Patents

Literature

516results about "Apparatus for repairing insulation/armouring cables" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

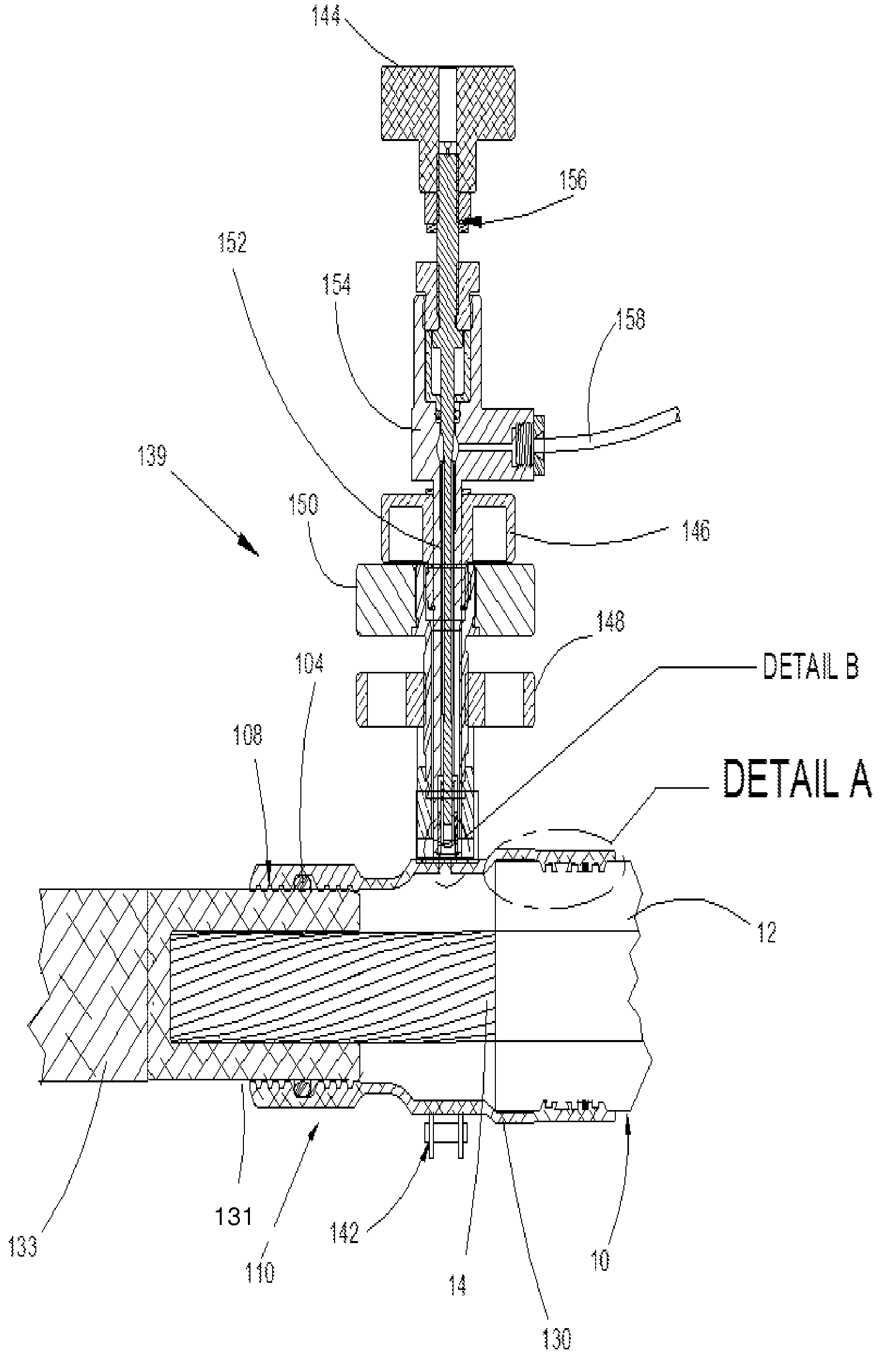

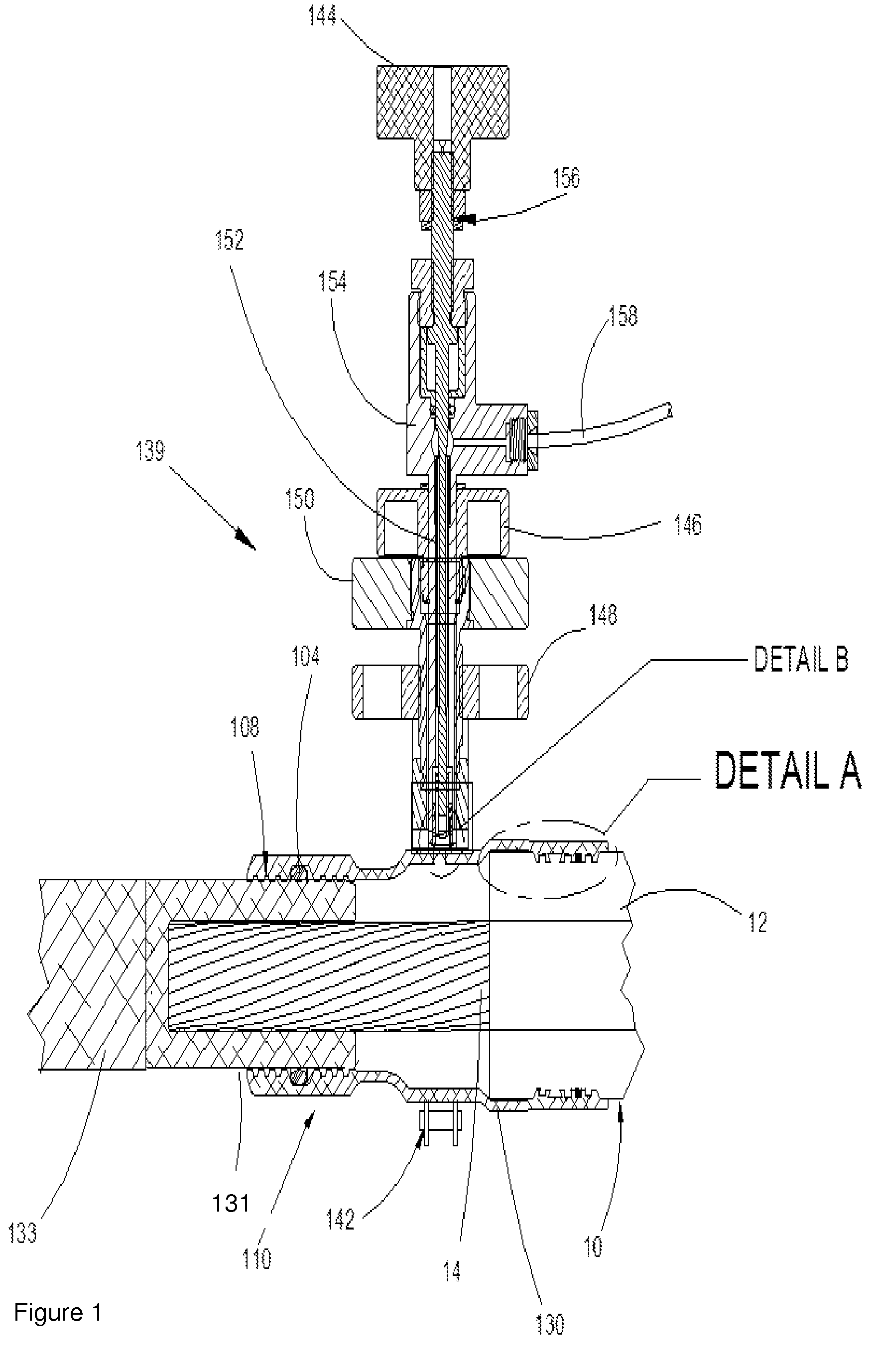

Integrated method for restoring electrical power cable

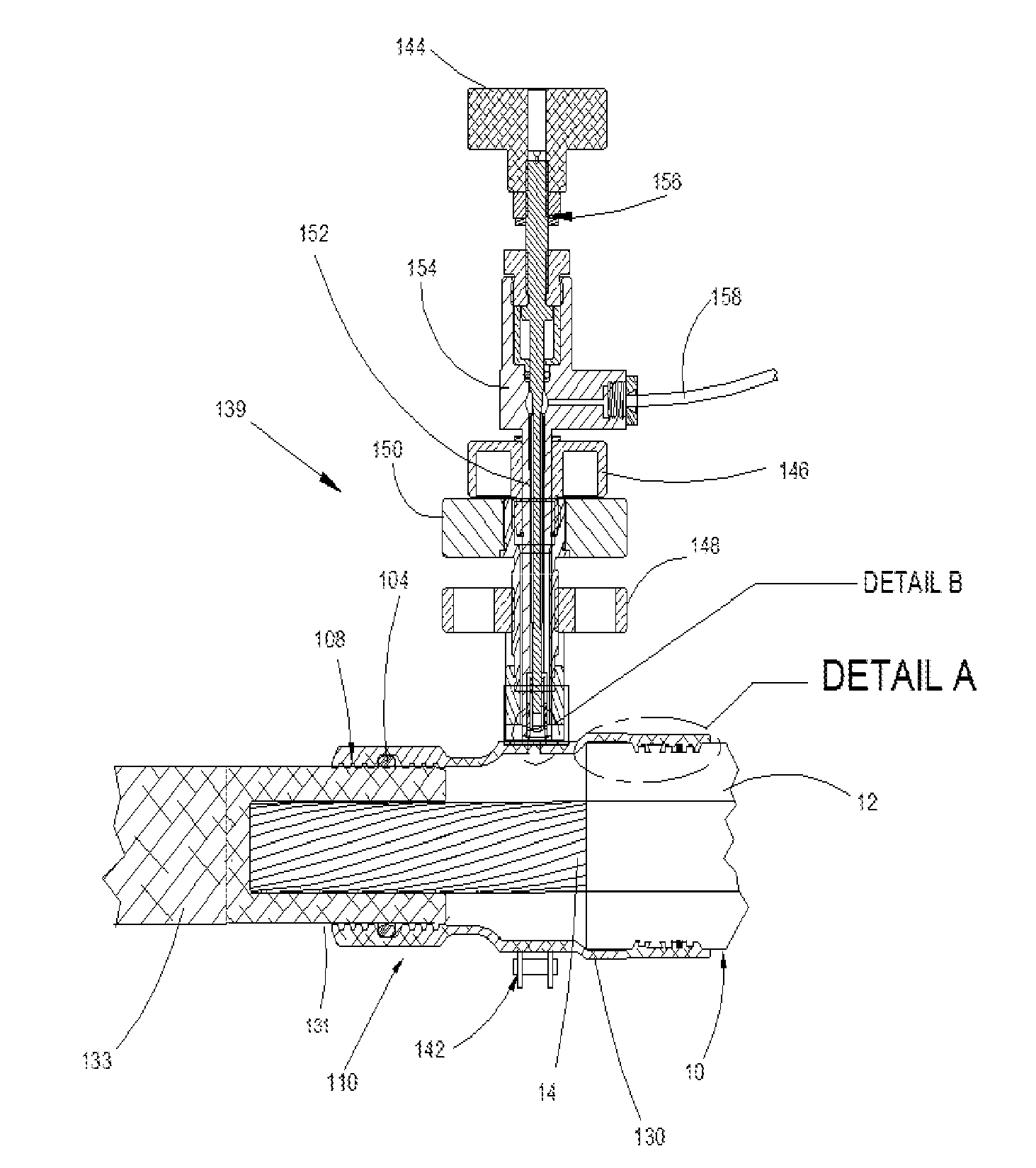

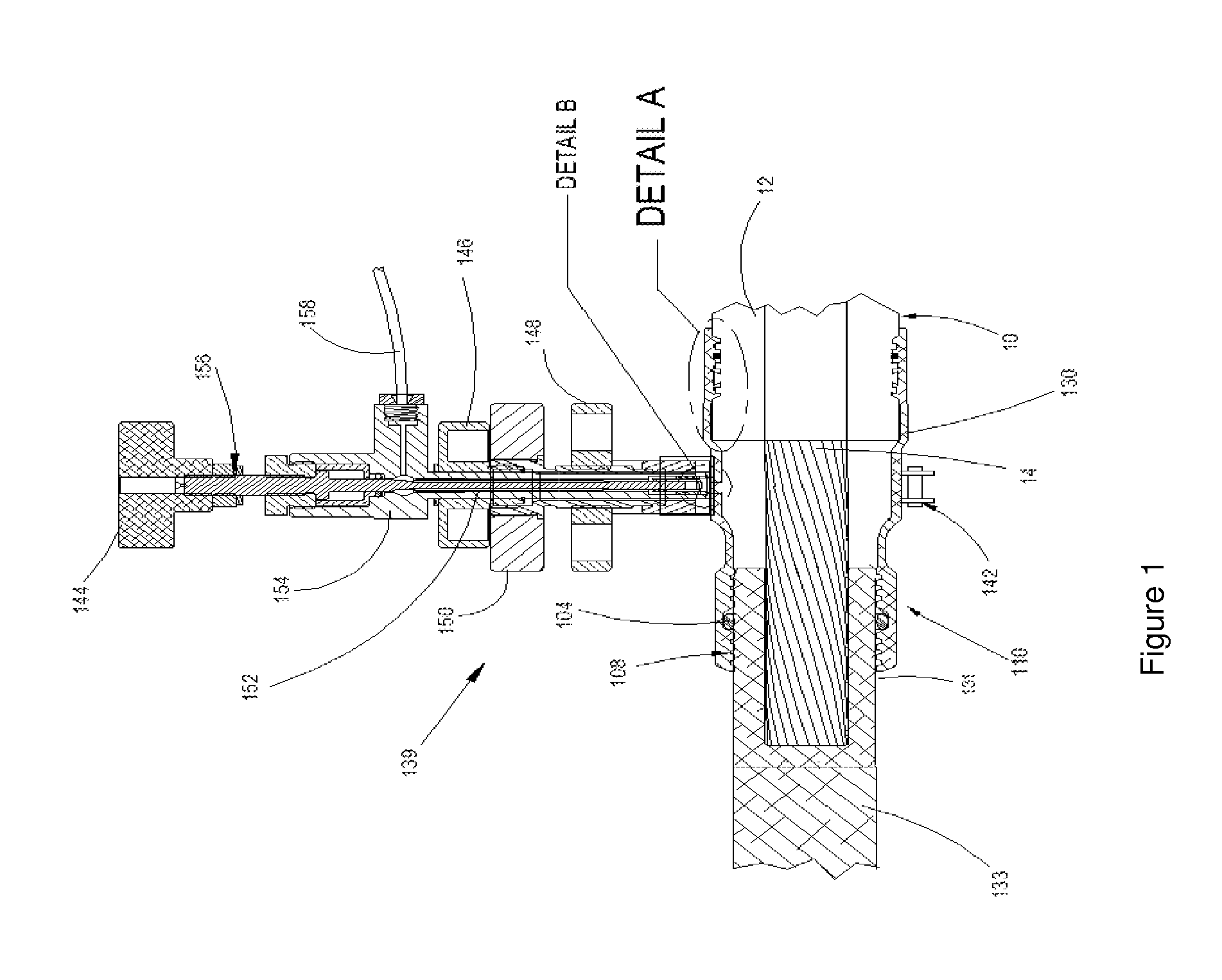

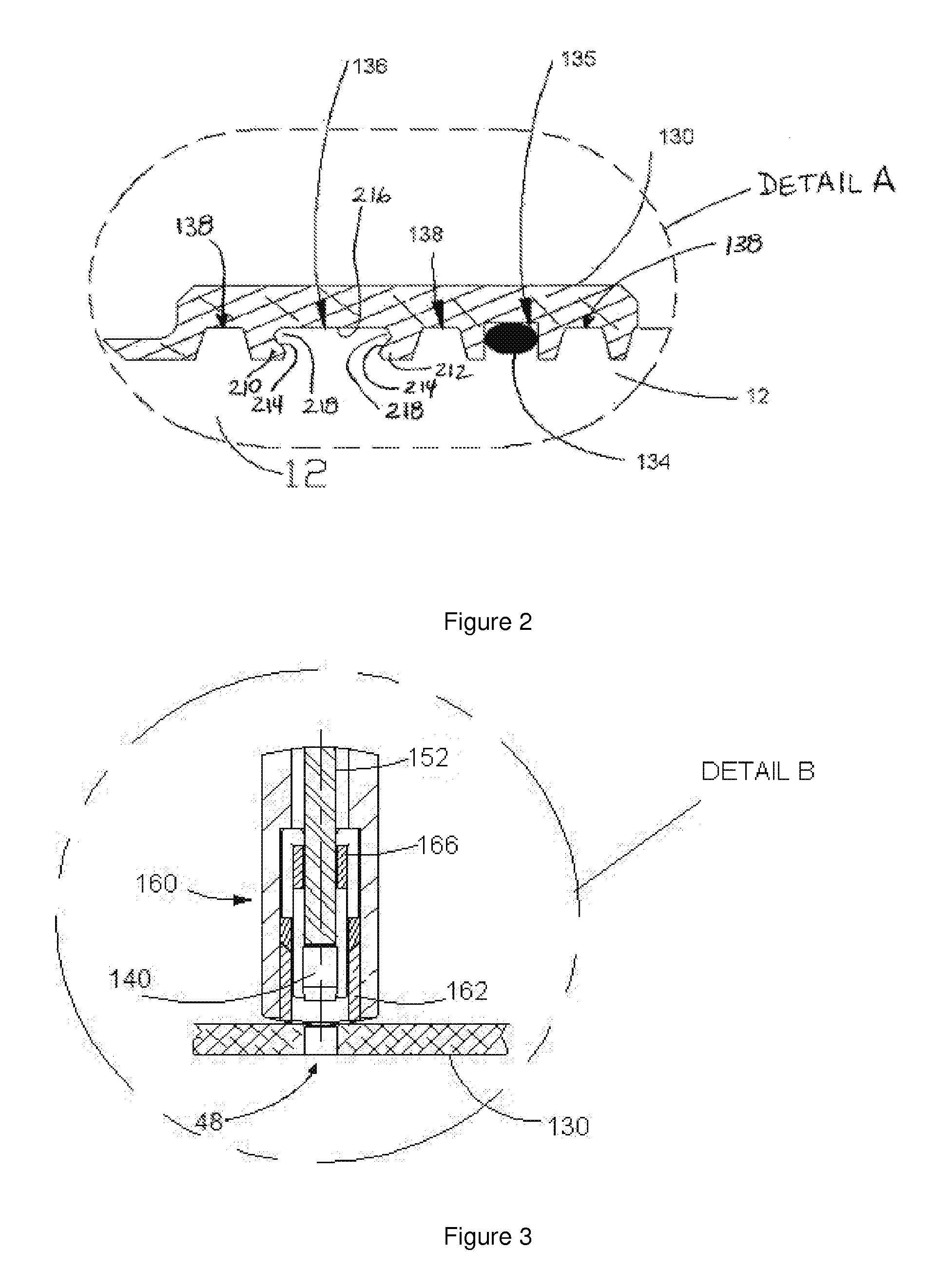

ActiveUS7353601B1Improve efficiencyFor quick replacementLine/current collector detailsApparatus for repairing insulation/armouring cablesPower cableElectrical conductor

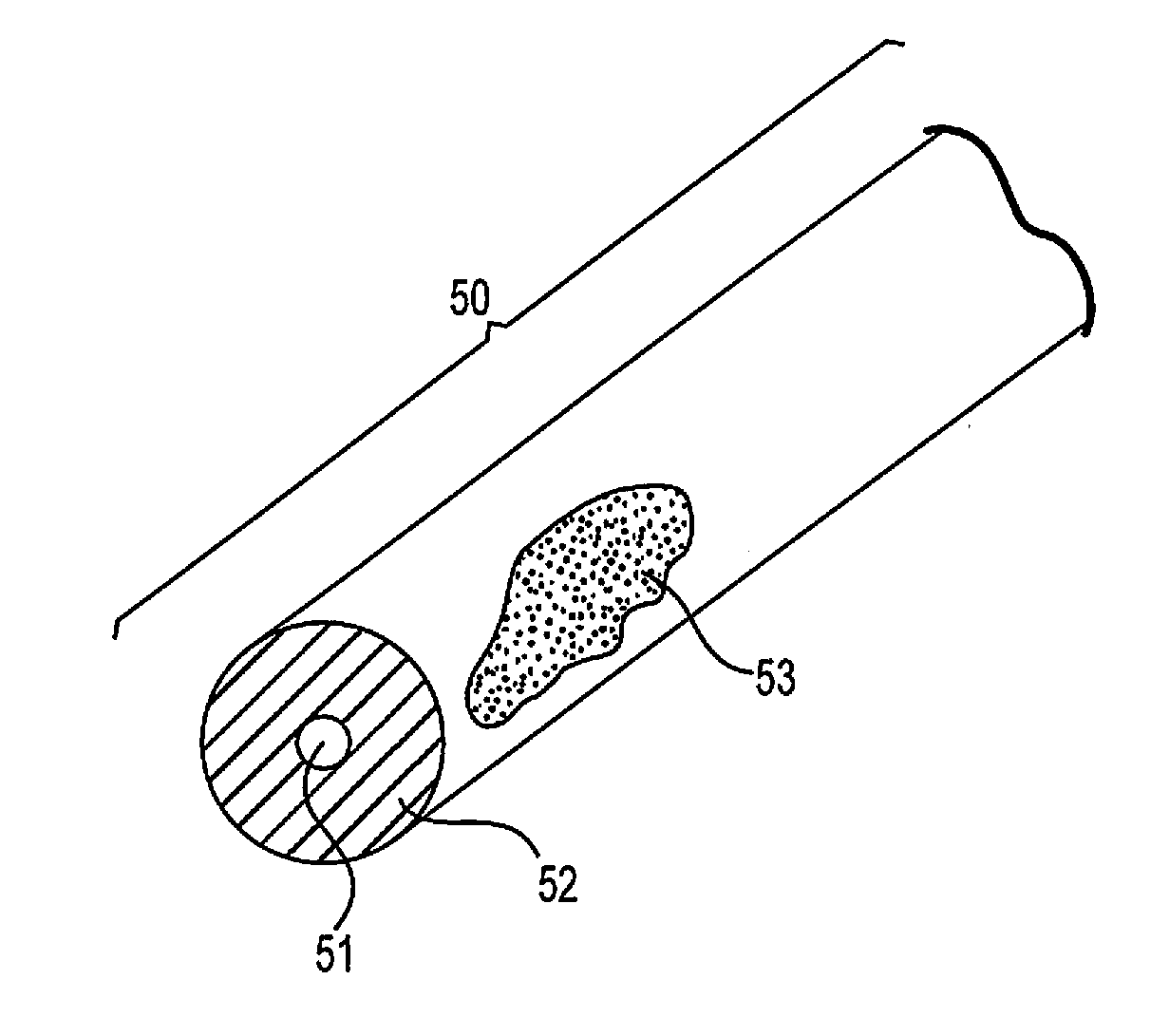

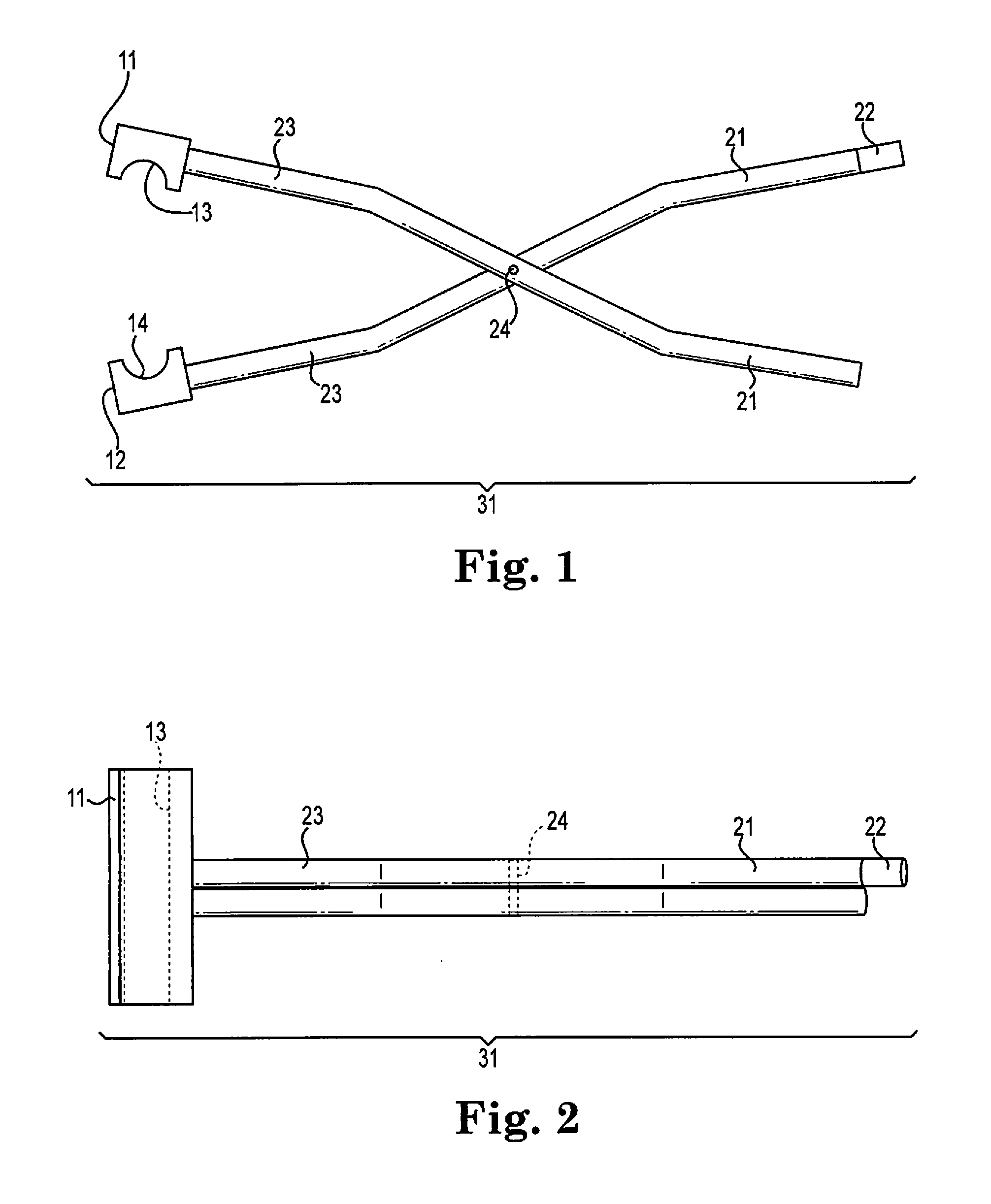

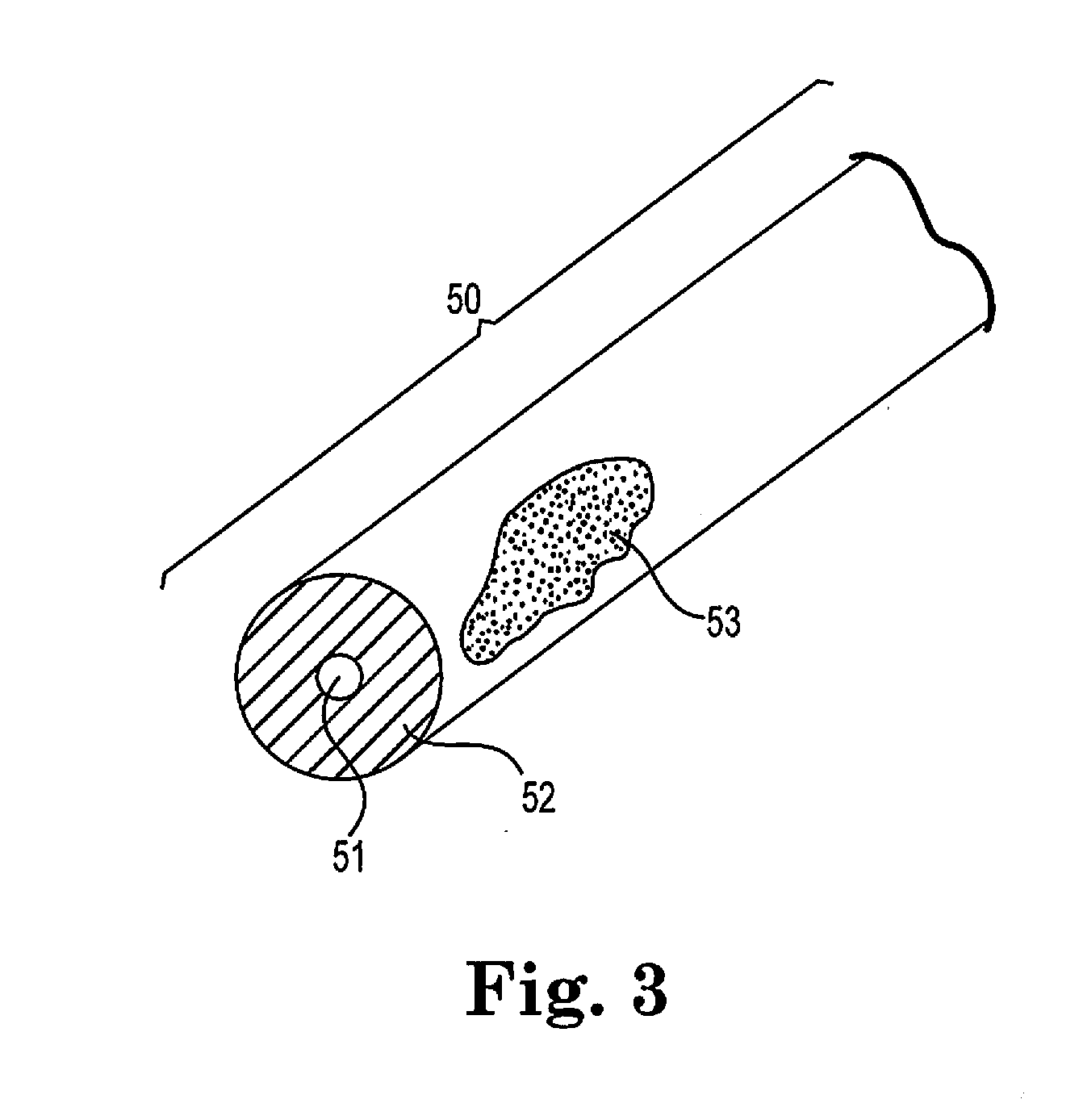

A method for extending the useful life of an in-service electrical cable section having at least two existing connectors attached thereto and a conductor surrounded by a conductor shield encased in a polymeric insulation jacket with an interstitial void volume in the region of the conductor. The method includes replacing each connector with a corresponding high-pressure connector, and injecting a dielectric enhancement fluid into the void volume and confining the fluid therein at a pressure sufficient to introduce at least about 0.75Q of the fluid. Wherein Q represents the weight of the fluid which would saturate the conductor shield and insulation jacket, and the void volume at atmospheric pressure being less than that which would accommodate the amount 0.75Q. The method is carried out using only a single switching cycle.

