Electrified repair device for cross-inked polyethylene power cable and electrified repair method thereof

A cross-linked polyethylene and power cable technology, applied in the direction of insulation/armoured cable repair equipment, etc., can solve the problems of complex internal structure, increase of cable power outage maintenance time, pressure reduction, etc., and achieve low precision and effective Conducive to large-scale promotion and the effect of avoiding gas consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

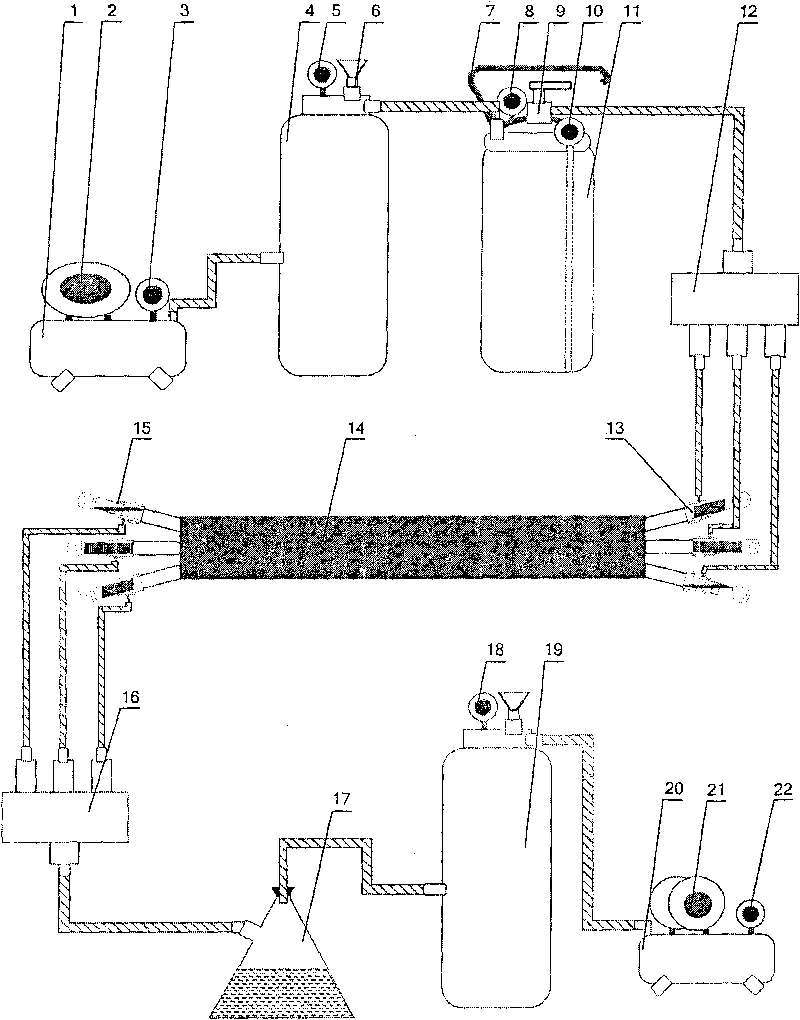

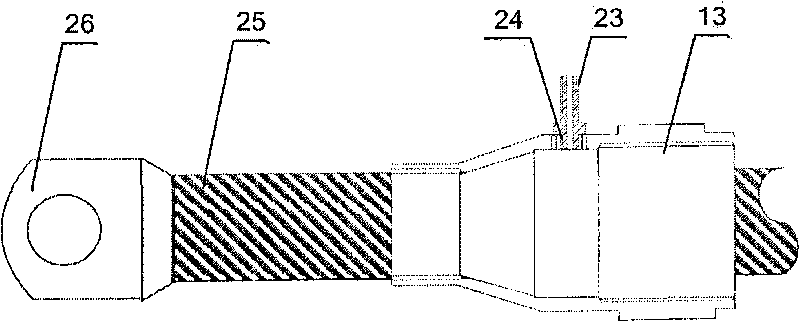

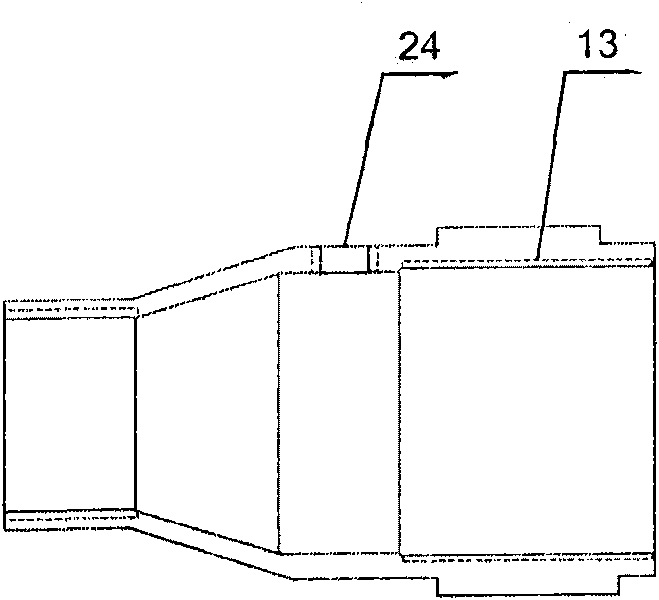

[0038] Cross-linked polyethylene power cable live repair device such as figure 1As shown, the device consists of a repair fluid pressure injection system and a vacuum extraction system. The device also includes repair fluid adapters 13, 15 and taps 12, 16 at both ends of the cable. The repair fluid adapter 13 at one end of the cable connects with the tap 12. The repair fluid pressure injection system is connected, and the repair fluid adapter 15 at the other end of the cable is connected to the vacuum extraction system through a tap 16. The repair fluid pressure injection system is sequentially composed of an air compressor 1, a gas suction tank 4, a repair liquid tank 11 and a branch The joint 12 is connected with the repair fluid adapter 13; the vacuum extraction system is sequentially connected by the repair fluid adapter 15, the tap 16, the remaining liquid collection bottle 17, the filter tank 19, and the vacuum aspirator 20.

[0039] An air tank, a compressor 2, and a pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com