Patents

Literature

42results about How to "Limit operations" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

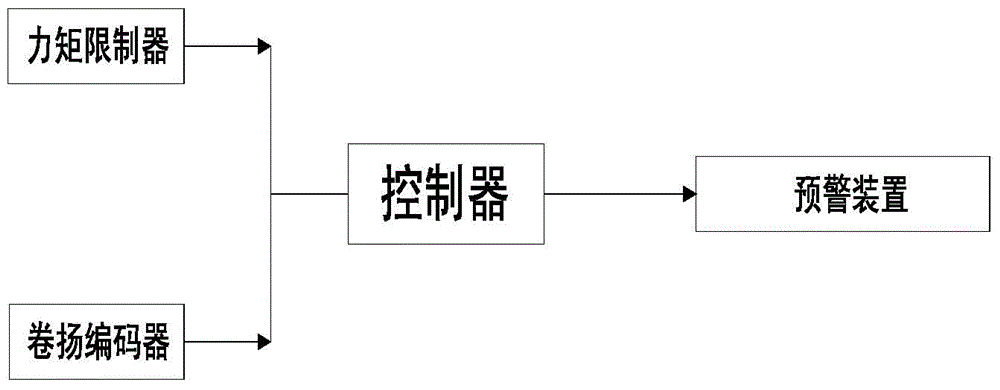

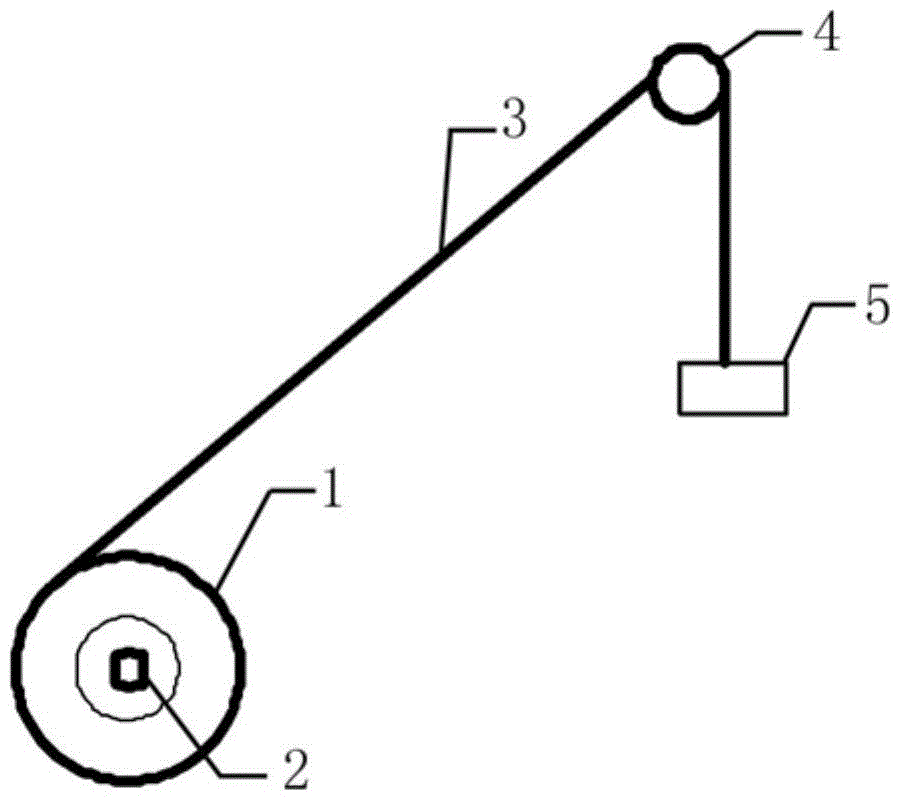

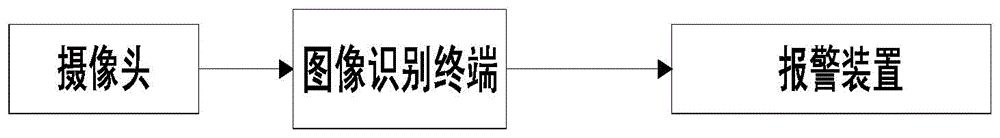

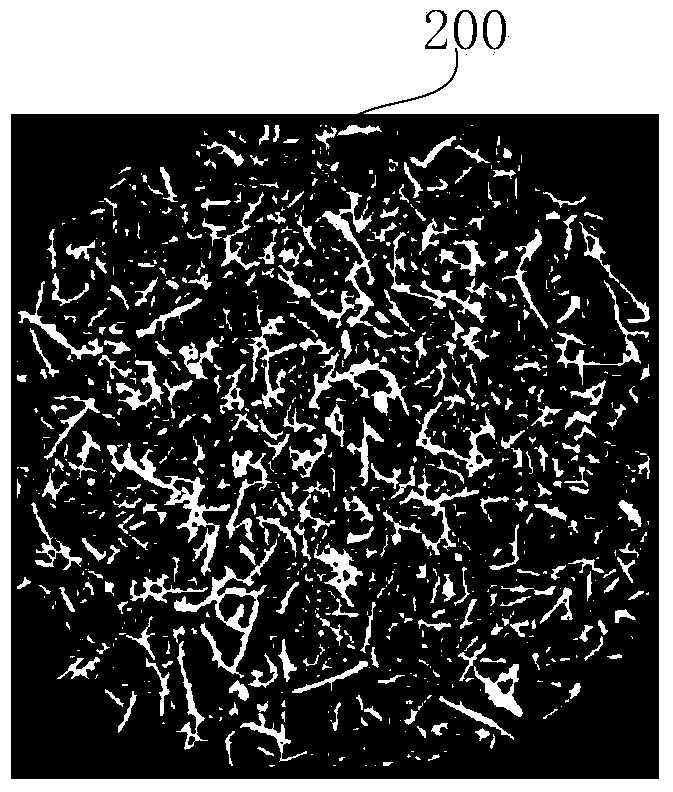

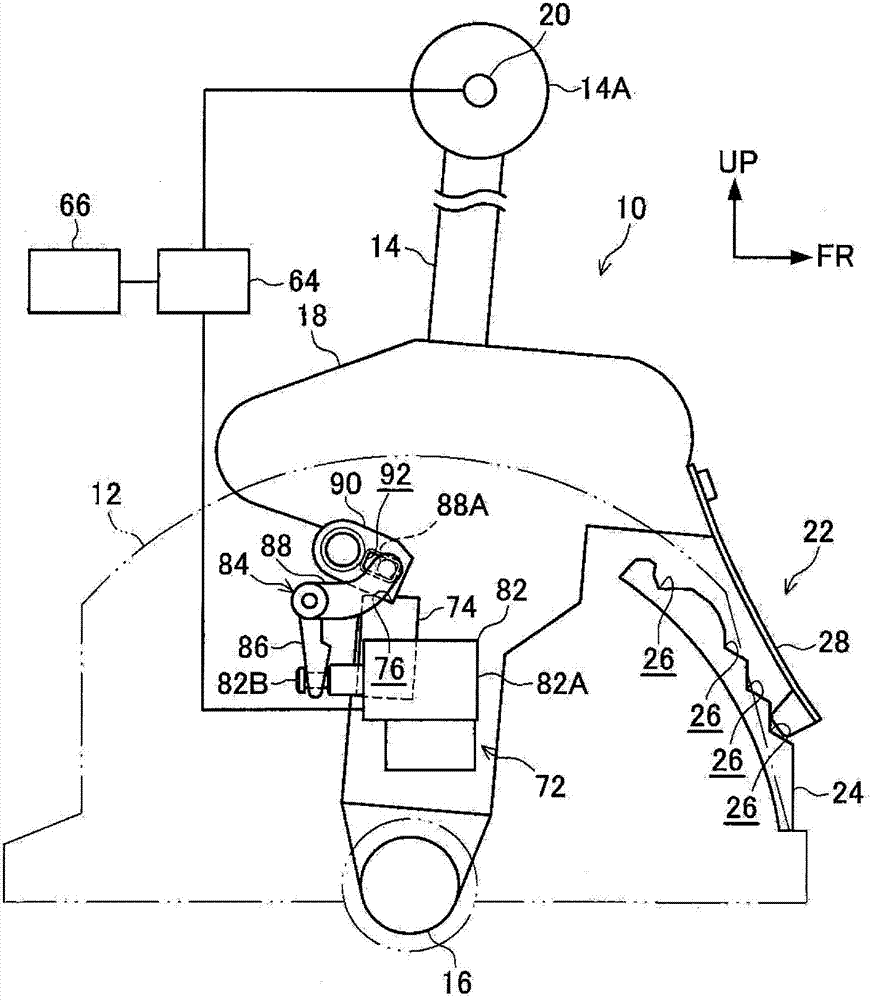

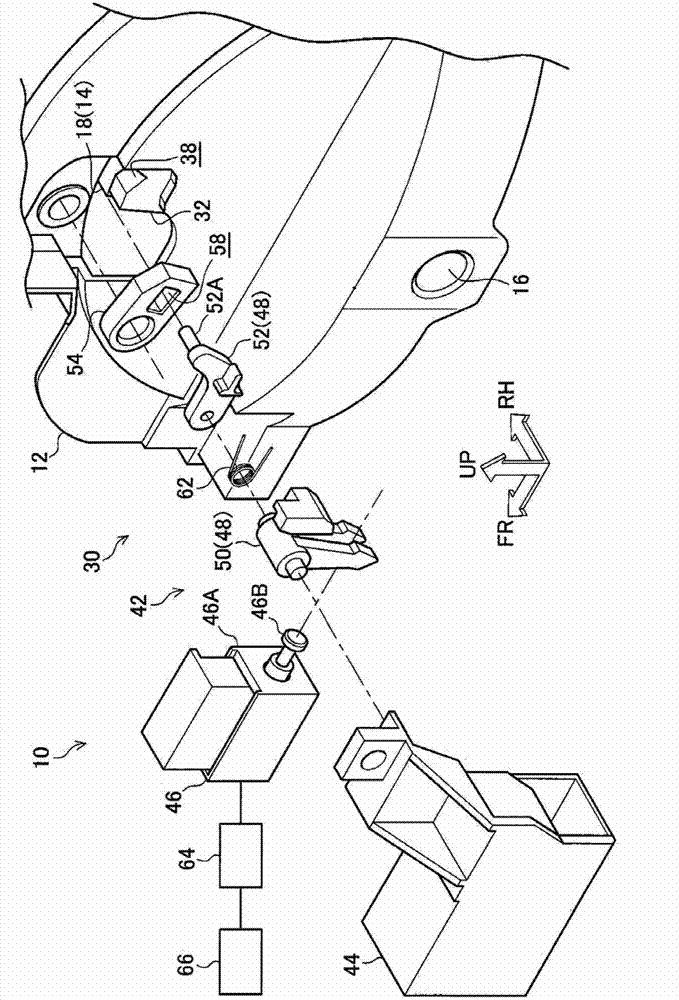

Engineering machinery and engineering machinery winding disorder cable monitoring device and method

ActiveCN105438983AReal-time monitoring of arrangement statusAvoid wear and tearSafety gearImaging processingPull force

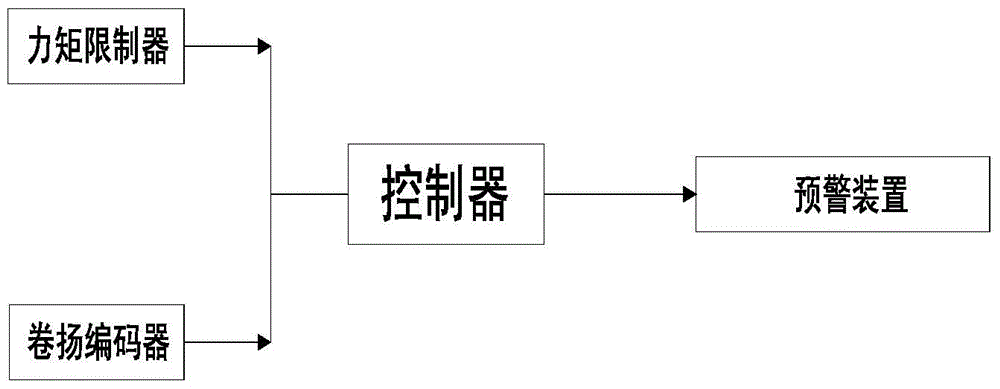

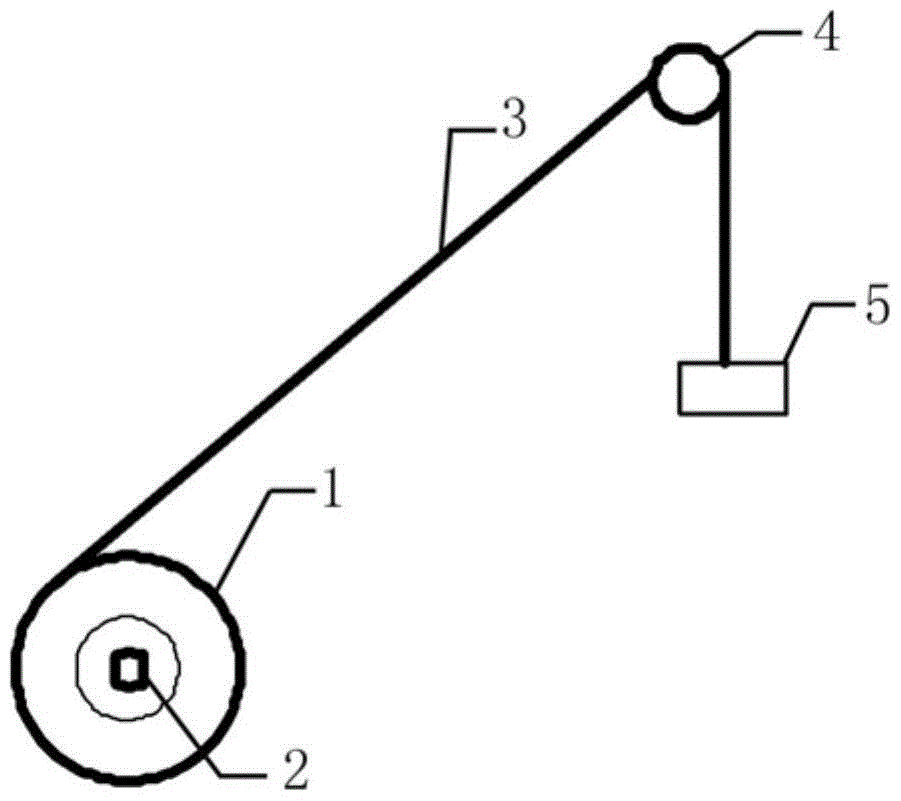

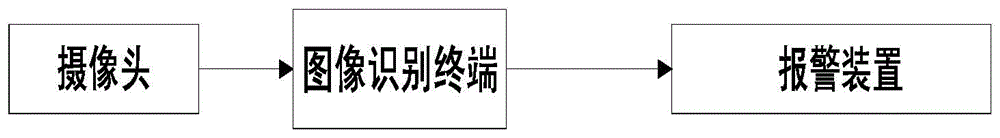

The present invention discloses a winding disorder cable monitoring device, a winding disorder cable early warning unit comprises a first detection part for acquiring winding lifting weight information, a second detection part for acquiring winding winding-drum rotation information and a controller to acquire a winding steel wire rope pull force F, acquire a winding steel wire rope deploying and retracting speed V and output early warning information according to the case that whether the steel wire rope pull force F or the steel wire rope deploying and retracting speed V exceeds a limit value; a winding disorder cable alarm unit comprises a winding monitoring camera part for capturing a steel wire rope image and an image processing apparatus, and the image processing apparatus is used for extracting steel wire rope position information from the steel wire rope image for parallelism analysis and outputting the alarm information according to the judgment that whether the steel wire rope parallelism exceeds a threshold value. The device has winding disorder cable early warning and alarm functions, and can greatly improve reliability of a crane. The present invention also provides a winding disorder cable monitoring method and engineering machinery using the winding disorder cable monitoring device.

Owner:XUZHOU HEAVY MASCH CO LTD

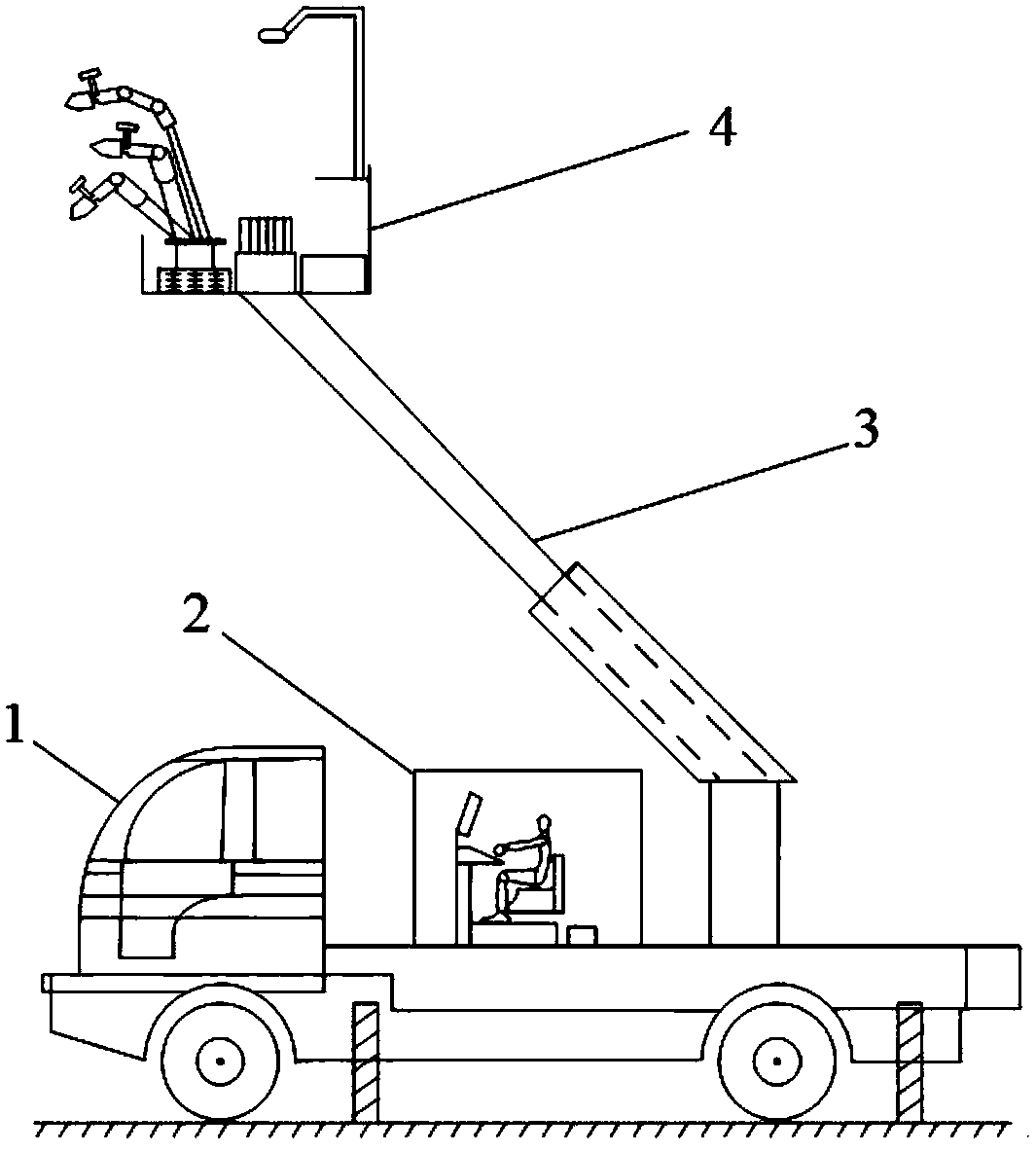

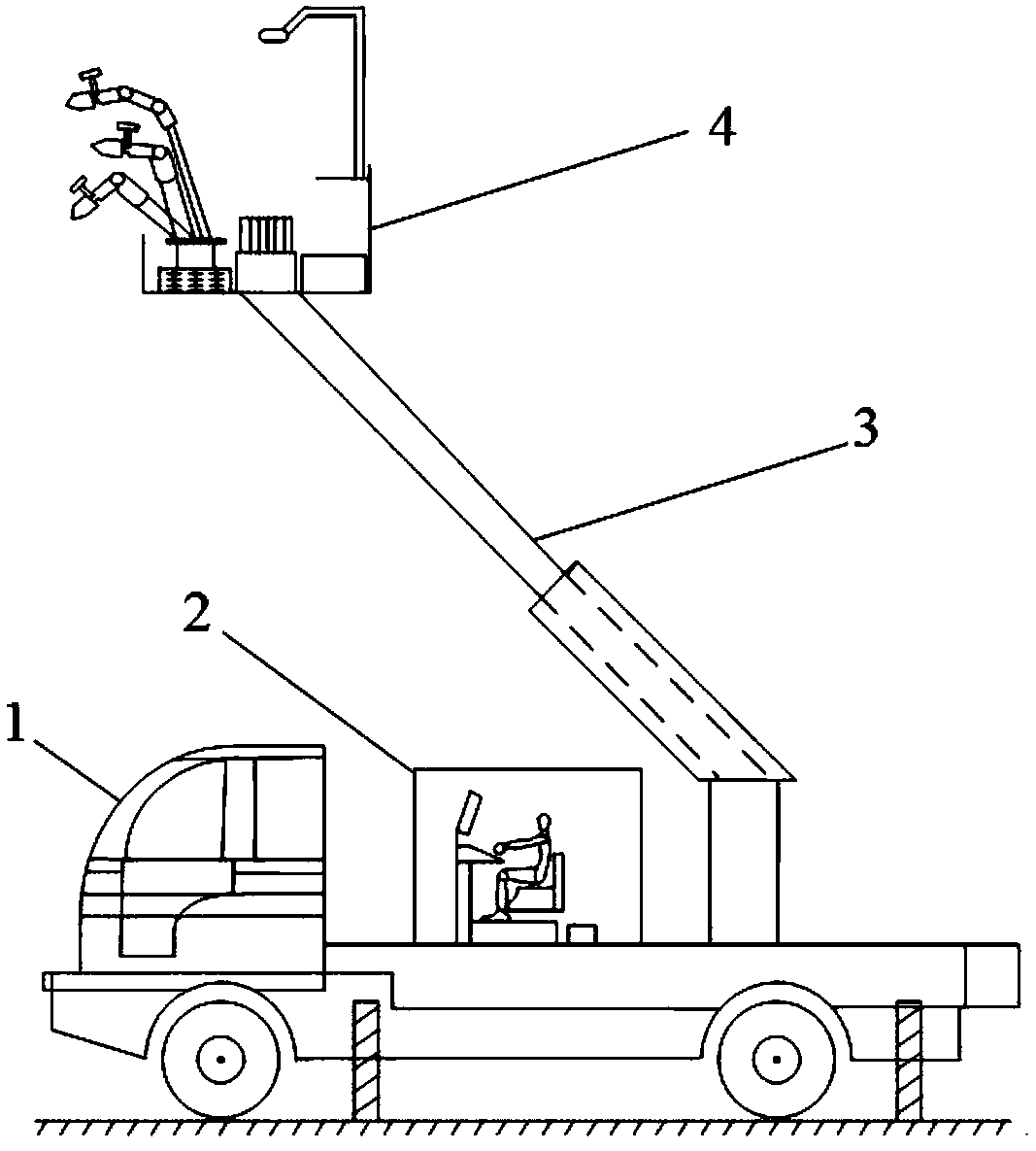

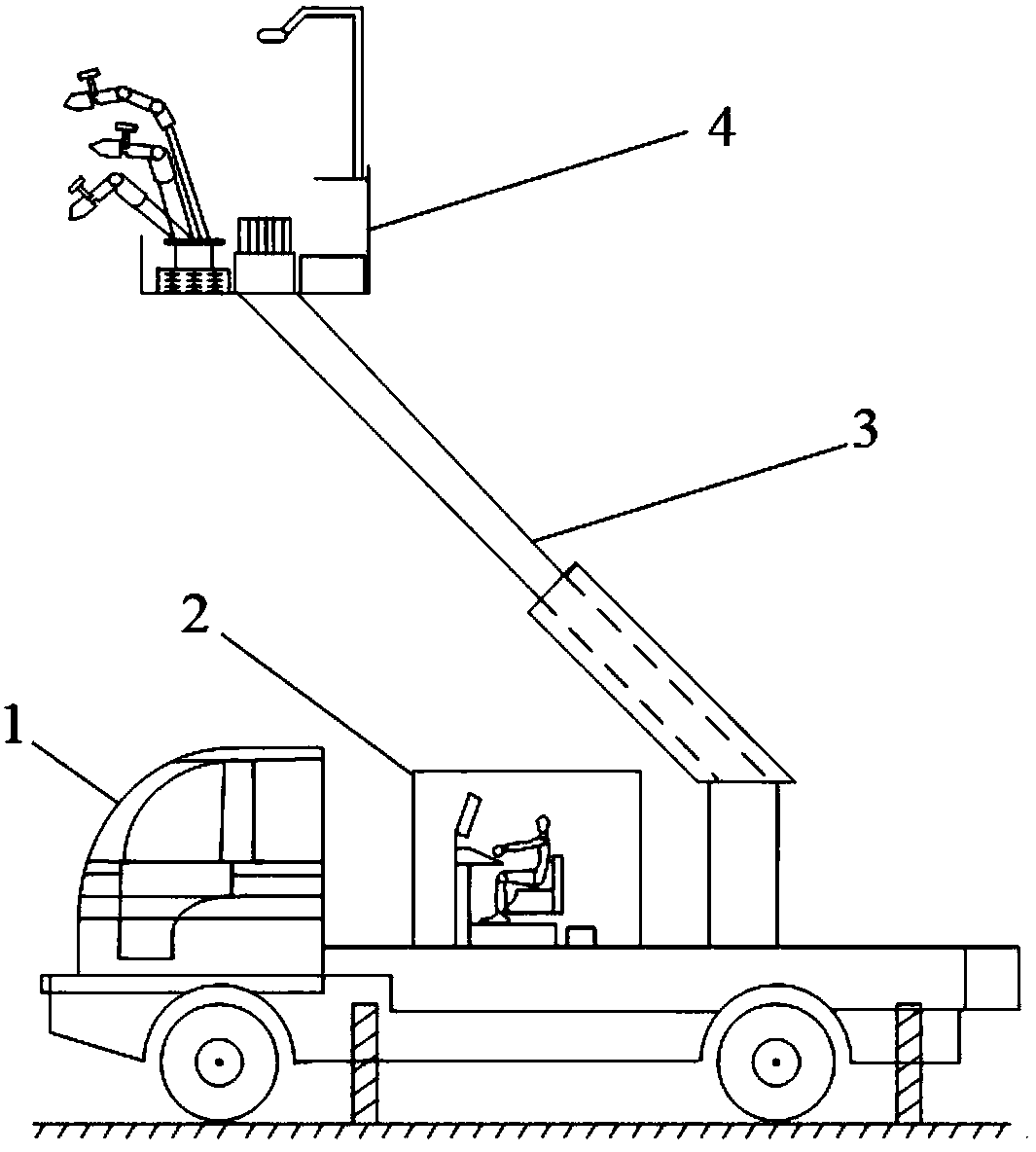

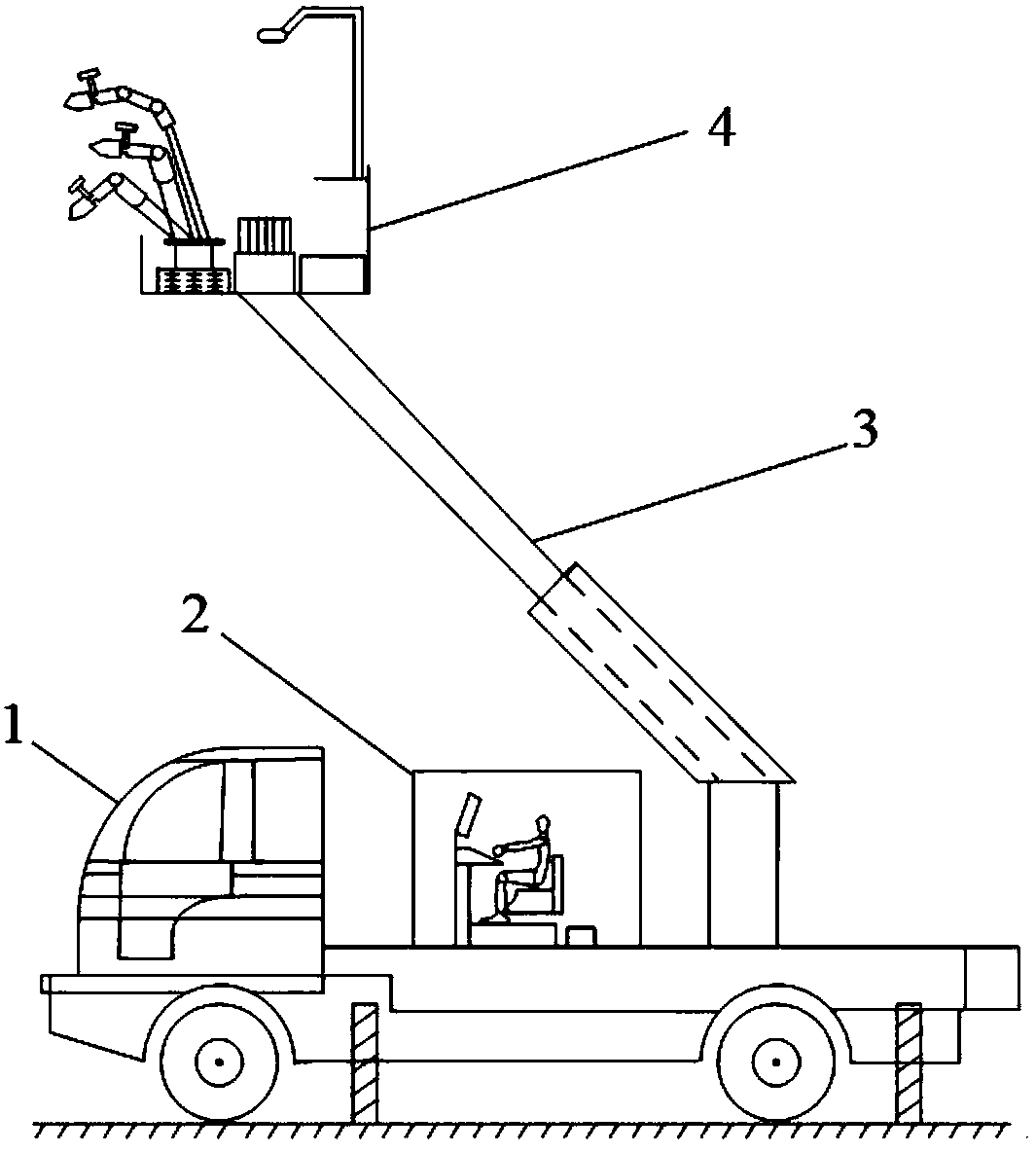

Supporting and connecting lead lapping method of live working robot based on force feedback master-slave control

InactiveCN108582031AEasy to operateFlexible operationProgramme-controlled manipulatorGripping headsControl systemVelocity vector

The invention provides a supporting and connecting lead lapping method of a live working robot based on force feedback master-slave control. A mechanical arm, a master manipulator and an industrial personnel computer form a force feedback master-slave control system, wherein the industrial personnel computer calculates torque data of joints of the master manipulator according to stress data at thetail end of the mechanical arm to control the joints of the master manipulate to output torque through a control interface of the master manipulator, so that the master manipulator feeds the force back, and an operator confirms the force of the mechanical arm according to the feedback stress of the master manipulator; the operator changes the posture of the tail end of the master manipulator, theindustrial personnel computer calculates a expected number of a velocity vector at the tail end of the mechanical arm according to the angle data of the rotary joints of the master manipulator; through the control interface of the mechanical arm, the mechanical arm is controlled to move according to the expected number to change the force of the mechanical arm. According to the method provided bythe invention, the operating sense of immediacy is improved, and whether operations are in position precisely or not can be precisely judged.