Owner:NOVINIUM LLC

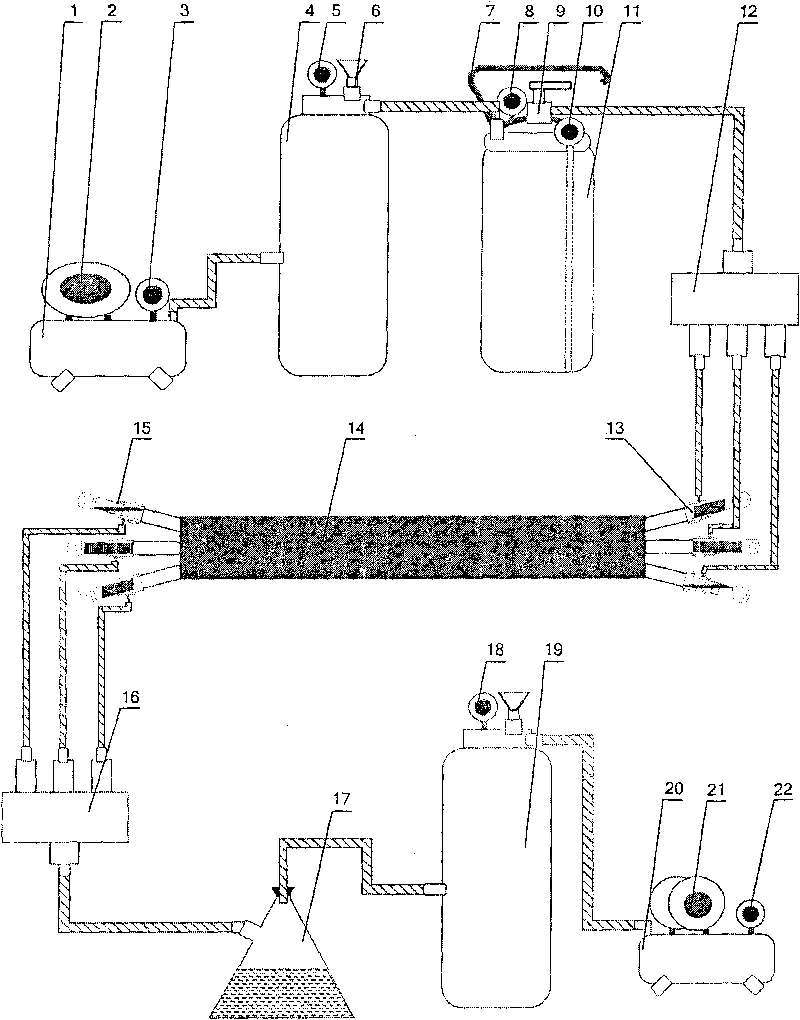

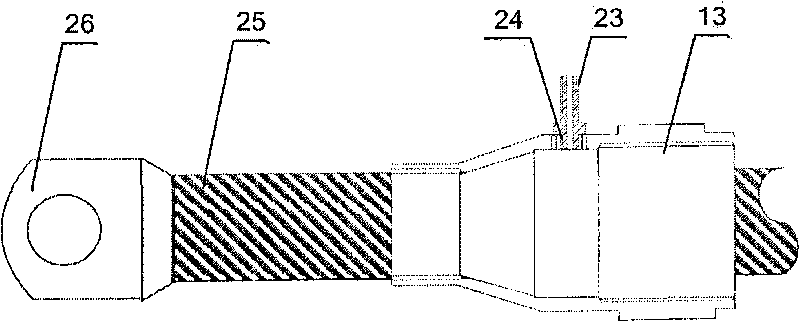

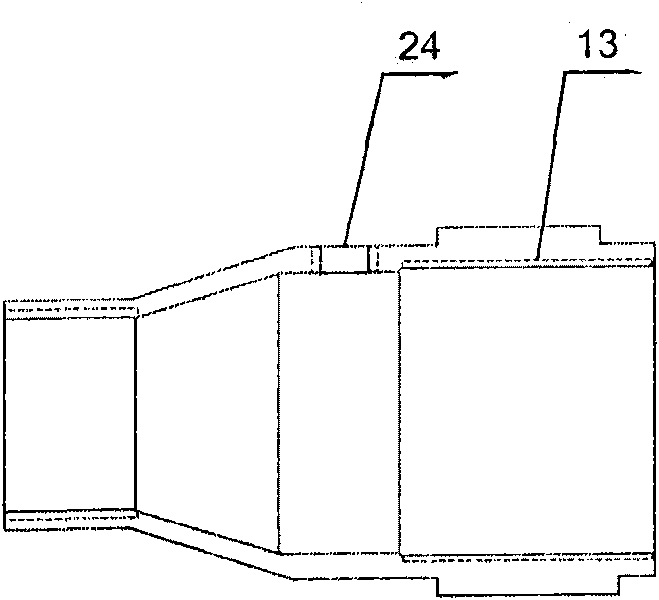

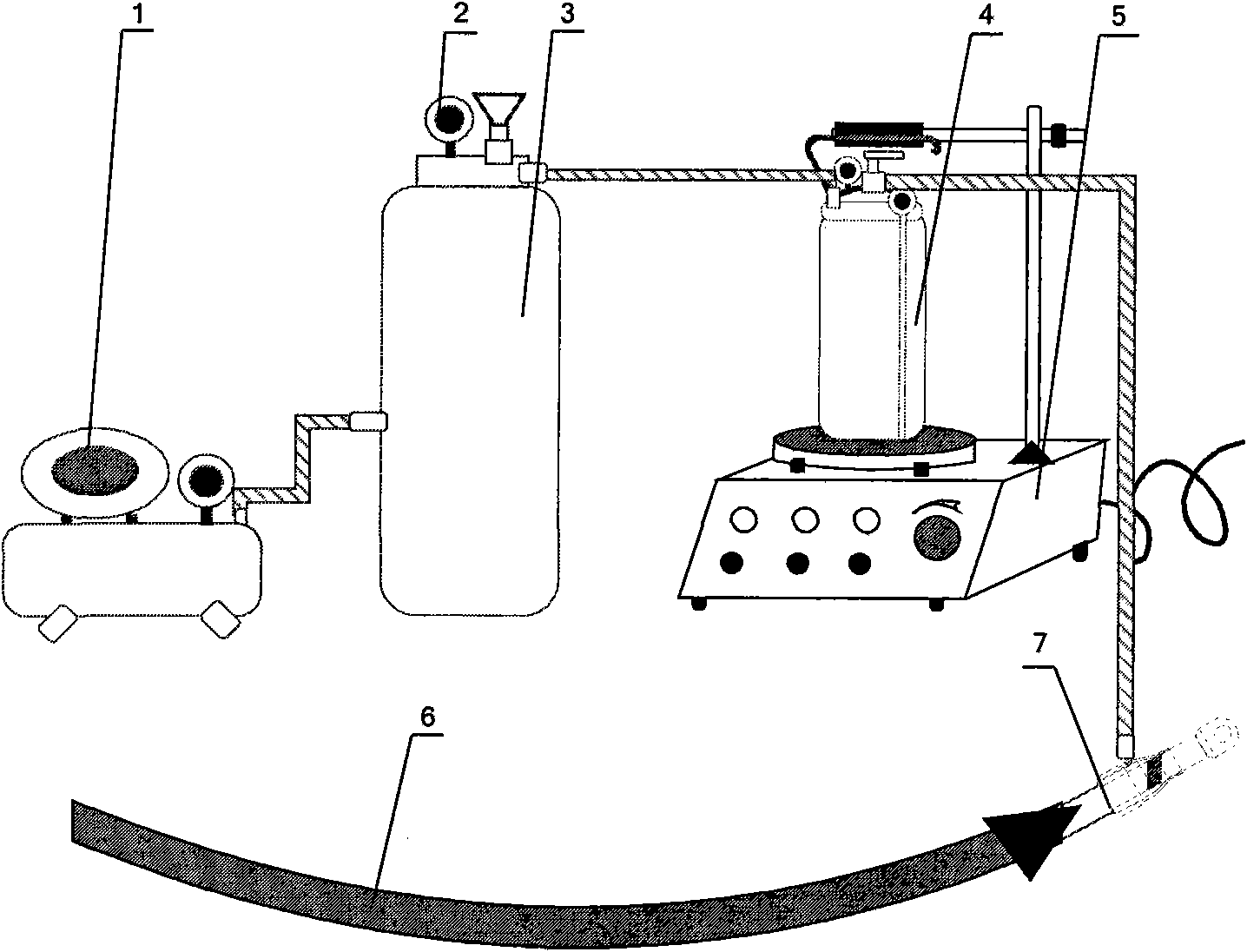

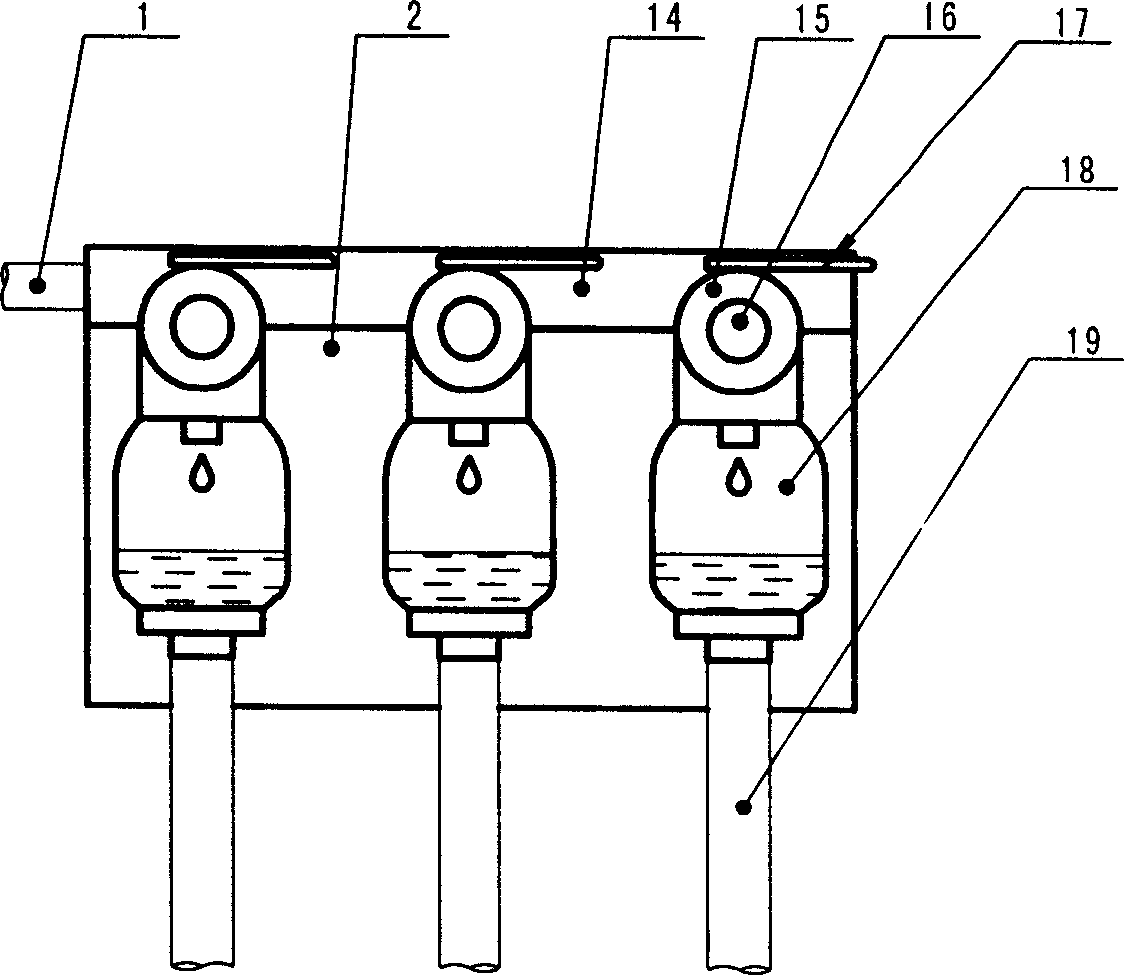

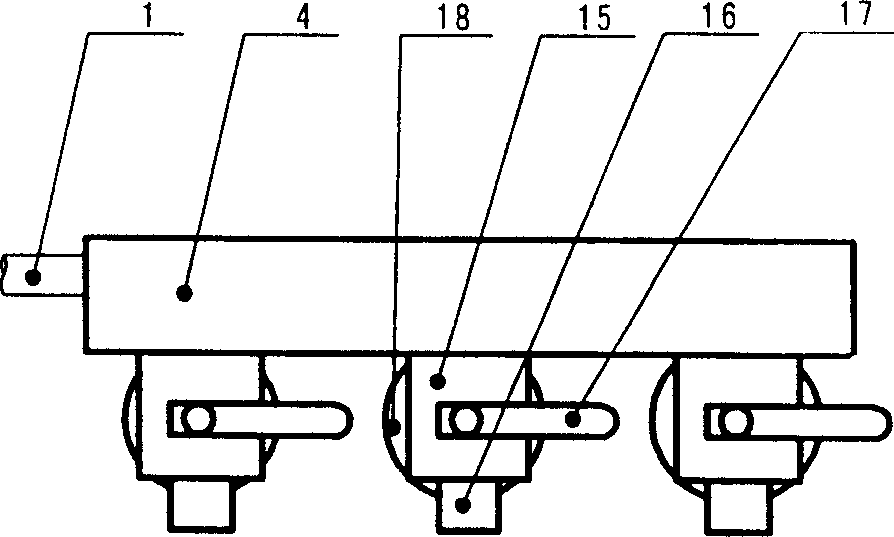

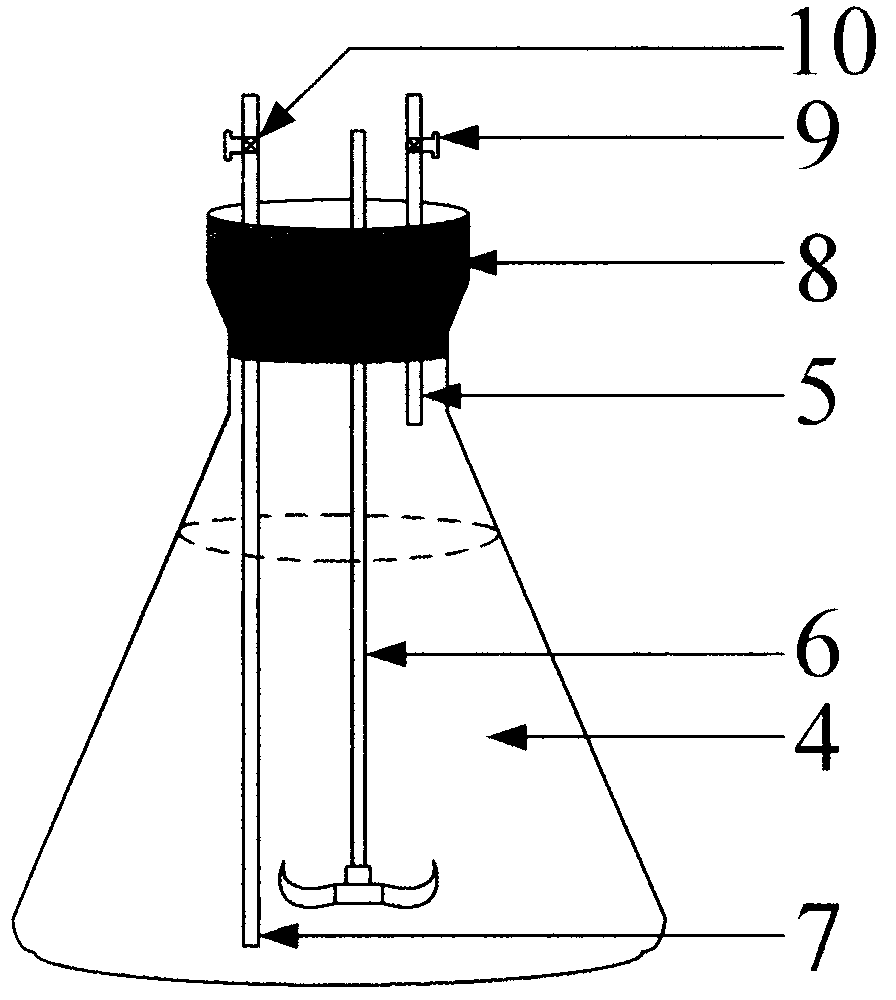

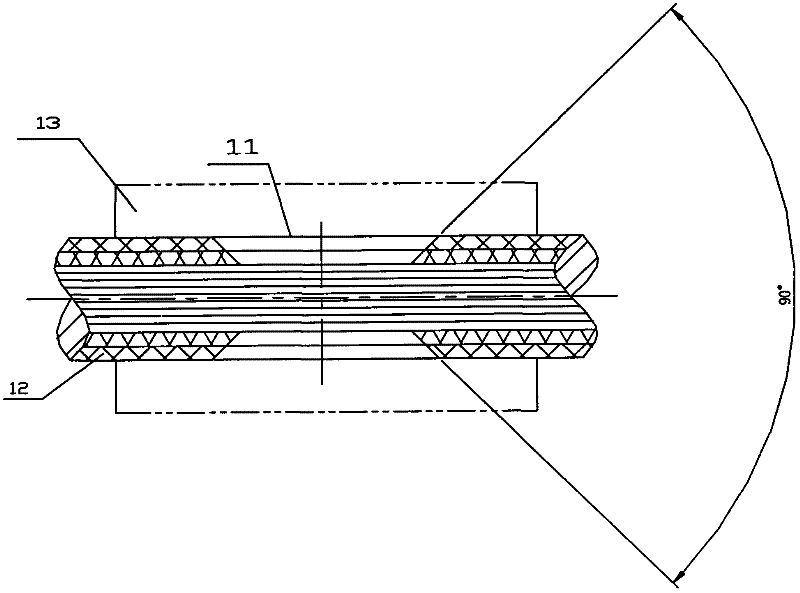

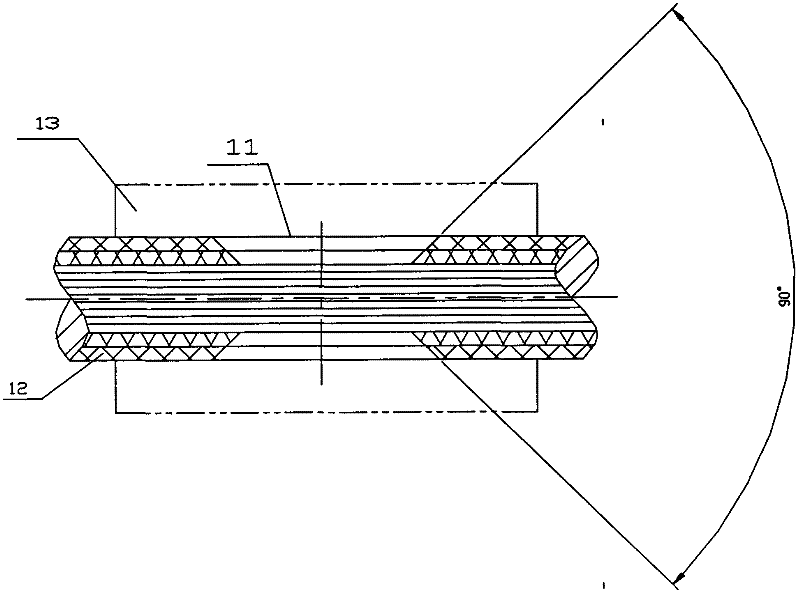

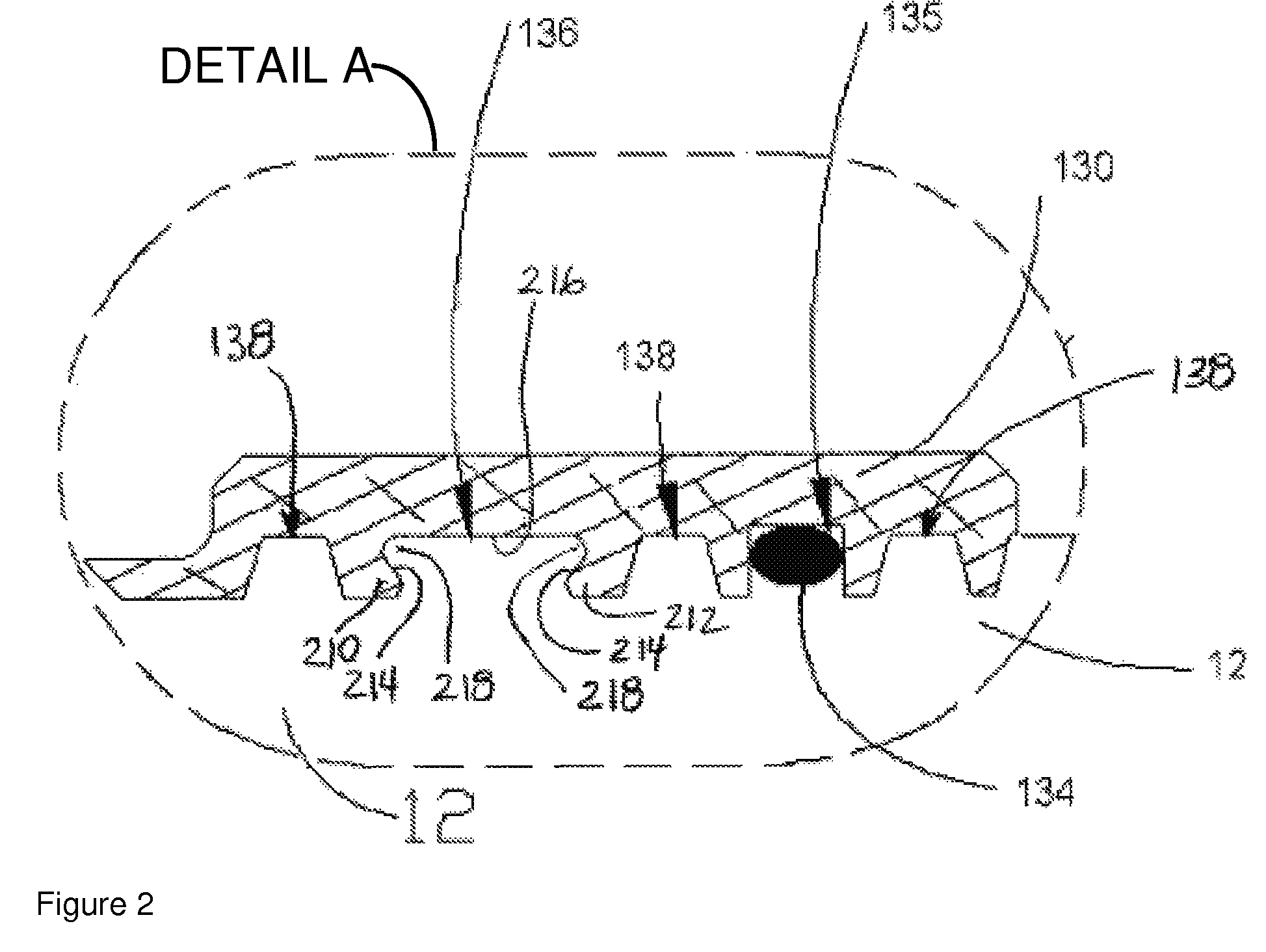

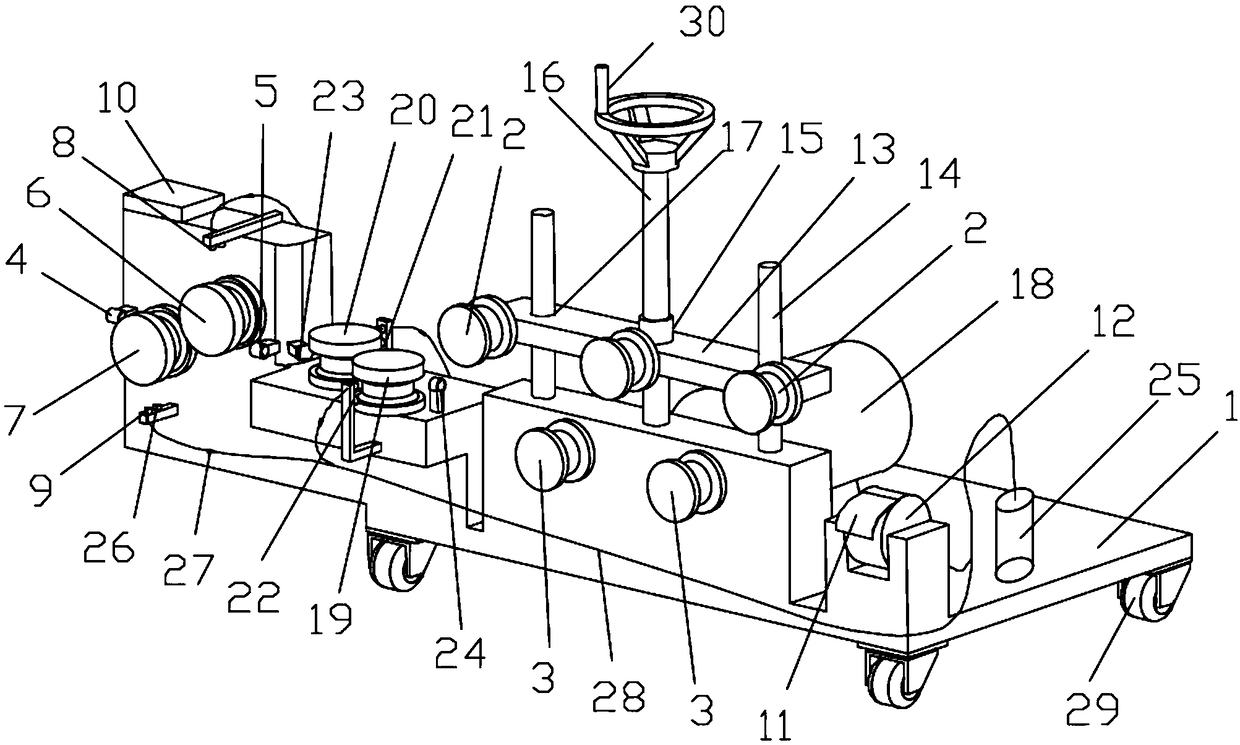

Electrified repair device for cross-inked polyethylene power cable and electrified repair method thereof

ActiveCN101728792AEnsure safetyLow costApparatus for repairing insulation/armouring cablesVacuum pumpingPower cable

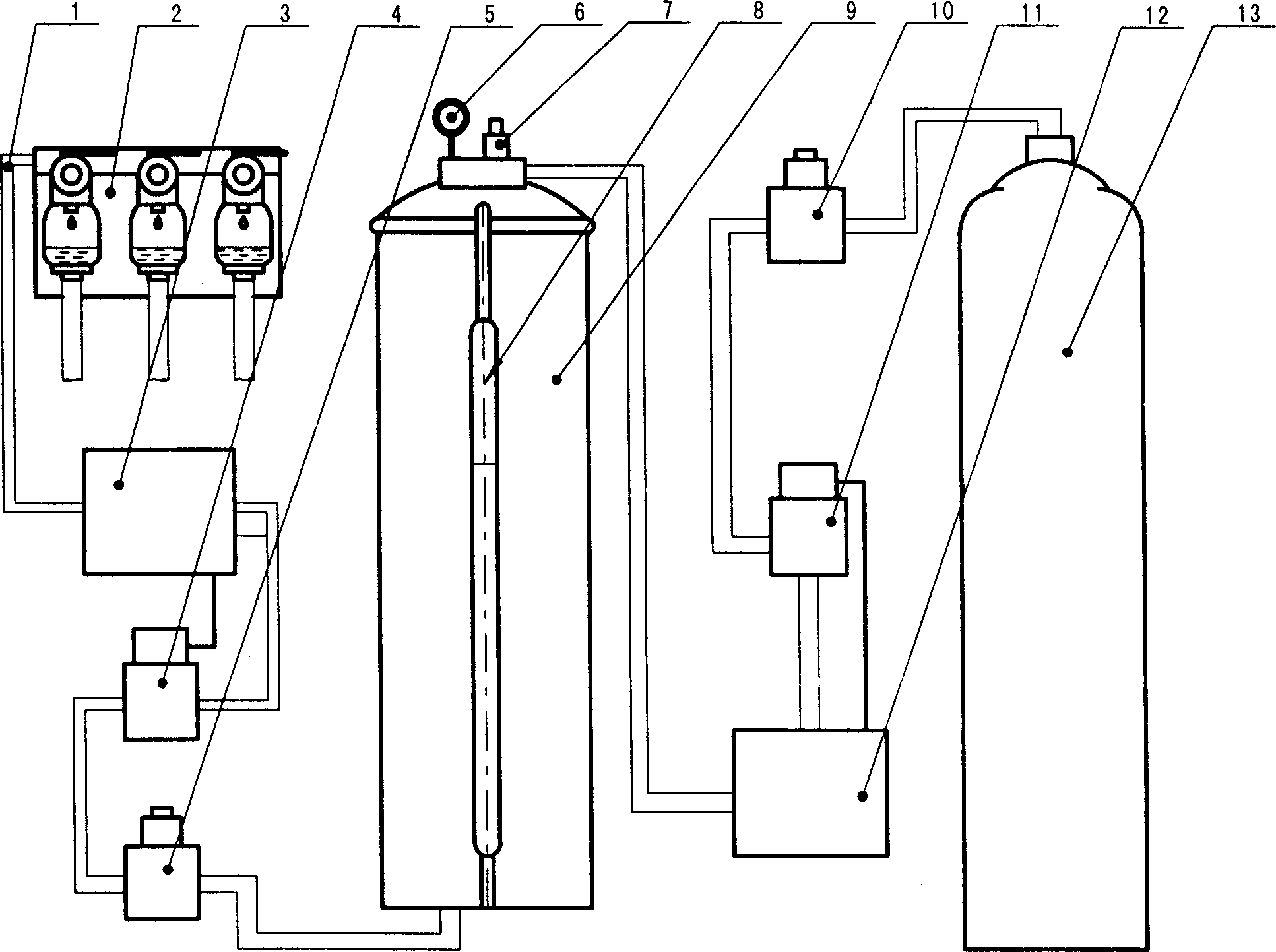

The invention discloses an electrified repair device for a cross-inked polyethylene power cable and an electrified repair method thereof. The device is characterized in that the device comprises a repair hydraulic pressure injection system, a vacuum pumping system as well as repair liquid adapters (13, 15) and taps (12, 16) which are positioned at both ends of a cable, wherein the repair liquid adapter (13) at one end of the cable is connected with the repair hydraulic pressure injection system through the tap (12), and the repair liquid adapter (15) at the other end of the cable is connected with the vacuum pumping system through the tap (16); the repair hydraulic pressure injection system is that an air compressor (1), a gas water-absorbing tank (4) and a repair liquid tank (11) are orderly connected with the tap (12) and the repair liquid adapter (13); and the vacuum pumping system is that the repair liquid adapter (15), the tap (16), a residual liquid collection bottle (17), a filtering tank (19) and a vacuum aspirator (20) are orderly connected.

