Induction melting cold crucible

A technology of induction melting and cold crucible, which is applied in the direction of crucible furnace, furnace, lighting and heating equipment, etc., to achieve the effect of expanding the application range, improving the cooling speed, and simplifying the processing of parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described in detail below in conjunction with the accompanying drawings.

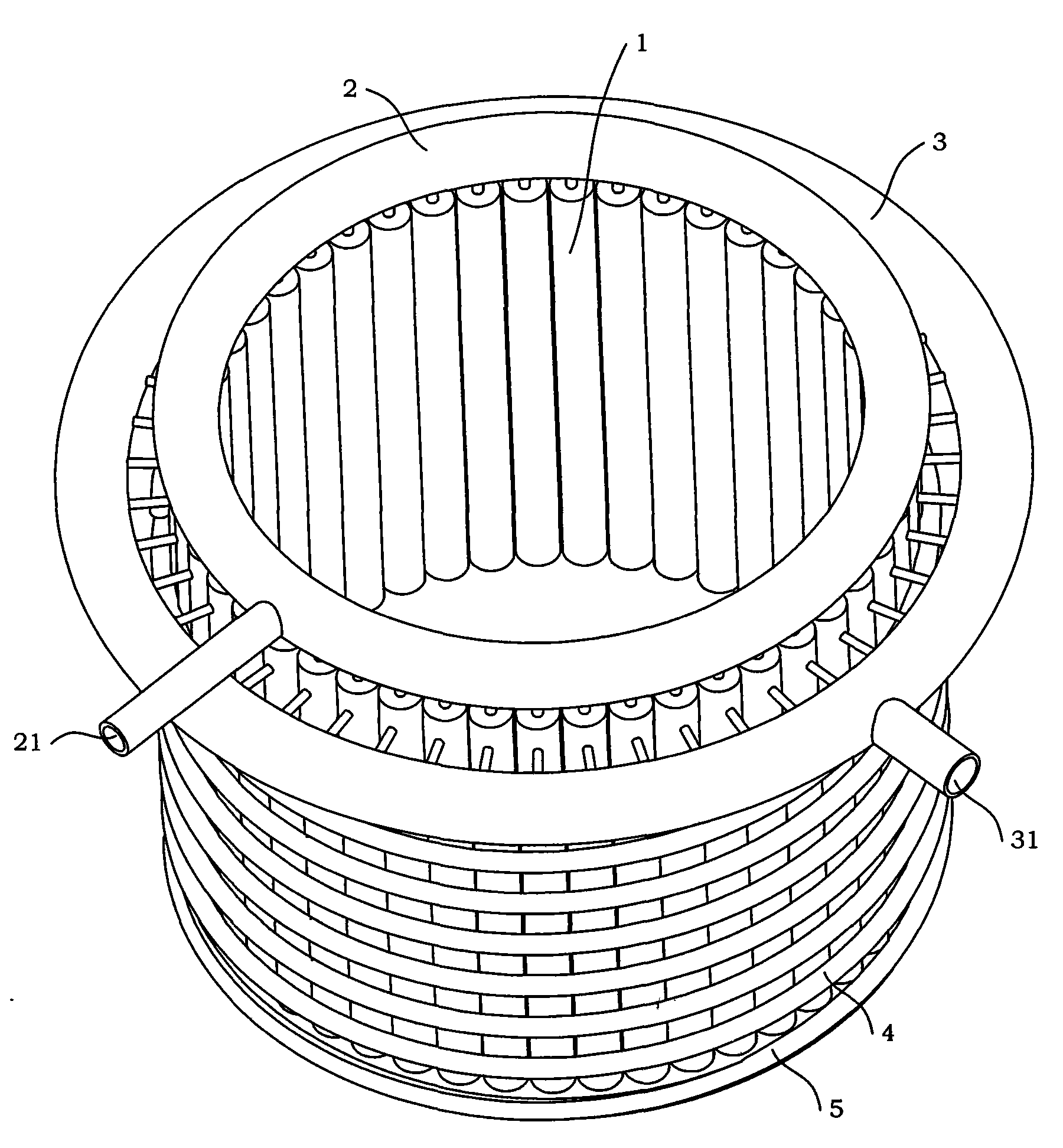

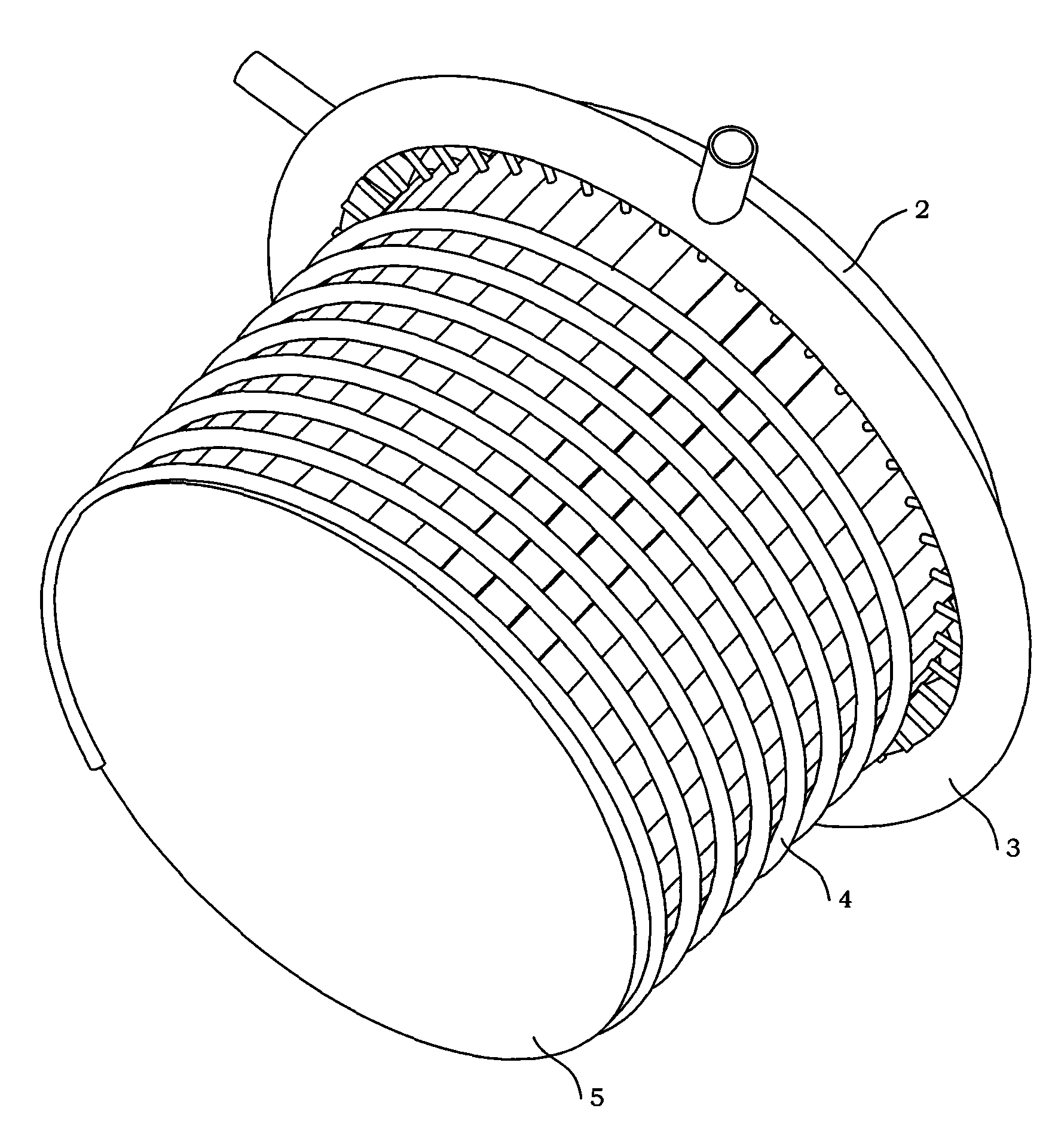

[0037] see figure 1 , Figure 1A As shown, a kind of induction melting cold crucible suitable for electron beam or ion beam of the present invention is used for vacuum smelting, and this cold crucible includes a plurality of cooling water pipe middle tubes 1, a base 5, a water inlet pipe 2, a water outlet Pipeline 3 and induction coil 4. The lower ends of the pipes 1 in the plurality of cooling water pipes are installed in the circular cavities of the base 5 respectively, that is, the arrangement of the pipes 1 in the plurality of cooling water pipes follows the layout of the circular cavities on the base 5 .