Owner:NANJING UNIV OF SCI & TECH

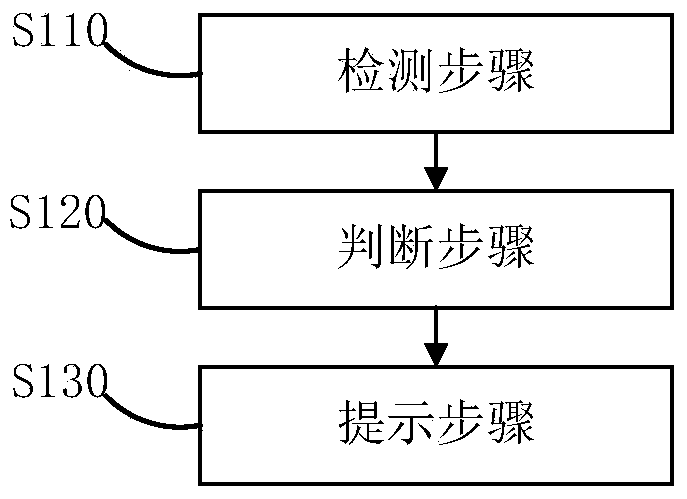

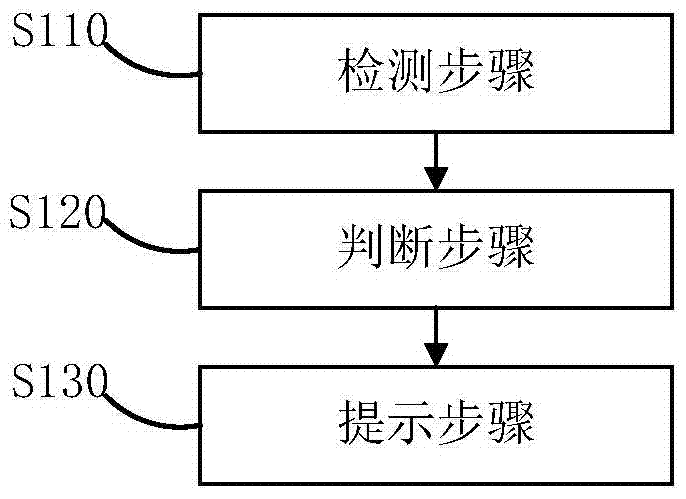

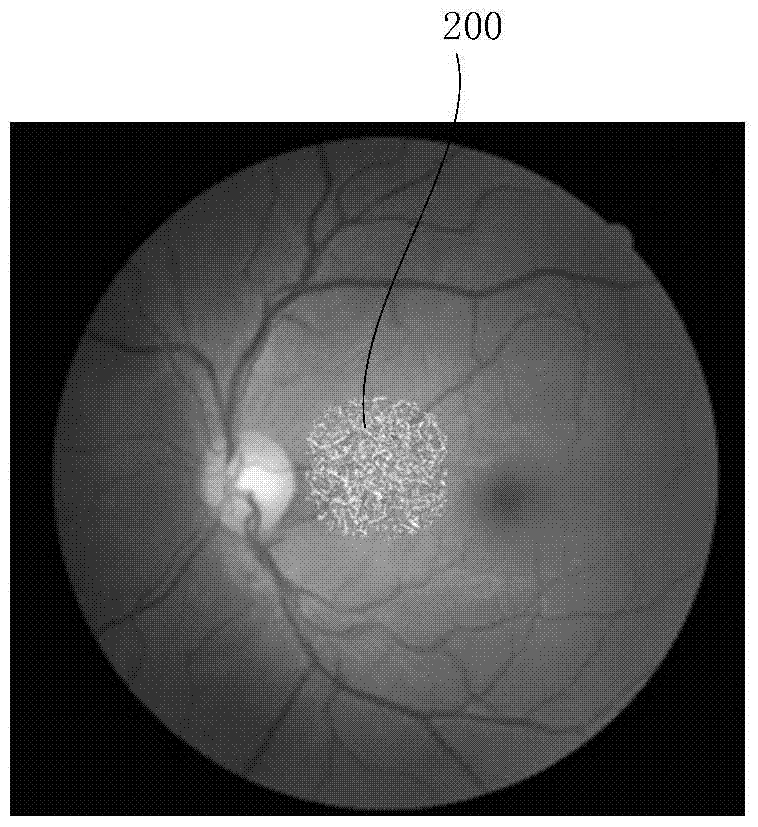

Information observation method and information observation device

ActiveCN103530623ALimit operationsAvoid missingImage analysisCharacter and pattern recognitionFocal positionNeglect

The invention discloses an information observation method and an information observation device, and relates to the field of multimedia information processing technologies. The information observation method comprises a detection step of detecting a focal position of sight of an observer; a judging step of judging whether the observer observes all important information in an observation object when a focal point of the sight of the observer leaves the observation object; and a prompting step of prompting the observer when the observer is judged to not observe all important information in the observation object. The information observation method and the information observation device, which are provided by the embodiment of the invention, start out from the actual observation behavior of the observer, and the observation behavior of the observer about the important information is determined by detecting the focal position of the sight of the observer, so that neglect of the important information can be prevented fundamentally.

Owner:BEIJING ZHIGU RUI TUO TECH

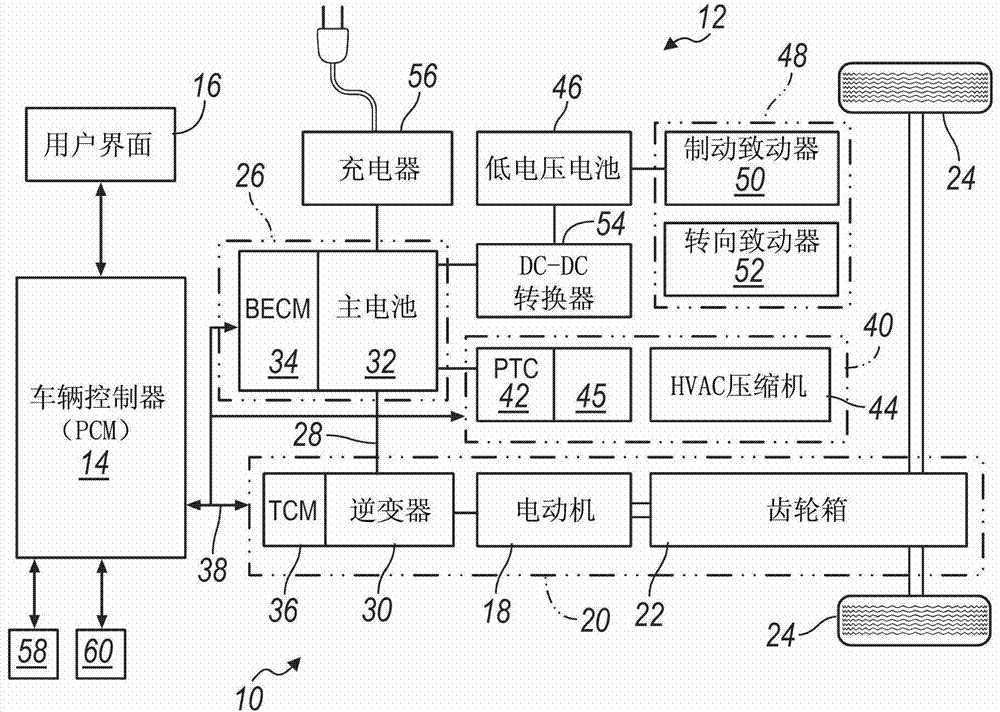

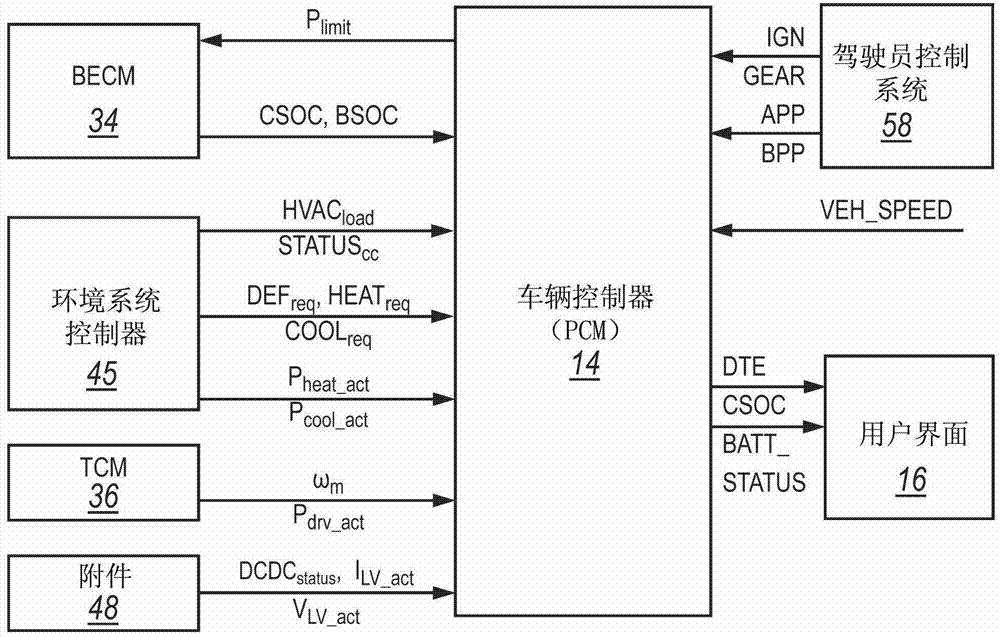

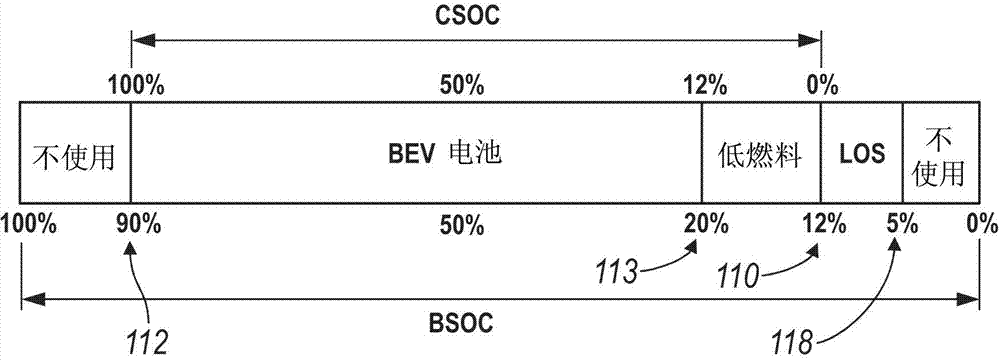

Vehicle system

ActiveCN103287279ALimit operationsIncrease mileageCircuit monitoring/indicationPower to auxillary motorsBattery state of chargeControl system

The invention discloses a vehicle. The vehicle is provided with a climate control system and a battery that is connected to the climate control system for supplying power. The vehicle also includes at least one controller that is configured to receive input indicative of a battery state of charge (BSOC). The at least one controller is also configured to disable the climate control system and reduce the battery power limit when the BSOC is less than a discharge limit.

Owner:FORD GLOBAL TECH LLC

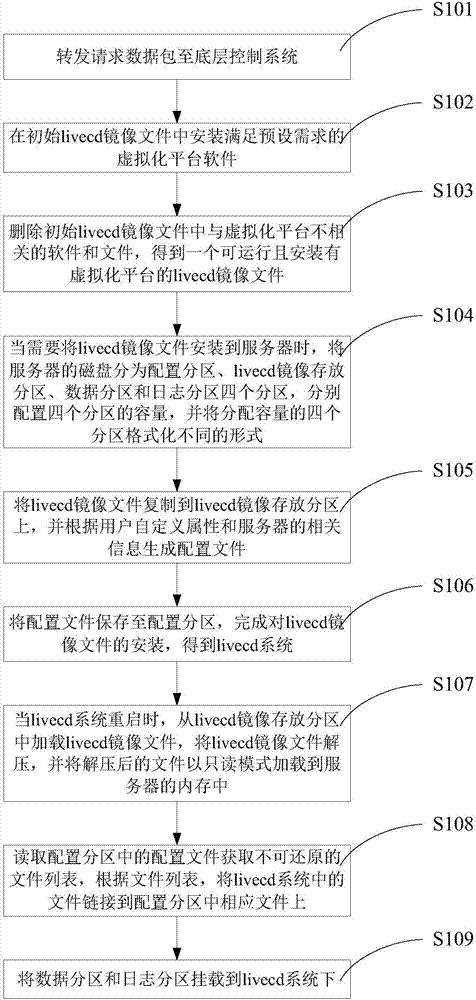

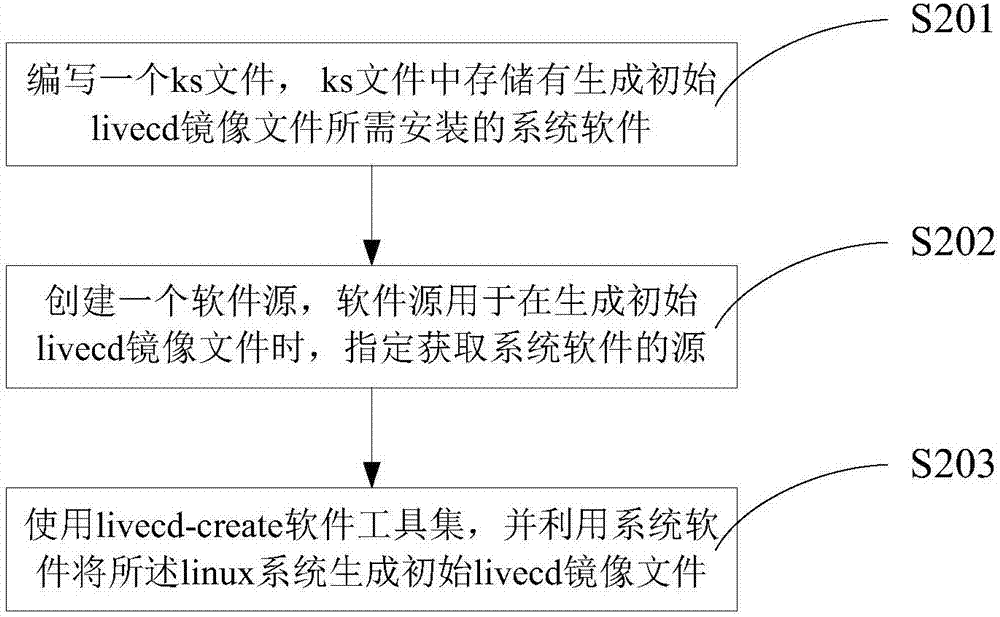

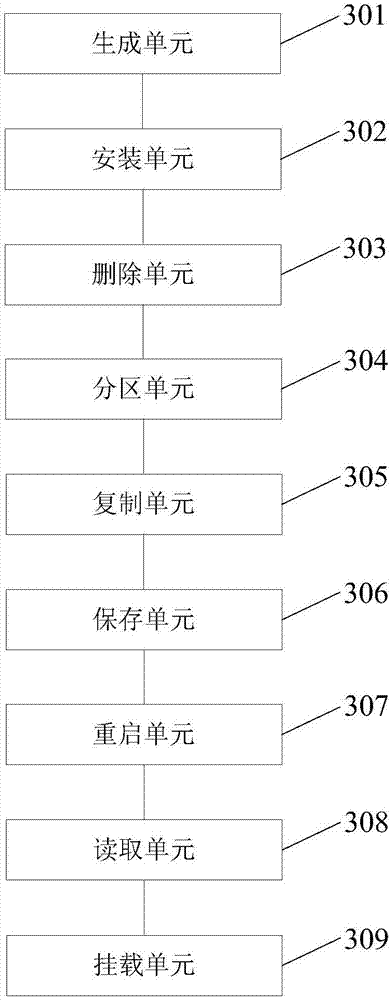

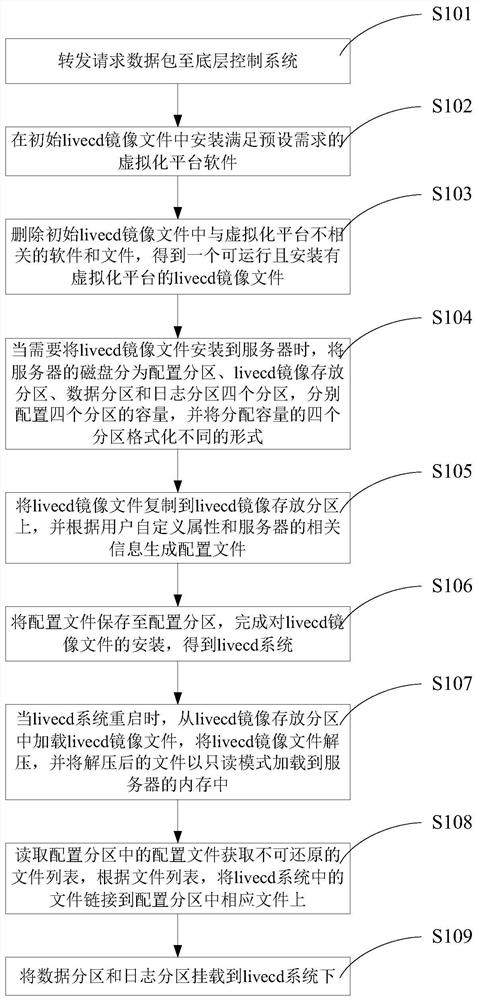

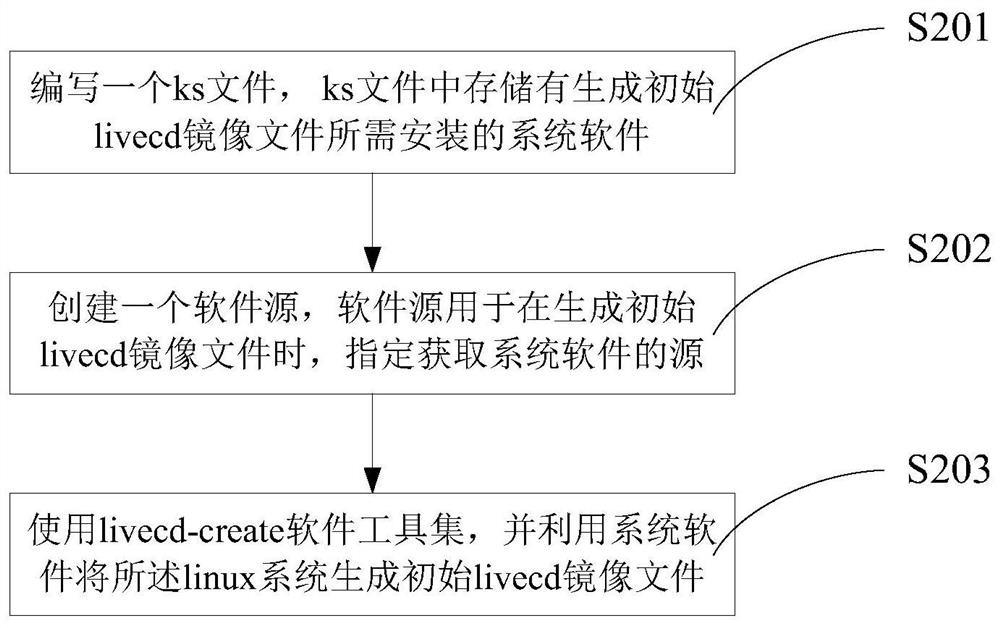

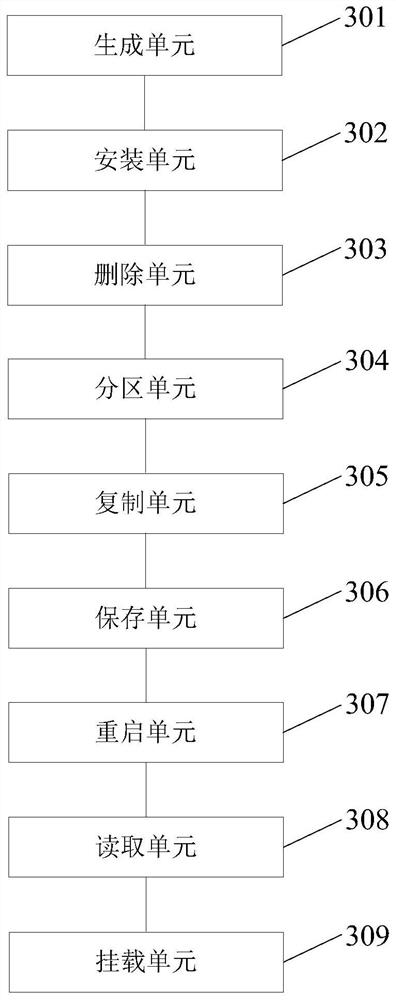

Method and system for quickly restoring virtualization platform

ActiveCN107463467AQuick restorePromote recoveryRedundant operation error correctionVirtualizationThird party

The invention discloses a method and system for quickly restoring a virtualization platform. A disk of a server is divided into a configuration partition, a livecd mirror partition, a data partition and a log partition, and the partitions are formatted into different forms so as to limit the operation of a user; because of the characteristic that a livecd system runs in a memory and can be eliminated after the memory is powered down and the unwriteable specificity of the cd-rom in a livecd mirror storage partition, livecd mirror files in the livecd mirror storage partition cannot be modified, and consequently, the livecd system can be restored to the initial installation state after restarting every time. By means of the method and system for quickly restoring the virtualization platform, when error operations exist in the virtualization platform and / or the virtualization platform suffers from hostile attack of third parties, the livecd system is quickly restored to the initial state in the mode of restarting the server, and therefore, the quick restoration of the virtualization platform is achieved.

Owner:INSPUR BEIJING ELECTRONICS INFORMATION IND

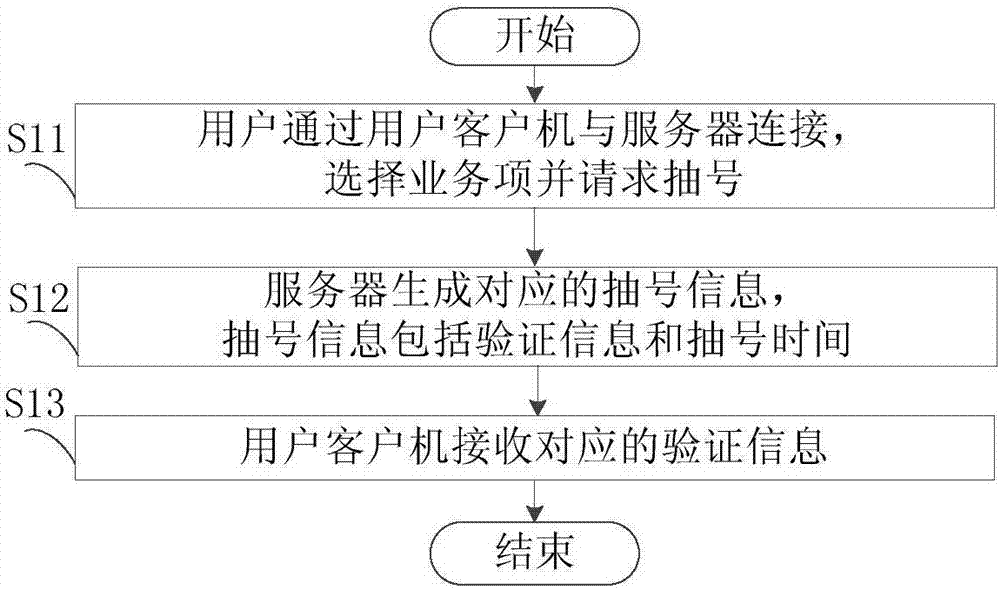

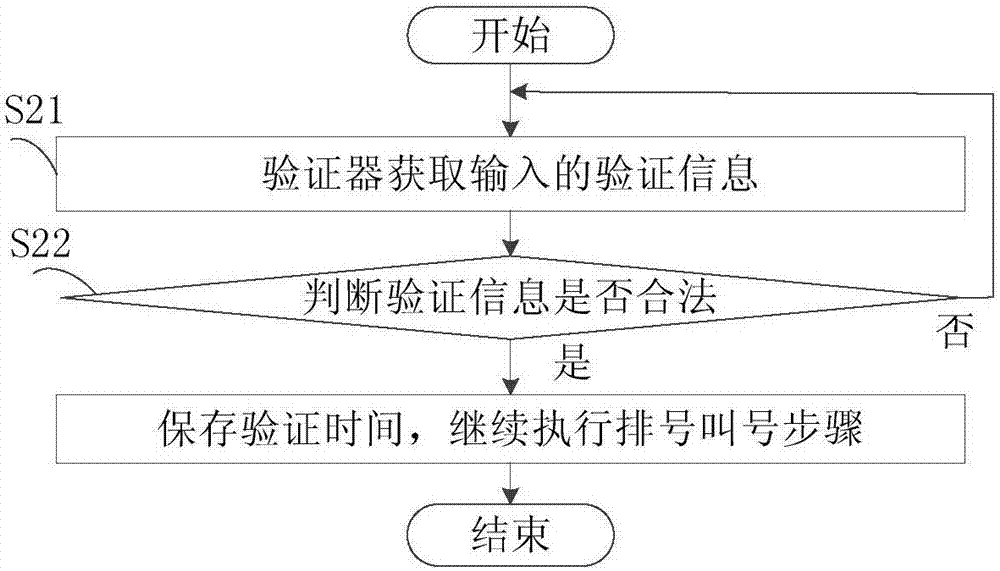

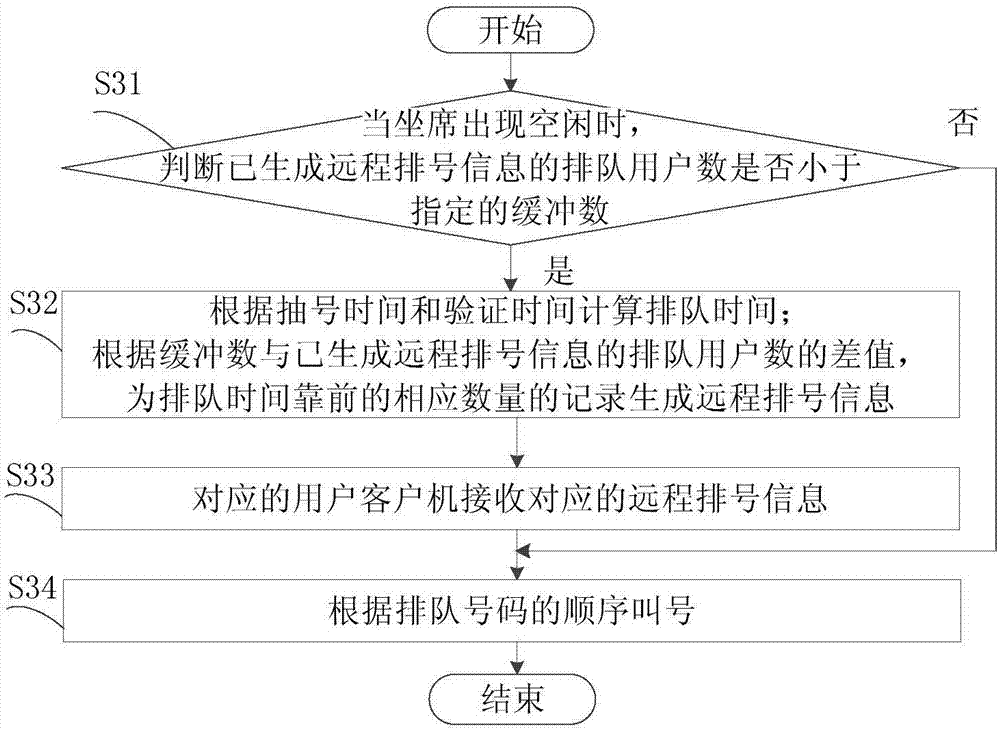

A number queuing verifying method and system

ActiveCN107358711AEasy to divertRealize remote drawing number queuingChecking apparatusValidation methodsTrusted client

A remote number-drawing queuing verifying method and system are disclosed. According to the method, a user draws a number in a remote manner and receives verification information; the verification information is checked by a verifier after the user shows up; when a vacant seat occurs, queuing time is calculated according to number-drawing time and verification time, queuing numbers for top records are generated and number calling is performed; and a user shows a received queuing number to a seat or a seat client receives user identity information to determine the user identity. The system includes a server, a user client, the verifier, queue equipment and a number calling terminal, and can also comprises the seat client to support real-name authentication. The method and system perfectly balance benefits of users drawing numbers in a remote manner and users drawing numbers on site, performs comprehensive queuing of the two types of users, and achieves a continuous number calling sequence. Number drawing in a remote manner and attendance according to preset arrival time to the greatest extent are encouraged, and missing number calling does not occur. The method and the system are suitable for a plurality of application occasions, can achieve real-name or non-real-name authentication. A user can leave temporarily, and repeated number calling is prevented. The method and the system are convenient, flexible, and low in implementation cost.