Owner:SICHUAN UNIV

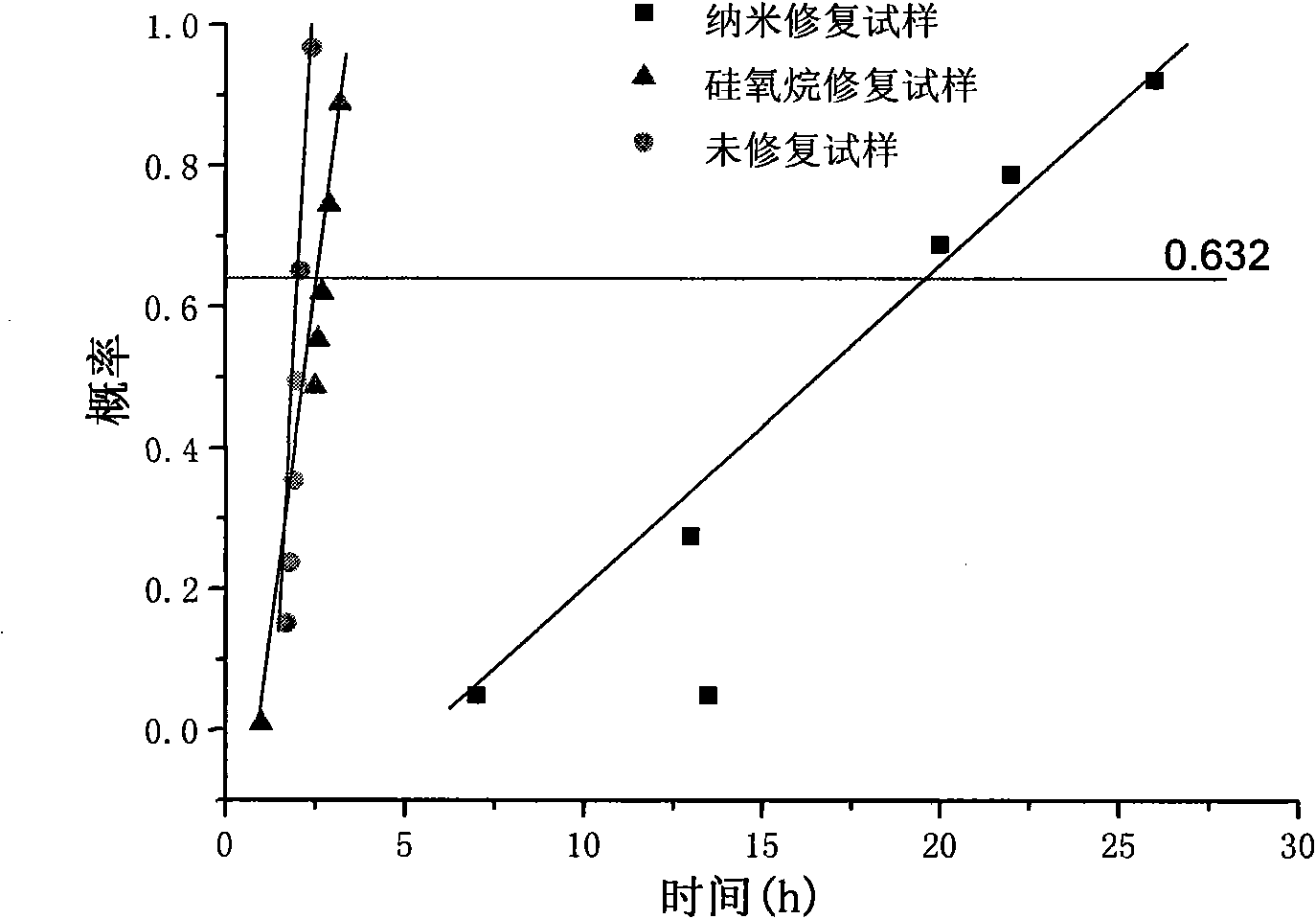

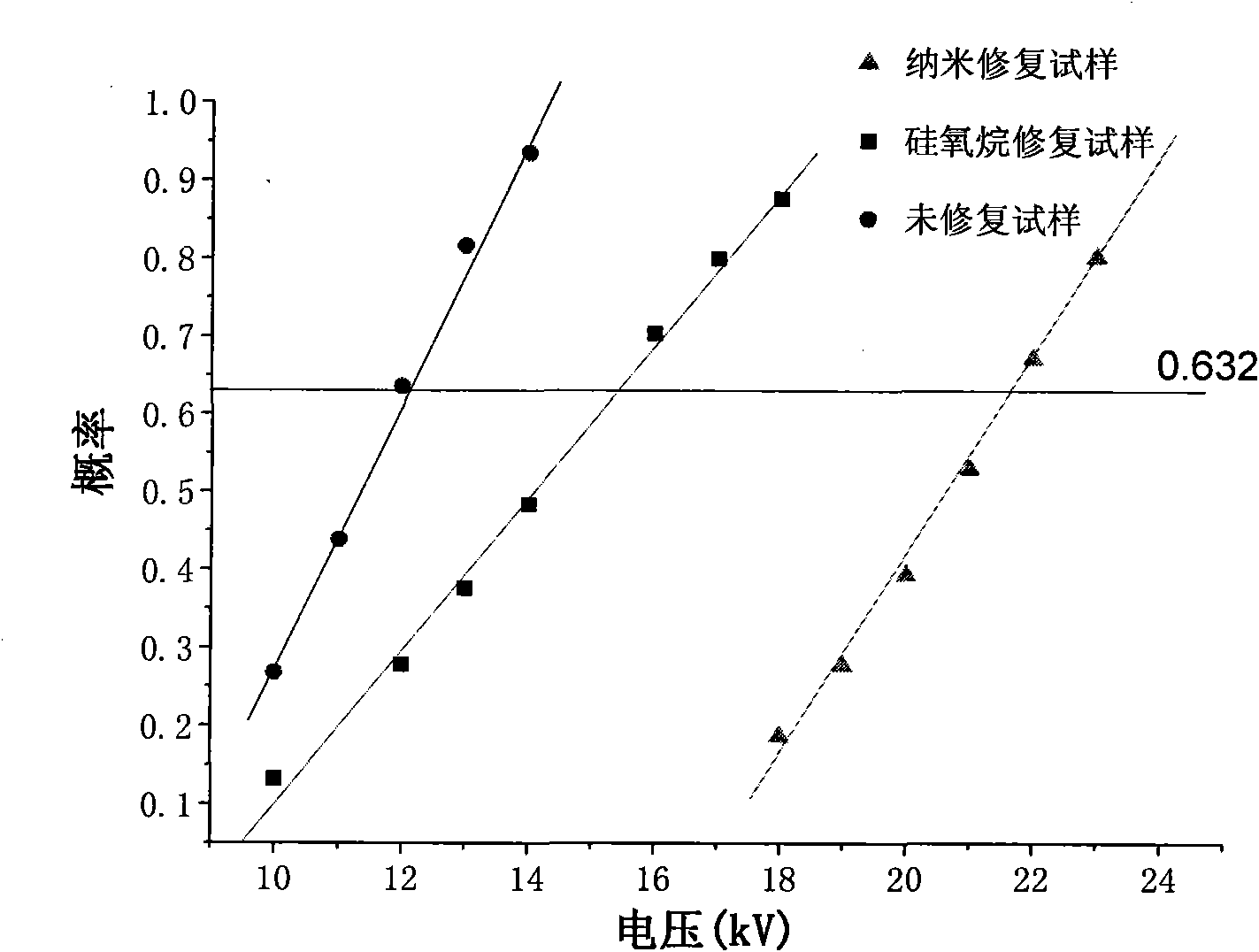

Cross-linked polyethylene power cable nano repairing liquid and repairing method thereof

ActiveCN101866706AEnsure safetyImprove conductivityPlastic/resin/waxes insulatorsApparatus for repairing insulation/armouring cablesOrganic solventPower cable

The invention discloses a cross-linked polyethylene power cable nano repairing liquid and repairing method thereof, which is characterized in that inorganic nano particles and organic solvent form nano dispersion, and a layer of inorganic nano protective film is formed by filing air gaps or micropores inside the cable through the inorganic nano particles based on a siloxane repairing liquid so as to protect a polyethylene insulating layer. Compared with the traditional siloxane repairing technology, the invention can prolong the residual service life of the power cable by 5-10 times, has the advantages of advanced technology, safety and stability, short repairing time and good repairing effect.

Owner:SICHUAN UNIV

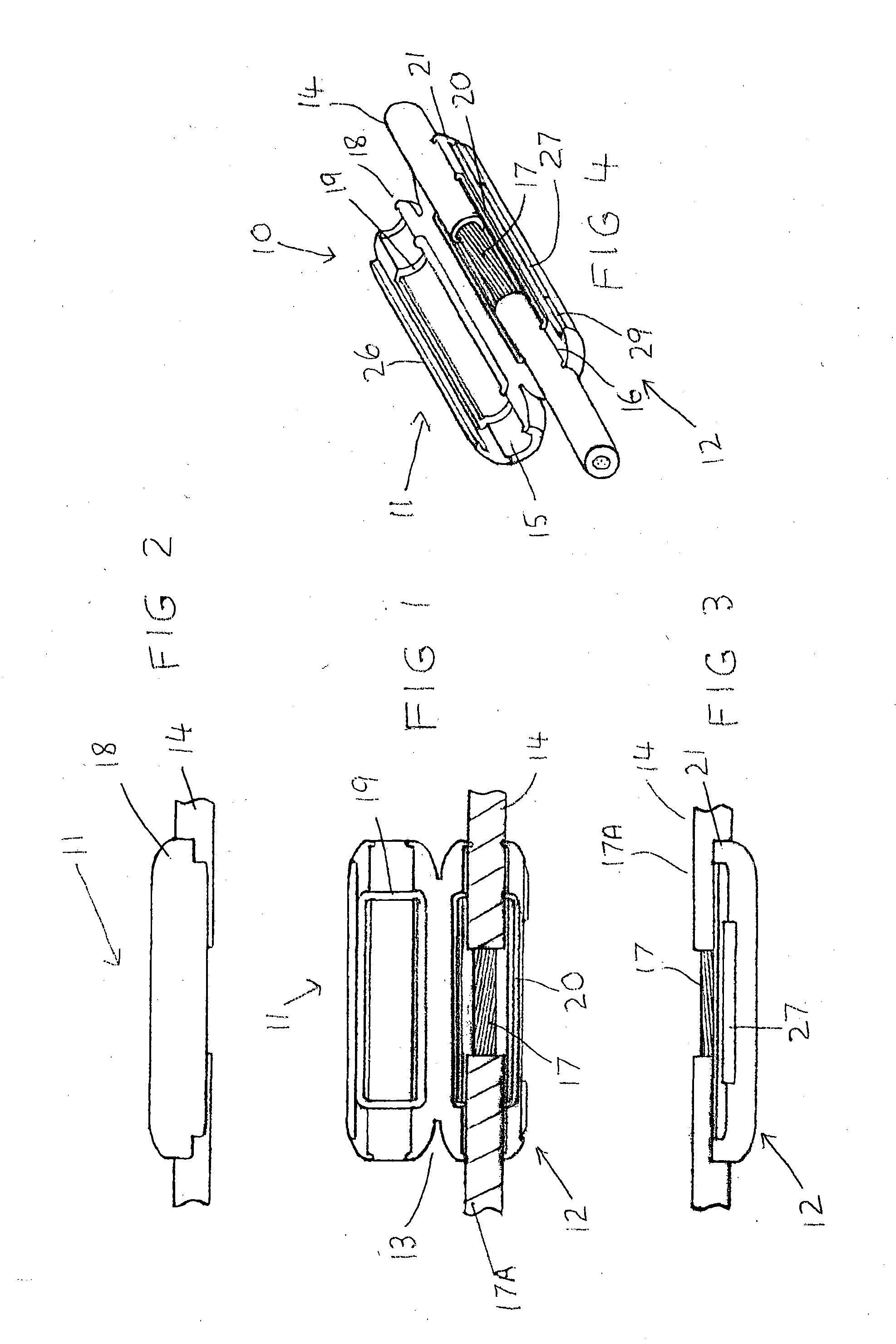

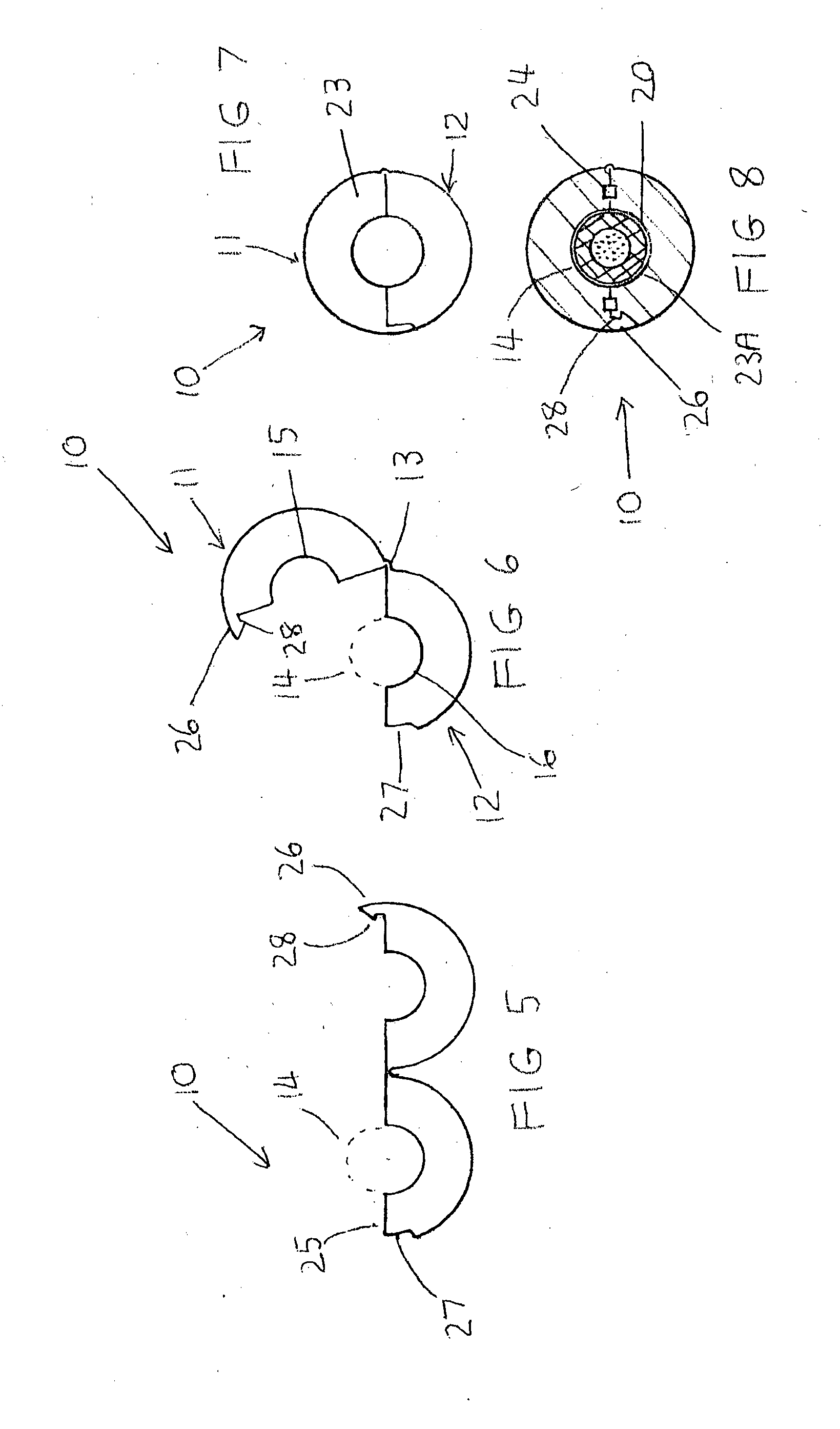

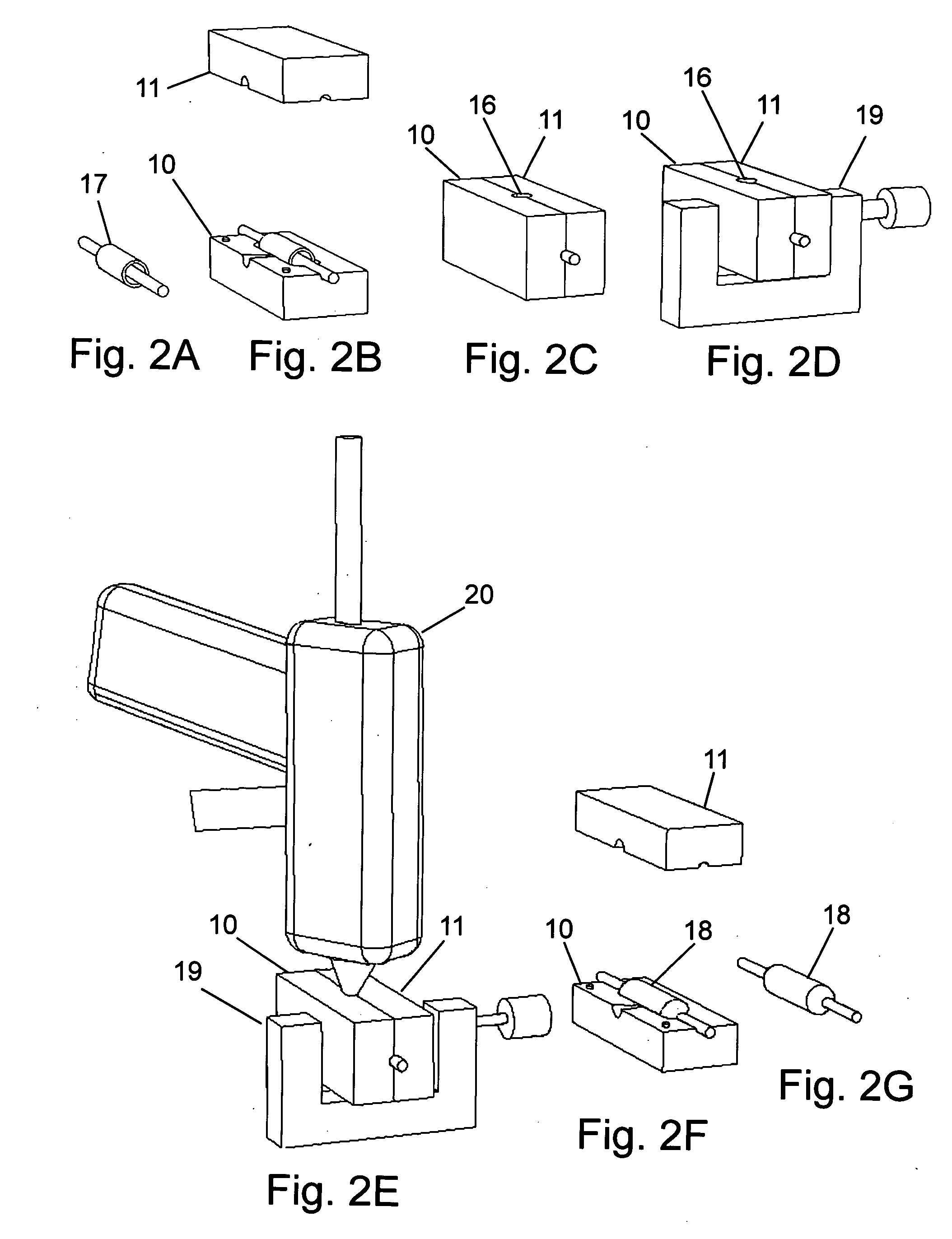

Cable holder

InactiveUS20150144394A1Labor efficientEasy to participateApparatus for repairing insulation/armouring cablesCable inlet sealing meansEngineeringMechanical engineering

A cable holder useful for holding a single insulated cable assembly or a multiplicity of insulated cable assemblies wherein the cable holder is formed by a pair of components attached to or integral with each other so as to form a sheath or sleeve for containing the cable assembly or cable assemblies. Adjacent metal ends of the adjoining cable parts are interconnected by a metal joint.

Owner:NEXT WAVE DESIGN

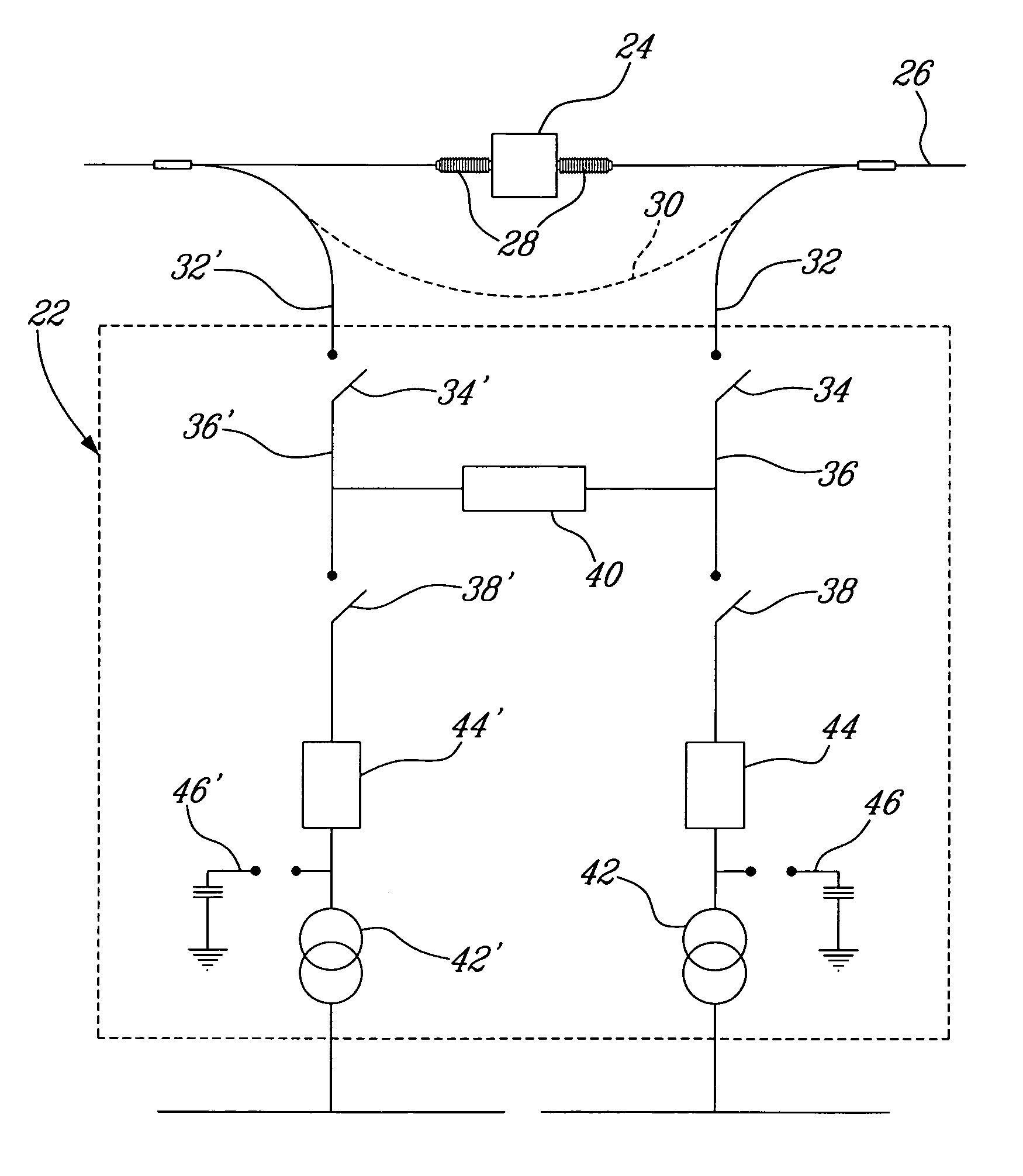

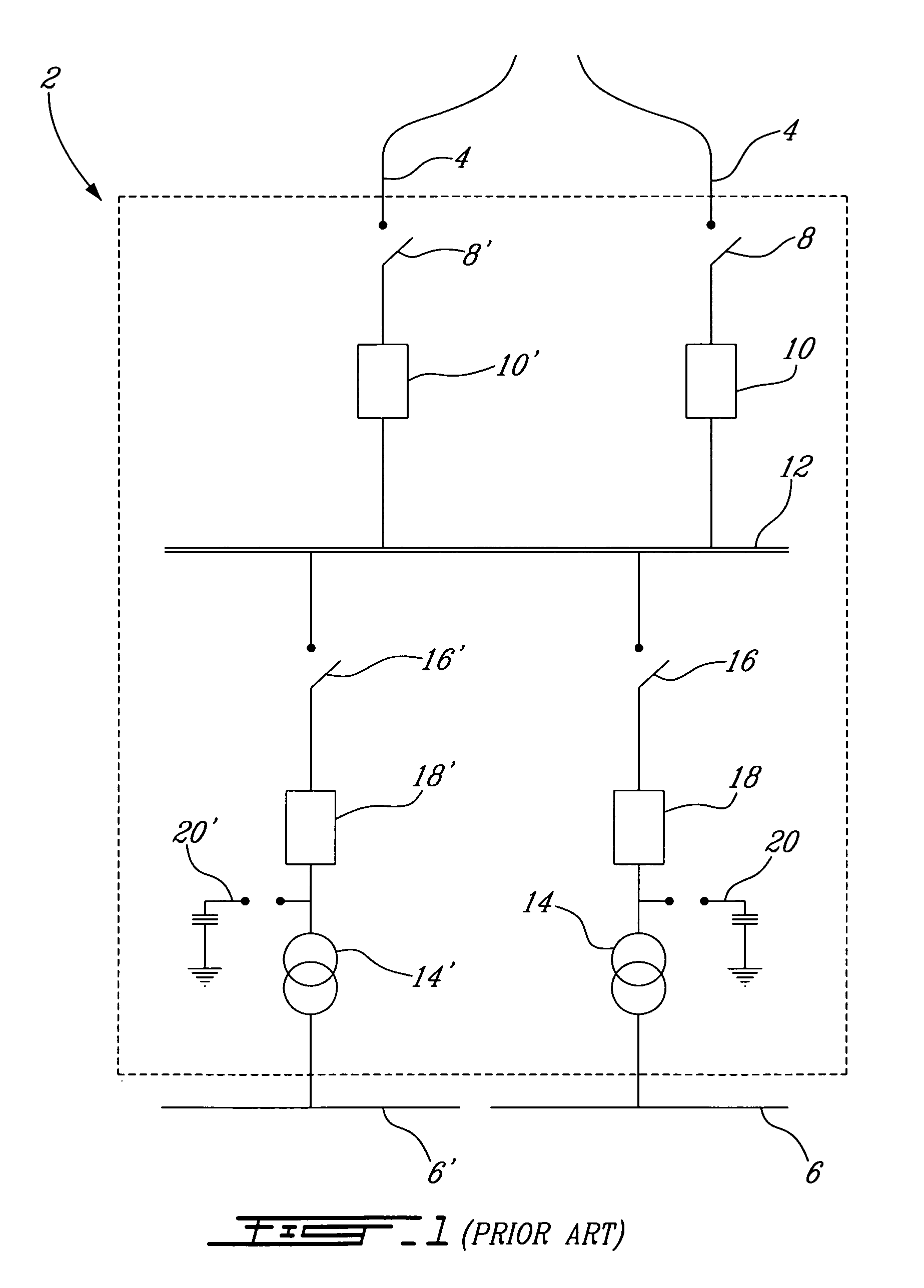

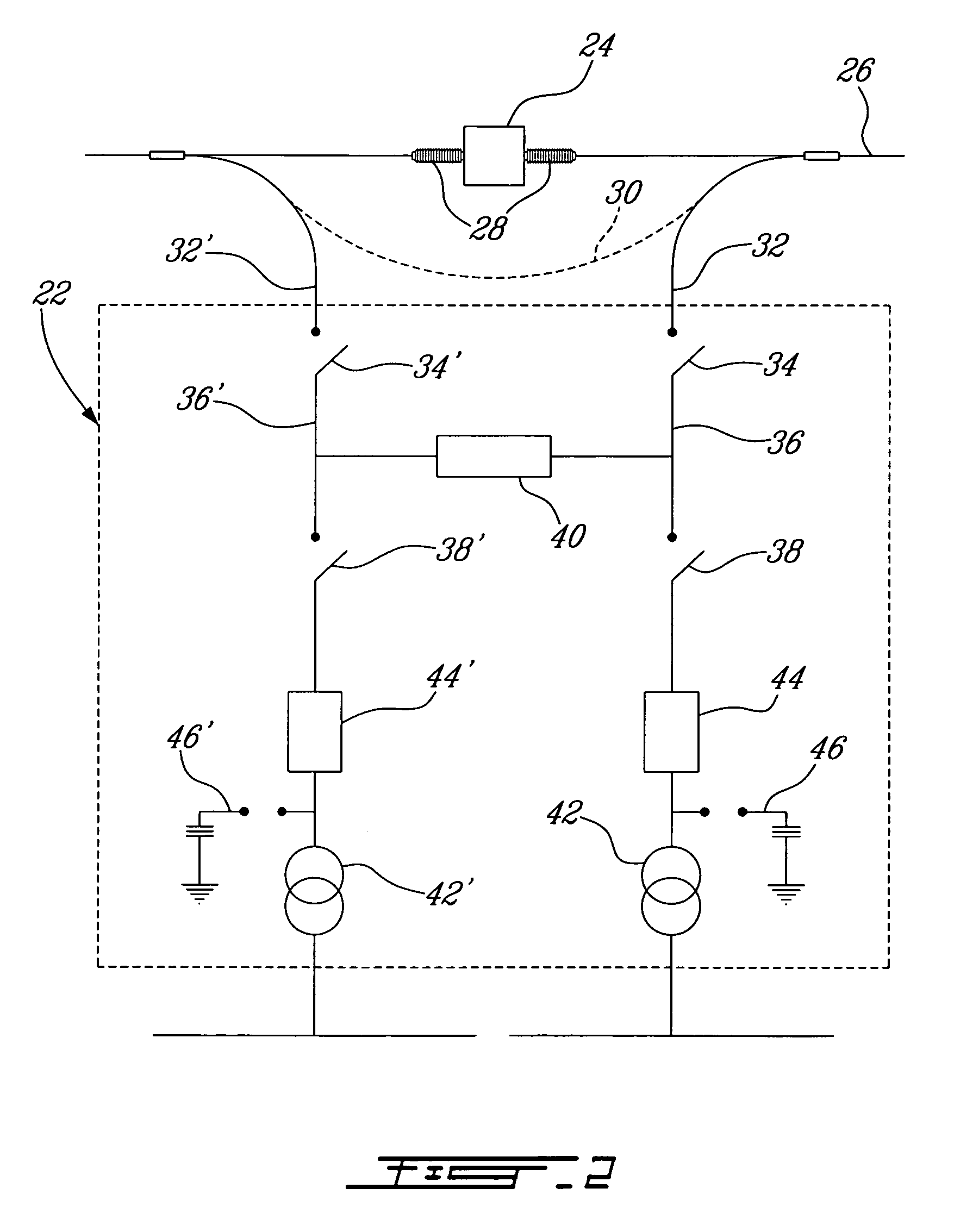

Method for tapping a high voltage transmission line and substation using the same

A method of tapping a high voltage transmission line for input into a power distribution substation is disclosed. The method comprises the steps of dividing the transmission line and attaching the conductors to the primaries of at least two transformers via a series connected first disconnect switch, second disconnect switch and circuit breaker. A bus interconnects the first disconnect switch and the second disconnect switch and the bus of the first transformer bay is connected to the bus of the second transformer bay using a circuit breaker. A system for the conversion of tapped high voltage electricity to medium voltage electricity is also disclosed.

