Patents

Literature

56results about How to "Limited size" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

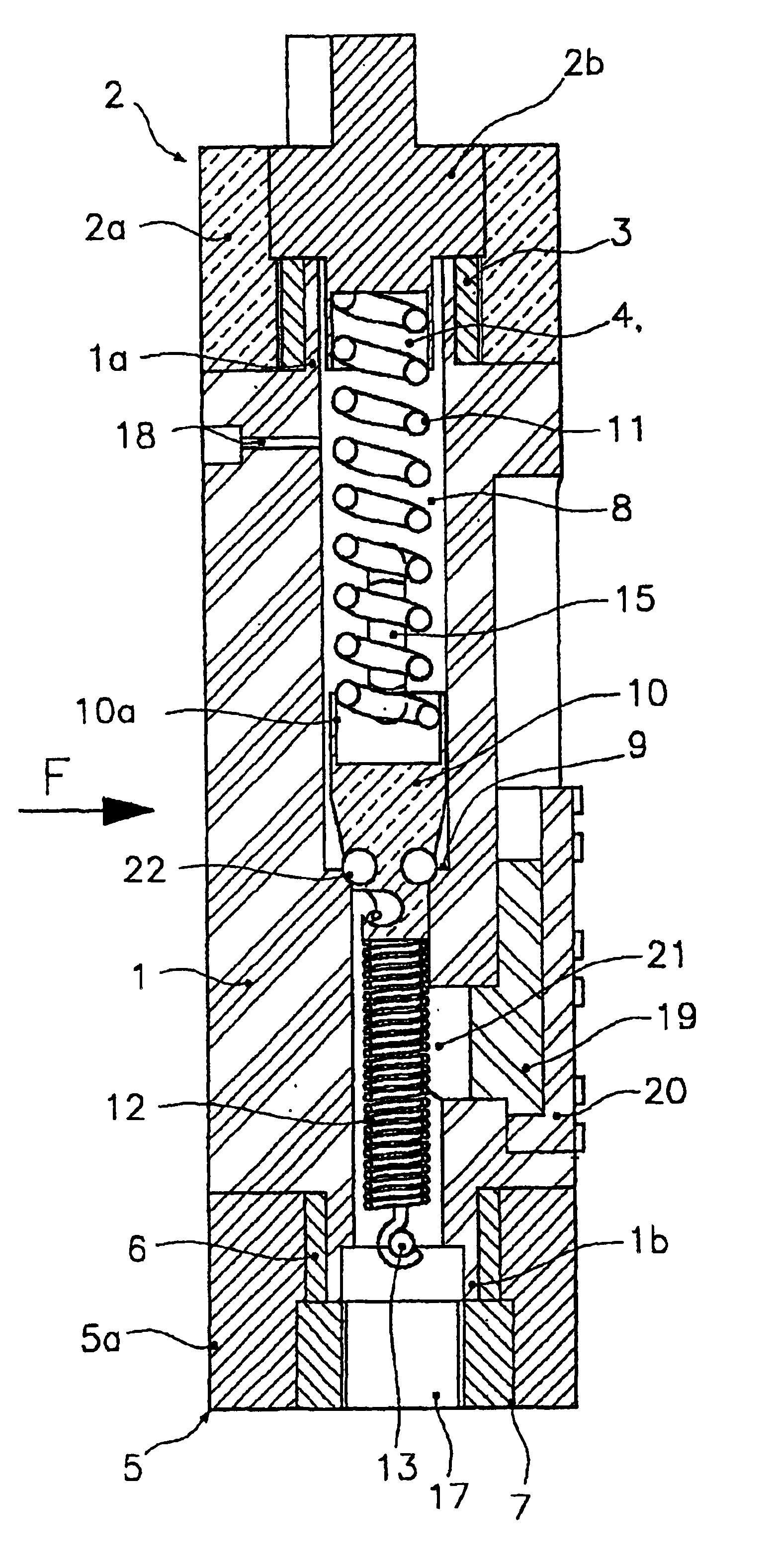

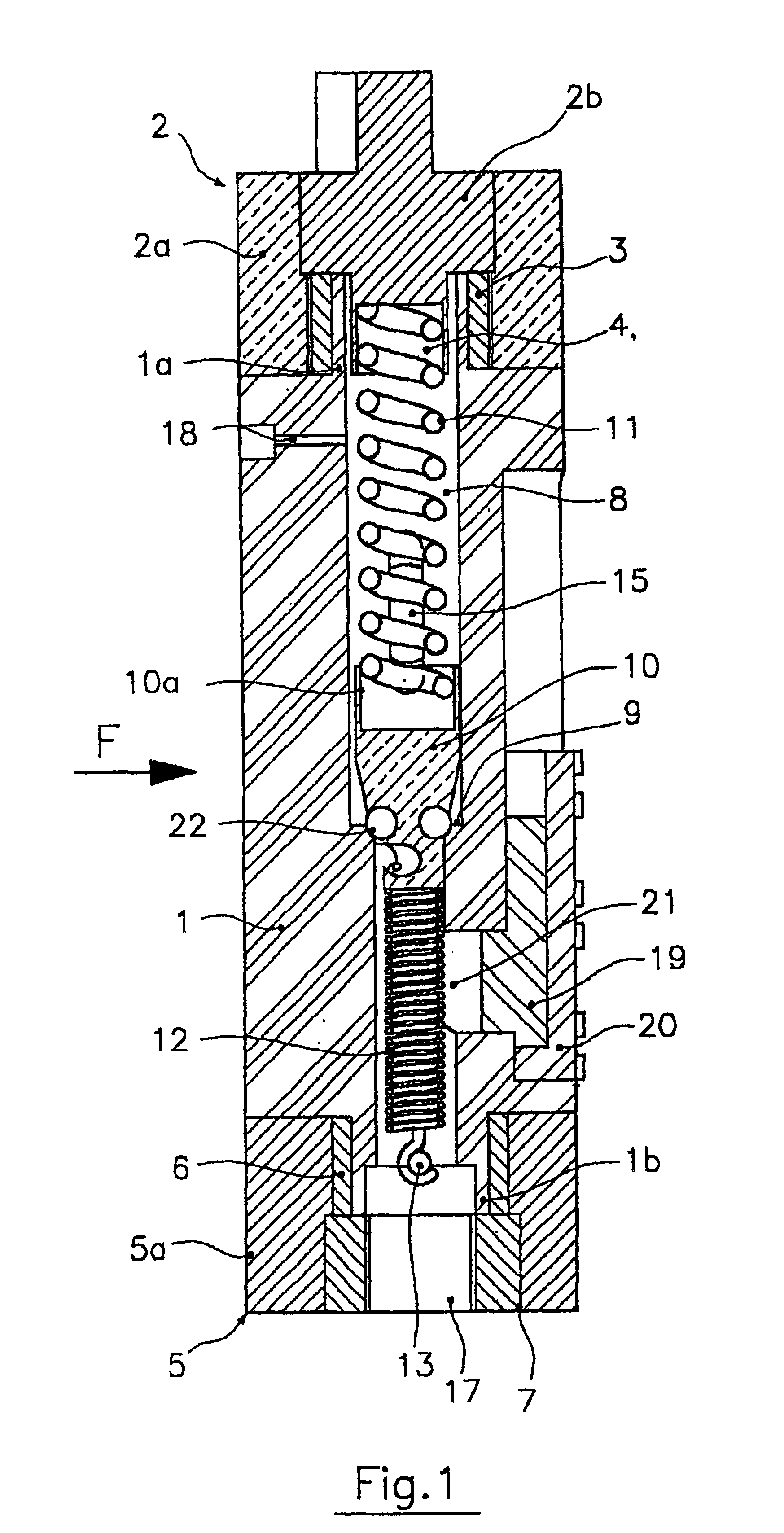

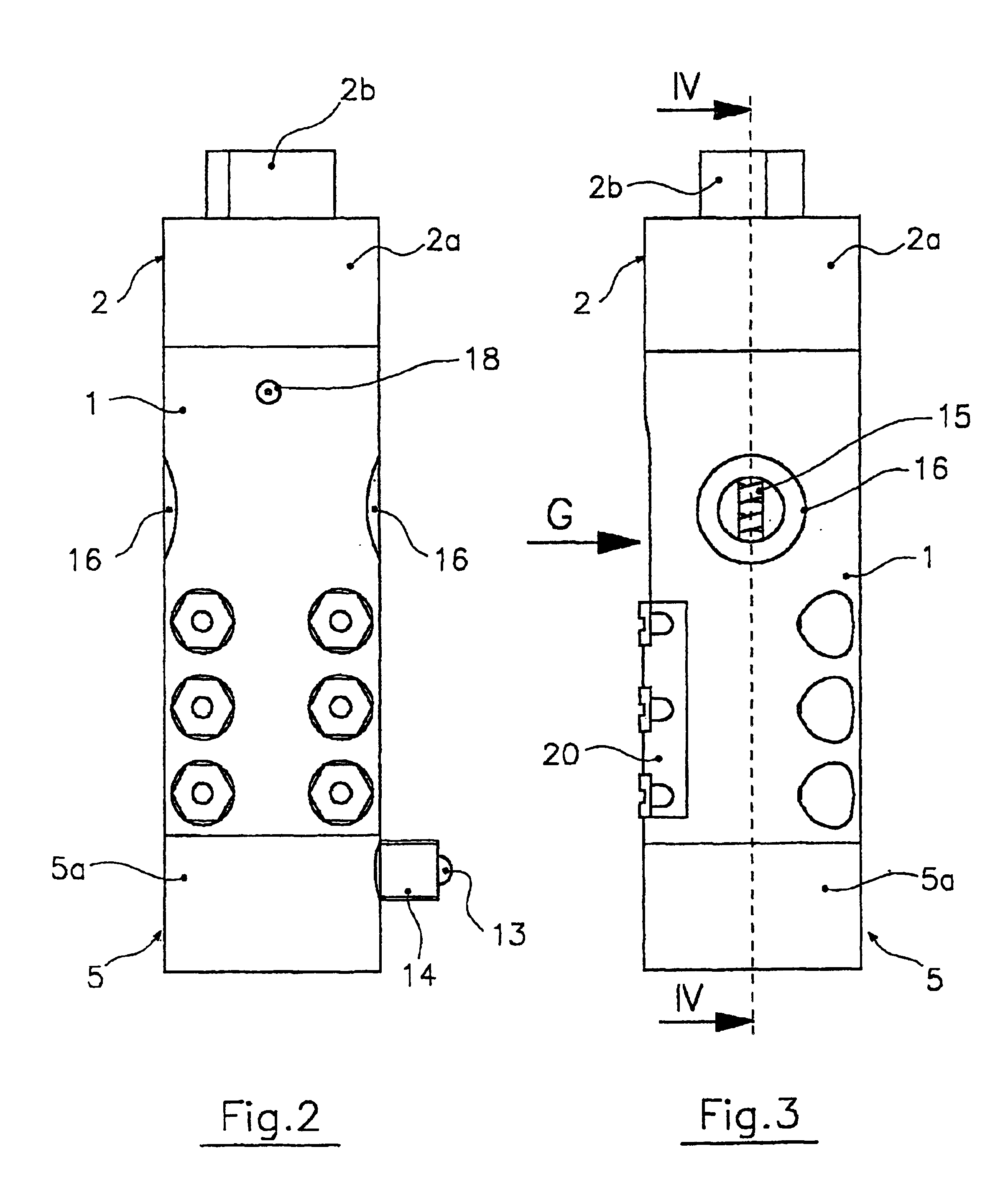

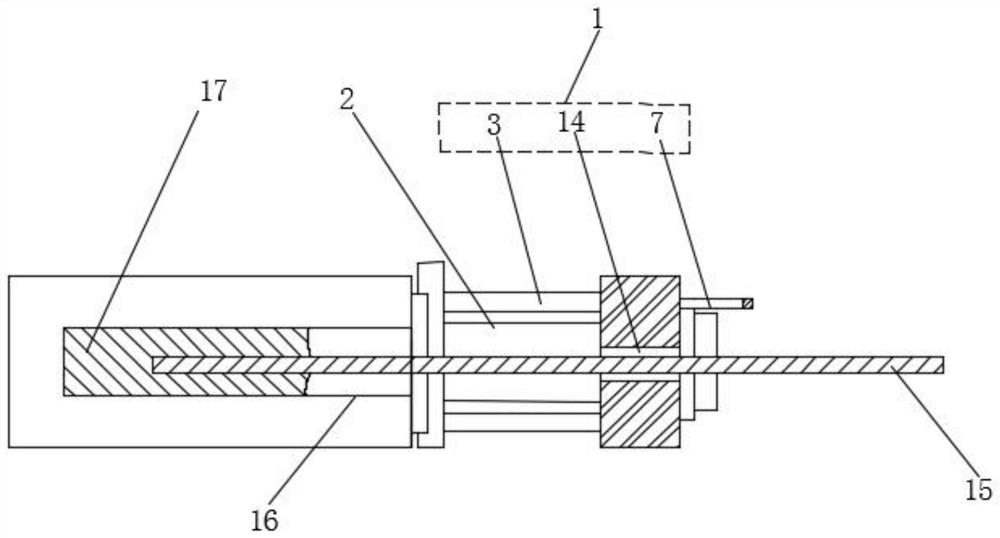

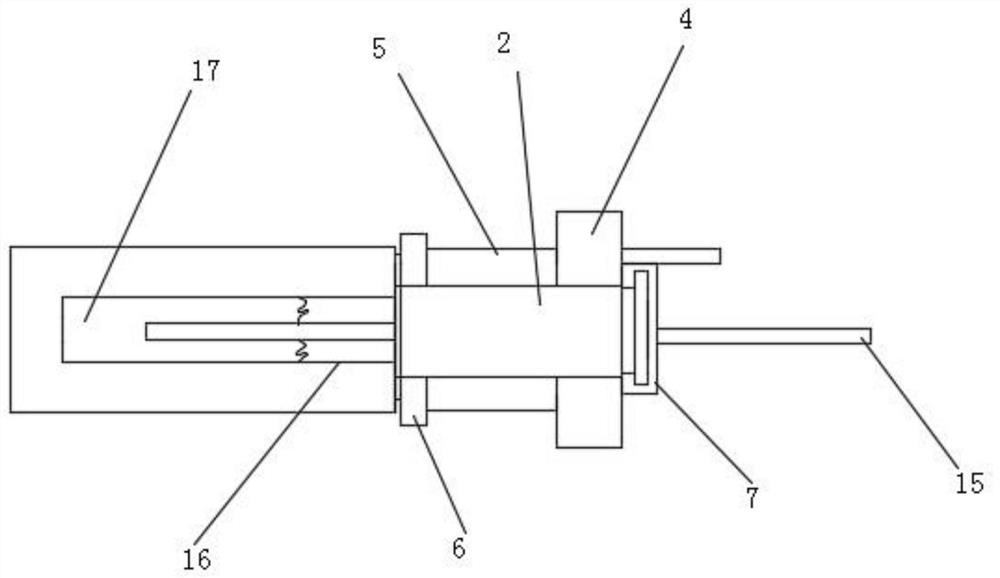

Proportional valve with shape memory alloy actuator

InactiveUS6840257B2Limited sizeReduce weightTemperature control without auxillary powerOperating means/releasing devices for valvesClosed loopAlloy

A proportional valve is disclosed for controlling the outlet pressure of a fluid flowing therethrough. The valve comprises a valve body having an inlet port and an outlet port for the fluid. The valve also has an inner chamber, within which there is formed a valve seat that may be opened and closed variably by a shutter axially movable from and towards the valve seat. Movement of the shutter is controlled by a shape memory alloy (SMA) actuating member operating antagonistically to an elastic member, the temperature of the fluid being lower than the transition temperature of the shape memory alloy. The actuating member and the elastic member are connected to the body valve at opposite sides relative to the valve seat. A power control circuit is also provided for circulating an electric current through the actuating member so as to heat the same by Joule effect from a temperature lower than the transition temperature to one that is higher. At least one vent hole is formed in the valve body for putting a portion of the chamber upstream of the valve seat into fluid communication with the outside or a collection network. The actuating member is housed in that portion of chamber corresponding to the inlet port of the fluid, whereby a continuous flow of fluid around the actuating member is ensured for accelerating the cooling process. A closed-loop control circuit for the power control circuit controls the circulating current as a function of a pressure signal generated by fluid pressure sensing means and in such a way as to offset the retarding effect produced by the fluid during heating of the actuating member.

Owner:ARENA ALBERTO +2

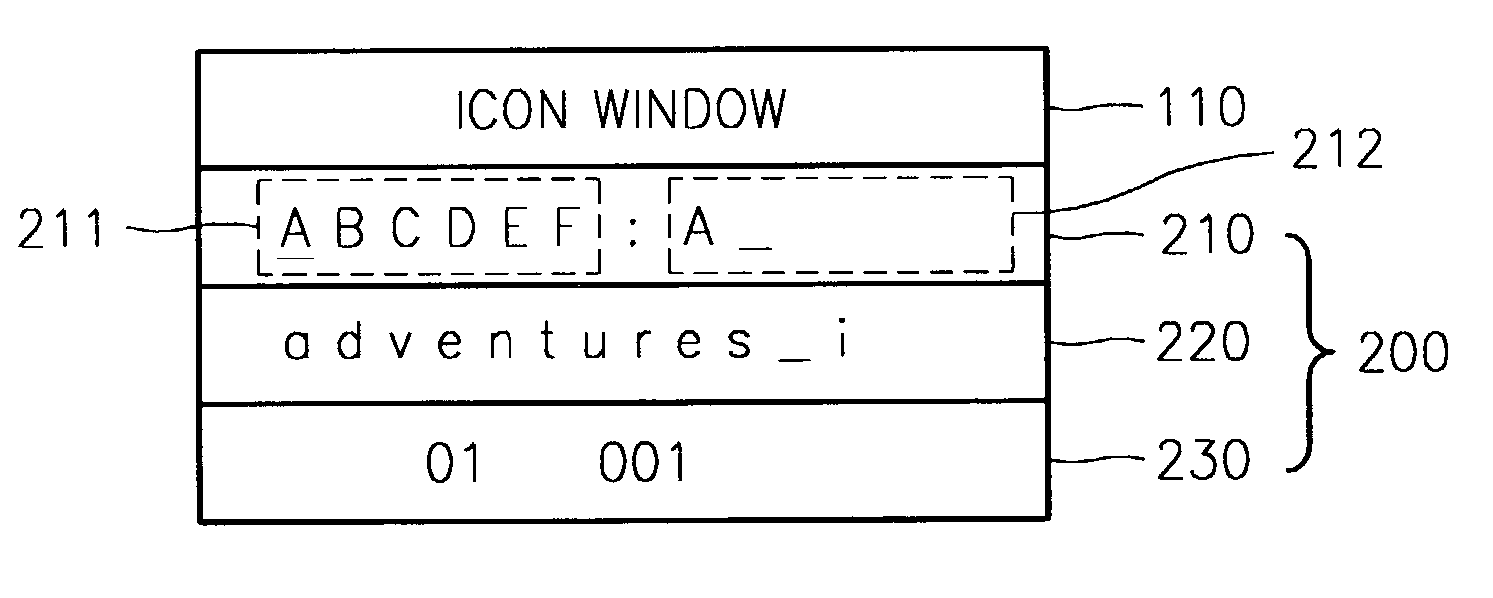

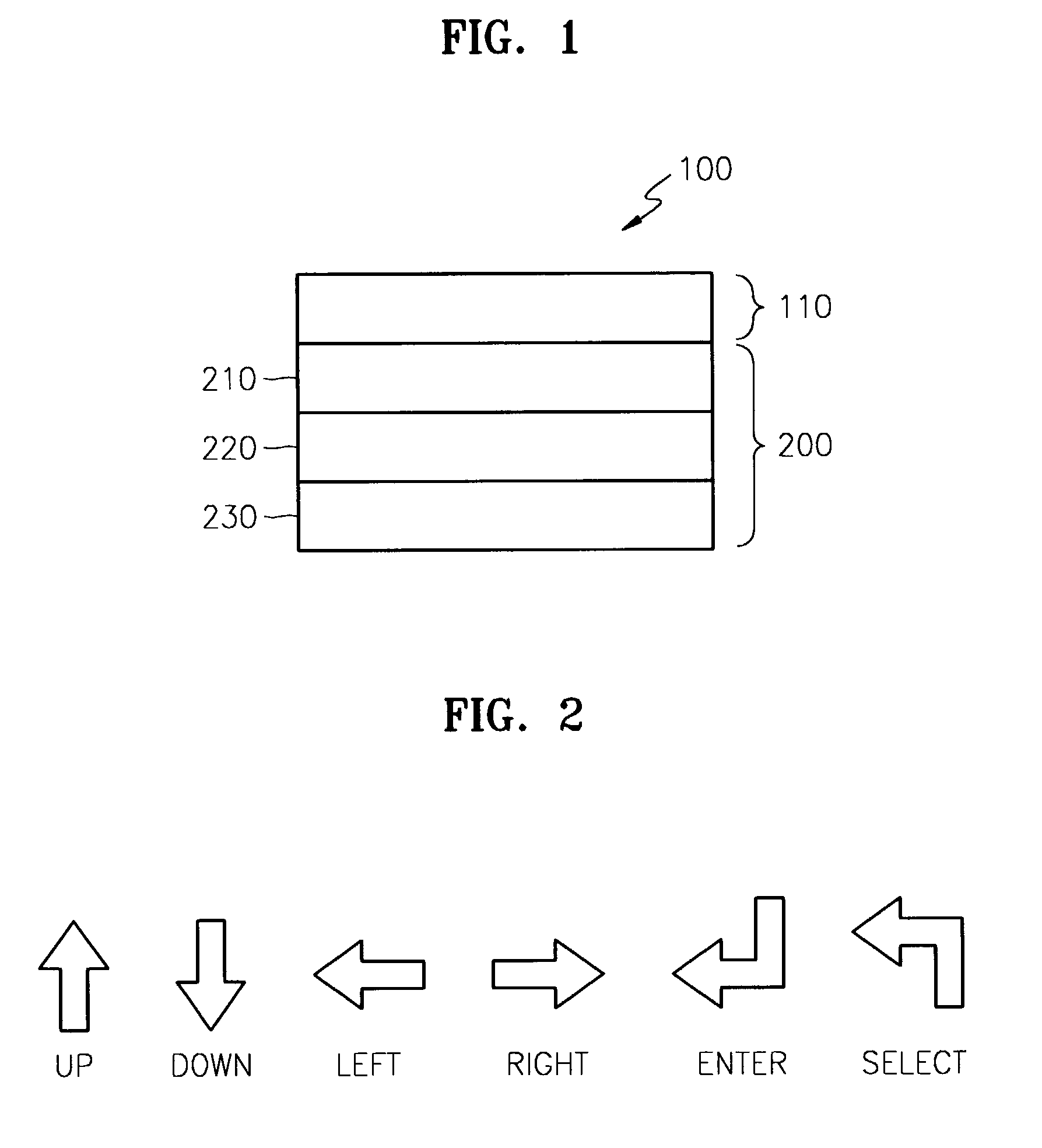

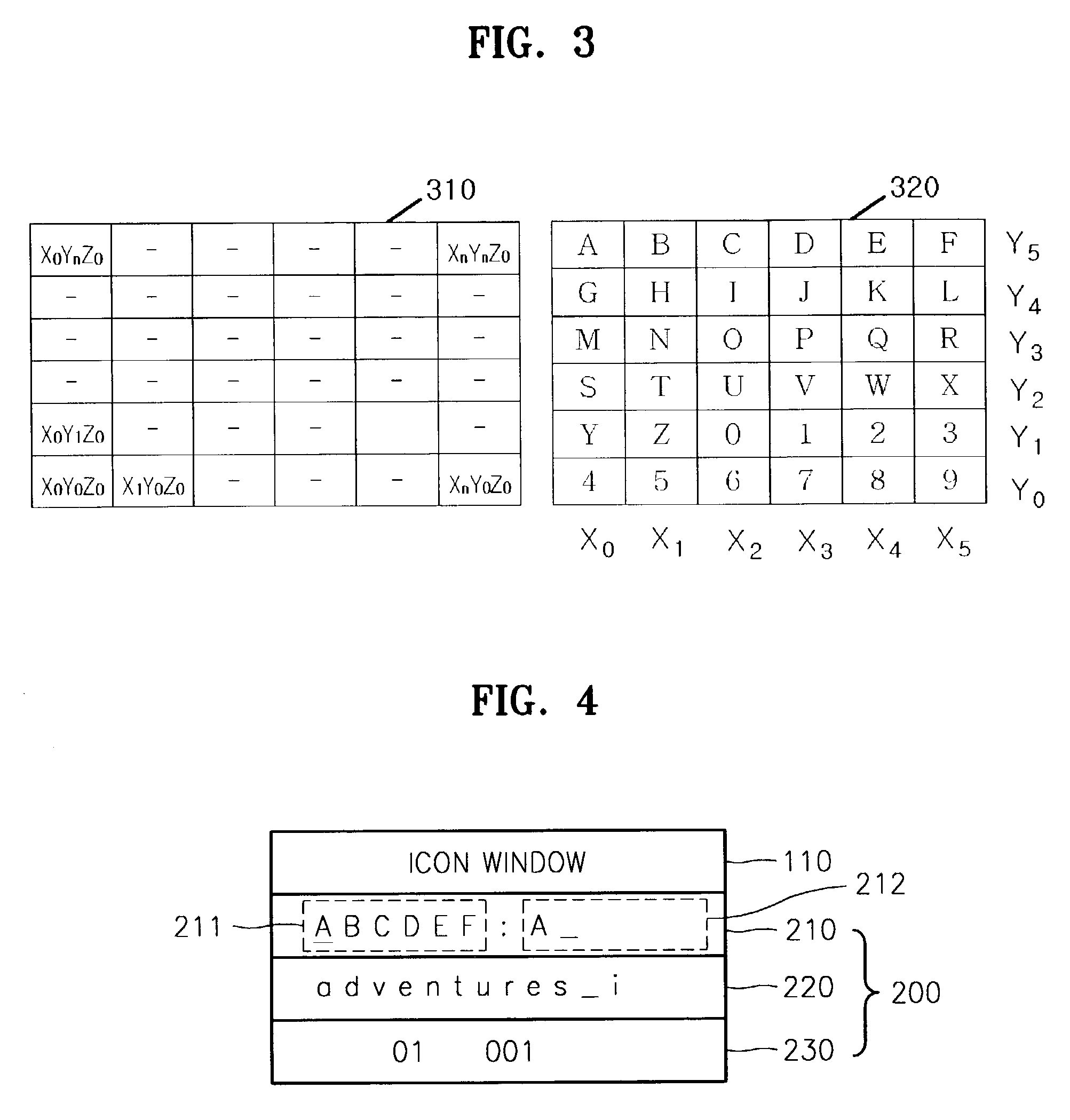

Method for inputting characters in portable device having limited display size and number of keys, and portable device using the same

ActiveUS7015899B2Easy and fast inputLimited numberInput/output for user-computer interactionDigital computer detailsComputer graphics (images)Virtual coordinates

A portable device includes a display unit, a memory, input keys, and a microprocessor. The display unit has a character window, which includes a selecting character window and a selected character window, for displaying characters. One character line including the character which has virtual coordinates indicated by a cursor is displayed in the selecting character window, and the character selected from the characters in the selecting character window is displayed in the selected character window by input keys. The memory stores the characters having intrinsic virtual coordinates, and several input keys serve for navigating across the characters by using the virtual coordinates of the characters to select the characters. The microprocessor controls the display of the characters on the display unit in correspondence to the input of the input keys.

Owner:SAMSUNG ELECTRONICS CO LTD

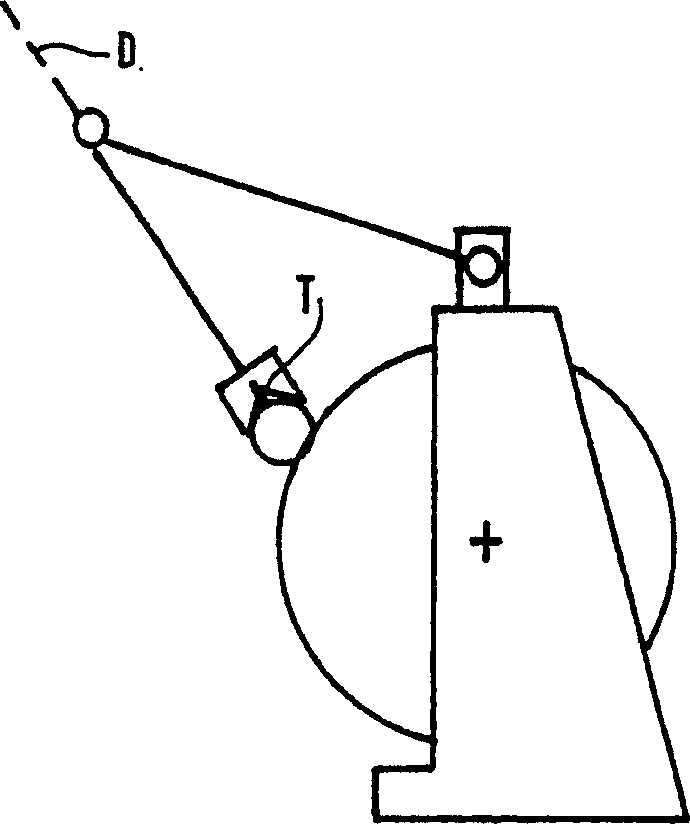

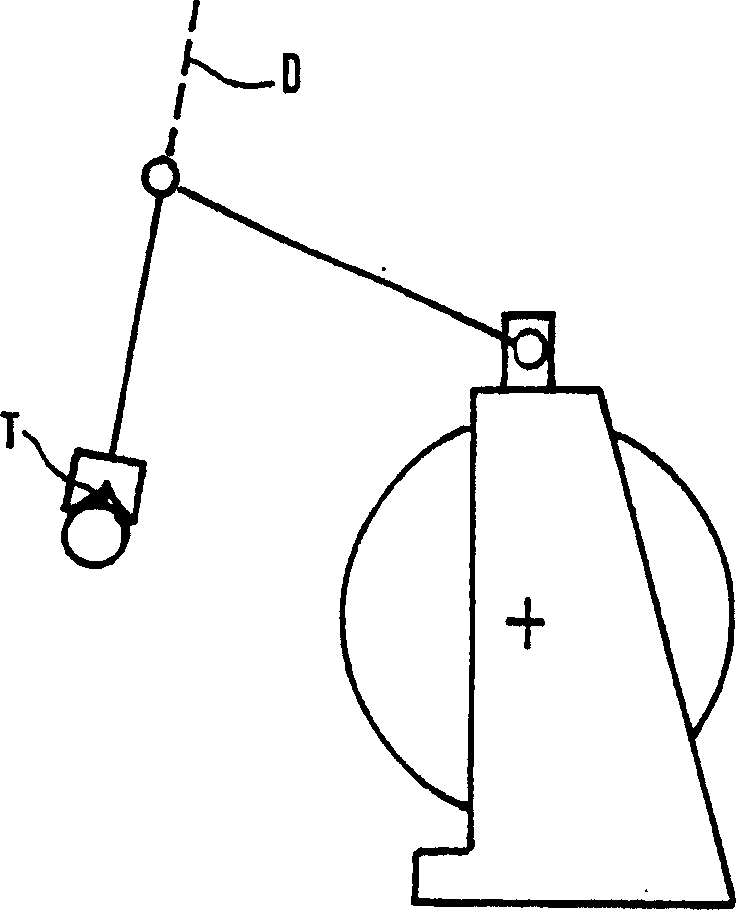

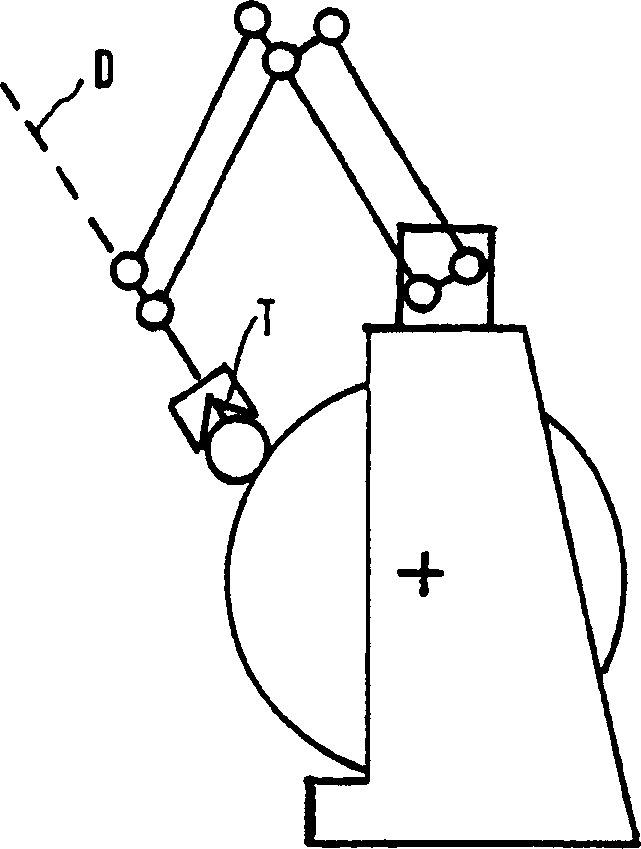

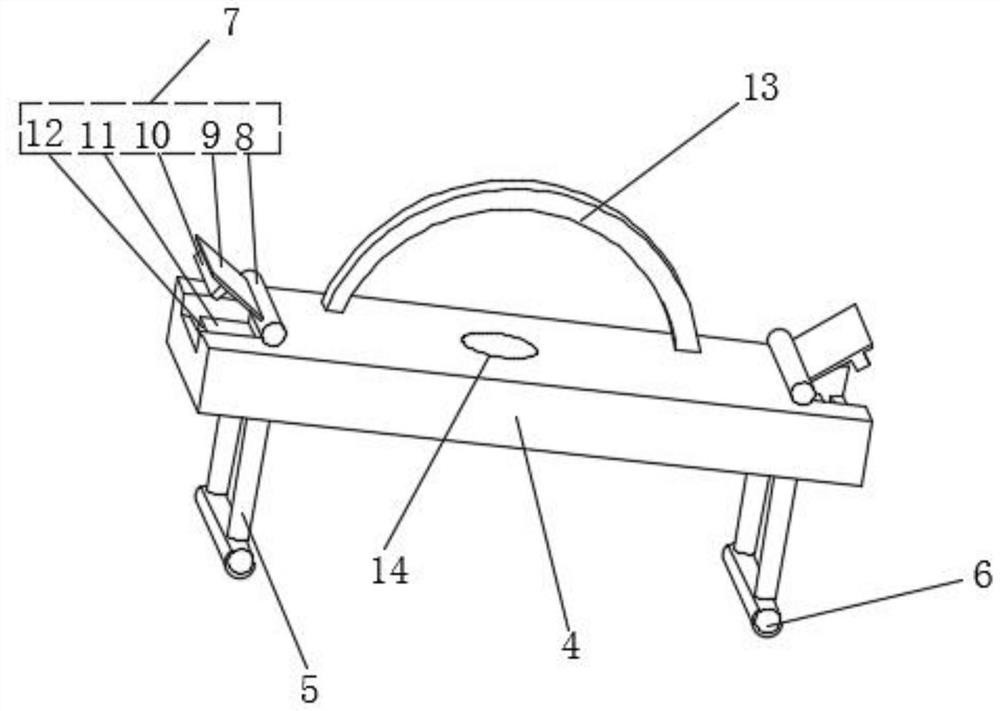

Apparatus for checking the dimensional and geometric features of pins

InactiveCN1659000AWith manufacturing characteristicsEnsure manufacturing featuresRevolution surface grinding machinesMechanical counters/curvatures measurementsMachining processEngineering

An apparatus for checking diameter and roundness of crankpins ( 42 ) in the course of the machining in a grinding machine, includes a Vee-shaped reference device ( 70 ), a gauging device with a movable feeler ( 67 ) associated with the Vee-shaped device ( 70 ) and a movable support ( 5, 40, 41, 60 ) device for the Vee-shaped reference device. The movable support device is coupled ( 5 ) to the grinding-wheel slide ( 1 ) and includes, in working condition, two parallelogram structures ( 40, 41 ) in series enabling substantially translation displacements of the Vee-shaped device ( 70 ). One of the two parallelogram structures ( 40, 41 ) includes an axially movable stem ( 32 ), with end surfaces ( 38, 39 ) that, in working condition, contact the external surface of bearings ( 15, 19 ), thereby setting the distance separating two of the four vertexes ( 11, 7, 14, 18 ) of the parallelogram ( 40 ), whereas when the apparatus is in the rest position, at least one of said end surfaces ( 38, 39 ) is separated from the surface of the associated bearing. During the checking, the direction of the feeler ( 67 ) displacements remains substantially unaltered.