Owner:胡飞虎

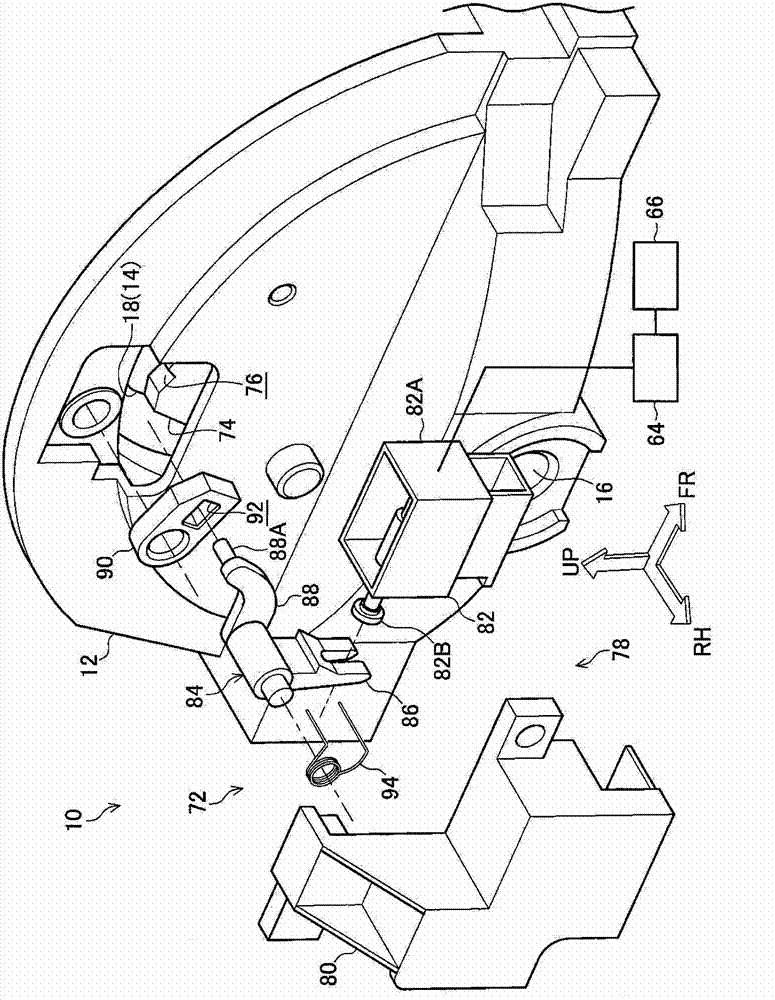

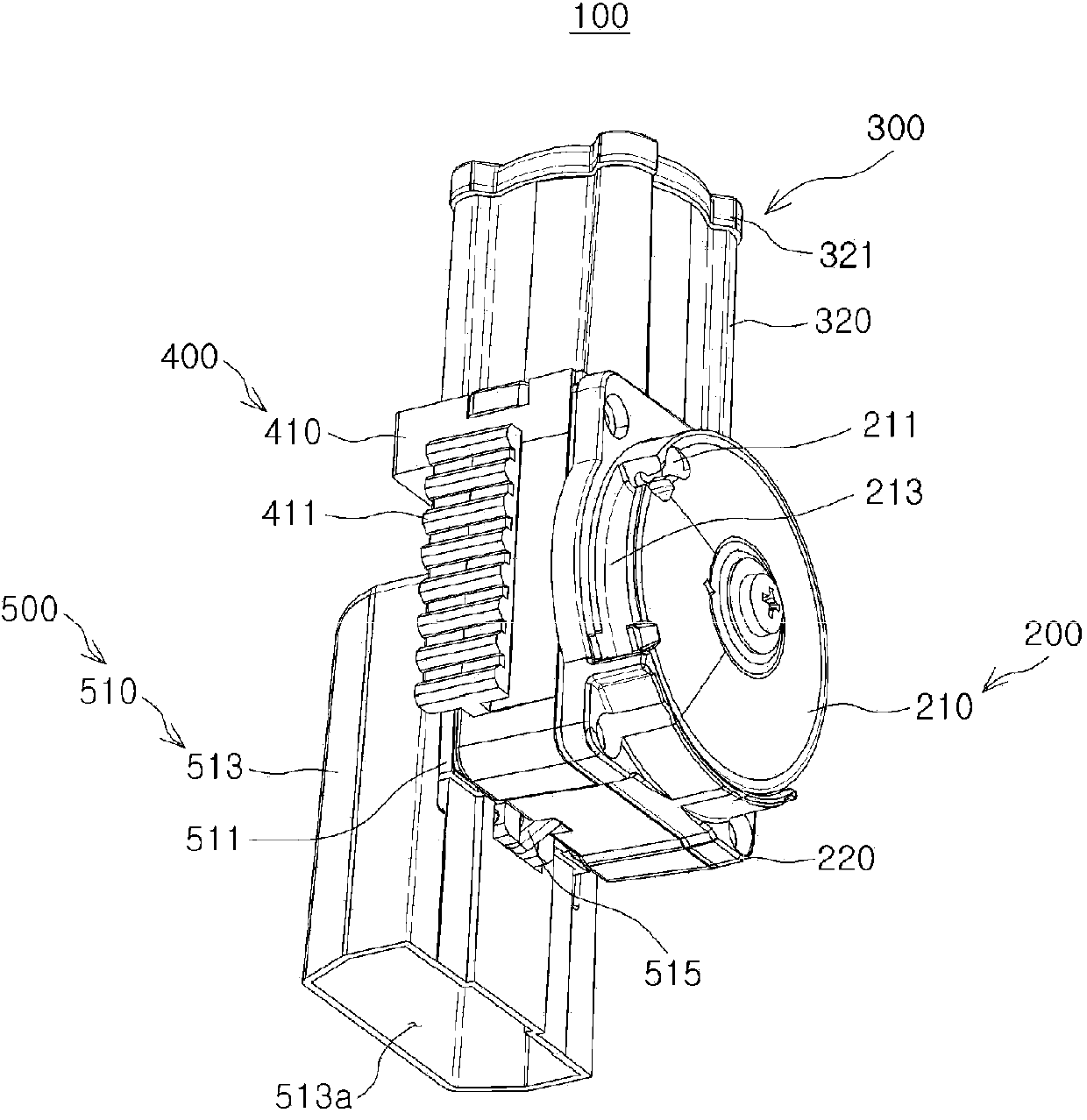

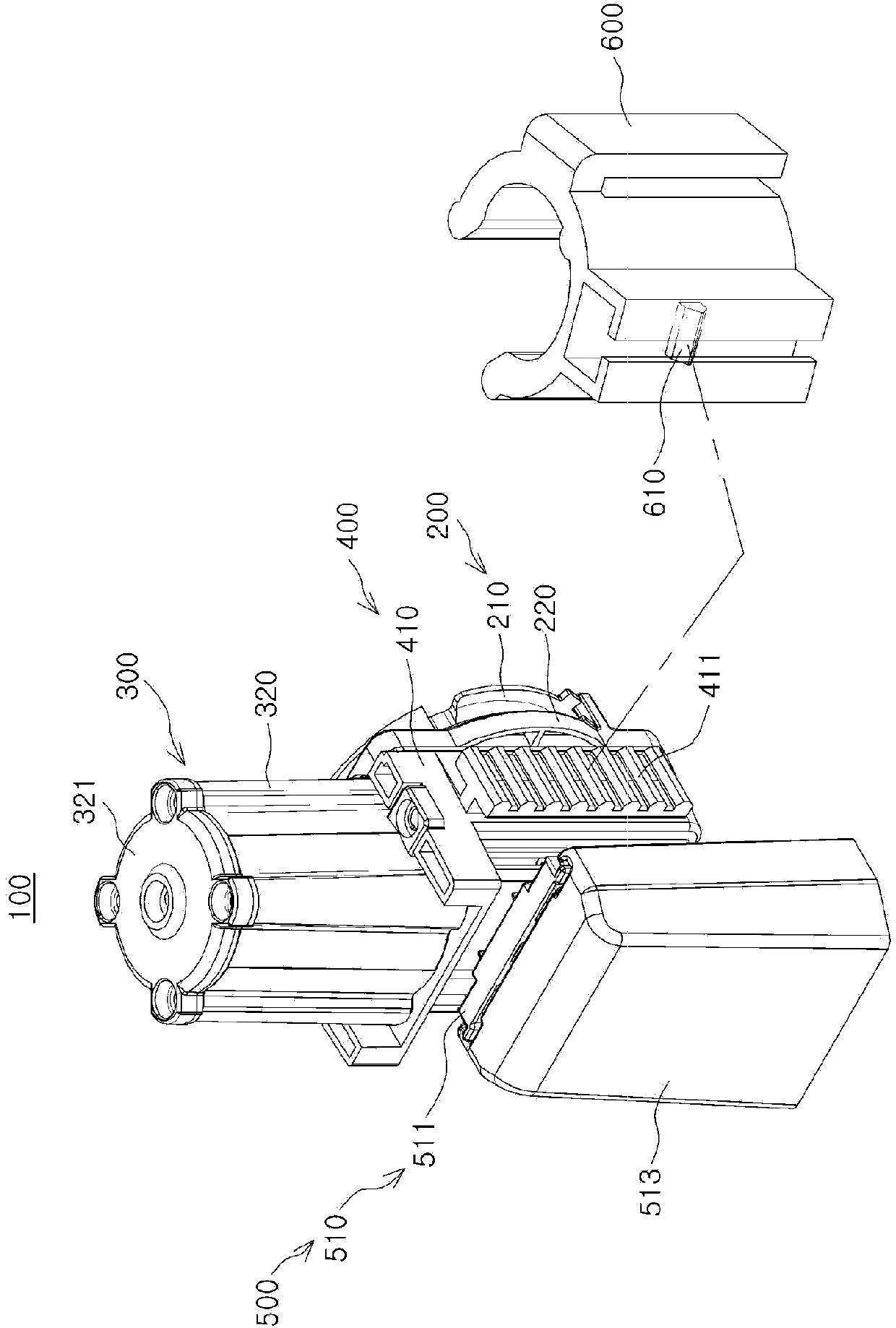

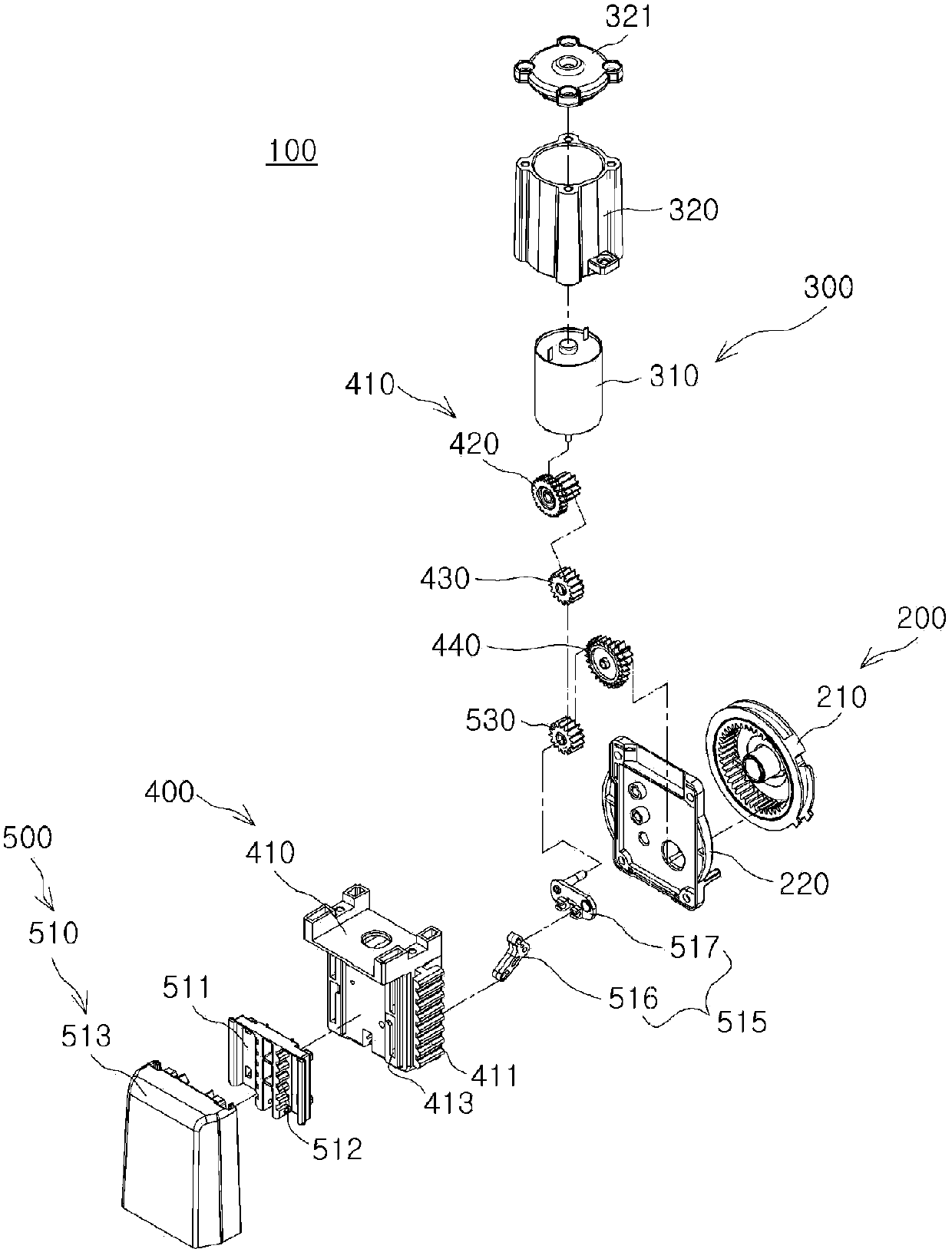

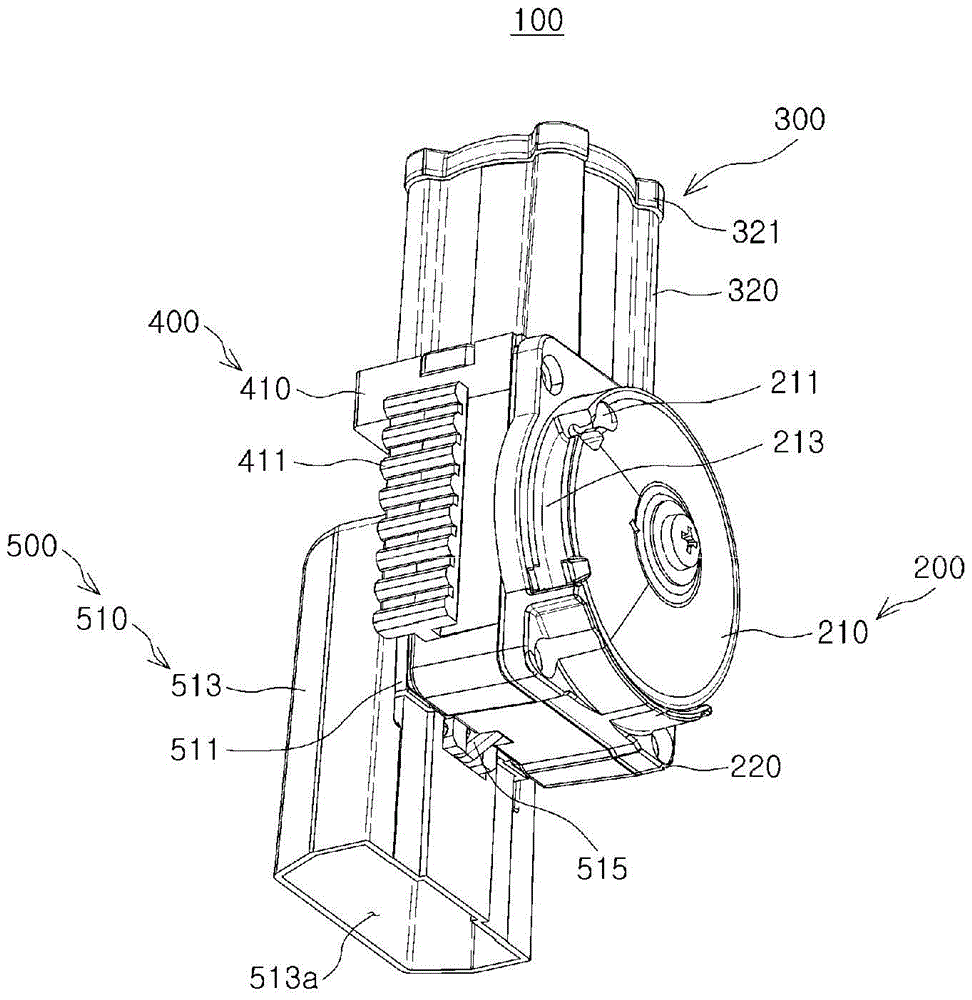

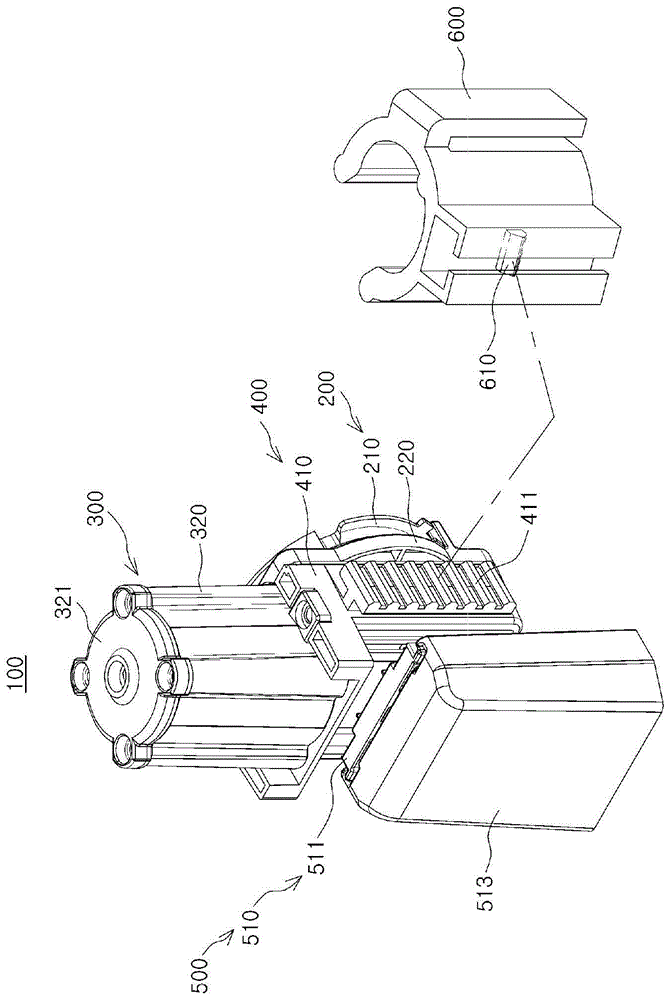

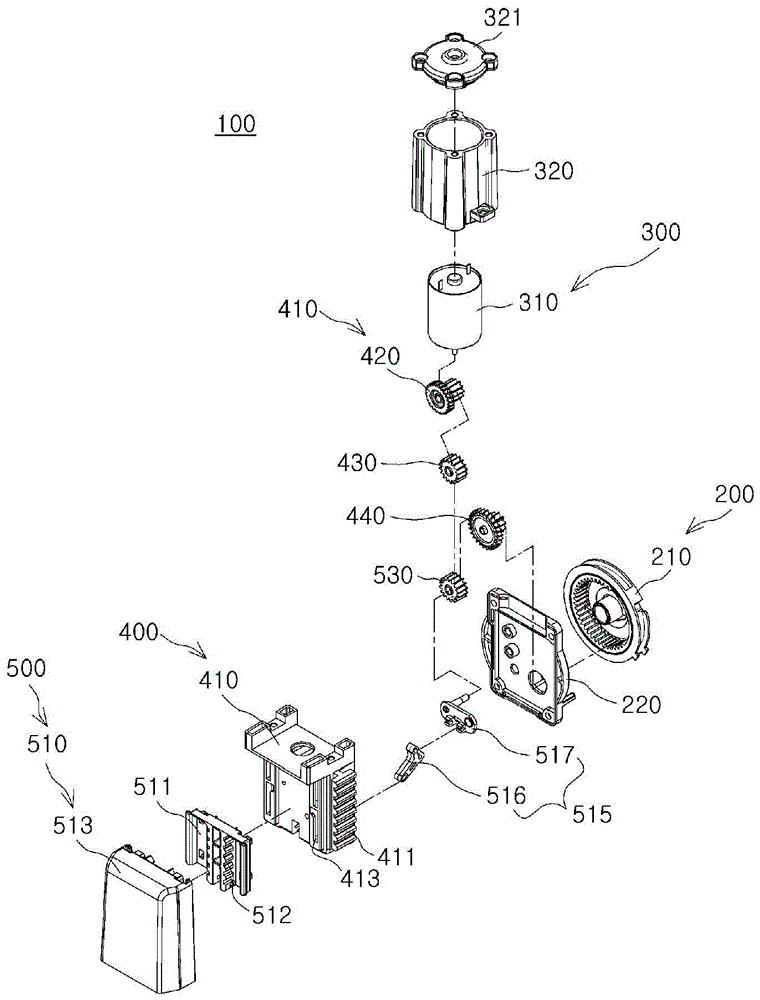

Shift device

Owner:KK TOKAI RIKA DENKI SEISAKUSHO

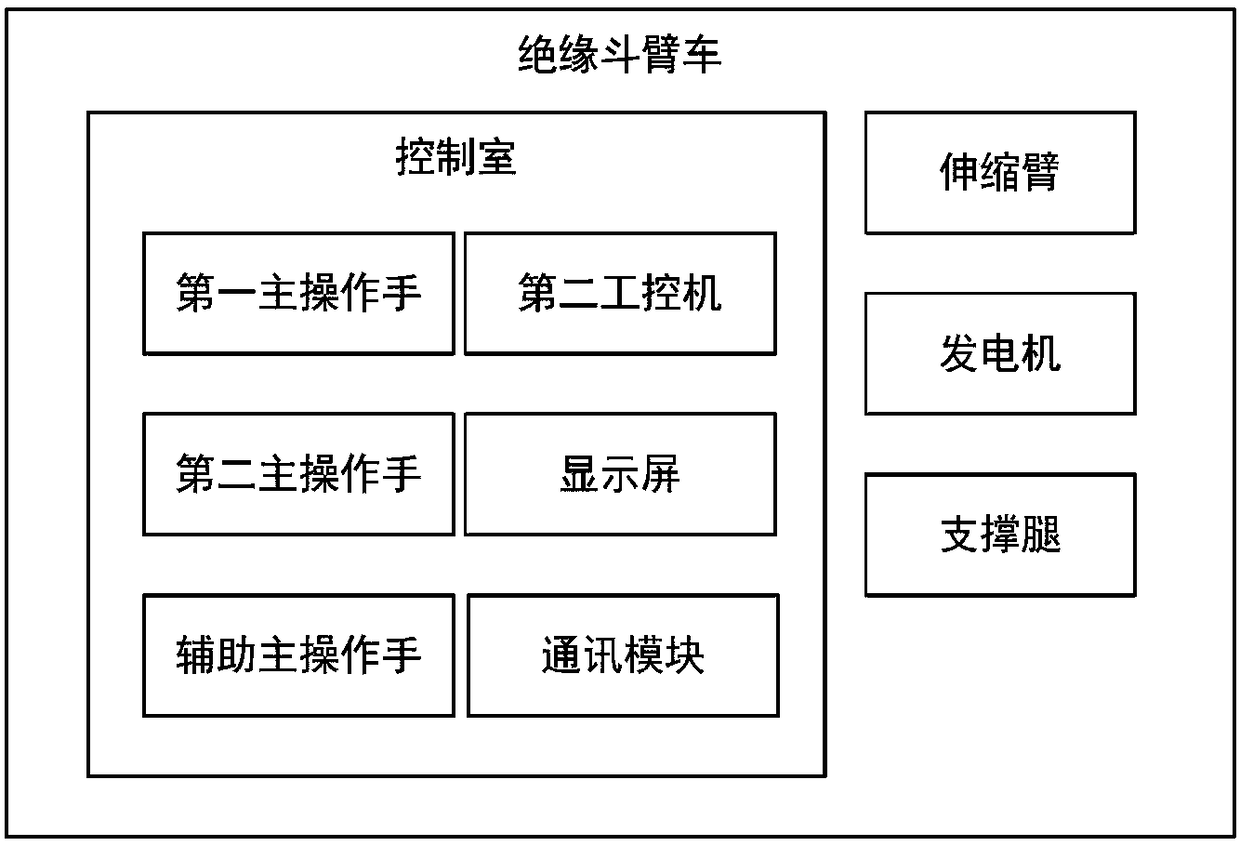

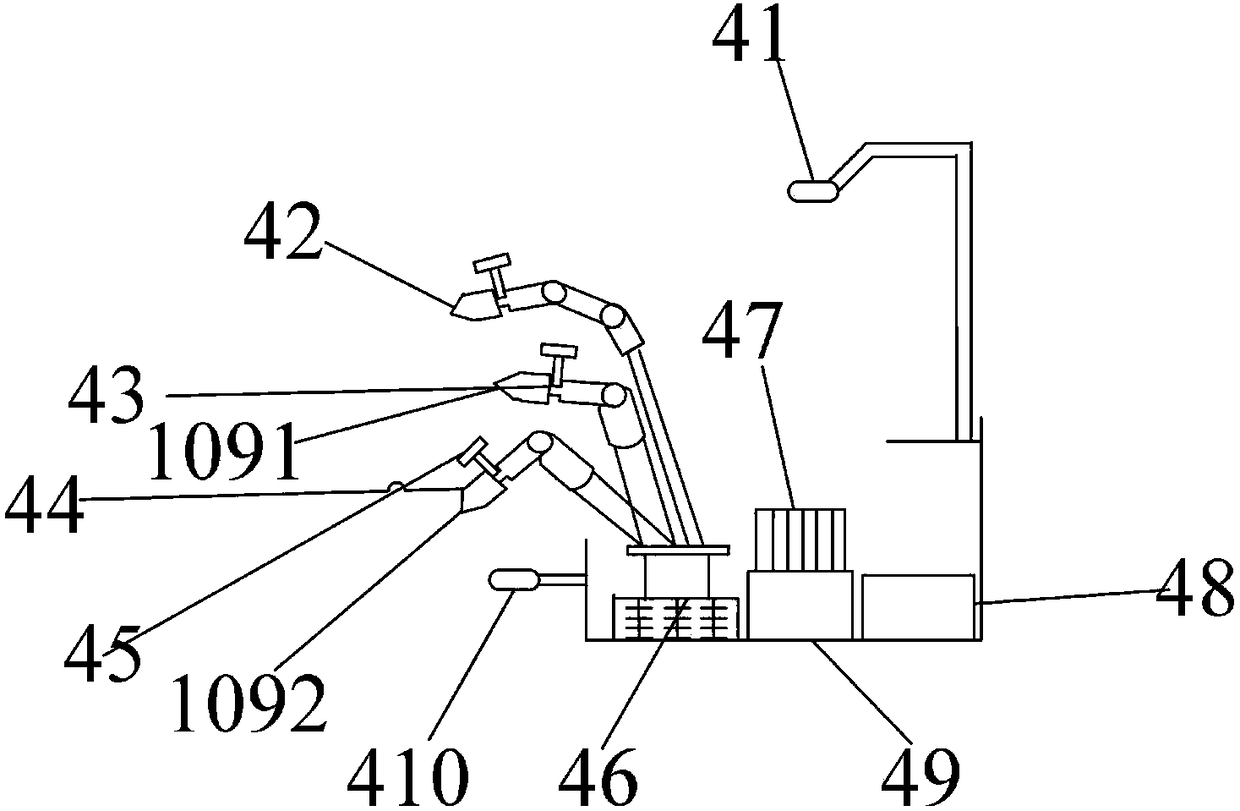

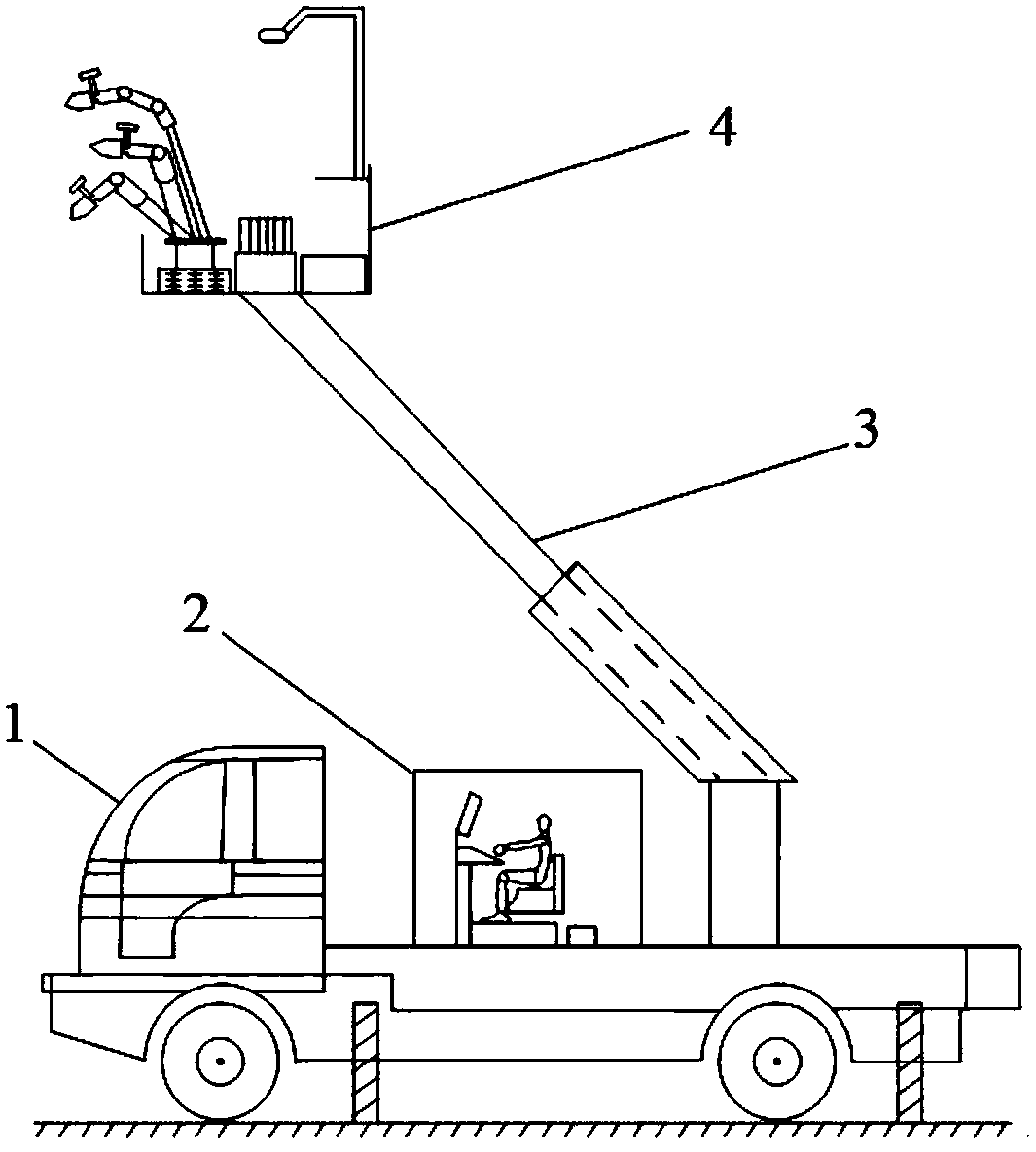

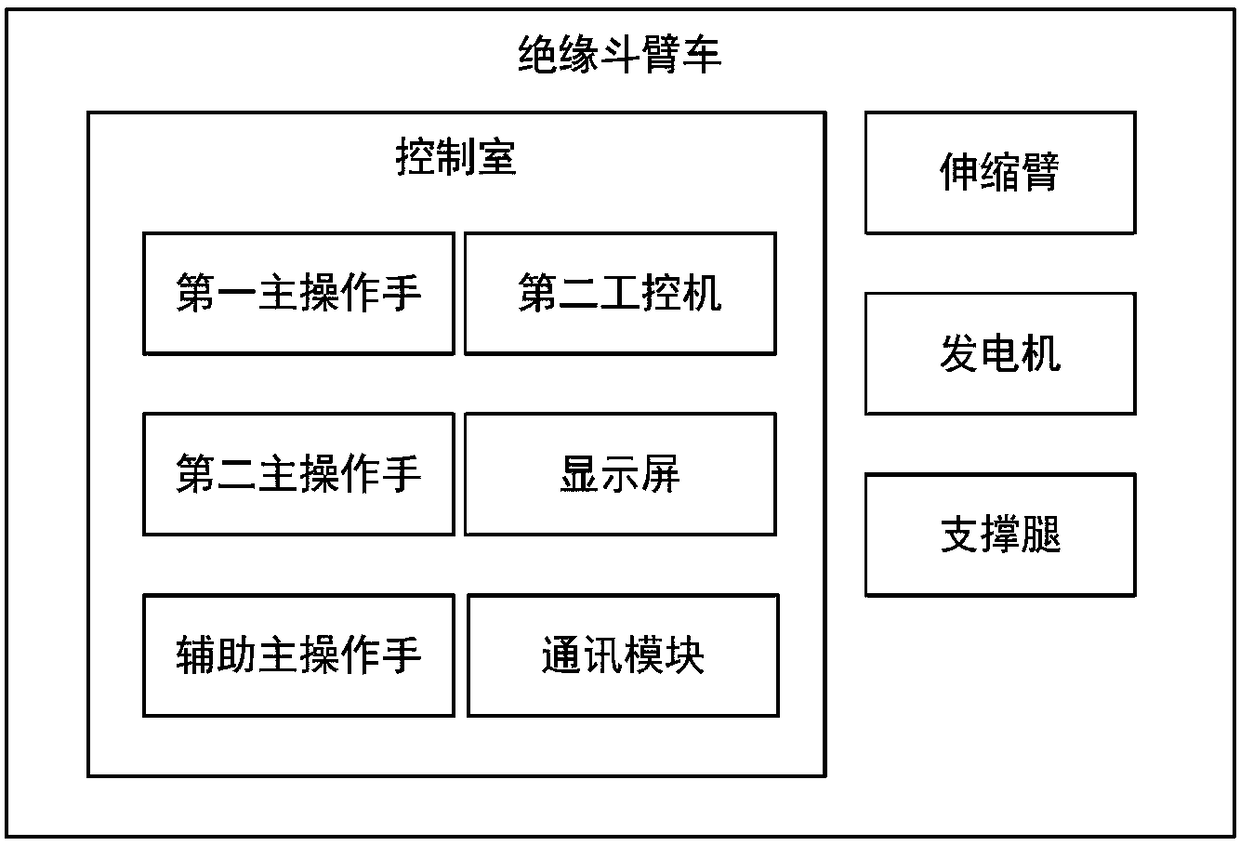

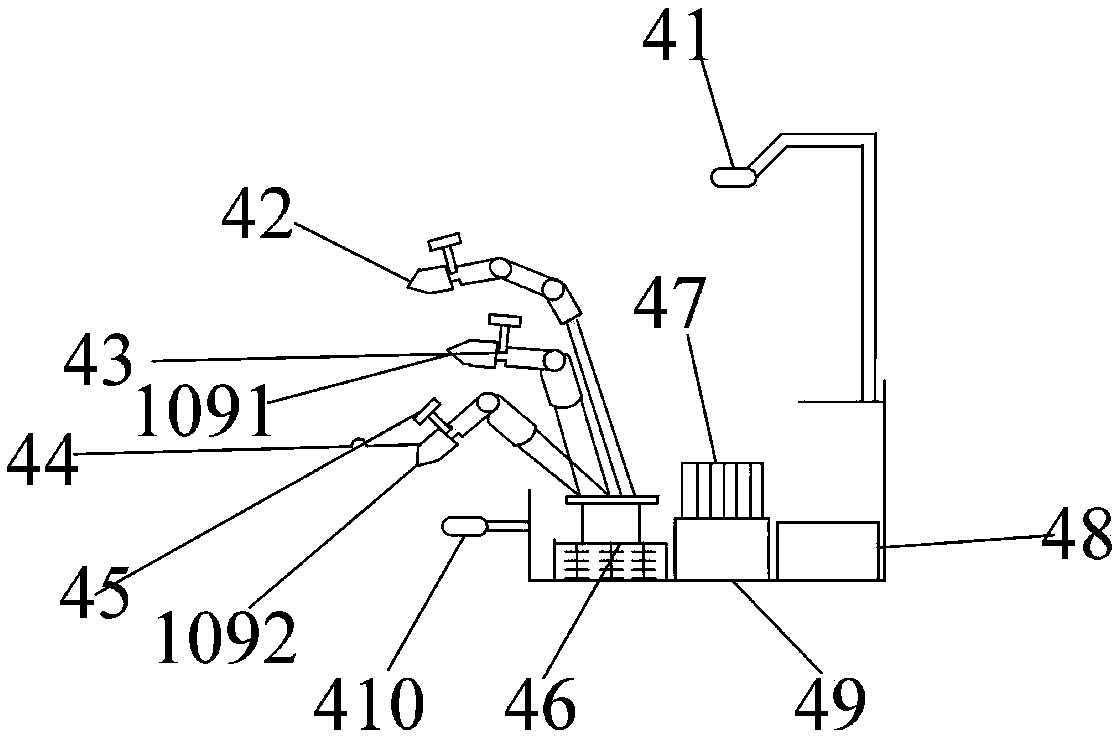

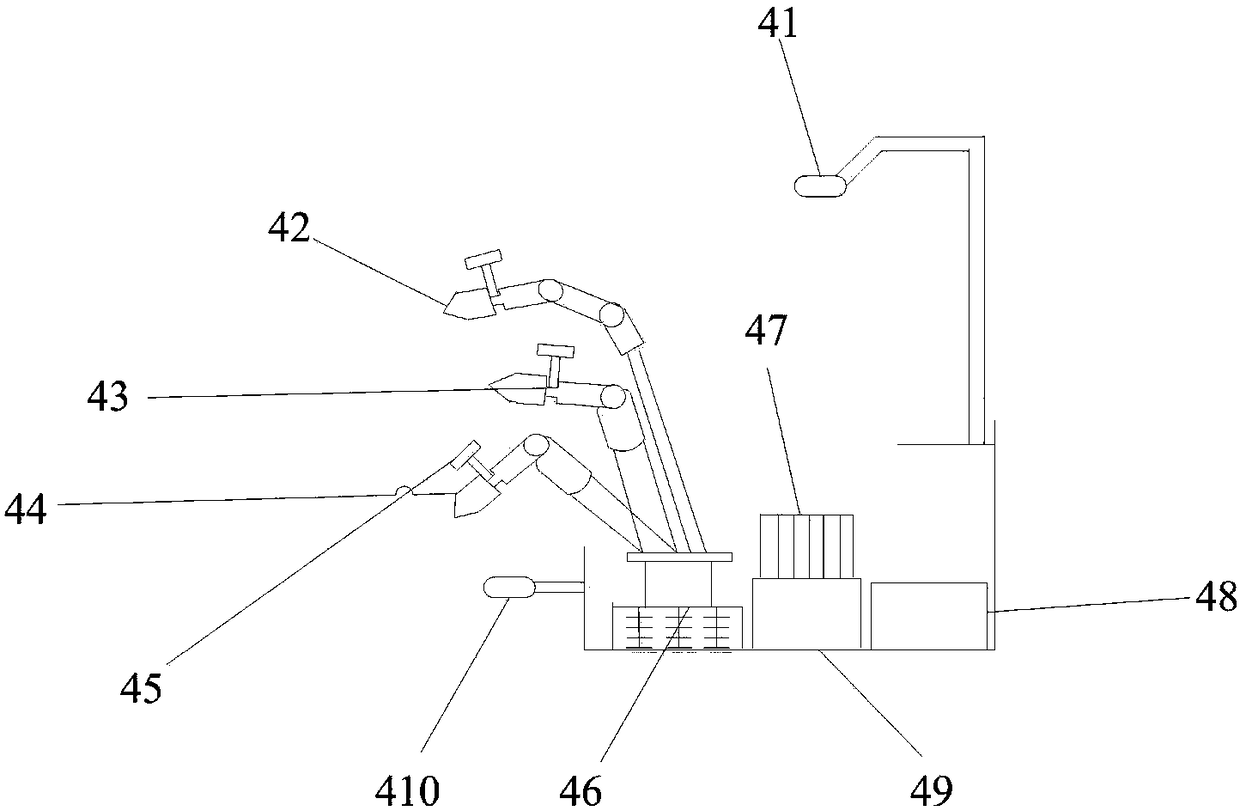

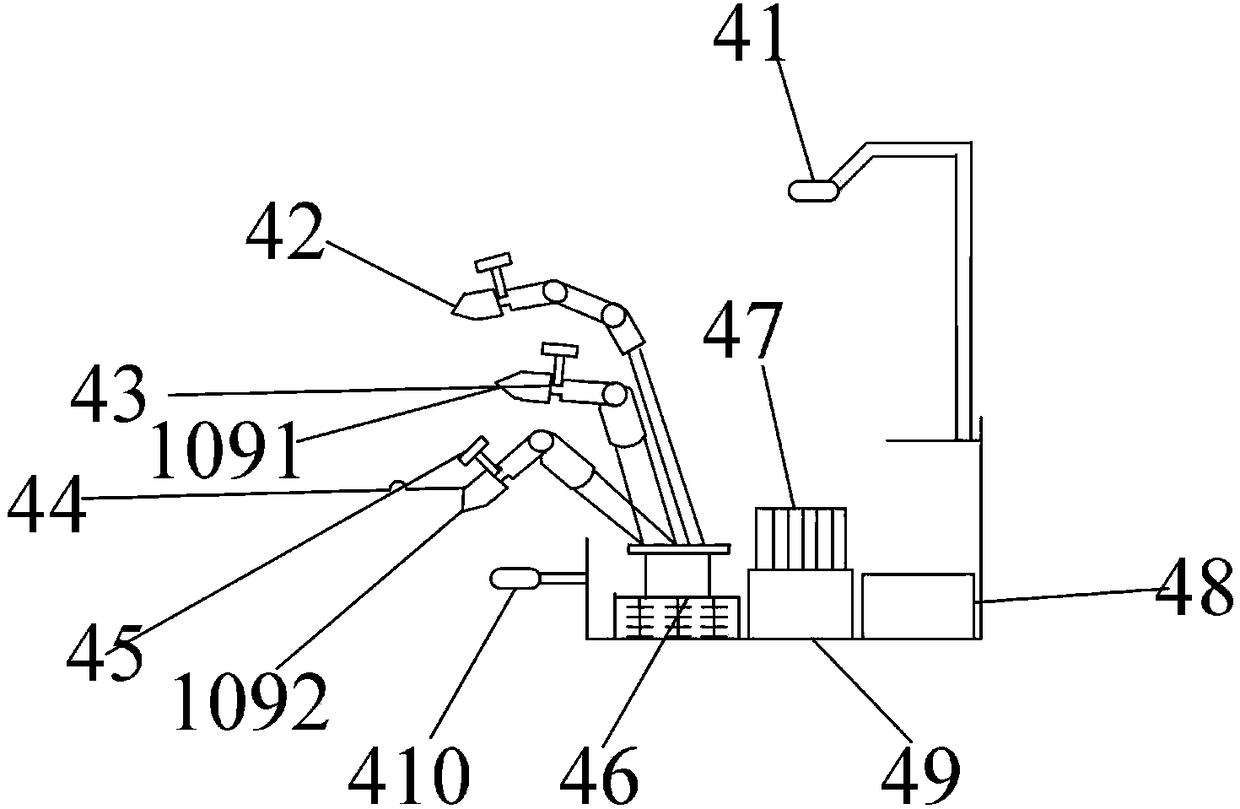

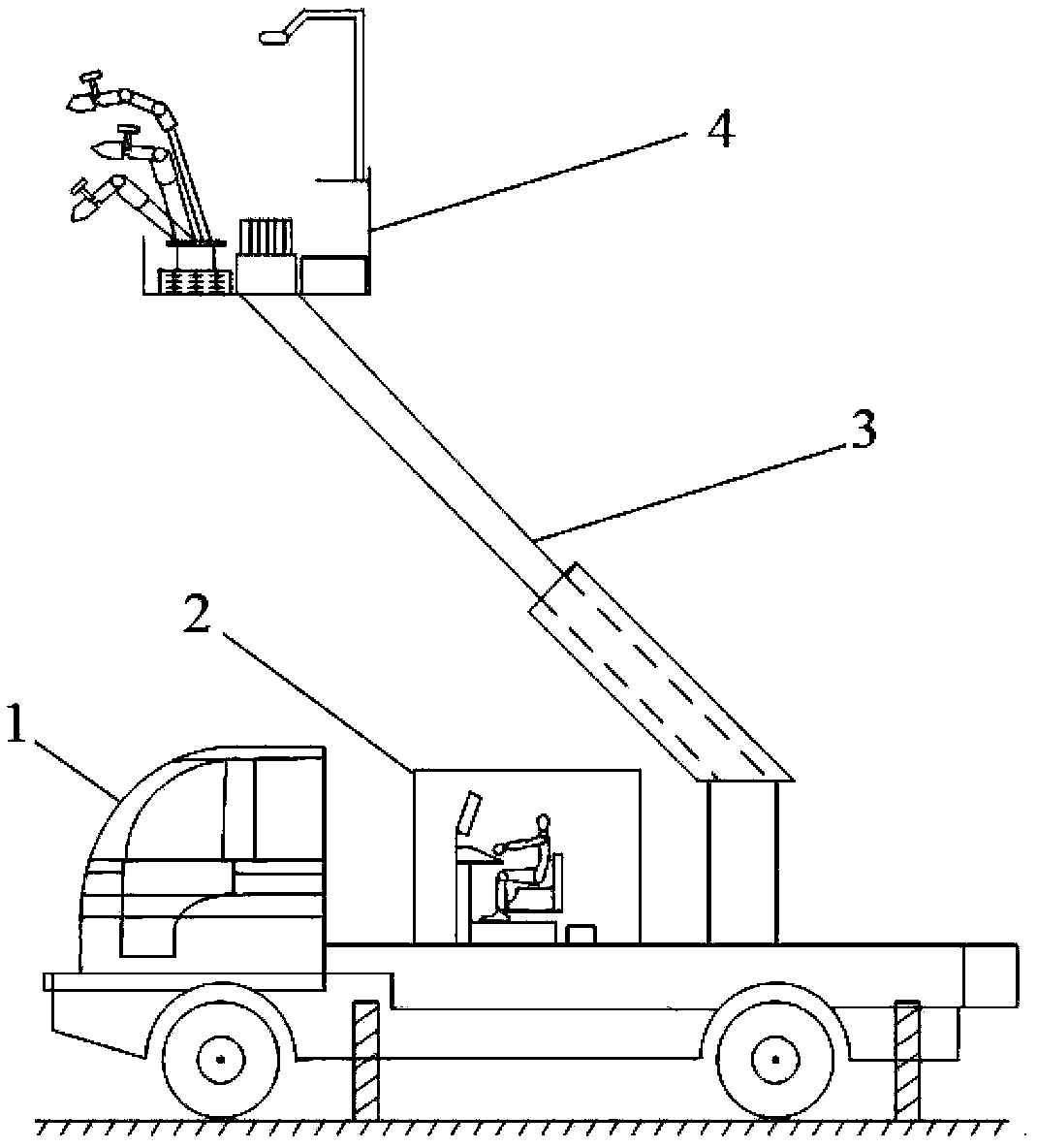

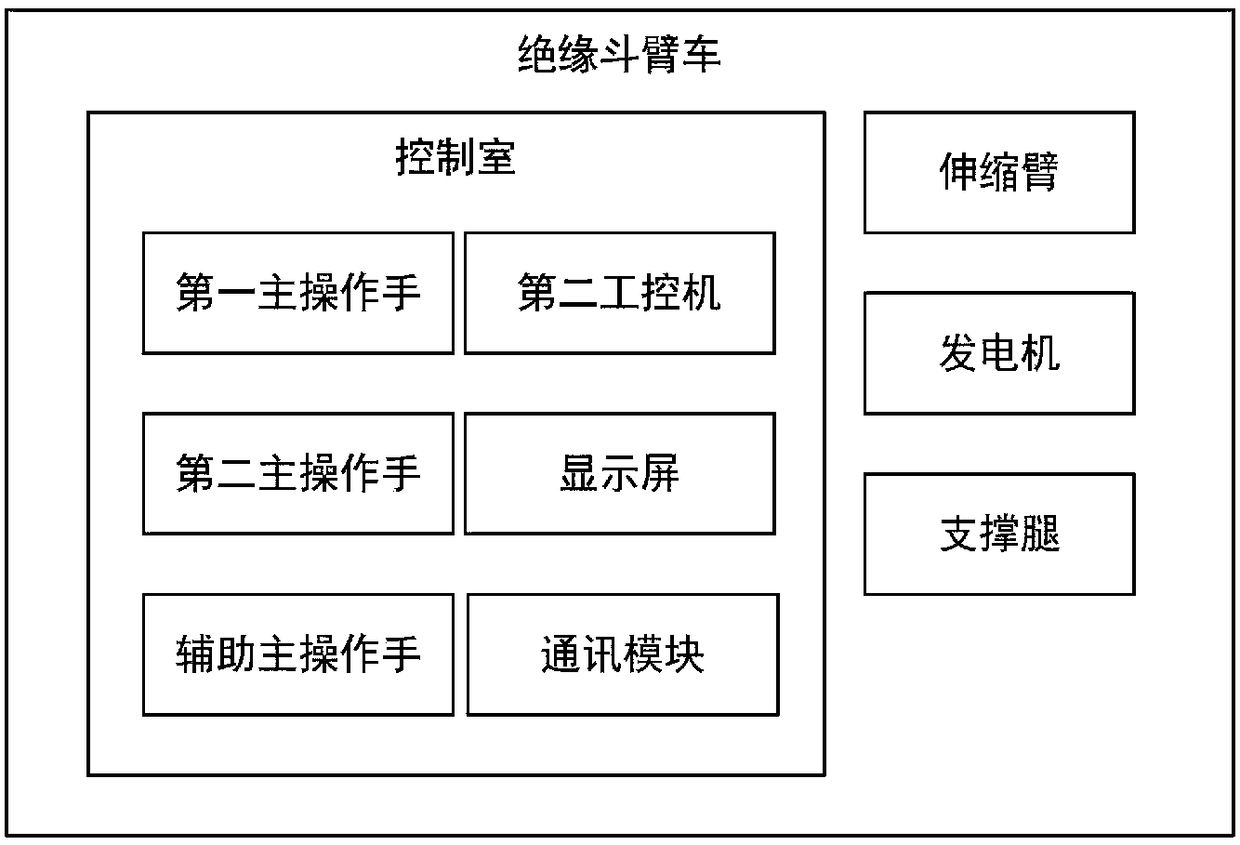

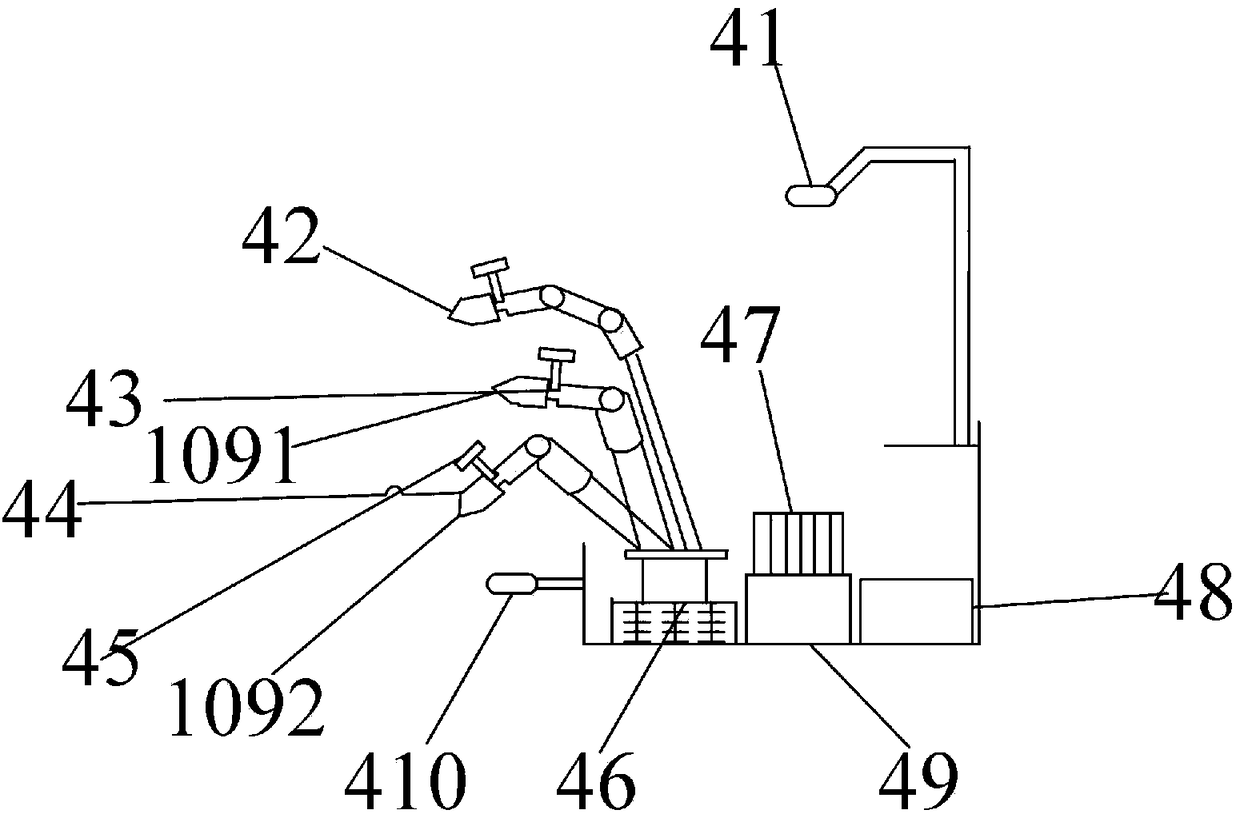

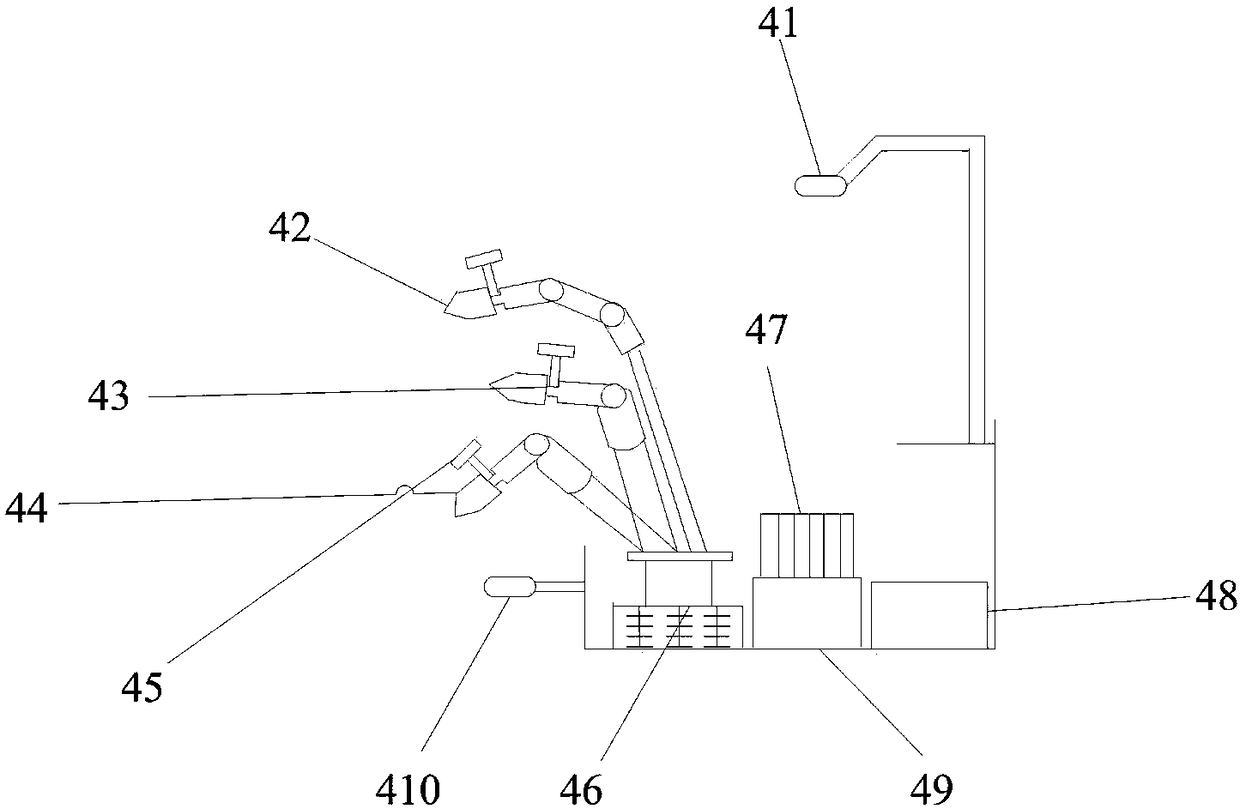

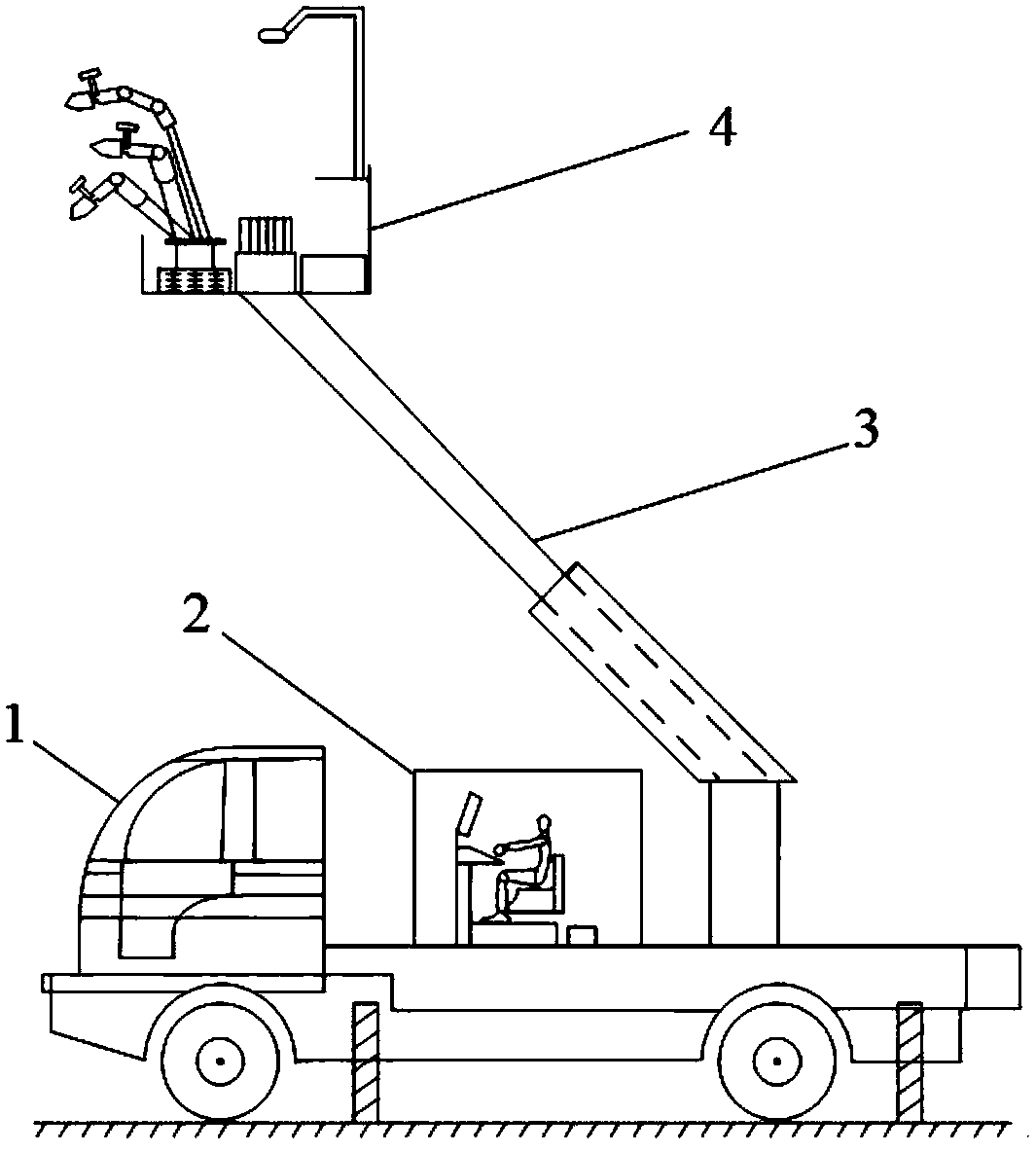

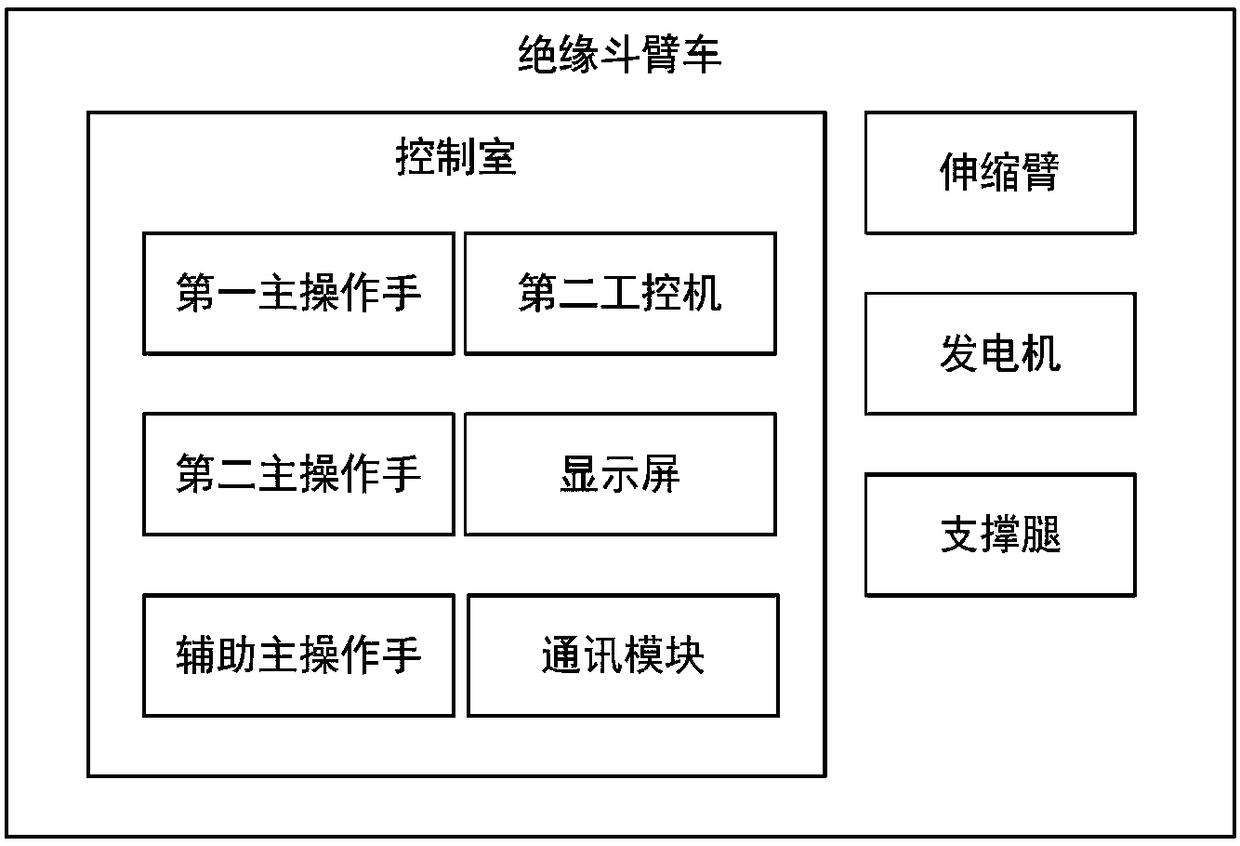

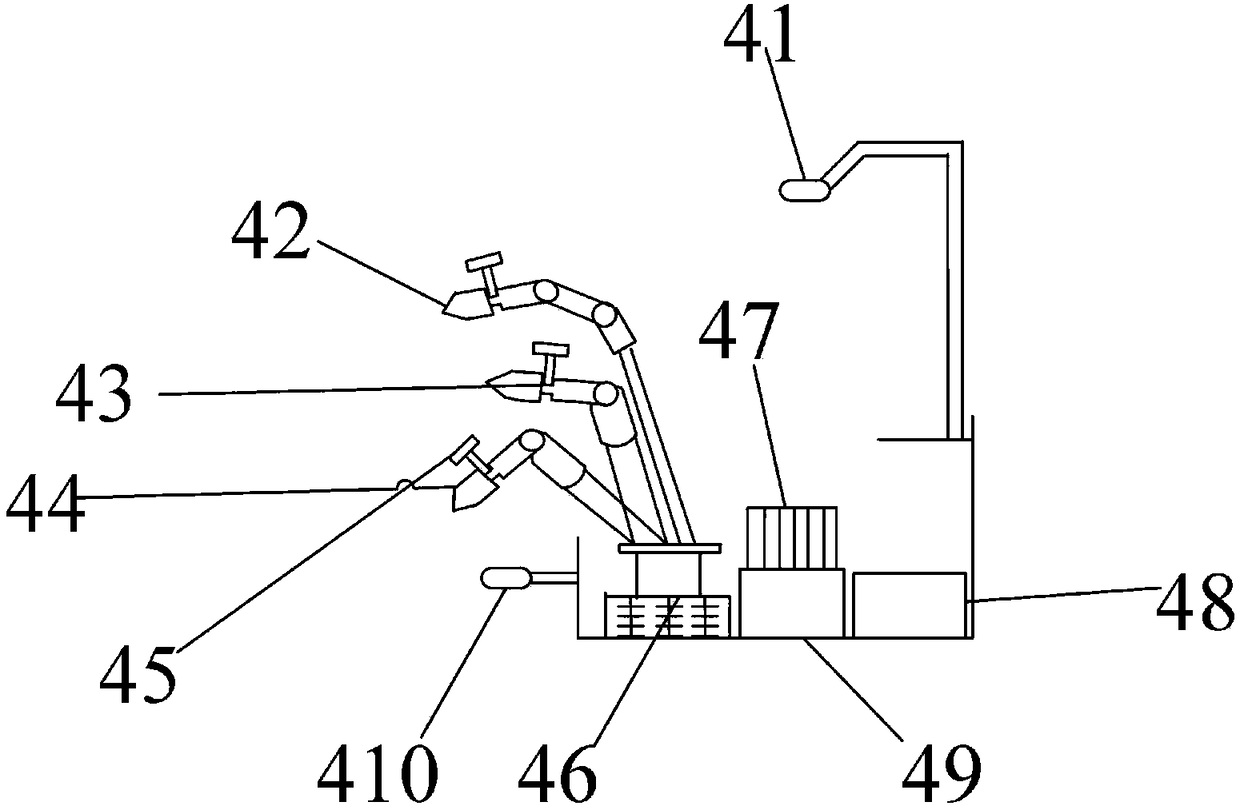

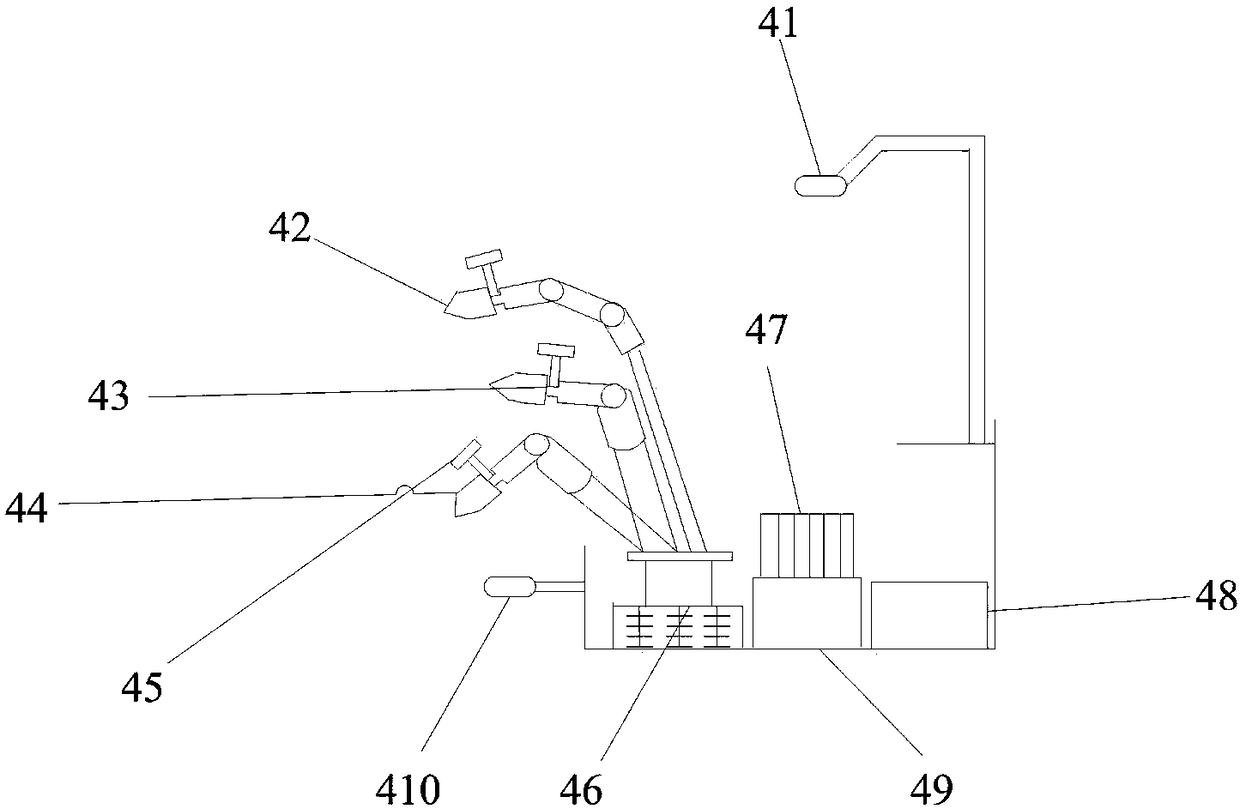

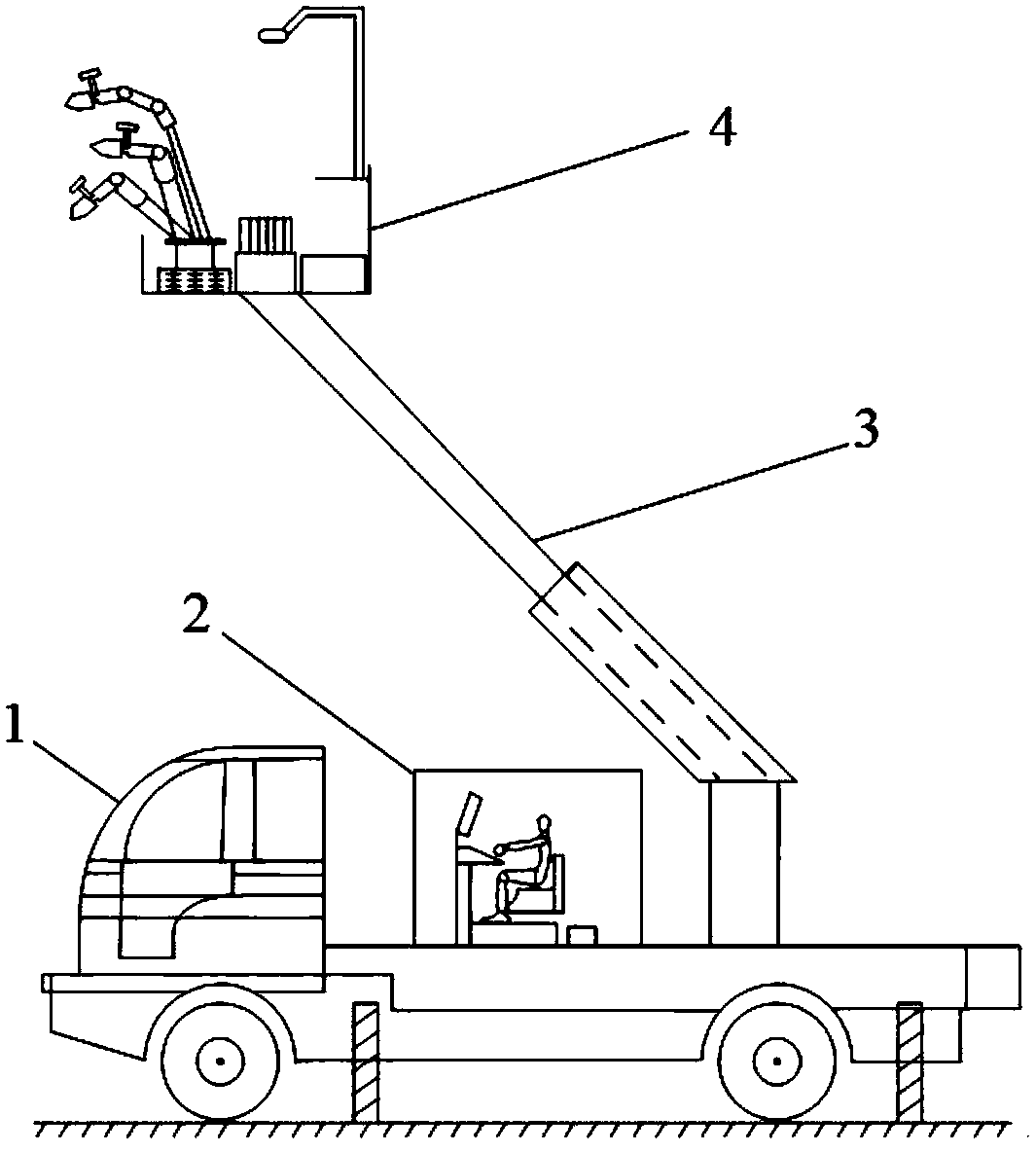

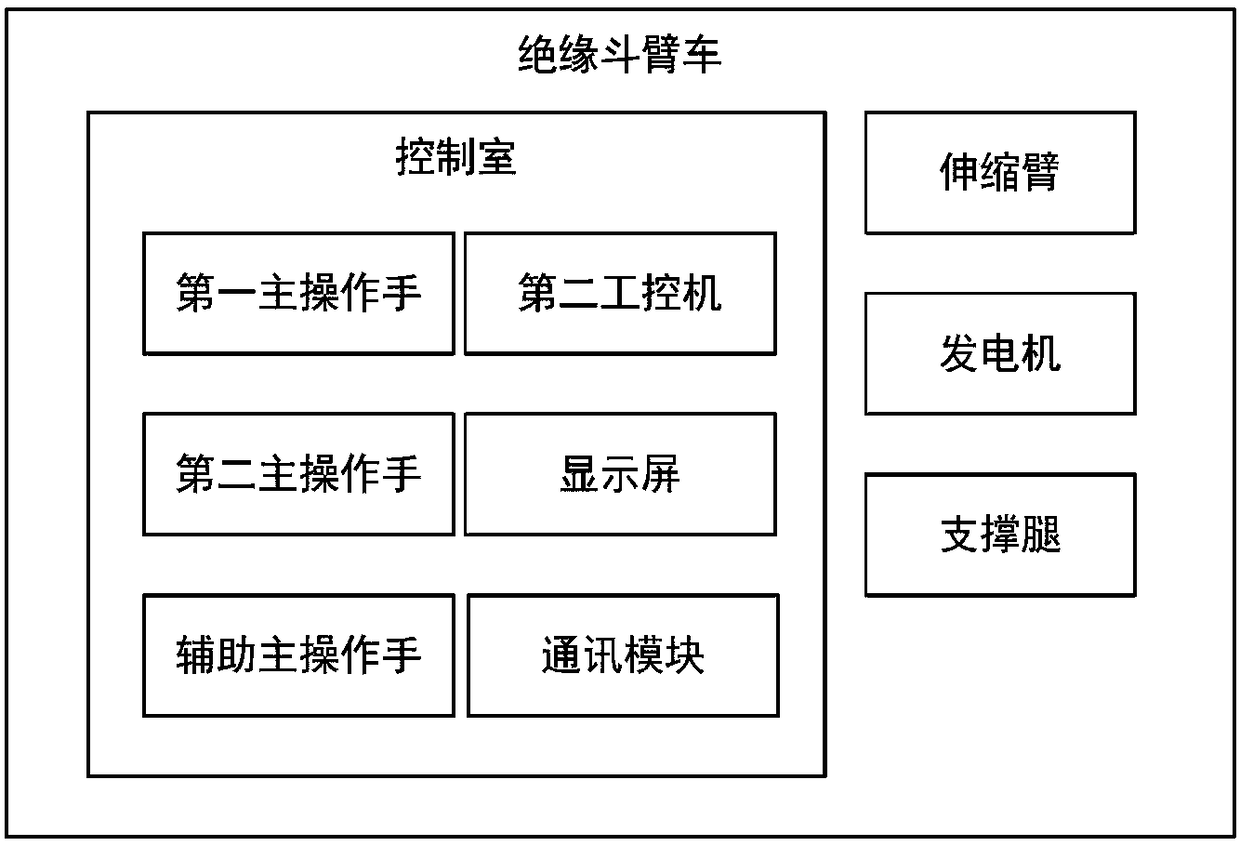

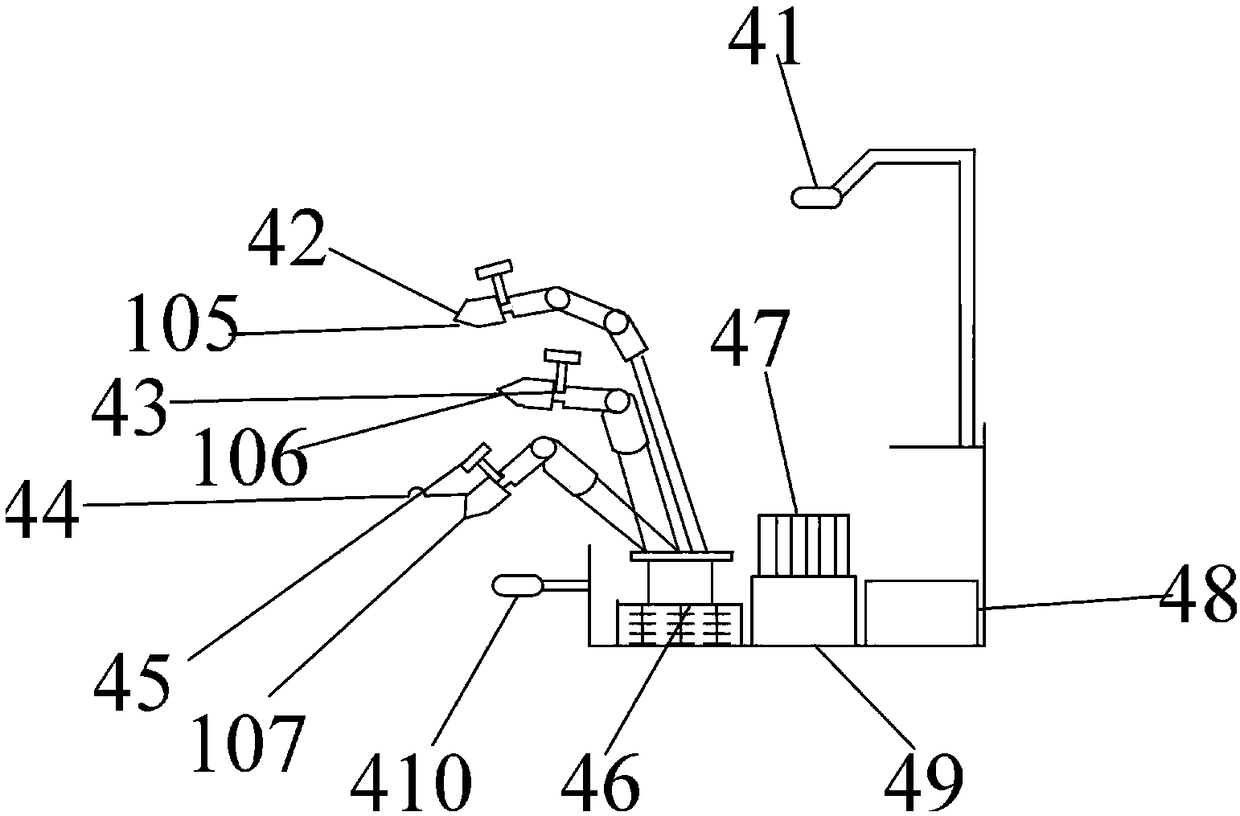

Replacement method for special tool for hot-line robot based on force feedback master-slave control

InactiveCN108297068AEasy to operateFlexible operationProgramme-controlled manipulatorGripping headsControl systemPersonal computer

The invention provides a replacement method for a special tool for a hot-line robot based on force feedback master-slave control. A force feedback master-slave control system is composed of a mechanical arm, a main manipulator and an industrial personal computer. The industrial personal computer calculates torque data of various joints of the main manipulator according to mechanical arm tail end force bearing data, the joints of the main manipulator are controlled to output torques through a control interface of the main manipulator, the main manipulator is made to feed back borne force, and the force of the mechanical arm is determined by operators according to the borne force fed back by the main manipulator. The operators change the pose of the tail end of the main manipulator, the industrial personal computer calculates the expected value of the velocity vector of the tail end of the mechanical arm according to angle data of the rotating joints of the main manipulator, the mechanical arm is controlled to move according to the expected value through a control interface of the mechanical arm, and the force of the mechanical arm is changed. By means of the replacement method, thesense of immediacy of working is improved, and whether various operations are accurately performed in place can be judged more accurately.

Owner:NANJING UNIV OF SCI & TECH

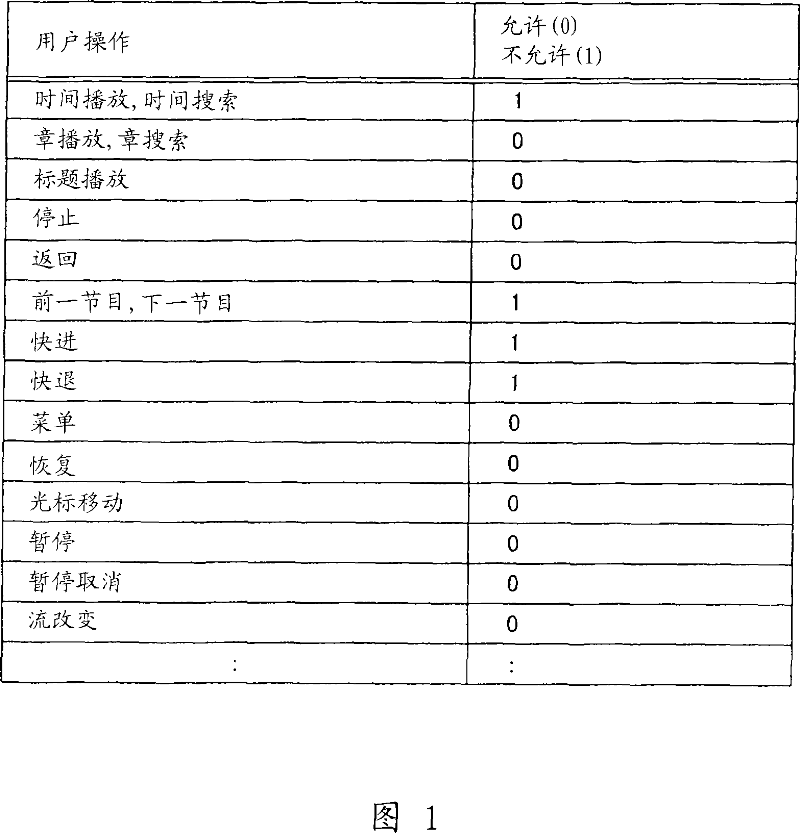

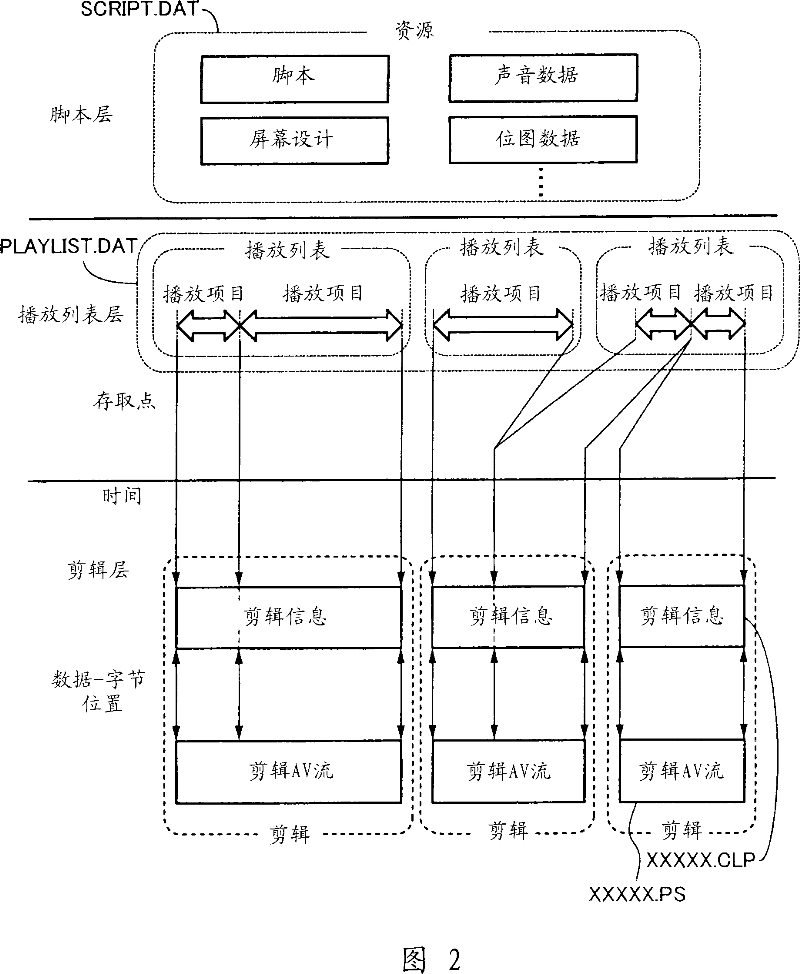

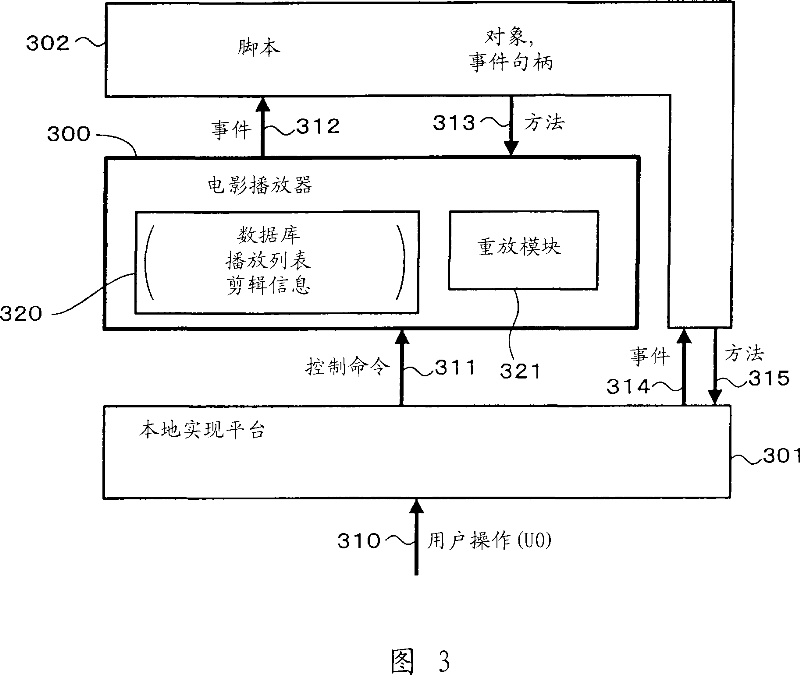

Reproduction device, reproduction method, reproduction program, recording medium, and data structure

InactiveCN101044572ALimit operationsEasy to operateRecord information storageCarrier indexing/addressing/timing/synchronisingComputer hardwareContent creation

