Repairing liquid injection system for cross-linked cable

A technology for injecting systems and cross-linked cables, which is applied in the direction of insulation/armored cable repair equipment, cable installation, cable installation devices, etc., and can solve hidden dangers, inability to guarantee quality, repair fluid pressure, injection speed, and injection volume There are no problems such as control and display design to achieve the effect of guaranteeing the injection quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

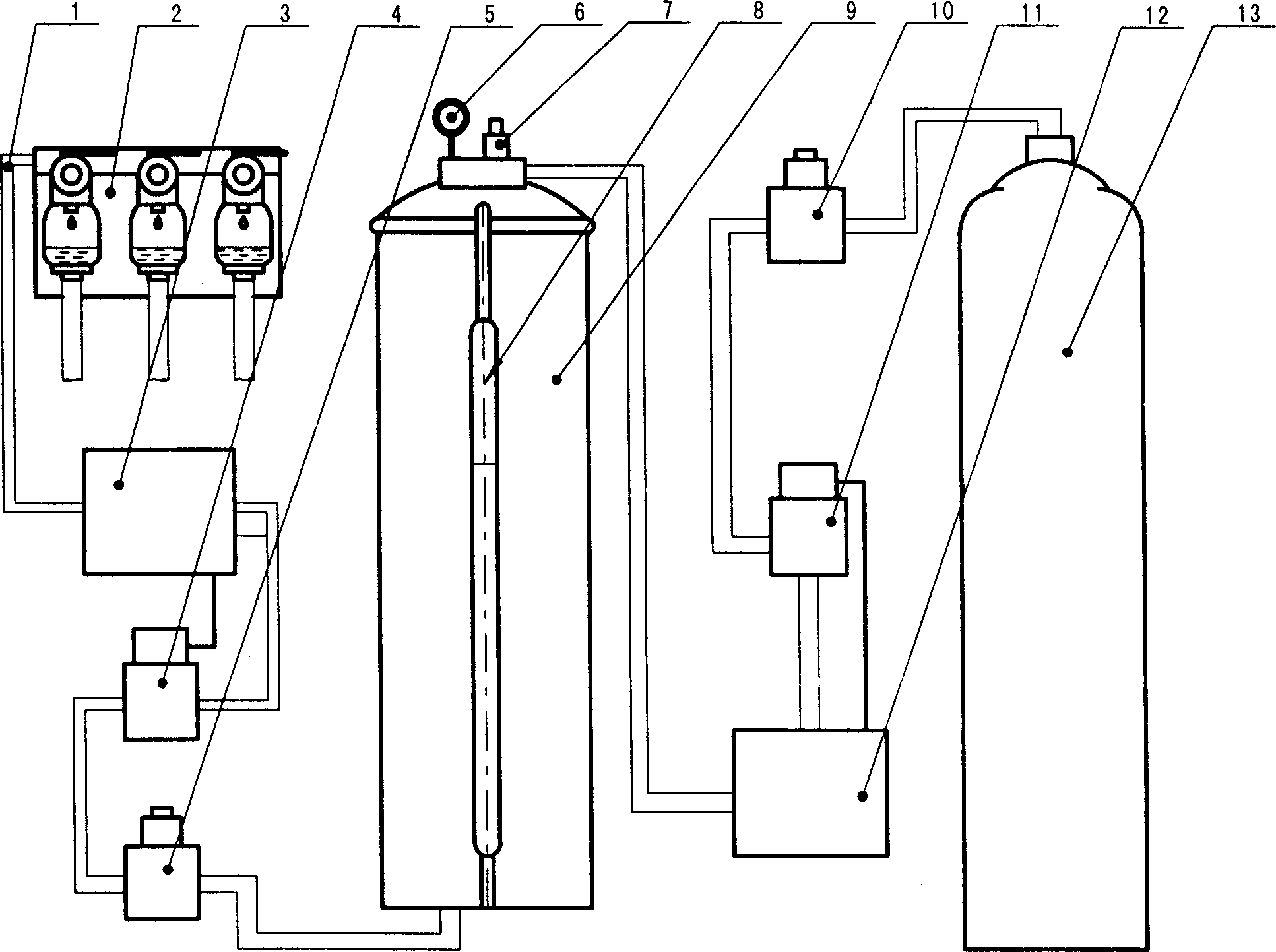

[0018] Embodiments of the present invention are described in further detail below in conjunction with the accompanying drawings:

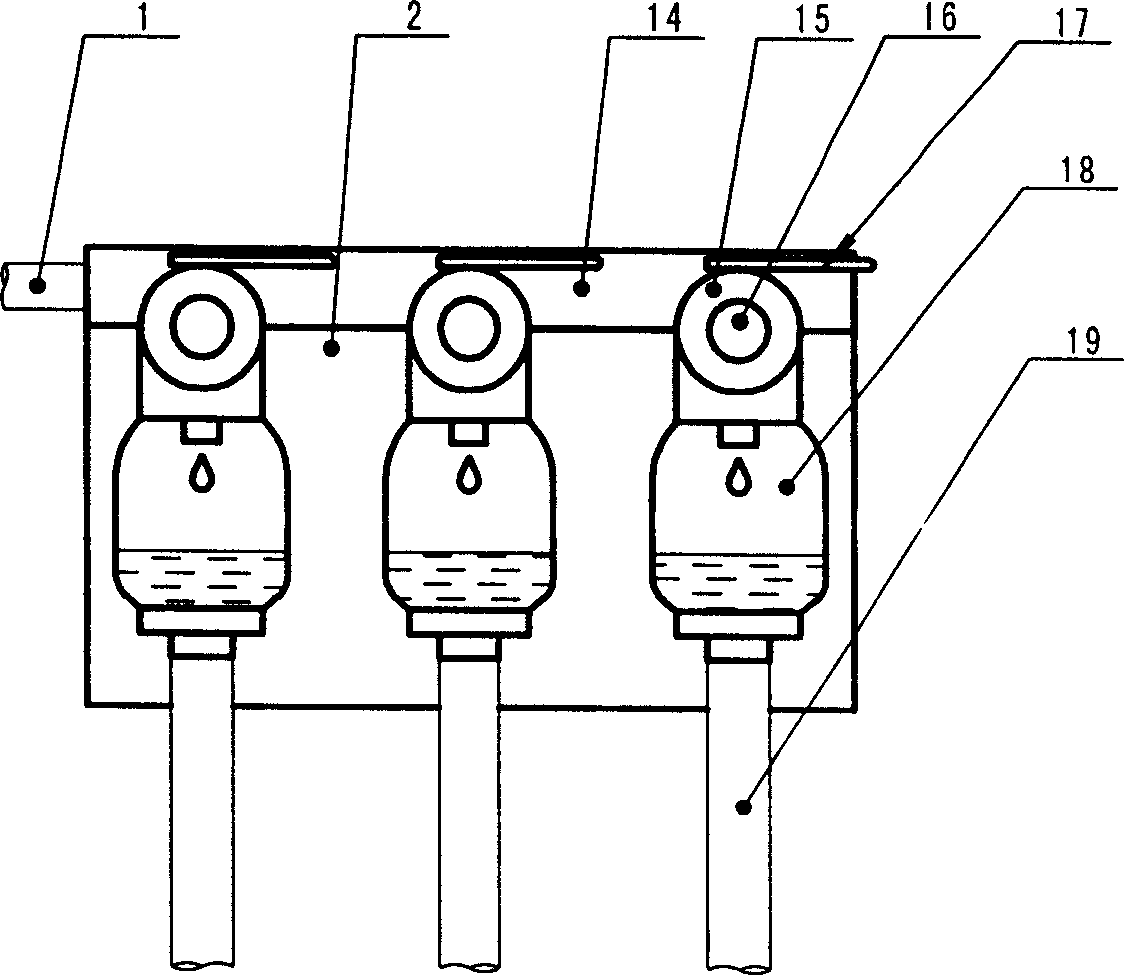

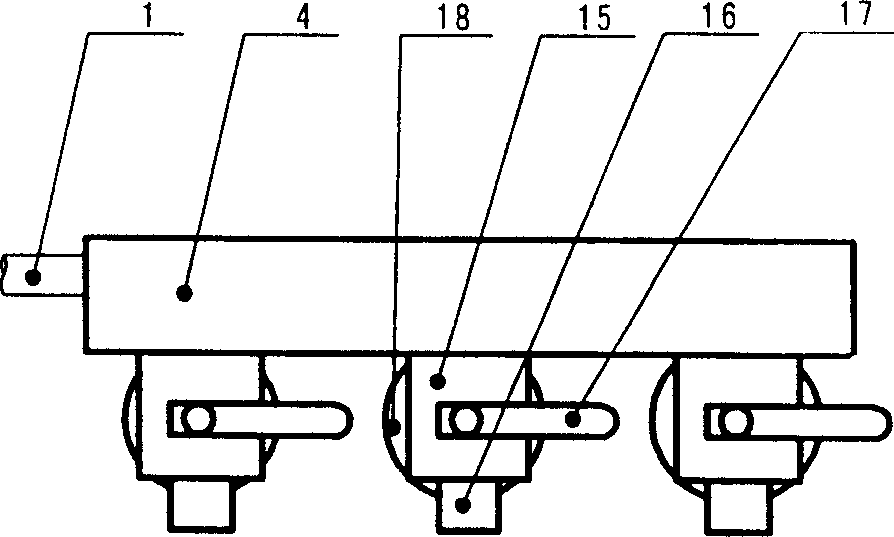

[0019] The cross-linked cable repair liquid injection system is composed of a gas pressure tank 13, a repair liquid tank 9, a connecting pipeline 1, and a liquid outlet pipe 19, and the connecting pipelines between the gas pressure tank and the repair liquid tank are respectively installed with limited A pressure valve 10, an electromagnetic switch valve 11 and a pressure sensor 12 are connected through connecting pipelines among several devices. The pressure gas contained in the pressure gas tank is nitrogen or inert gas, and this type of gas has no other side effects on the electric field generated in the insulator. A pressure limiting valve 5, an electromagnetic switch valve 4, a pressure sensor 3 and a liquid flow distribution plate 2 are respectively installed in sequence on the connection pipeline between the repair liquid tank and the liquid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com