Owner:MARPOSS SPA

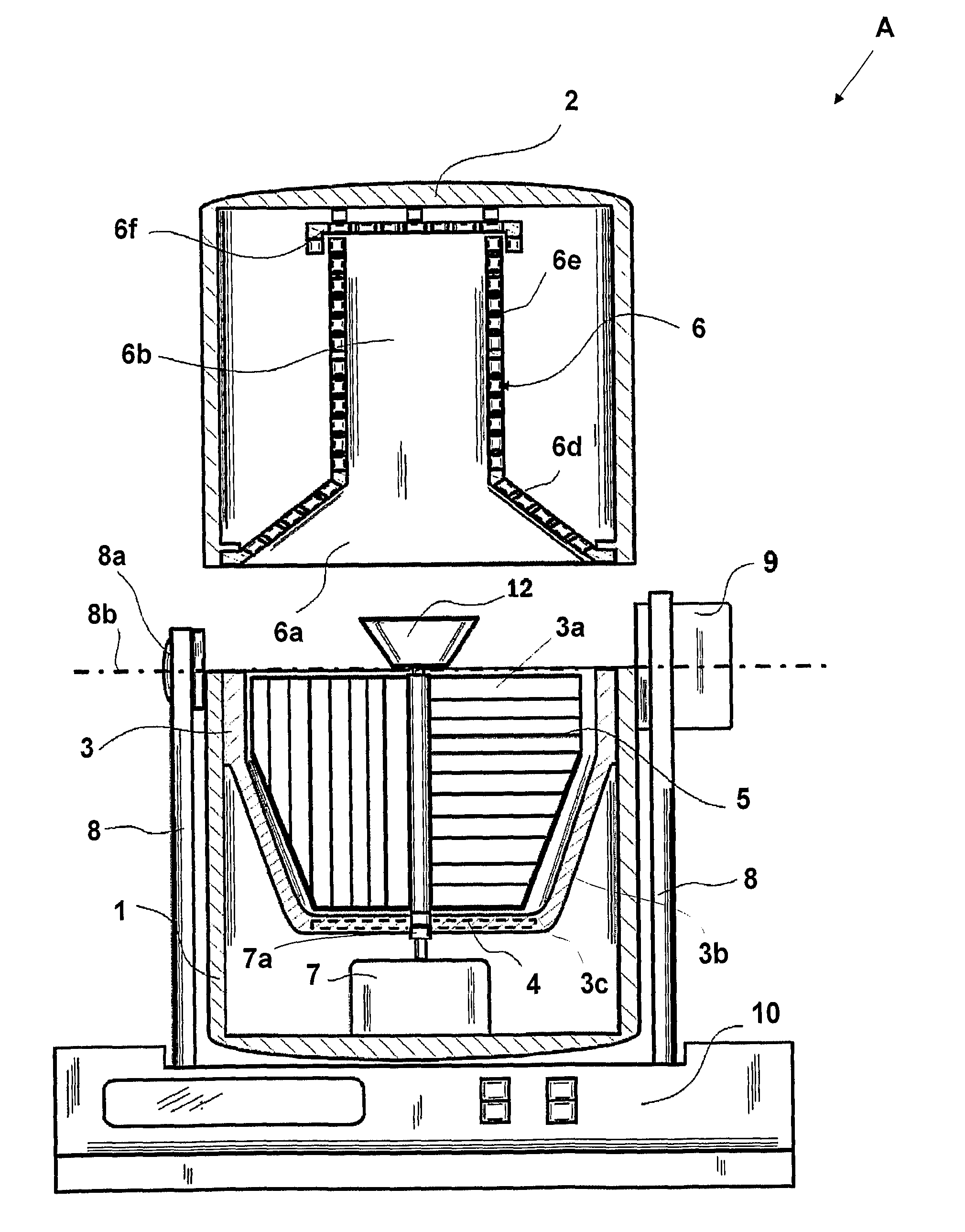

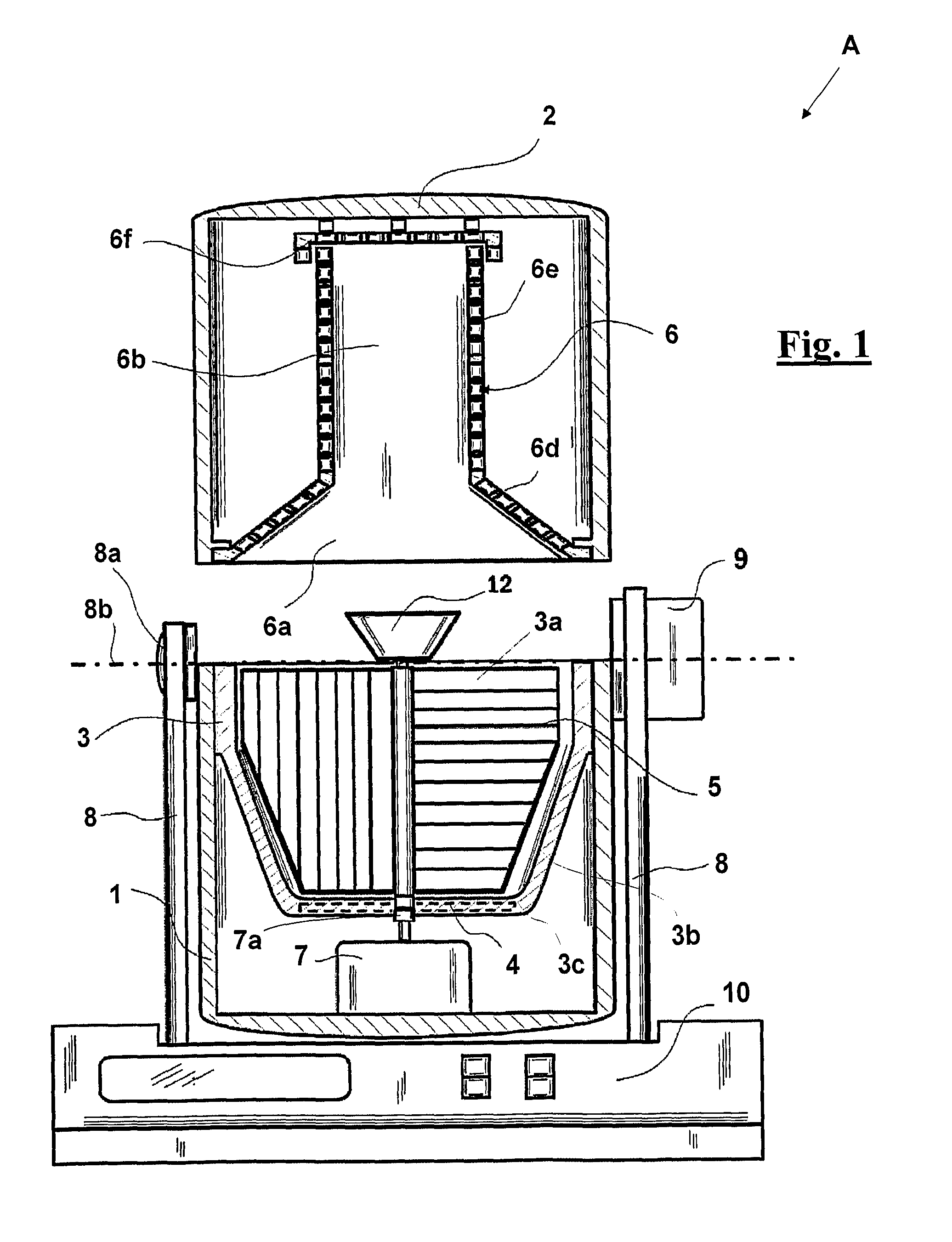

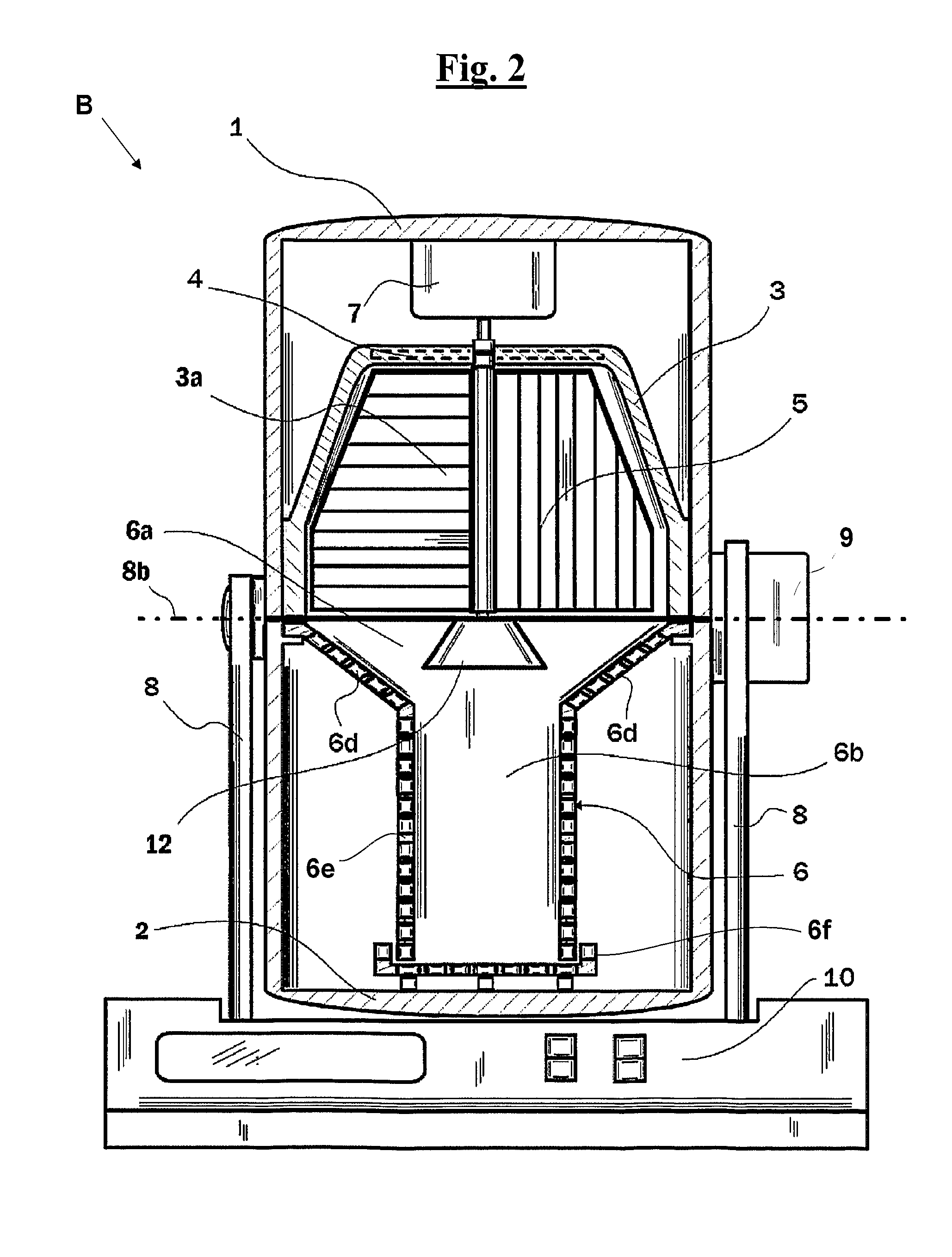

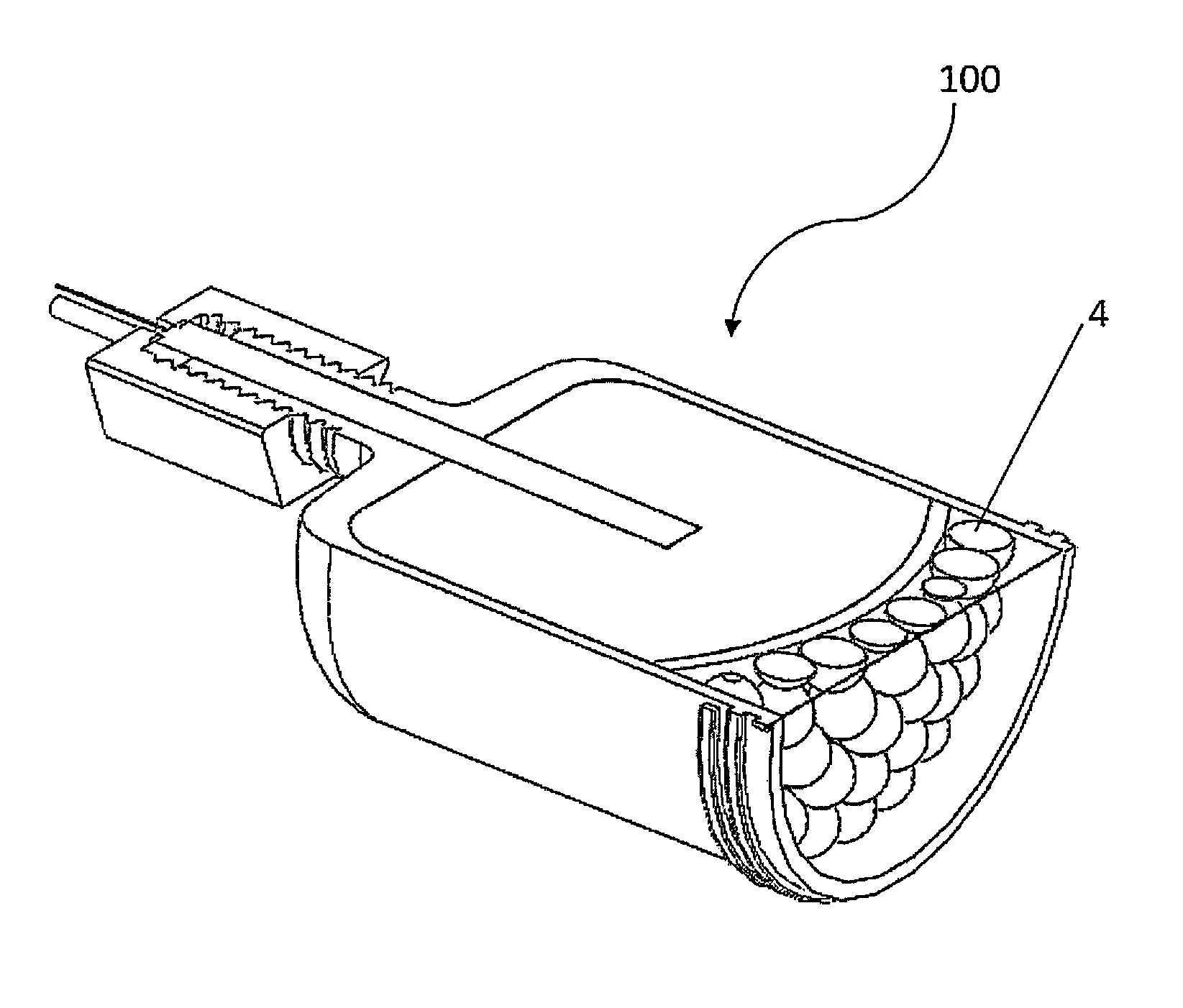

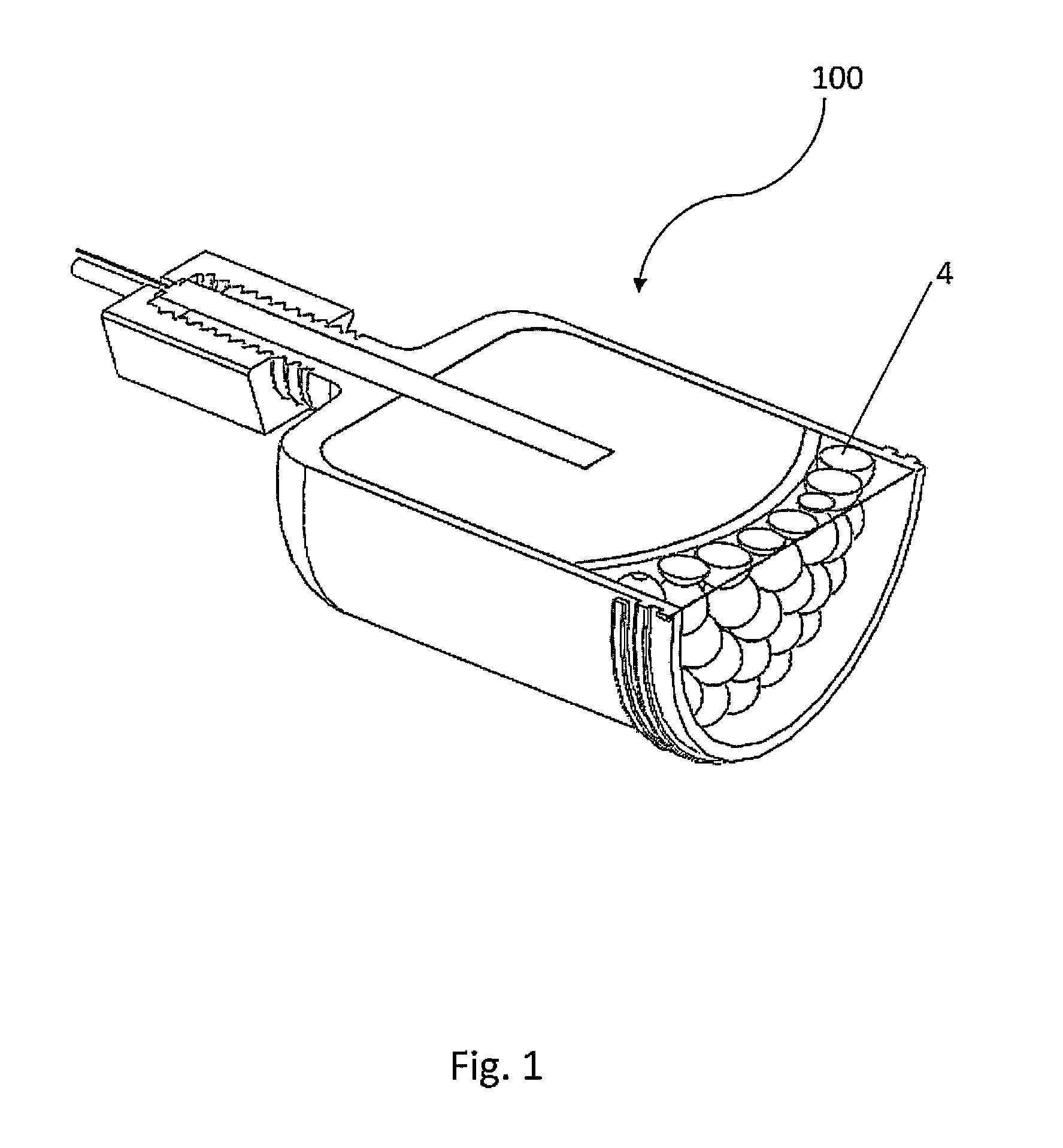

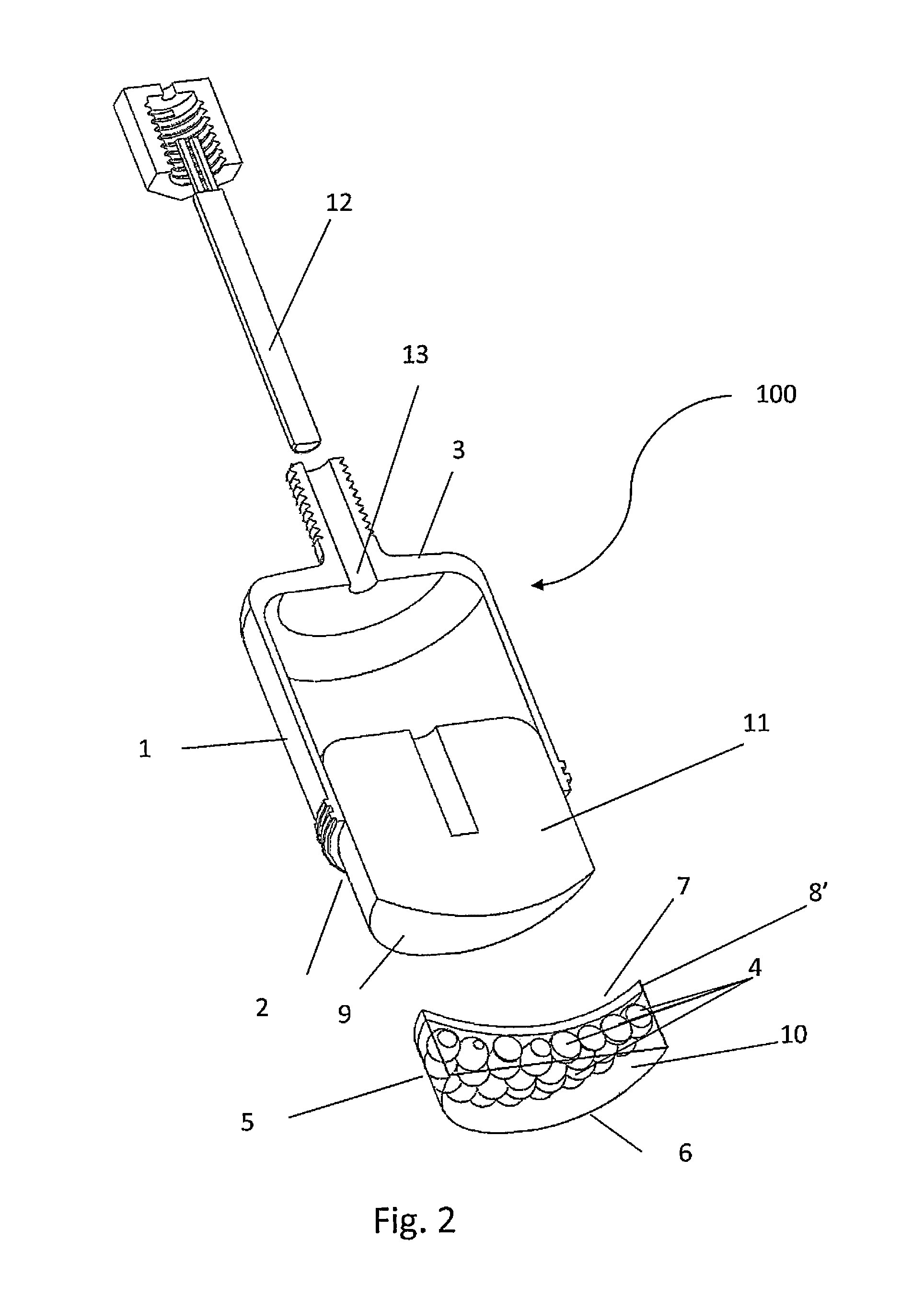

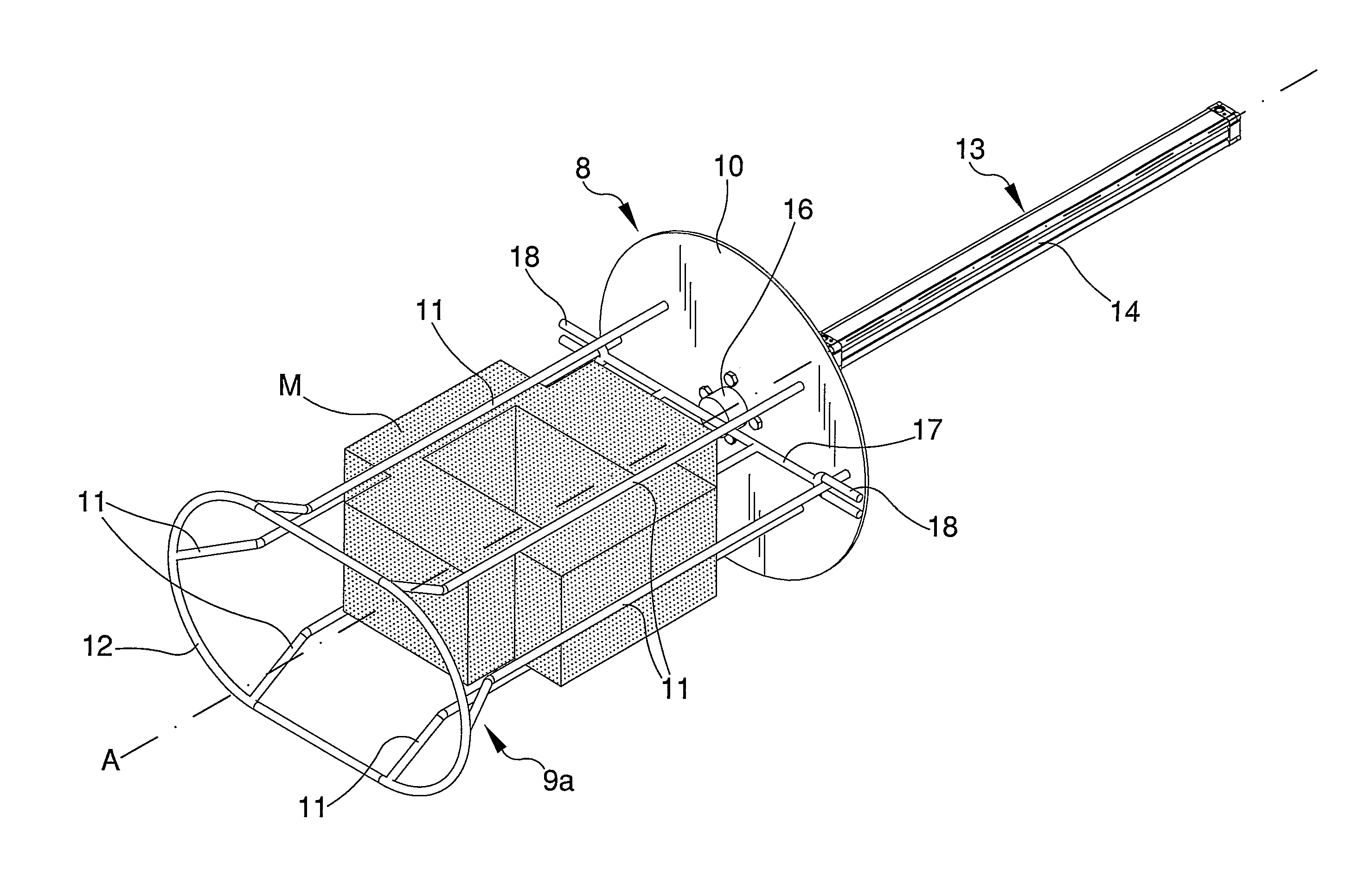

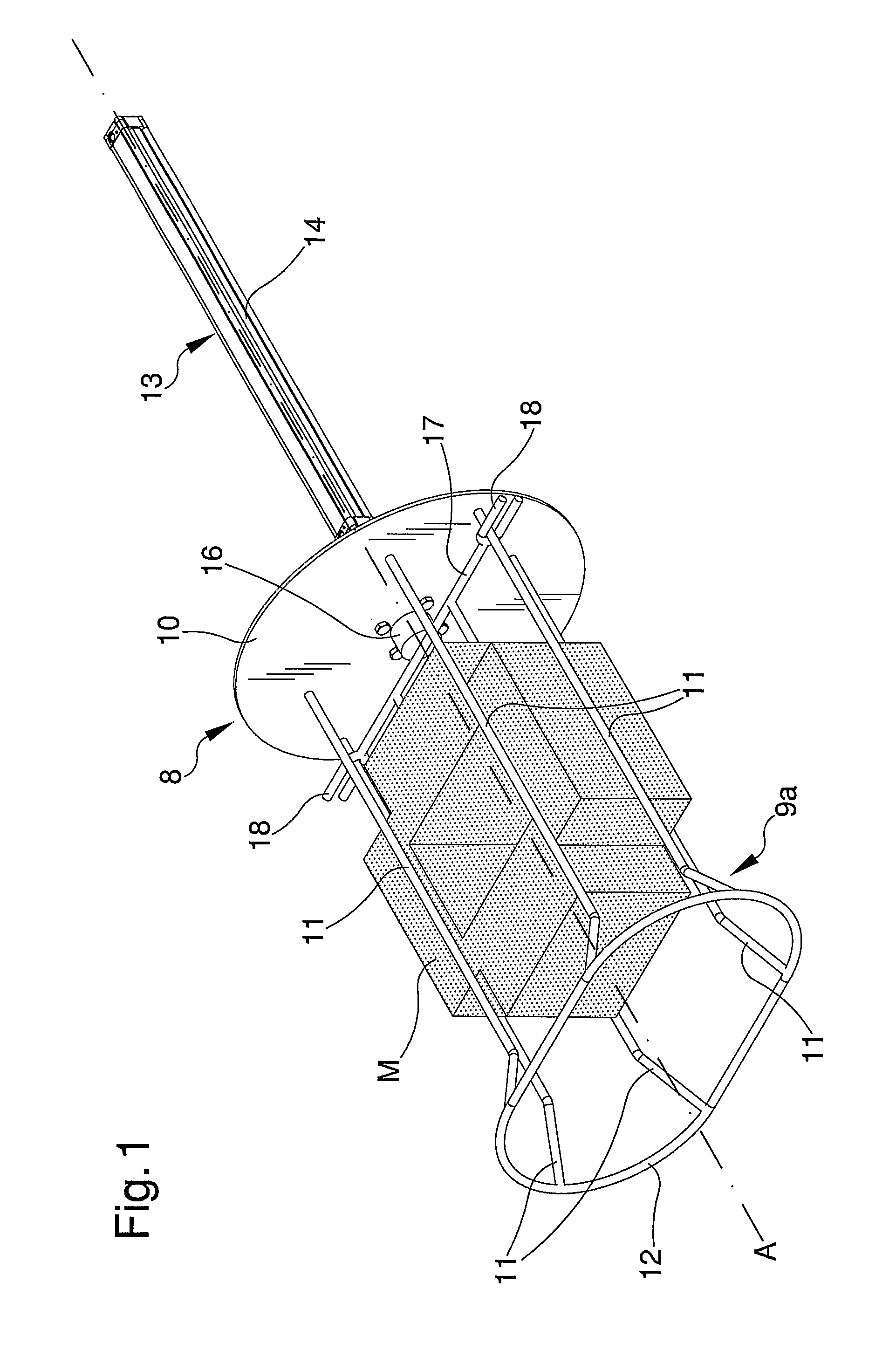

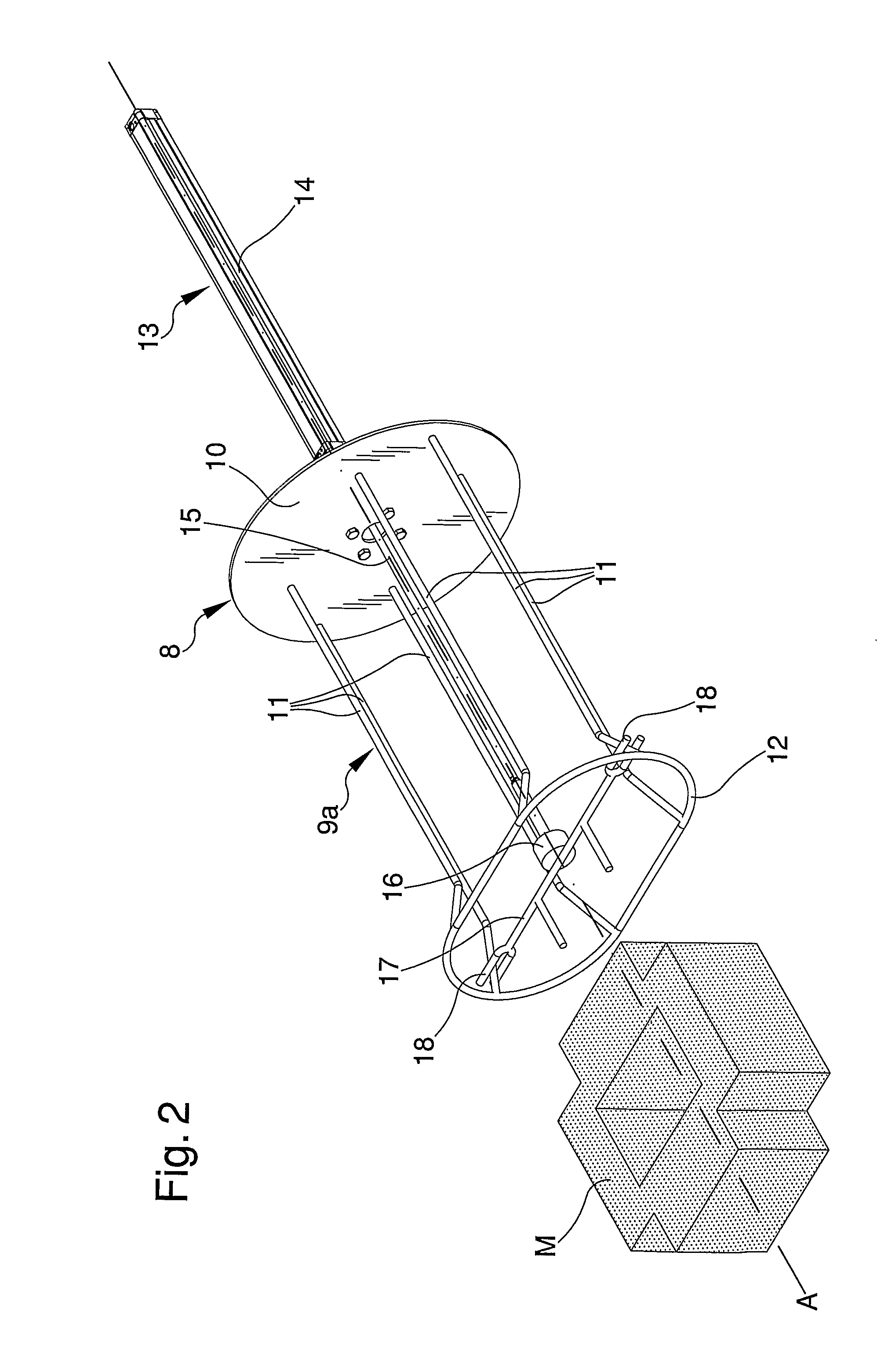

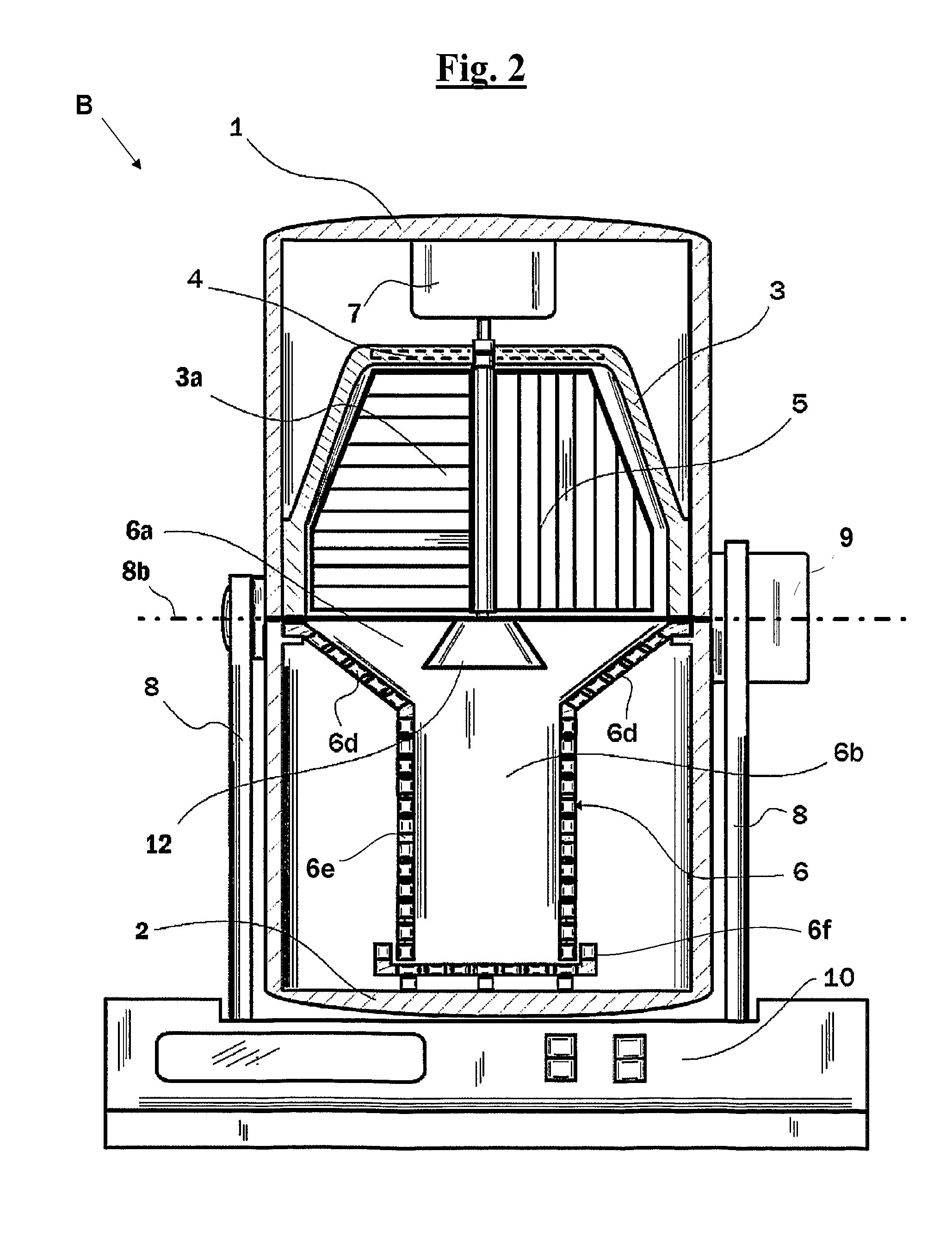

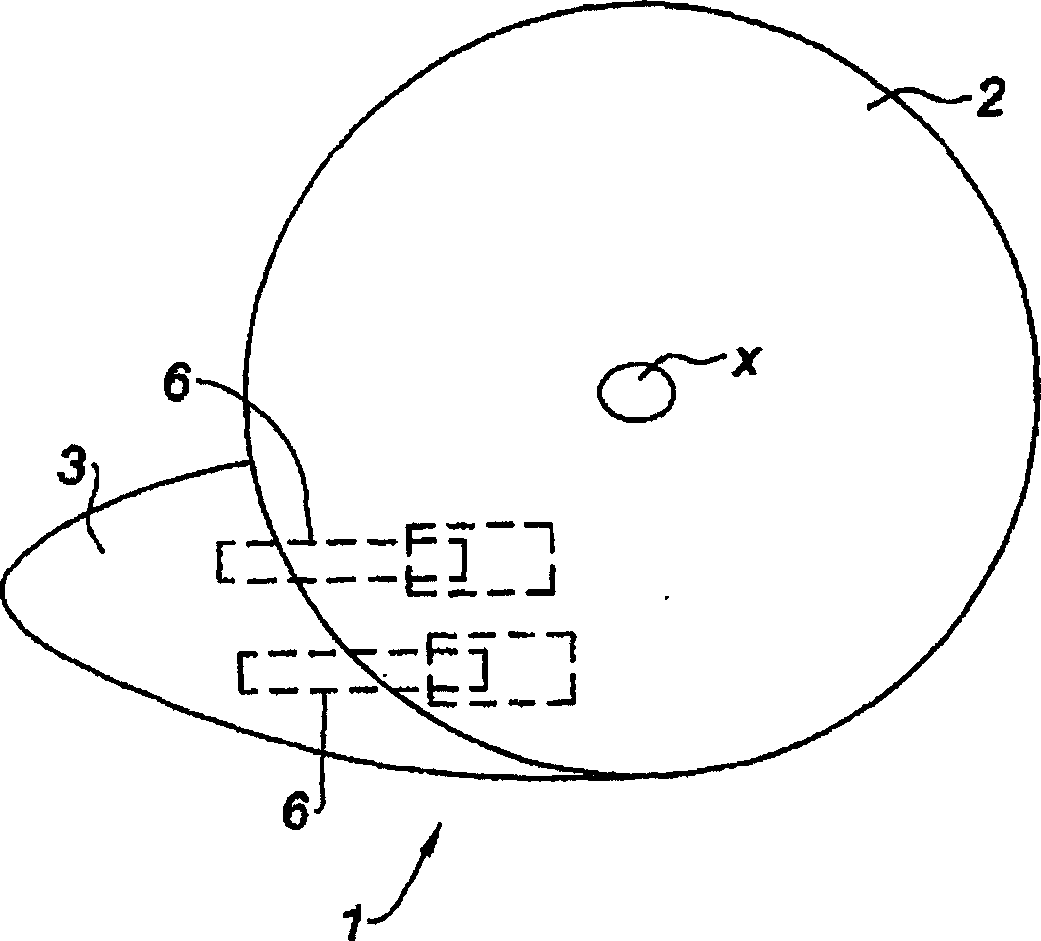

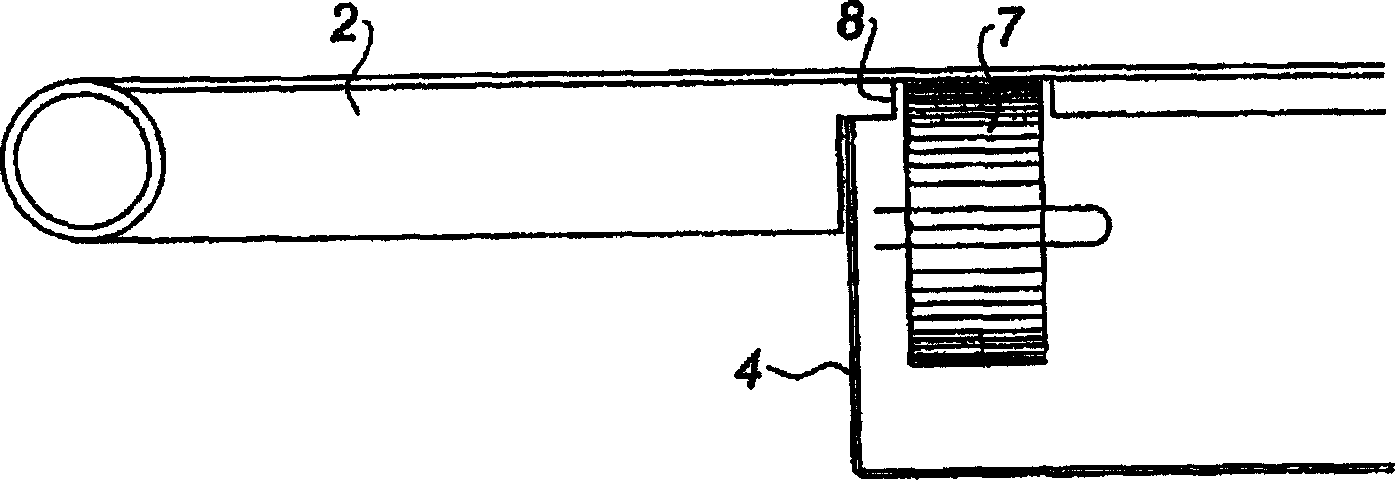

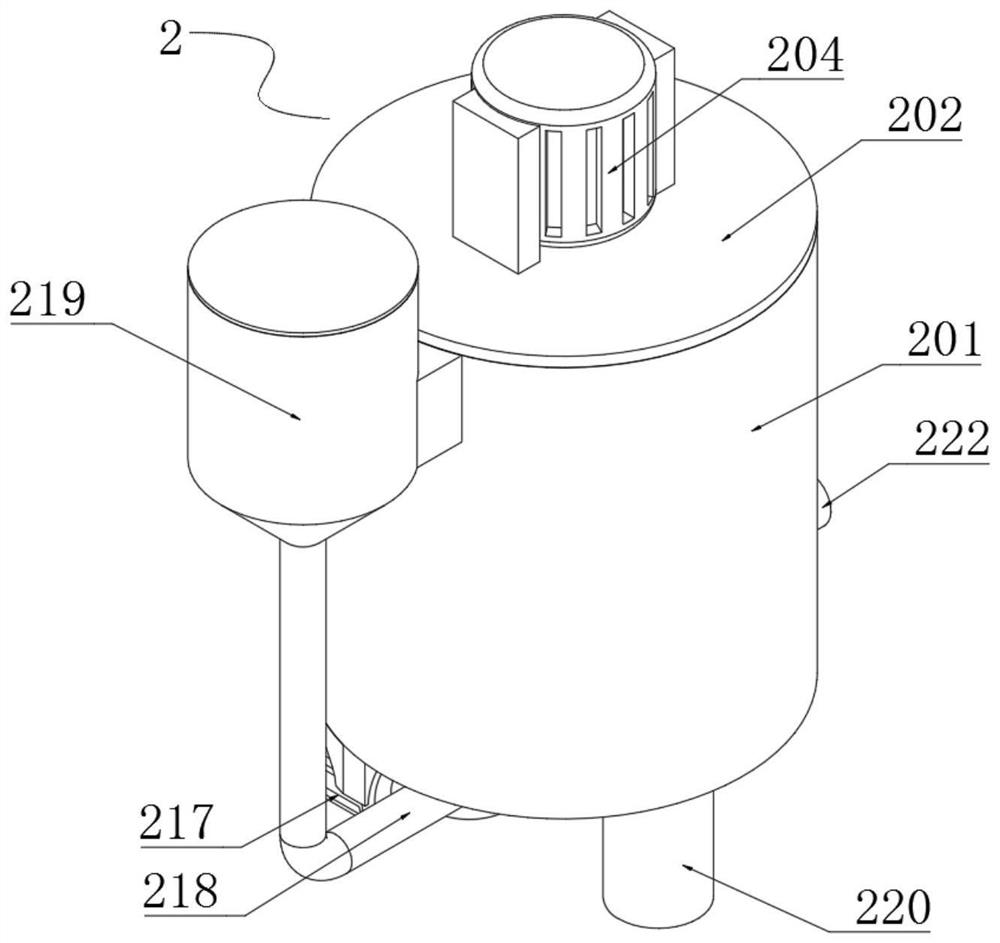

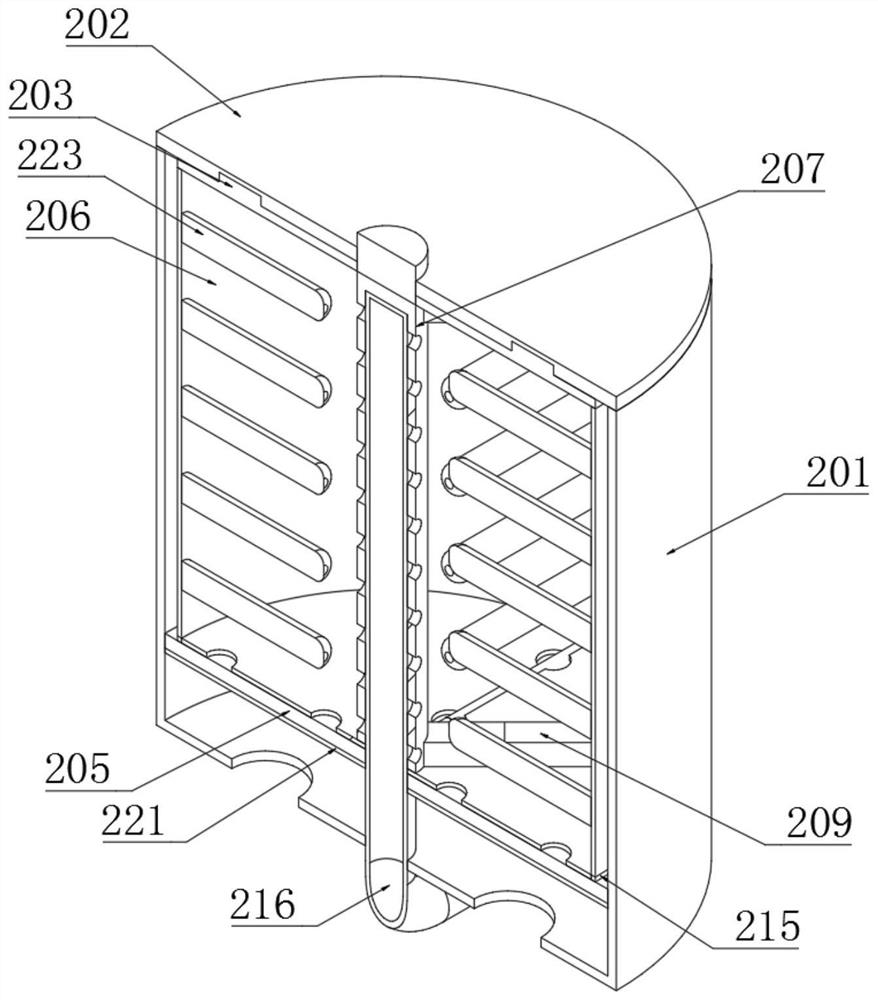

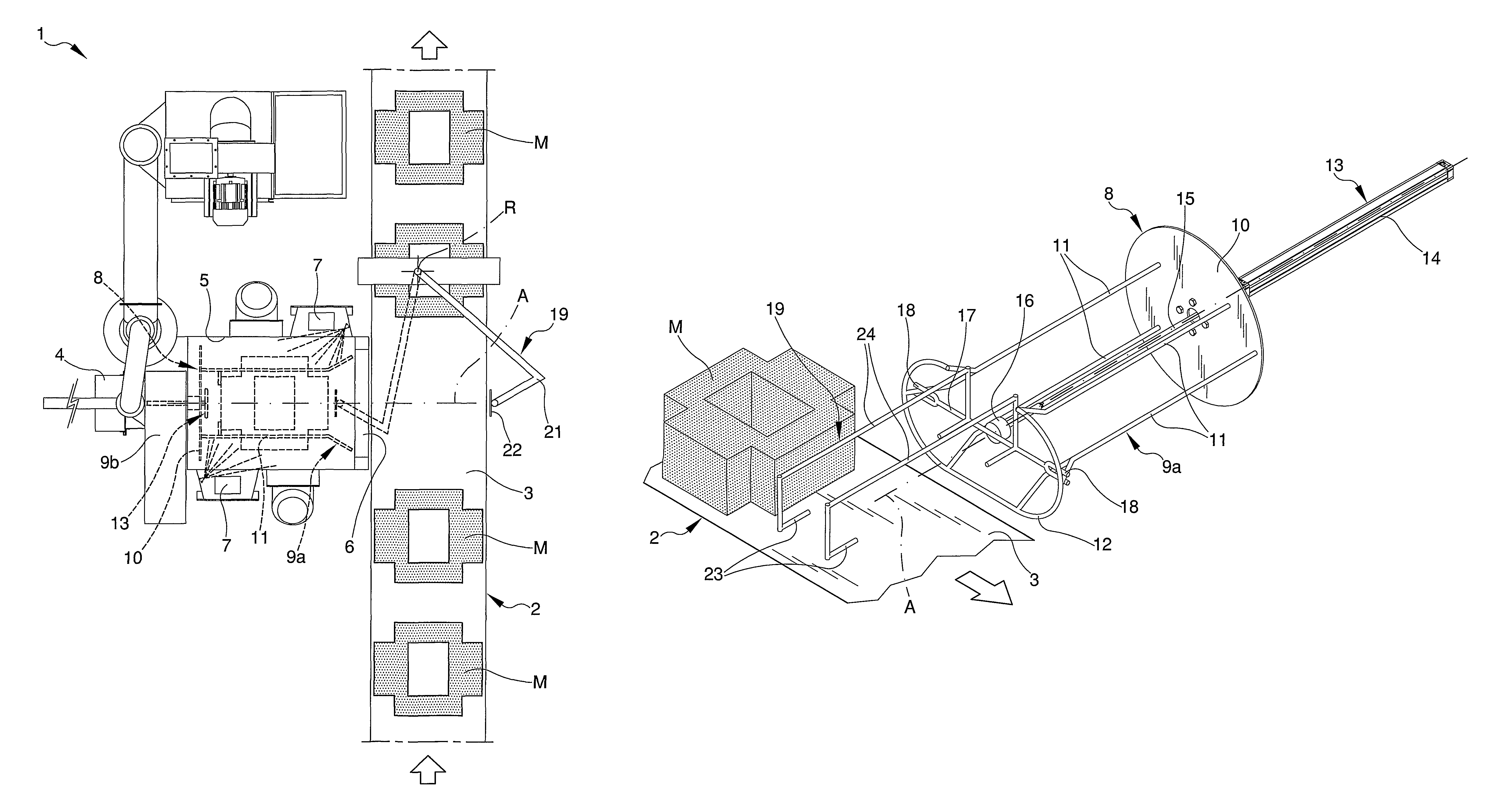

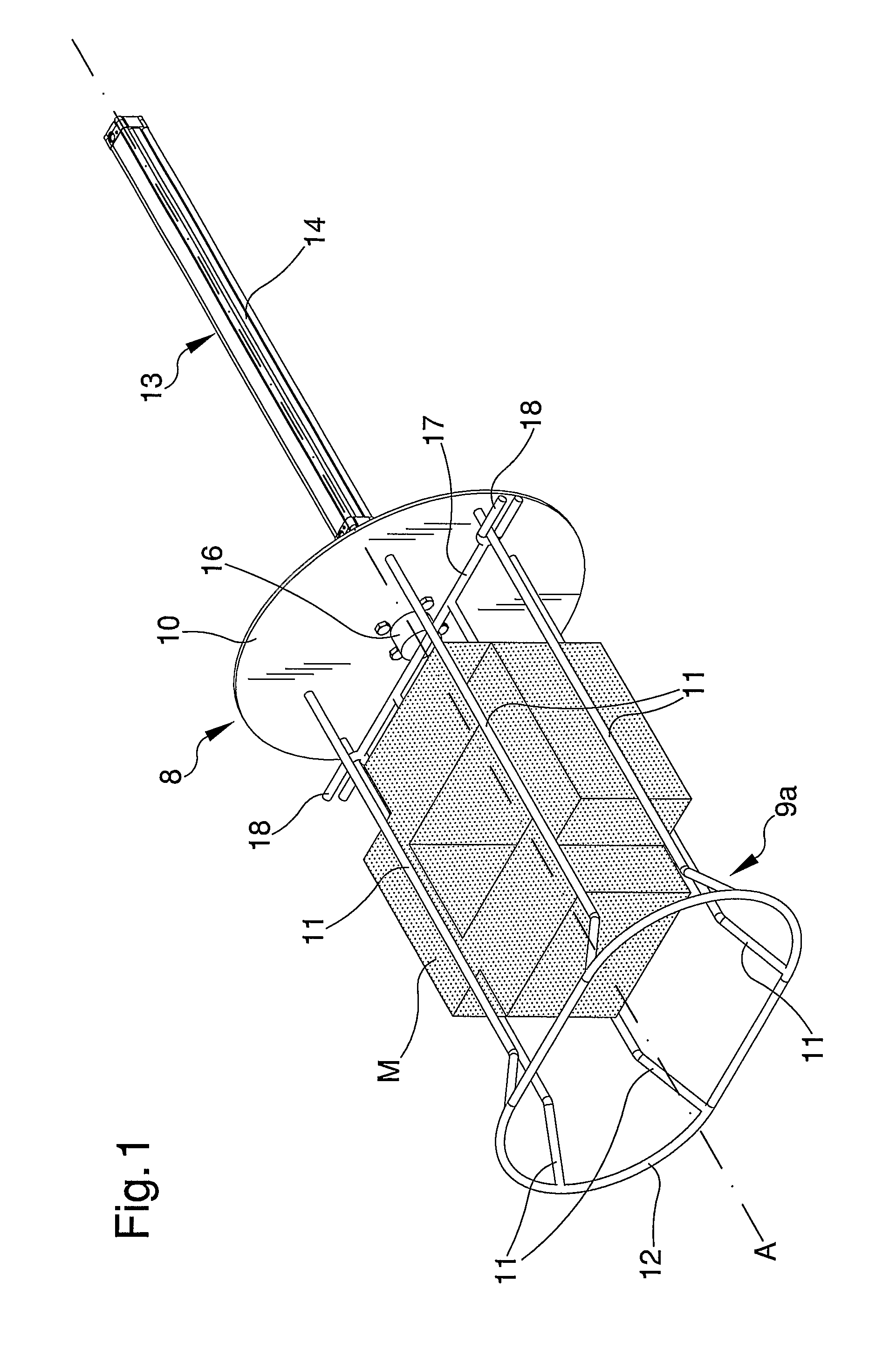

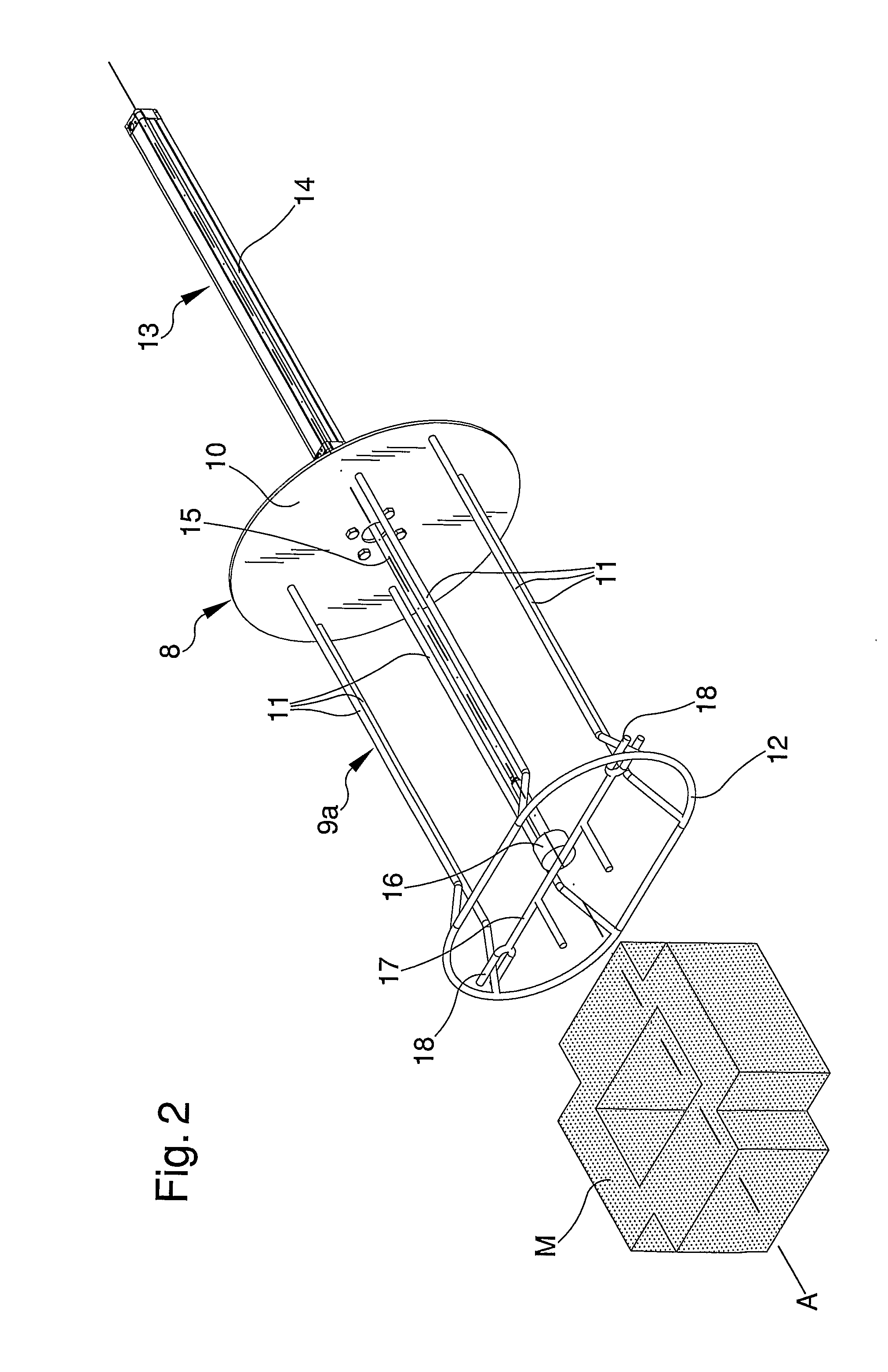

Device for making cheese, other milk-derivatives and tofu

ActiveUS20100263551A1Limited sizeSimple structureMilk preservationJuice extractionEngineeringMechanical engineering

Compact machine for making cheese, other milk-derivatives and tofu comprising a shell (1) in which an impermeable basin (3) is inserted, a collecting container (2) in which a permeable basket (6) is inserted for collecting the product and a support structure comprising a lower base member (10) having two side arms (8). The machine comprises, furthermore, a motor (7) integral to the shell (1) for operating a stirring member (5), and heating means (4) adapted to heat to various temperature the content of the basin (3). The basin (3) and the permeable basket (6) are open and