Flexible surface layer fabricated soil nail wall structure for foundation pit slope and construction method of flexible surface layer fabricated soil nail wall structure

A flexible surface and assembled technology, which is applied in the direction of foundation structure engineering, excavation, sheet pile wall, etc., can solve the problems of weak force at nodes, unclear force mechanism, waste of building materials, etc., so as to achieve little impact on the surrounding environment, The effect of convenient construction and fast progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

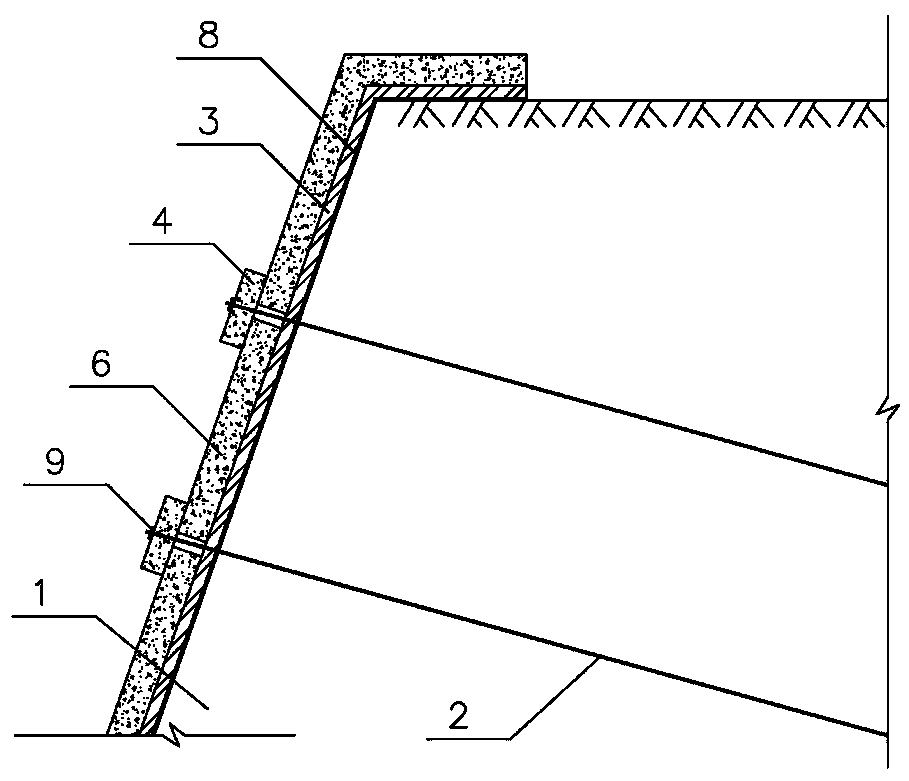

[0045] Embodiment 1, the construction method of the flexible surface layer assembled soil nail wall structure of the foundation pit slope, includes the following steps.

[0046] Step 1, excavating and repairing the side slope 1 of the foundation pit.

[0047] Step 2, accurately locate the position of the first layer of soil nails 2, and construct the first layer of soil nails 2.

[0048] Step 3, laying the flexible surface layer 3 from top to bottom.

