Well bottom shearing foam maker for foam combination flooding

A foamer and foam technology, applied in mixers, mixing methods, wellbore/well components, etc., can solve problems such as defoaming and foam breaking that cannot be overcome, and achieve convenient use and operation, enhanced recovery, and operation simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with accompanying drawing:

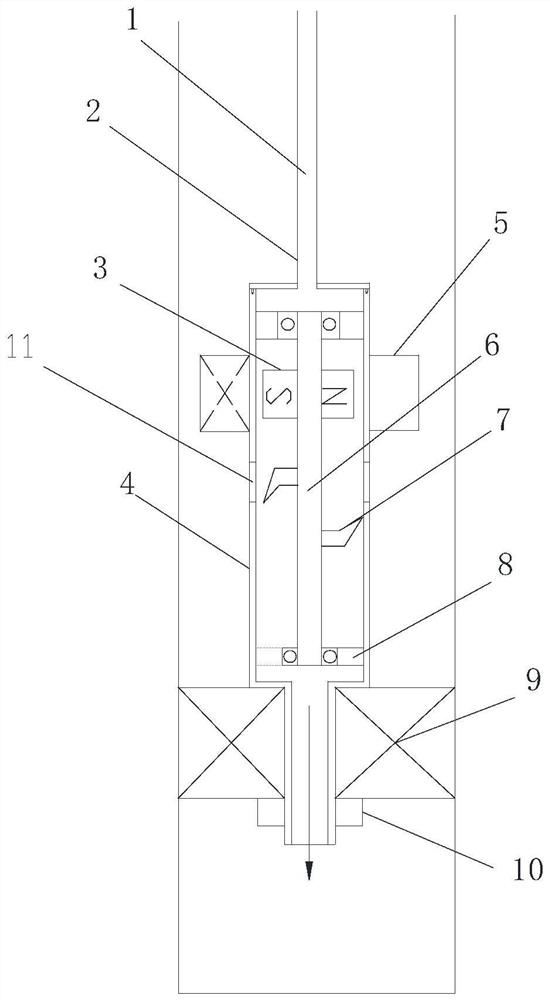

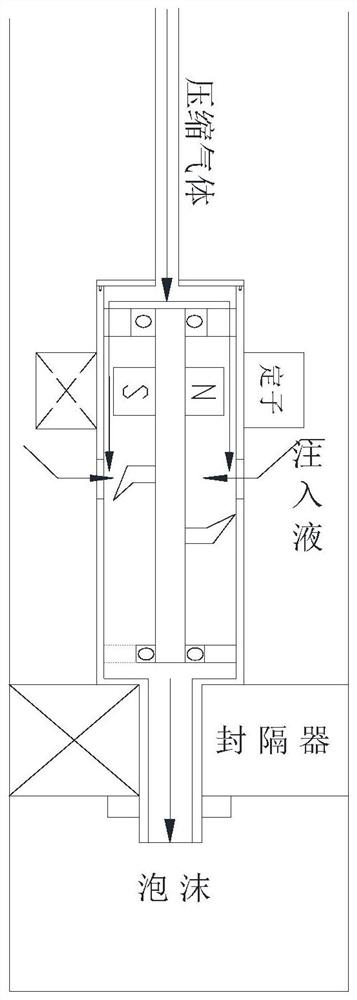

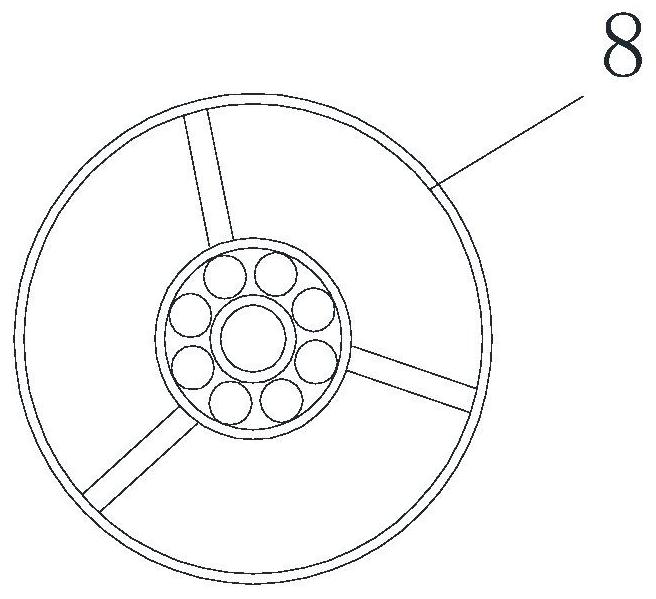

[0017] as attached figure 1 As shown, a bottom hole shearing foamer for foam composite flooding includes a shearing foamer 4, the upper and lower parts of the shearing foamer 4 are two circular steel drum shells with different diameters, and the upper circular steel The diameter of the barrel shell is larger than the diameter of the lower circular steel barrel; the upper and lower ends of the upper steel barrel shell are respectively provided with an inlet end cover and a lower outlet, and the inlet end cover of the shear foamer 4 and the inlet pipeline 2 are threaded Connected, the compressed gas 1 is passed into the intake pipeline; the upper part of the outlet of the lower part of the shear foamer 4 is fixed with a bearing support frame 8, and the center hole of the bearing support frame 8 is fixedly connected to the bearing 6, such as image 3 As shown, several connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com