It is possible to easily limit a user operation when reproducing a content. A limit mode for limit the user operation to control reproduction of a content is set in advance and a value indicating the limit mode is recorded for each play list as attribute information in the disc. A player generates a table based on the limit mode for each play list during reproduction of the disc and subjects the control command for controlling reproduction of the content generated by the user operation to filtering by the command filter by referencing the table. The limit mode is, for example, a mode in which the play list is should be reproduced at a predetermined speed such as the normal speed from the head and a mode in which jump of the play list during reproduction is inhibited. Thus, it is possible to reduce the load of verification for the user operation limit at the content creation side and the verification load of the operation at the player side.

Owner:SONY CORP +1

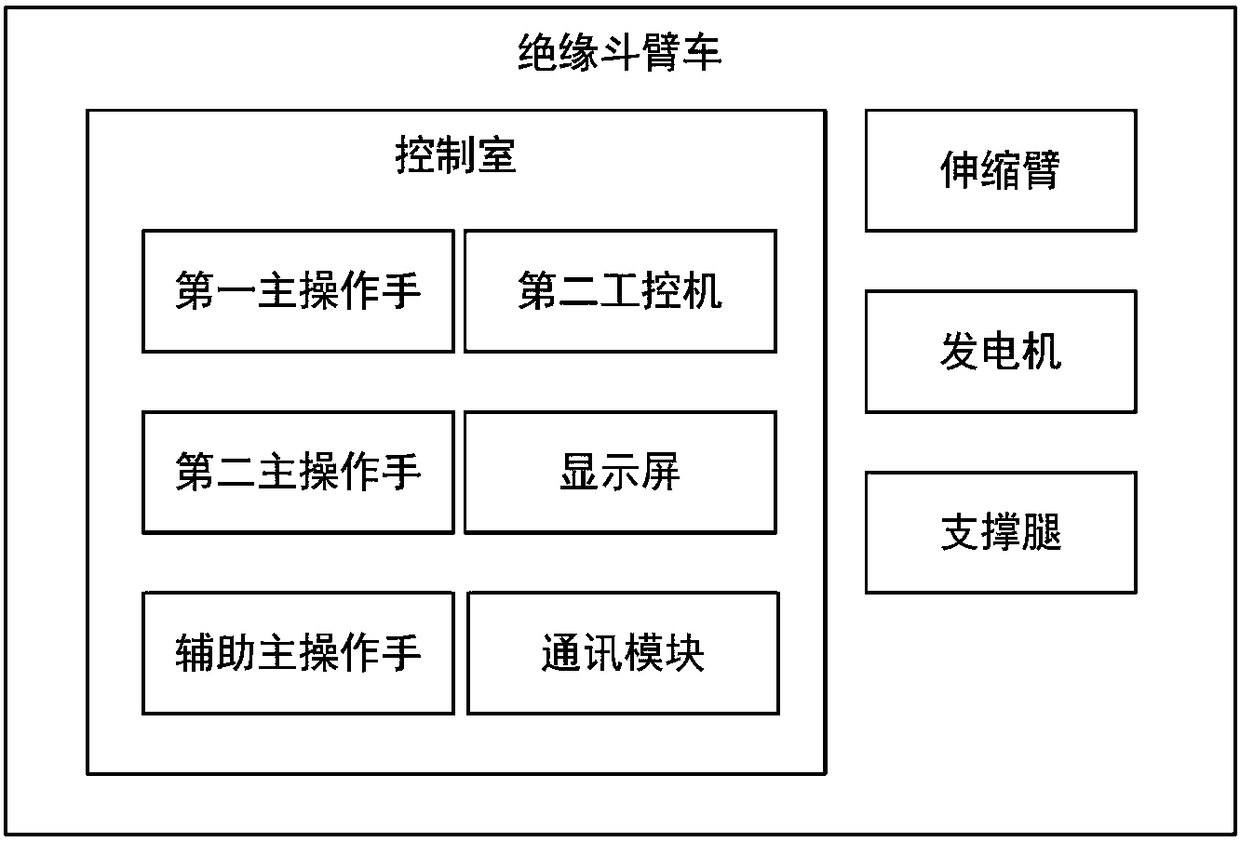

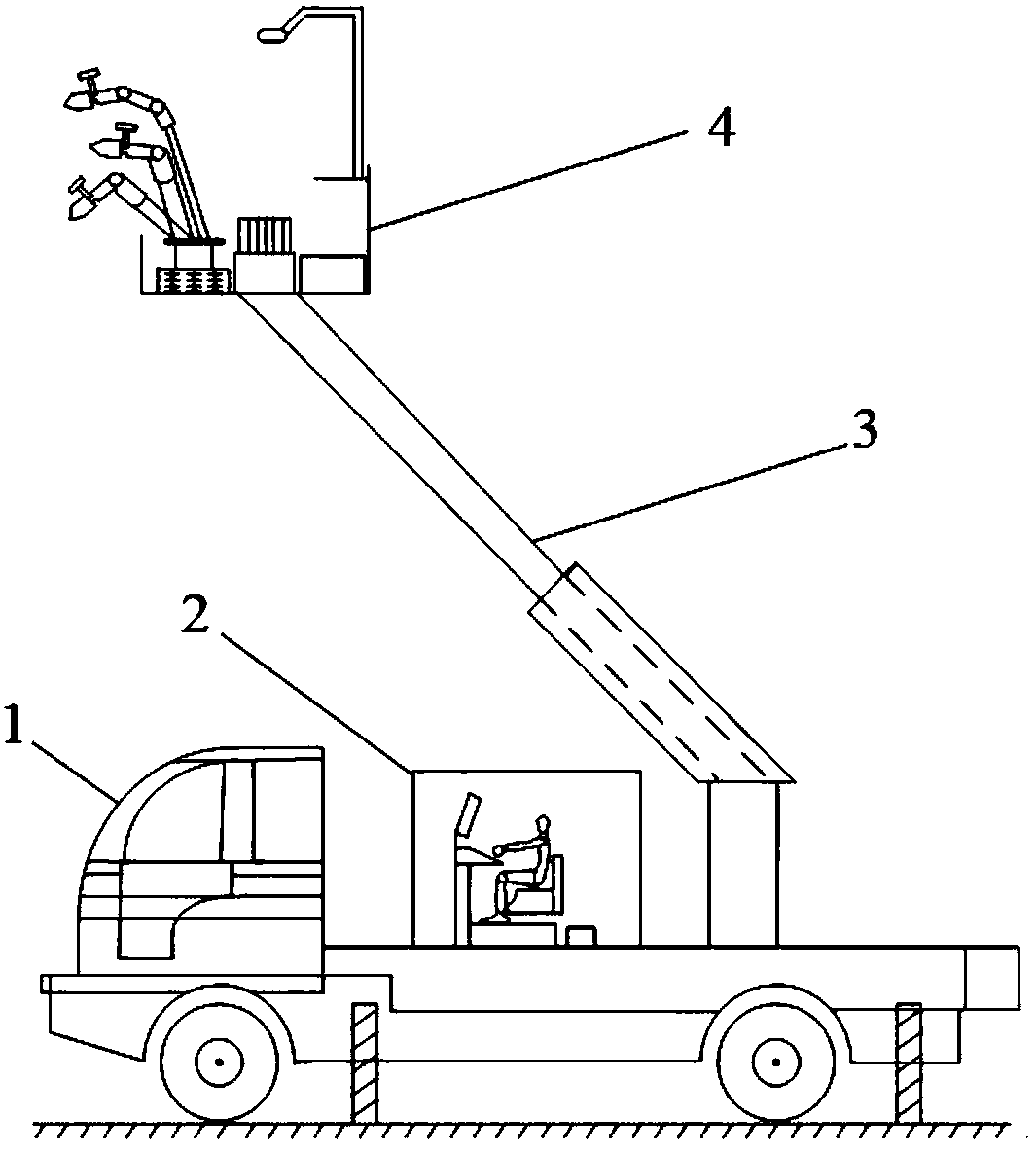

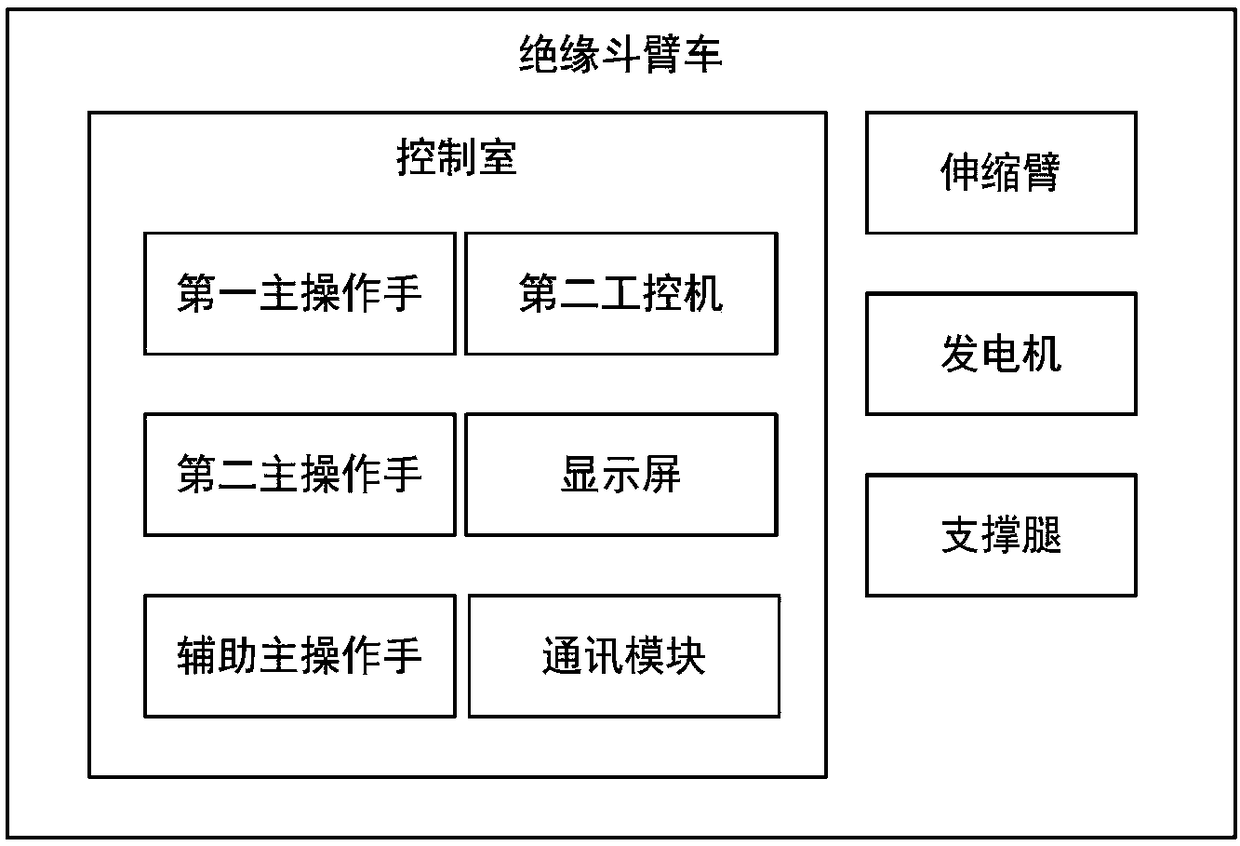

Hot-line work robot force feedback master-slave control method and system based on virtual reality technology

InactiveCN108527305ALimit operationsImprove securityProgramme-controlled manipulatorManipulatorFeedback control

The invention provides a hot-line work robot force feedback master-slave control method and system based on the virtual reality technology. The hot-line work robot force feedback master-slave controlsystem based on the virtual reality technology comprises a main manipulator, a mechanical arm and an industrial control computer. During force feedback control over the main manipulator, the industrial control computer calculates the torque data of each joint of the main manipulator according to the stress data of the tail end of the mechanical arm, and each joint of the main manipulator is controlled to output the torque through a control interface of the main manipulator. The scalar of the stress data of the tail end of the mechanical arm is six-freedom-degree force / torque data, and the stress data of the tail end of the mechanical arm are obtained by the industrial control computer through calculation based on the virtual reality technology according to the tail end pose data and tailend speed data of the mechanical arm. During pose control over the mechanical arm, the industrial control computer calculates the expectation value of the velocity vector of the tail end of the mechanical arm is worked out according to the angle data of each rotation joint of the main manipulator, and through a control interface of the mechanical arm, the mechanical arm is controlled to move according to the expectation value. By the adoption of the hot-line work robot force feedback master-slave control method and system based on the virtual reality technology, hot-line work can be accurately, efficiently and safely completed.

Owner:NANJING UNIV OF SCI & TECH

Master-slave force feedback control technology-based overhead ground wire replacement and repair method for hot-line robot