coupled with respect to each other, in a releasable way, one against the another. The coupled basin (3) and the permeable basket (6) are adapted to be integrally rotated, in order to be moved alternatively between a first position (A), where the basin (3) is down and the basket (6) is up, and a second position, where the basket (6) is down and the basin (3) is up. The cheese can be extracted from the basket (6) after a plurality of preparation steps.

Owner:PAVERO RICCARDO

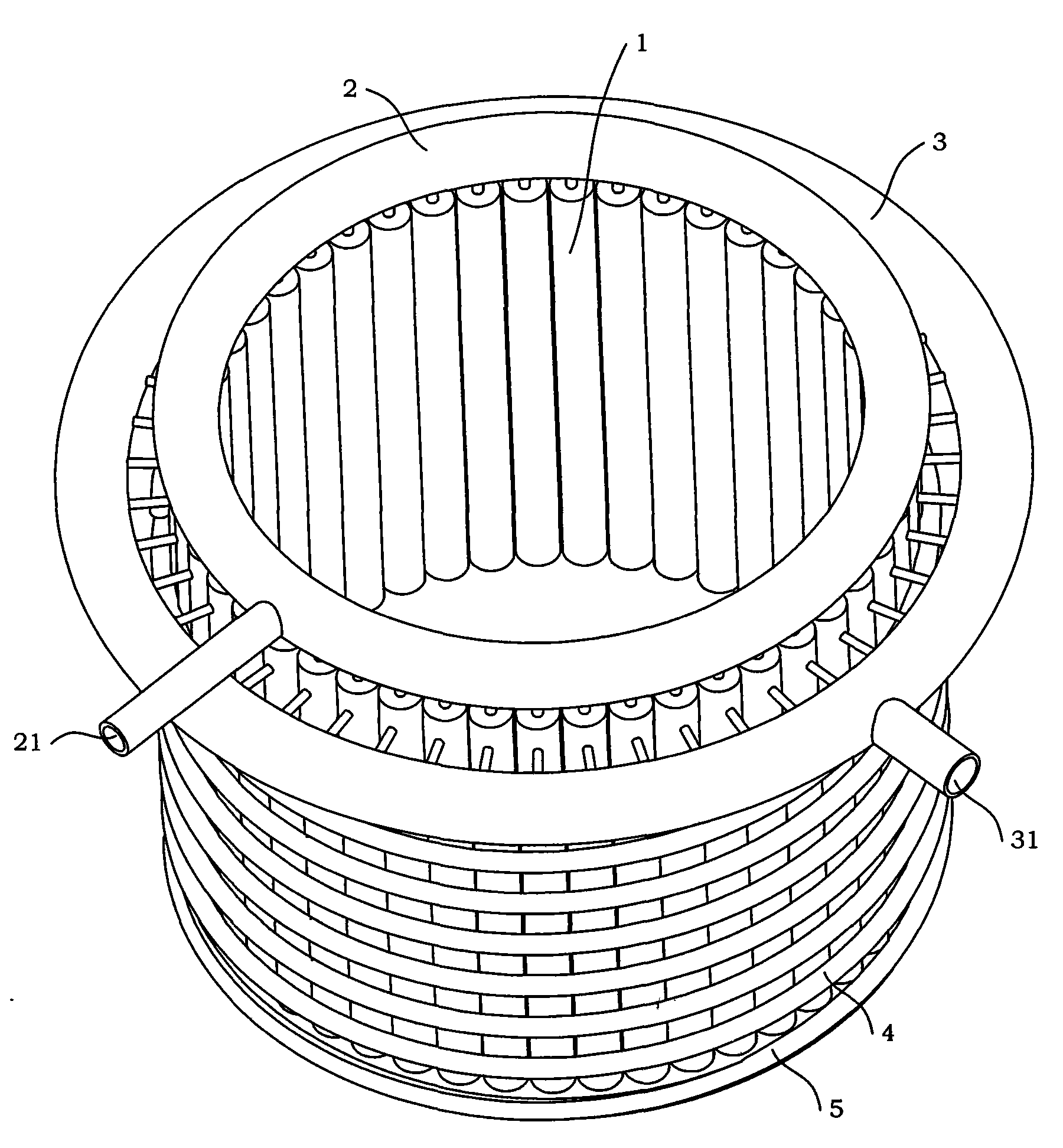

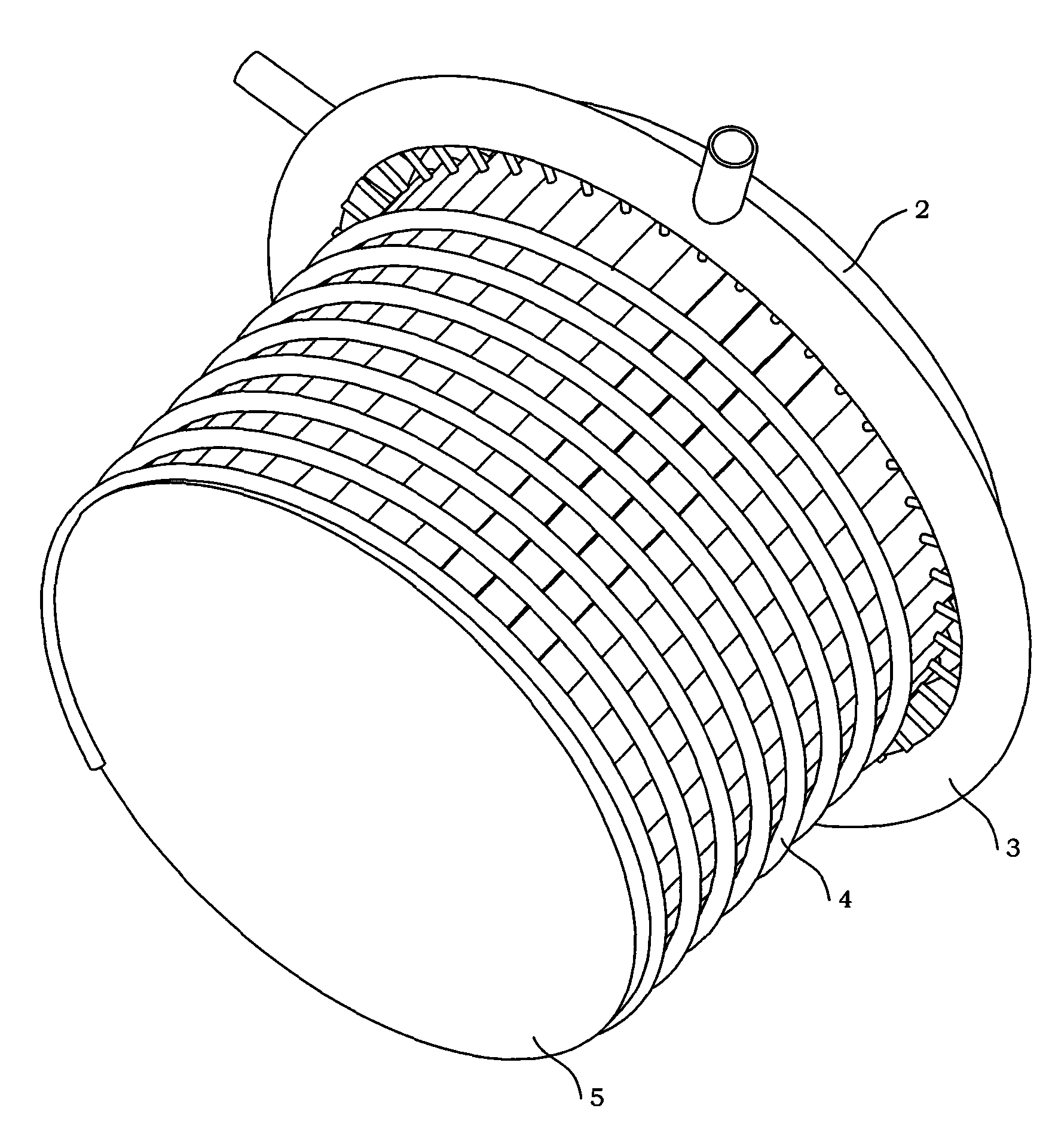

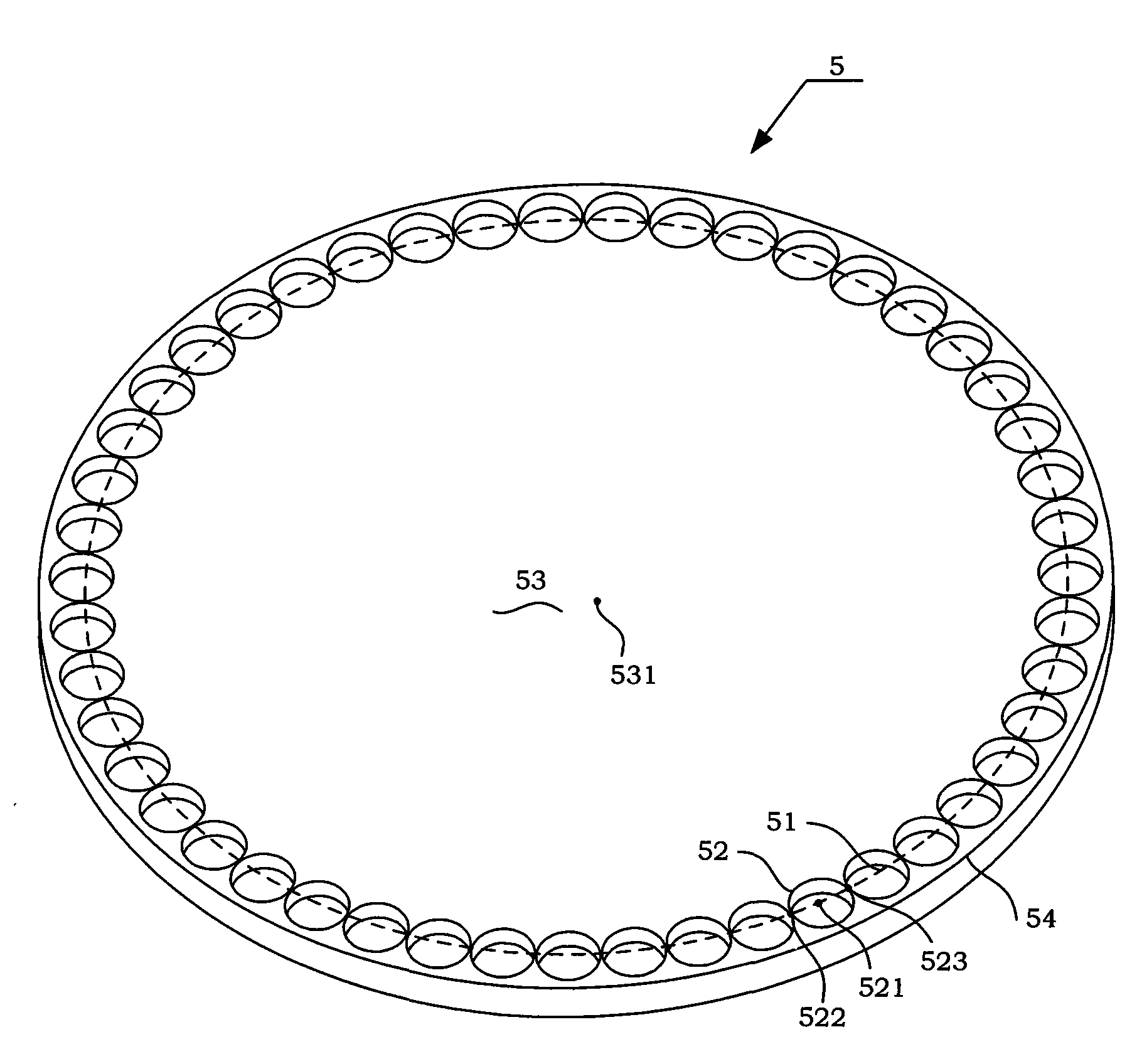

Induction melting cold crucible

The invention discloses an induction melting cold crucible. The induction melting cold crucible comprises a cooling water tube-in-tube(1), a base(5), a water inlet pipeline(2), a water outlet pipeline (3) and an induction coil(4), wherein the lower part of the cooling water tube-in-tube(1) is arranged on the base(5); the water inlet pipeline (2) and the water outlet pipeline (3) are arranged on the upper part of the cooling water tube-in-tube(1) respectively; and the induction coil(4) is wound around the outer part of the cooling water tube-in-tube(1). The induction melting cold crucible formed by the combination of the design idea of discrete components and the base positioning has the advantages of simple processing of parts, low production cost, further low smelting cost of certain rare metals and alloy, and big application range.