Owner:GHALI GAMAL A

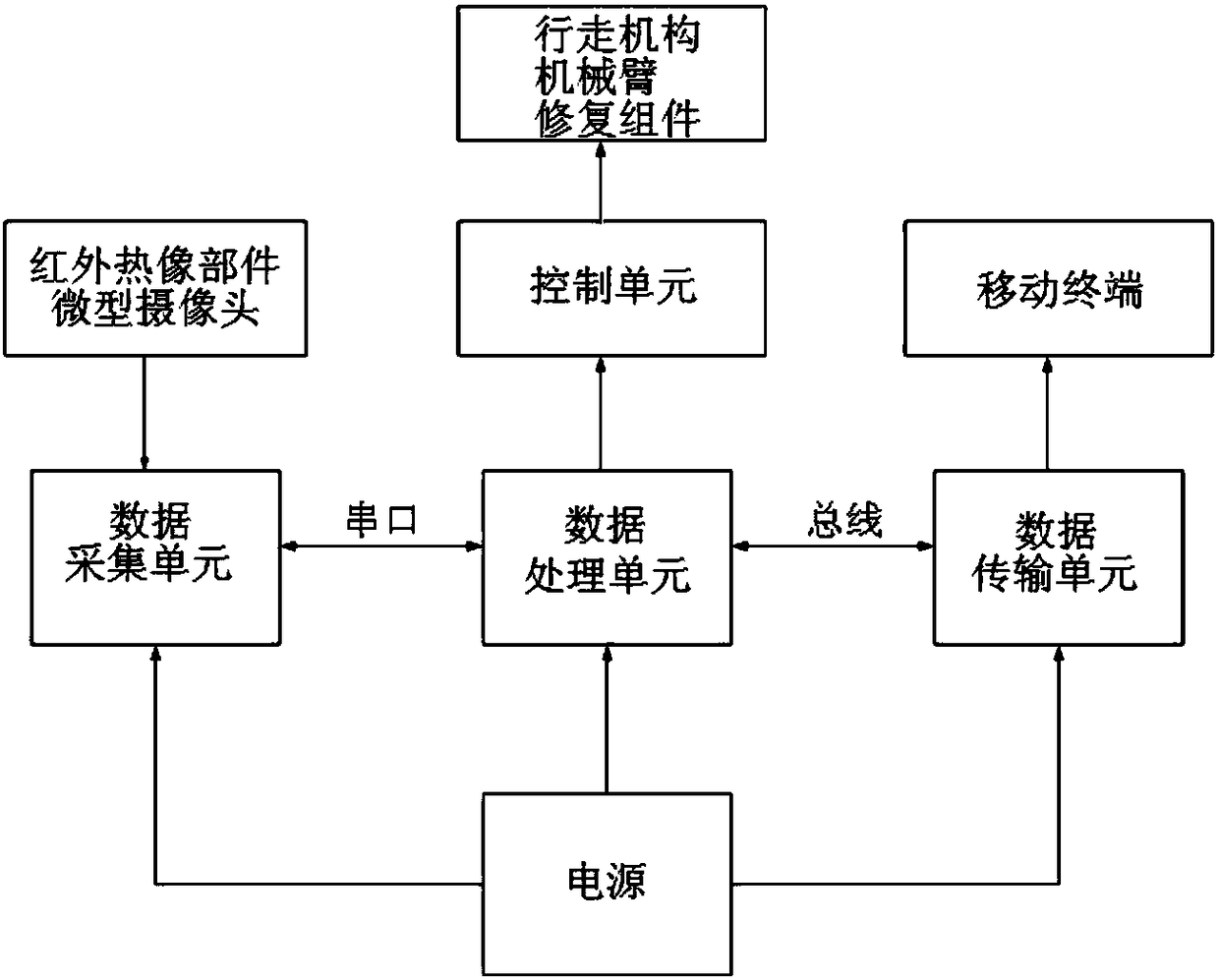

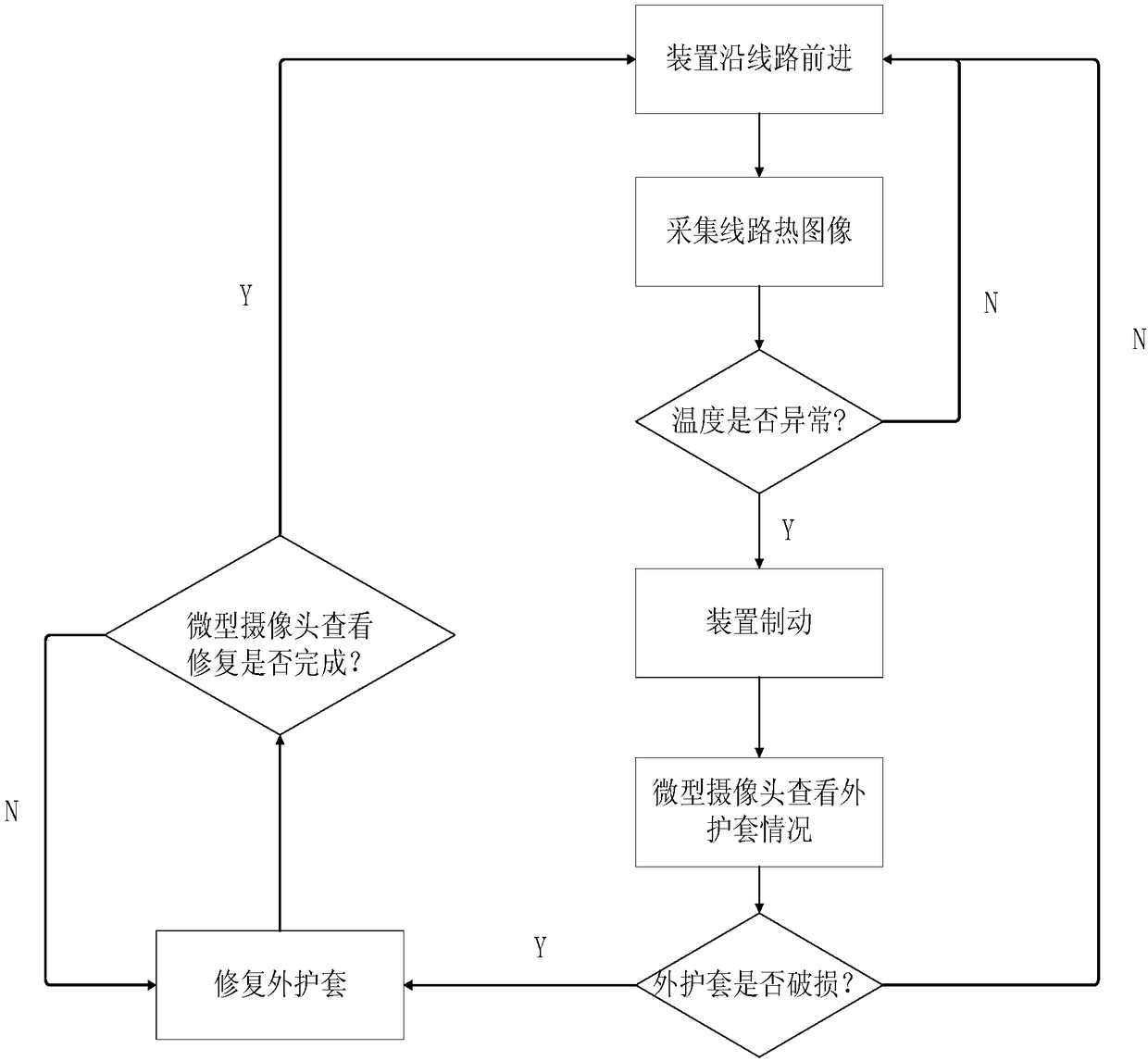

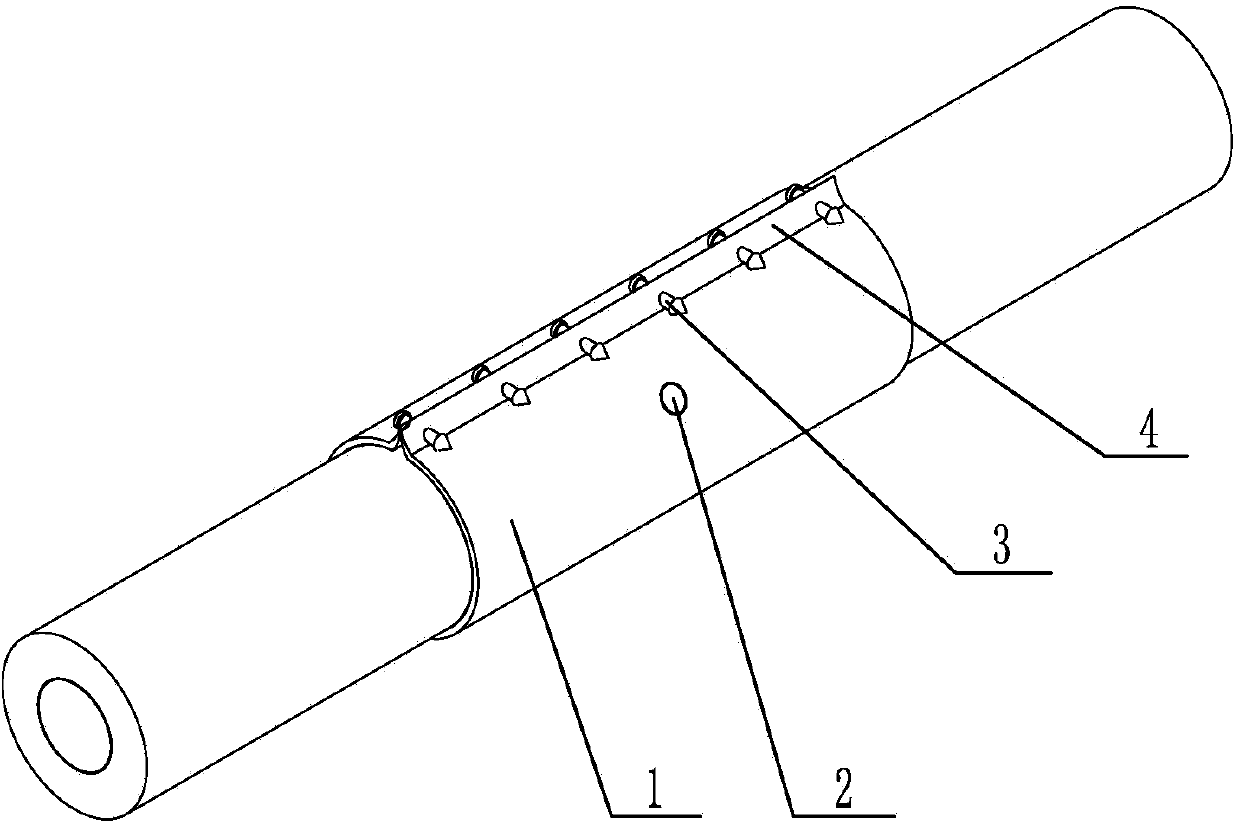

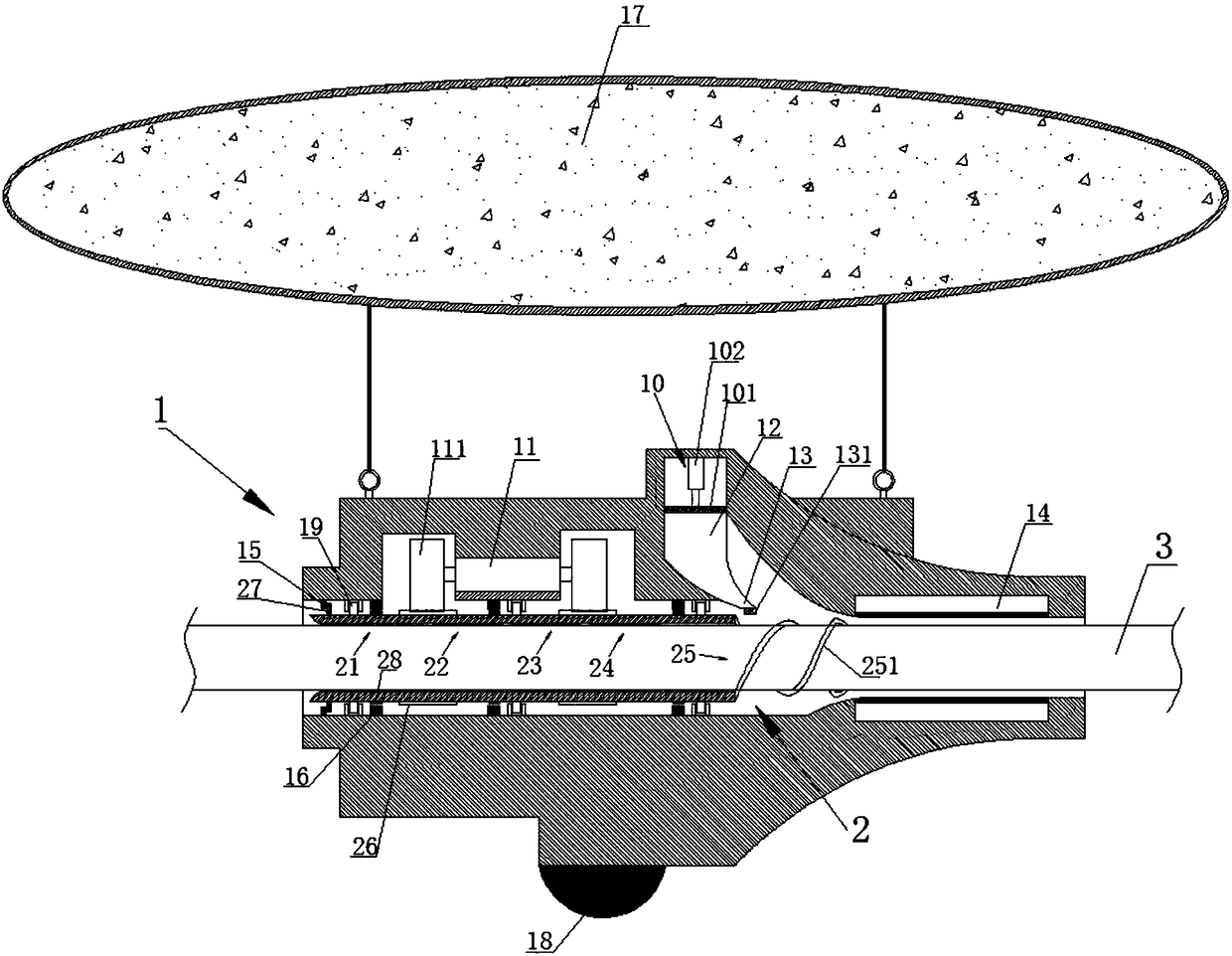

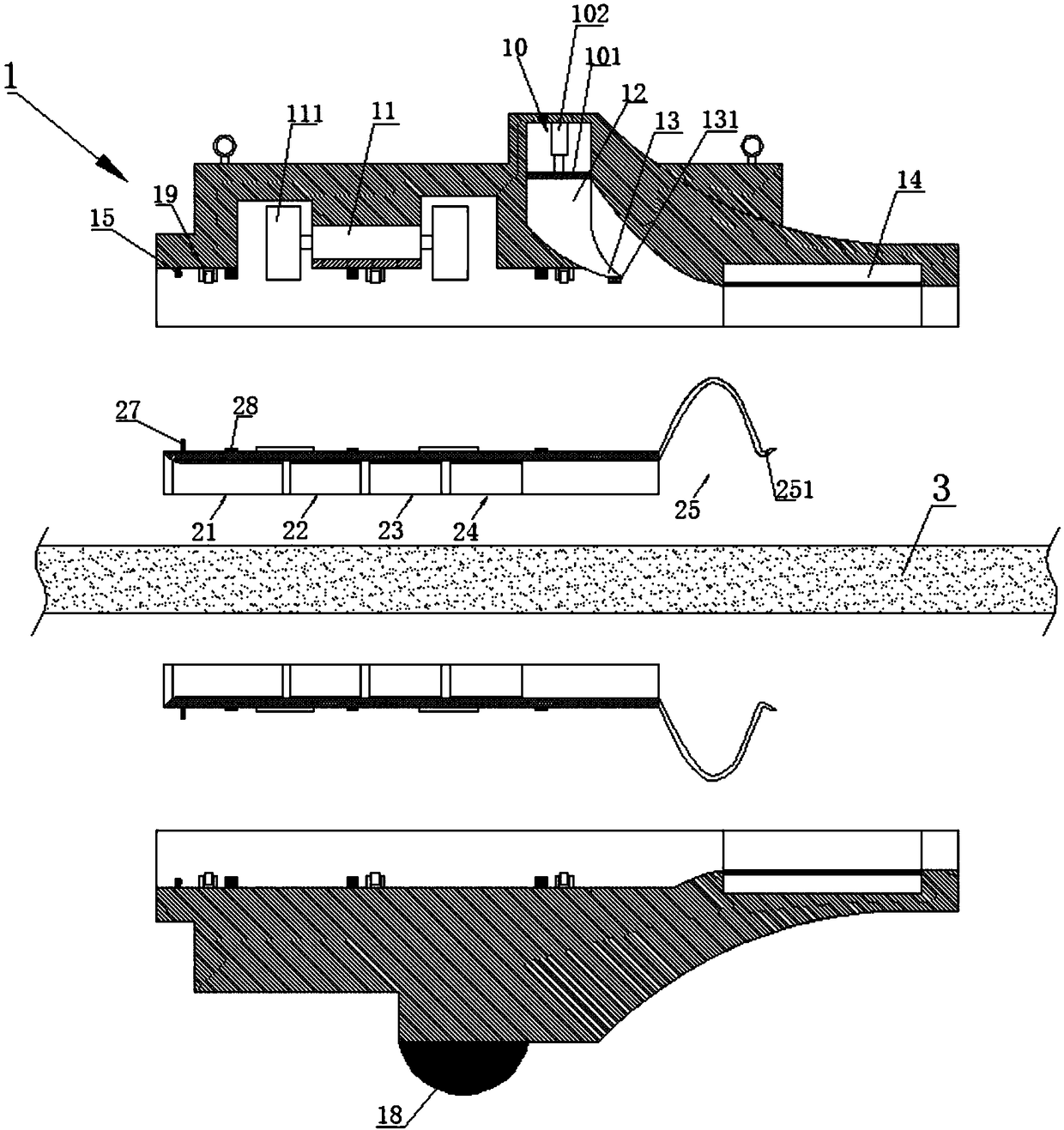

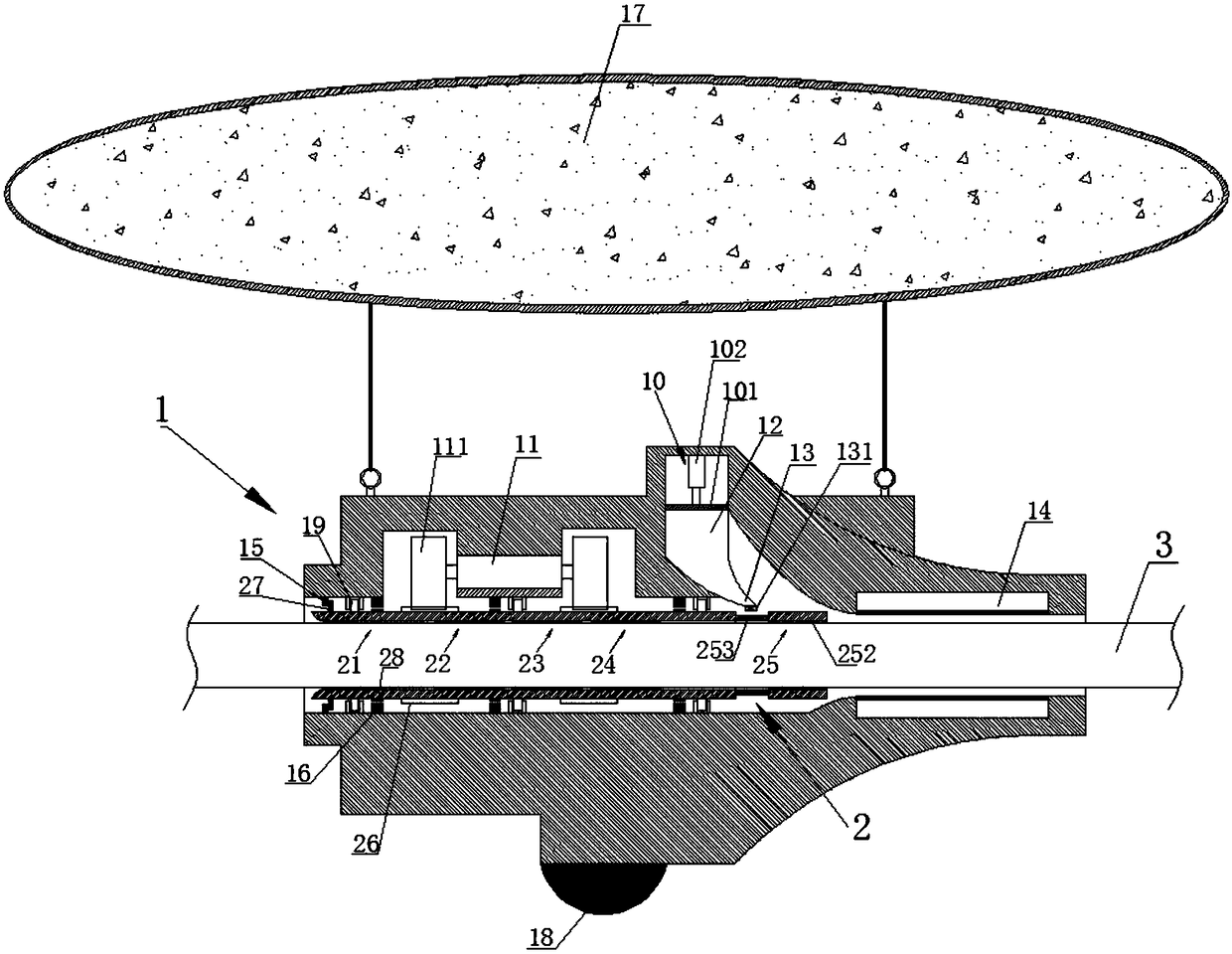

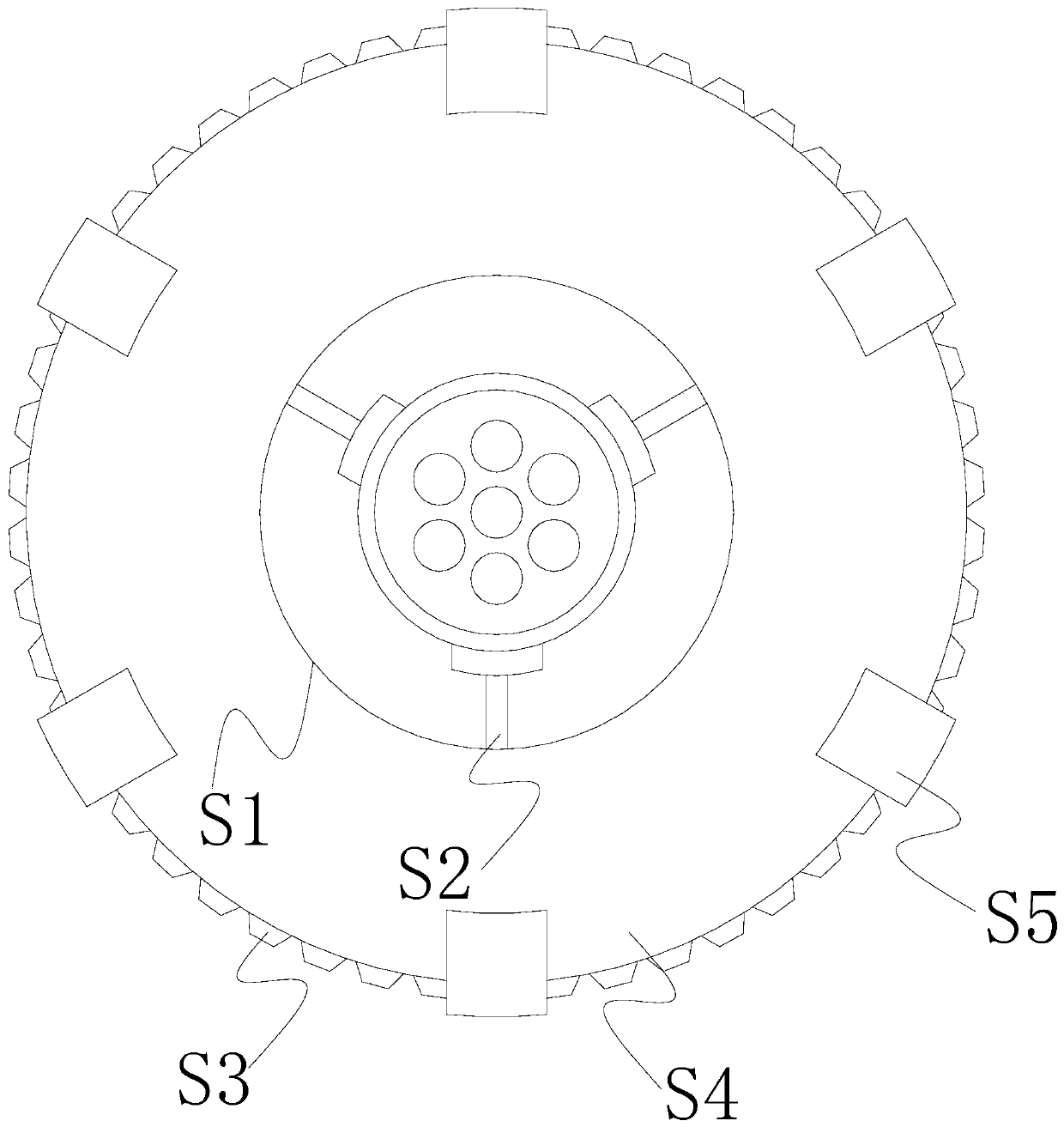

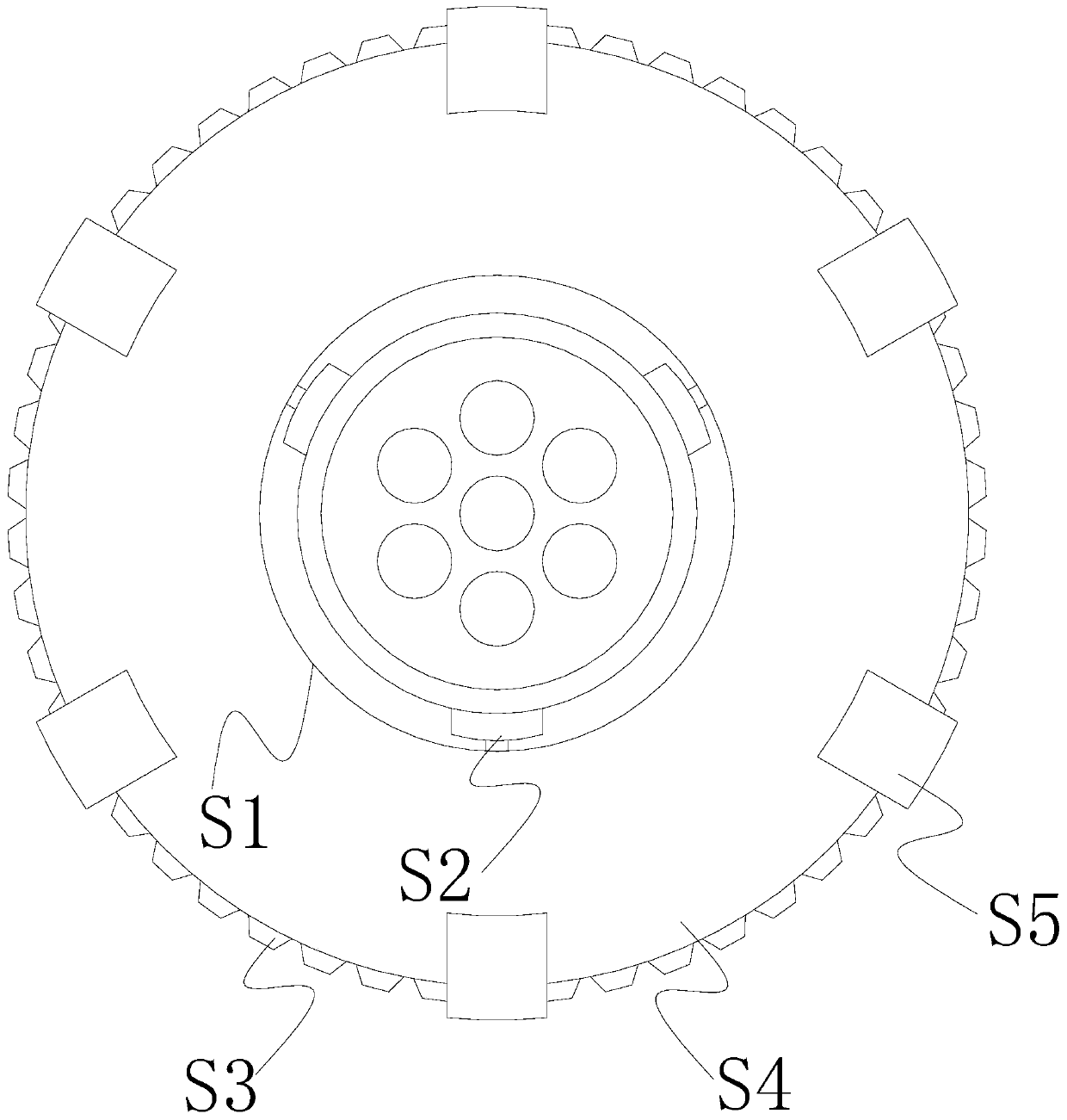

Tour inspection and restoration apparatus and method of outer sheath of power transmission line

InactiveCN108418135AWalking smoothlyEasy to operateApparatus for repairing insulation/armouring cablesApparatus for overhead lines/cablesElectric power transmissionEngineering

The invention discloses a tour inspection and restoration apparatus and method of an outer sheath of a power transmission line, and belongs to the technical field of electric power transmission lines.The apparatus comprises a body arranged on the power transmission line and connected through a travelling mechanism, and an infrared thermal imaging part, a micro camera and a restoration assembly arranged on the body; the micro camera and the restoration assembly are respectively arranged at two sides of the body along an extending direction of the power transmission line through mechanical arms; and the infrared thermal imaging part is arranged at the top of the body and located below the power transmission line. The method includes: monitoring a portion of the power transmission line traveled by the apparatus through the infrared thermal imaging part and the micro camera, analyzing obtained image information, and issuing a maintenance instruction after determining that the outer sheathof the power transmission line is in a damaged state to enable the apparatus to rapidly repair damage points. According to the apparatus and the method, the operation condition of the outer sheath ofthe power transmission line can be grasped in time, the occurrence of faults of the power transmission line can be effectively reduced, and accident hidden risks are eliminated in the bud.

