Restoration method of cable used by internal combustion engine traction locomotive and electric power traction locomotive

A repair method and cable technology, which can be used in insulation/armoured cable repair equipment, equipment for connecting/terminating cables, etc., which can solve the problems of high cost of replacing new cables and high requirements for cable reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in detail below in conjunction with specific embodiments.

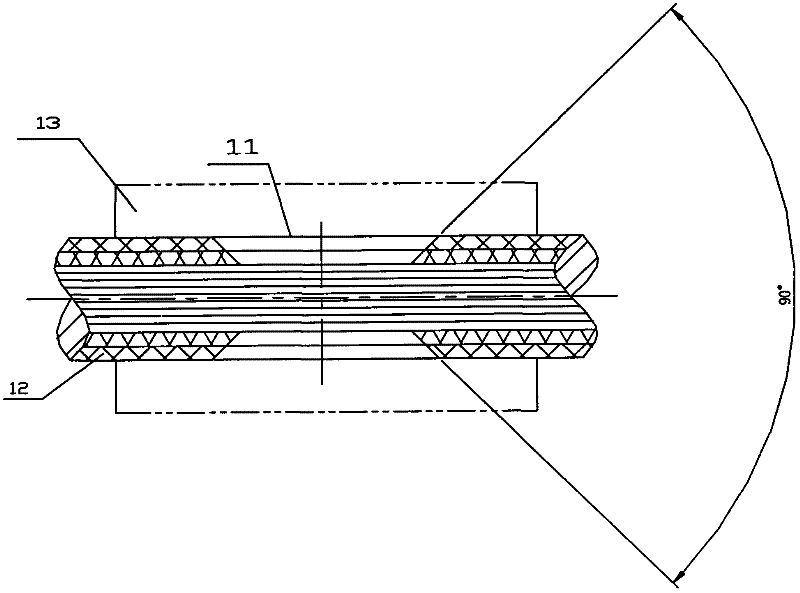

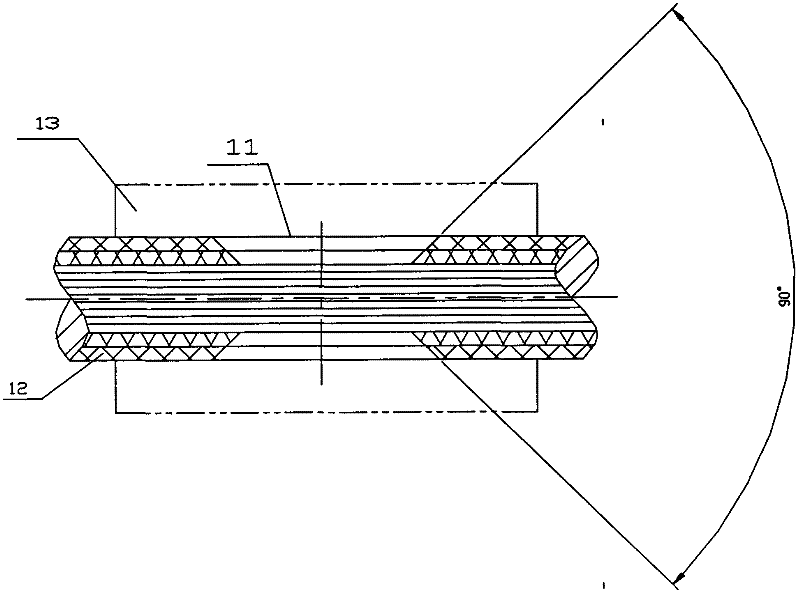

[0016] refer to figure 1 , the old cable flaw detection inspection and insulating rubber failure inspection, first peel off the cable sheath 12 at the grounding and phase failure, clean up the repaired cable, and check to determine how many broken wires the core copper wire has.

[0017] When the number of broken copper wires of the cable core wire exceeds 2 / 3 of the core wire copper wire, it cannot be repaired.

[0018] When the number of broken copper wires of the cable core wire does not exceed 1 / 3 of the core wire copper wire, the core wires with the same cross-sectional area can be used, the core wires are arranged in steps, and the contacts of each core wire are diverged (that is, the contacts are staggered by a certain amount). distance), and mutually equal-length docking.

[0019] Use a knife to cut the cable sheath at both ends of the fault into a 45-degree con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com