Owner:BEIHANG UNIV +1

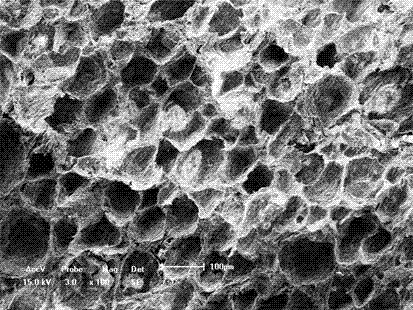

Preparation method for macroporous hydroxyapatite ceramic

The invention relates to the technical field of ceramic materials, in particular to a preparation method for macroporous hydroxyapatite ceramic. The preparation method comprises the following steps of: firstly preparing an uniform bonder polyvinyl alcohol aqueous solution, adjusting the pH value of the polyvinyl alcohol to be 4-5.5 by using concentrated hydrochloric acid, mixing the HA (hydroxyapatite) powder and the polyvinyl alcohol aqueous solution according to the mass ratio of (2-5): (10-20) to form a uniform sizing, and adding surfactant, i.e. lauryl sodium sulfate; adding the sizing into a polypropylene tank, sealing the polypropylene tank after adding corundum globules according to a ball-to-powder weight ratio of 1.5:1, slowly mixing the sizing till being uniform; then uniformly oscillating or mechanically stirring the sizing, and introducing air bubbles; transferring the sizing uniformly oscillated to a container of -17 DEG C, after freezing for 4 to 12 hours, extracting water in the frozen sizing at the room temperature or freezing condition, and then drying the sizing; and finally finishing sintering in air; wherein the sintering temperature is 1000-1200 DEG C, and the heat preservation time is 0.5-2h.

Owner:NORTHEASTERN UNIV

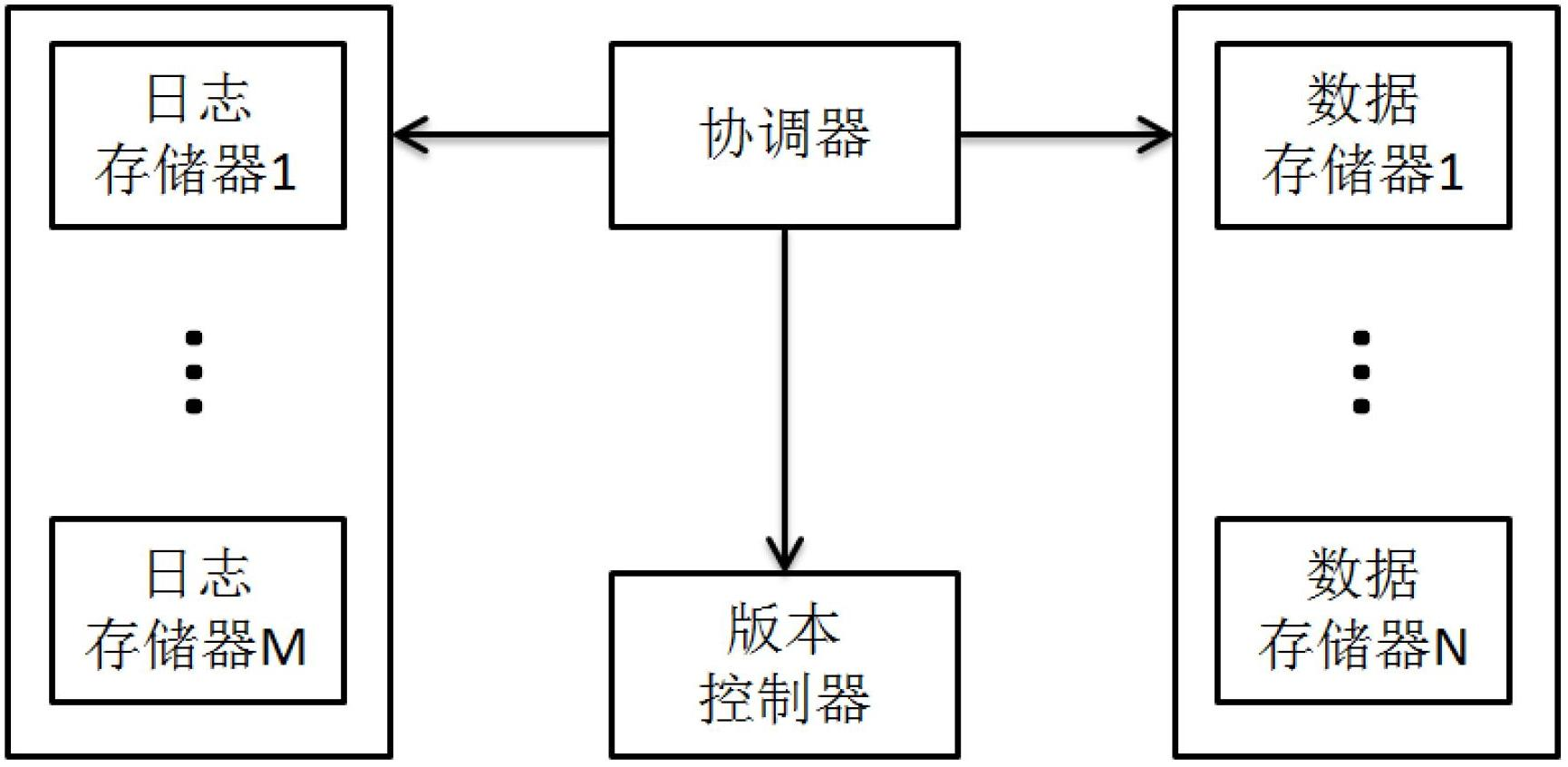

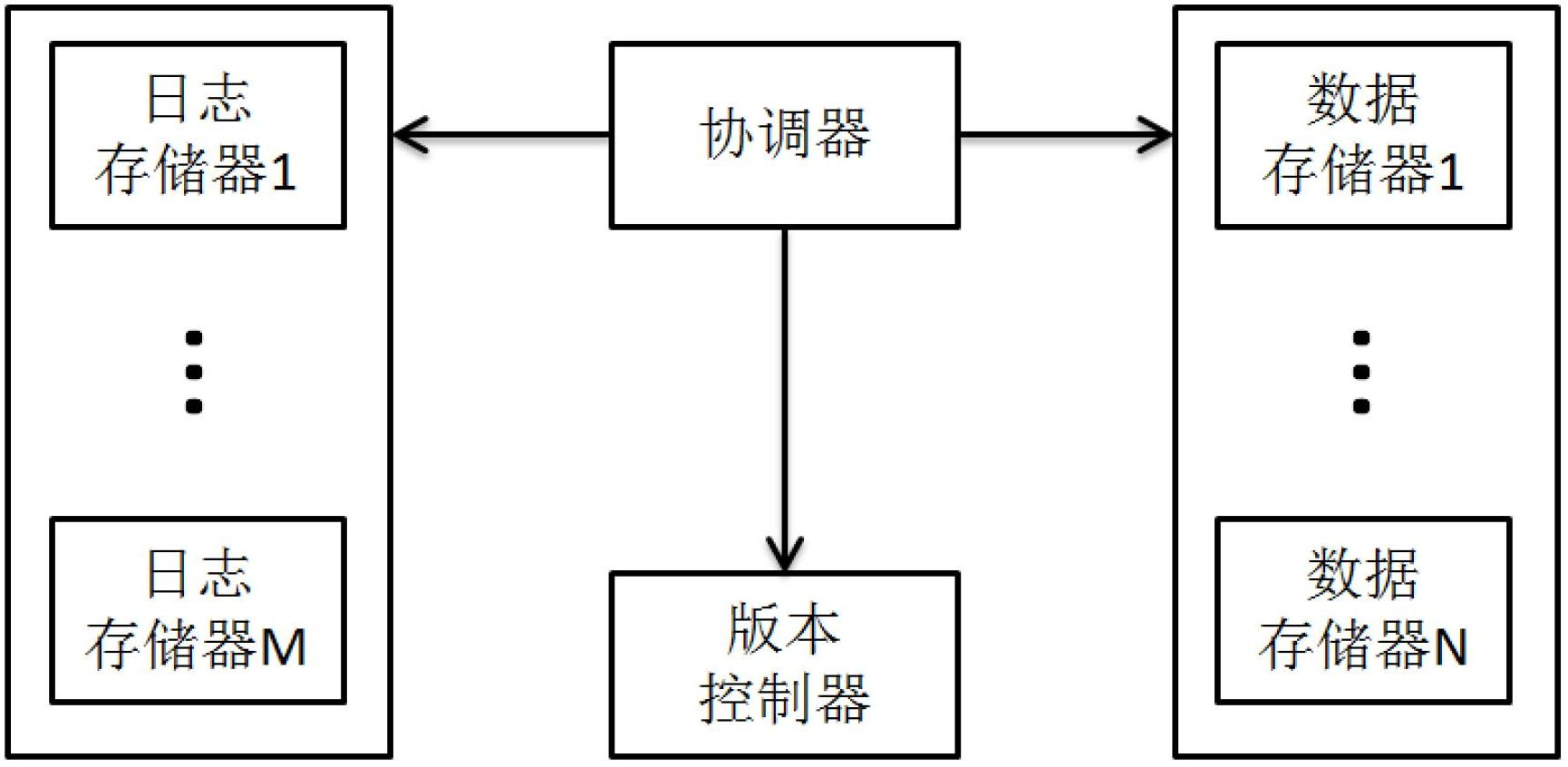

Flexible transaction management method in key-value store data storage

ActiveCN102693312AImprove concurrencyImprove fault toleranceSpecial data processing applicationsFault toleranceTransaction management

The invention belongs to the technical field of computer database management, and particularly relates to a flexible transaction management method in key-value store data storage, which includes the following steps: when data is written, a coordinative module packages a request into a log and obtains the existing log position, the Parkes algorithm is used to write the log into the new log position, the position is recorded, the successful operation information is returned, and the data and the log position are written into the data storage; when the data is read, the coordinative module obtains the newest log position and checks whether the data is updated, if the data is updated, the data is read and returned to the user, and if the data is not updated, the log is read, and the data is then corrected and read and returned to the user. The flexible transaction management method improves the concurrency, the fault tolerance and the expansibility of the key-value store data storage, can narrow the limitation range of the transaction as much as possible under the circumstance that the system consistency is ensured, and improves the concurrency of the system; and the design of the flexible transaction has high positive function in improving the flexibility and the adaptability of the database transaction.

Owner:TSINGHUA UNIV

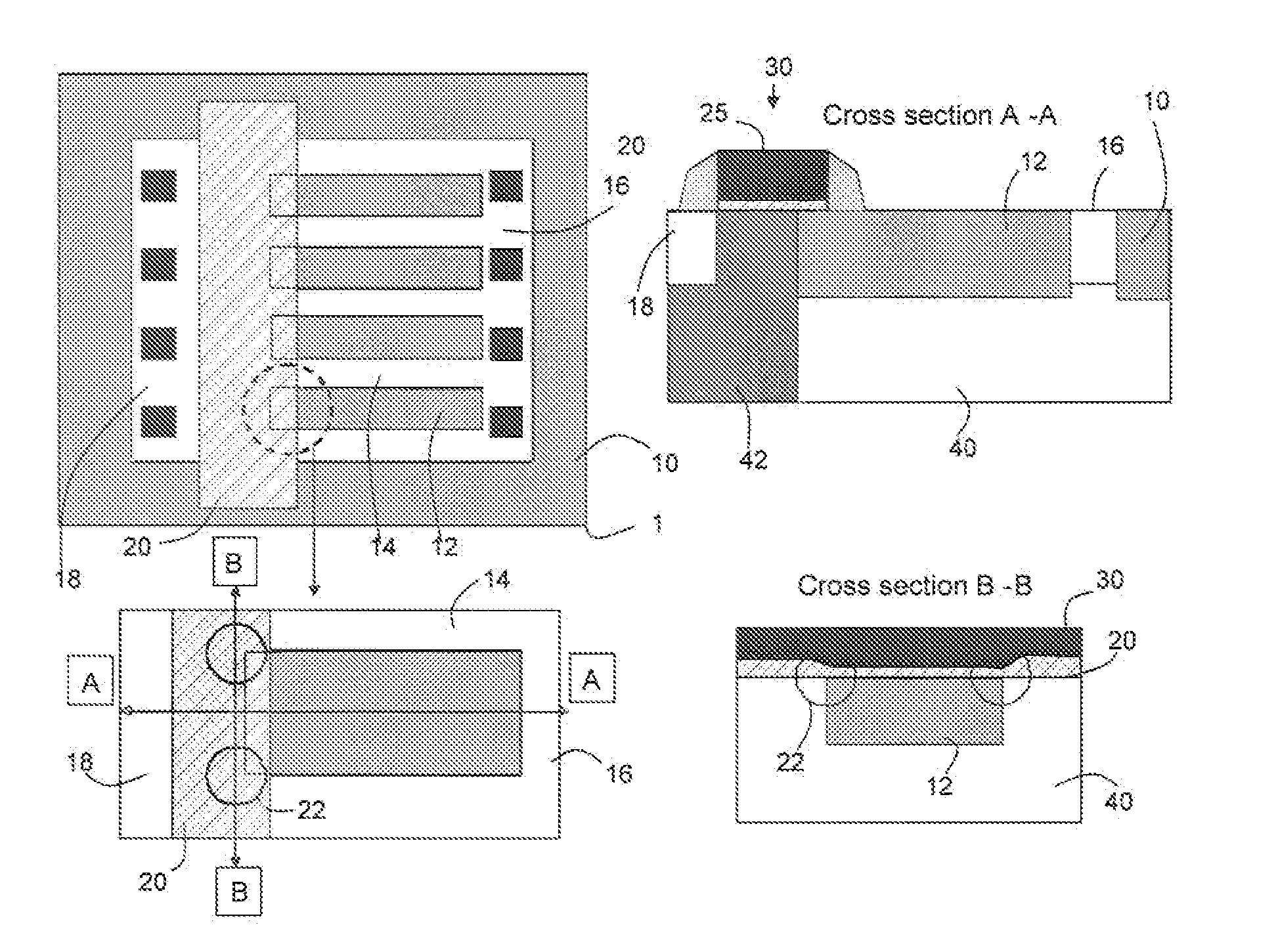

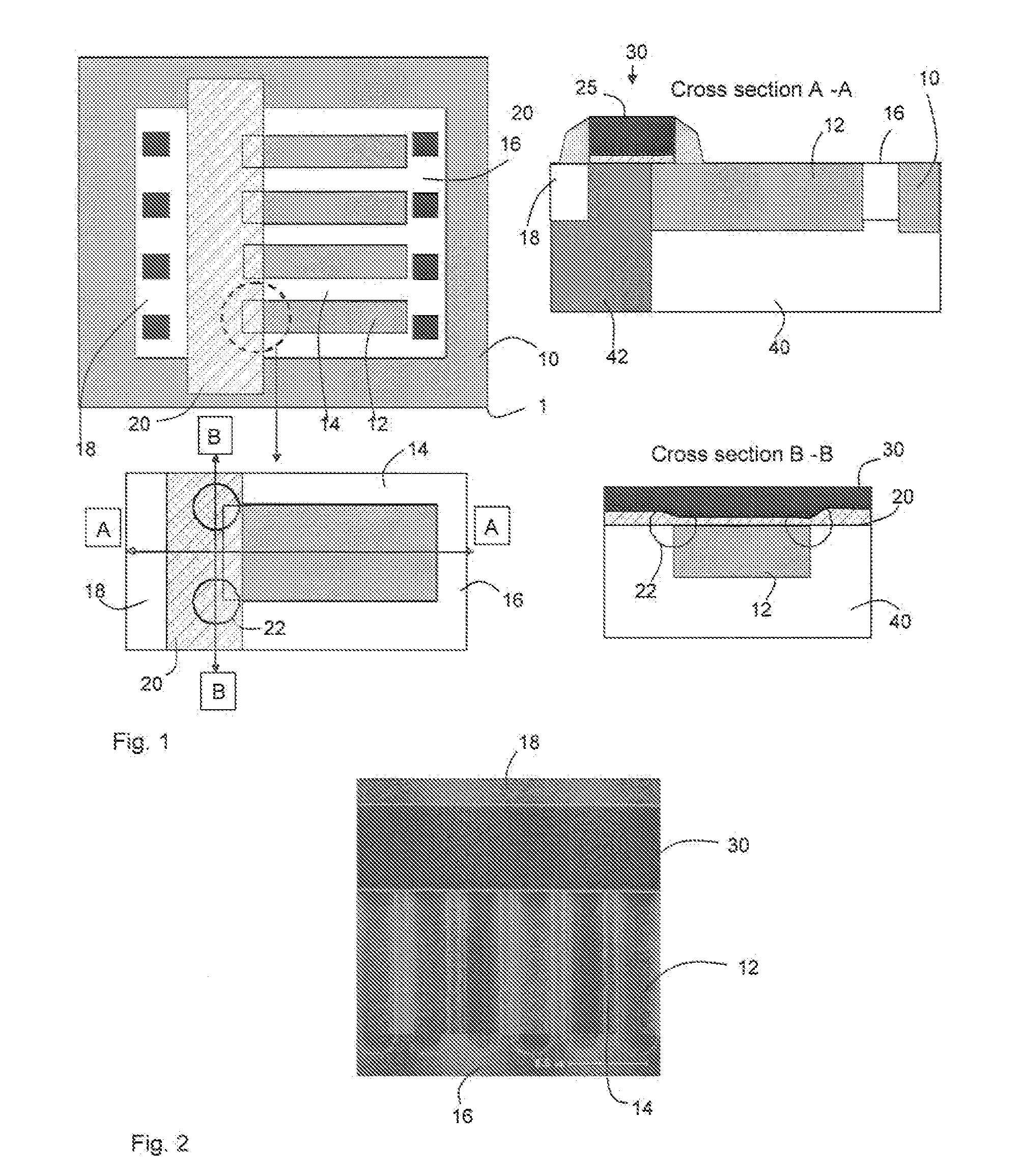

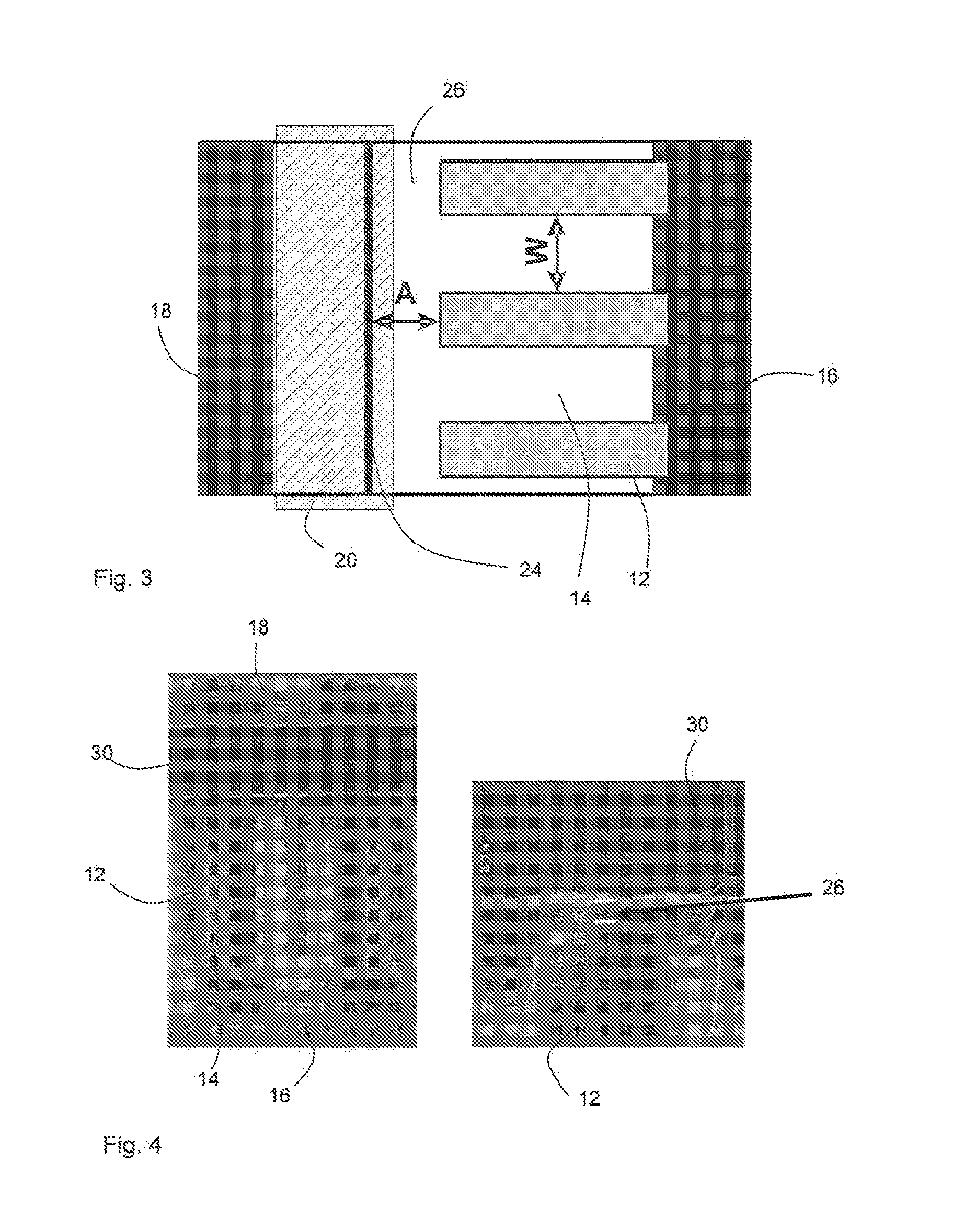

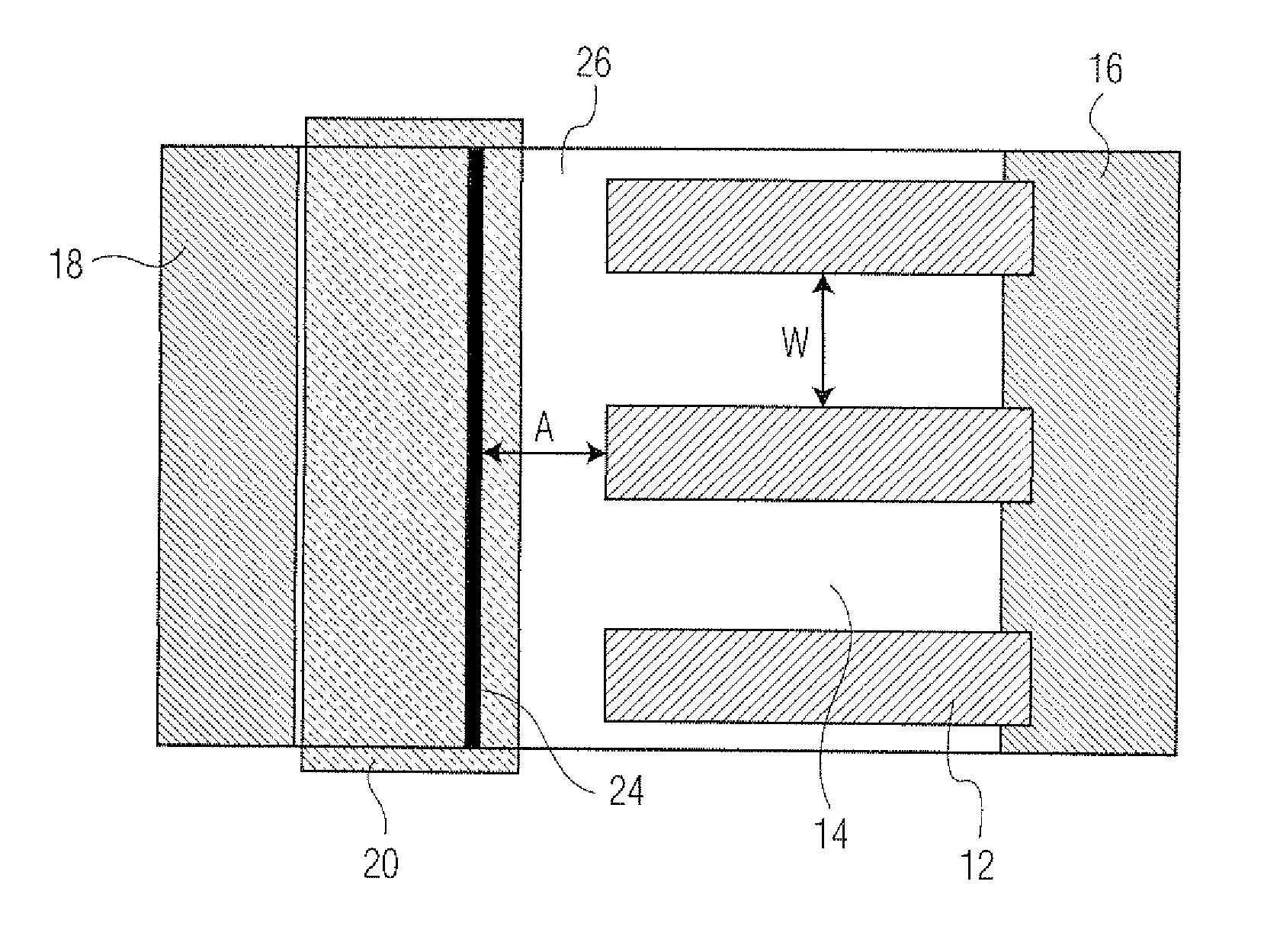

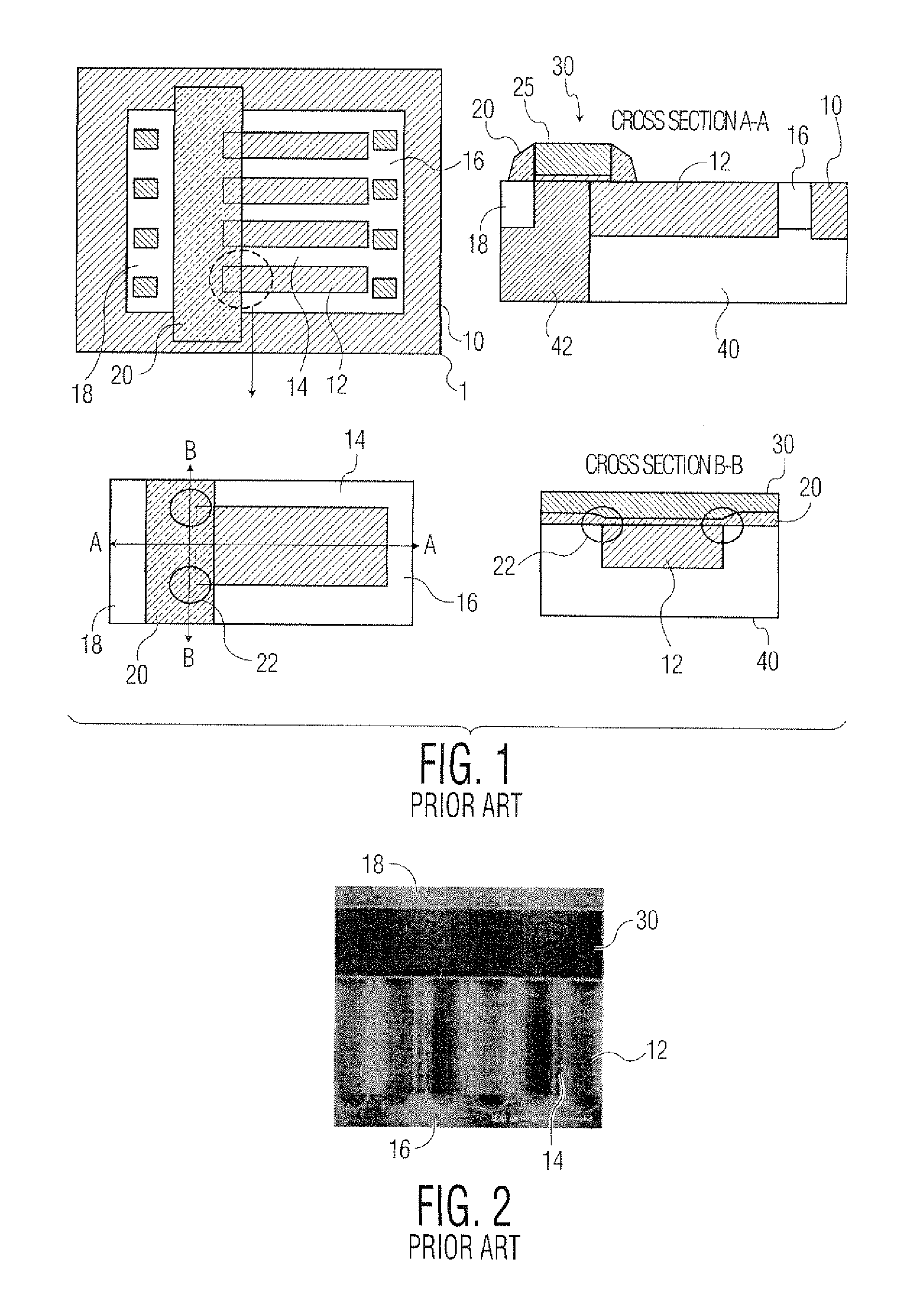

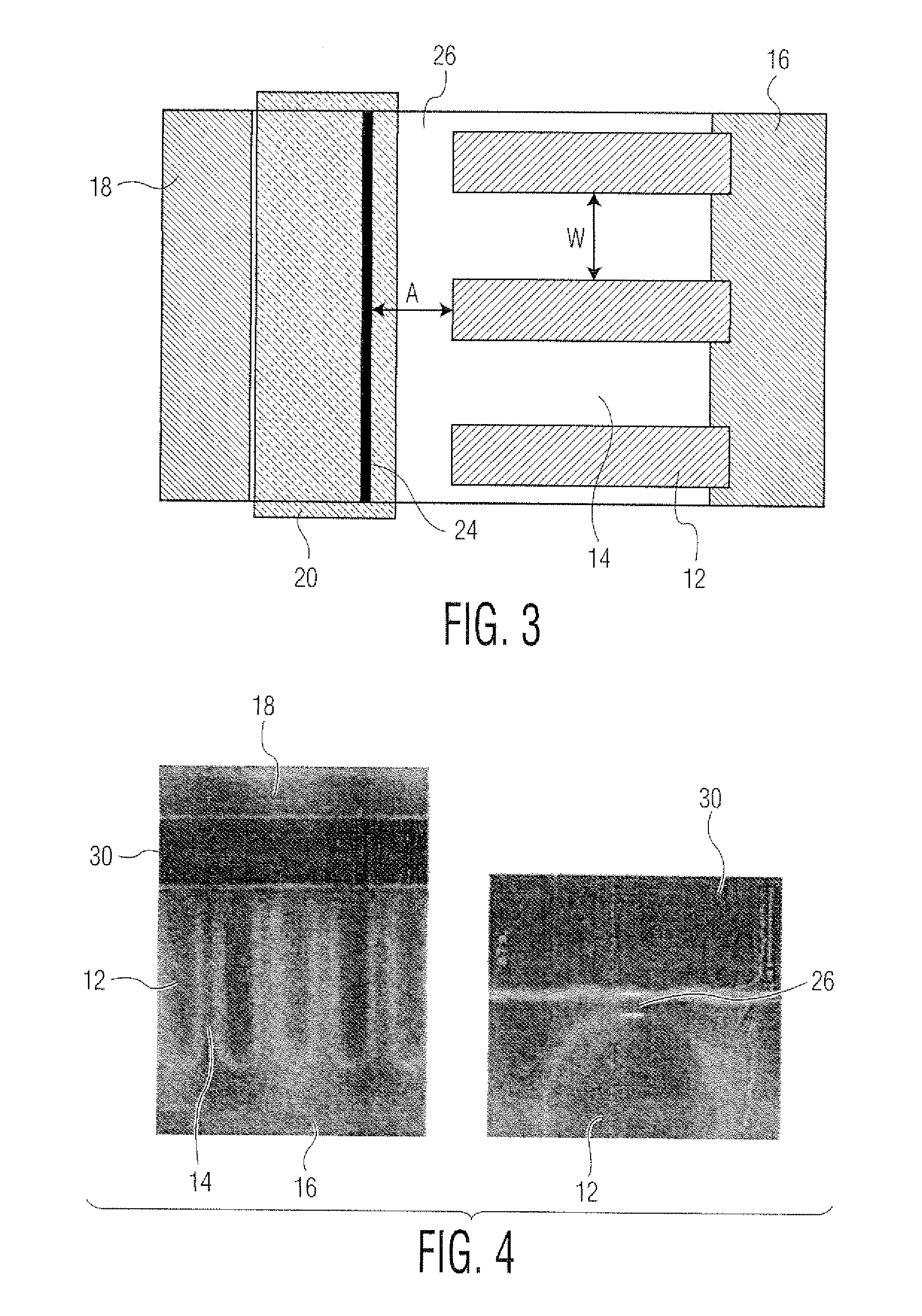

Semiconductor device and method of manufacturing such a device

ActiveUS20110198691A1Performance is not compromisedMore reliableSemiconductor/solid-state device manufacturingSemiconductor devicesPower semiconductor deviceMOSFET

A semiconductor device eg. a MOSFET (1) comprising a substrate (40) including a first region (18) and a second region (16) of a first conductivity type and a third region (42) between the first and second regions of a type opposite to the first conductivity type, and being covered by a dielectric layer (20), a plurality of trenches (12) laterally extending between the third and second region, said trenches being filled with an insulating material, and being separated by active stripes (14) comprising a doping profile having a depth not exceeding the depth of the trenches wherein each trench terminates before reaching the dielectric layer (20),namely is separated from the third region by a substrate portion (26) such that the respective boundaries between the substrate portions and the trenches are not covered by the dielectric layer. A method for manufacturing such a semiconductor device is also disclosed.