InactiveCN108598990AEasy to operateFlexible operationApparatus for overhead lines/cablesControl systemPersonal computer

The invention provides a master-slave force feedback control technology-based overhead ground wire replacement and repair method for a hot-line robot. Mechanical arms, main manipulators and industrialpersonal computers form a master-slave force feedback control system, wherein the industrial personal computers calculate torque data of various joints of the main manipulators according to end forcedata of the mechanical arms and control various joints of the main manipulators to output torque through control interfaces of the main manipulators, so that the main manipulators feed back the forceand an operator confirms the force of the mechanical arms according to the feedback force of the main manipulators; the operator changes end positions of the main manipulators; and the industrial personal computers calculate expected values of end velocity vectors of the mechanical arms according to angle data of various rotary joints of the main manipulators and control the mechanical arms to move to change the force of the mechanical arms through the control interfaces of the mechanical arms according to the expected values. According to the master-slave force feedback control technology-based overhead ground wire replacement and repair method for the hot-line robot, the operation telepresence is improved and whether various operations are accurate and in place or not can be more accurately judged.

Owner:NANJING UNIV OF SCI & TECH

Wire repairing method for live working robot based on force feedback master-slave control

InactiveCN108565793AEasy to operateFlexible operationProgramme-controlled manipulatorApparatus for repairing insulation/armouring cablesFeeding forceControl system

The invention provides a wire repairing method for a live working robot based on force feedback master-slave control. A force feedback master-slave control system is formed by a mechanical arm, a mainoperating hand and an industrial control computer. The industrial control computer calculates the torque data of each joint of the main operating hand according to force data of an end of the mechanical arm, controls each joint of the main operating hand to output torque through a control interface of the main operating hand, thus the main operating hand feeds force back, and an operator confirmsthe length of the mechanical arm according to the feedback force of the main operating hand. The operator changes the pose of a main operation end, the industrial control computer calculates an expected value of the speed vector of the end of the mechanical arm according to the angle data of each rotation joint of the main operating hand and controls the movement of the mechanical arm according to the expected value through a control interface of the mechanical arm to change the strength of the mechanical arm. According to the method, the telepresence of operation is improved, and whether each operation is accurate and in place can be more accurately judged.

