Preparation method of highly ordered phospholipid vesicle array

A highly ordered, phospholipid technology, used in the preparation of test samples, etc., can solve the problems of disordered phospholipid vesicles and uneven size of phospholipid vesicles, and achieve simple and rapid preparation, short preparation time, and simple method. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

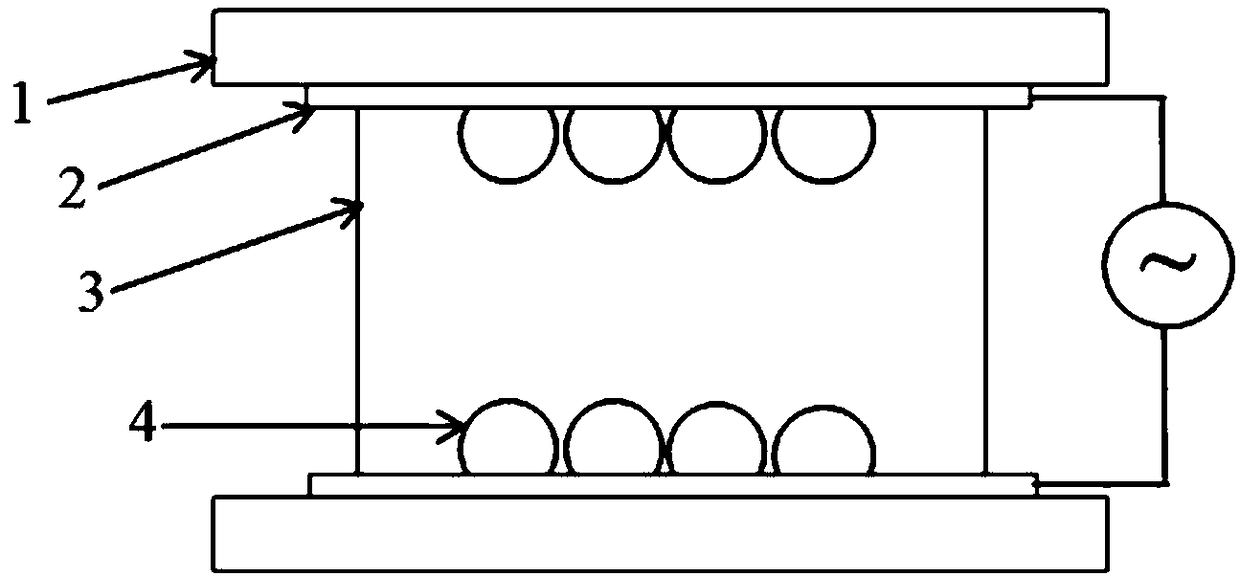

[0025] Embodiment 1: This embodiment is a method for preparing a highly ordered phospholipid vesicle array, which is completed in the following steps:

[0026] 1. Electrode preparation and cleaning:

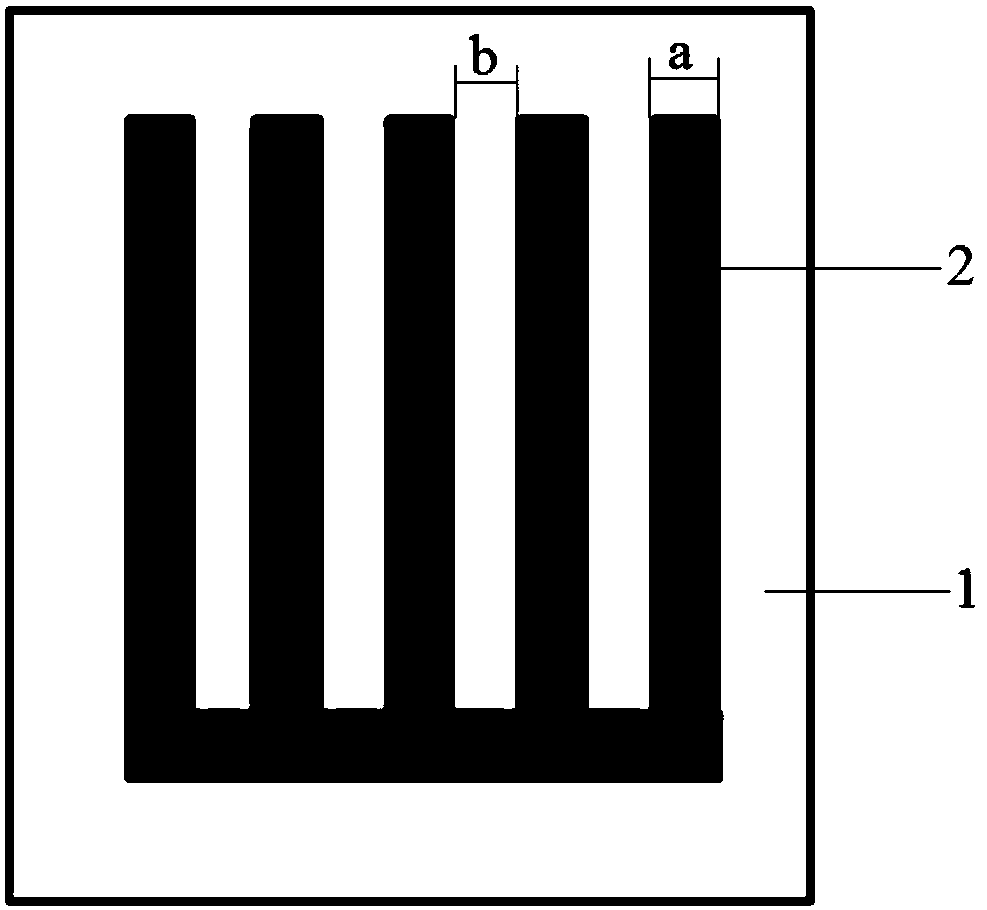

[0027] First, the striped microelectrode was prepared on the surface of ITO conductive glass by photolithography to obtain the striped microelectrode substrate; the striped microelectrode substrate was put into a sodium carbonate solution with a mass fraction of 1% to 1.5% and ultrasonically washed for 1min to 3min, and ultrasonically washed for 1min to 3min. The power is 250W ~ 300W, and then use distilled water to wash 2 to 3 times, and finally use nitrogen to dry to obtain the striped microelectrode substrate after cleaning;

[0028] The striped microelectrode described in step 1 is an array formed by a plurality of strip electrodes connected in parallel, wherein the width of each strip electrode is 10 μm to 50 μm, and the distance between every two strip electrodes is 10 μm t...

specific Embodiment approach 2

[0042] Specific embodiment two: the difference between this embodiment and specific embodiment one is: adopt photolithography described in step one to prepare striped microelectrode on the surface of ITO conductive glass and finish according to the following steps:

[0043]①. First, ultrasonically clean the ITO conductive glass in absolute ethanol at an ultrasonic power of 250W to 300W for 10min to 15min, then ultrasonically clean the ITO conductive glass in distilled water at an ultrasonic power of 250W to 300W for 10min to 15min before use Blow dry with nitrogen, and finally treat with a plasma cleaning machine for 25s~35s, then put it on a heating plate with a temperature of 105°C~115°C and heat it for 5min~15min to obtain a pretreated ITO conductive glass;

[0044] ②. First, use a plastic sealing machine with a temperature of 110°C to 115°C to press the photoresist on the pretreated ITO conductive glass to form a film, then place a mask with a pattern on the film, and then ...

specific Embodiment approach 3

[0049] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that in step 2 ①, the phospholipids are dissolved in chloroform to obtain a phospholipid solution with a concentration of 0.5 mg / mL-1 mg / mL. Other steps are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com