Owner:NXP BV

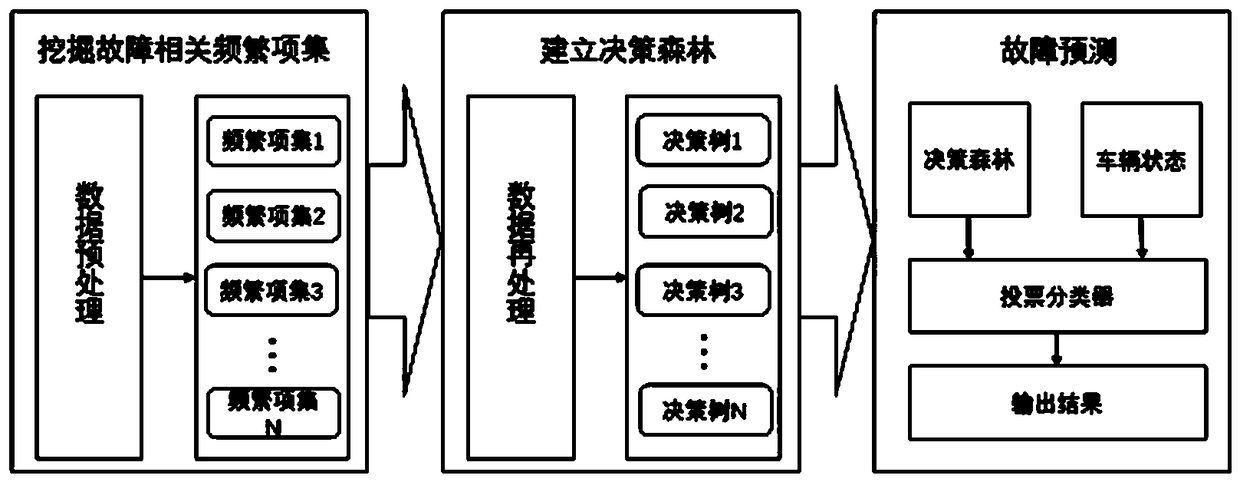

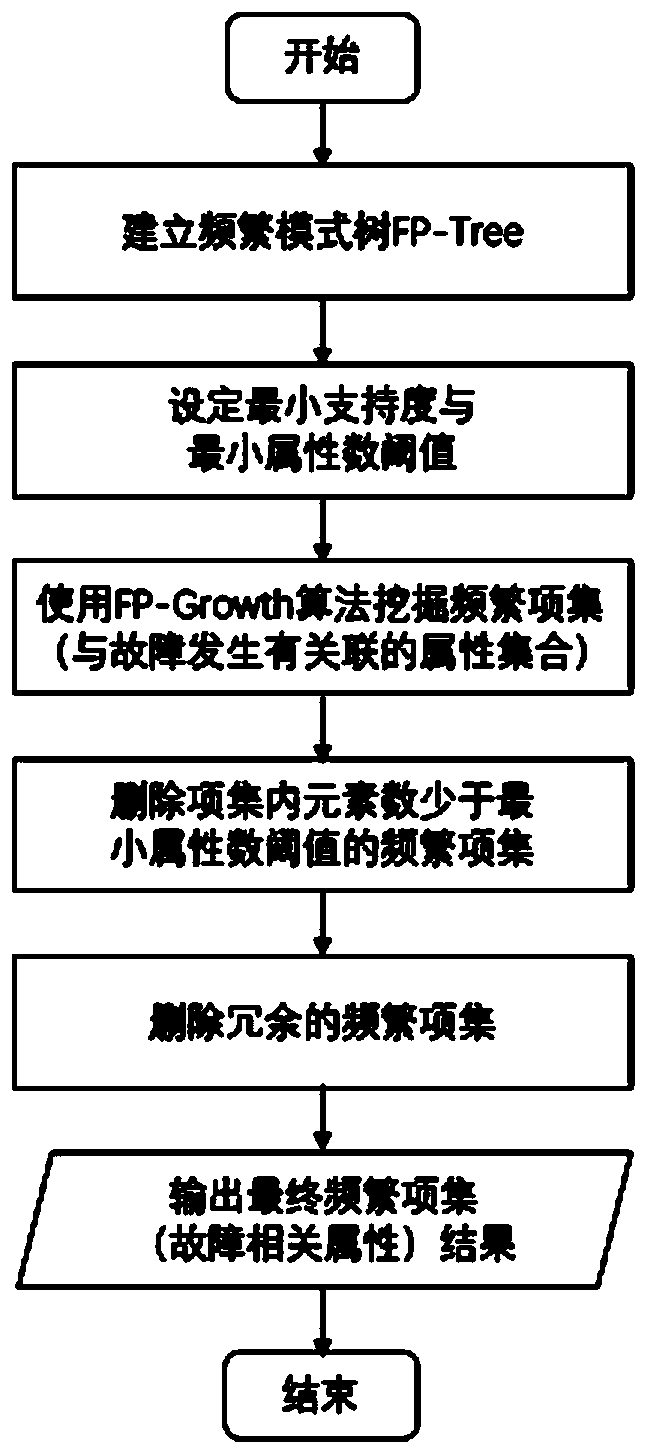

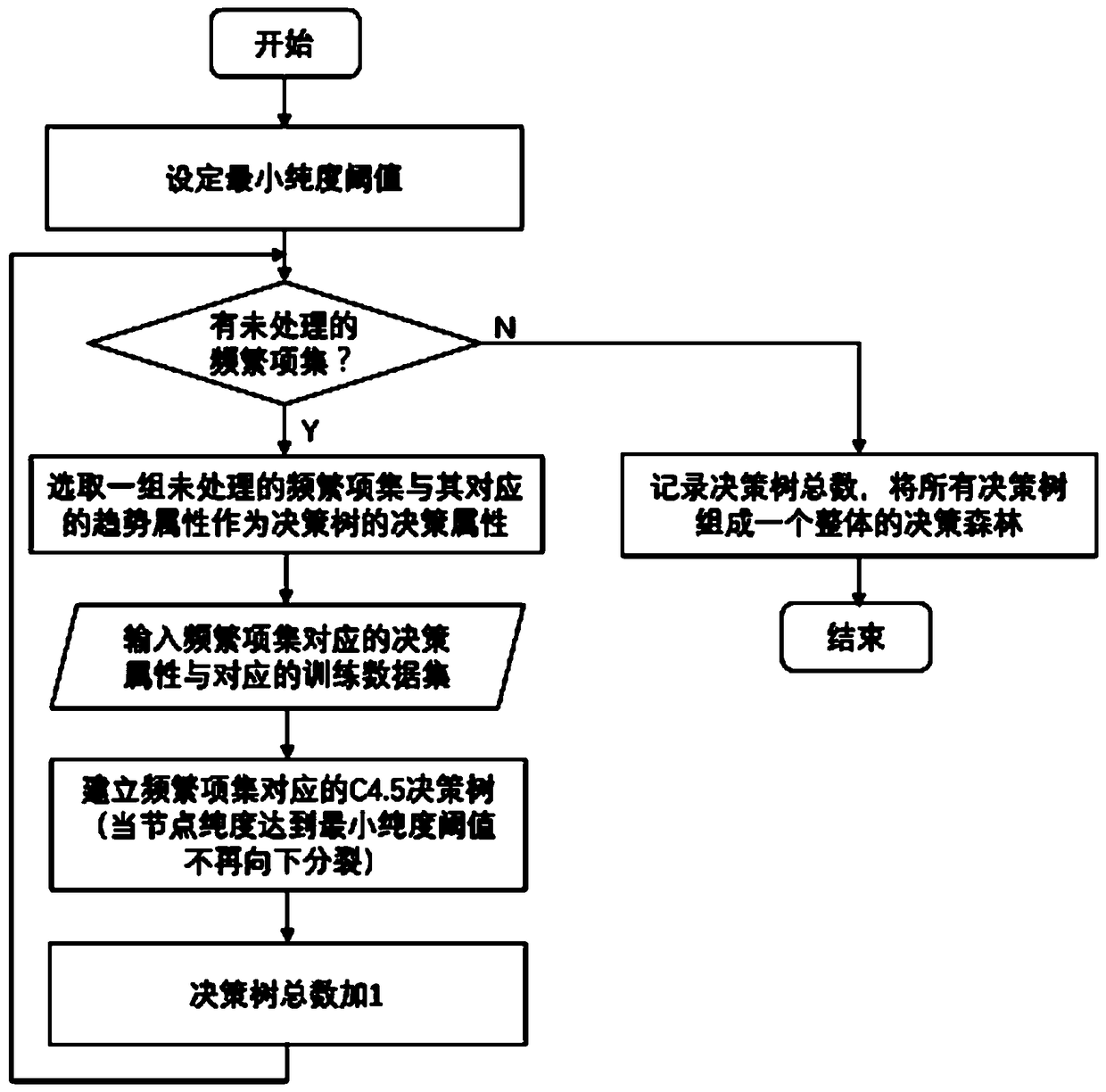

Data-mining-based engineering vehicle fault prediction system and prediction method

InactiveCN108958215AEasy to useEfficient and Fast Fault Prediction MethodProgramme controlElectric testing/monitoringComputer moduleFault occurrence

The invention, which belongs to the intersection field of data mining and engineering application, provides a data-mining-based engineering vehicle fault prediction system and prediction method. The fault prediction system comprises a mining fault-related frequent item set module, a decision-making forest establishment module, and a fault prediction module that are connected successively. The mining fault-related frequent item set module preprocesses basic data of an engineering vehicle to obtain a faulty vehicle attribute and acquires a frequent item set through the faulty vehicle attribute;the decision-making forest establishment module carries out data reprocessing, constructs a training set, and forms a decision-making tree and a corresponding decision-making forest and the fault prediction module carries out classification prediction on a fault risk of the engineering vehicle and outputs a result. Therefore, a rule relates to a fault is obtained from lots of irregular engineeringvehicle working condition information; a possible fault is predicted by using the existing engineering vehicle working condition information effectively; and the prediction method is one with fast operation and high efficiency.

Owner:TIANZE INFORMATION IND

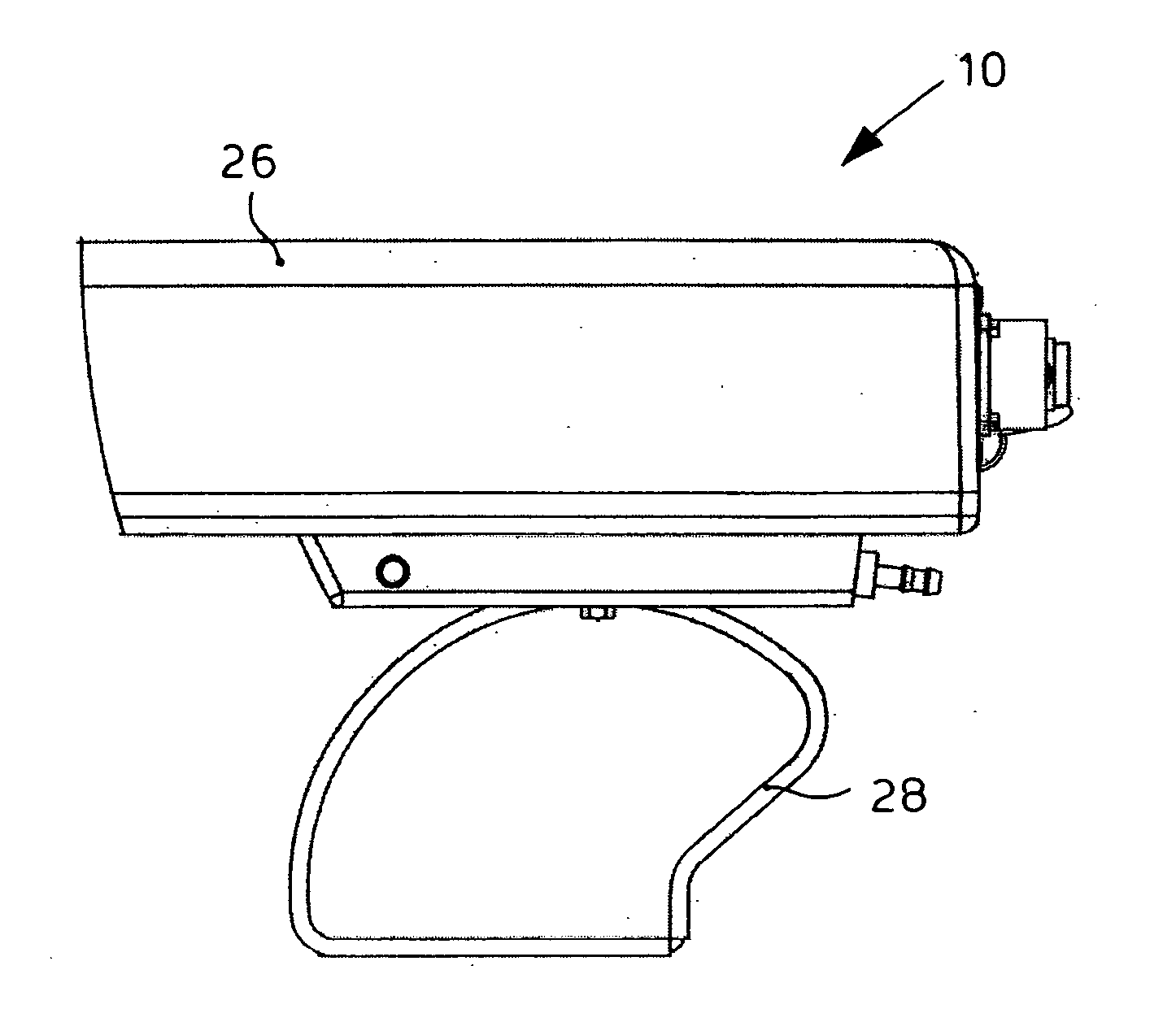

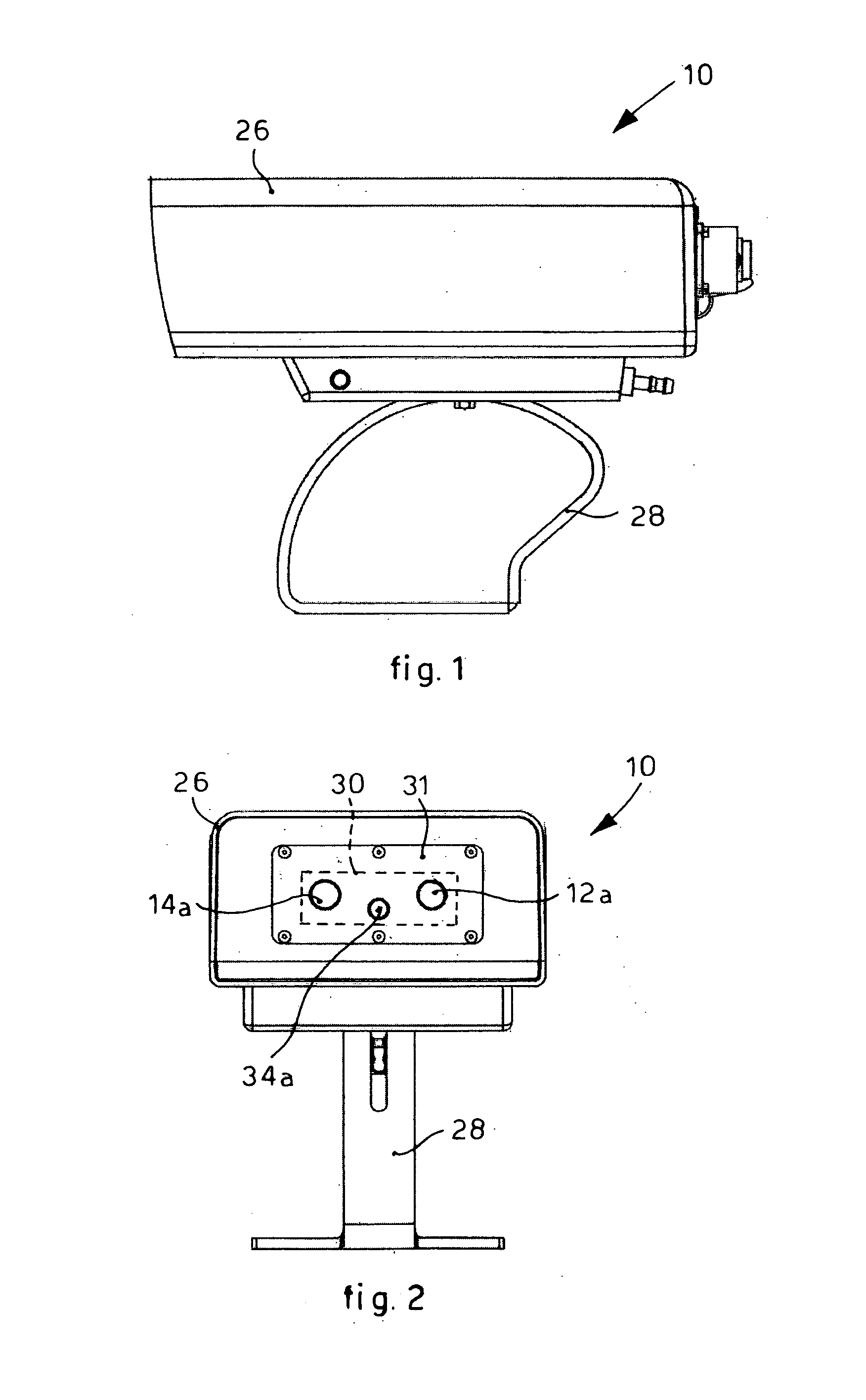

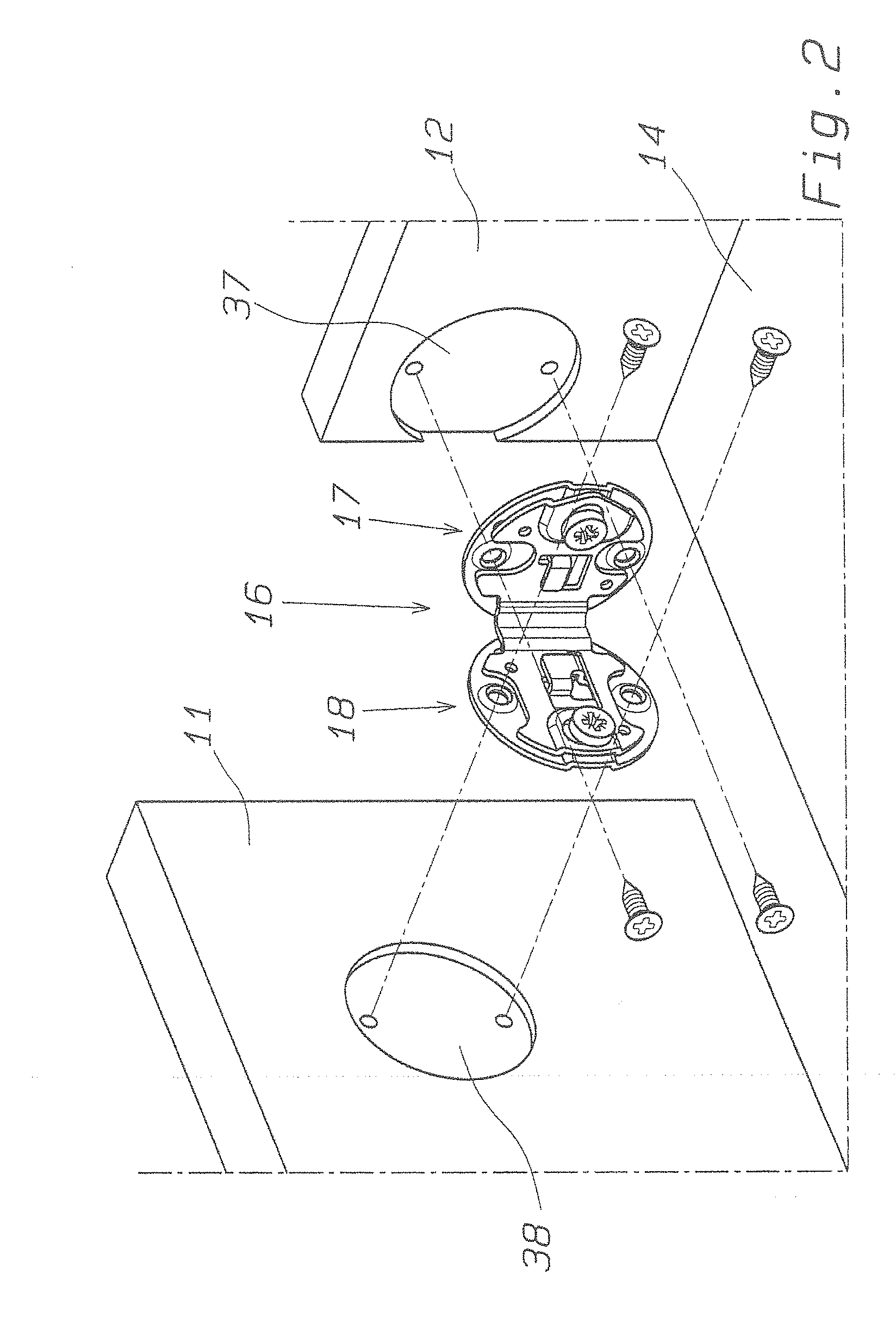

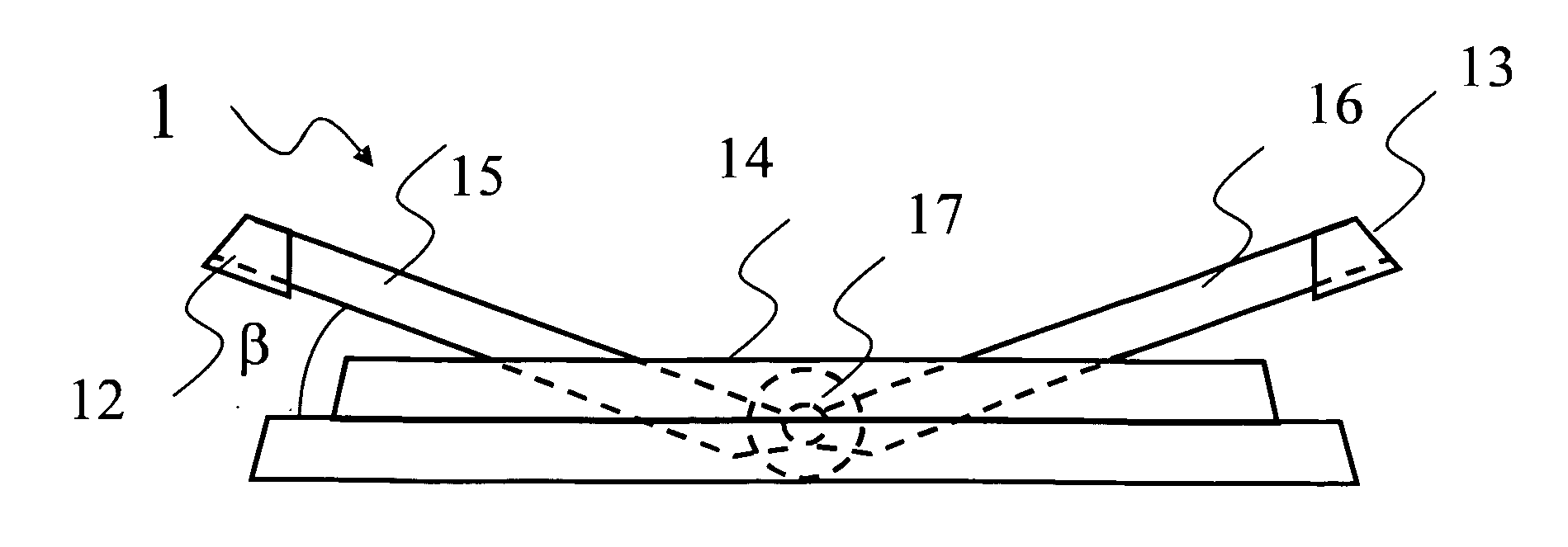

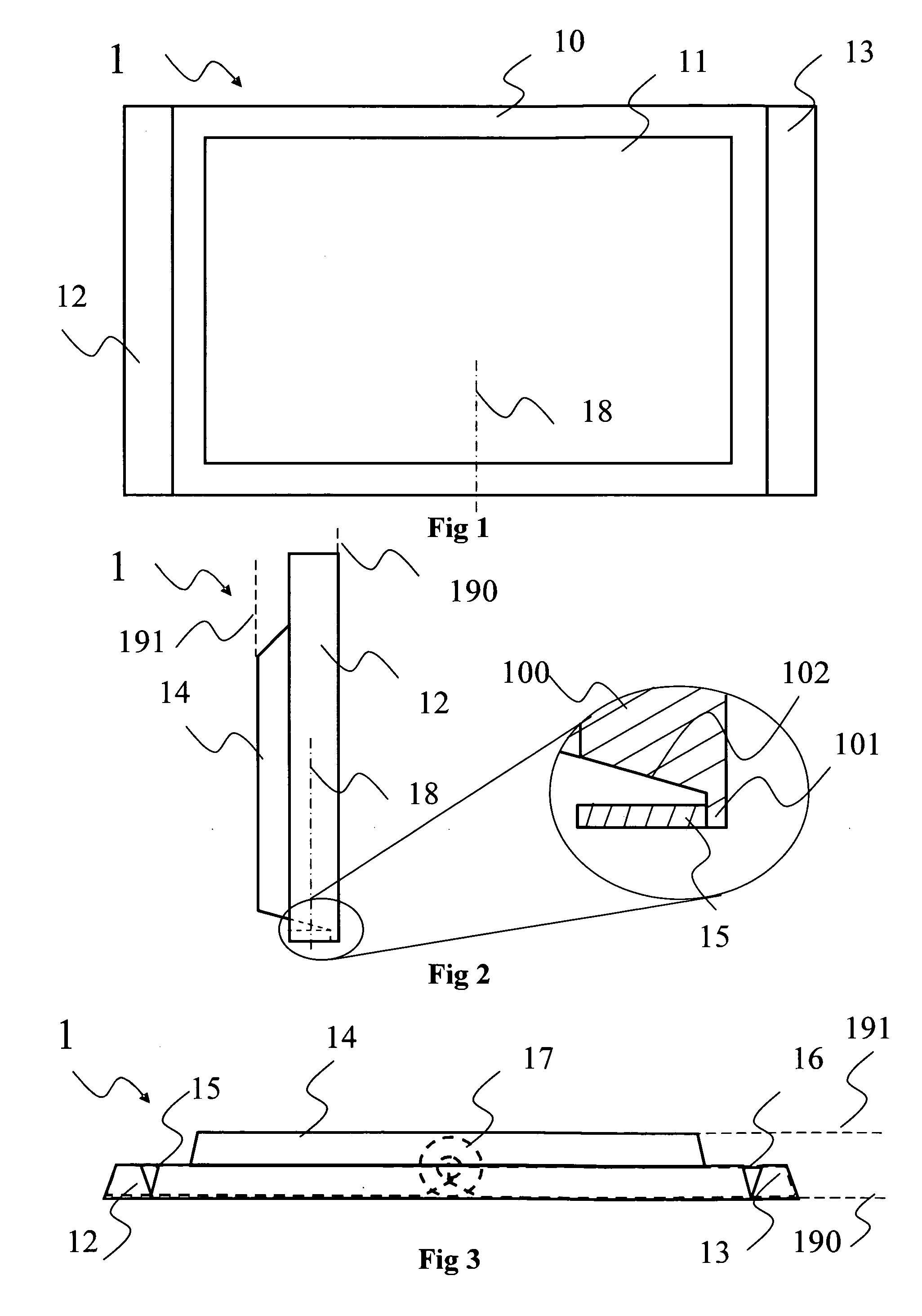

Device for Measuring the Speed of Products in Movement, in Particular Metal Rolled Products in a Rolling Line, and Relative Method

ActiveUS20120303315A1Facilitate correct trainingHighly reliable detectionAverage speed measurementDigital computer detailsEngineeringRadiation sensor

Device for measuring speed of oblong products moving along feed direction and emitting radiations, in particular rolled metal products in rolling line, including two radiation sensors, disposed reciprocally at close distance respectively defining an optical observation window, at pre-arranged distance from each other. Each window covers the image of an advancing product determinate portion equal to relative window width, irrespective of portion's movements transverse to feed direction. Sensors observe the presented product portion, on each occasion, in correspondence with associated windows consecutively along feed direction, and measure continuously intensity of radiation from the product portion in correspondence with the windows. Electronic processing unit determines, by processing electric signals associated with detected radiation intensity and arriving from sensors, using algorithms based on the correlation principle, time taken by the product portion to transit from first window to second, successive window, and then, based on distance between windows, calculates product speed.