Owner:NANJING UNIV OF SCI & TECH

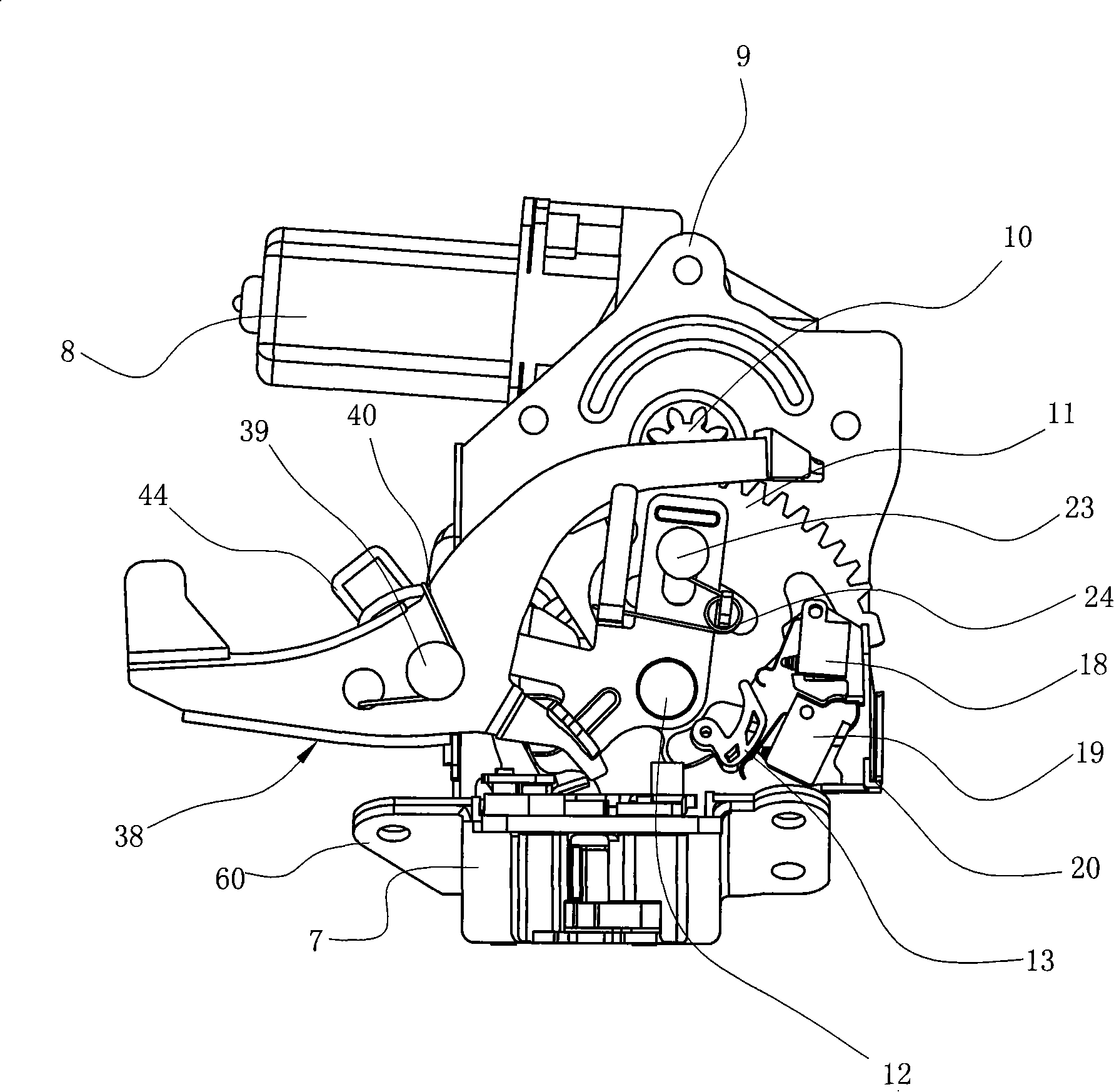

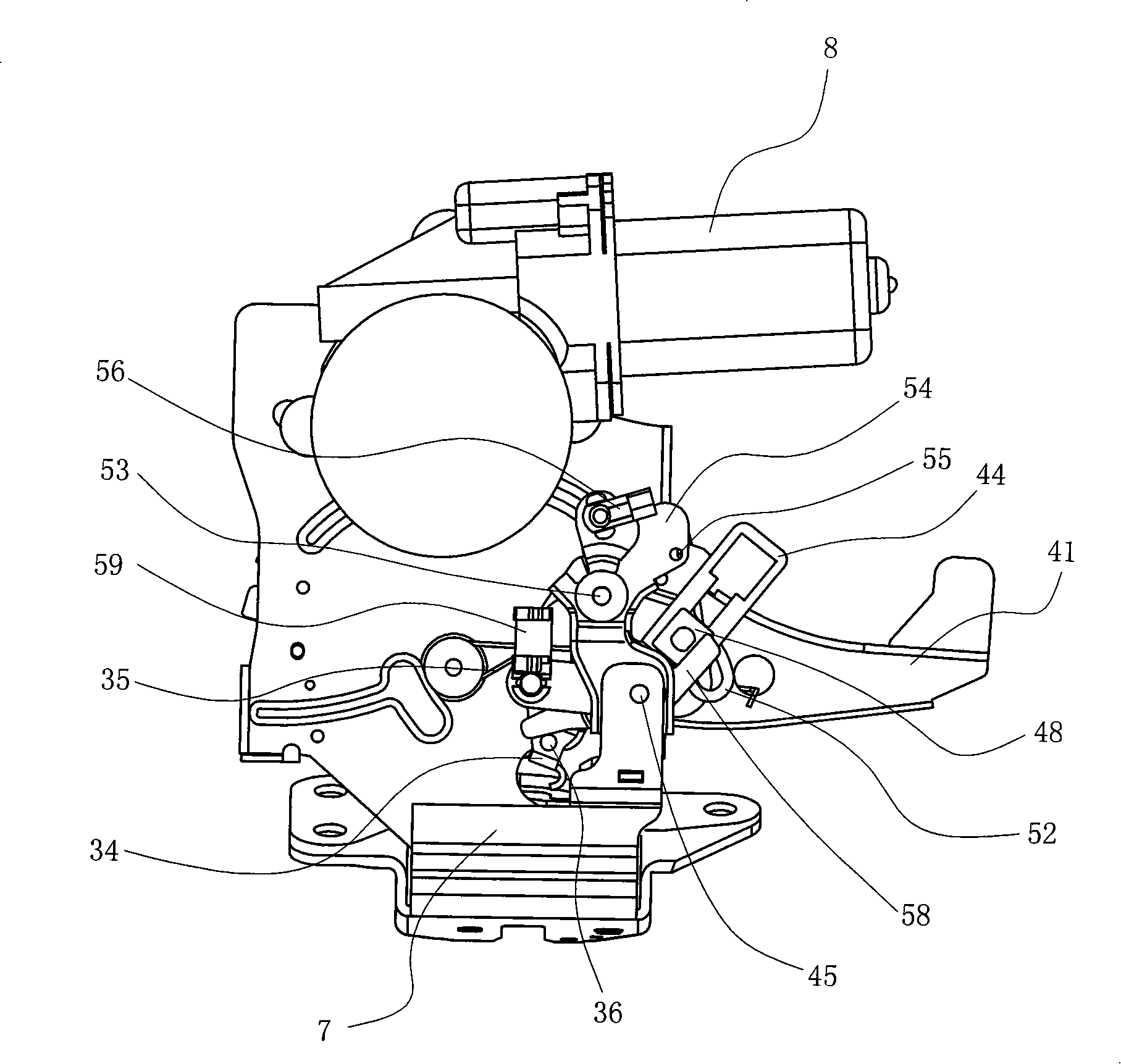

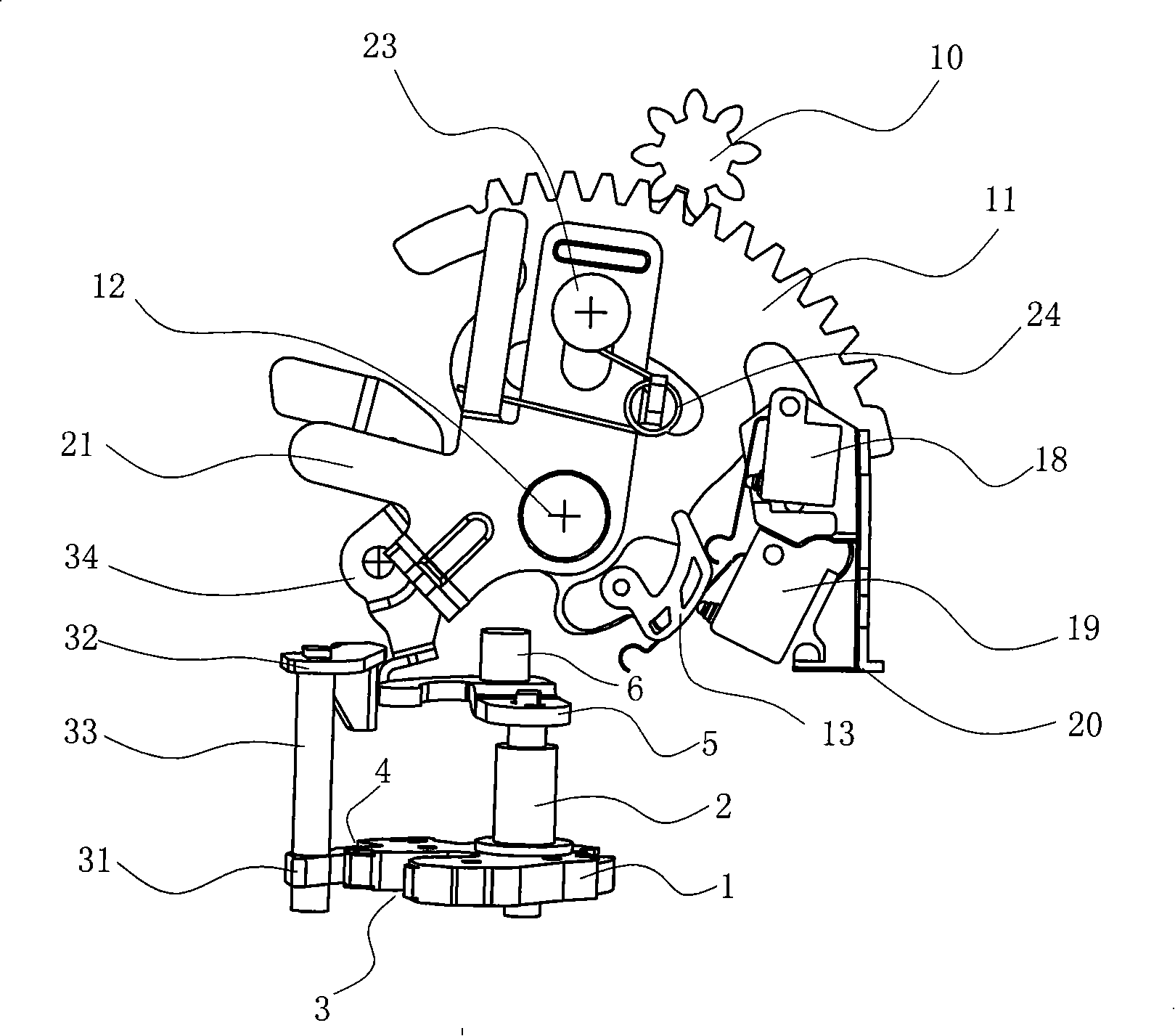

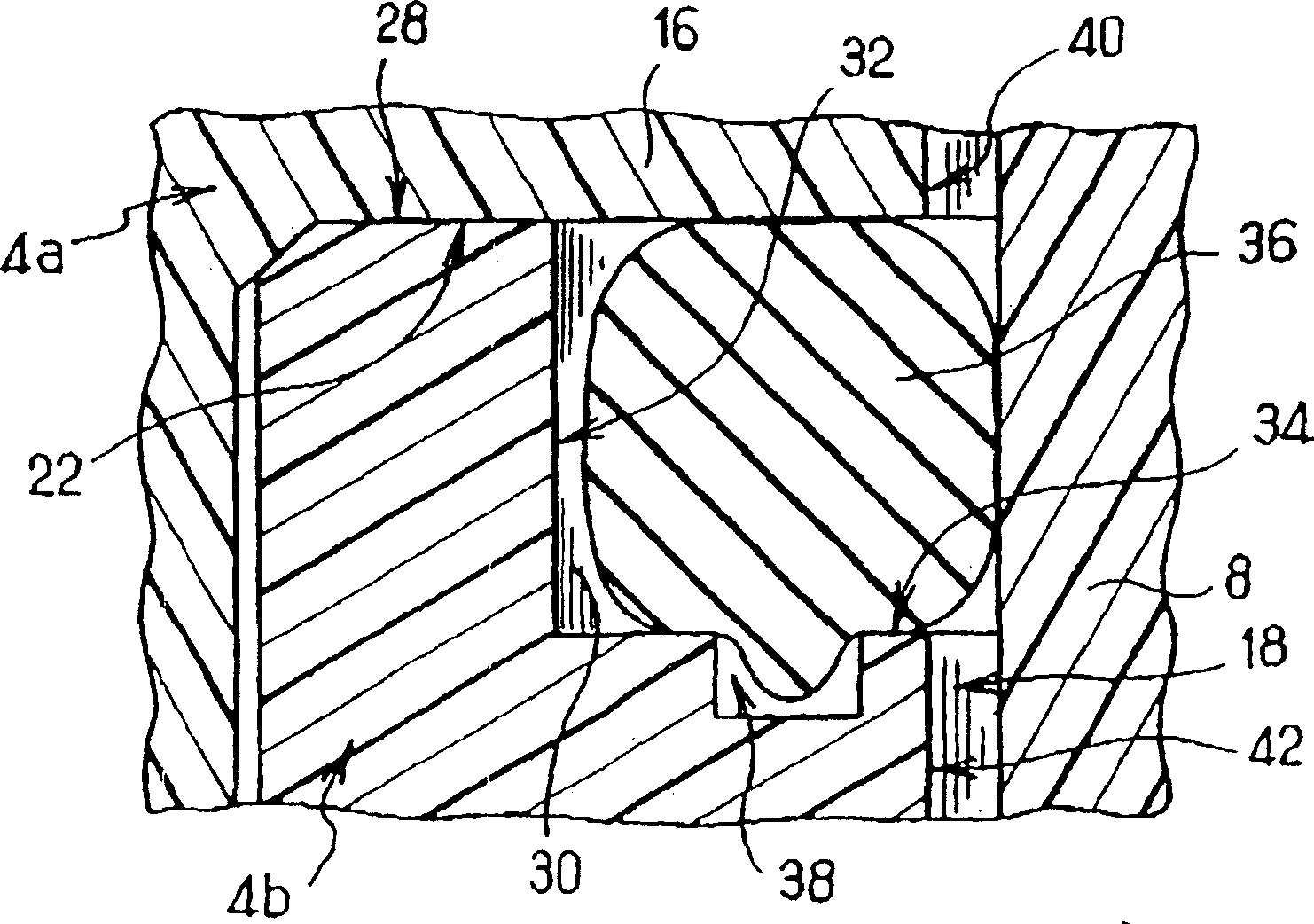

Door lock for luggage case for automobile

InactiveCN101315008BLimit operationsEnsure safetyVehicle locksNon-mechanical controlsEngineeringMechanical engineering

The invention relates to a door lock of a suitcase used for a vehicle. The door lock comprises a main ratchet wheel, a pawl, an opening arm, a motor and a transmission system. The door lock is characterized in that the door lock also comprises an external opening arm, a sliding block with a front lug and a rear lug, a secure arm and an external release arm, wherein a radial slide opening is formed at one end of the external opening arm, and the other end of the external opening arm is corresponding to the opening arm; the sliding block slides in the radial slide opening; a clasp of the securearm is fixed at one end of the secure arm and is connected with a lock core through a lock core connecting rod, and a limit groove for the rear lug to penetrate is formed at the other end of the secure arm; one end of the external release arm is corresponding to the front lug on the sliding block, a clasp of the external release arm is installed at the other end of the external release arm, and the clasp of the external release arm is used for connecting a push rod connected with an outer handle. Because the structure that the external release arm drives or fails to drive the external openingarm to rotate can be obtained as required through the movement of the secure arm to push the sliding block, the unlocking or the locking function of the door lock can be achieved, and the operation of the outer handle can be effectively limited through the door lock, thereby the operational security can be ensured.

Owner:NINGBO XINTAI MACHINERY

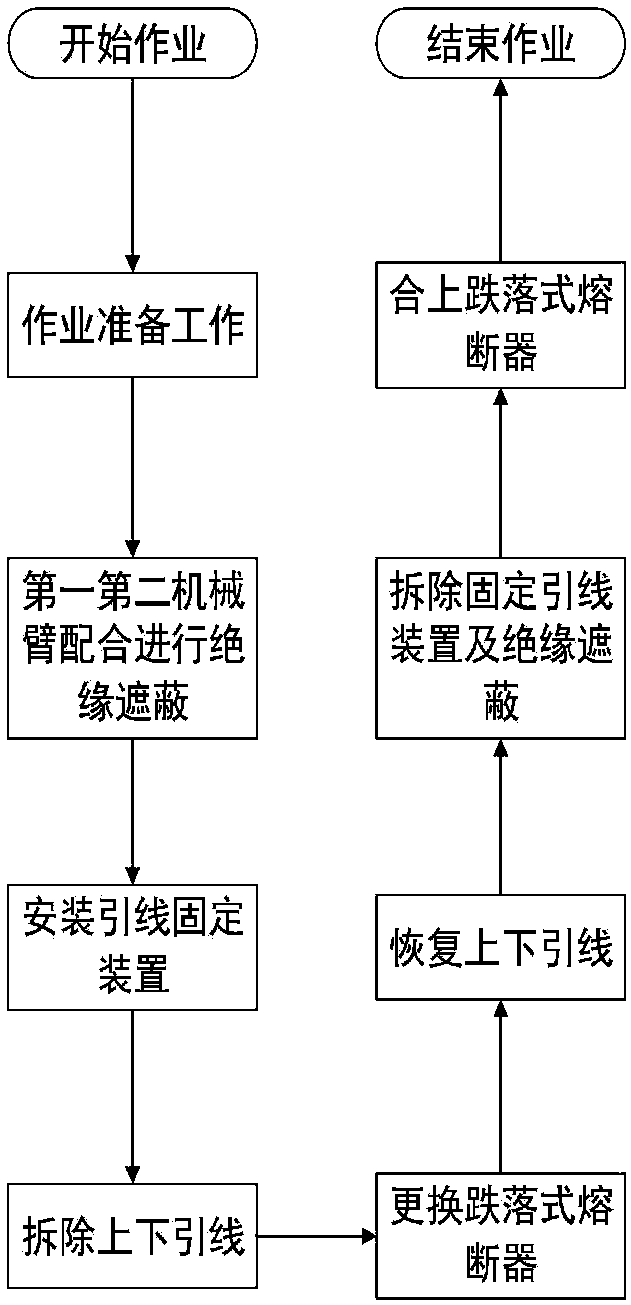

Method for replacing drop-out fuse of charged working robot based on force feedback master-slave control

InactiveCN108598989AEasy to operateFlexible operationManipulatorApparatus for overhead lines/cablesControl systemPersonal computer

The invention provides a method for replacing a drop-out fuse of a charged working robot based on force feedback master-slave control. A mechanical arm, a main manipulator and an industrial personal computer constitute a force feedback master-slave control system. The industrial personal computer calculates the torque data of each joint of the main manipulator according to the force data at the end of the mechanical arm, and controls each joint of the main manipulator to output torque through a control interface of the main manipulator, so that the main manipulator feeds back the force, and anoperator confirms the strength of the mechanical arm according to the feedback force of the main manipulator; the operator changes the position and pose of the tail end of the main operator; the industrial personal computer calculates an expected value of the speed vector of the tail end of the mechanical arm according to the angle data of each rotating joint of the main manipulator, and controlsthe movement of the mechanical arm according to the expected value through the control interface of the mechanical arm so as to change the strength of the mechanical arm. The method for replacing thedrop-out fuse of the charged working robot based on force feedback master-slave control in the invention improves the sense of immediacy of operation and can judge whether the operations are accurateand in place or not more accurately.

Owner:NANJING UNIV OF SCI & TECH

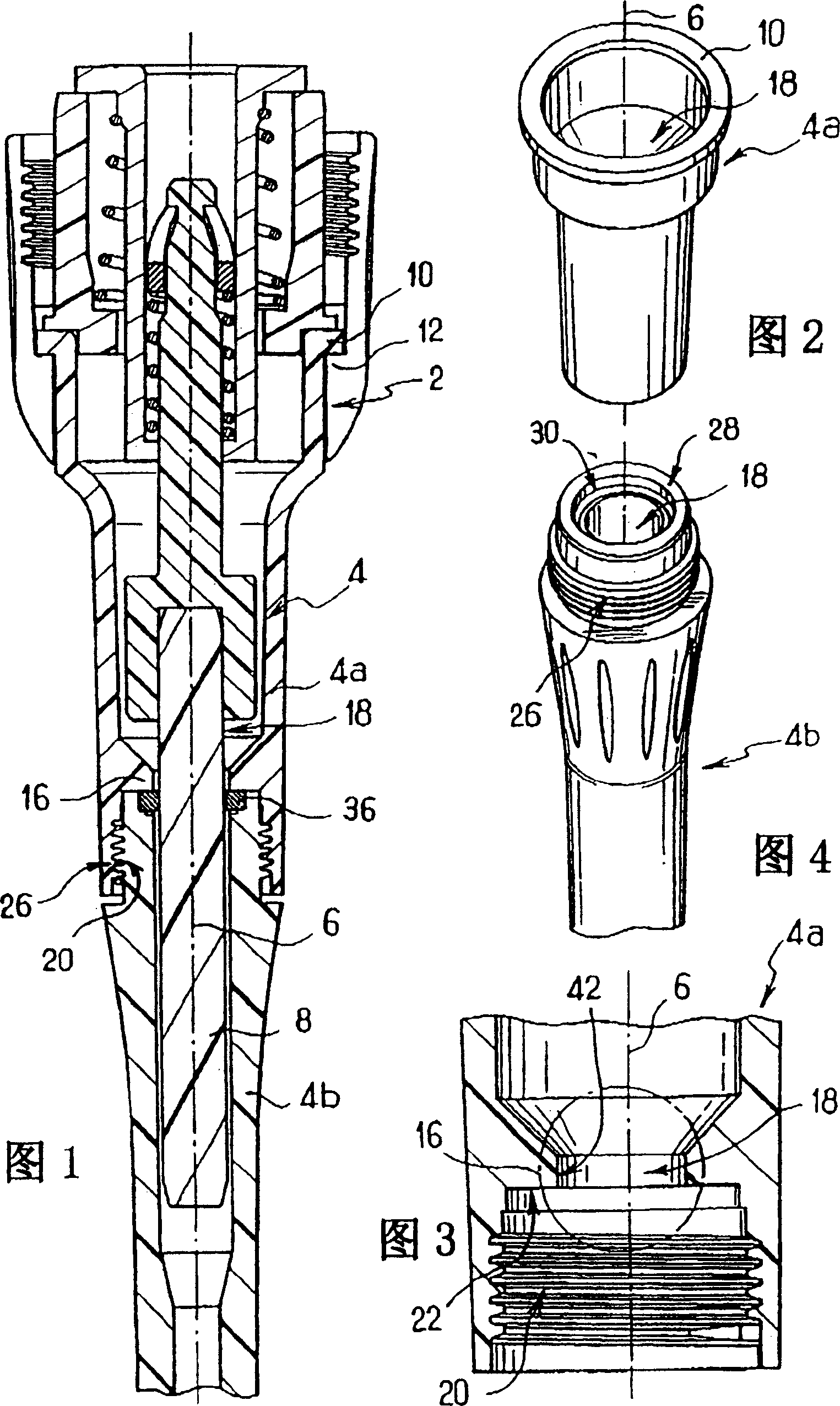

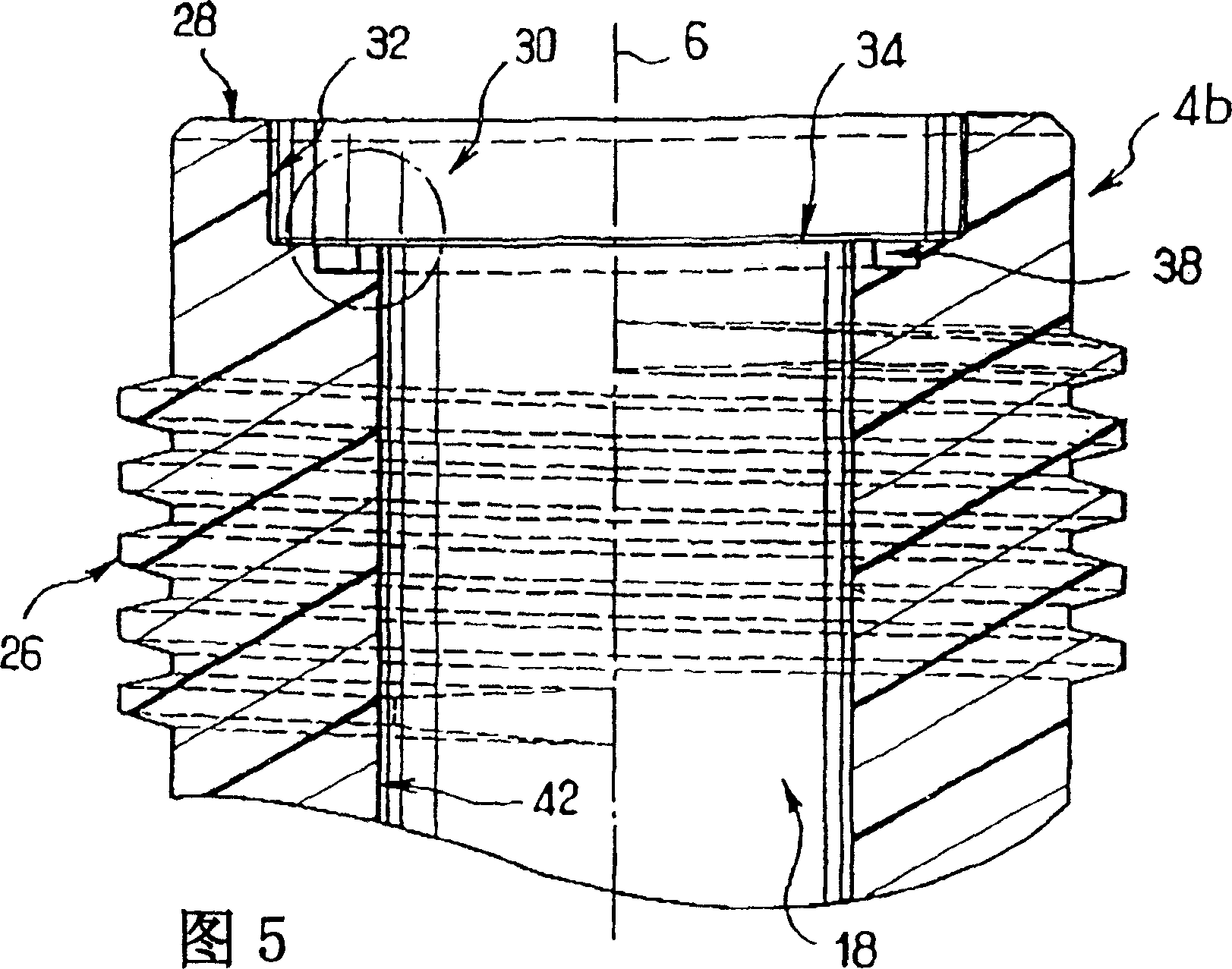

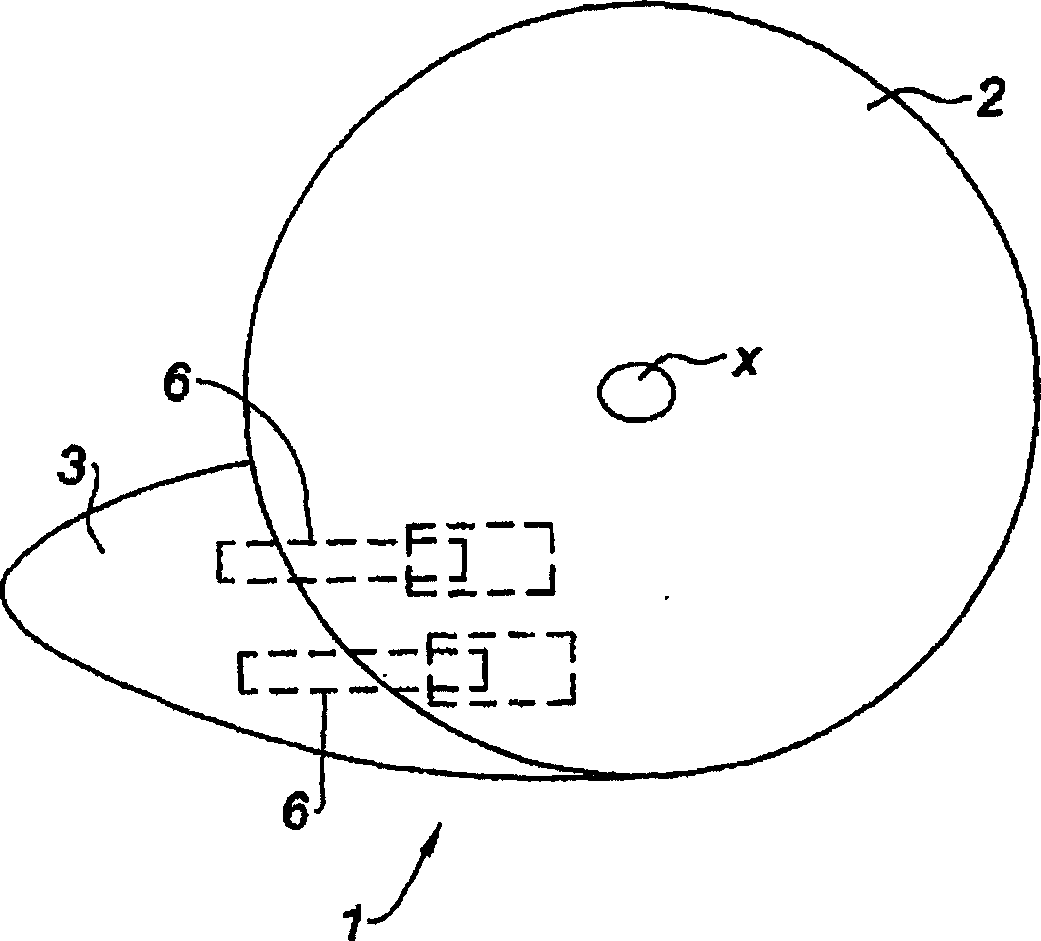

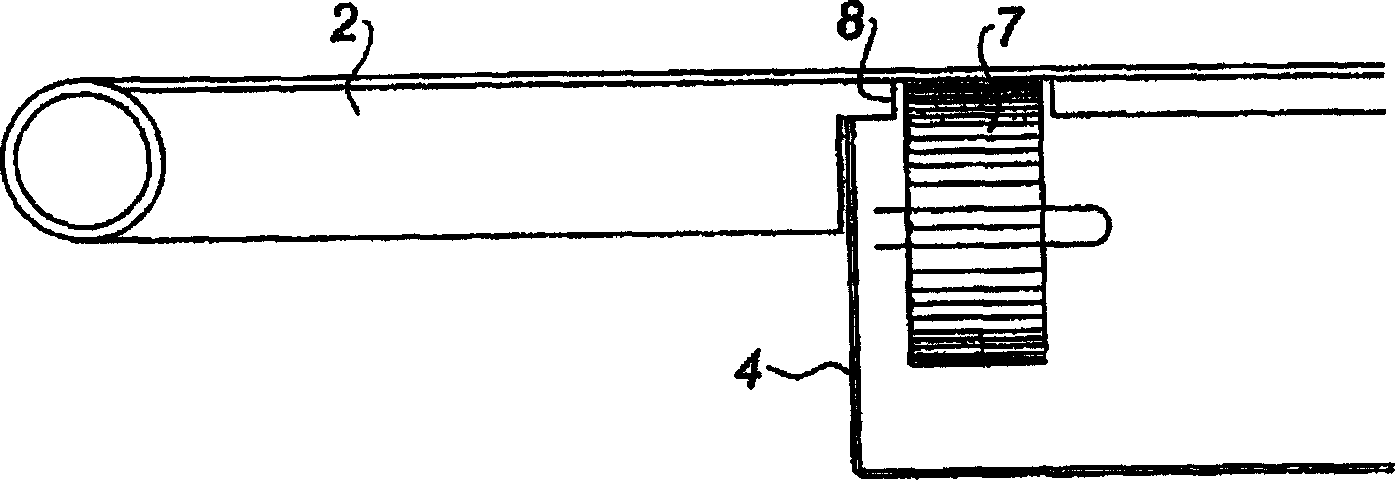

Pipette with simplified disassembly

The invention relates to a sampling pipette ,comprising an end piece including a first end piece portion and a second end piece portion with both having a flat, wherein the flat of the first portion contacts with the flat of the second one and two portions are fixed to each other in a detachable manner, a shell including a surface used for receiving a gasket ,wherein the shell is inserted between the two portions, an annular groove within a certain distance between the surface of the shell and the circle verge of the surface and a piston which can freely move in the end piece.