Owner:SOUTHWEST UNIVERSITY

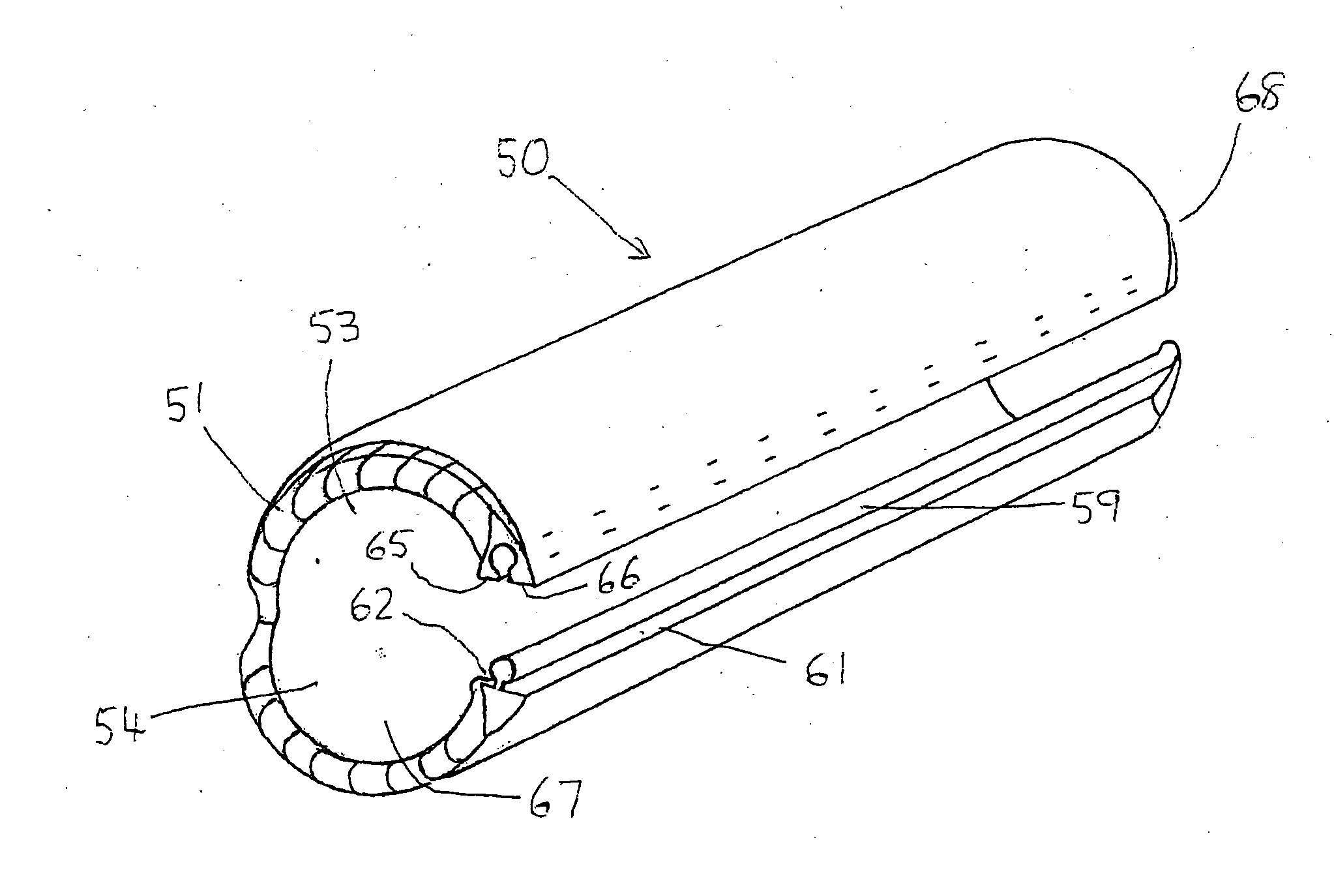

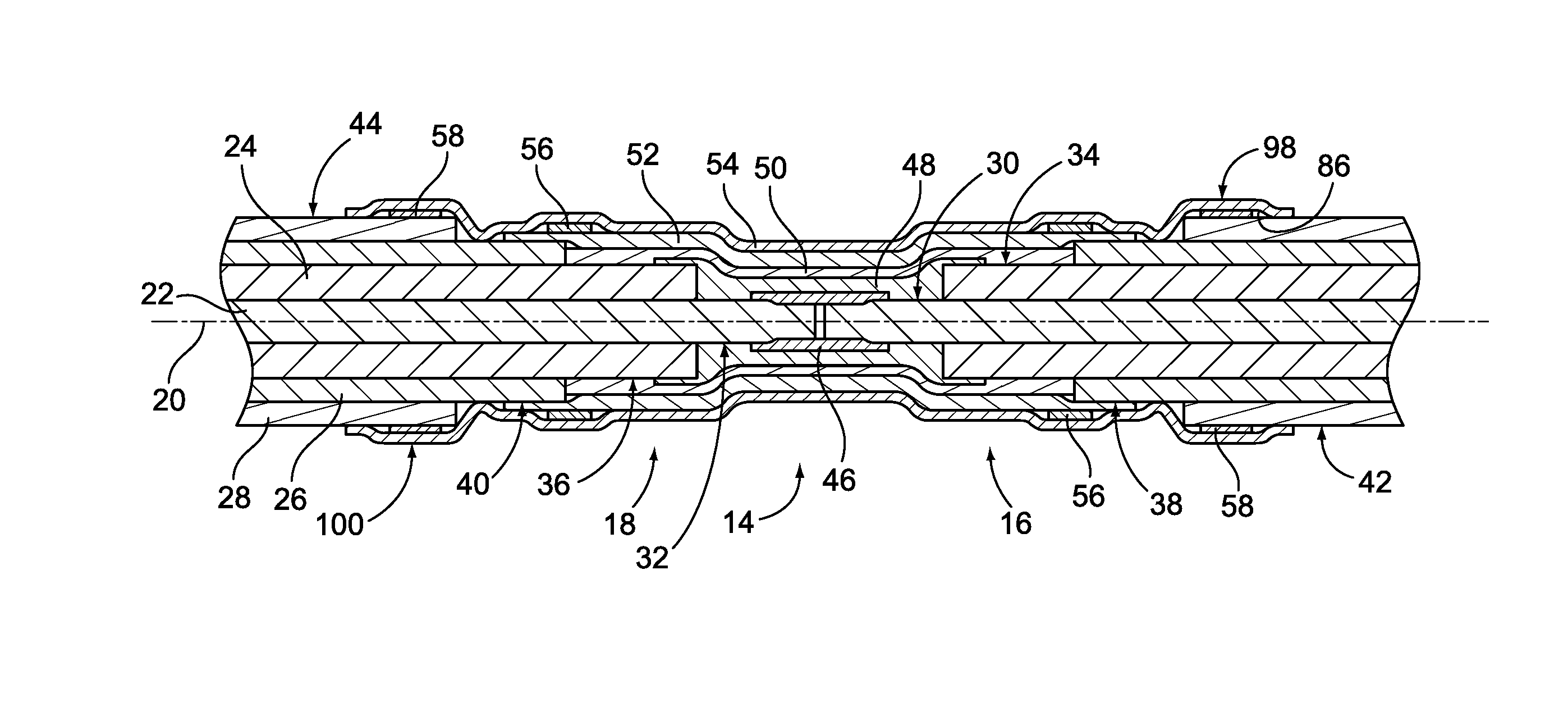

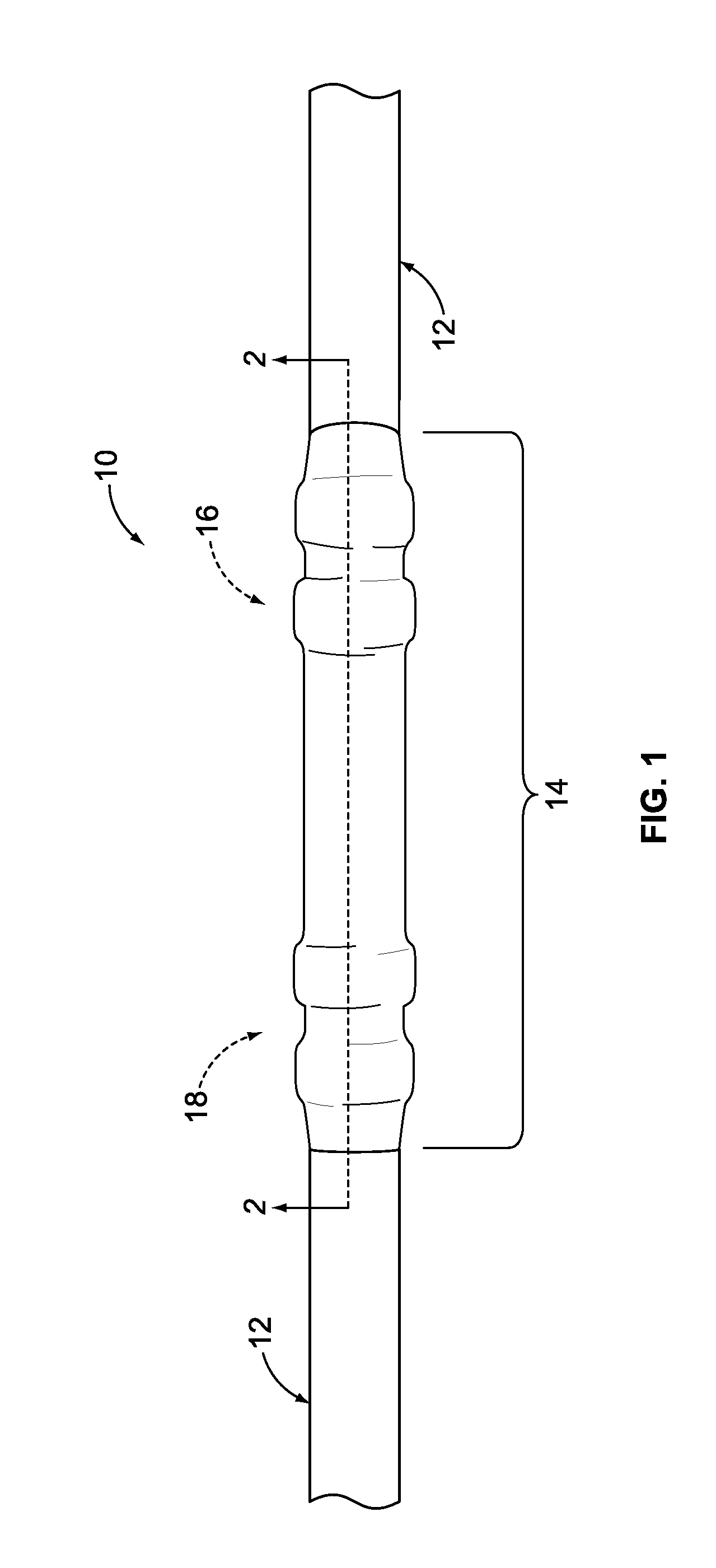

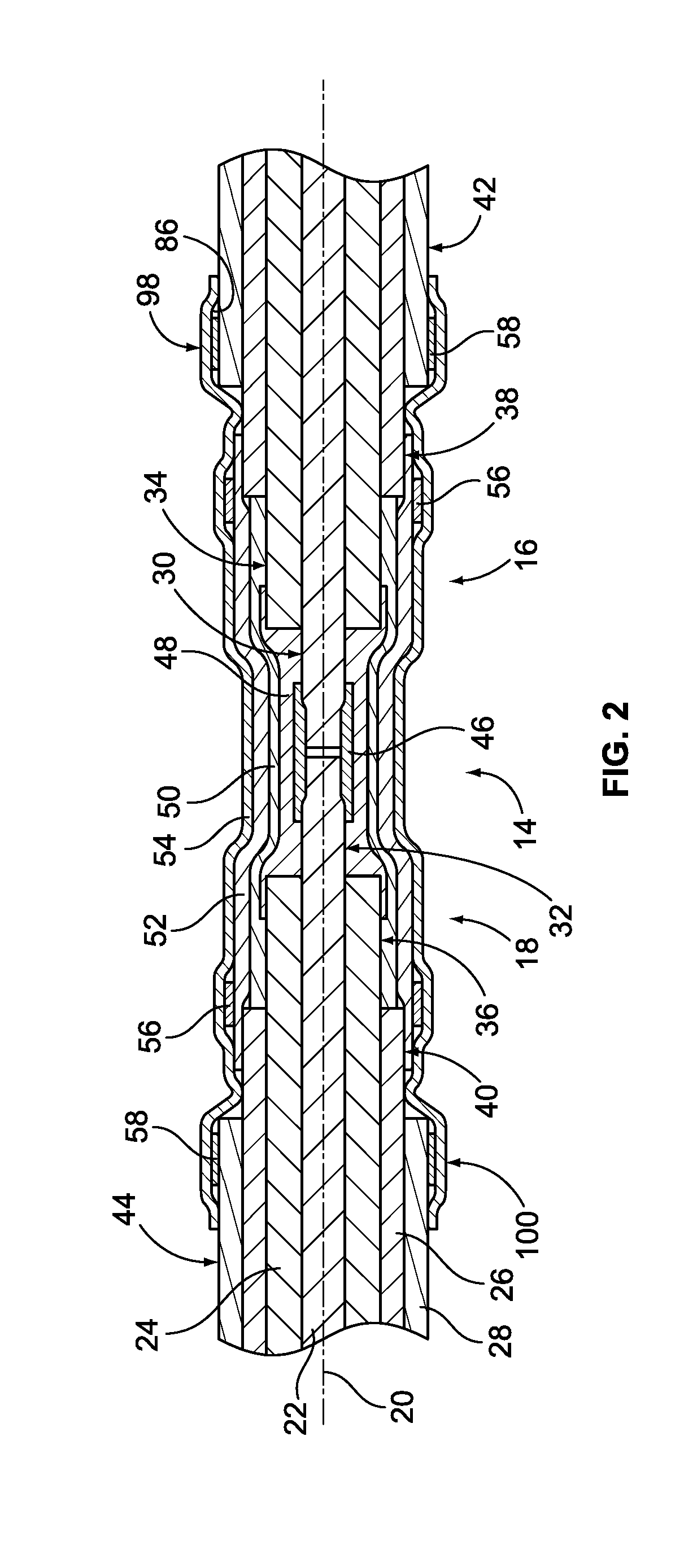

Cable Repair Splice

A splice kit is provided for repairing a cable having a central conductor, an insulator surrounding the central conductor, an outer conductive sheath surrounding the insulator, and a jacket surrounding the outer conductive sheath. The splice kit includes a central conductor joint that is electrically conductive and is configured to engage the central conductor of the cable such that the central conductor joint defines a portion of an electrical path of the central conductor. The splice kit also includes a dielectric insert configured to at least partially surround the central conductive joint and the central conductor of the cable, and an outer sheath joint that is electrically conductive and is configured to at least partially surround the dielectric insert. The outer sheath joint is configured to be electrically connected to the outer conductive sheath of the cable such that the outer sheath joint defines a portion of an electrical path of the outer conductive sheath. The splice kit further includes a jacket joint configured to at least partially surround the outer sheath joint and the jacket of the cable.

Owner:TYCO ELECTRONICS (UK) LTD +2

Hot-melt type cable middle connection mounting technology

InactiveCN109616962AConsistent Electrical StabilityNo air gap interfaceApparatus for repairing insulation/armouring cablesApparatus for joining/termination cablesInsulation layerElectrical conductor

The invention discloses a hot-melt type cable middle connection mounting technology, and belongs to the field of cable middle connection structures; the method comprises the following steps of S1, performing preprocessing on a cable; S2, performing connecting on conductors; S3, carrying out recovering of a cable insulating layer: a, enabling a recovery conductor formed in S2 to be wrapped with aninner semi-conductive band; b, enabling an insulating repairing layer to wrap the outside of the inner semi-conductive band, wherein the material of the insulating repairing layer is a cross-linked polyethylene insulating band; and c, moving a cold-shrinkable sleeve for wrapping the insulating repairing layer, and performing heating on the insulating repairing layer to be fused, wherein the fusedinsulating repairing layer is cooled and then is integrally formed with an insulating layer of a cable main body, and a new recovery insulation layer is formed; S4, enabling the cold-shrinkable sleeveto be stripped, and performing grinding on the recovery insulation layer; and S5, carrying out recovering of an outer shielding layer of the cable. The method has the advantages that the melting process and the process of repairing and continuous connection of the cross-linked polyethylene material can be simplified, and meanwhile, other large equipment or special auxiliary tools are not needed,so that the effects of improving the construction efficiency and saving the construction cost are achieved.

Owner:吴江市华鼎热缩制品有限公司

Low-Melt Poly(Amic Acids) and Polyimides and their Uses

ActiveUS20110212334A1Eliminate brittlenessRepair damageApparatus for heat treatmentApparatus for repairing insulation/armouring cablesElectricityElectric wire

Owner:NASA

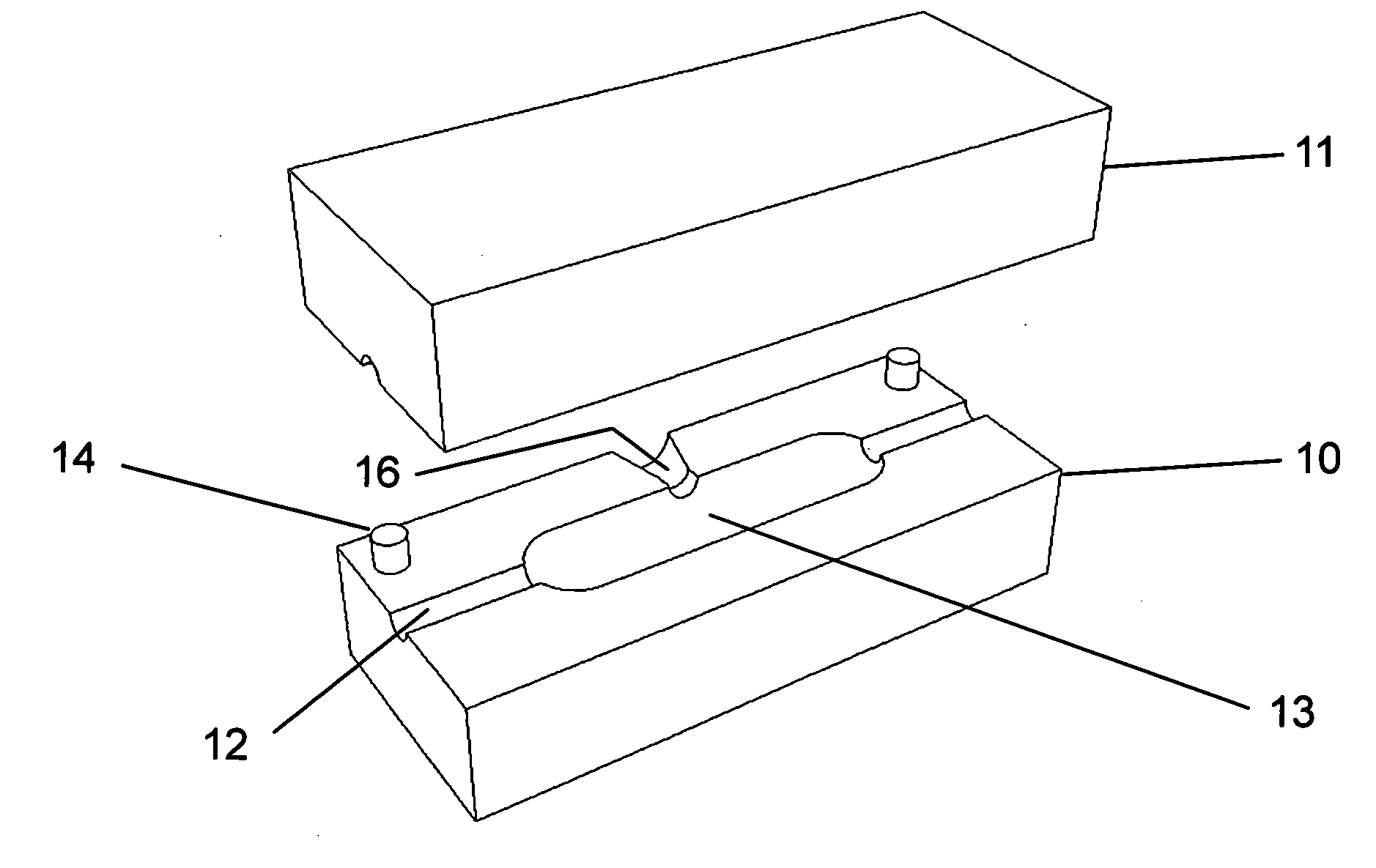

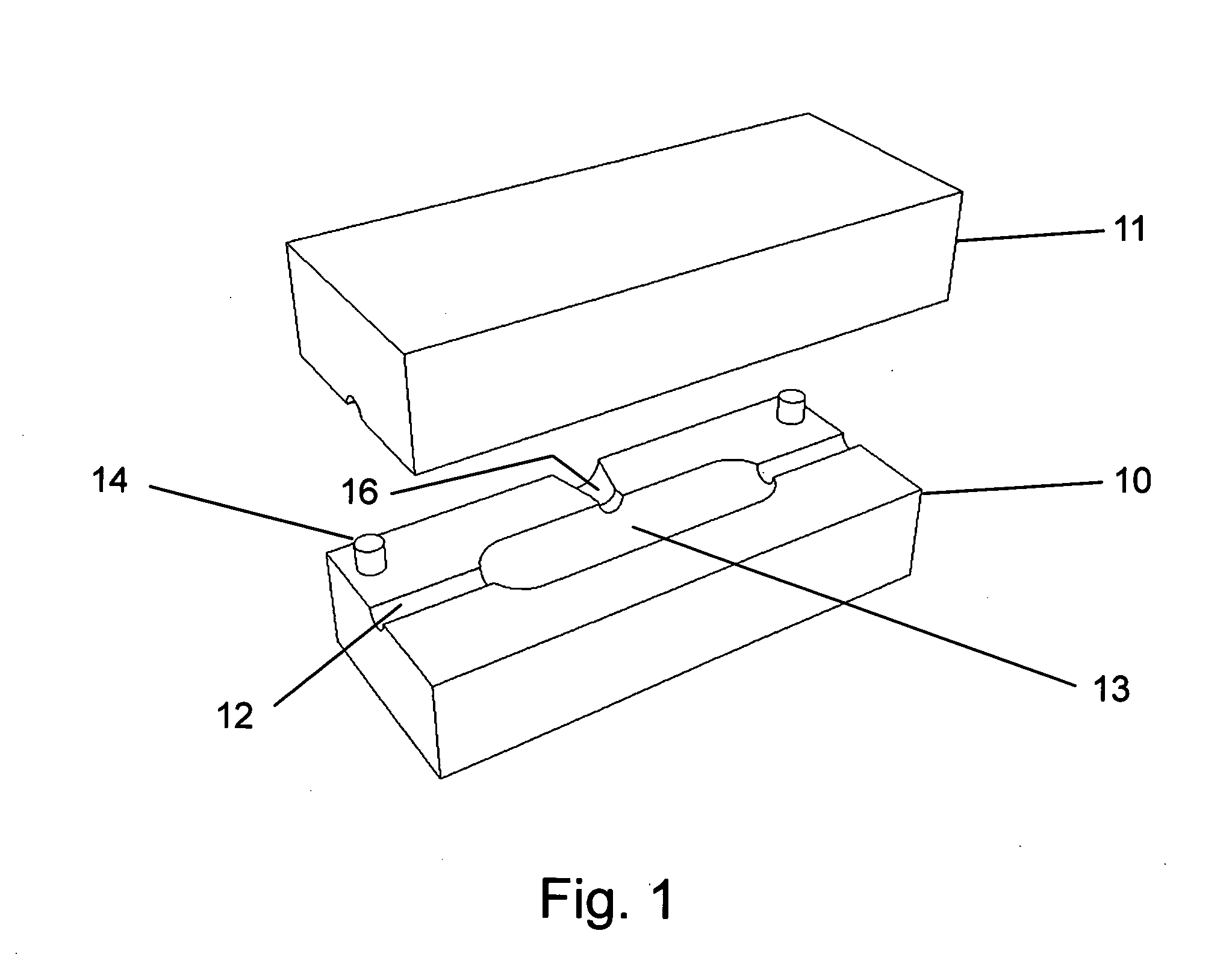

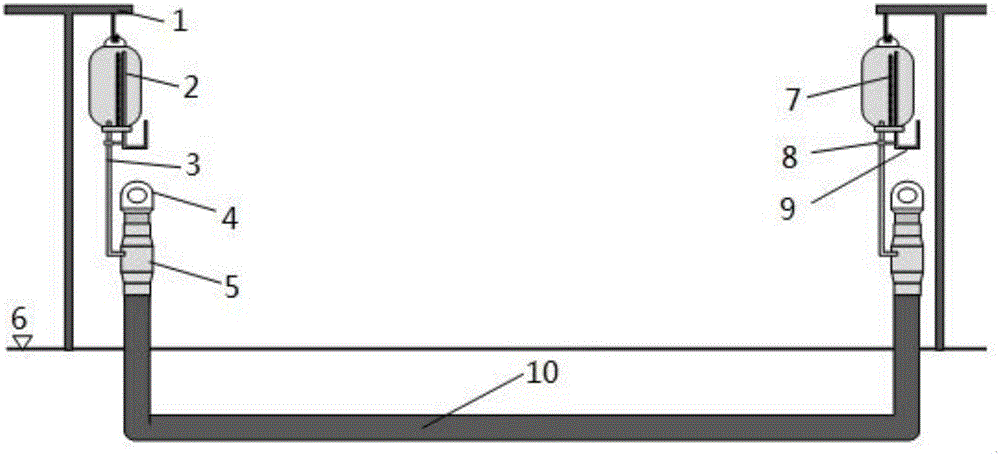

Repairing liquid injection system for cross-linked cable

ActiveCN1780078AGuarantee injection qualityControl pressureApparatus for repairing insulation/armouring cablesCross-linkEngineering

A preparing liquid injecting system for the cross-linked electric cable is composed of a compressed gas tank, repairing liquid tank, connecting pipelines and liquid outlet tube. The pressure limiting valve, electromagnetic valve, pressure sensor, and liquid flow distributing plate are respectively installed to relative connecting pipelines.

Owner:中国华北电力集团公司天津市电力公司

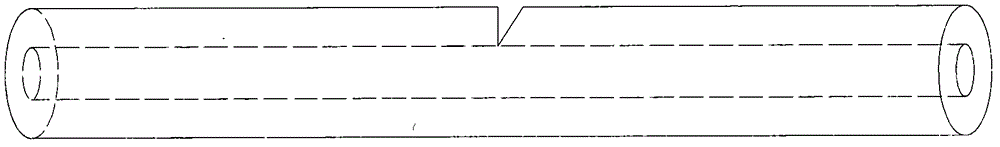

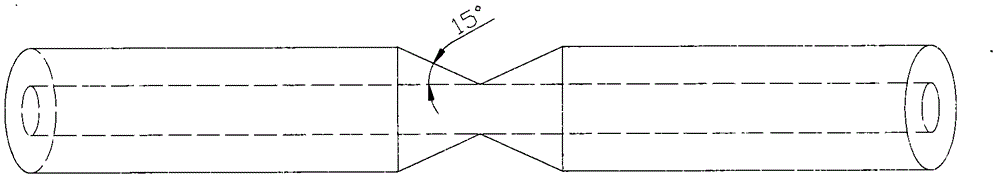

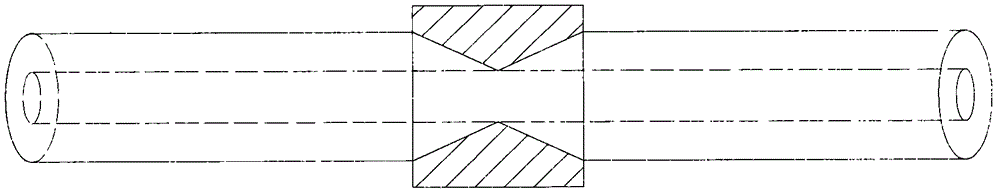

Method for repairing thermoplastic sheath cable

InactiveCN103701073AAvoid wastingAvoid increased workApparatus for repairing insulation/armouring cablesBandageBiomedical engineering

The invention relates to a method for repairing a thermoplastic sheath cable. The method comprises the following steps: removing a flaw part, and cleaning a to-be-repaired part; wearing down from a position which is about 15mm away from the flaw part to form a taper, and cleaning up the taper part; getting a section of thermoplastic sheath material for repair, and cleaning up the thermoplastic sheath material and drying; heating the thermoplastic sheath material for the repair; sticking the treated thermoplastic sheath material for the repair to the flaw part, and cooling the thermoplastic sheath material; cutting off excess parts, and polishing the repaired part; twining with a bandage and covering the repaired part; heating the twined repaired part, and cooling the repaired part when the color of the repaired part becomes into the color of the repaired cable; testing the quality of the repaired part, and repairing again if testing is not ideal. The method provided by the invention has the beneficial effects that the phenomenon that a mountain of work is increased due to the fact that the cable is laid again is avoided; the phenomenon that the whole cable is wasted due to a cable sheath is damaged is avoided; complicated equipment is not used during a whole repair process, and unnecessary production cost is not increased.

Owner:ZHEJIANG SHIPBUILDING CO LTD

Method and apparatus for encapsulating wire, hose, and tube splices, connections, and repairs

InactiveUS20090260736A1Line/current collector detailsElectrically conductive connectionsElectrical conductorEngineering

An improved method and apparatus for encapsulation of splices, connections, and repairs of wires, tubes, hoses, and similar conductors. Encapsulation is accomplished by securing the area to be encapsulated in a mold set and injecting a hot-melt sealant. Further embodiments allow for the addition of mounting lugs or tabs to the encapsulation for the purpose of mounting or identification. Method can also be used to mold mounting lugs or identification tabs over uninterrupted portions of the aforementioned conductors. The method provides superior resistance to ingress of contaminants and provides strain relief of encapsulated areas by supporting the conductors to reduce movement. The adhesive nature of the sealant reduces the likelihood of conductors being pulled apart.

Owner:CHARETTE STEVEN MICHAEL

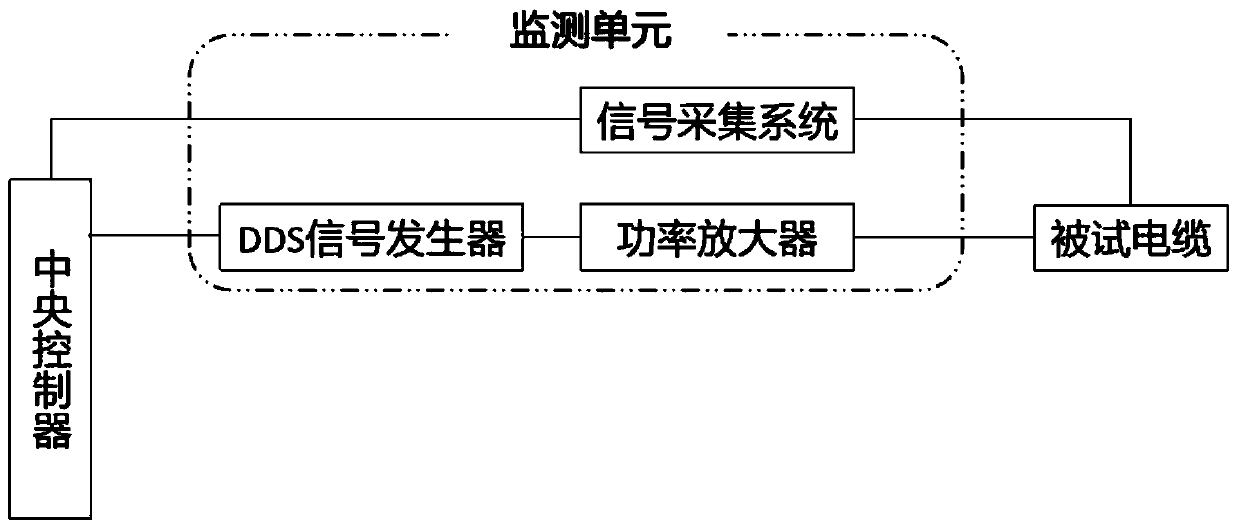

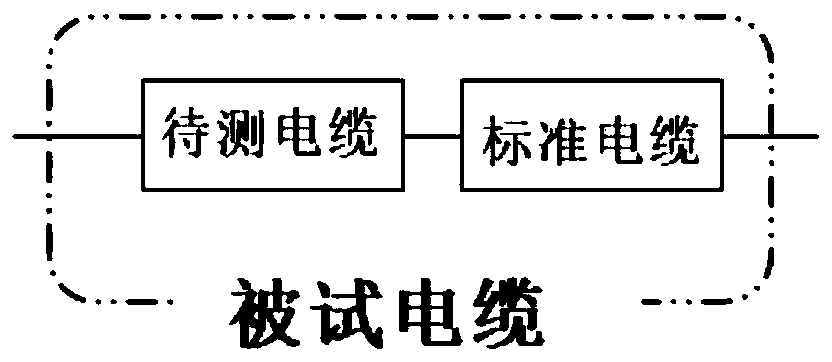

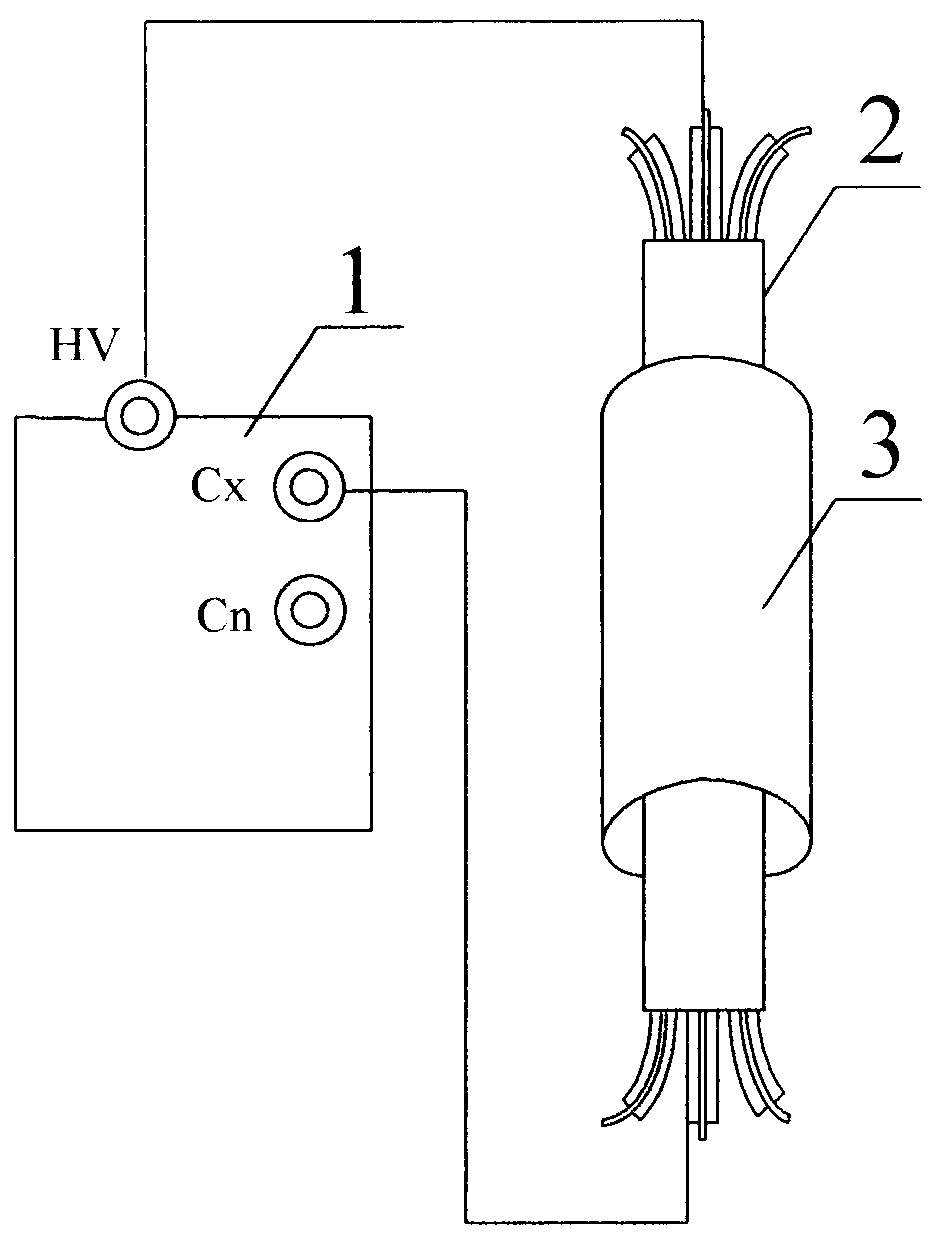

Cable aging treatment and monitoring method and device

PendingCN110082656AMonitoring the process of aging repairReliable and economical meansSpectral/fourier analysisTesting dielectric strengthFrequency spectrumEngineering

The invention provides a cable aging treatment and monitoring method, which is characterized by assembling a cable to be measured and a standard cable with fixed length into a tested cable, wherein the standard cable has a stable dielectric constant; outputting a signal source through a DDS signal generator, wherein the signal source passes through a power amplifier and then, passes through the tested cable; obtaining calculated length L1 of the tested cable through a frequency domain analysis method of impedance spectrum or phase spectrum or a time-domain reflectometry method containing powerenergy; and comparing the calculated length L1 of the tested cable and actual length is L0 of the tested cable. With the help of the standard cable and cable length calculation, the method not only can evaluate the aging condition of the cable to be measured, but also can monitor the aging repair process, and is a very reliable and economical method.