Owner:DANIELI AUTOMATION SPA

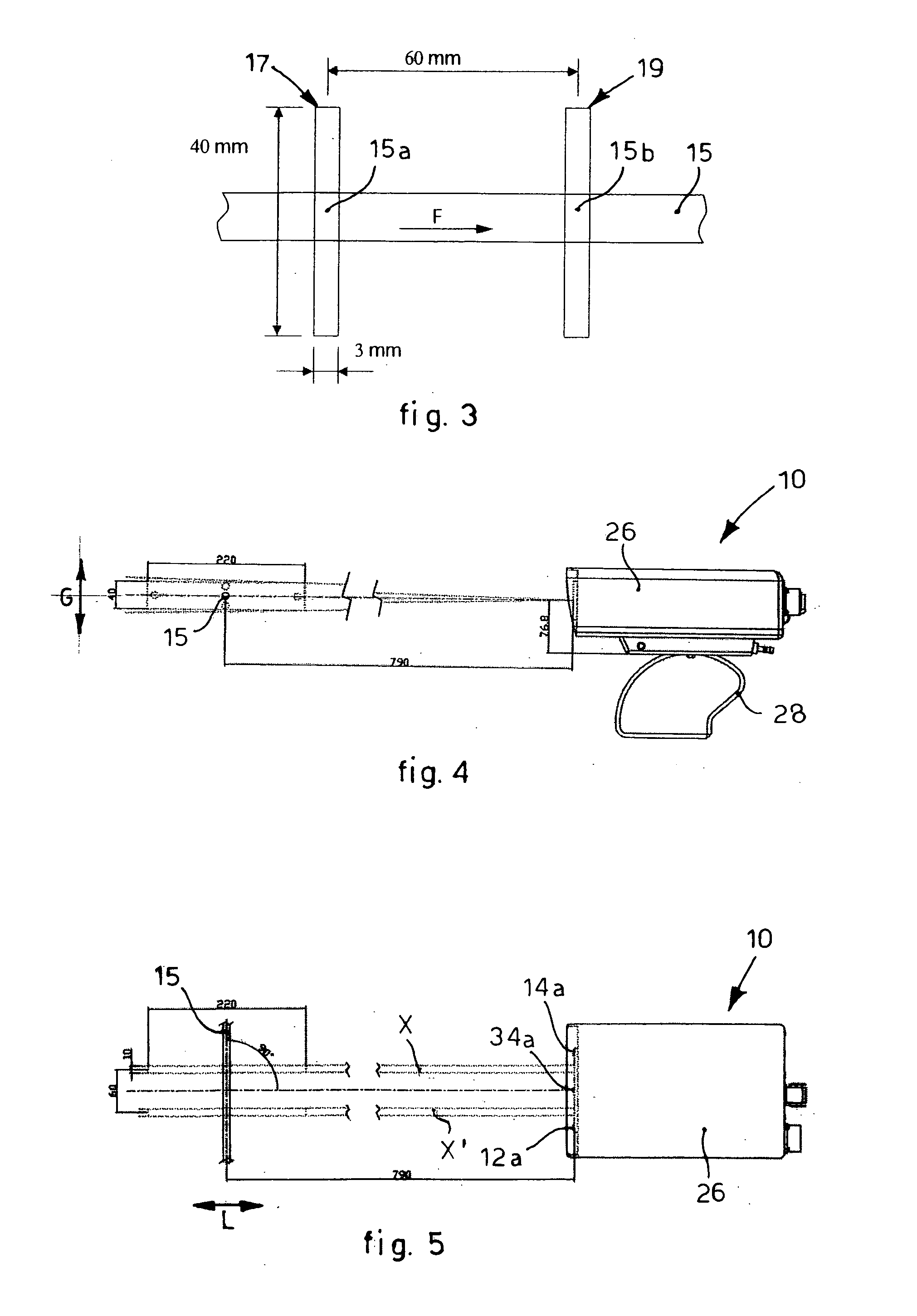

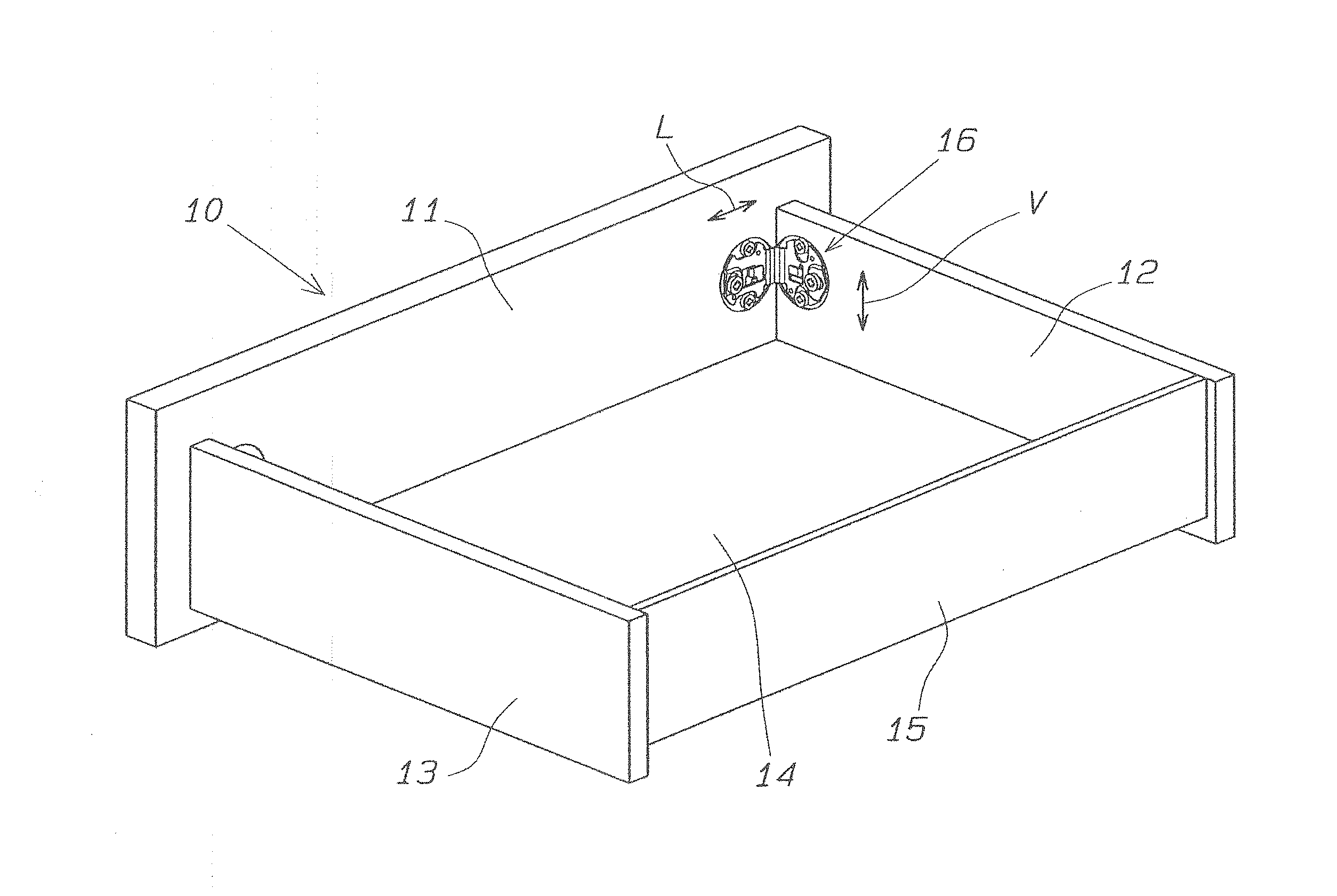

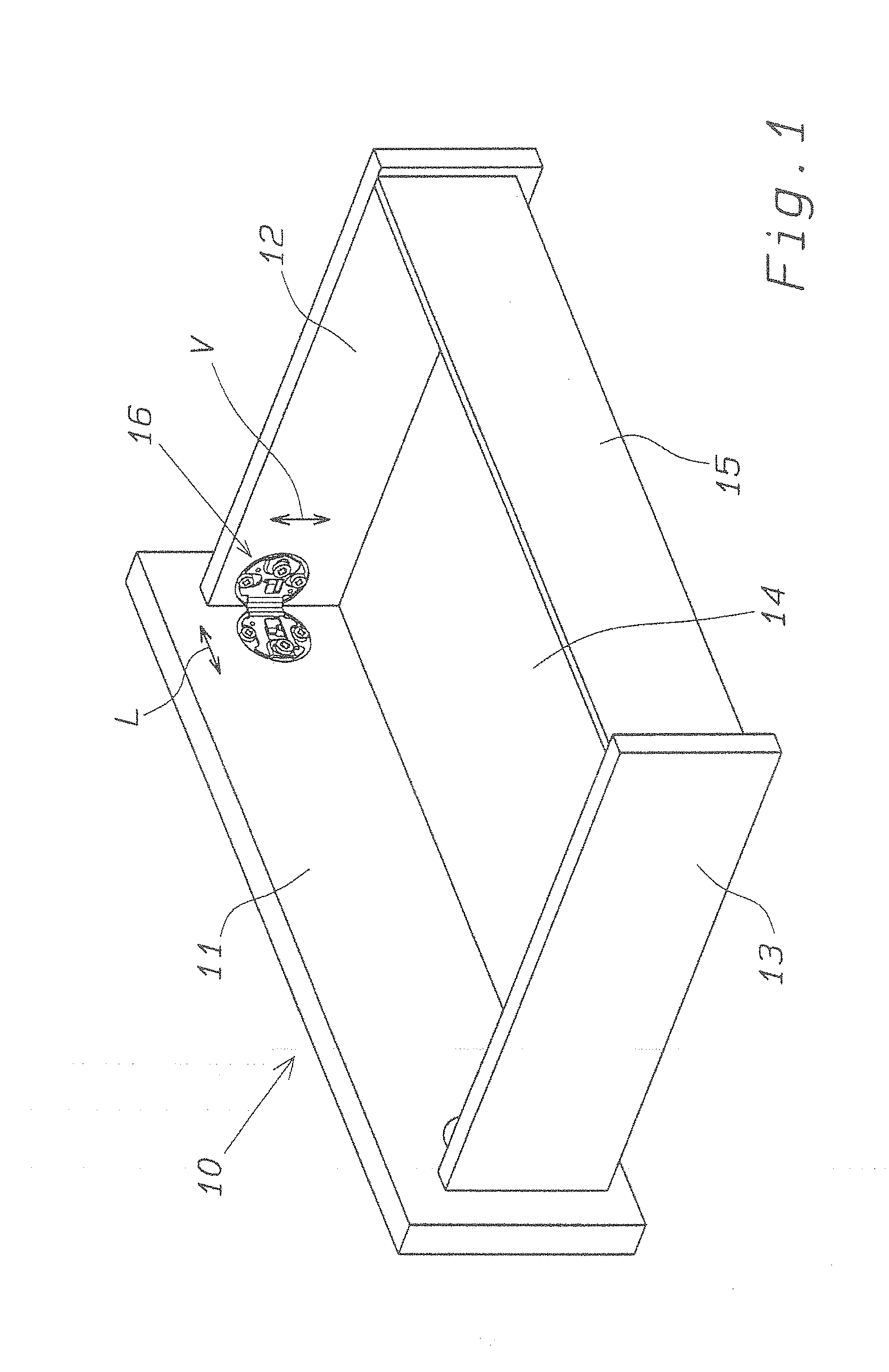

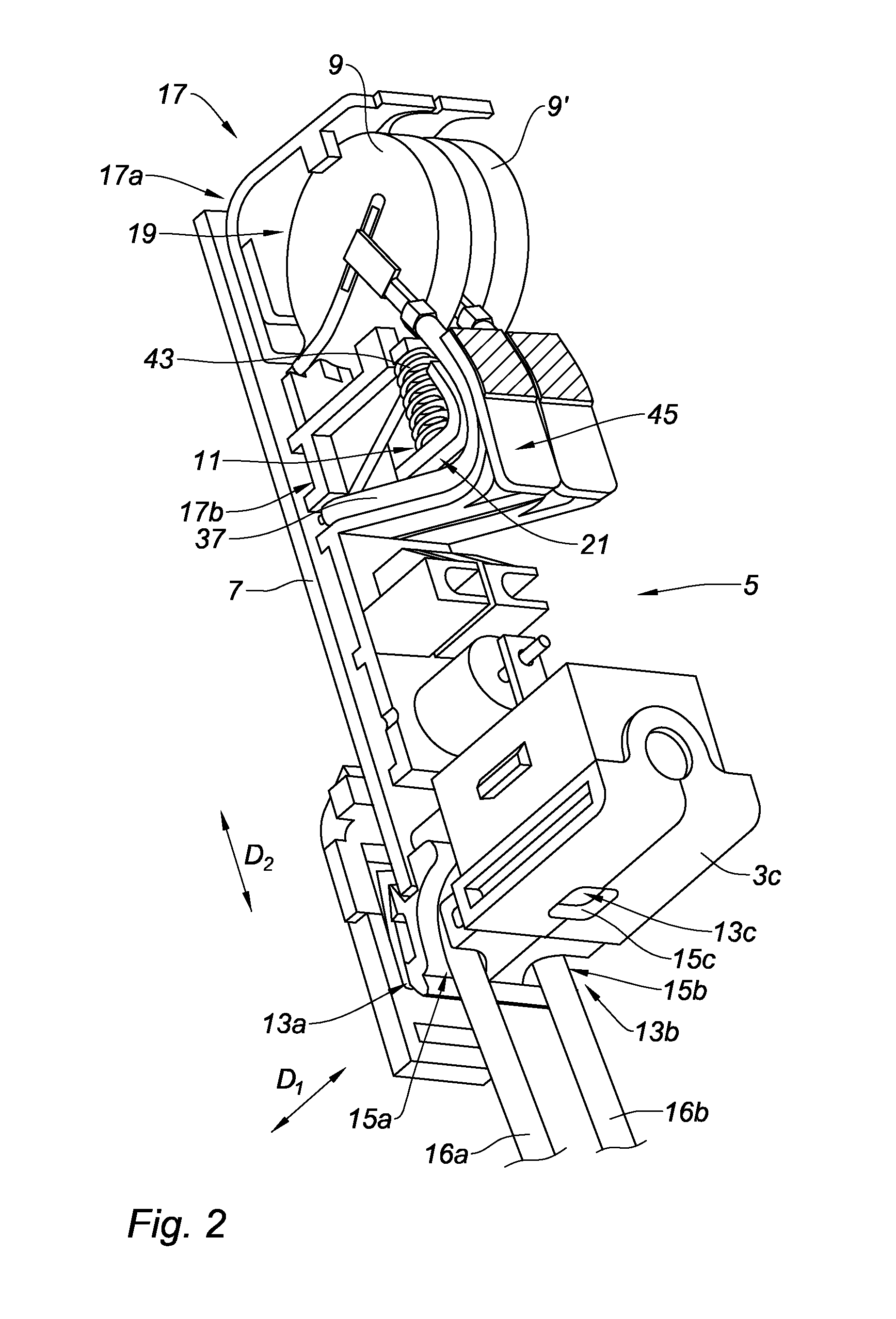

An Adjustable Fixing Device of a Front Panel of a Drawer or the Like, and a Drawer Provided with the Adjustable Fixing Devices

InactiveUS20150359334A1Limited sizeImproved structure is simpleDrawersFurniture joiningEngineeringLateral position

The device (16) for adjustably fixing a front panel (11) to side walls (12, 13) of a drawer (10) or the like comprises a first part (17) fixable to a side wall (12, 13) of the drawer (10), and a second part (18) fixable to the front panel (11) of the drawer (10); the first part (17) and / or the second part (18) comprise at least a first and a second element (19, 20; 21, 22; 43, 44, 45) connected slidably to one another along a vertical and / or lateral direction, between which adjusting means (31, 32; 53, 54) are interposed so as to adjust the vertical and / or lateral position of the front panel (11) with respect to the lateral walls (12, 13) of the drawer (10).

Owner:ARTURO SALICE

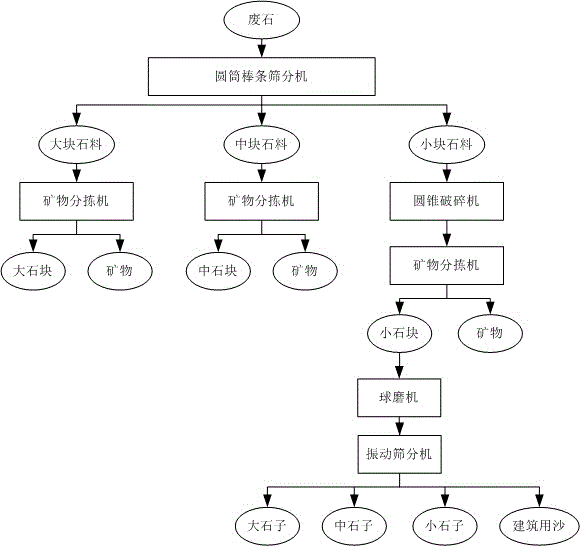

Machining method for comprehensive utilization of waste rock of Hainan Shilu iron mine

The invention discloses a machining method for comprehensive utilization of waste rock of the Hainan Shilu iron mine. According to the machining method, the waste rock is evenly fed into a first screening machine through a feeding machine, and the first screening machine screens the waste rock into three types including large rock, medium-sized rock and small rock; minerals and large stone are sorted out from the large rock through a mineral sorting machine; minerals and medium-sized stone are sorted out from the medium-sized rock through a mineral sorting machine; the small rock is broken through a breaker and then conveyed into a mineral sorting machine, and minerals and small stone are sorted out; and the small stone and powder are fed into a ball mill to be ground, the ground small stone and the ground powder are then conveyed into a second screening machine, and then gravel and building sand of three specifications including the large size, the medium size and the small size are screened out. By the adoption of the machining method for comprehensive utilization of the waste rock of the Hainan Shilu iron mine, the waste rock is recycled to be manufactured into products having the economic value, so that the economic benefit is improved, and the environment is protected.

Owner:杜建国 +1

Projector for defeating buried mines

An relatively small anti-personnel mine device having a housing about 2 to about 3 inches in diameter, by about 2 to about 4 inches in length, which device projects a dispersion pattern of ⅛ to ⅜ inch diameter hard fragments over at least a 3 to 4 inch radius circle to neutralize a typical, buried, anti-personnel mine. The device contains about 125 to 190 grams of plastic explosive, which when detonated impacts a gas push plate against which an array of the fragments are lodged—the gas push plate and the fragments being encased in a puck shaped matrix of plastic or resin. The effect of the device is such that in addition to neutralizing the mine, the overburden atop the buried mine is expelled exposing the mine, providing enhanced safety in removal and a warning if the mine is daisy-chained to other mines.

Owner:UNITED STATES OF AMERICA THE AS REPRESENTED BY THE SEC OF THE ARMY

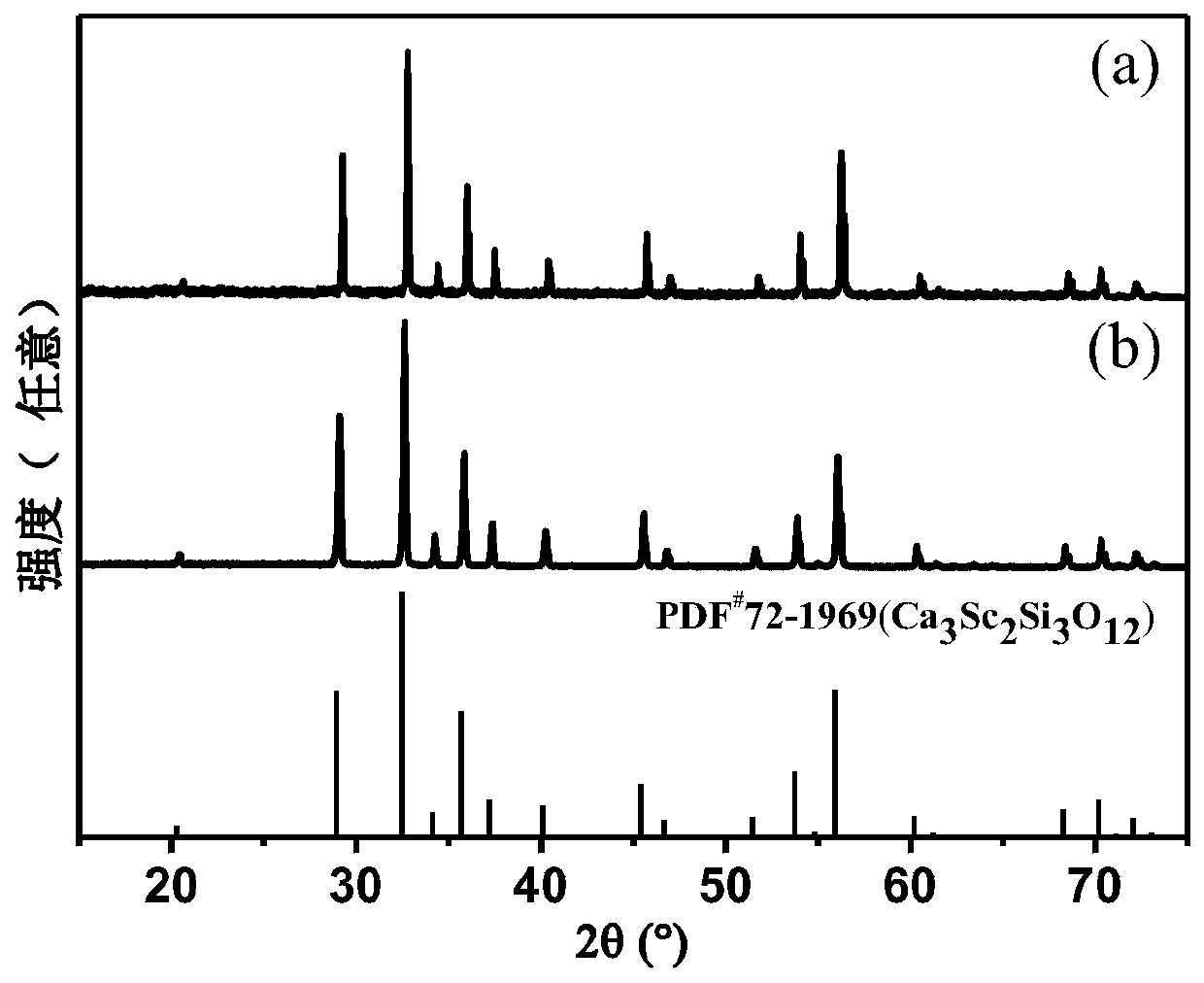

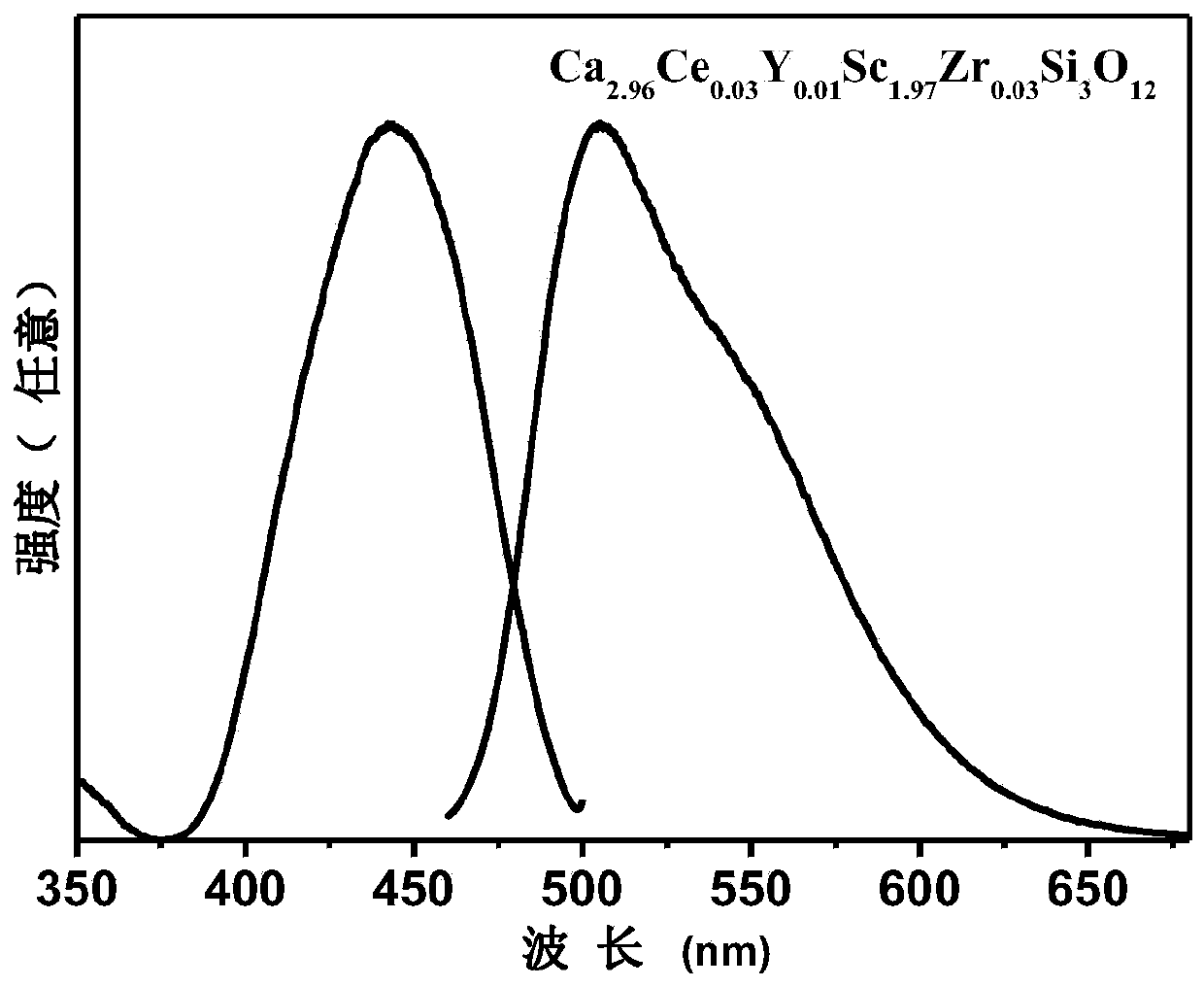

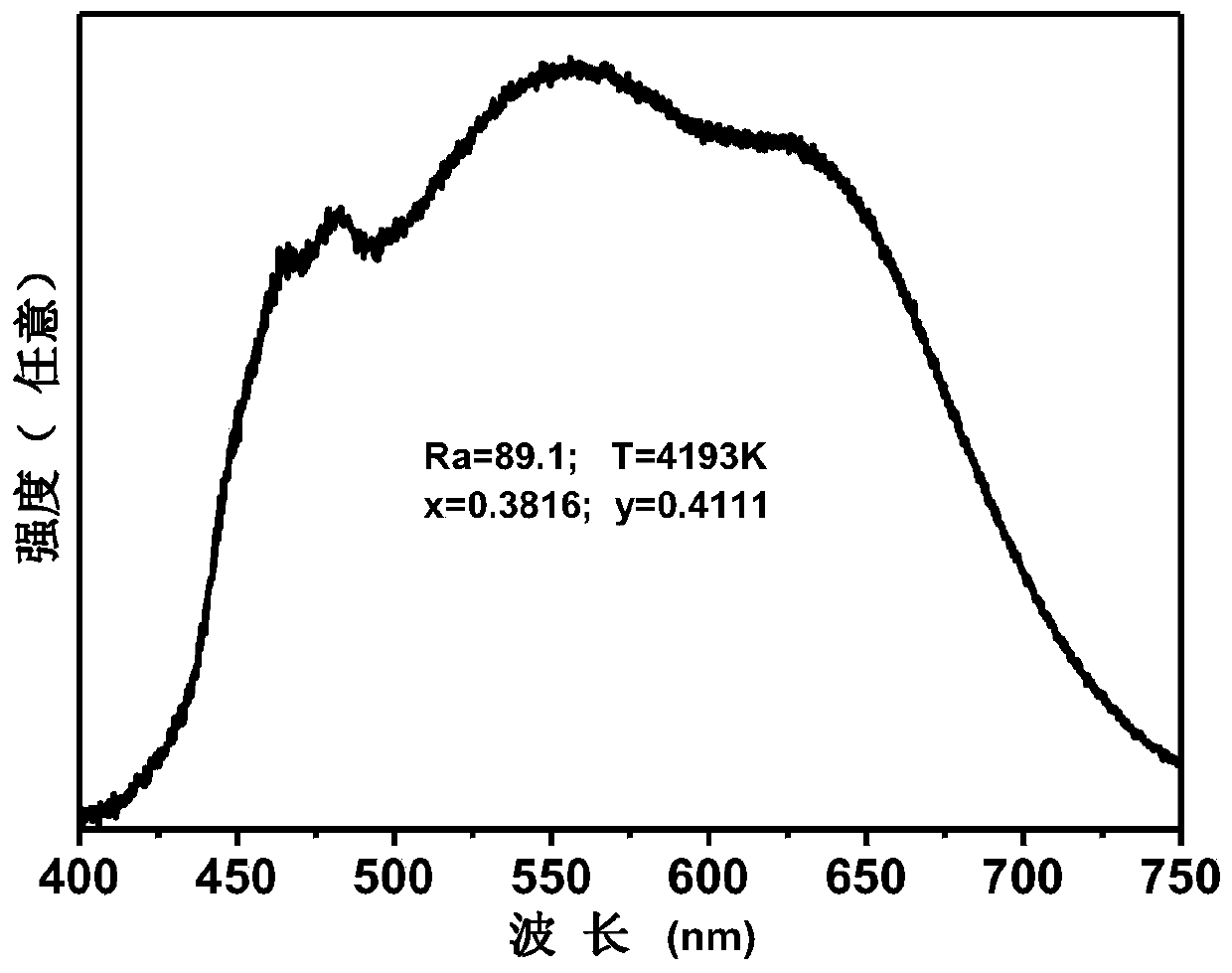

Fluorescent transparent ceramic capable of emitting blue-green light and preparation method thereof

The invention provides a fluorescent transparent ceramic capable of emitting blue-green light and a preparation method of the fluorescent transparent ceramic, belonging to the technical field of luminescent materials. The chemical formula of the transparent ceramic is as shown in (I): (Ca<1-x-y>Ce<x>R<y>)<3>(Sc<1-z>L<z>)<2>(Si<1-m>K<m>)<3>O<12>, wherein R is one or more selected from the group consisting of elemental Y, Gd, La, Lu, Tb, Li and Na; L is one or more selected from the group consisting of elemental Zr, Hf and Mg; K is one or two selected from the group consisting of elemental Al and P; x is greater than or equal to 0.0002 and less than or equal to 0.02; y is greater than or equal to 0 and less than or equal to 0.03; z is greater than or equal to 0 and less than or equal to 0.02; m is greater than or equal to 0 and less than or equal to 0.02; and the sum of y, z and m is greater than 0 and less than 0.05. The invention also provides a preparation method of the fluorescent transparent ceramic capable of emitting blue-green light. The transparent ceramic disclosed by the invention can be effectively excited by blue light and emits broadband blue-green light with a peak value of 505 nm, so high-power monochromatic green light LED / LD can be prepared.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

Shot-blasting machine for surface treatment of procucts

ActiveUS20100130110A1Limited sizeDrawback can be obviatedImpeller wheelsRotor bladesEngineeringPeening

The shot-blasting machine for surface treatment of products comprises a base frame, a containing chamber for containing at least a product to be treated associated to the base frame and provided with at least an access opening, one or more projecting organs associated internally of the chamber for projecting a flow of shot-blasting particles onto the product, and automated unloading means associated to the base frame which cause the product to exit from the chamber through the access opening.

Owner:C M SURFACE TREATMENT

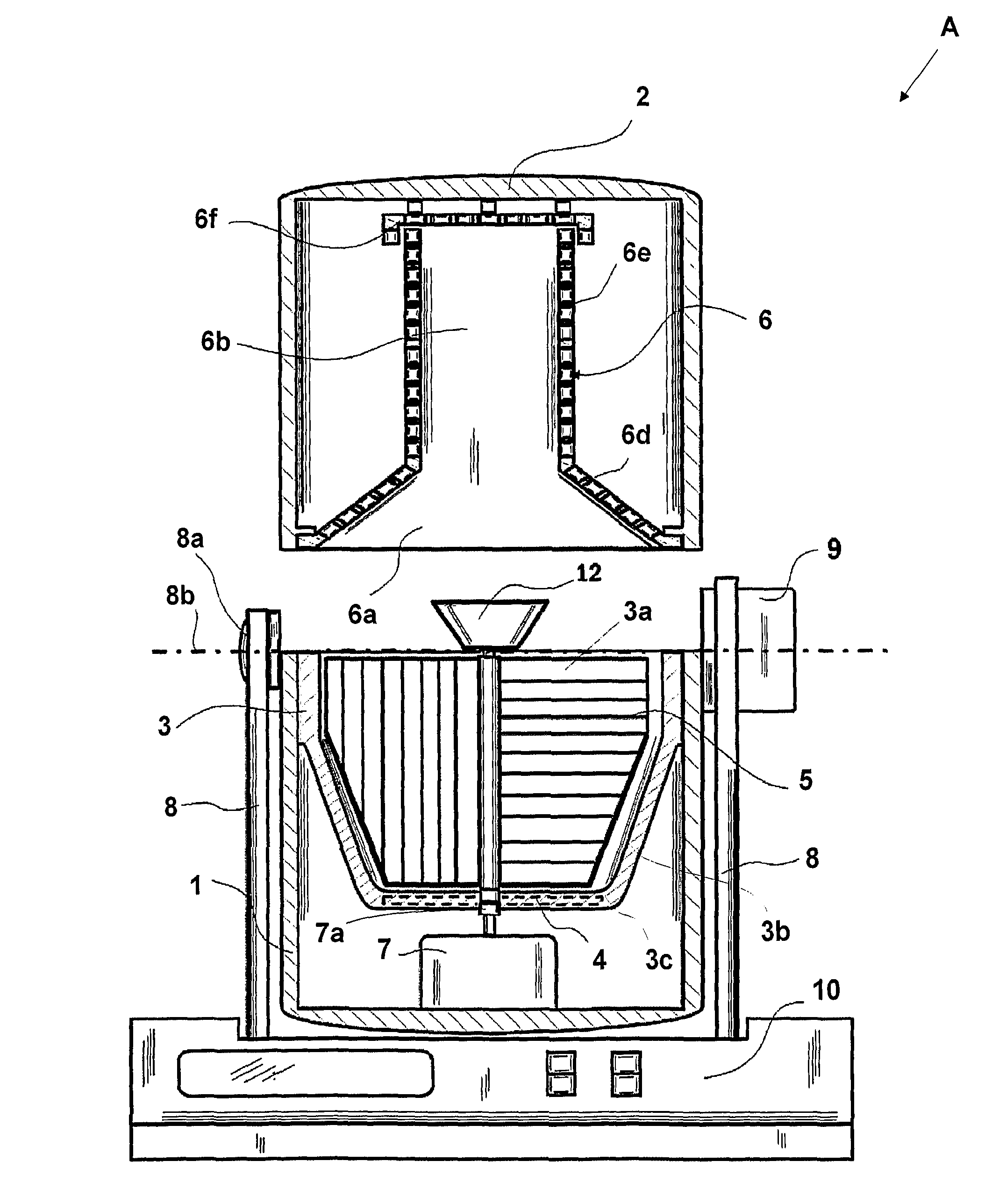

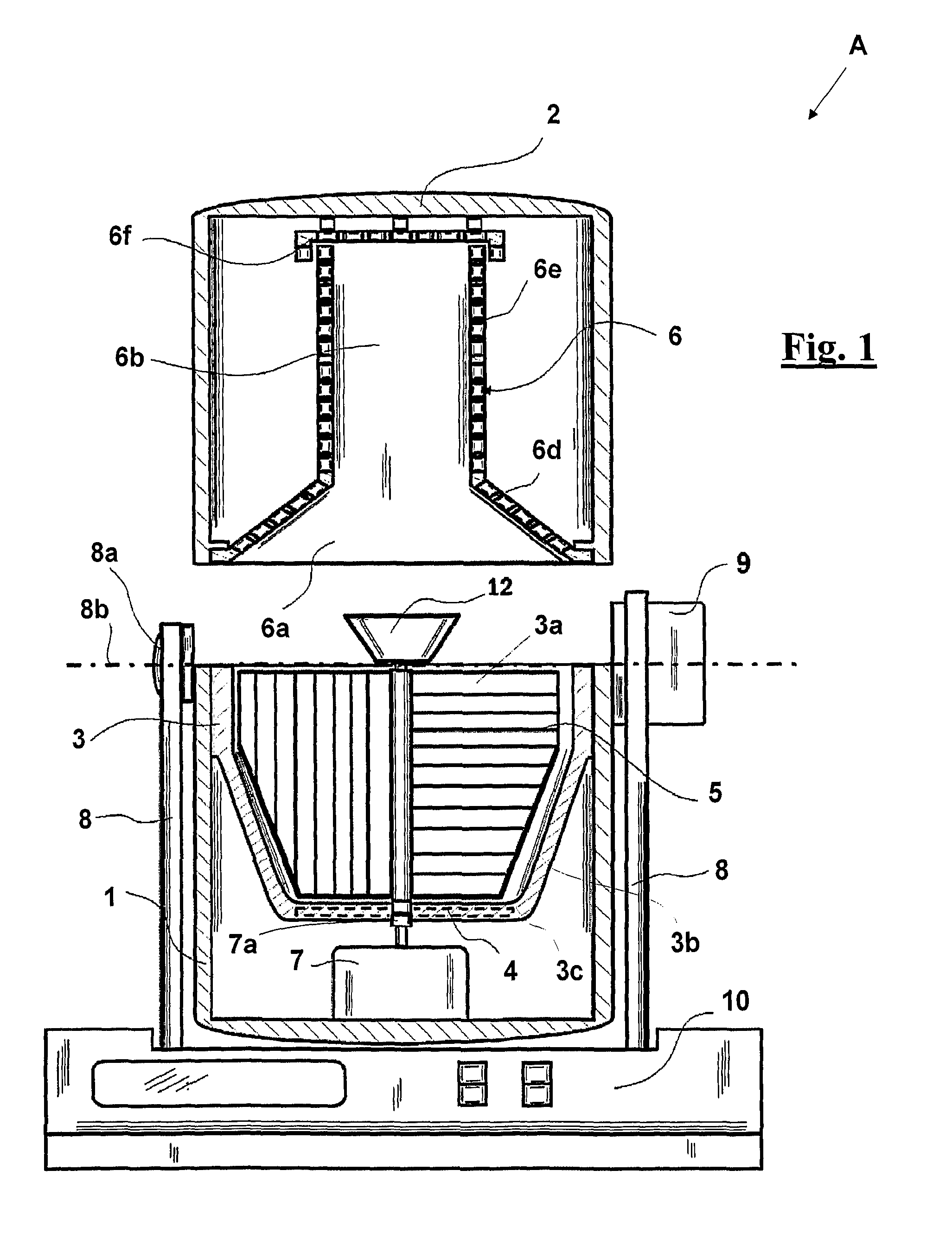

Device for making cheese, other milk-derivatives and tofu

ActiveUS8534189B2Limited sizeSimple structureMilk preservationJuice extractionEngineeringMechanical engineering

Compact machine for making cheese, other milk-derivatives and tofu comprising a shell (1) in which an impermeable basin (3) is inserted, a collecting container (2) in which a permeable basket (6) is inserted for collecting the product and a support structure comprising a lower base member (10) having two side arms (8). The machine comprises, furthermore, a motor (7) integral to the shell (1) for operating a stirring member (5), and heating means (4) adapted to heat to various temperature the content of the basin (3). The basin (3) and the permeable basket (6) are open and coupled with respect to each other, in a releasable way, one against the another. The coupled basin (3) and the permeable basket (6) are adapted to be integrally rotated, in order to be moved alternatively between a first position (A), where the basin (3) is down and the basket (6) is up, and a second position, where the basket (6) is down and the basin (3) is up. The cheese can be extracted from the basket (6) after a plurality of preparation steps.

Owner:PAVERO RICCARDO

Semiconductor device and method having trenches in a drain extension region

ActiveUS8373227B2Performance is not compromisedMore reliableSemiconductor/solid-state device manufacturingSemiconductor devicesDielectric layerSemiconductor

A semiconductor device comprises a substrate including a first region and a second region of a first conductivity type and a third region between the first and second regions of a second conductivity type opposite to the first conductivity type, and being covered by a dielectric layer. A plurality of trenches laterally extend between the third and second region, are filled with an insulating material, and are separated by active stripes with a doping profile having a depth not exceeding the depth of the trenches wherein each trench terminates before reaching the dielectric layer and is separated from the third region by a substrate portion such that the respective boundaries between the substrate portions and the trenches are not covered by the dielectric layer. A method for manufacturing such a semiconductor device is also disclosed.