Owner:GILSON SAS

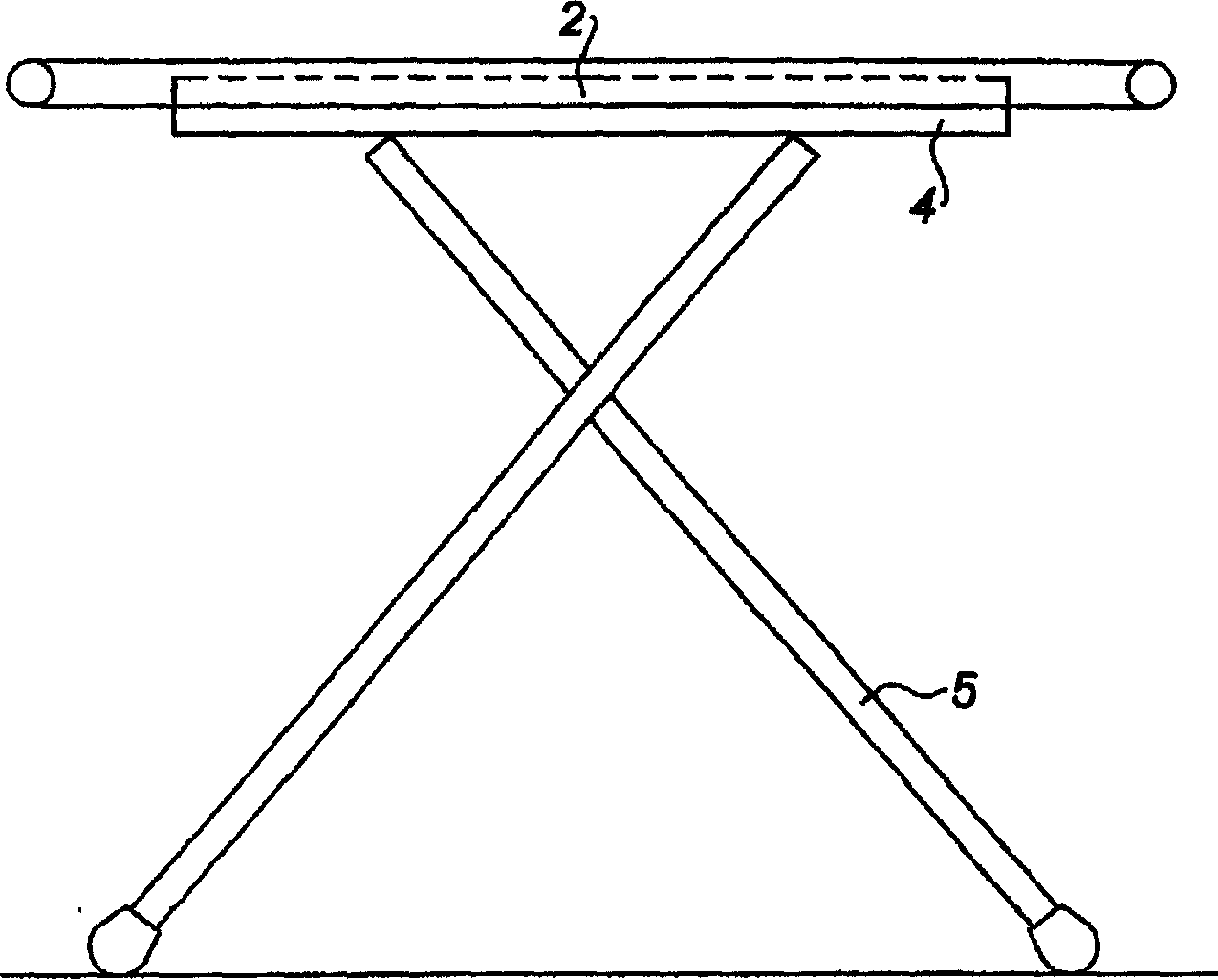

Ironing board

Owner:亚历山大·沙尼奥 +2

Device and method for monitoring engineering machinery and hoisting disordered ropes thereof

ActiveCN105438983BReal-time monitoring of arrangement statusAvoid wear and tearSafety gearPull forceImaging processing

Owner:XUZHOU HEAVY MASCH CO LTD

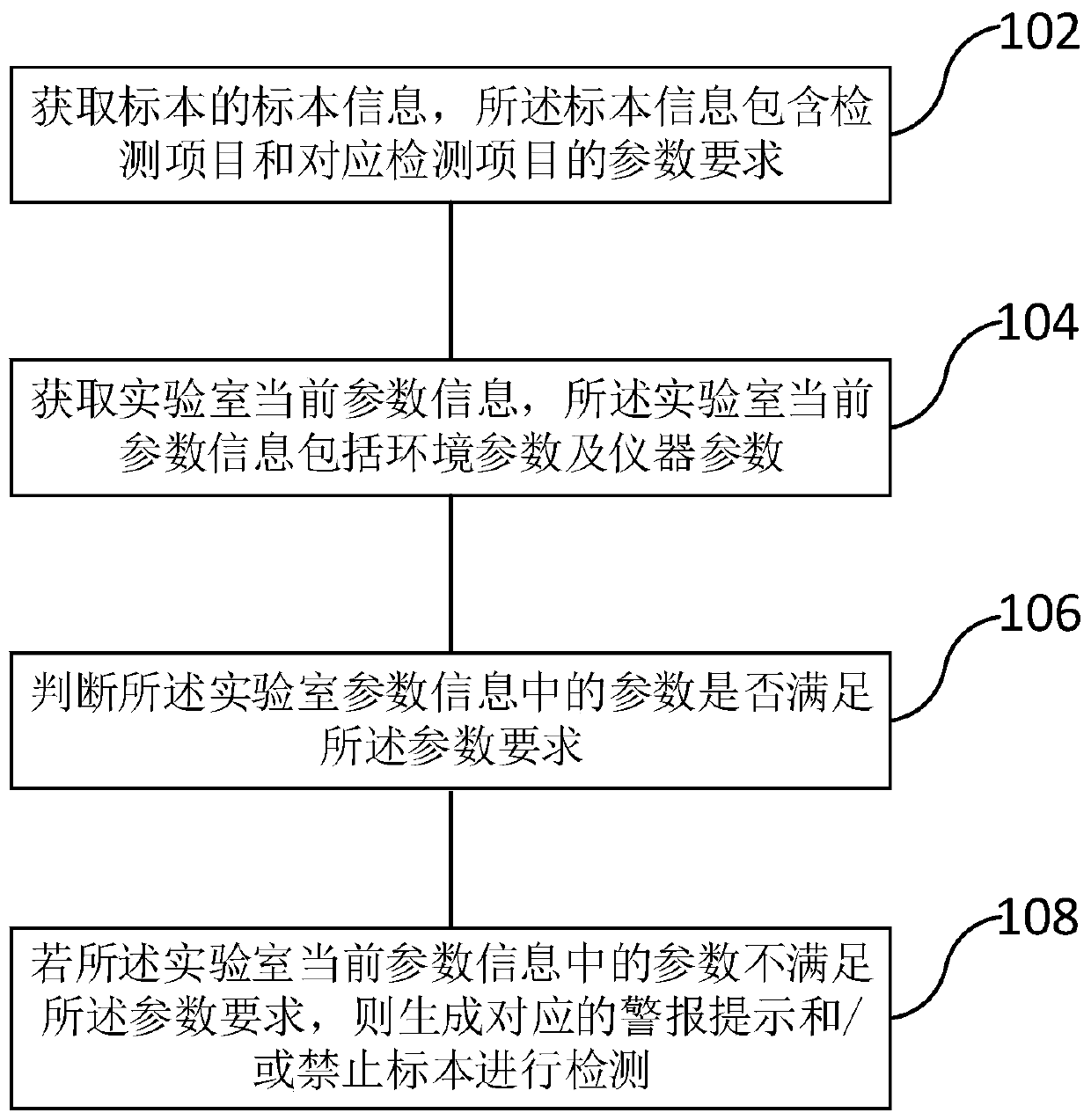

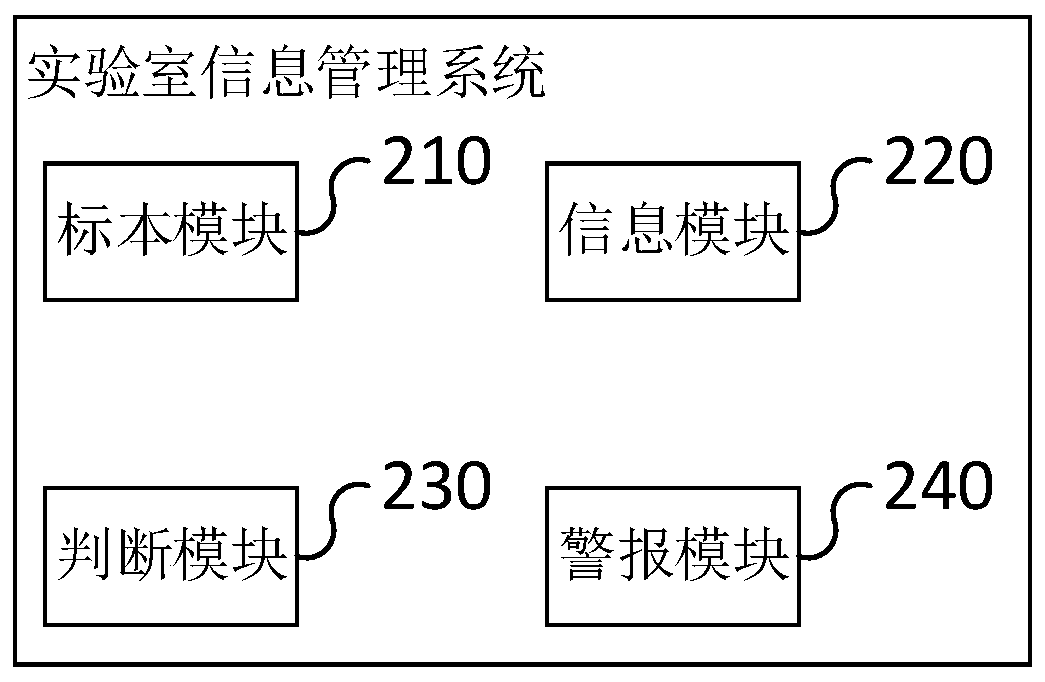

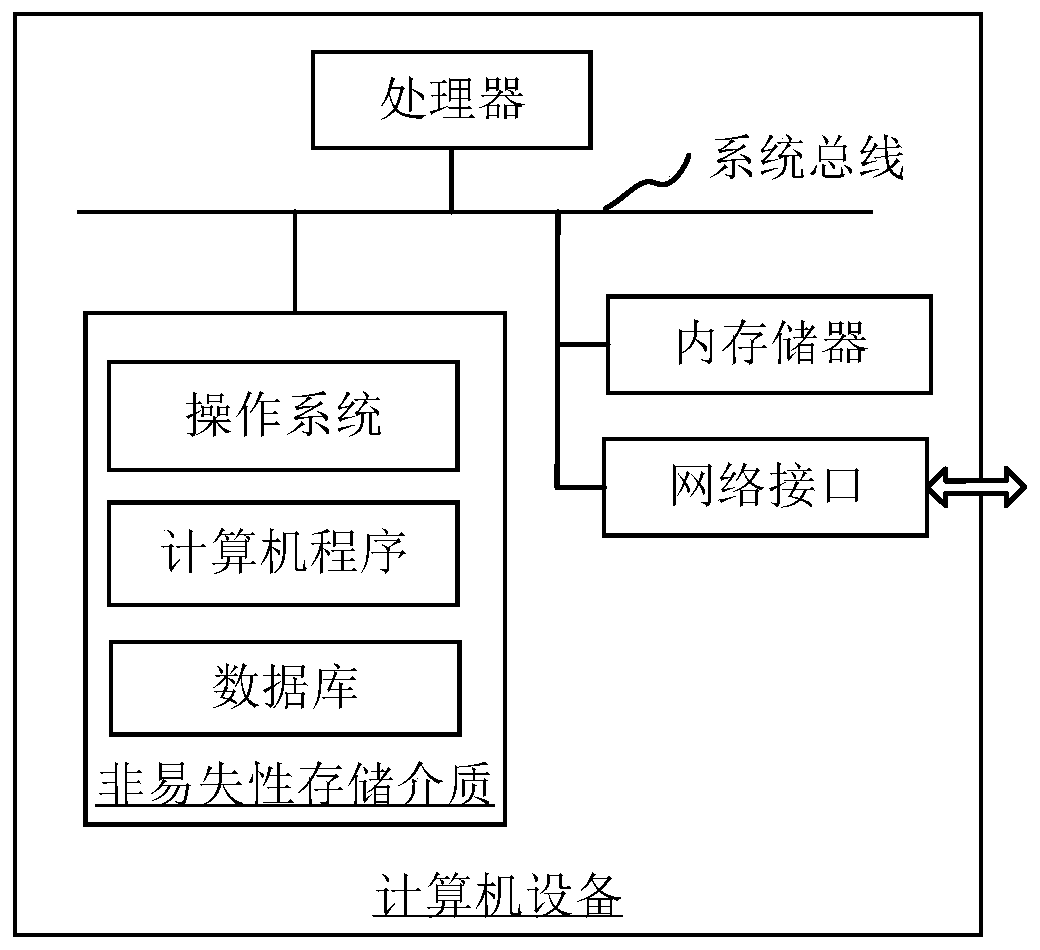

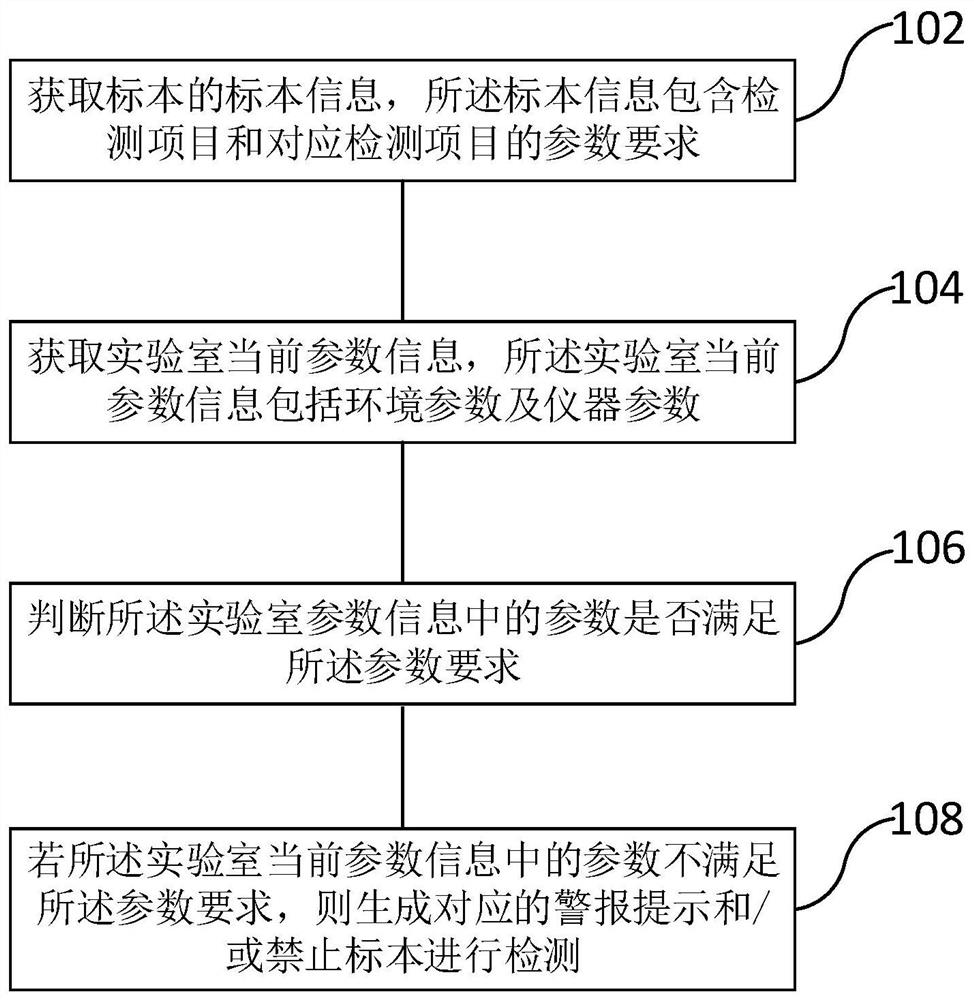

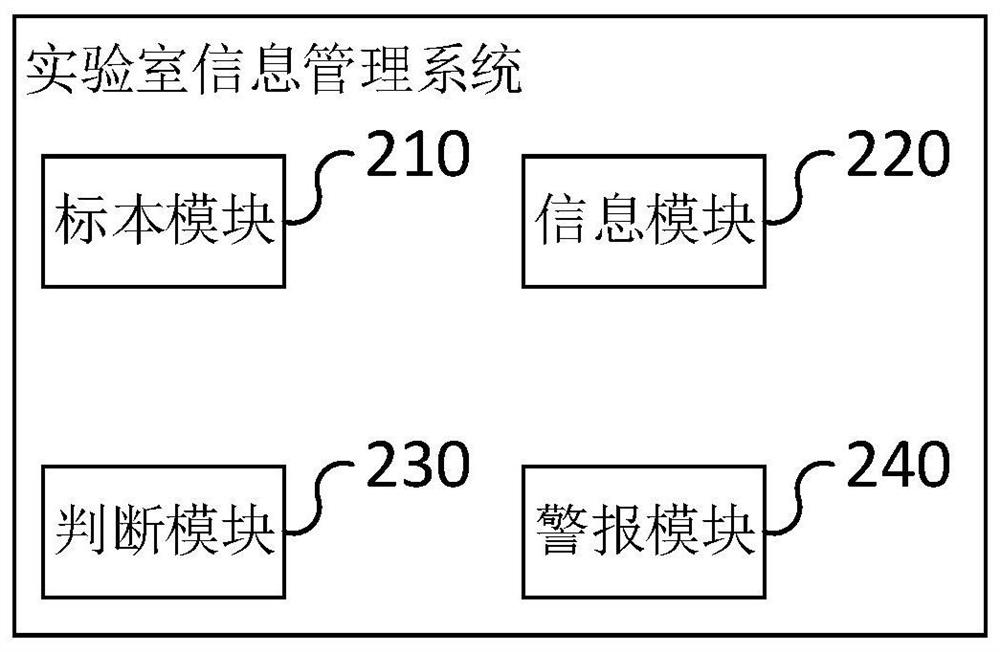

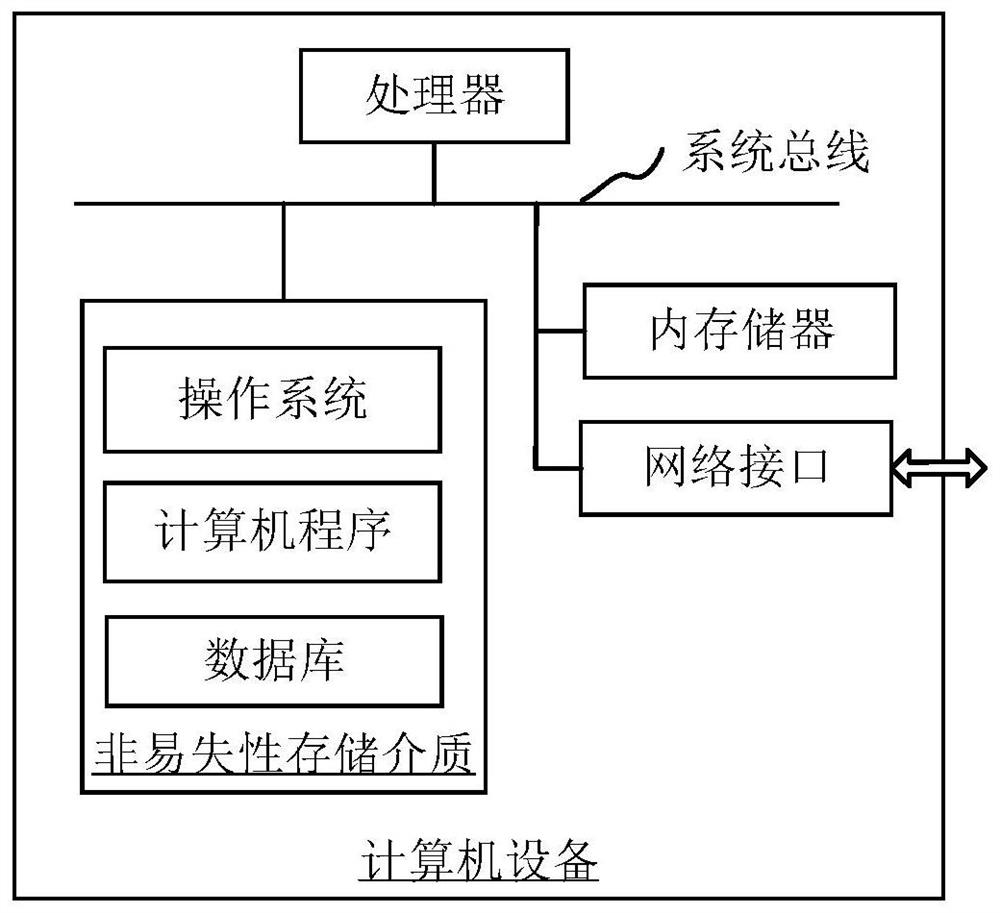

Laboratory management method and system, computer equipment and storage medium

ActiveCN110211343ALimit operationsControlling the riskMeasurement devicesAlarmsComputer scienceLaboratory facility

The application relates to a laboratory management method and system, computer equipment and a storage medium. The method comprises the following steps: acquiring specimen information of a specimen, wherein the specimen information comprises a test item and a parameter requirement corresponding to the test item; acquiring current parameter information of the laboratory, wherein the current parameter information of the laboratory comprises an environment parameter and an instrument parameter; judging whether the parameter in the laboratory parameter information satisfies the parameter requirement; if the parameter in the current parameter information of the laboratory cannot satisfy the parameter requirement, generating corresponding alarm and / or forbidding specimen test. By adopting the method disclosed by the application, the current parameter information of the laboratory can be monitored, the alarm can be given out in time and / or the specimen test can be prohibited when discoveringthat the parameter in the current parameter information of the laboratory is abnormal, the problem can be discovered in advance, the instrument operation is limited, and the risk is comprehensively controlled.

Owner:龙峰 +2

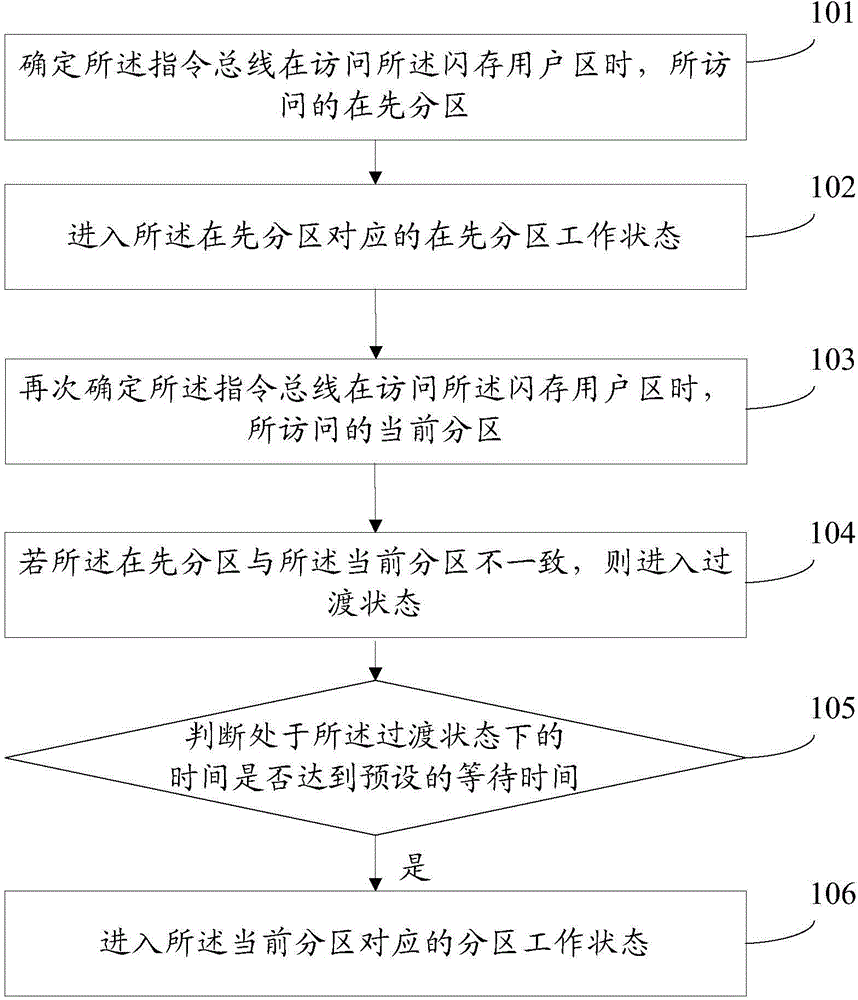

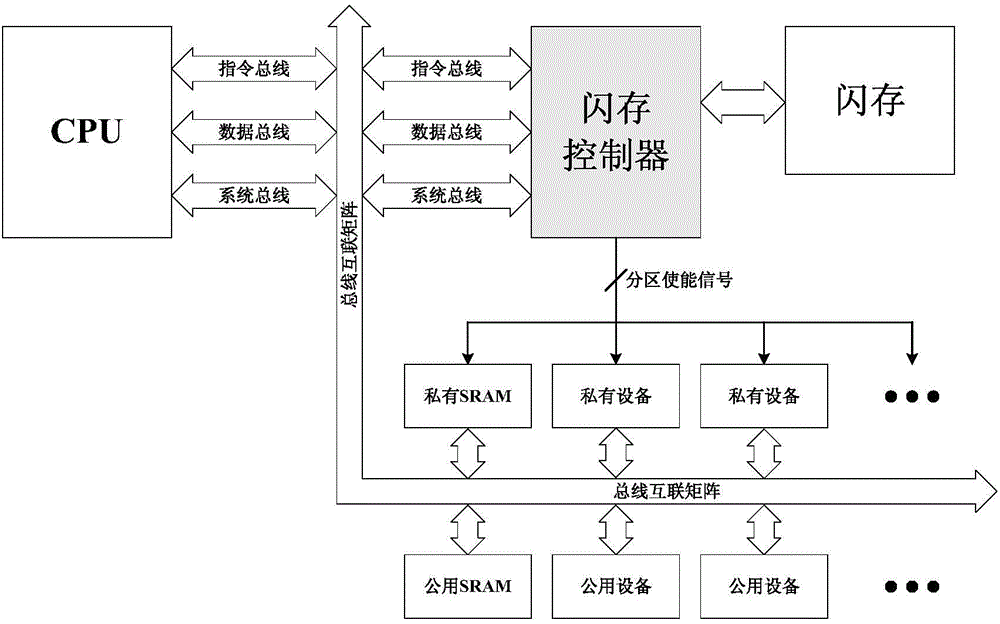

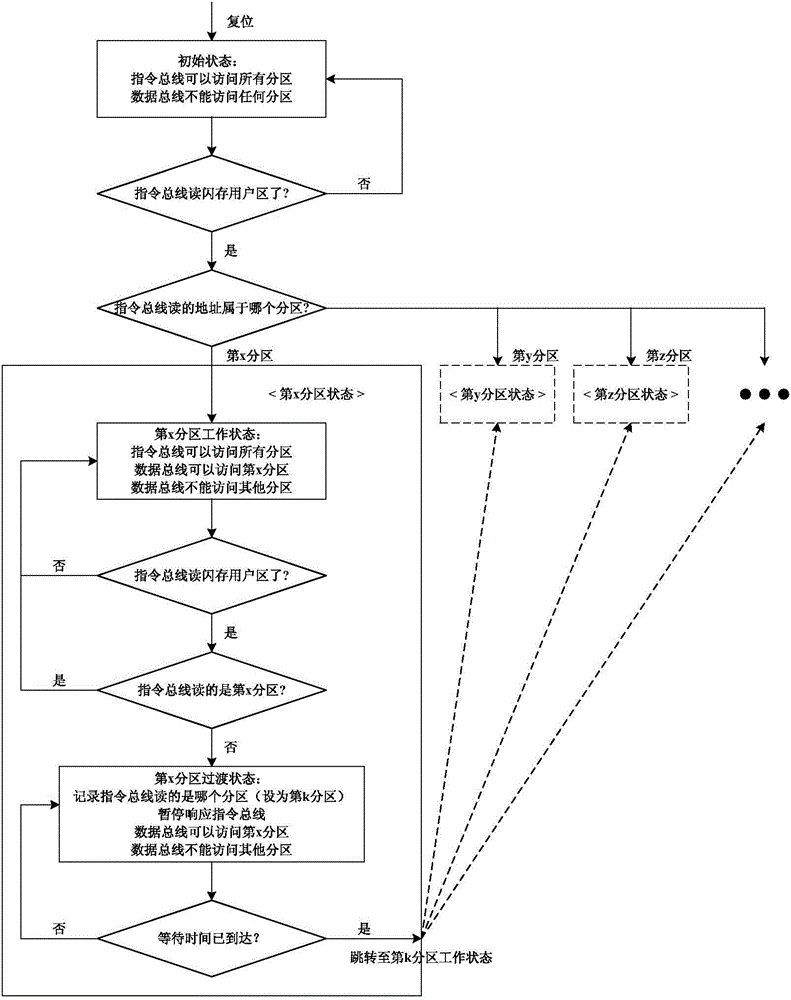

Multi-partition based MCU chip information protection method and device

ActiveCN104573421ANot to be stolenProtect development resultsMemory architecture accessing/allocationUnauthorized memory use protectionFlash memory controllerTransition state

The invention provides multi-partition based MCU chip information protection method and device. An MCU chip comprises an instruction bus, a data bus, a flash memory controller and a flash user area. The method comprises the steps of determining the accessed prior partition when the instruction bus accesses the flash user area; entering the prior partition working state corresponding to the prior partition; determining the accessed current partition when the instruction bus accesses the flash user area; entering a transition state in case that the prior area is different from the current partition; determining whether the time under the transition state reaches the preset waiting time; if so, entering the partition working state corresponding to the current partition. With the adoption of the method and device, programs can be protected from being stolen by a user, and meanwhile, the companies cooperating to develop the programs cannot steal programs from each other.

Owner:GIGADEVICE SEMICON (BEIJING) INC

Master-slave force feedback control-based isolation switch replacement method for hot-line robot

InactiveCN108598965AEasy to operateFlexible operationApparatus for overhead lines/cablesSwitchgearControl systemBase isolation

The invention provides a master-slave force feedback control-based isolation switch replacement method for a hot-line robot. Mechanical arms, main manipulators and industrial personal computers form amaster-slave force feedback control system, wherein the industrial personal computers calculate torque data of various joints of the main manipulators according to end force data of the mechanical arms and control various joints of the main manipulators to output torque through control interfaces of the main manipulators, so that the main manipulators feed back the force and an operator confirmsthe force of the mechanical arms according to the feedback force of the main manipulators; the operator changes end positions of the main manipulators; and the industrial personal computers calculateexpected values of end velocity vectors of the mechanical arms according to angle data of various rotary joints of the main manipulators and control the mechanical arms to move to change the force ofthe mechanical arms through the control interfaces of the mechanical arms according to the expected values. According to the master-slave force feedback control-based isolation switch replacement method for the hot-line robot, the operation telepresence is improved and whether various operations are accurate and in place or not can be more accurately judged.

Owner:NANJING UNIV OF SCI & TECH

Auto flushing devices of toilet bowl

ActiveCN104011304APrevent leakageAdjustable dischargeWater resource protectionFlushing devicesWater levelBuoyancy

An automatic flushing device of a toilet bowl is provided to block a leakage of washing water discharged to ceramic ware by buoyant materials which is a control unit blocking the power transmission from a driving unit. The automatic flushing device of a toilet bowl comprises an operation unit, a driving unit, a power transmission unit, and a clutch unit. The clutch unit comprises a clutch gear and a buoyancy material. The clutch gear is engaged with a plurality of gears in the power transmission unit while a position is moved. The buoyancy material is lifted due to buoyancy according to a water level in a water tank and moves the clutch gear. A height is changed in order to control the discharge amount of washing water when the buoyancy material descends.

Owner:COWAY CO LTD

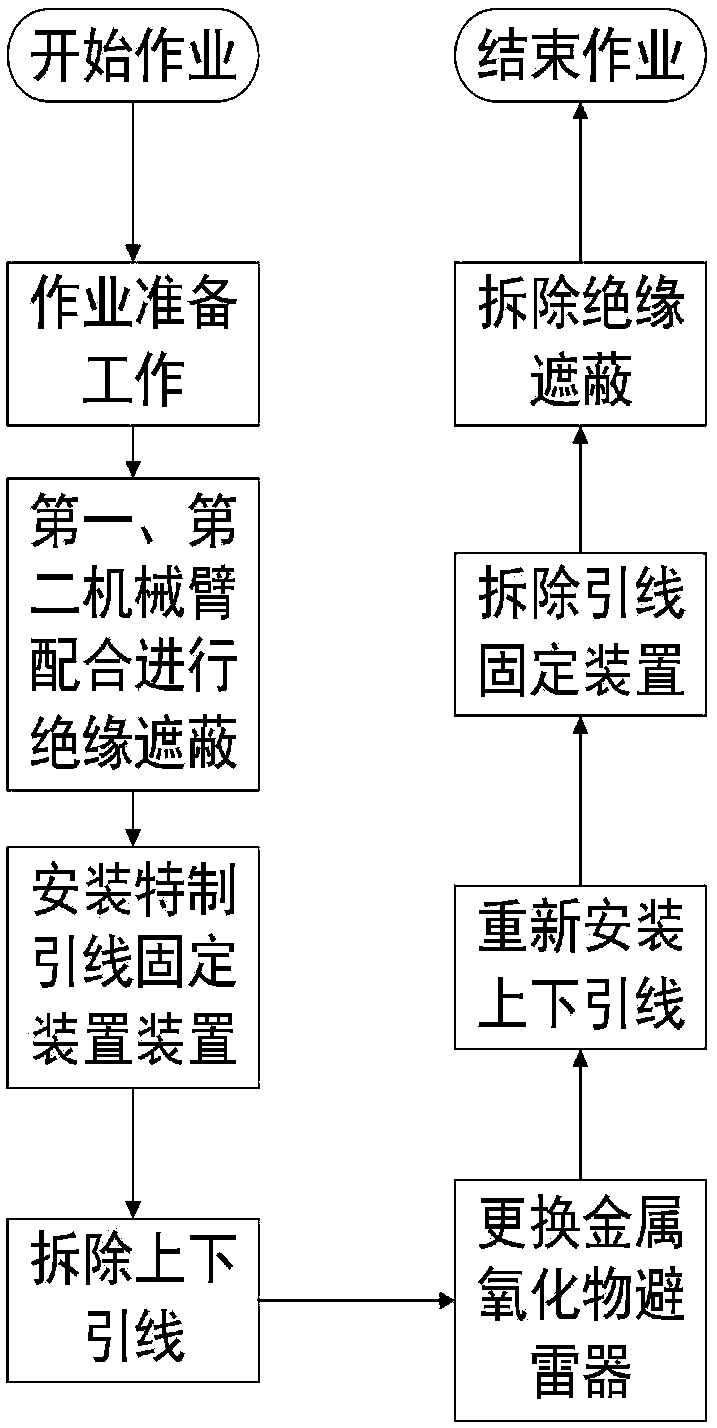

Method of replacing lightning arrester through hot-line working robot on basis of force feedback master-slave control

InactiveCN108544215AEasy to operateFlexible operationProgramme-controlled manipulatorMetal working apparatusControl systemPersonal computer

The invention provides a method of replacing a lightning arrester through a hot-line working robot on the basis of force feedback master-slave control. Mechanical arms, a master manipulator and an industrial personal computer are combined to form a force feedback master-slave control system. The industrial personal computer calculates torque data of various joints of the master manipulator according to stress data of the tail ends of the mechanical arms, and controls the output torque of the joints of the master manipulator through a control interface of the master manipulator so that the master manipulator can feed back the stress, and an operator determines the force of the mechanical arms according to the stress fed back by the master manipulator. The operator changes the pose of the tail end of the master manipulator, and the industrial personal computer calculates the expected values of velocity vectors of the tail ends of the mechanical arms according to angle data of various rotating joints of the master manipulator, and controls the mechanical arms to move through control interfaces of the mechanical arms according to the expected values so that the force of the mechanicalarms can be changed. The method has the advantages that the working tele-presence is improved, and whether various kinds of operation are accurately conducted in place can be more accurately judged.