[0038] (1) Pipe 1 in the cooling water pipe

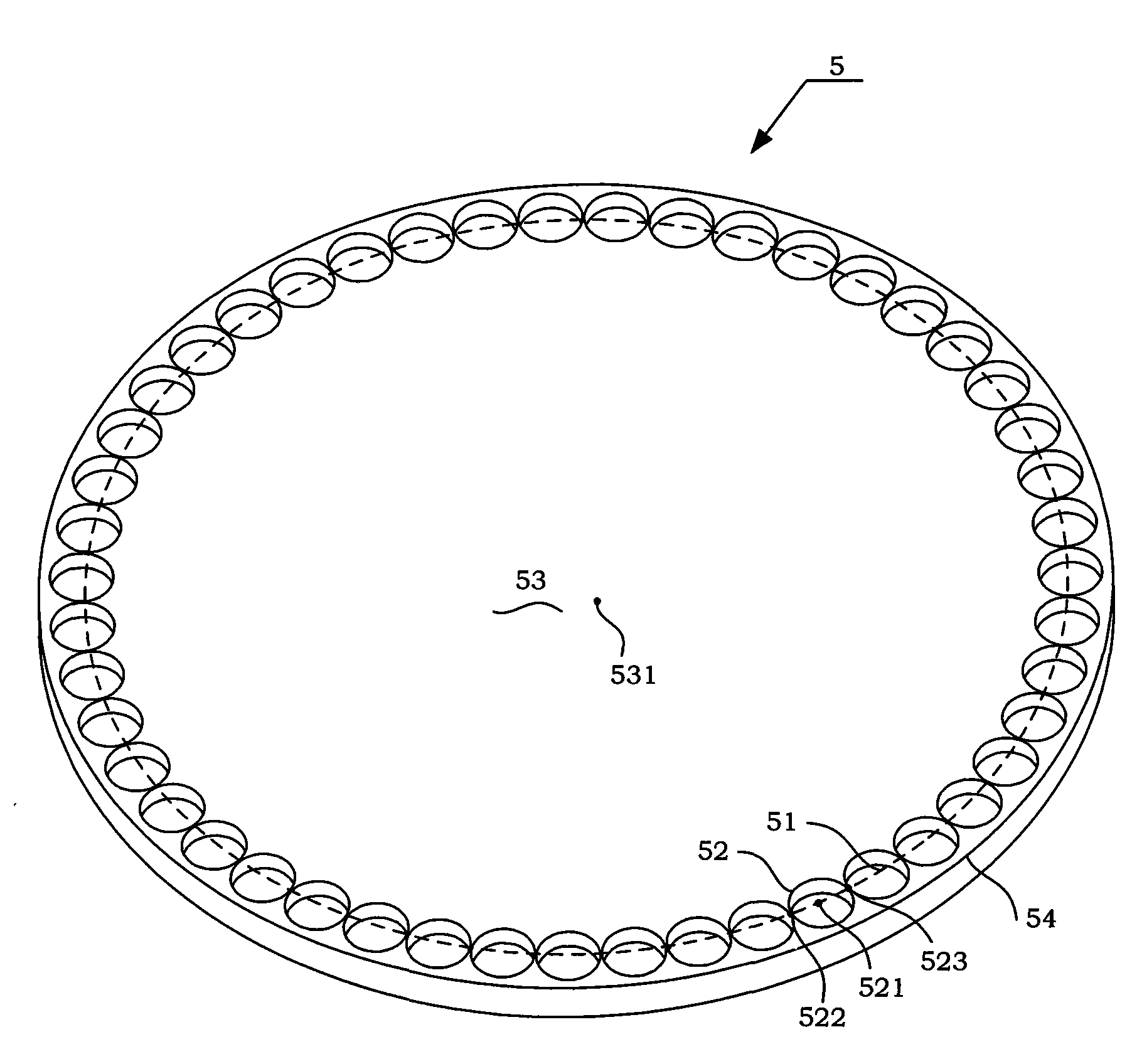

[0039] see figure 1 , Figure 1A , image 3 , Figure 3A , Figure 3B , Figure 3C As shown, the middle pipe 1 of the cooling water pipe includes an outer pipe 11 , an inner pipe 12 , an outer bran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com