Owner:NXP BV

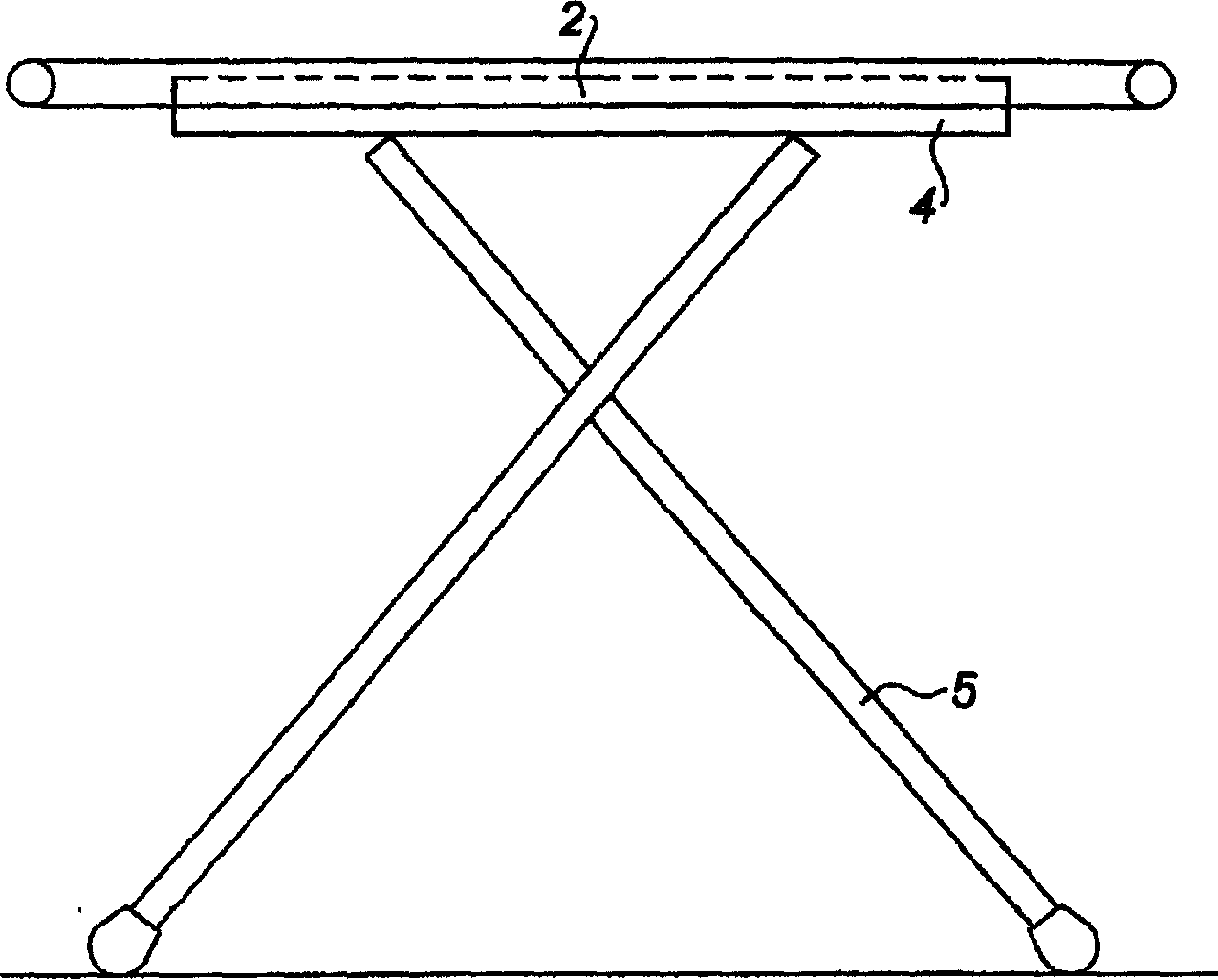

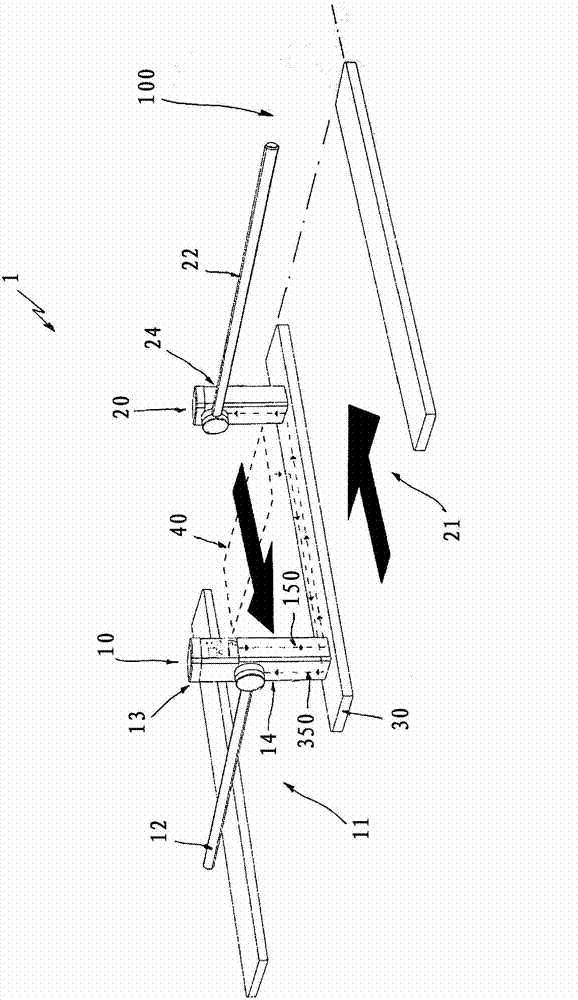

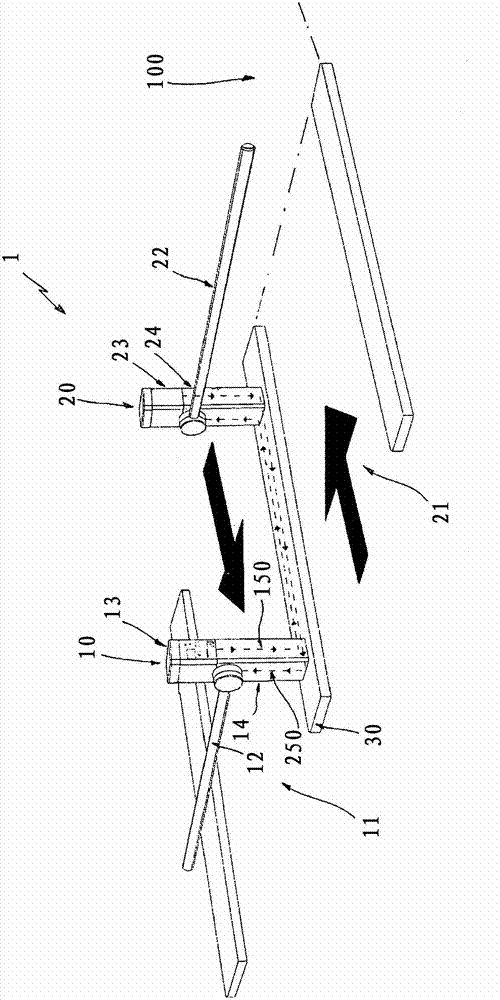

Ironing board

Owner:亚历山大·沙尼奥 +2

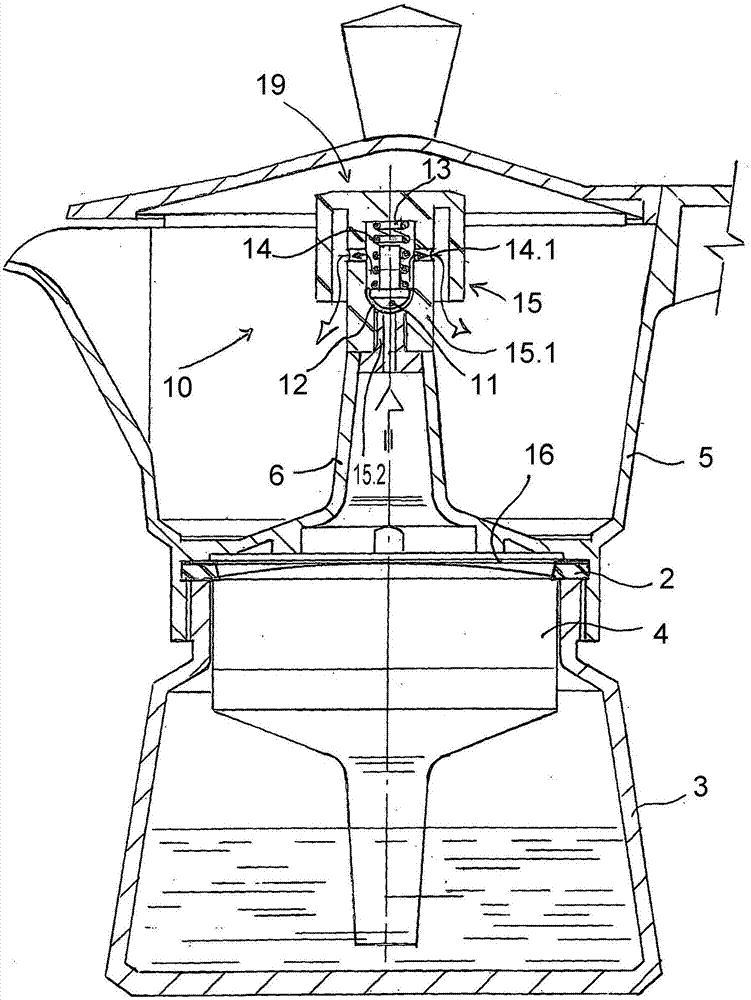

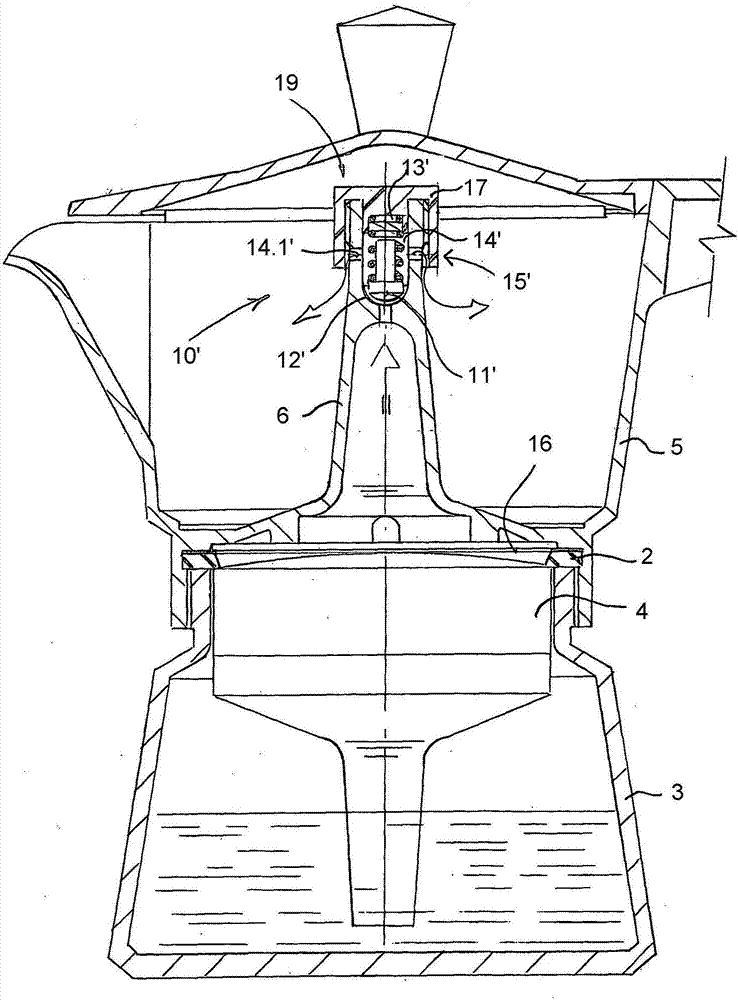

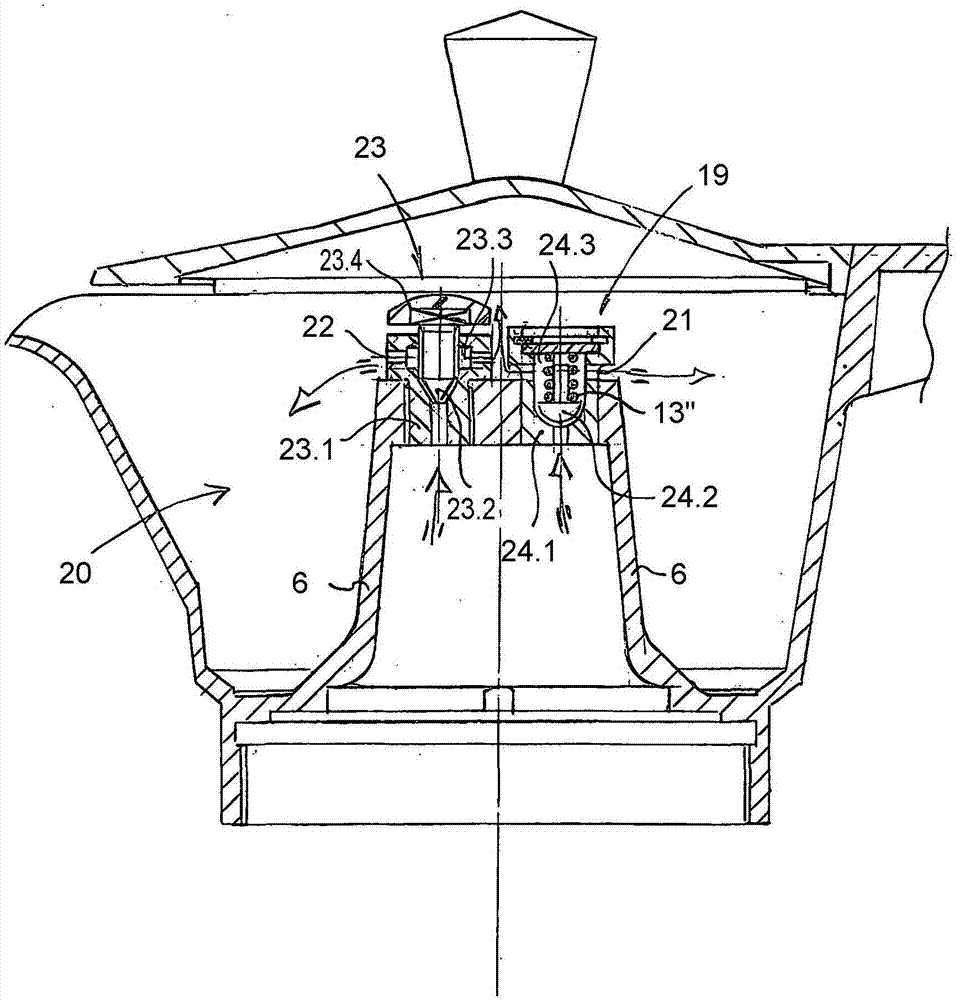

Stovetop espresso maker

Stovetop espresso maker comprising a boiler (3), a filter for holding ground coffee (4), and a collector (5) adapted to collect the brew produced by means of the passage of hot water through the grounds, wherein said stovetop espresso maker also comprises a device (10) for dispensing the brew, which is arranged on a dispensing duct (6) and includes overpressure valve means (19) arranged along a path of said brew from the boiler (3) to the collector (5) and wherein said device (10) comprises: - said overpressure valve means (19), in which a valve body (11) is movable parallel to the axis of said dispensing duct (6), with respect to a corresponding valve seat (12), and opposing elastic means (13), which act on said valve body (11), are housed in a decompression chamber (14) arranged downstream of said dispensing duct (6) and comprising at least one brew dispensing outlet (14.1), and - manual adjustment means of the dispensing pressure (15) of said brew, between at least a first pressure value and a second pressure value, greater than the first, in correspondence of at least one of which said overpressure valve means (19) allow the passage of the brew from said dispensing duct (6) to said at least one dispensing outlet (14.1), so that a brew without foam and with foam can be produced with said stovetop espresso maker.

Owner:达维德马里奥博伊多

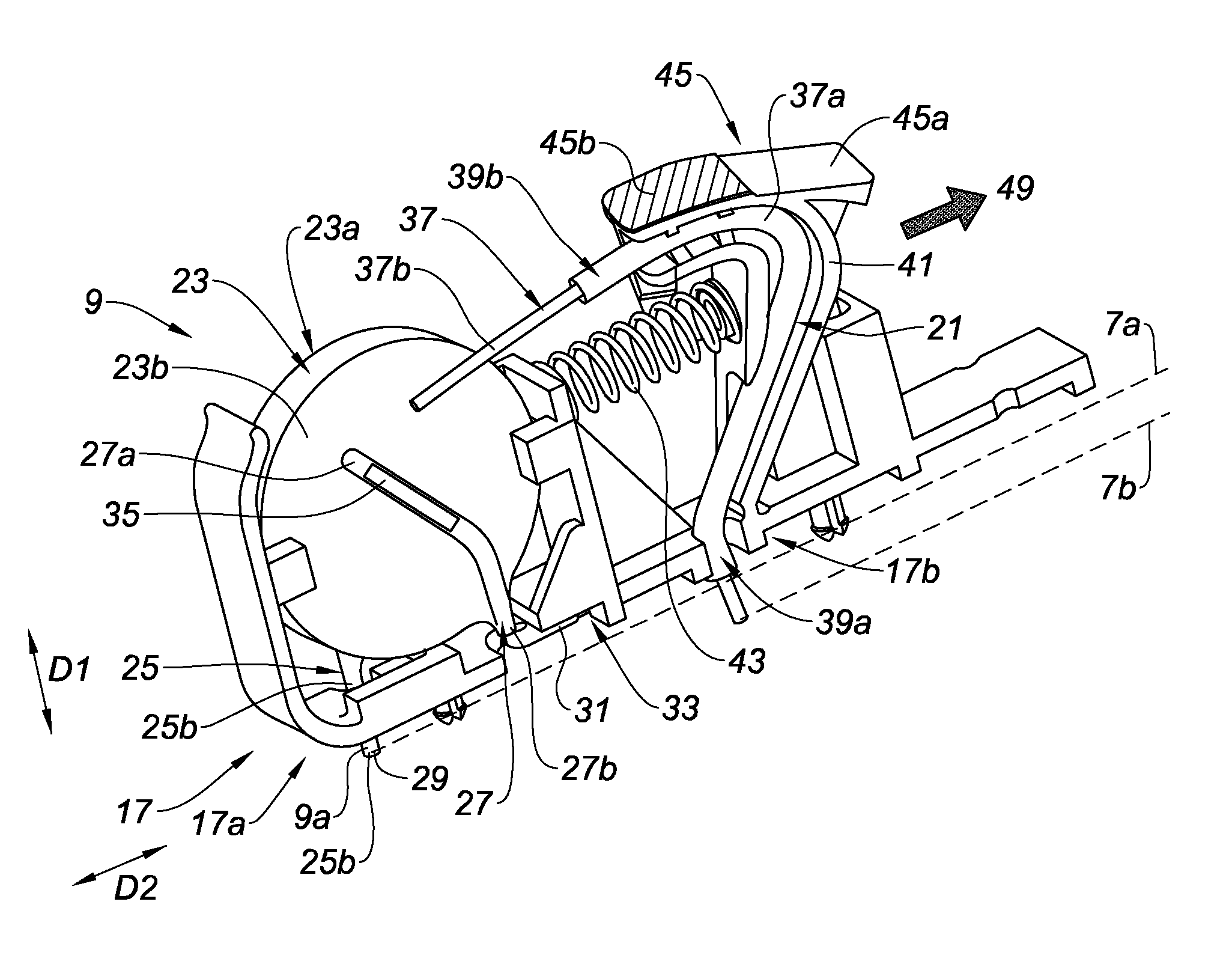

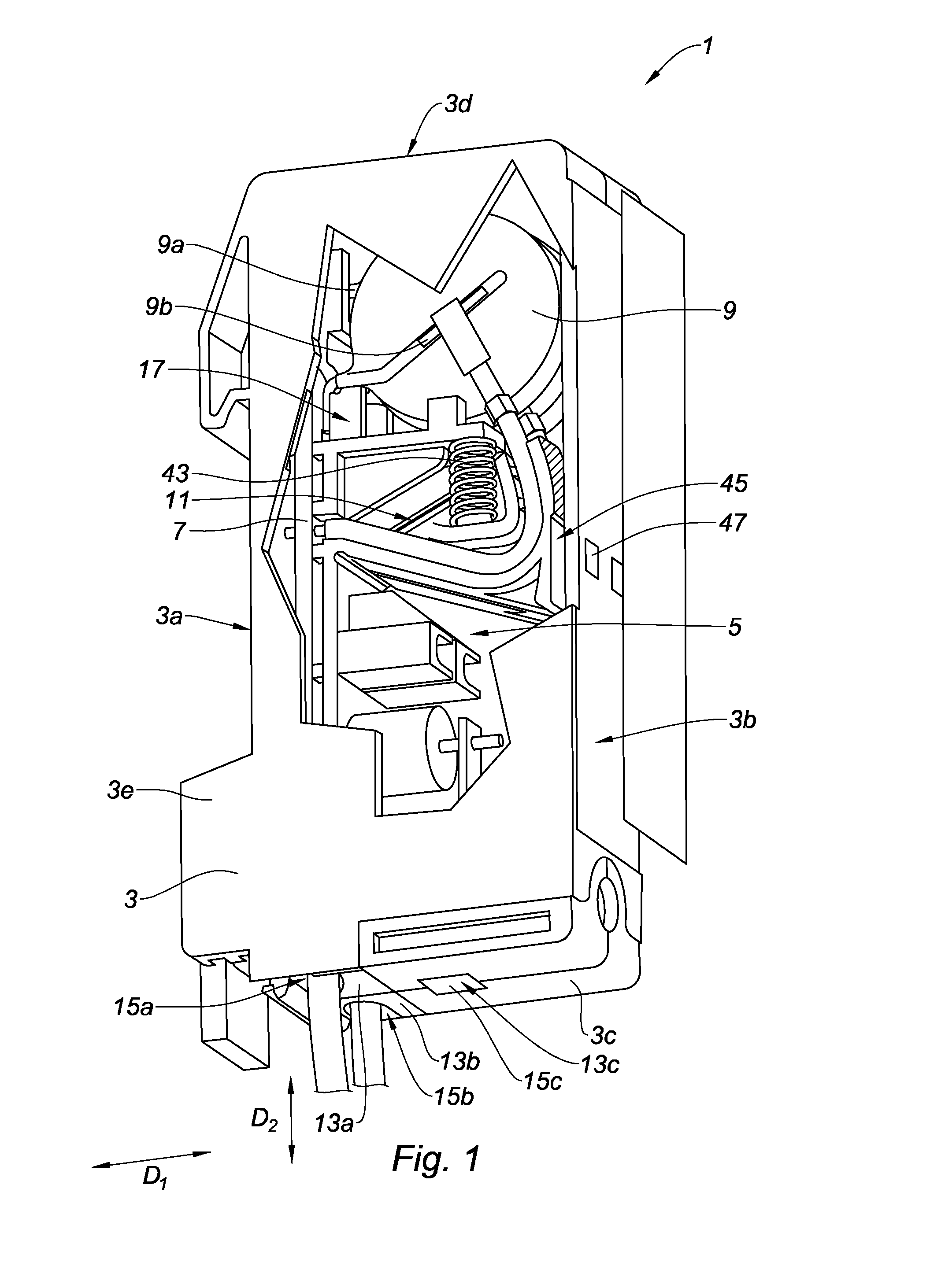

Disconnection indicator of an active component of a device for protecting an electrical installation

ActiveUS20150372472A1Limited sizeLimit wearInstallation of lighting conductorsThermal switch detailsActive componentEngineering

A device for protecting an electrical installation including an insulating body electrically defining an internal housing, the protective device including, within the internal housing: an active component of a device for protecting an electrical installation; a disconnection system for disconnecting the active component moveable between a contact position corresponding to a connected state of the active component and an open position corresponding to a disconnected state of the active component; a disconnection indicator, where the disconnection indicator is secured in movement to the disconnection system and the disconnection indicator and the insulating body are arranged to have a first configuration, which corresponds to the contact position, and a second configuration, which corresponds to the open position, the relative positioning of the disconnection indicator with respect to the insulating body in the first configuration being visually distinct from the outside of the insulating body from the relative positioning of the disconnection indicator with respect to the insulating body in the second configuration.

Owner:ABB FRANCE SAS

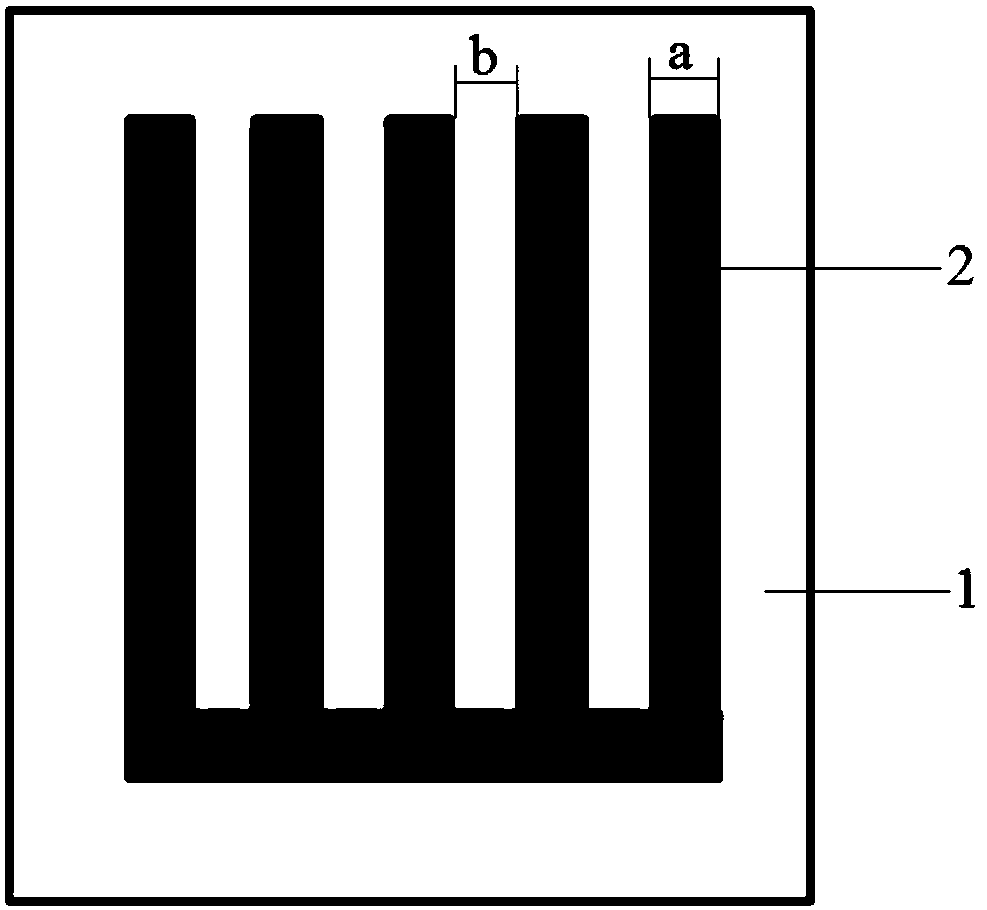

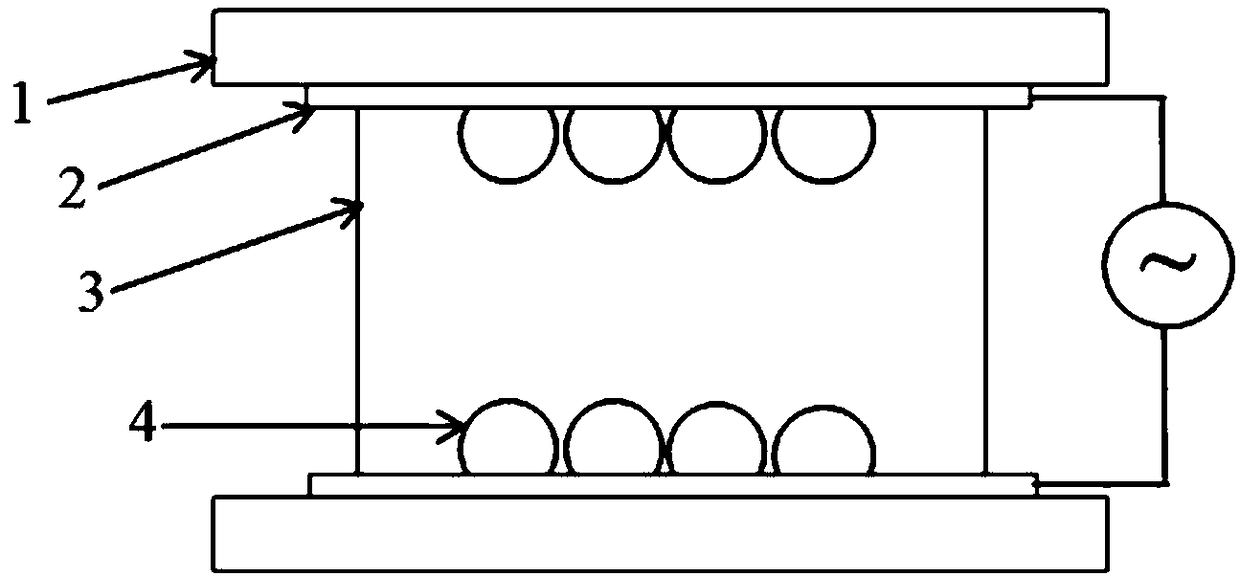

Preparation method of highly ordered phospholipid vesicle array

ActiveCN109297784AEasy to manufactureUniform sizePreparing sample for investigationForming processesChemistry

The invention provides a preparation method of a highly ordered phospholipid vesicle array, and relates to a preparation method of phospholipid vesicles. The object of the invention is to solve the problems that the phospholipid vesicles prepared by an existing large-area electrode are disordered, and the sizes of the phospholipid vesicles are not uniform. The method comprises the following steps:first, preparation and cleaning of an electrode; second, coating and drying of a phospholipid dry film; third, assembly; and fourth, performing an electric vesicle forming process to obtain the highly ordered phospholipid vesicle array. By adoption of the preparation method provided by the invention, the simple and rapid preparation of the phospholipid vesicles with highly ordered arrangement anduniform size is creatively achieved, the preparation time is short, and the preparation method is suitable for industrial production. The invention provides the preparation method of the highly ordered phospholipid vesicle array.

Owner:HEILONGJIANG BAYI AGRICULTURAL UNIVERSITY

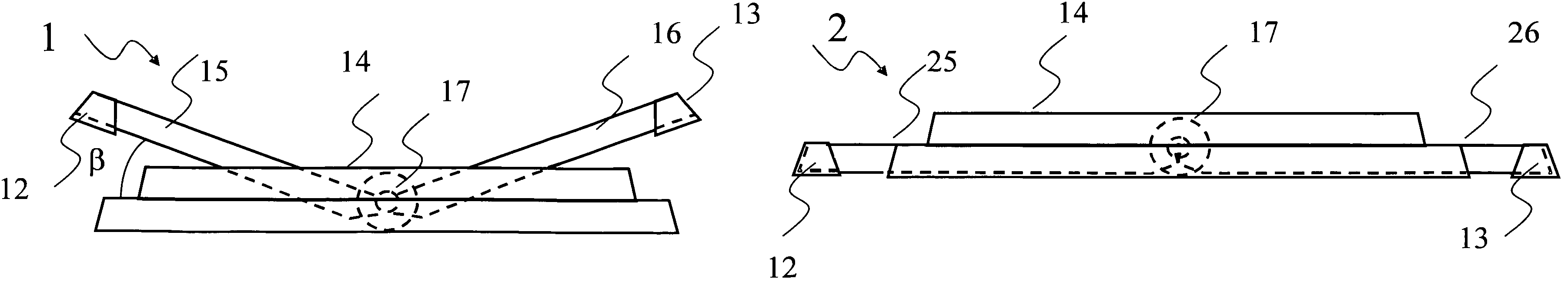

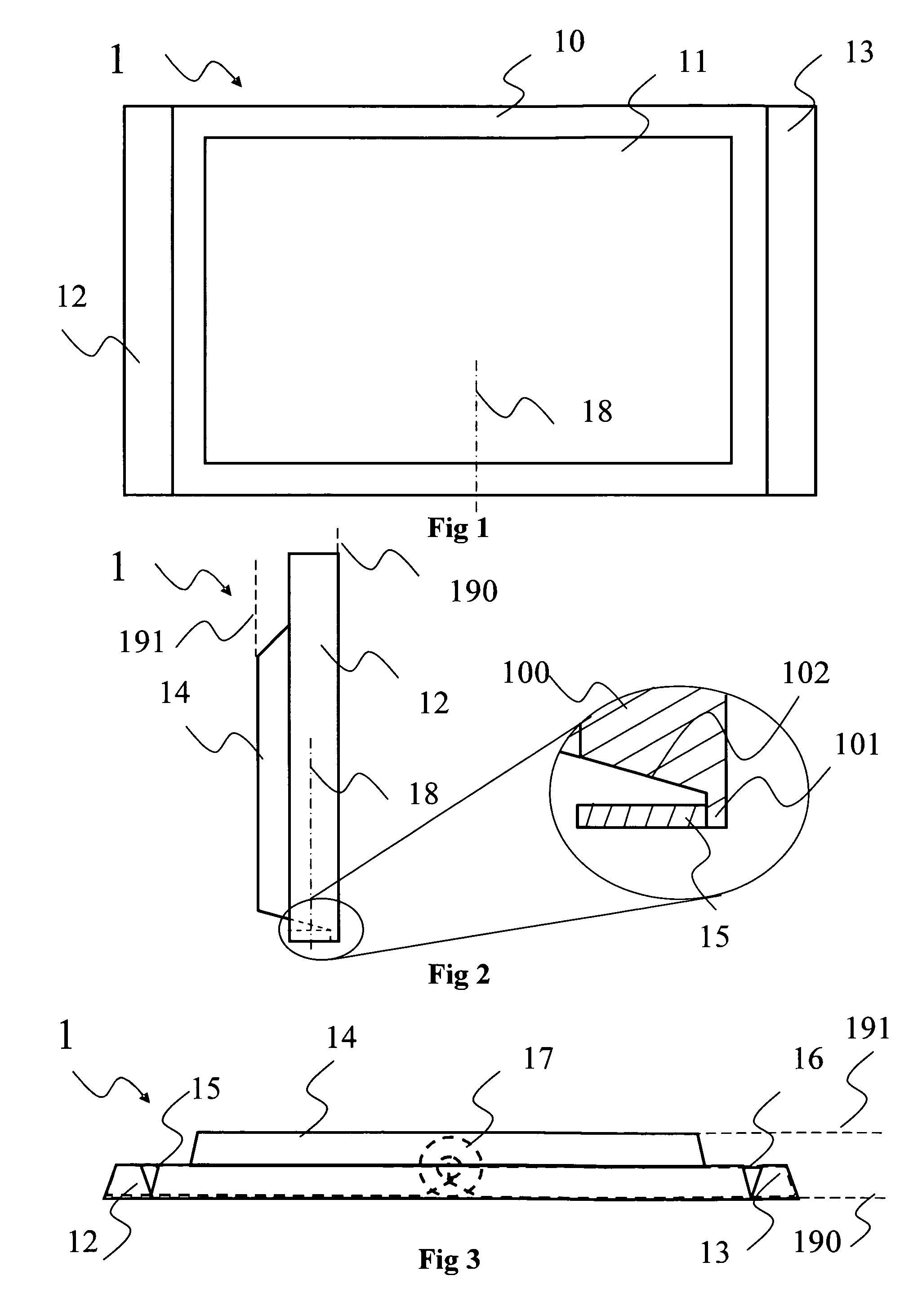

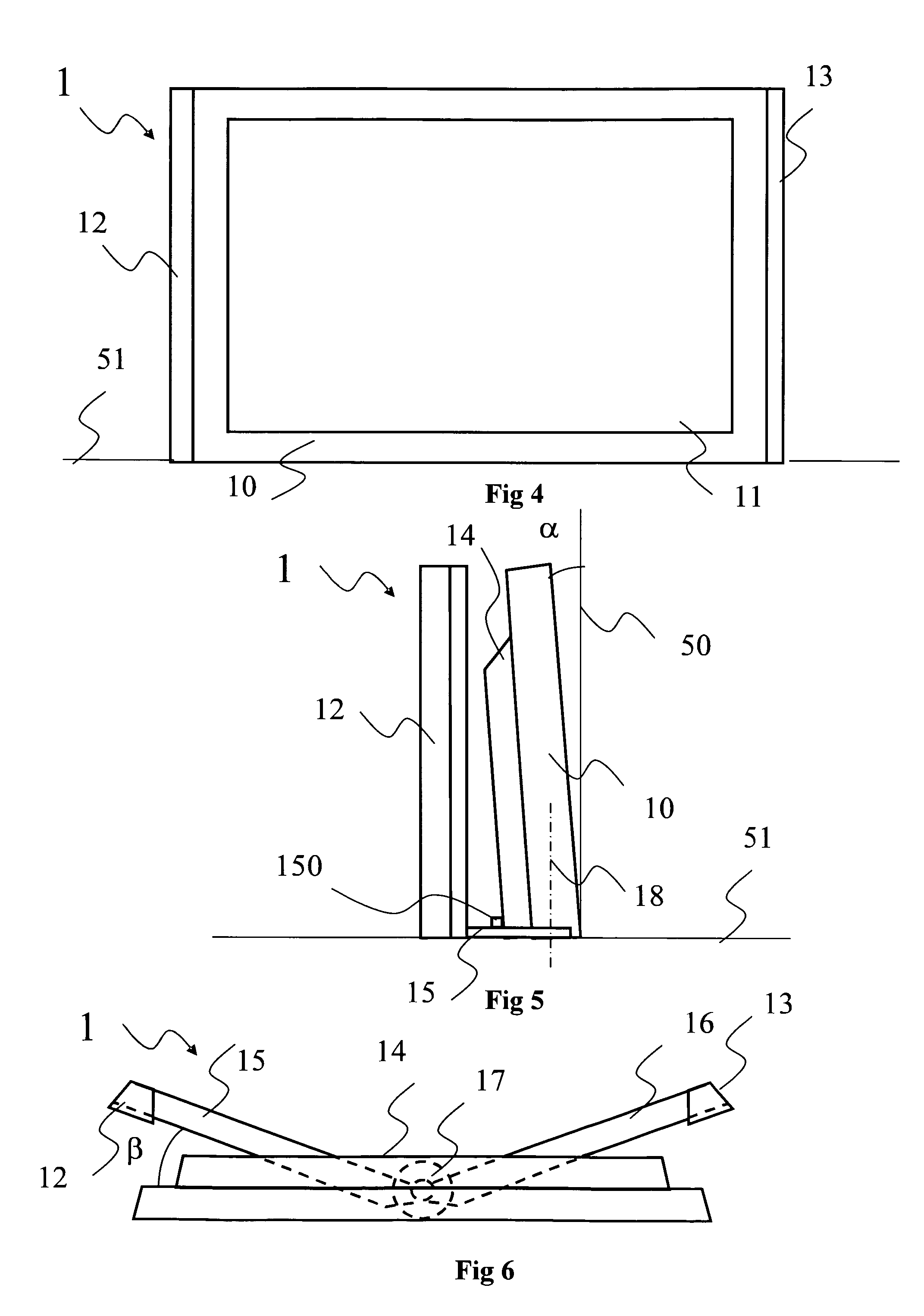

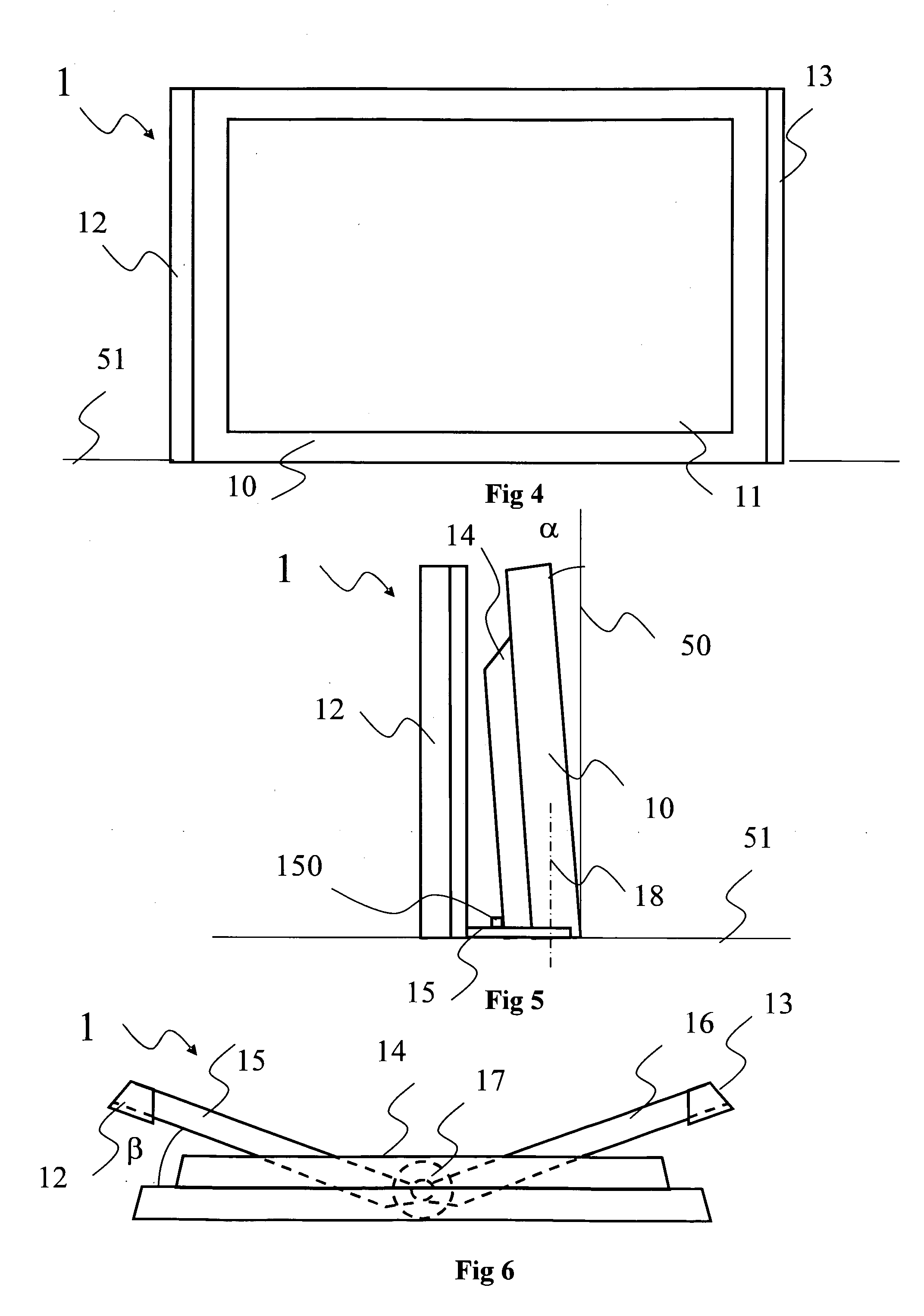

Flat screen display device

ActiveUS7760494B2Improve ergonomicsEasily set down and mountedTelevision system detailsStands/trestlesDisplay deviceEngineering

The invention concerns to a display device comprising a flat screen, a cabinet and at least one mobile arm capable of taking up first and second positions:in the first position, one end of the mobile arm or mobile arms is space apart from a plane corresponding to the front surface of the screen along a horizontal direction, one part at least of the arm or arms being adapted to maintain the screen in a noticeably vertical position when the device is resting on a horizontal plane, andin the second position, the arm(s) are in the space between the planes parallel to the screen and tangent respectively to the front and to the rear of the cabinet.

