45t AOD ladles for AOD smelting.

[0111] 2. AOD smelting

[0112] (1) Decarburization process: Transfer the above two ladles with molten steel to the AOD station for smelting. Nitrogen is blown throughout the AOD smelting process, and the nitrogen flow rate is 2200Nm 3 / h, the temperature at which AOD starts nitrogen blowing is 1470°C, and the decarburization process is carried out. During the decarburization process, lime and high-carbon ferrochrome are continuously added to each ladle. The total amount is 2t; during the smelting process, the oxygen-nitrogen ratio is adjusted according to...

Embodiment 3

[0129] 1. Batching and electric furnace smelting

[0130] Mix 10t of 20Mn23Al steel scrap, 24t of Cr13 steel scrap and 42t of high-carbon ferrochrome, add them into a 90t electric furnace, and remove the steel from the electric furnace; the composition of the steel at this time is determined to be: C 2.20%, Si 0.82% , Cr 27.80%, Mn 3.17%, P 0.02%. Pour the above molten steel into two 45t AOD ladles for AOD smelting;

[0131] 2. AOD smelting

[0132] (1) Decarburization process: Transfer the above two ladles with molten steel to the AOD station for smelting. Nitrogen is blown throughout the AOD smelting process, and the nitrogen flow rate is 2000Nm 3 / h, the temperature at which AOD starts nitrogen blowing is 1520°C, and the decarburization process is carried out. During the decarburization process, lime and high-carbon ferrochrome are continuously added to each ladle. The total amount is 1t; during the smelting process, the oxygen-nitrogen ratio is adjusted according to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com