Hot-line work robot force feedback master-slave control method and system based on virtual reality technology

A virtual reality technology and live operation technology, applied in the electric power field, can solve the problem of difficulty in judging whether the operation accuracy meets the operation requirements, etc., and achieve the effect of improving operation safety, improving automation and operation accuracy, and improving convenience and accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

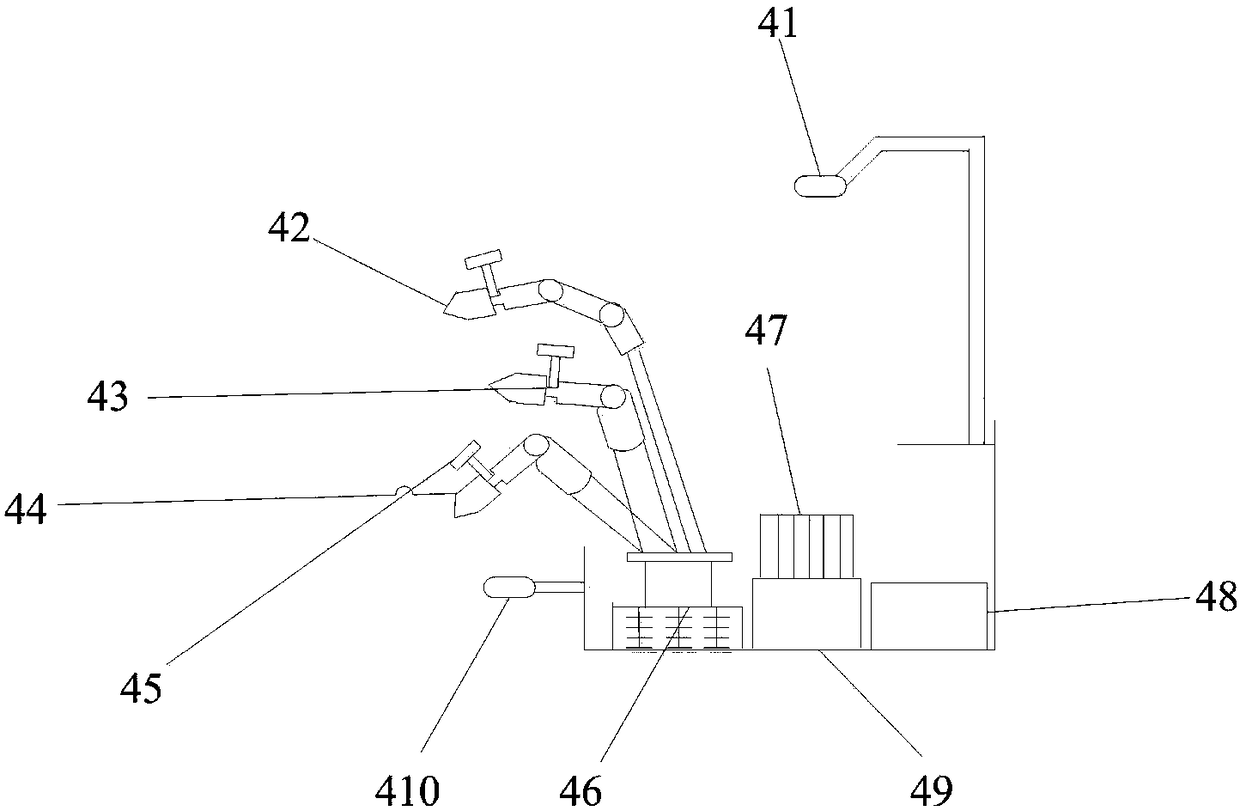

[0087] The specific implementation manner of the present invention will be described below as an example of avoiding the collision between the first mechanical arm 43 and the charging device.

[0088] When the operator is operating the first main operator, the first main operator sends the angle data of the six rotary joints 501, 502, 503, 504, 505, and 506 to the second industrial computer, and the second industrial computer The conversion relationship between the angle data of the six rotary joints of the main manipulator and the end pose data of the main manipulator is calculated to obtain the end pose data of the first main manipulator, and the end pose data of the first main manipulator is obtained by differential operation The first master operator's terminal speed data.

[0089] The second industrial computer calculates the control amount of the first mechanical arm 43 by using the speed feed-forward PID controller according to the pose data of the end of the first main...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com