Owner:GAUSS ELECTRONICS TECH

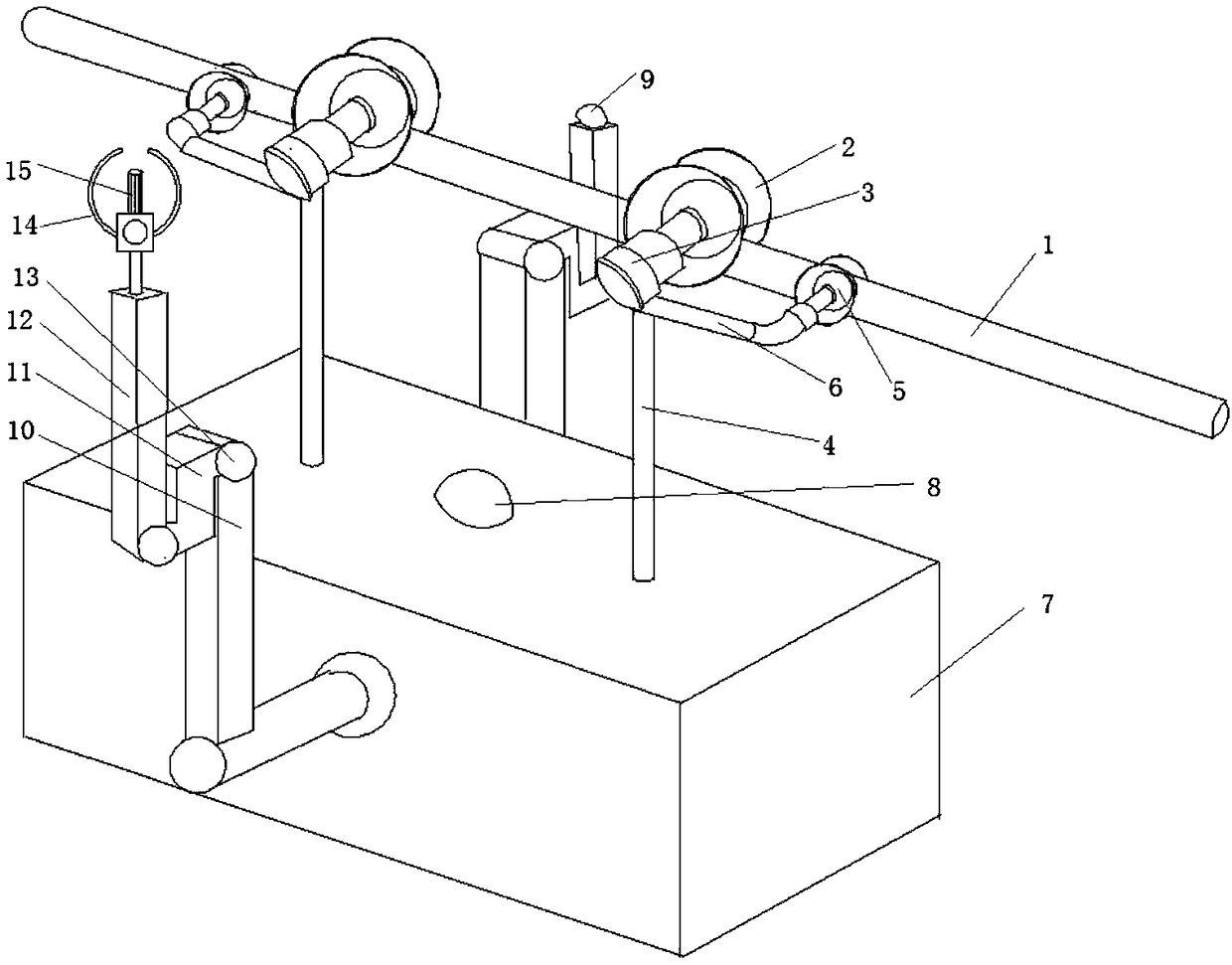

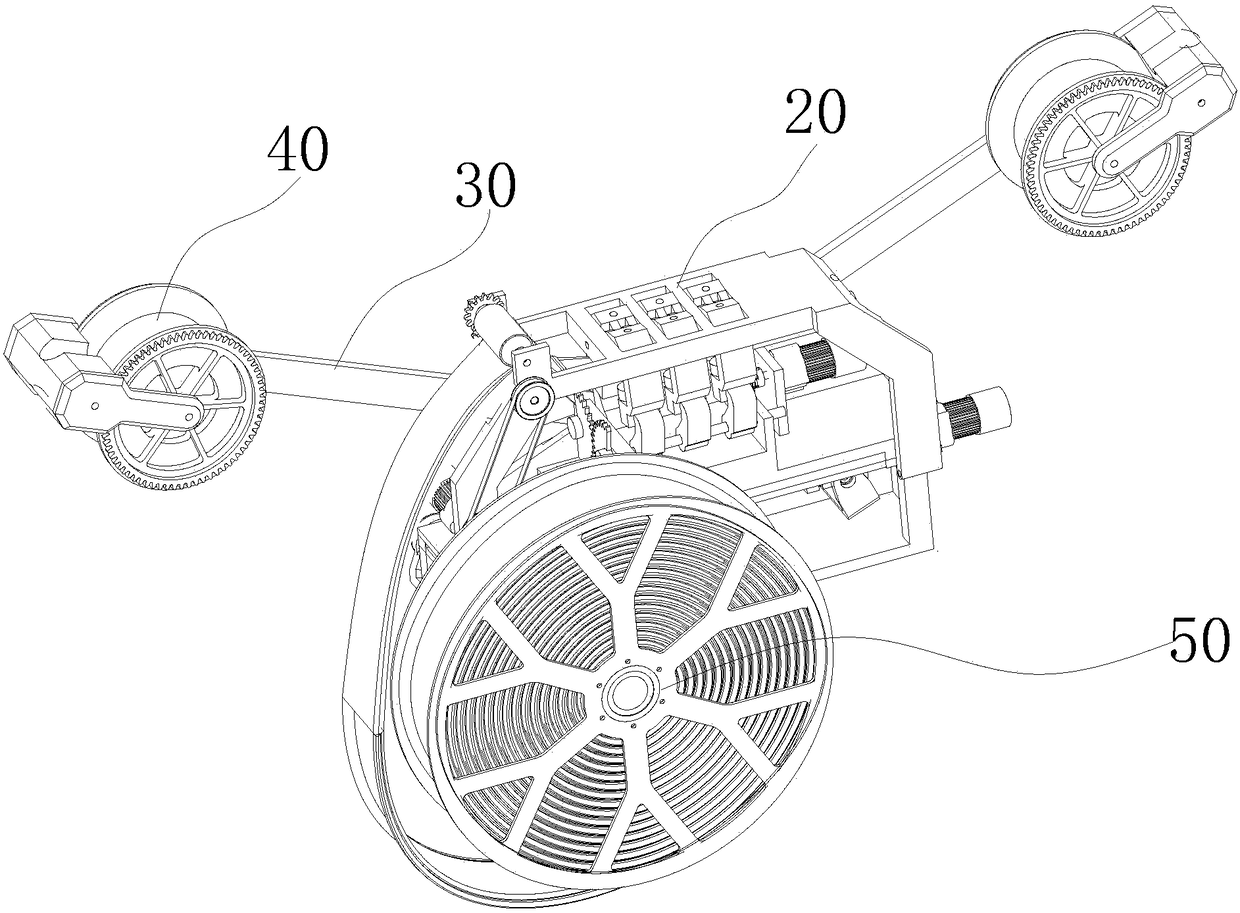

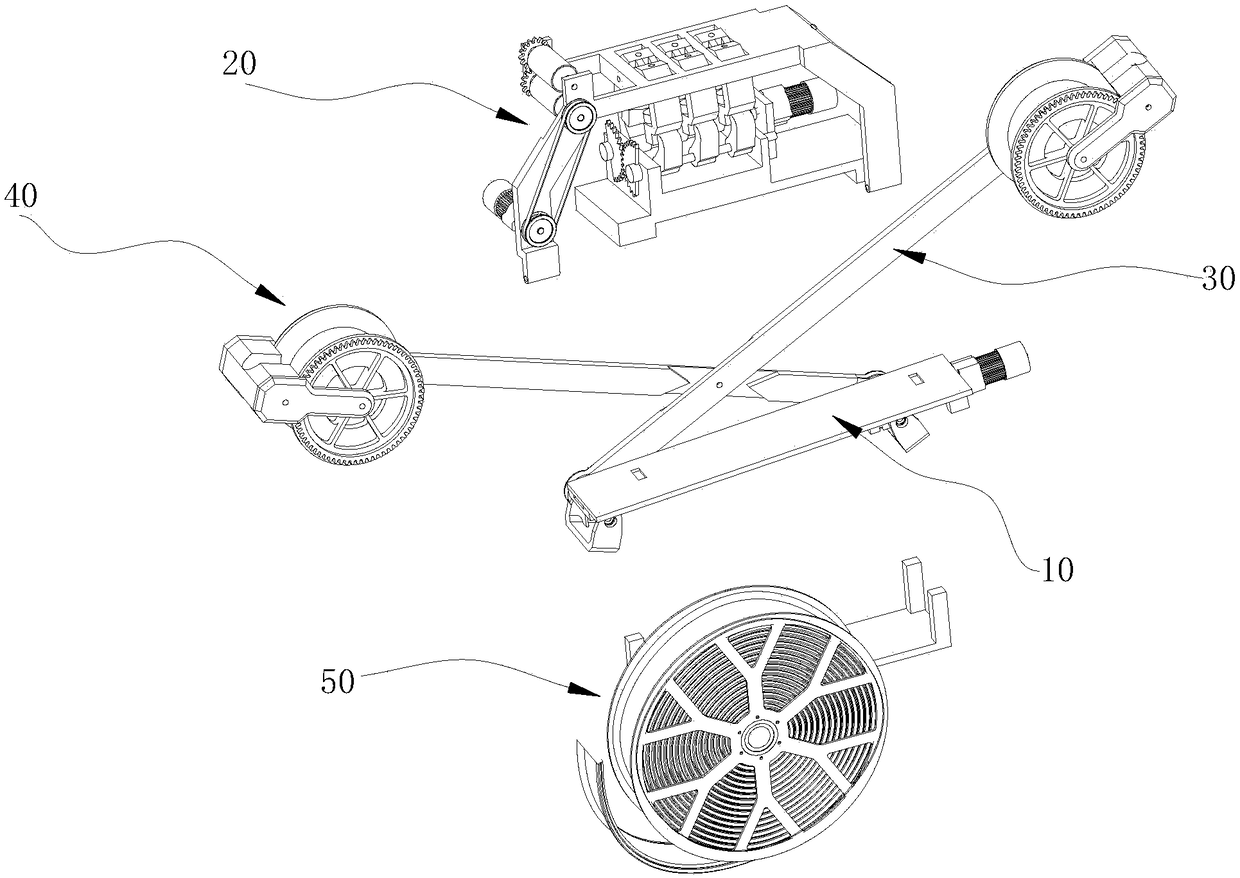

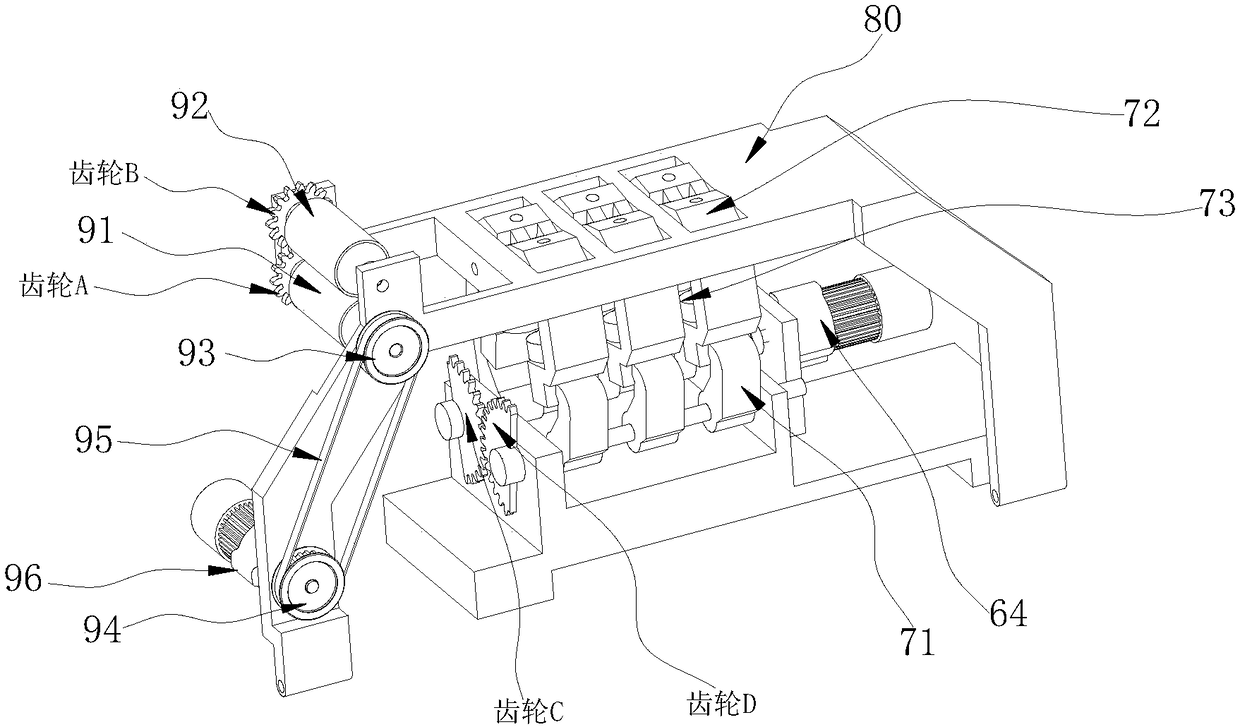

Cable damage point detection and repair device and method

InactiveCN108539673AImprove stabilityWith online self-detection functionOptically investigating flaws/contaminationApparatus for repairing insulation/armouring cablesEngineeringControl circuit

The invention discloses a cable damage point detection and repair device and method. The device comprises a base assembly, a transmission assembly, a walking assembly, a packaging box, a detection assembly, a repair assembly and a control circuit. Through the cooperation of front pulley components, rear pulley components and locking components in the walking assembly, the moving manner of advancing on a cable is higher in stability compared with conventional pulleys; the device has an online autonomous detection function for cable damage points, and is more efficient, more convenient, simplerand safer compared with artificial detection; the device has an online repair function for the cable damage points, and is simple in repair structure and convenient to operate, so that the disadvantages of risk and low efficiency caused by traditional cable climbing of workers are replaced.

Owner:SOUTHWEST UNIVERSITY

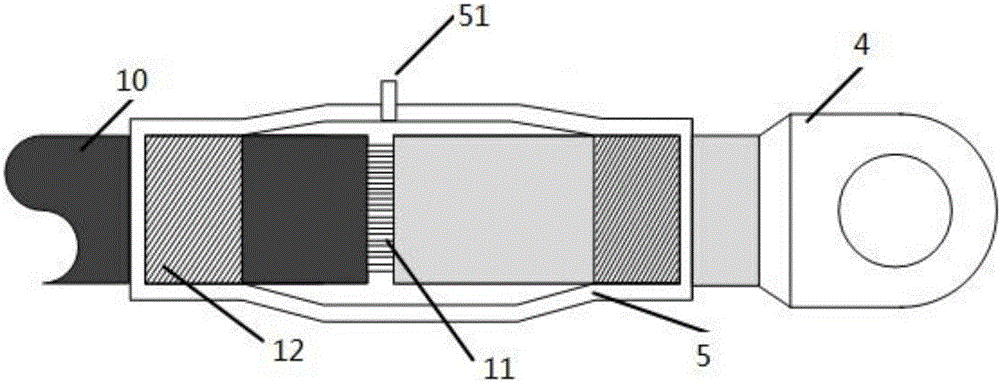

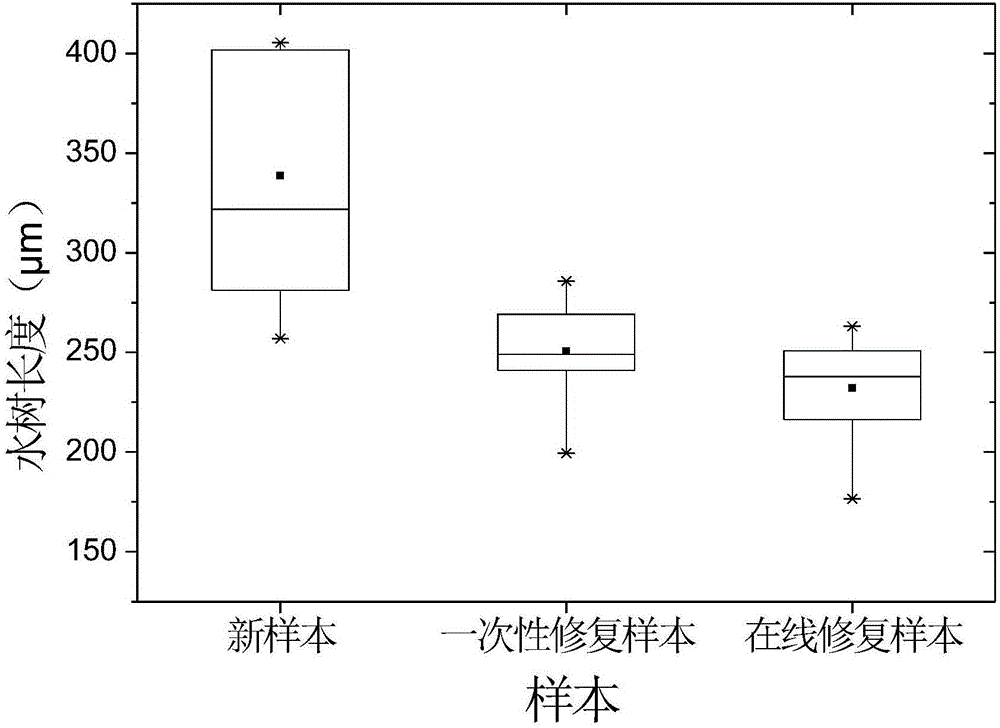

Method for intelligently repairing insulating water tree of crosslinked polyethylene power cable

InactiveCN103001155AFill in the gapsEfficient determination of aging statusApparatus for repairing insulation/armouring cablesPower cableAdditive ingredient

The invention discloses a method for intelligently repairing an insulating water tree of a crosslinked polyethylene power cable. The method is characterized by comprising the steps of determining the proportion of all ingredients of a repairing liquid according to a test value of dielectric loss angle tangent caused by the insulating water tree of the cable and injecting the prepared repairing liquid into the cable. The method has the advantages of being good in repairing effect and low in cost.

Owner:SOUTHWEST JIAOTONG UNIV +1

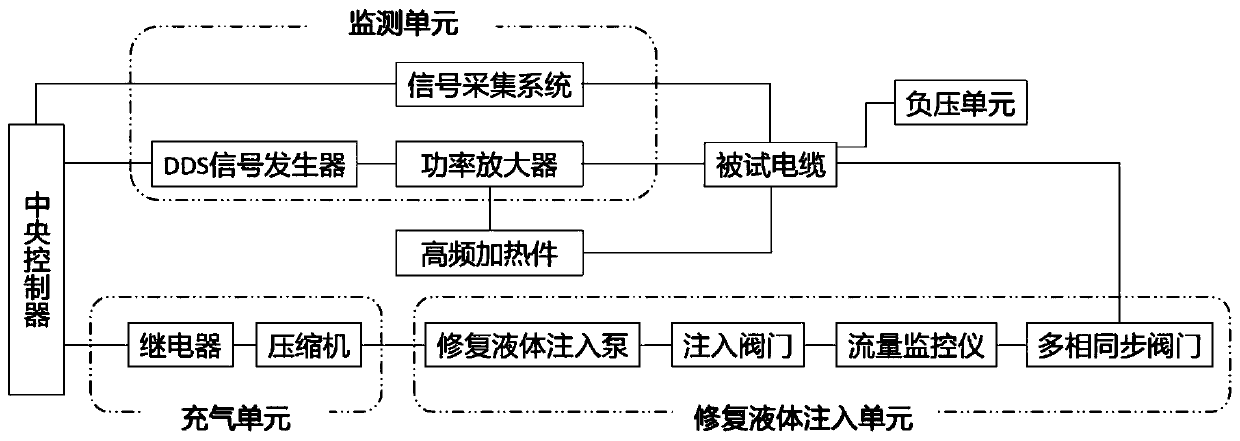

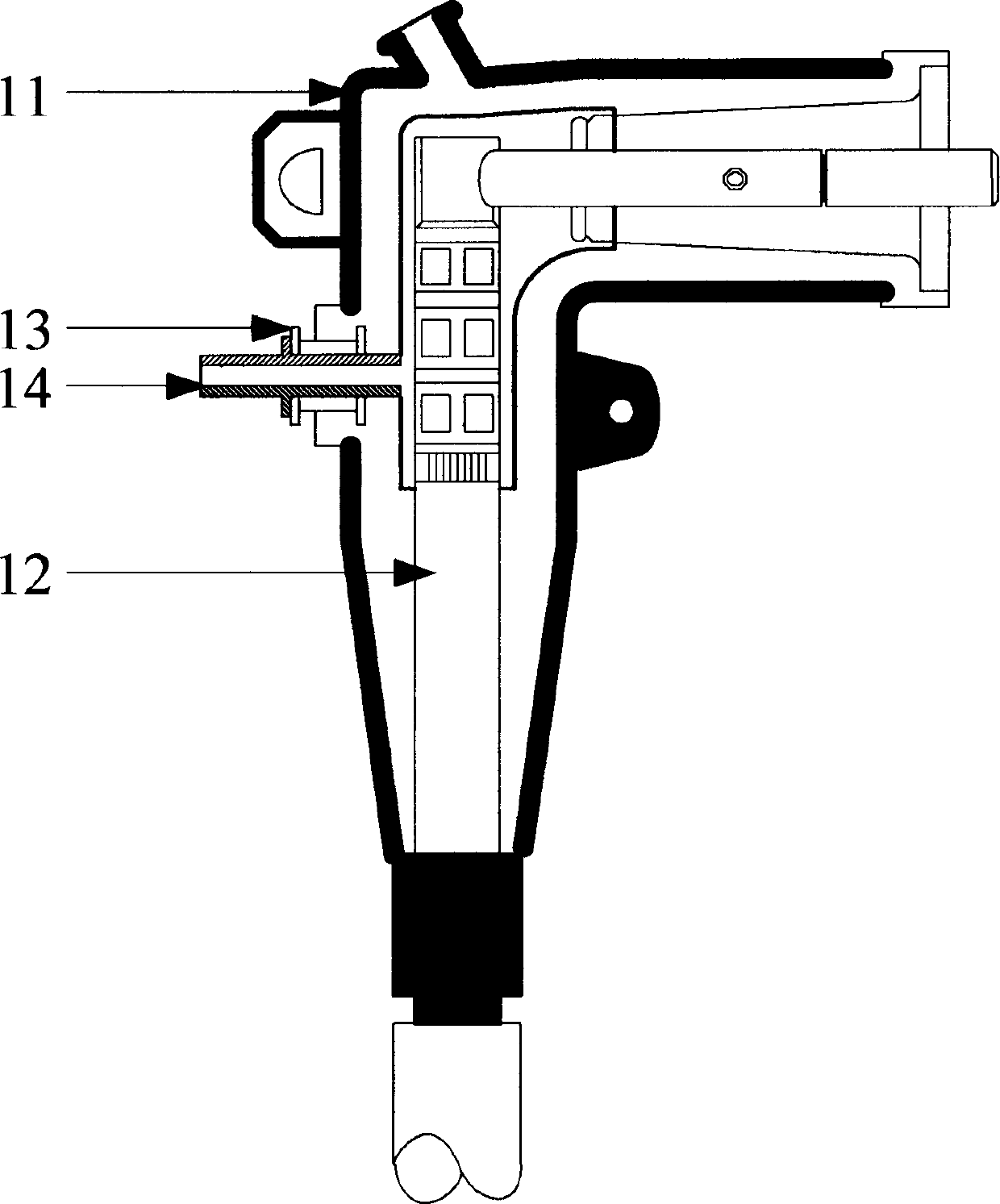

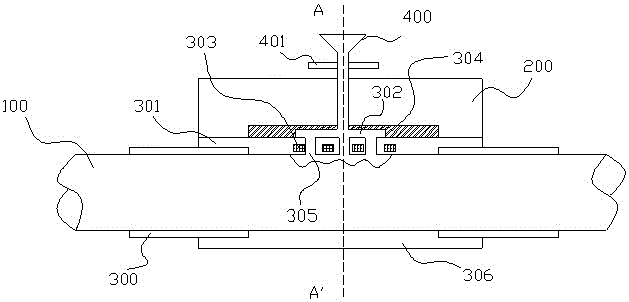

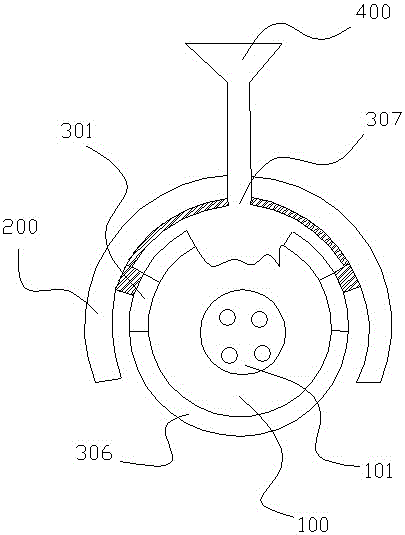

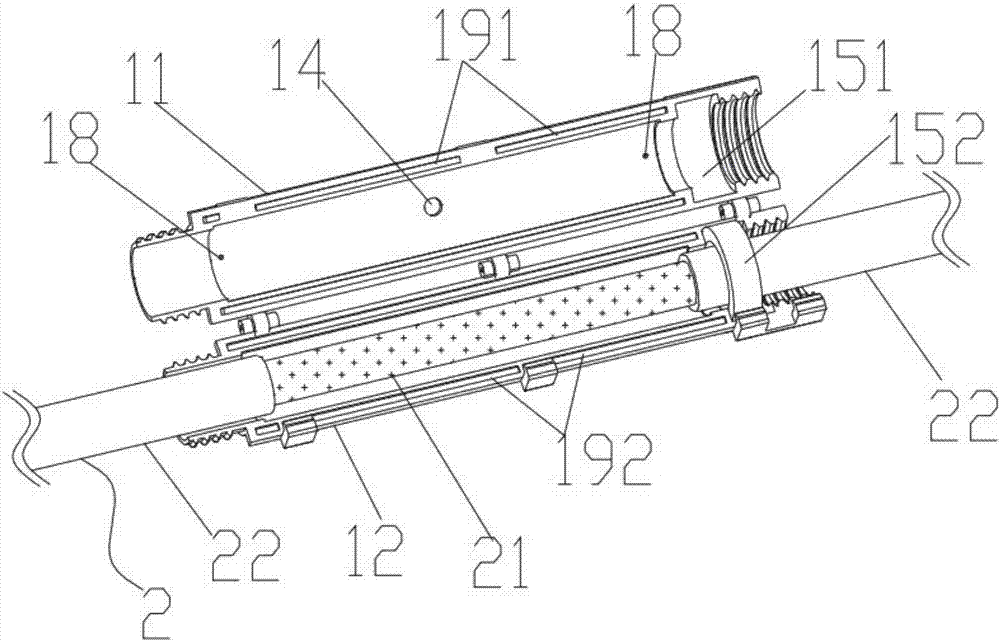

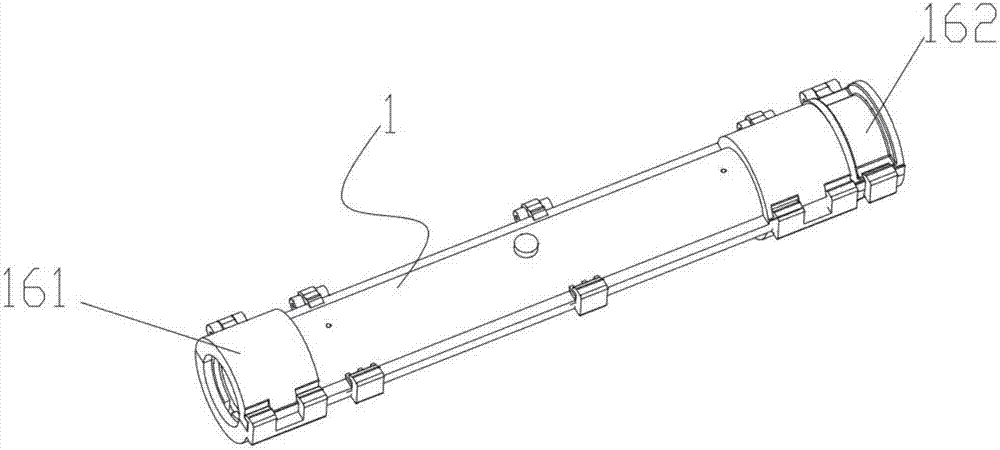

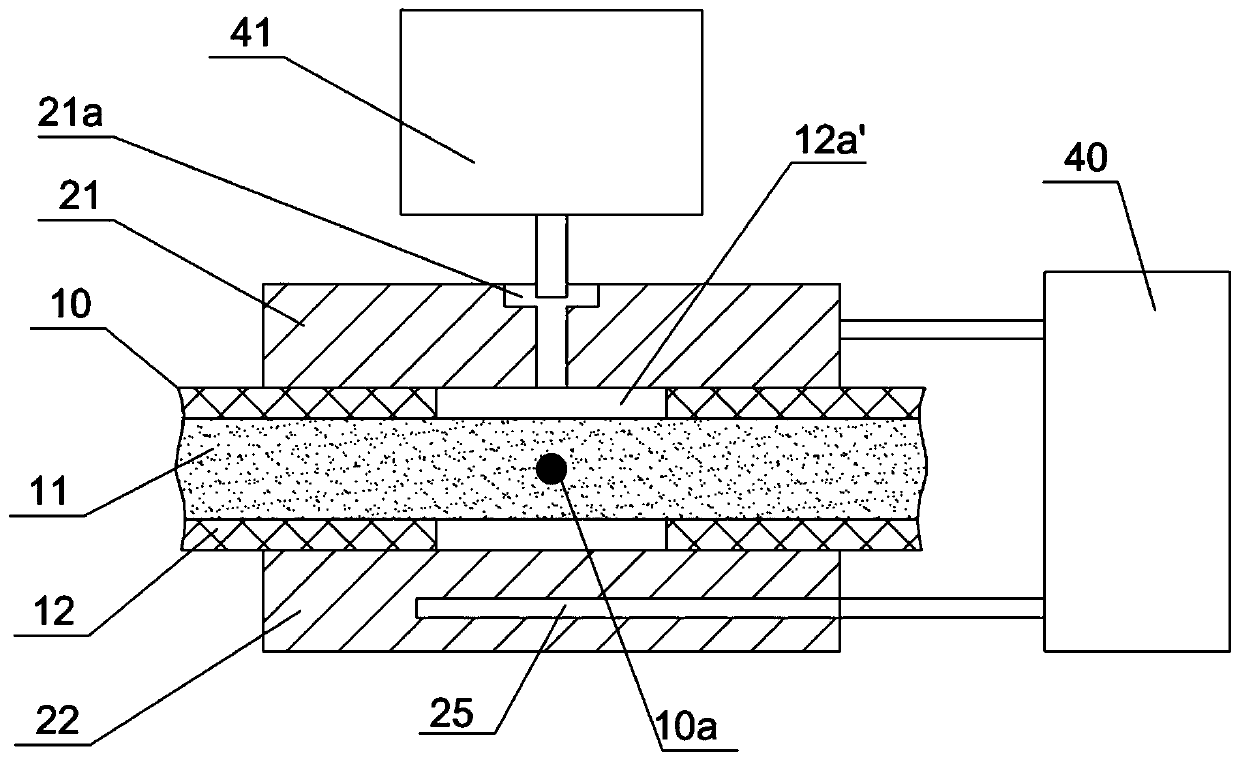

Online insulating property repairing method and device during operation of crosslinked polyethylene power cables

ActiveCN106786231AShorten power outage maintenance timeImprove repair effectApparatus for repairing insulation/armouring cablesPower cableRepair time

The invention discloses an online insulating property repairing method and device during operation of crosslinked polyethylene power cables and belongs to the field of cable insulation repairing. According to the online repairing method, in the cable operation process, the cables are filled with a repairing solution, that is, an electric field is provided in the cable repairing process, a water tree channel is opened, the repairing effect is better, the cable power outage repairing time is shortened, meanwhile, the cable is in both working and repairing states, and the cable operation reliability is improved. The repairing manner is characterized in that the electric field is applied to the cables, the cable repairing effect is improved, the cable power-outage maintenance time is obviously shortened, the medium and long-term repairing effect of cables as well as the repairing effect of long-distance and small-section cables are good, and the method and the device have the advantages of being advanced in technology, safe, stable, low in cost and wide in application range.