Owner:INTERDIGITAL MADISON PATENT HLDG

Broccoli block processing and cleaning treatment device

ActiveCN114451566AReduce usageAvoid damageSievingFruits/vegetable preservation by heatingBroccoli raabElectric machinery

A limiting sealing plate is connected to the bottom end of a fixed supporting plate, a transmission motor is installed at the top end of the fixed supporting plate, a porous cleaning barrel is placed at the top end of a cross-shaped limiting plate, a porous water inlet pipe is welded to the bottom end of the inner side of the porous cleaning barrel, and sealing electric push rods are symmetrically clamped to the bottom end of a fixed barrel; a plurality of rubber rods are clamped on the inner side of the porous cleaning barrel at equal intervals, a booster water pump sprays water into the inner side of the porous cleaning barrel through a conveying pipe and a concentration hopper, and a transmission motor drives a limiting sealing plate, a porous water inlet pipe and the porous cleaning barrel to rotate, so that tubers rotate at a high speed in the porous cleaning barrel, and impurities attached to the surfaces of the tubers are separated; and sewage can be discharged through a discharging plate during cleaning, and a sealing electric push rod drives a protective sealing plate to seal the fixed barrel, so that the tubers can be effectively soaked during cleaning, and the use of water is effectively reduced.

Owner:JINZHOU MEDICAL UNIV

Flat screen display device

ActiveUS20090308997A1Improve ergonomicsSmall sizeTelevision system detailsFurniture partsDisplay deviceEngineering

The invention concerns to a display device comprising a flat screen, a cabinet and at least one mobile arm capable of taking up first and second positions:in the first position, one end of the mobile arm or mobile arms is space apart from a plane corresponding to the front surface of the screen along a horizontal direction, one part at least of the arm or arms being adapted to maintain the screen in a noticeably vertical position when the device is resting on a horizontal plane, andin the second position, the arm(s) are in the space between the planes parallel to the screen and tangent respectively to the front and to the rear of the cabinet.

Owner:INTERDIGITAL MADISON PATENT HLDG

Shot-blasting machine for surface treatment of products

ActiveUS8562393B2Limited sizeDrawback can be obviatedImpeller wheelsRotor bladesChassisSurface finishing

Owner:C M SURFACE TREATMENT

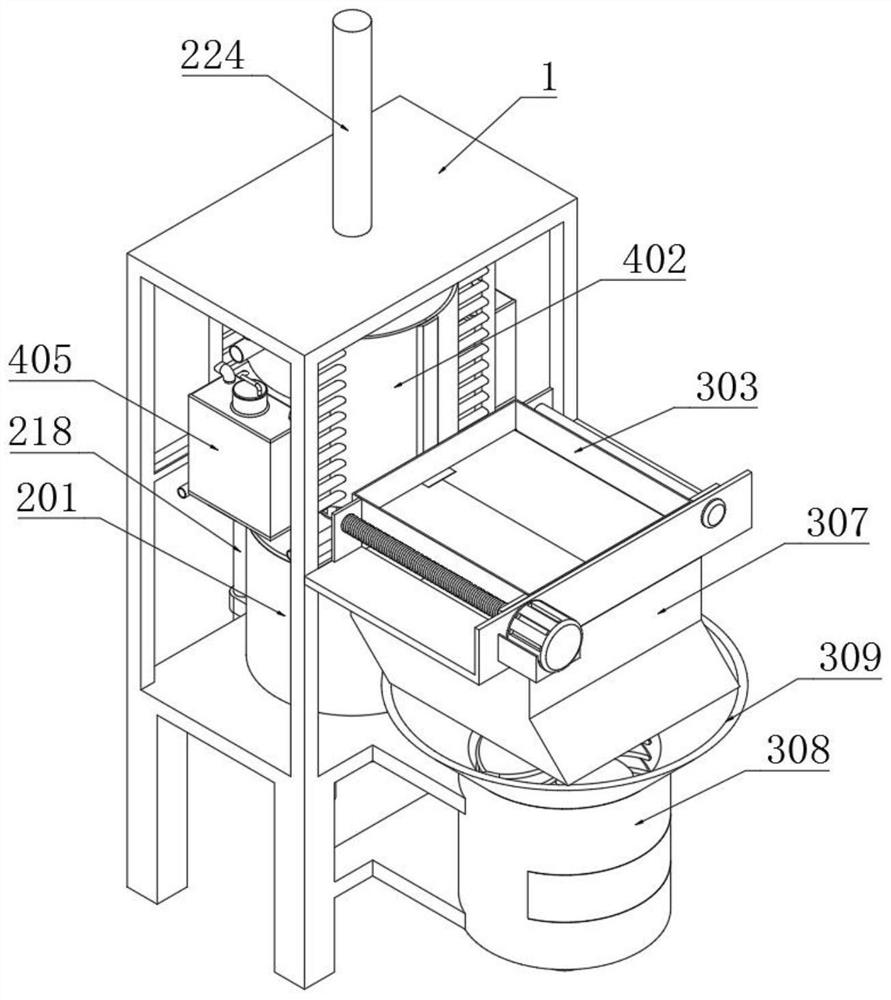

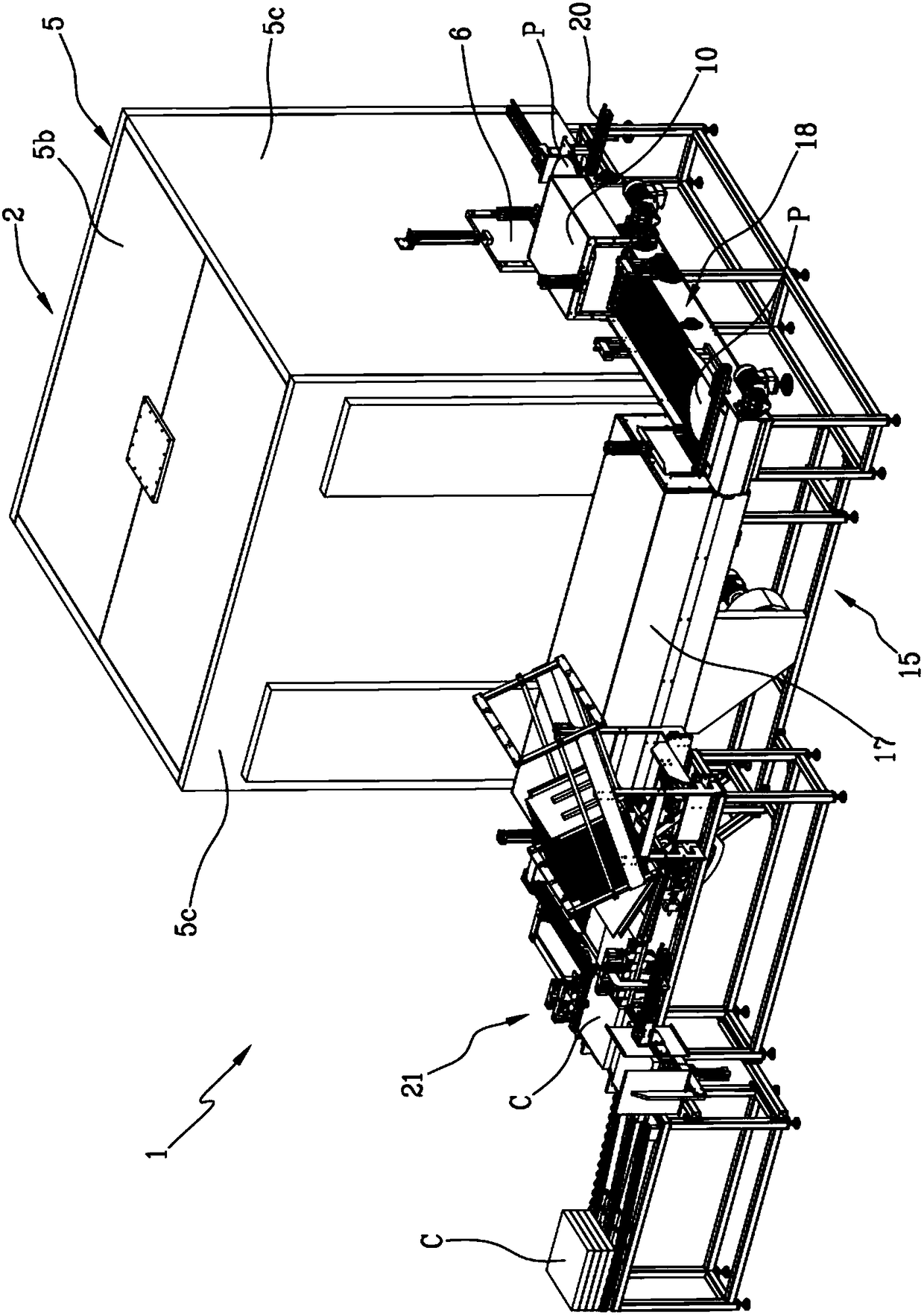

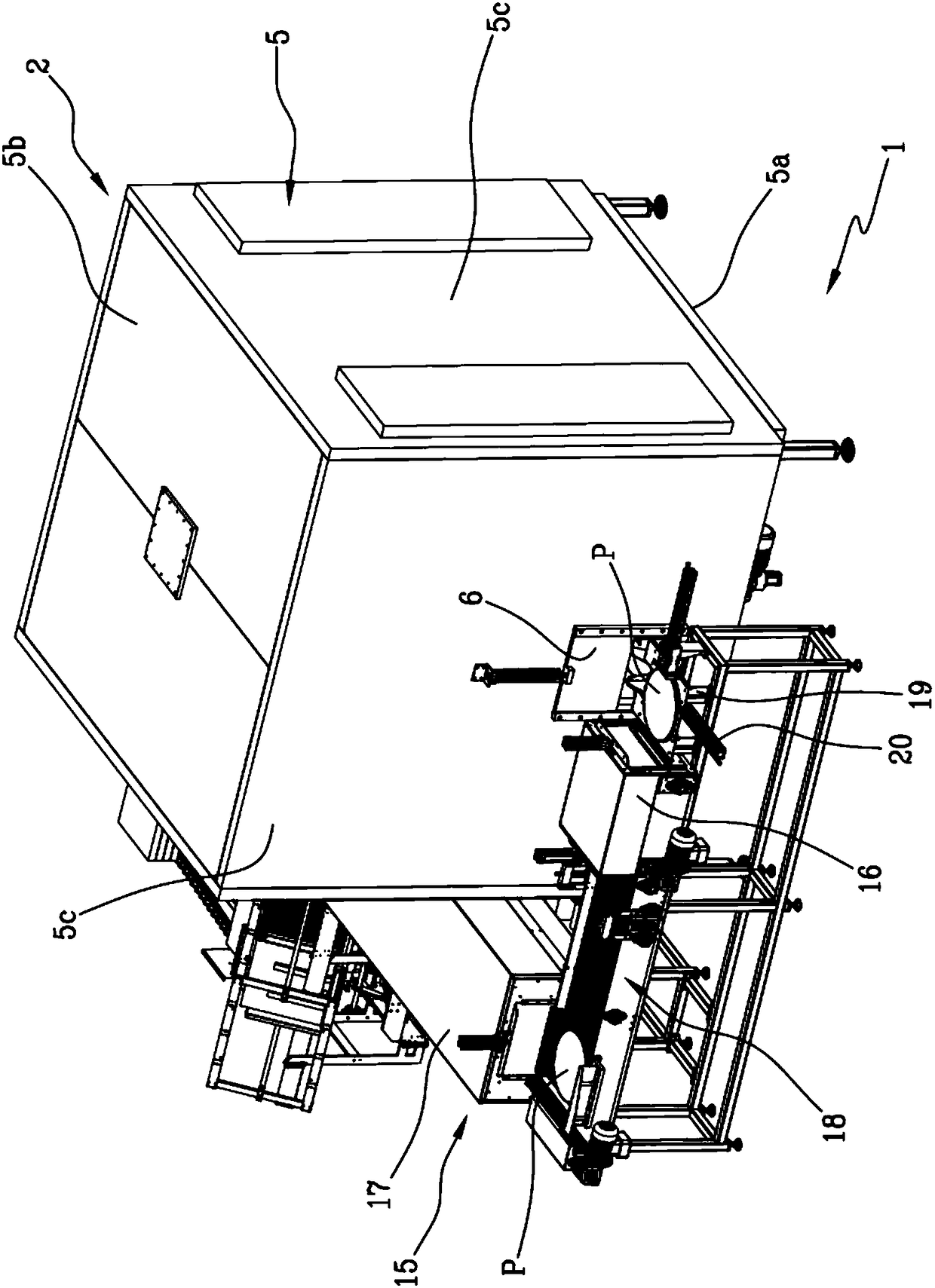

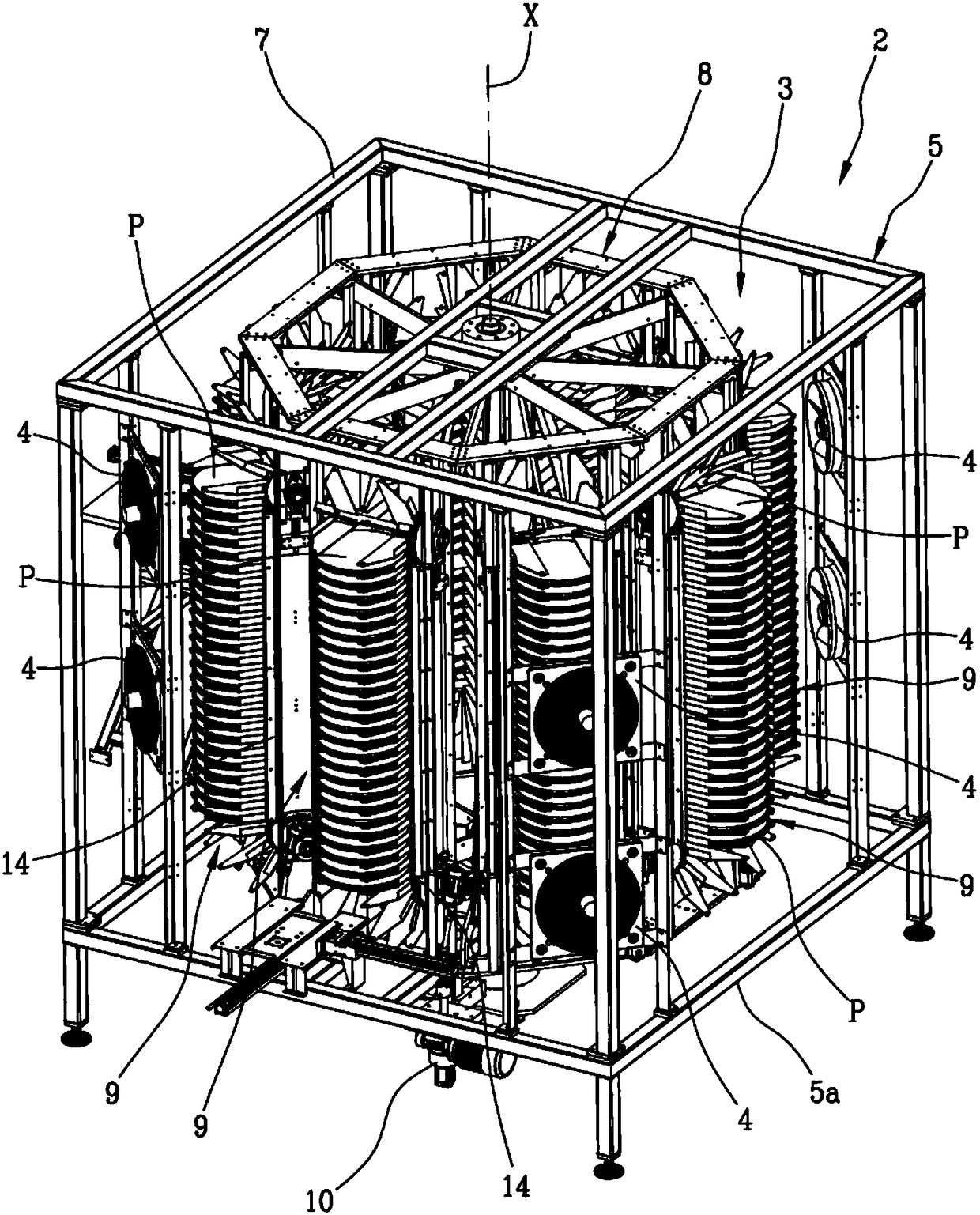

Apparatus for the preparation and dispensing of bakery food products

ActiveCN108719368AOvercome limitationsVersatilityLighting and heating apparatusCoin-freed apparatus detailsProcess engineeringFood products

An apparatus (1) for the preparation and dispensing of bakery food products, in particular pizzas, comprising: a magazine (2) containing a plurality of food products (P) having a storage compartment (3) for storing said products (P) in a respective semi-cooked condition; cooling means (4) arranged inside the magazine (2) to keep the compartment (3) of said food products (P) at a predetermined freezing temperature; a supply line (15) for supplying said food products (P) extending between a product loading station arranged in the area of the magazine (2) and a dispensing station for dispensing the food products (P), packaging means (21), located in the area of said dispensing station to arrange each product (P) leaving the supply line (15) inside a respective package (C); said supply line comprising: a first oven (16) arranged downstream of the loading station and configured to thaw the food products (P) leaving the magazine (2); and a second oven (17) interposed between said first ovenand said dispensing station and configured to cook the thawed food product at a given temperature depending on the type of the product (P) itself.

Owner:马丁纳莉莎卡斯特利亚诺

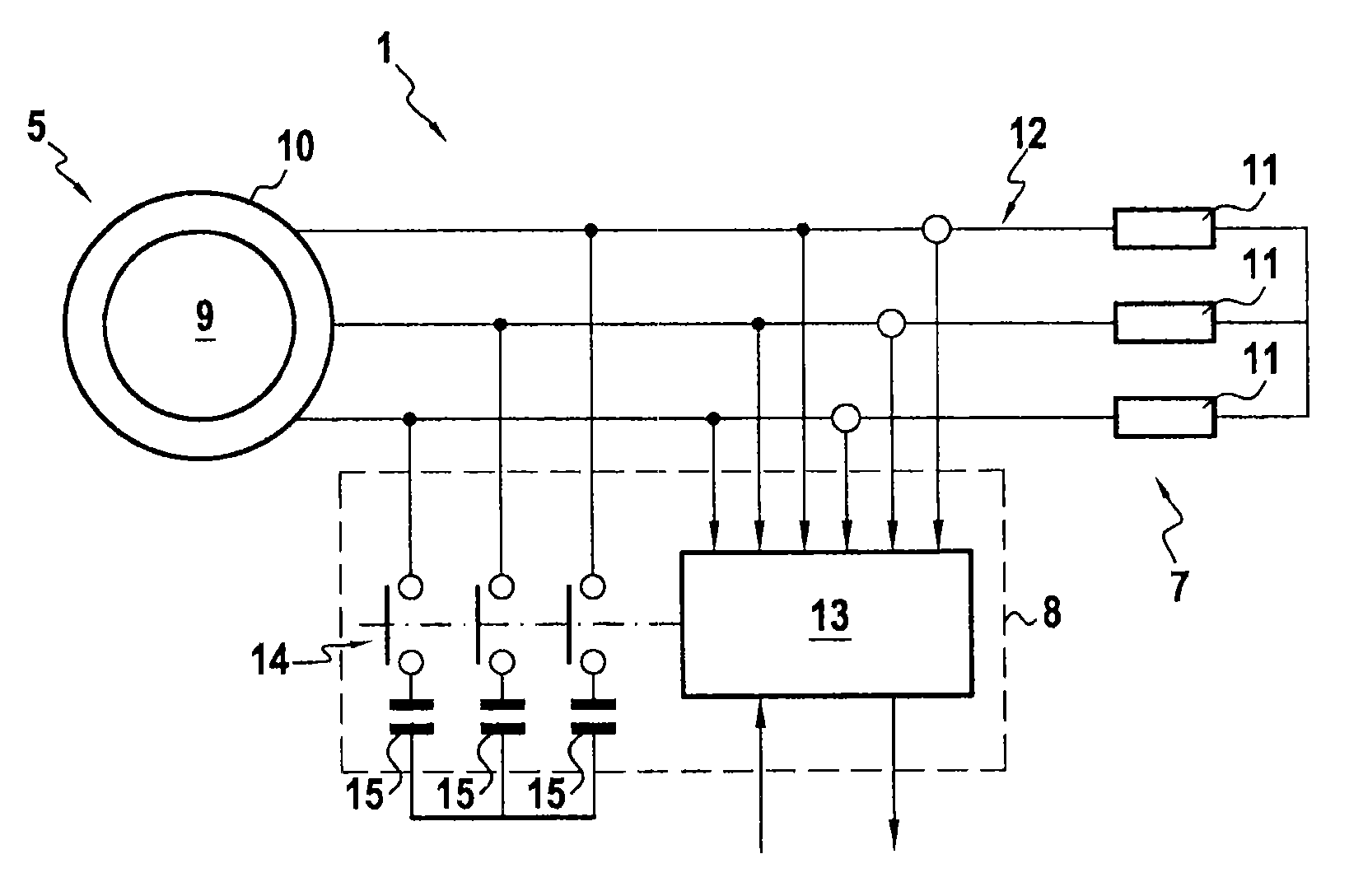

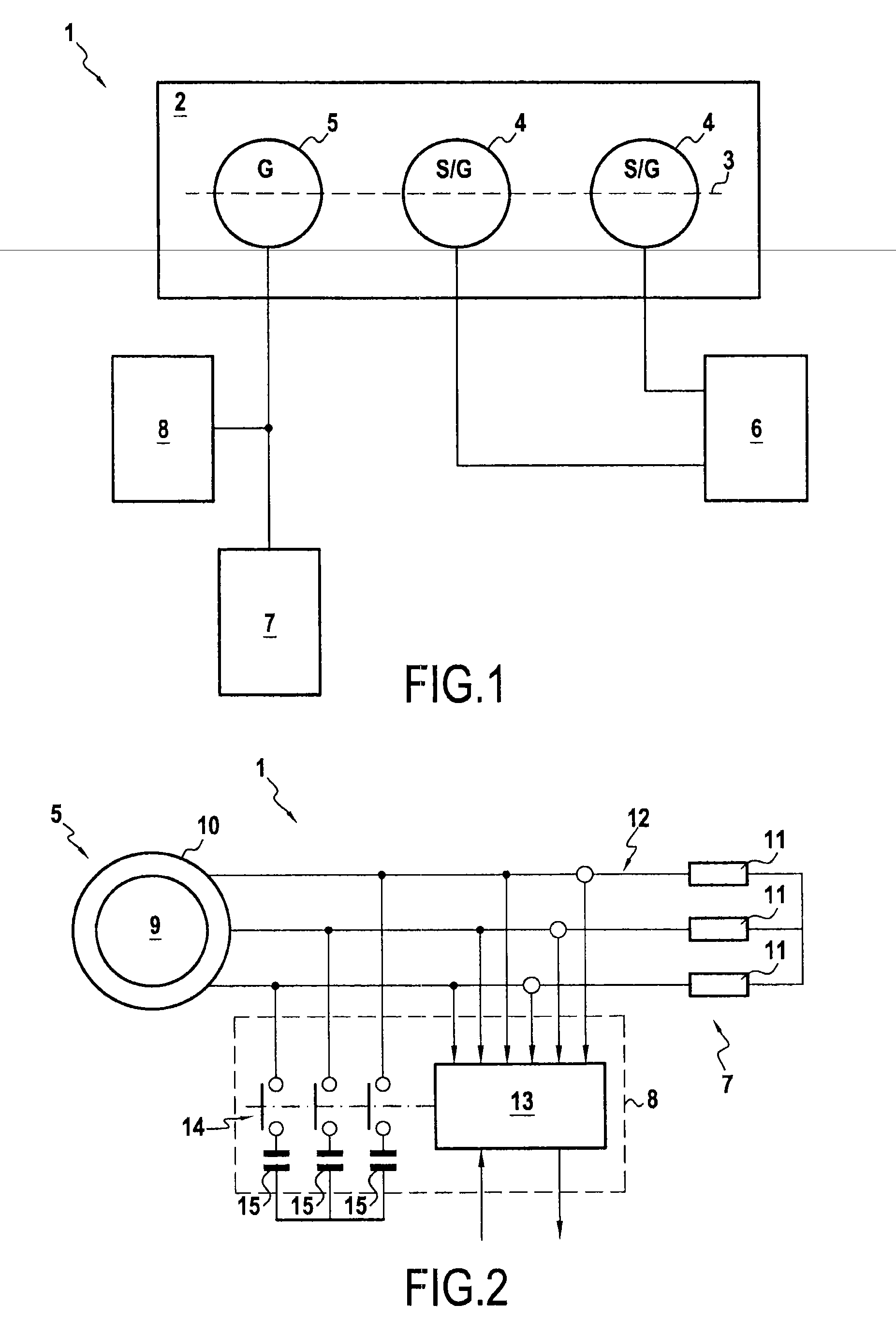

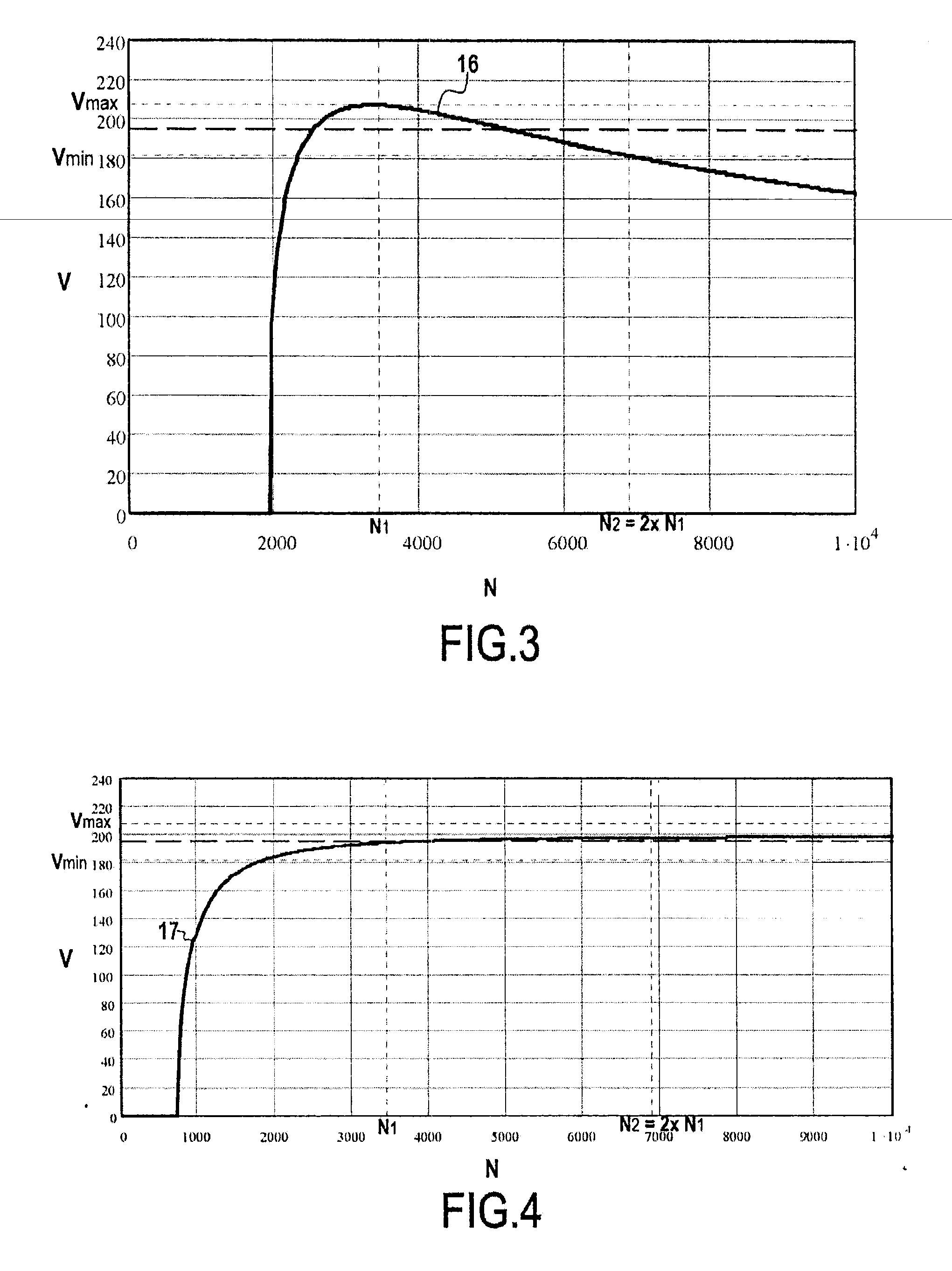

Aircraft power supply circuit including an asynchronous machine

ActiveUS20130234679A1Improve reliabilitySmall sizeAsynchronous generator controlElectrical devicesAirplane

A power supply circuit for supplying electrical energy in an aircraft, the circuit including a power supply generator configured to be driven in rotation by the engine of the aircraft to power electrical equipment of the aircraft engine. The power supply generator includes an asynchronous machine connected to an excitation device. The asynchronous machine includes a rotor configured to be driven in rotation by the engine and a stator connected to the electrical equipment. The excitation device is configured to cause a reactive current of flow in the stator.

Owner:SAFRAN ELECTRICAL & POWER

Preparation method of nectarine juice

InactiveCN109315659APrevent oxidationPrevent discolorationNatural extract food ingredientsFood ingredient as mouthfeel improving agentPectinaseFruit juice

The invention discloses a preparation method of nectarine juice. The method comprises the following steps that diced nectarine pulp is taken, water and color fixative are added, and pulping is conducted to obtain pulp; the pulp is taken for enzymolysis, rough filtering and fine filtering, sugar is added to adjust a sugar-acid ratio, then an additive is added, and heating, dissolution and sterilization are conducted to obtain the nectarine juice, wherein pectinase and cellulase are used for enzymolysis, and ceramic film is used for fine filtering. The preparation method of nectarine juice is high in juice yield, and the nectarine juice is high nutrition content.

Owner:芜湖县兰馨油桃种植专业合作社

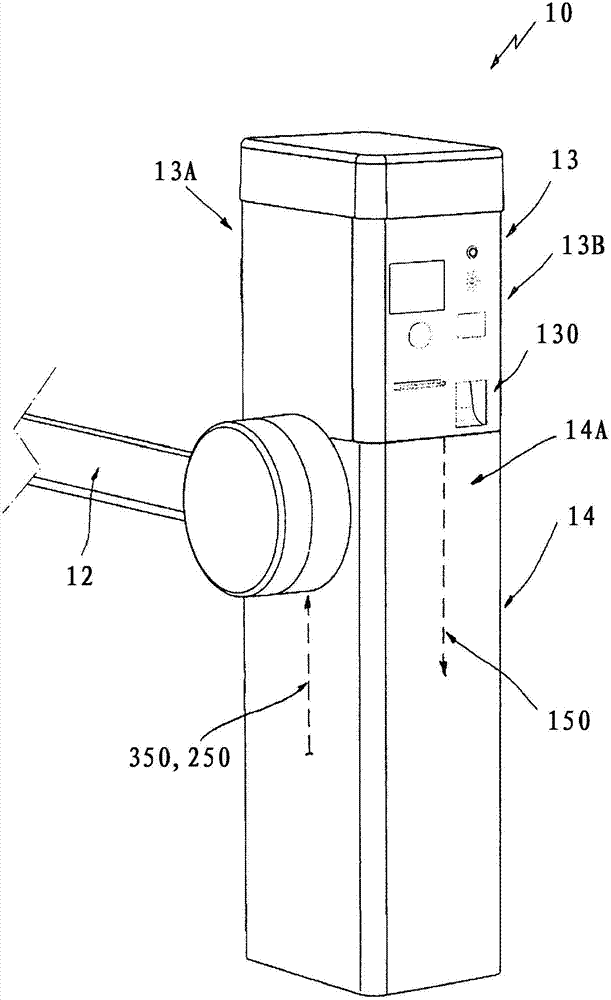

Apparatus for controlling vehicle entry to and/or exit from a space

InactiveCN103250186ACompact structureLimited sizeTicket-issuing apparatusTraffic restrictionsControl signalActuator

An apparatus for controlling vehicle entry to and / or exit from a space comprising: - at least a first barrier device comprising at least a first moving barrier element and first actuator means to reversibly move said first barrier element between a first operating position, in which the first barrier element obstructs transit along a first transit lane to / from said space, and a second operating position, in which the first barrier element allows transit along said first transit lane; and - at least a second barrier device comprising at least a second moving barrier element and second actuator means to reversibly move said second barrier element between a first operating position, in which the second barrier element obstructs transit along a second transit lane to / from said space, and a second operating position, in which the second barrier element allows transit along said second transit lane. At least the first barrier device comprises a first control module, provided with a first user interface, accessible to a user travelling along the second transit lane. The aforesaid first control module is adapted to send first control signals to the second barrier device to activate at least the second actuator means of the second barrier device.

Owner:NICE SPA

A device for avoiding glue leakage of planting reinforcement glue

ActiveCN111622520BAvoid glue leakageAchieve leak-proof effectBuilding repairsPlant GumsAgricultural engineering

The invention discloses a device for avoiding glue leakage of the reinforcement glue, which includes pre-installed steel bars, holes for installing the reinforcement and glue glue, and also includes a leak-proof mechanism for preventing the glue glue from leaking, and the leak-proof mechanism includes a mounting frame and a sealing body, the mounting frame is fixedly installed on the wall outside the hole, the sealing body is installed on the mounting frame, and the sealing body is used to block the hole; the present invention basically solves the problem of planting bars generated when installing steel bars The problem of glue leakage ensures the drawing strength of the planting bars, and there is no need to clean up the leaked glue and incur costs.

Owner:CHINA MCC17 GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com