Owner:NANJING UNIV OF SCI & TECH

Force feedback master-slave control-based electrified operation robot tension insulator replacement method

InactiveCN108462108AEasy to operateFlexible operationApparatus for overhead lines/cablesControl systemPersonal computer

The invention provides a force feedback master-slave control-based electrified operation robot tension insulator replacement method. A mechanical arm, a main manipulator and an industrial personal computer form a force feedback master-slave control system; the industrial personal computer works out torque data of each joint of the main manipulator according to stressed data of the tail end of themechanical arm; through a control interface of the main manipulator, the output torque of each joint of the main manipulator is controlled, so that the main manipulator feeds back the stressed force,and an operator determines the force of the mechanical arm according to the feedback stressed force of the main manipulator; the operator changes the tail end posture of the main manipulator, and theindustrial personal computer works out the expected value of the speed vector at the tail end of the mechanical arm according to angle data of each rotary joint of the main manipulator; and through the control interface of the mechanical arm, the mechanical arm movement can be controlled according to the expected value so as to change the force of the mechanical arm. By virtue of the method, operational sense of immediacy is improved, and whether each operation is in place accurately or not can be judged more accurately.

Owner:NANJING UNIV OF SCI & TECH

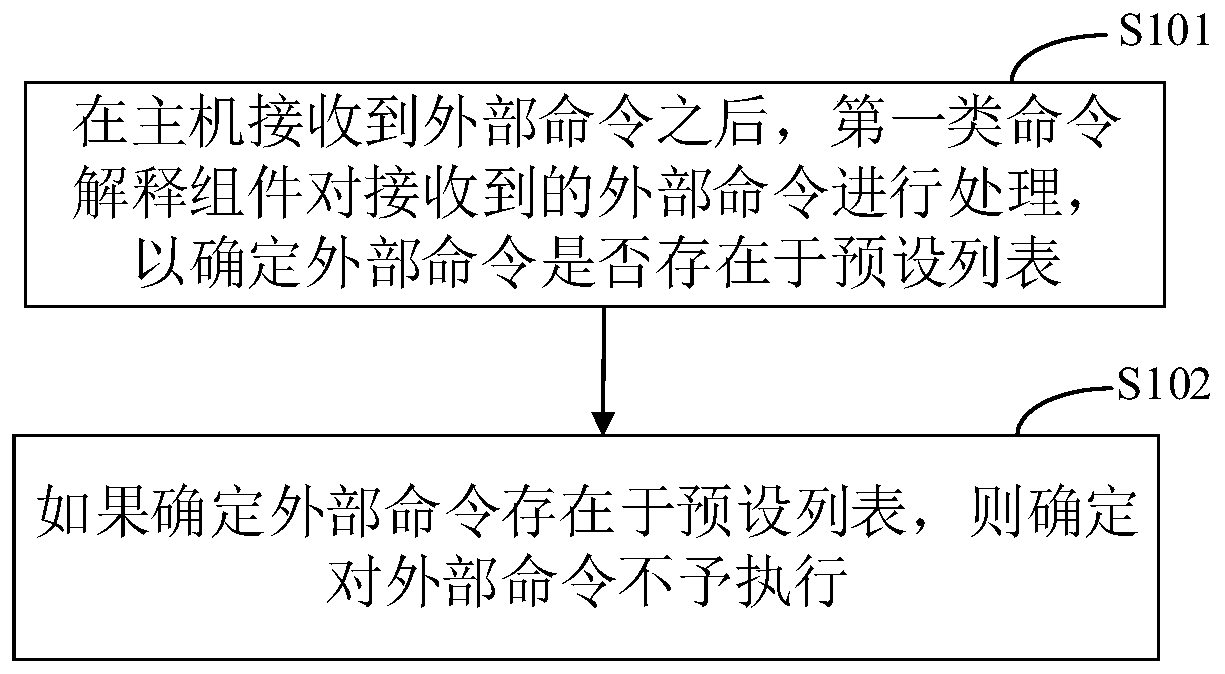

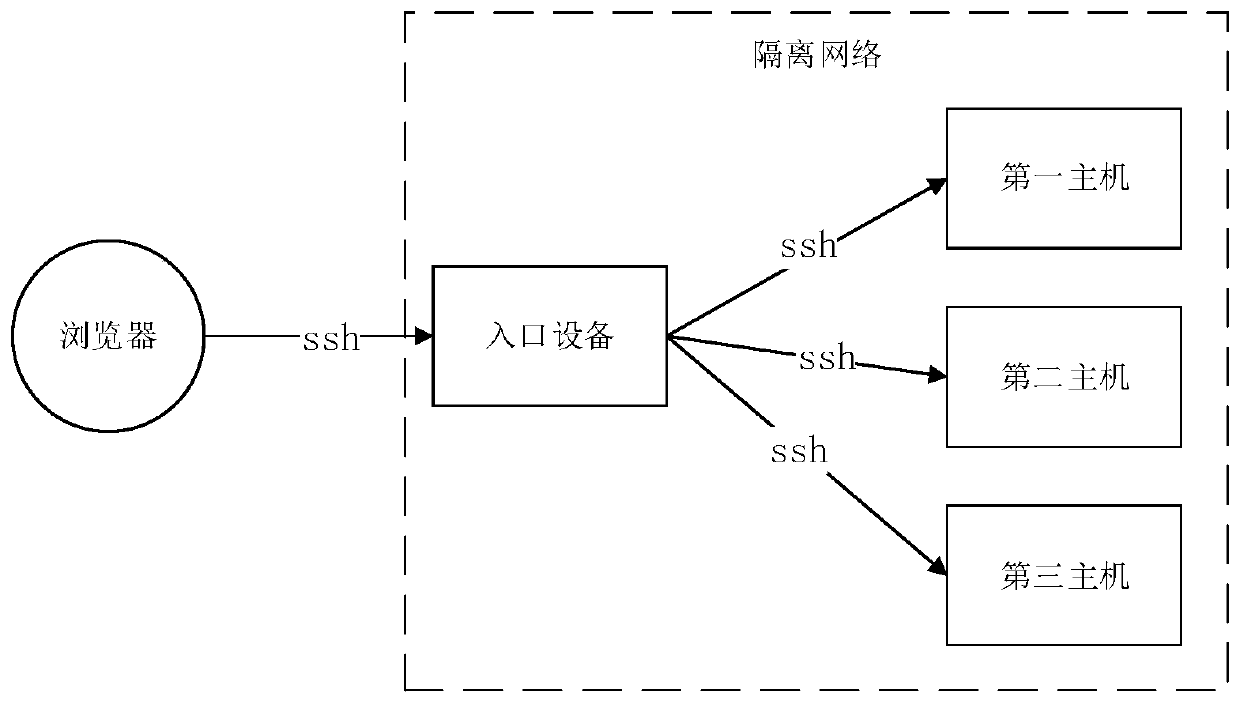

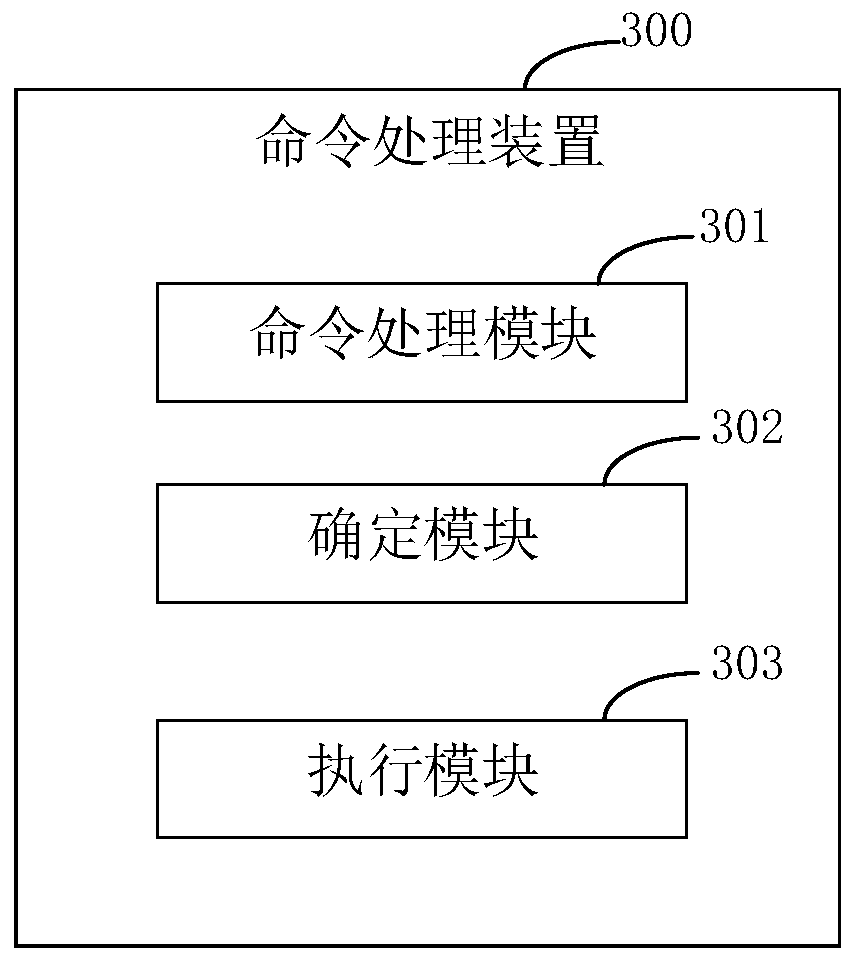

Command processing method and device for host, electronic equipment and storage medium

ActiveCN111008041ALimit operationsImprove securityInterprogram communicationDigital data protectionEngineeringHost (network)

The invention discloses a command processing method and device for a host, electronic equipment and a storage medium, and relates to the technical field of network isolation. According to the specificimplementation scheme, a host comprises at least one first-class command interpretation component, wherein the first-class command interpretation component is configured to comprise a preset list. The command processing method for the host comprises the steps that after the host receives an external command, the first-class command interpretation component processes the received external commandto determine whether the external command exists in the preset list or not; and if it is determined that the external command exists in the preset list, it is determined that the external command is not executed; and under the condition that the received external command meets the preset condition, corresponding preset processing is executed on the external command, so that the received external command cannot be switched to other command interpretation components in the host. By utilizing the embodiment of the invention, the security of information interaction can be improved.

Owner:BEIJING BAIDU NETCOM SCI & TECH CO LTD

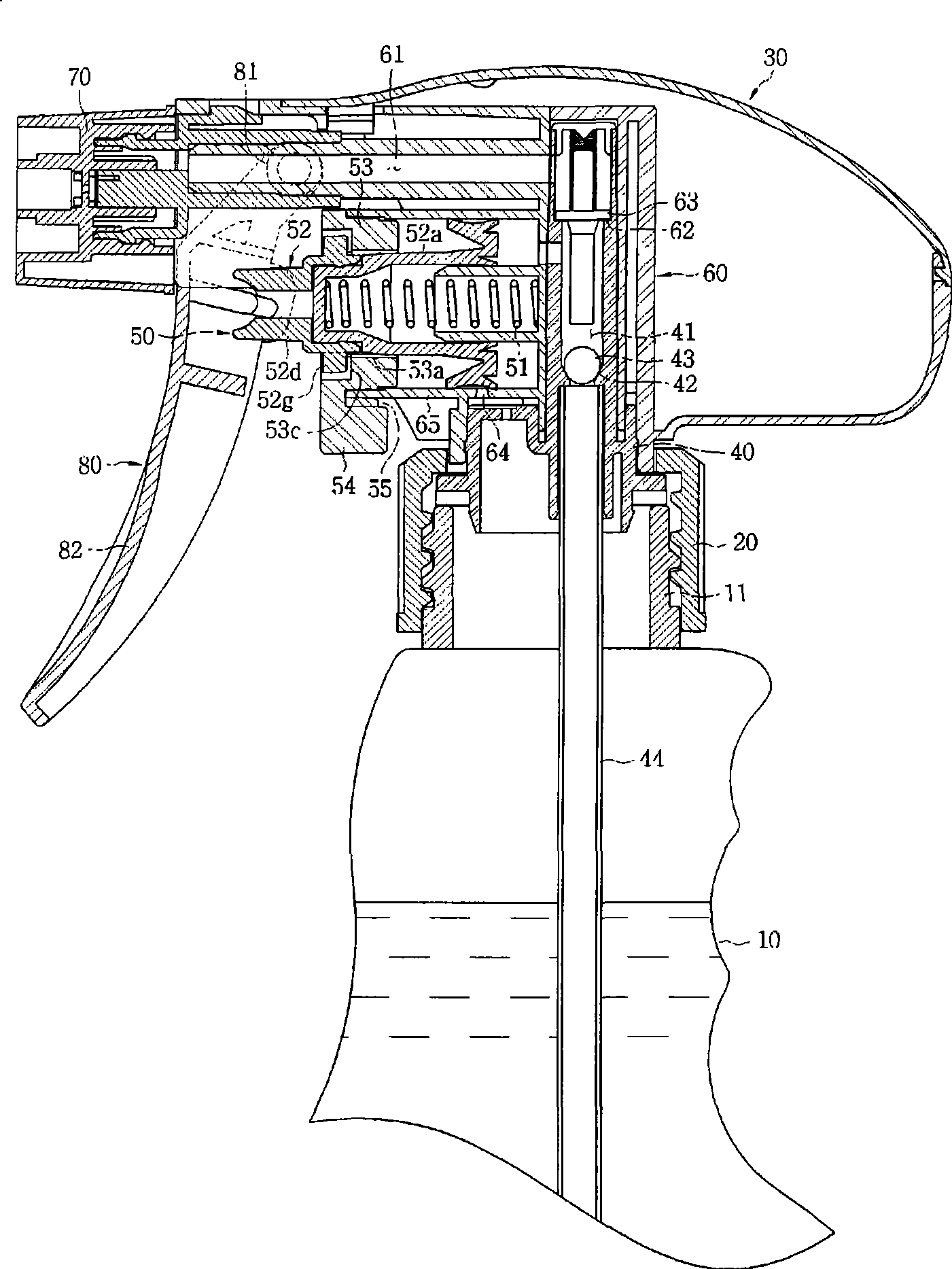

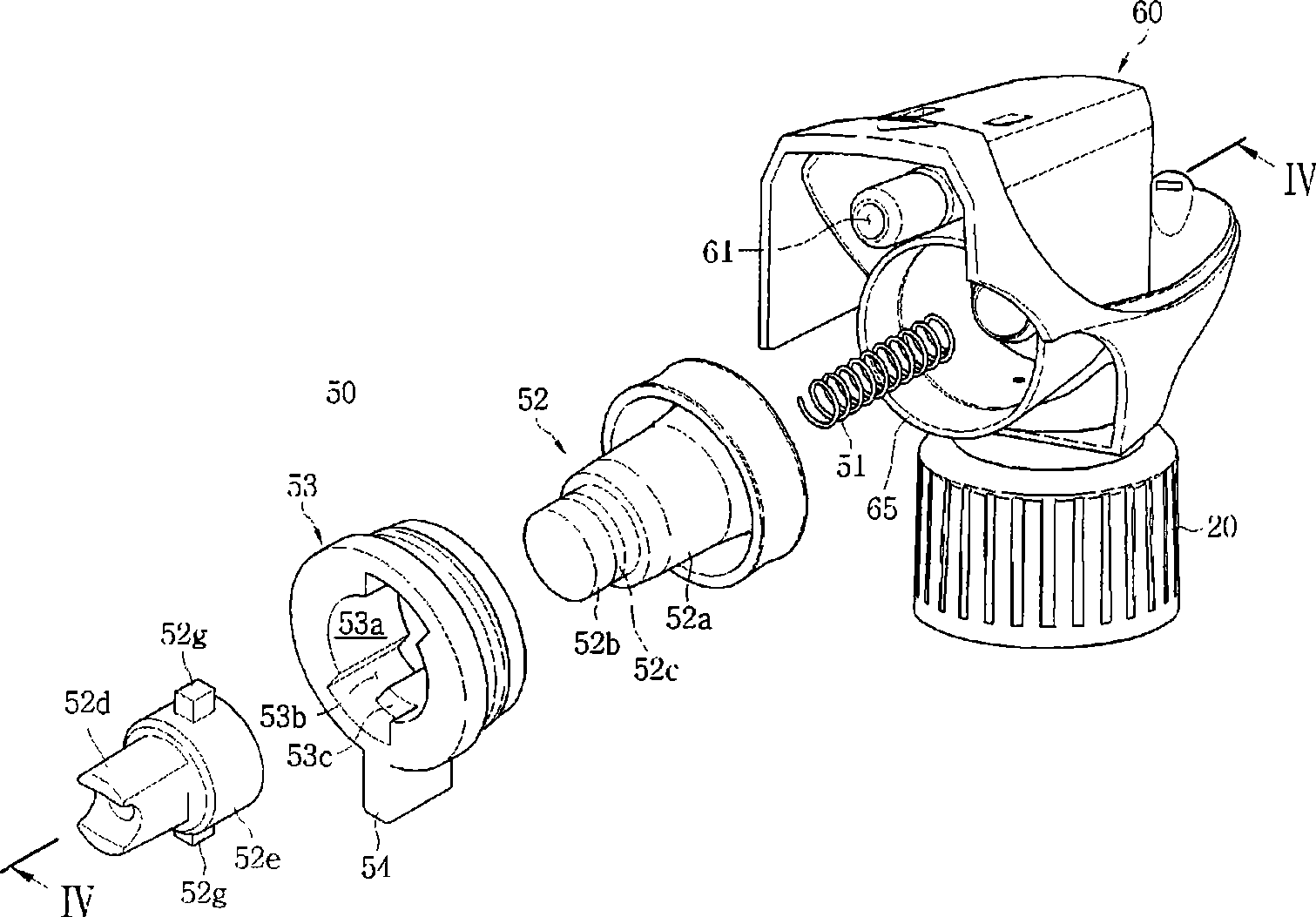

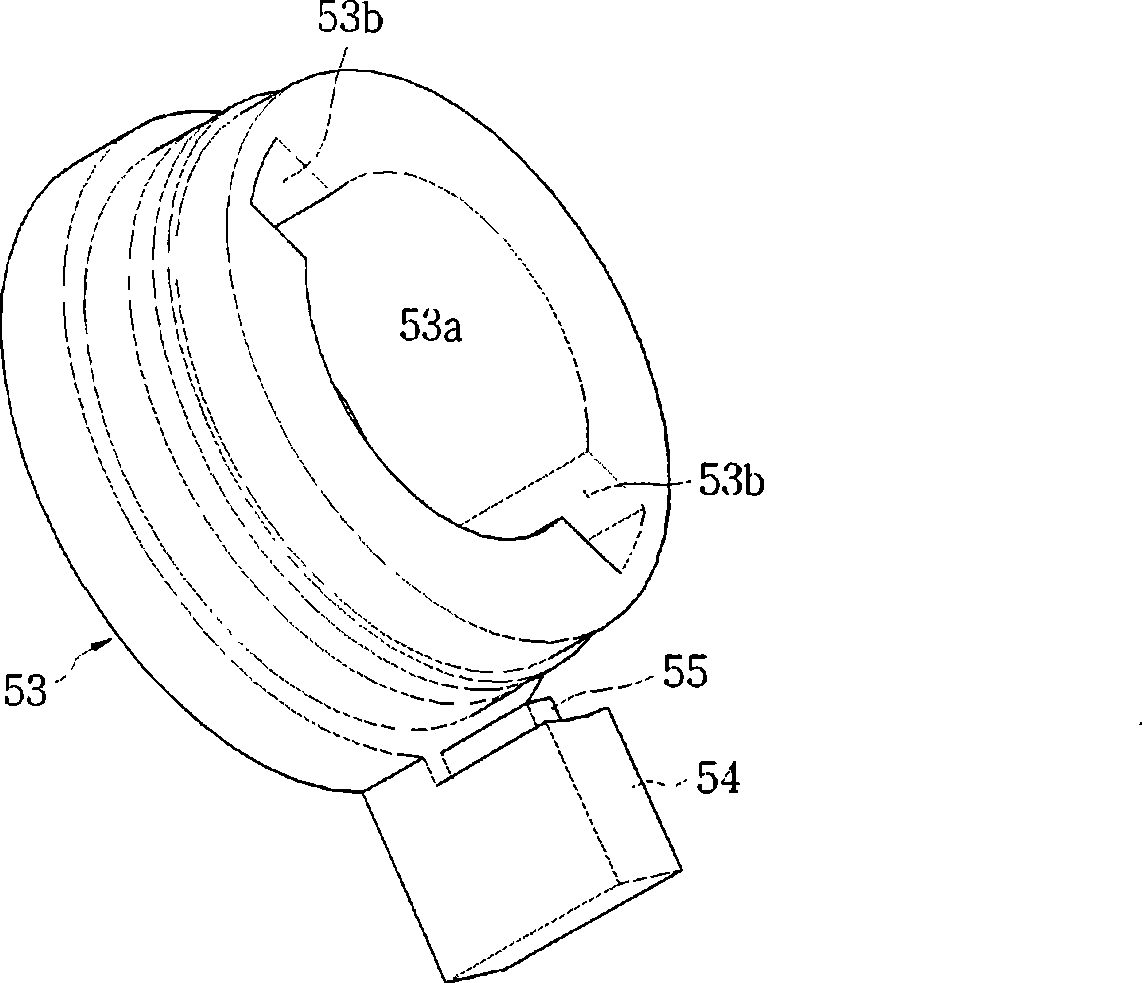

Trigger type sprayer

ActiveCN101394934ALimit operationsWill not deformSingle-unit apparatusLiquid spraying apparatusInjectorEngineering

A trigger sprayer device is disclosed, which is configured in such a way that the trigger and plunger are operable only after unlocking, to be childproof. The trigger sprayer device includes: a plunger unit (52) that is placed to reciprocate inside the cylinder (65) and elastically supported by a restoring spring (51), in which the front end of the plunger unit (52) is associated with a rear side of the trigger (80) and the sides of the plunger unit (52) protrudently forms locking ribs; and a locking member (53) that is pivotally fitted in an opened end of the cylinder (65), and has a through hole (53a), shaped as a ring, to allow the front end of the plunger unit (52) to be past through, forming slide grooves (53b) on the inner circumference of the through hole (53a) to se not lectively allow the locking ribs (52g) to be moved. Therefore, when the slide grooves (53b) and the locking ribs (52g) are not parallel with each other, the trigger (80) and the plunger unit (52) maintain their locking state. Thus, the operation of the trigger (80) can be restricted. Ac not cordingly, the trigger sprayer device is childproof. In addition, since the plunger unit (52) has always been received in the through-hole (53a), the plunger unit (52) is not deformed although the trigger is pressed from both its sides and impacted while the sprayer is carried.

Owner:APOLLO IND

Laboratory management method, system, computer equipment and storage medium

ActiveCN110211343BLimit operationsControlling the riskMeasurement devicesAlarmsExperimental laboratoryComputer science

Owner:龙峰 +2

Toilet automatic flushing device

ActiveCN104011304BPrevent leakageAdjustable dischargeWater resource protectionFlushing devicesEngineeringWater level

Owner:COWAY CO LTD

Information observation method and information observation device

ActiveCN103530623BLimit operationsAvoid missingImage analysisCharacter and pattern recognitionComputer visionArtificial intelligence

The present application discloses an information observation method and an information observation apparatus, and relates to the field of multimedia information processing technologies. The method comprises: detecting a position of a sightline focusing point of an observer; in response to that it is detected that the sightline focusing point of the observer moves away from an observed object, judging whether the observer has observed all important information on the observed object; and in response to that it is judged that the observer has not observed all important information on the observed object, reminding the observer. For the method and the apparatus in embodiments of the present application, from the perspective of an actual observation behavior of an observer, a position of a sightline focusing point of the observer is detected to determine an observation behavior of the observer for important information, so as to radically prevent missing of important information.

Owner:BEIJING ZHIGU RUI TUO TECH

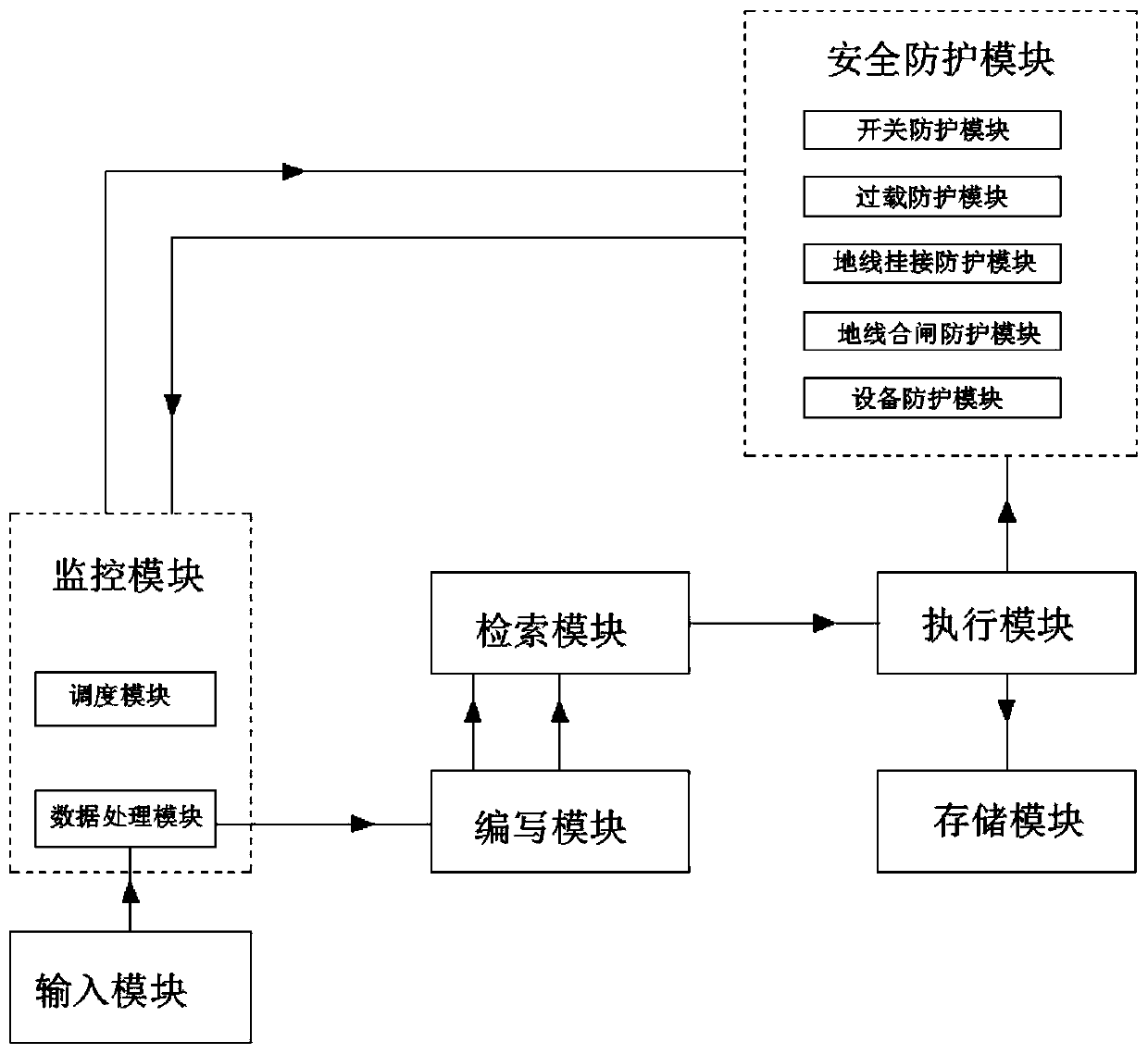

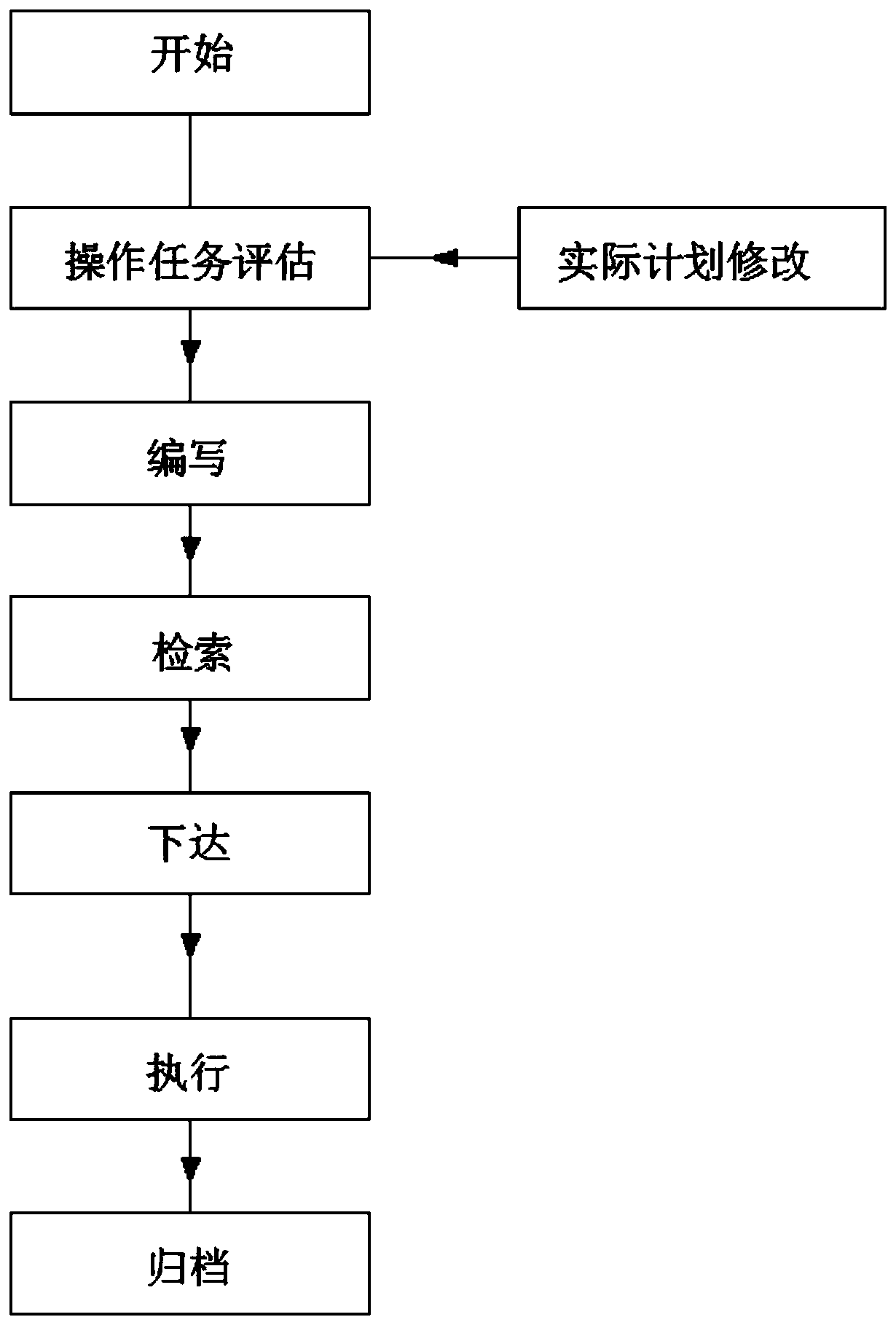

Artificial intelligence technology optimized dispatching switching operation system

PendingCN110930066AUseful for exception repairEasy to save dataResourcesField conditionsOperational system

The invention discloses an artificial intelligence technology optimized dispatching switching operation system, and relates to the field of electrical equipment. For solving the problems that the existing switching operation is generally monitored manually, and then corresponding changes are made according to field conditions, thus not facilitating switching system operation and timely protectionof equipment switching; the existing switching operation is not provided with a storage module, so that the switching operation instruction cannot be stored, and repeated use of switching operation isnot facilitated and the intelligence of a switching operation system is influenced, the invention provides the following scheme that the artificial intelligence technology optimized dispatching switching operation system comprises a monitoring module, a safety protection module and an input module, and is characterized in that the output end of the monitoring module is connected with the input end of the safety protection module, and the monitoring module comprises a scheduling module and a data processing module. According to the artificial intelligence technology optimized dispatching switching operation system, through the switch protection module, the overload protection module, the ground wire hanging protection module, the ground wire closing protection module and the equipment protection module, used equipment is protected, and protection of equipment closing operation is facilitated.

Owner:TELLHOW SOFTWARE

A method and system capable of quickly restoring a virtualization platform

ActiveCN107463467BQuick restorePromote recoveryRedundant operation error correctionVirtualizationThird party

The invention discloses a method and system for quickly restoring a virtualization platform. A disk of a server is divided into a configuration partition, a livecd mirror partition, a data partition and a log partition, and the partitions are formatted into different forms so as to limit the operation of a user; because of the characteristic that a livecd system runs in a memory and can be eliminated after the memory is powered down and the unwriteable specificity of the cd-rom in a livecd mirror storage partition, livecd mirror files in the livecd mirror storage partition cannot be modified, and consequently, the livecd system can be restored to the initial installation state after restarting every time. By means of the method and system for quickly restoring the virtualization platform, when error operations exist in the virtualization platform and / or the virtualization platform suffers from hostile attack of third parties, the livecd system is quickly restored to the initial state in the mode of restarting the server, and therefore, the quick restoration of the virtualization platform is achieved.

Owner:INSPUR BEIJING ELECTRONICS INFORMATION IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com