Owner:SICHUAN UNIV

Device for repairing damaged cable

ActiveCN105140832AInject evenlyReduce the problem of patch unevennessApparatus for repairing insulation/armouring cablesInjection portEngineering

The invention discloses a device for repairing a damaged cable. The cable repair device consists of a molding die, a molding die fixing member and a UV glue pouring funnel; and the molding die comprises a die sealing member, a first transparent molding die, a UV glue horizontal flow region, a ultraviolet curing lamp, a molding die shell, a plurality of UV glue outflow ports, a second transparent molding die and a molding die UV glue injection port. By adoption of the abovementioned scheme, the glue adopted by the device for repairing the damaged cable is UV glue, the molding die is internally provided with the ultraviolet curing lamp, and thus UV glue can be cured in very short time through irradiation of the ultraviolet curing lamp, thereby saving much time for electric power workers; and the device is also provided with the UV glue horizontal flow region, the main purpose is to spread glue injected through the funnel in the horizontal flow region, and then the glue is injected to places where the cable is damaged through the plurality of UV glue outflow ports, and thus the glue can be injected to different places evenly.

Owner:国网江苏省电力有限公司金湖县供电分公司 +1

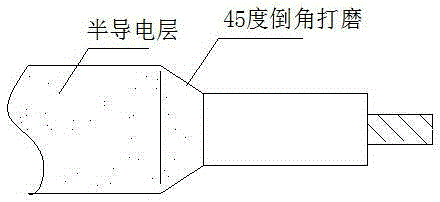

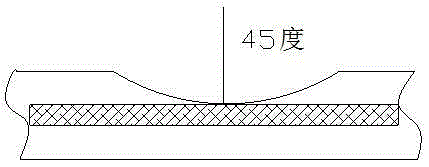

Restoration method of cable used by internal combustion engine traction locomotive and electric power traction locomotive

InactiveCN102361270AApparatus for repairing insulation/armouring cablesApparatus for joining/termination cablesRough surfaceRasp

The invention discloses a restoration method of a cable used by an internal combustion engine traction locomotive and an electric power traction locomotive. The method comprises the following steps: stripping off a skin of a cable of an earth fault position or a phase failure fault position, cleaning a position of the cable to be repaired, using a knife to cut two ends of the fault position and forming a 45 degrees cone, beating the cable by using a wood rasp to form a rough surface, and carrying out cleaning by using gasoline or CCl4; drying the cable, and winding an insulated rubber raw rubber belt being equal to the cable round the cable to be repaired; pasting talcum powder on a winding position, placing the cable into a cable hot repairing device for sulfurization hot repairing, and increasing clamp force of a mould with temperature rising, wherein when a temperature reaches 150 DEG C, the clamp force of the mould reaches the maximum, and an upper part and a lower part of the mould contact consistently; disconnecting a power supply when the temperature of the hot repairing device reaches 160 DEG C to 180 DEG C, carrying out natural cooling on the cable, when the temperature decreases and reaches 50 DEG C-80 DEG C, carrying down the cable, and repairing a rough edge of a hot repairing position; carrying out a 15000 V voltage experiment on the cable, wherein if the cable passes the experiment, restoration of the cable is successful.

Owner:李林霄

Power distribution line insulation wrapping device

Owner:国网安徽省电力有限公司凤台县供电公司 +2

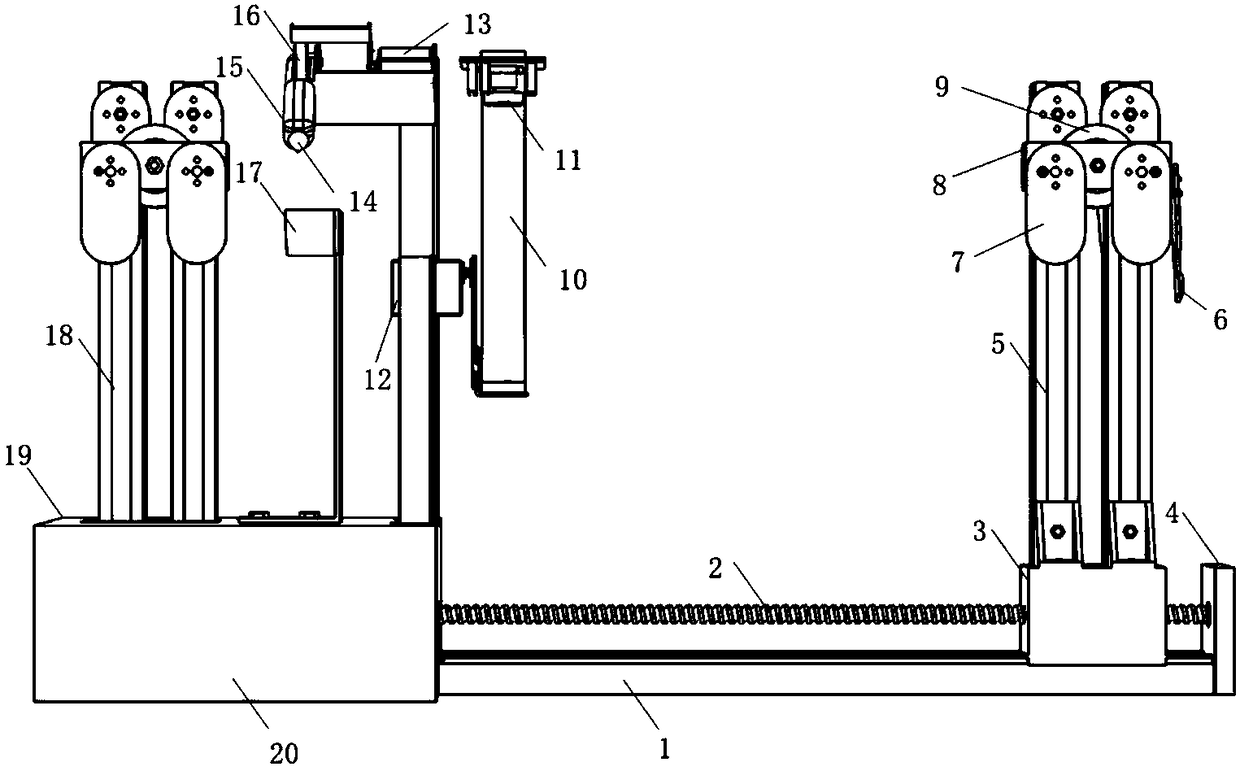

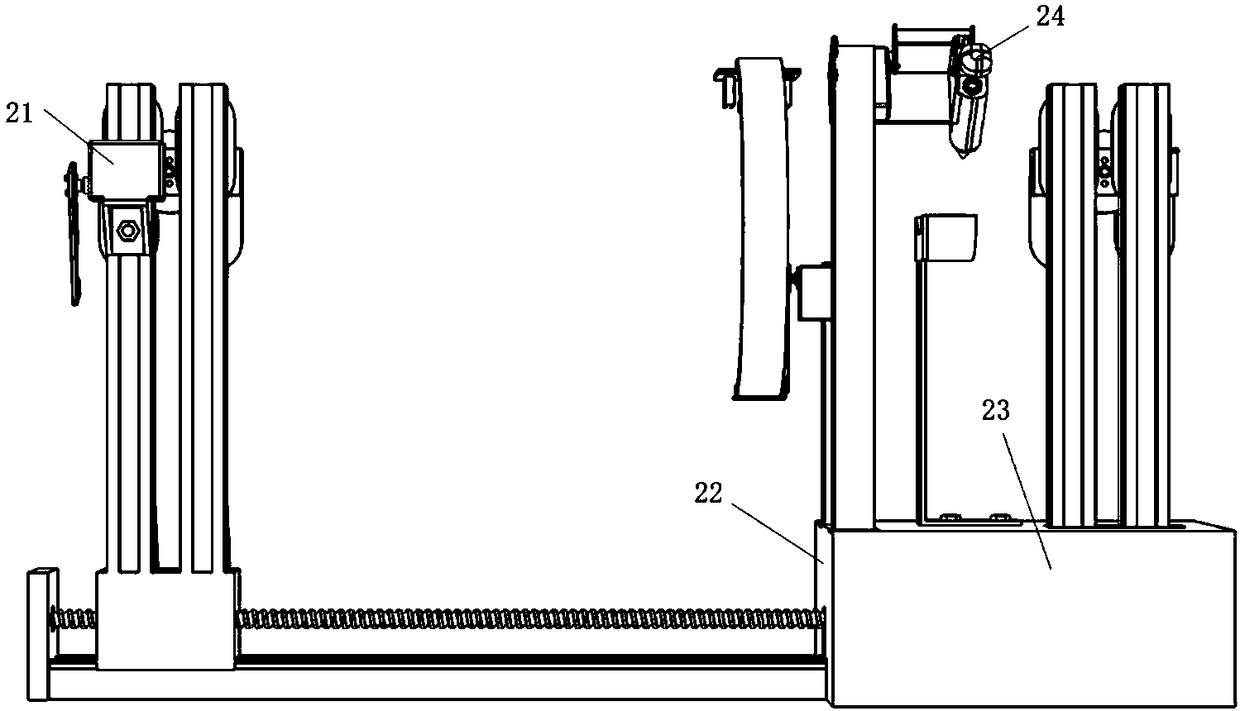

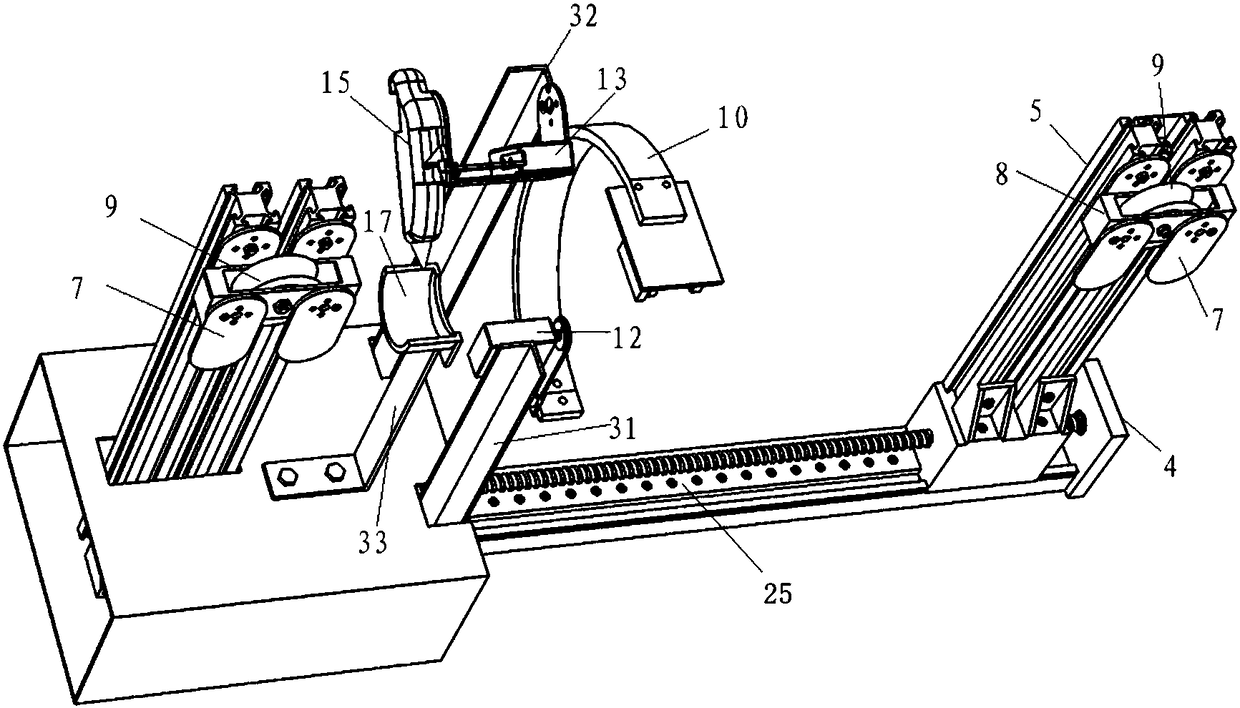

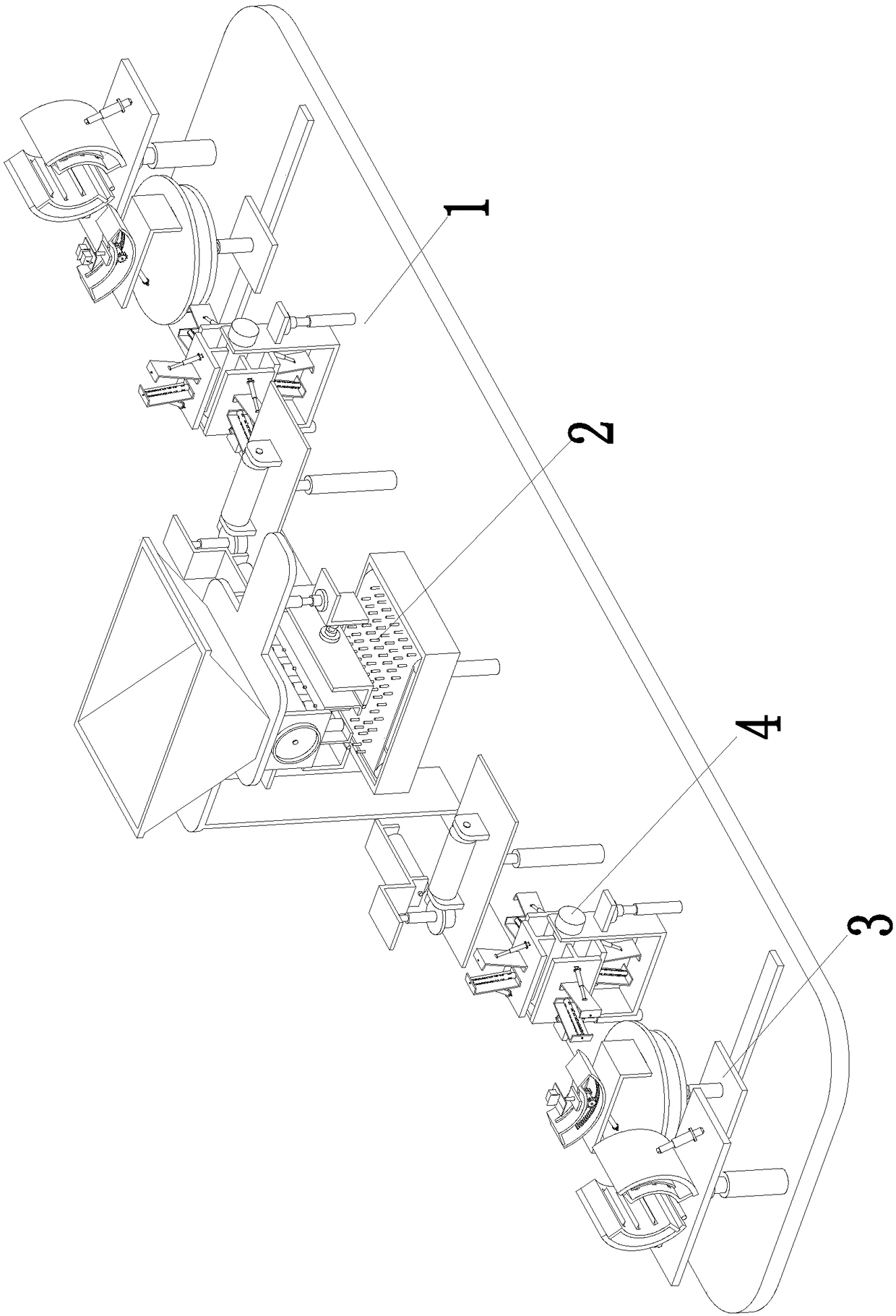

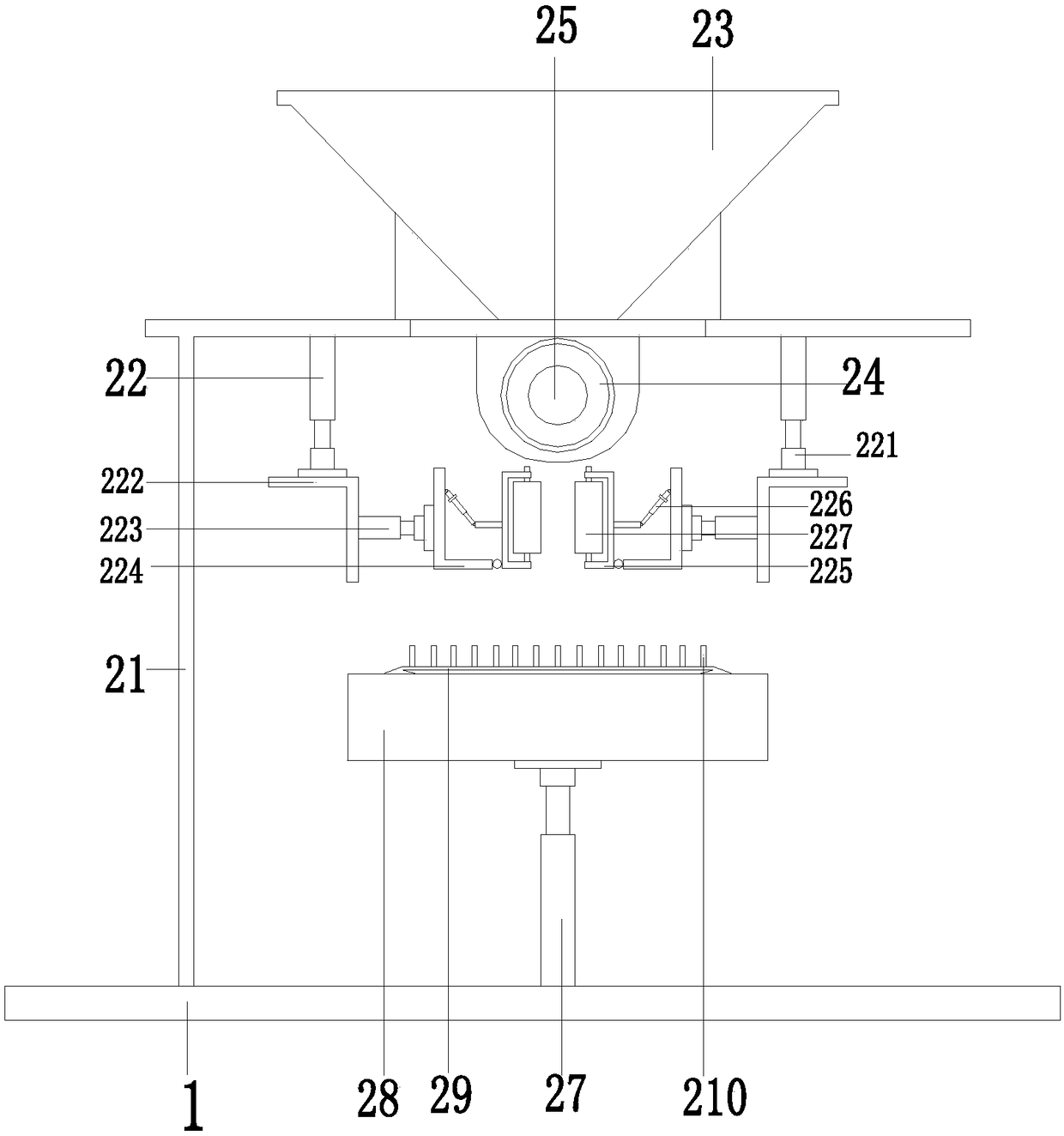

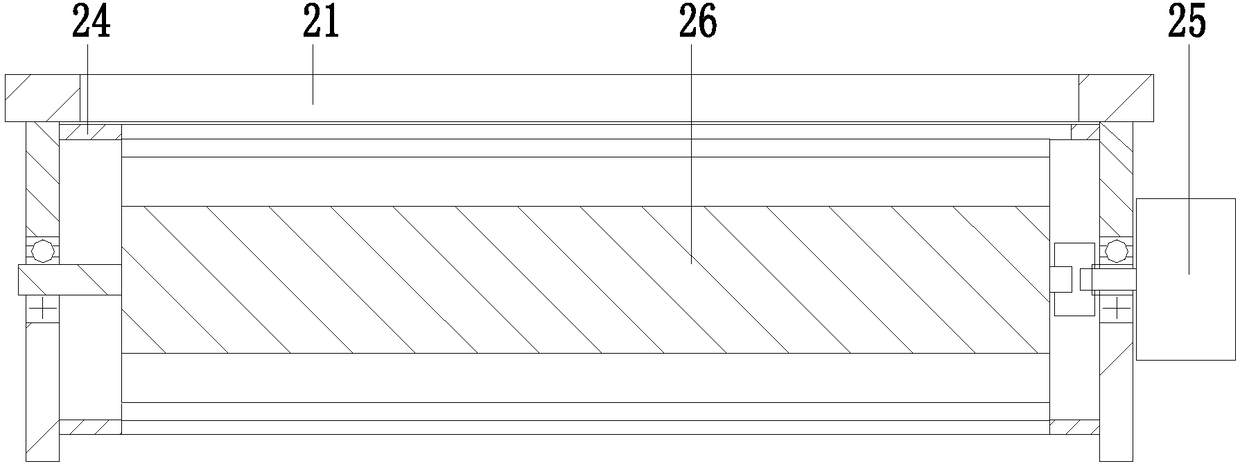

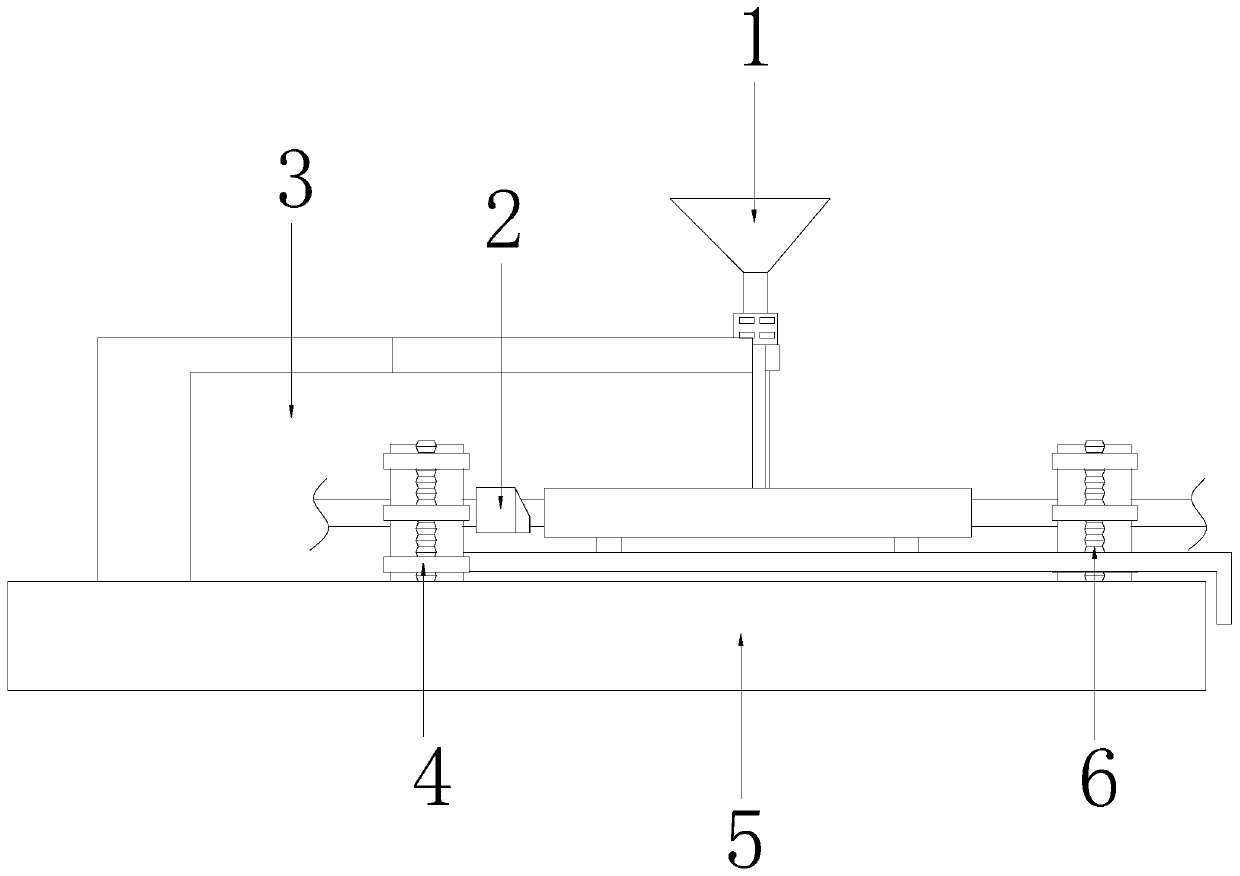

Automatic construction equipment of power cable

InactiveCN108306227AReduce labor intensityReduce the difficulty of dockingApparatus for repairing insulation/armouring cablesApparatus for removing/armouring cablesCable transmissionPower cable

The invention relates to automatic construction equipment of a power cable. The automatic construction equipment comprises a bottom plate, wherein a sleeve device is arranged at a middle part of an upper end of the bottom plate, two cable surface processing devices are arranged on the bottom plate, the two cable surface processing devices are symmetrically arranged at outer sides of a front end and a rear end of the bottom plate, and two cable transmission devices are arranged on the bottom plate and are symmetrically arranged at inner sides of the front end and the rear end of the bottom plate. By the automatic construction equipment, the problems that an insulator on a surface of the cable is needed to be processed by manual during the existing cable recovery process by manual, the cableis needed to be pulled and transmitted by manual, a copper pipe is needed to be taken and placed for abutting, a corresponding processing tool is needed to be selected according to the size of the cable during manual processing insulator on the surface of the cable, the corresponding processing tool is needed to be selected with regard to cables with different sizes, the operation is complicated,manual cable control and copper pipe abutting are not stable and a gap between the cable and the internal size of the copper pipe during the abutting process is relatively small are solved.

Owner:丁佐琳

Aerial insulation wire electrification repairing method

ActiveCN104009421ANon-stickReduce the temperatureApparatus for repairing insulation/armouring cablesSilicone tapeElectrical tape

The invention relates to an aerial insulation wire electrification overhauling method, in particular to an aerial insulation wire electrification repairing method. The method comprises the steps that polyimide adhesive tape is wrapped on the exposed part of an aerial insulation wire through a half fold packaging method, the outer side of the exposed part wrapped by the polyimide adhesive tape is coated with a layer of teflon coating film, an injection hole is formed in the middle of the teflon coating film, and a spray gun sprays a polyurethane foam joint mixture to the position between the teflon coating film and the polyimide adhesive tape through the injection hole for joint filling. According to the aerial insulation wire electrification repairing method, the problems that the insulation performance of the aerial wire is lowered, and a grounded short circuit accident is caused due to the facts that the aerial wire is exposed and the insulation adhesive tape is aged, unglued and chapped are effectively prevented, large-area power failure is avoided, power supply reliability is provided for reducing interphase short circuits and ground faults, and hidden dangers existing when workers work are avoided.

Owner:STATE GRID CORP OF CHINA +1

Method for restoring power cables

A method for extending the useful life of an in-service electrical cable section having a stranded conductor surrounded by a conductor shield encased in a polymeric insulation jacket and having an interstitial void volume in the region of the conductor, the cable section having an average conductor temperature T. The method comprising (i) continuously introducing a non-condensing exclusion fluid into the interstitial volume, the exclusion fluid comprising at least one non-condensing exclusion component having a solubility in the insulation polymer at least 100 times the corresponding solubility of water, each solubility being determined at temperature T; and (ii) injecting a condensing dielectric enhancement fluid into the interstitial void volume, wherein the dielectric enhancement fluid has a virtual flow rate within the interstitial void volume of less than about 0.1 liter per hour.

