General repair method for cable damage

A repair method and technology for cable damage, applied in the direction of insulation/armored cable repair equipment, etc., can solve the problems of high repair cost, troublesome operation, electrical corrosion of materials, etc., and achieve the effect of wide application range, convenient operation and firm combination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

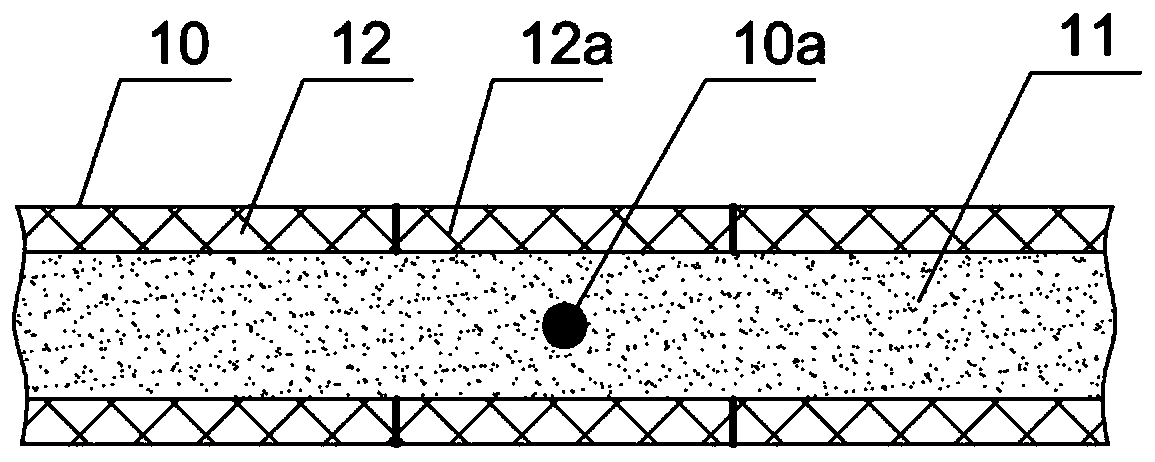

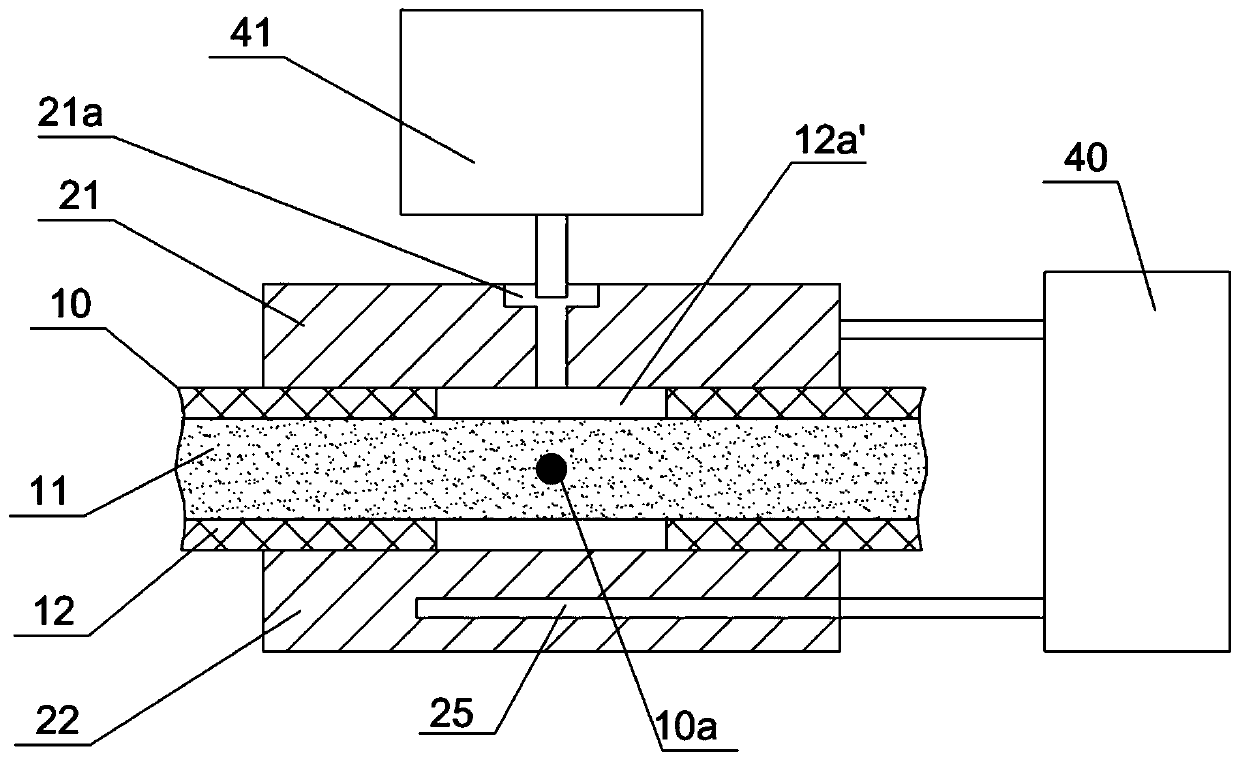

[0058] Figure 1-3 It shows that the first specific implementation of the present invention is: a general repair method for cable damage, the cable 10 is composed of a conductor 11 in the center and an insulating layer 12 outside the conductor 11; the general repair method, the steps of which are:

[0059] A. Removal of insulation damage section

[0060] Use a leakage detector to measure the center position and length of the insulation damage section 12a where the insulation damage part of the cable 10 is located, and record the center position as the repair center 10a of the cable, and then remove the insulation damage section 12a to form an insulation repair gap 12a ', get the cable 10 with the insulation damaged section removed;

[0061] B. Selection of insulation layer repair mold

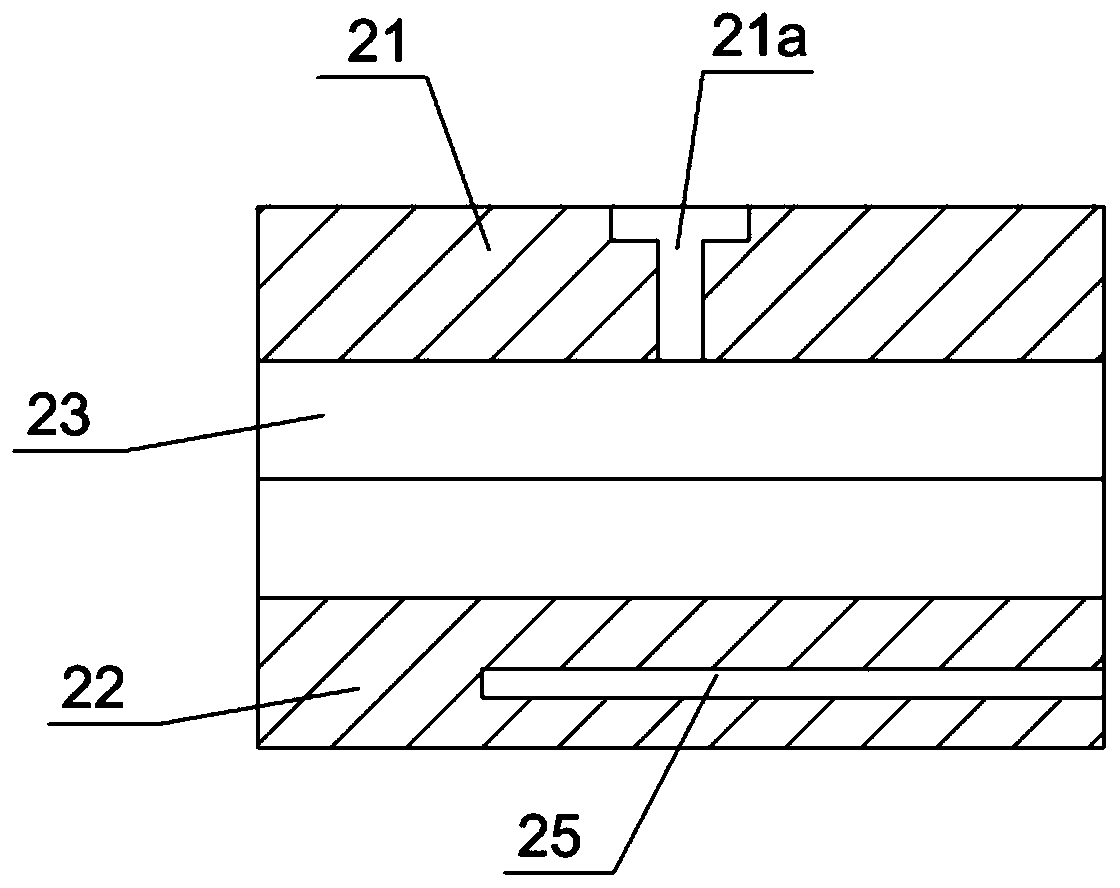

[0062] Select the insulating layer repair mold that is made of upper mold base 21, lower mold base 22 for use, form circular through-hole 23 between described upper mold base 21, lower mold ...

Embodiment 2

[0069] figure 1 , 4 , 5 show that the second embodiment of the present invention is basically the same as the method of Example 1, the difference is only: the two ends of the circular through hole 23 of the selected insulating layer repair mold are also provided with a diameter larger than the insulating layer. Large via hole 24 of layer 12 diameter.

Embodiment 3

[0071] Figure 6-10 It shows that the third specific implementation of the present invention is: a general repair method for cable damage, the cable 10 is composed of a central conductor 11, an insulating layer 12 outside the conductor 11, and a sheath outside the insulating layer 12. Cover layer 13 is formed; Described general restoration method, its steps are:

[0072] a. Removal of insulation damage section and sheath layer

[0073] Use a leakage detector to measure the center position and length of the insulation damage section 12a where the insulation damage part of the cable 10 is located, and record the center position as the repair center 10a of the cable, and then remove the sheath layer 13 outside the insulation damage section 12a , the removed sheath layer is recorded as the removed sheath section 13a, and then the insulation damage section 12a is removed to form an insulation repair gap 12a'; and the length of the removed sheath section 13a is greater than the len...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com