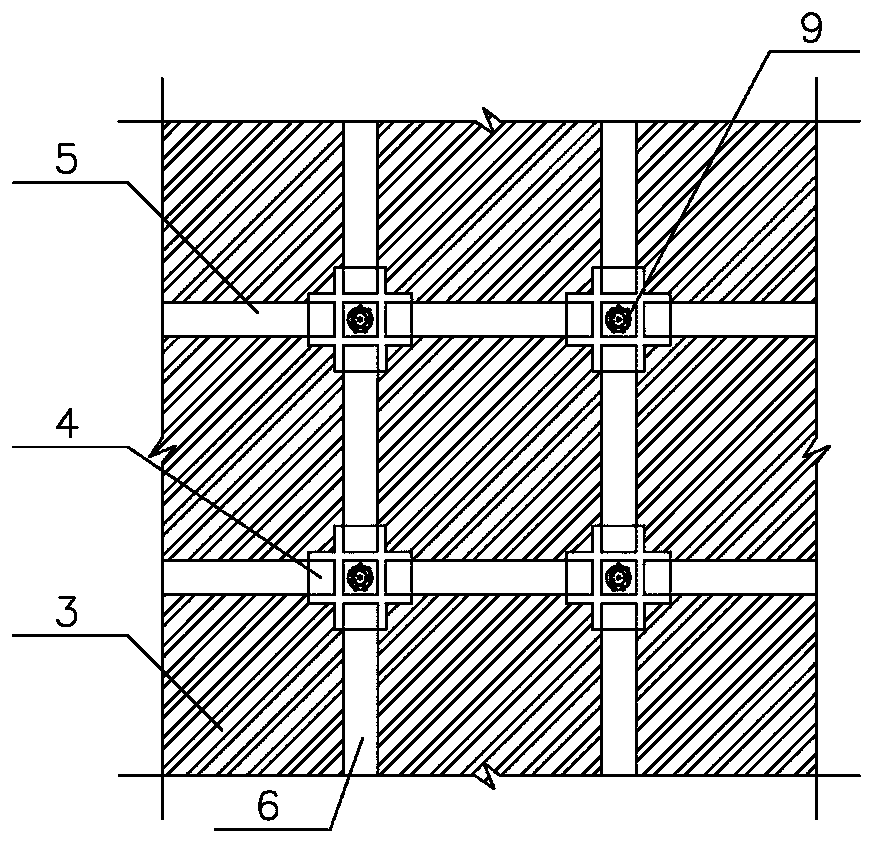

[0049] Step 4, arrange horizontal beams 5 and inclined beams 6 around each soil nail 2 in the first layer of soil nails 2 .

[0050] Step 5, install the prefabricated connector 4 at the position of each soil nail 2 in step 4, and press the lateral side 4.1.1 of the prefabricated connector 4 on the outer surface of the horizontal beam 5, and the vertical The edge 4.1.2 is pressed on the outer surface of the inclined beam 6 .

[0051] In step six, the anchor 9 is used to lock the soil nail 2, and the prefabricated connector 4 i...

Embodiment 2

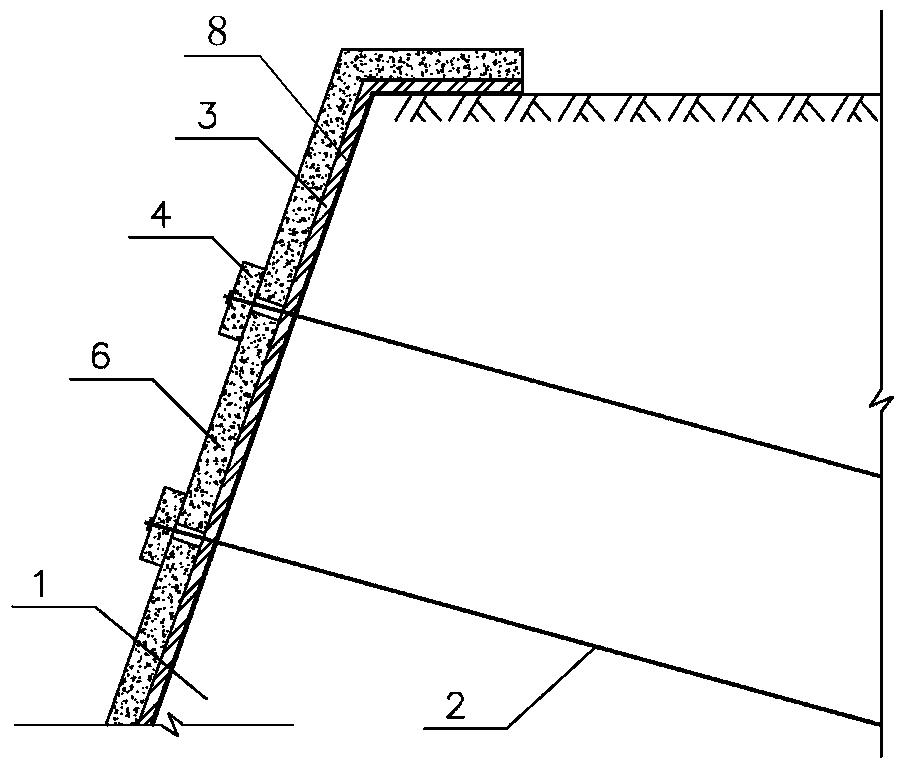

[0055] Embodiment 2, the construction method of the flexible surface layer assembled soil nail wall structure of the foundation pit slope, includes the following steps.

[0056] Step 1, excavating and repairing the side slope 1 of the foundation pit.

[0057] Step 2, laying the flexible surface layer 3 from top to bottom.

[0058] Step 3, arrange horizontal beams 5 and inclined beams 6 around each soil nail 2 in the first layer of soil nails 2 .

[0059] Step 4, install the prefabricated connecting piece 4 at the position of each soil nail 2 in step 4, and press the lateral side 4.1.1 of the prefabricated connecting piece 4 on the outer surface of the horizontal beam 5, and the vertical The edge 4.1.2 is pressed on the outer surface of the inclined beam 6 .

[0060] Step five, accurately locate the position of the first layer of soil nails 2, and construct the first layer of soil nails 2.

[0061] In step six, the anchor 9 is used to lock the soil nail 2, and the prefabrica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com