Owner:NOVINIUM LLC

Cable repair device and cable repair method

ActiveCN107275991ALong-term effective operationExtended service lifeApparatus for repairing insulation/armouring cablesAdhesiveEngineering

The invention relates to the field of cable maintenance, in particular to a cable repair device and a cable repair method. The cable repair device comprises a repair shell which consists of two sub shells combined oppositely. One adjacent sides of the two sub shells are hinged to each other, and the other adjacent sides of the two sub shells can be connected by a locking device. One of the two sub shells has an adhesive injection hole. After the two sub shells of the repair shell are combined together, a cable wiring cavity with both ends open is formed. The inner diameter of the cable wiring cavity is larger than the outer diameter of a cable to be repaired. The cable repair method includes the following steps: a cable damage sheath is covered with the repair shell; the two ends of the repair shell sleeve and are in sealing connection with cable insulation sheathes at the two ends of the cable damage sheath; liquid repair adhesive is injected via the adhesive injection hole; and after the repair adhesive is solidified, the repair adhesive and the repair shell are used as a repair layer of the cable damage sheath. The cable repair device has a simple structure, and is convenient to use. The repair layer has good waterproof and damp-proof properties and high strength, and is not easy to damage.

Owner:GUANGZHOU PANYU CABLE WORKS

Insulation repair method for 10 kV high-voltage cable

InactiveCN105262013AGuaranteed factory workmanshipReduce the chance of failureApparatus for repairing insulation/armouring cablesElectrical conductorHigh pressure

The invention belongs to the technical field of cable repair, and specifically relates to an insulation repair method for a 10 kV high-voltage cable. According to the method, when the 10 kV three-core cable has a phase core breakdown fault, according to the damaged conditions of insulation and a wire core, three wire core bodies can be maintained without sawing three conductor wire cores of the cable if the conductor wire cores of the cable after breakdown are not obviously damaged, and the 10 kV high-voltage cable "main insulation repair" manufacturing process is employed at a fault wire core insulation breakdown position for rapid repair processing. According to the method, cable wire core insulation with fault breakdown can be rapidly, simply, and effectively repaired, and recovery of power transmission is rapidly achieved.

Owner:JIUQUAN IRON & STEEL GRP

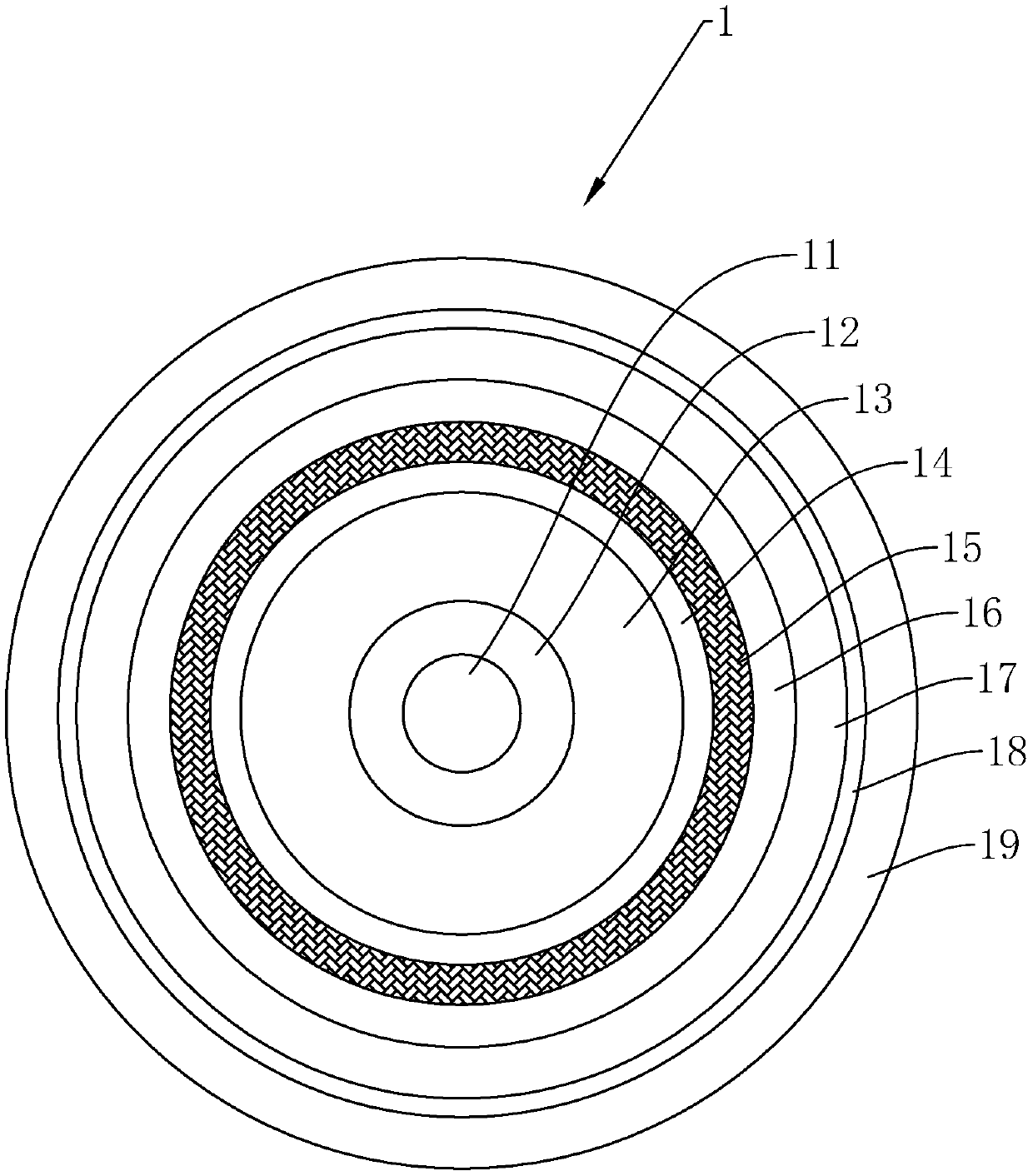

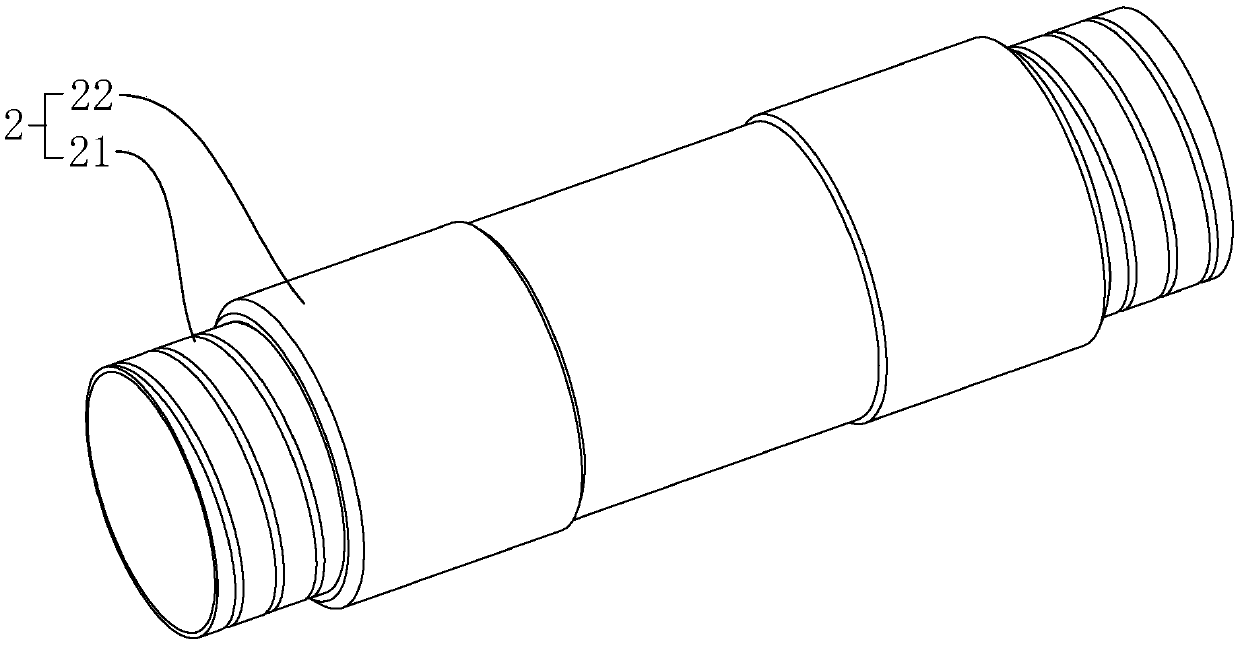

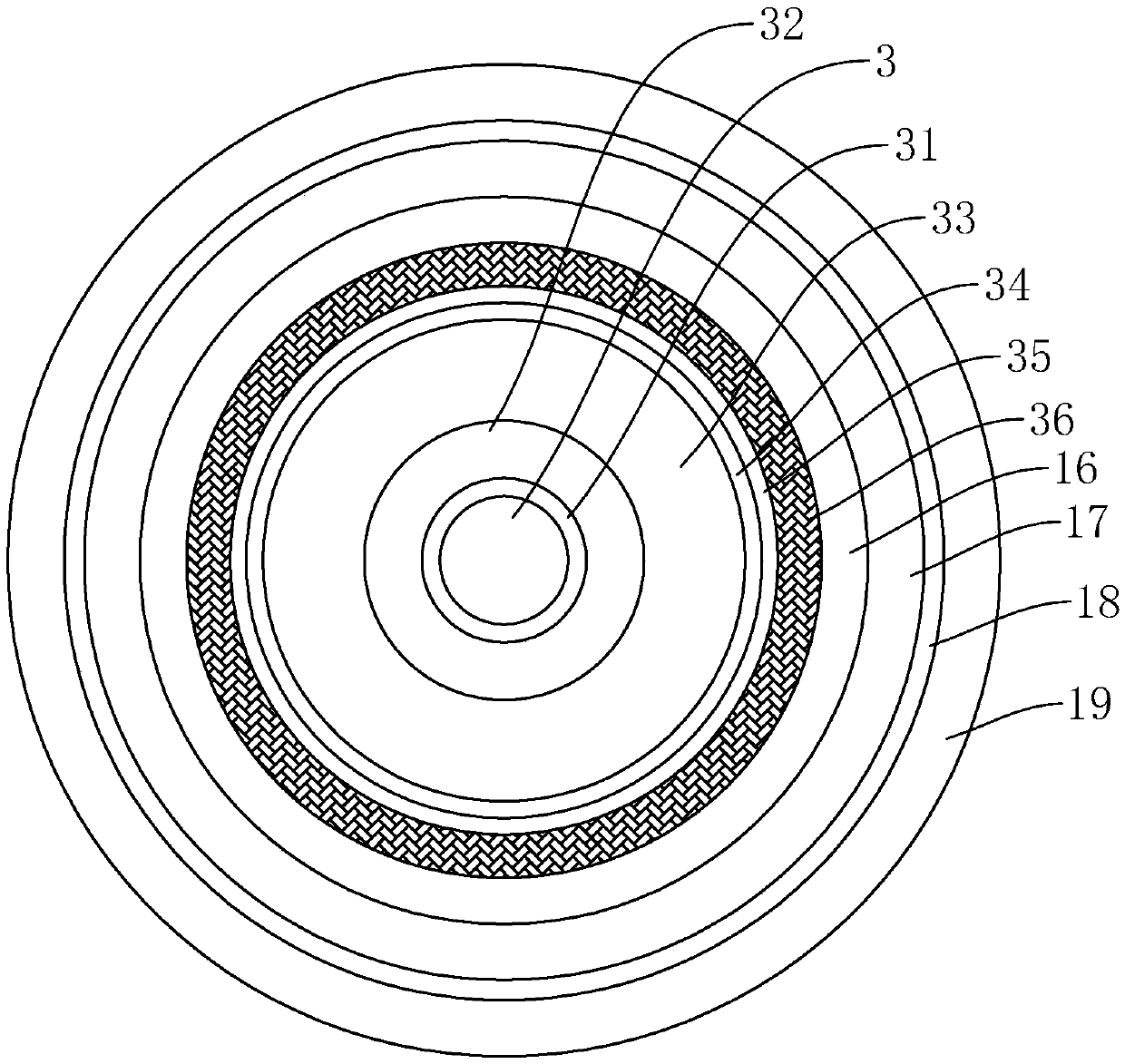

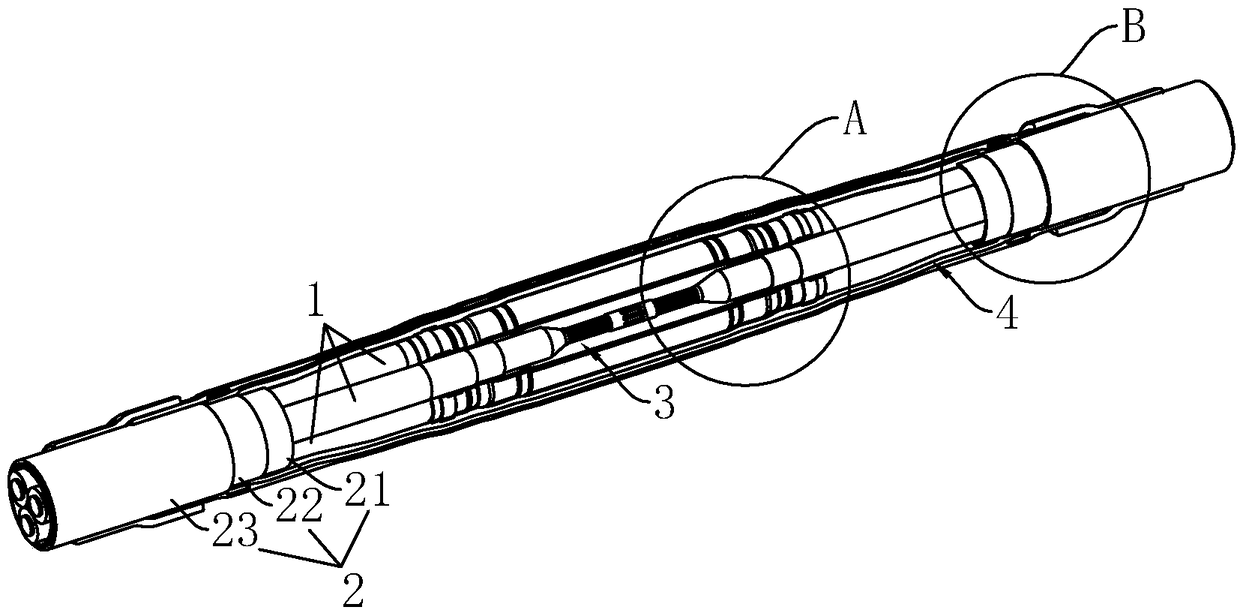

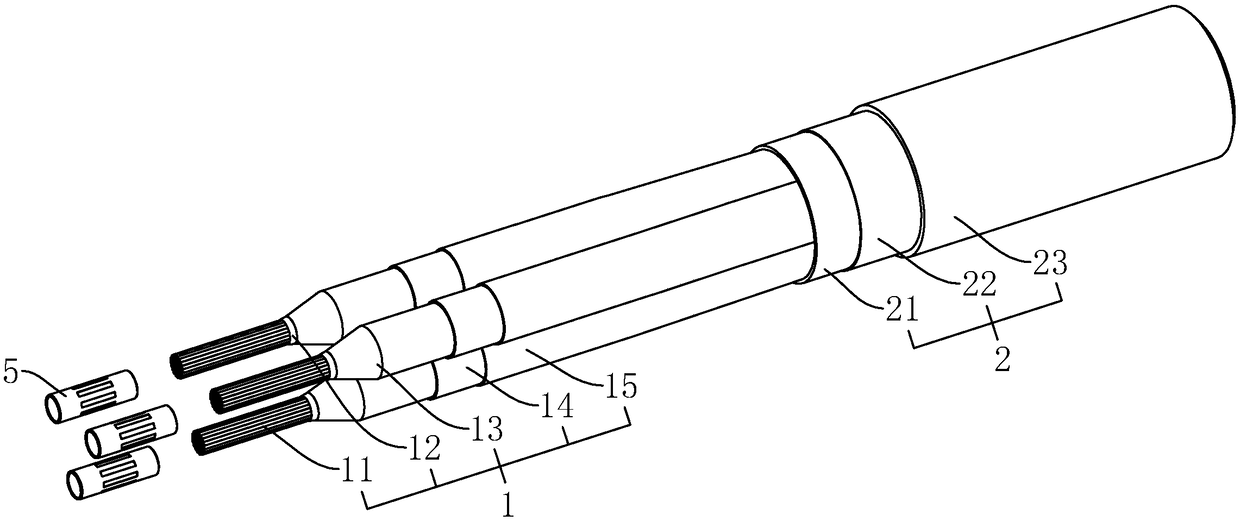

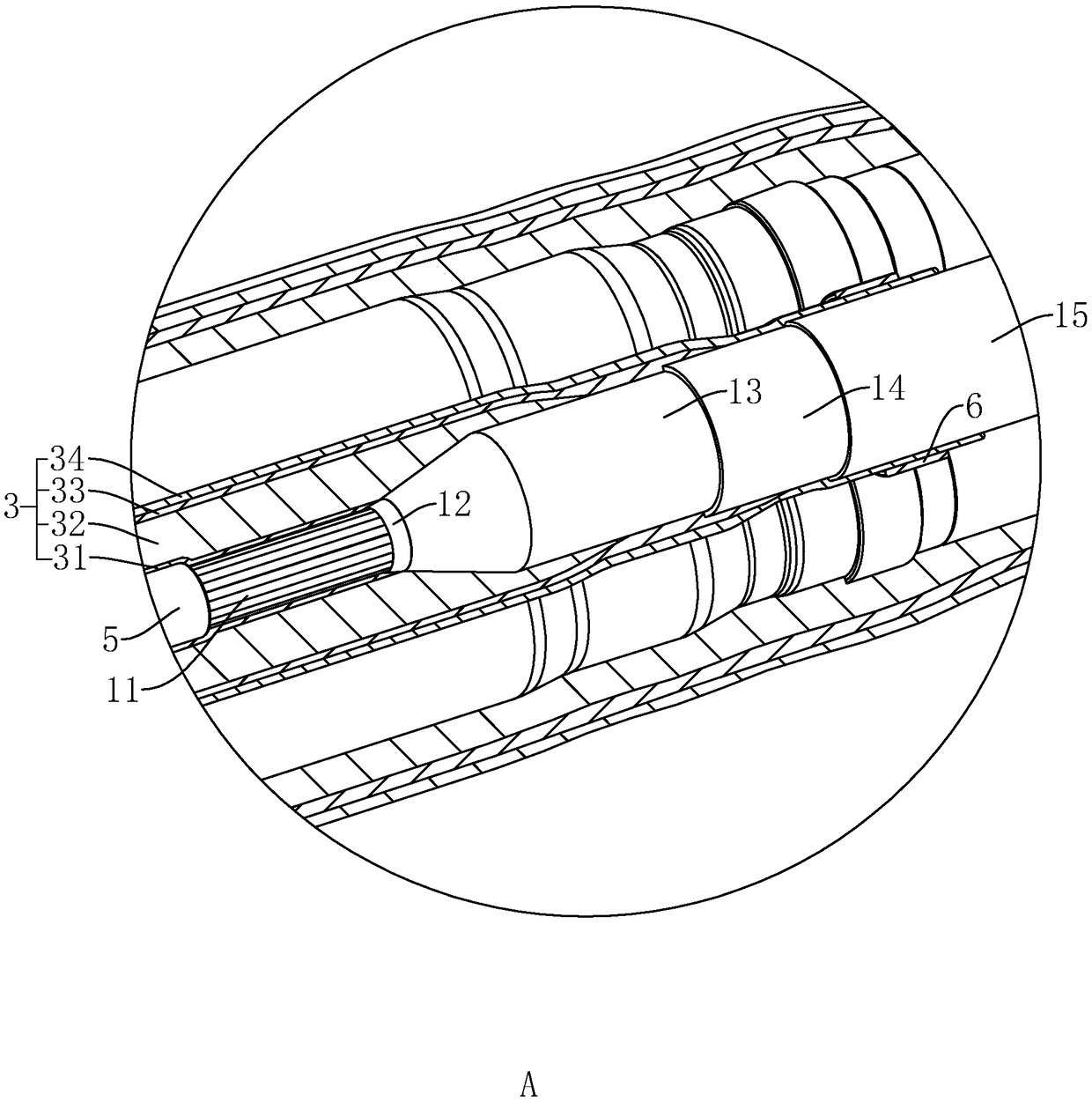

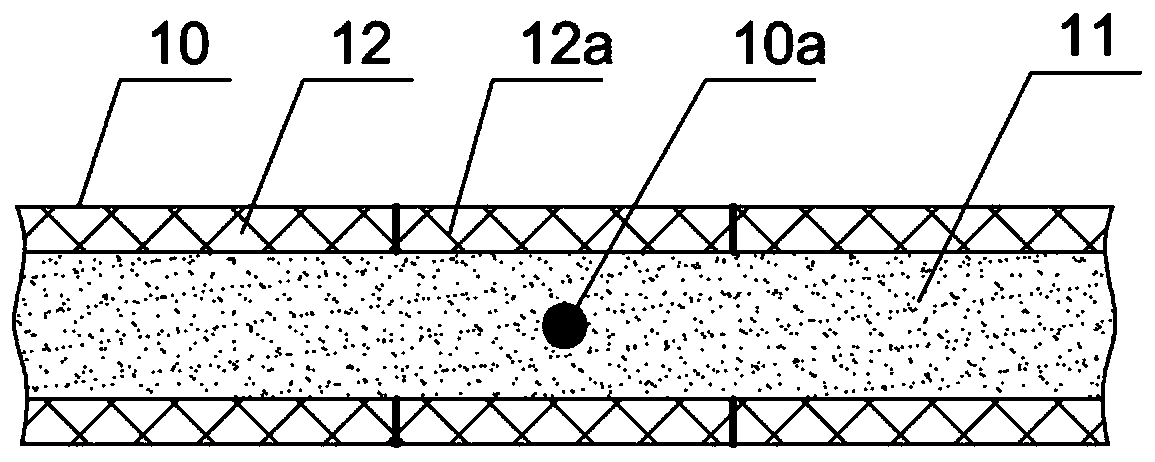

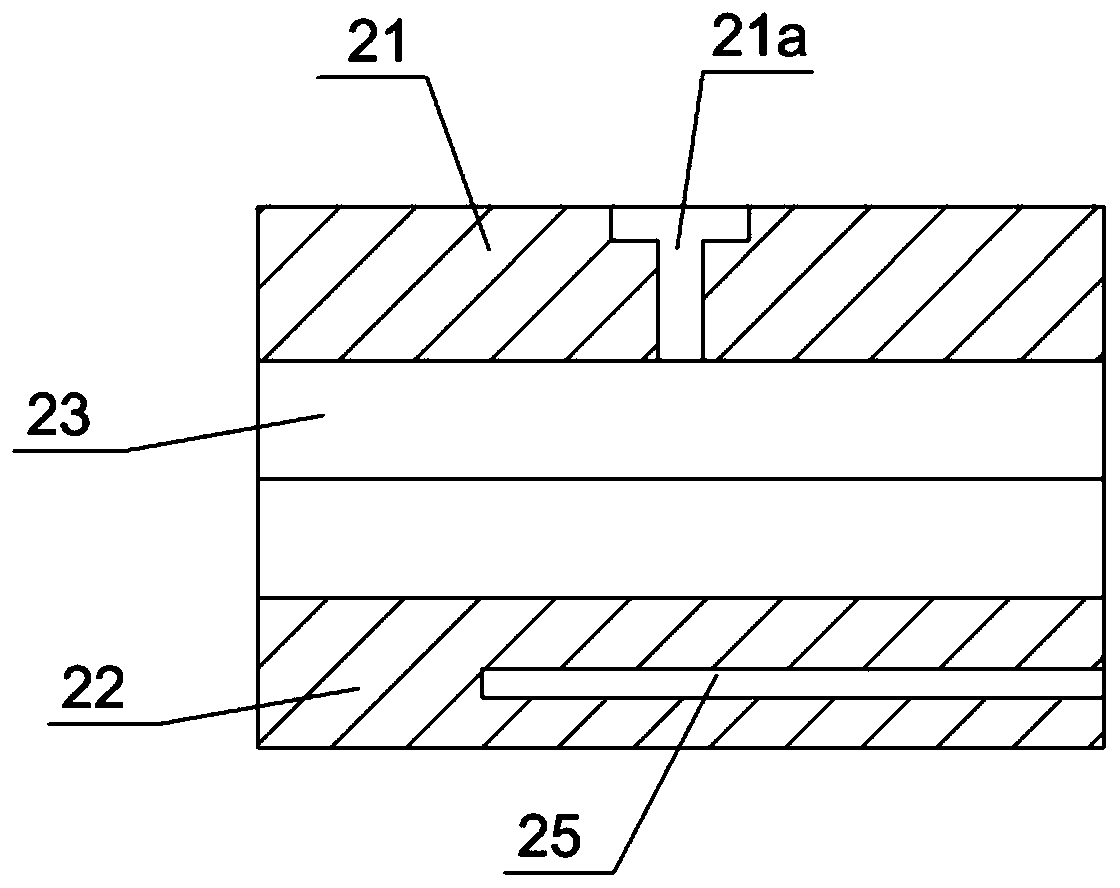

Three-core cable fusion joint and installation technology thereof

InactiveCN109286083ALarge elastic shrinkageFit tightlyLine/current collector detailsSoldered/welded conductive connectionsInterference fitElectric power transmission

The invention discloses a three-core cable fusion joint, and relates to the technical field of electric power transmission. The joint comprises two mutually connected cables, an inner repairing layergroup and an outer repairing layer group, wherein the inner repairing layer group and the outer repairing layer group are used for repairing the cables, each cable includes three conductor cores and an outer protection layer group coated outside the three conductor cores, the outer protection layer group includes an inner sheath layer, an armor layer and an outer sheath layer in sequence, the outer repairing layer group includes an inner sheath repairing layer, an armor repairing layer and an outer sheath repairing layer in sequence, the outer sheath repairing layer is set to be a heat shrinkable casing, and two ends, which are lapped with the outer sheath repairing layer, of the outer sheath layer are sleeved with cold shrinkage casings. The cold shrinkable casings are great in elastic shrinkage force and can carry out permanent elastic coating on the lapping parts at two ends of the outer sheath repairing layer, thereby forming interference fit for a long time, and effectively improving the relative stability between two ends of the outer sheath repairing layer and the outer sheath layer. In addition, the cold shrinkable casings can firmly adhered to the outer side of the outer sheath layer, thereby effectively improving the waterproof performance of the cable after the repair.

Owner:华依电缆附件有限公司

Repair method of insulation defect of power cable thermoplastic materials

ActiveCN104617525ARepair insulation defectsConsistent qualityApparatus for repairing insulation/armouring cablesInsulation layerAfter treatment

The invention discloses a repair method of the insulation defect of power cable thermoplastic materials. The repair method is characterized by comprising the following steps of step 1, grooving the defect position of an insulation layer; step 2, producing an adhesive tape; step 3, enabling the adhesive tape to wrap the inside of an annular groove; step 4, placing a wire core into a shaping mould, wherein an adhesive tape repair layer wraps the wire core; step 5, performing extrusion forming; step 6, trimming a connecting opening; step 7, achieving the repair after the detection. According to ye repair method of the insulation defect of power cable thermoplastic materials, the insulation defect of the 6 KV and 6 KV below of power cable thermoplastic materials can be safely, reliably and effectively repaired, the same quality of the insulation wire core after treatment and a normal insulation wire core is ensured, the long-term safe operation of the products can be ensured, and the waste is avoided due to the effective repair on the wire core.

Owner:INNER MONGOLIA RENDA SPECIAL CABLE

Cable straightening repair device

ActiveCN109127952AEasy to put inExtended service lifeApparatus for repairing insulation/armouring cablesEngineeringChassis

The invention discloses a cable straightening repair device. The cable straightening repair device comprises a bottom frame, a straightening device, a checking device and a repair device, wherein eachdevice is mounted on the bottom frame, and is convenient to move. When a cable is wound on an upper bending wheel and a lower bending wheel, the cable is bent; defects on outer skin of the cable areamplified during bending; a first camera arranged on the upper bending wheel and a second camera arranged under the lower bending wheel acquire a cable image, and the cable image is displayed on a display screen after being processed by a processor, so that a worker finds defects on the outer skin of the cable through the display screen. After the defects are found, straightening for the cable isstopped, so that a worker pulls out insulation paste at one end from a roller and winds the insulation paste on damaged outer skin of the cable, and therefore, the cable is continuously straightened after being completely bundled at the defects. The cable straightening repair device can timely repair after finding defects of the cable, so that the service life of the cable is prolonged, and use safety of the cable is improved.

Owner:海南电网有限责任公司海口供电局

Repair apparatus and repair method specific to high-altitude cable insulation layer aging

ActiveCN108173176AFast repairLow costApparatus for repairing insulation/armouring cablesApparatus for removing/armouring cablesInsulation layerEngineering

The invention relates to a repair apparatus and a repair method specific to high-altitude cable insulation layer aging. The repair apparatus comprises a shell and a rotational body rotationally arranged in the shell in a sleeving manner; the rotational body is rotationally arranged outside a high-altitude cable in a sleeving manner; the rotational body is driven by a motor fixedly arranged in theshell to rotate; a material coating cavity is formed in the middle part, positioned above the high-altitude cable, of the shell; a waterproof insulating coating material is mounted in the material coating cavity; a material outlet is formed in the bottom, towards the high-altitude cable, of the material coating cavity; an electromagnetic valve for opening and closing the material outlet is arranged on the material outlet; the waterproof insulating coating material in the material coating cavity is extruded out of the material outlet by a material extrusion material; and a pushing part for enabling the repair apparatus to move forwards along the high-altitude cable through rotation of the rotational body, and a rough grinding part, a fine grinding part and an accurate grinding part for grinding the insulating layer of the high-altitude cable through rotation of the rotational body in sequence, and a uniform coating part for uniformly coating the surface of the high-altitude cable with the waterproof insulating coating material extruded from the material outlet through rotation of the rotational body are arranged one surface, in contact with the high-altitude cable, of the rotationalbody in the length direction in sequence.

Owner:福建礼恩科技有限公司

Cable and wire outer insulating layer repair mold

ActiveCN110518505AEasy to repairPrevent looseningApparatus for repairing insulation/armouring cablesRepair timeEngineering

The invention discloses a cable and wire outer insulating layer repair mold. The structure comprises a repair device, a repair residual material cutting device, a base body, a fixed clamping device, abase and a moving clamping device. The base is fixedly connected with the base body. The repair device and the repair residual material cutting device are arranged on the base body. The fixed clamping device and the moving clamping device are arranged on that base. Compared with the molds in the prior art, the cable and wire outer insulating layer repair mold has the beneficial effects that the cable can be quickly clamped through the combined arrangement of the inner ring, the clamping assembly, the rotating assembly, the fastening sleeve and the U-shaped piece so that the clamping time is short, the efficiency is high, the effect is good, the repair time of the cable insulating layer is shortened, the mold can be adapt to cables with different caliber sizes, the contact area with the cable is large, the clamping degree is high, the cable can be effectively prevented from loosening during chip cutting, the insulating layer is prevented from being cut and the insulating layer can be protected.

Owner:李贺敏

General repair method for cable damage

InactiveCN110601097AEasy to operateFully integratedApparatus for repairing insulation/armouring cablesRepair materialEngineering

The invention discloses a general repair method for cable damage. The method mainly comprises a step of removing an insulation damage section, namely forming an annular insulation repair notch to obtain a cable without the insulation damage section, a step of selecting an insulating layer repairing mold, wherein the diameter of a circular through hole of the mold is equal to that of an insulatinglayer, and the length is larger than that of an insulation damage section, a step of repair the insulating layer, namely placing a cable in the insulating layer repair mold, and enabling the center ofthe insulation damage section to coincide with a center of a middle section through hole of the mold, and a step of starting a mold temperature controller and an injection molding machine to carry out injection molding on the insulation repair notch to obtain a repaired cable. According to the method, various cable insulation damages can be repaired, a repairing material can reach a fine and island-type defect part, the repairing material and an existing insulating layer of the cable are fully melted, the combination is good, the thickness of a repairing layer is consistent and uniform, and the repairing quality is good.

Owner:SOUTHWEST JIAOTONG UNIV

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com