Patents

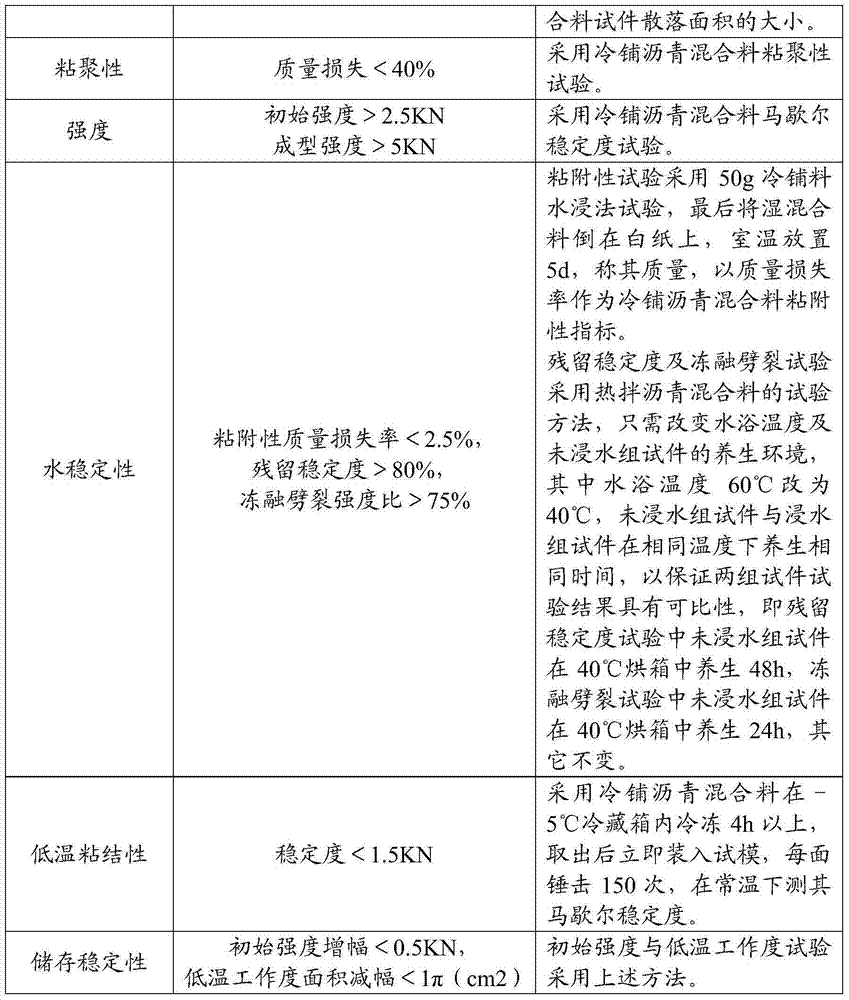

Literature

228results about How to "Improve repair quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

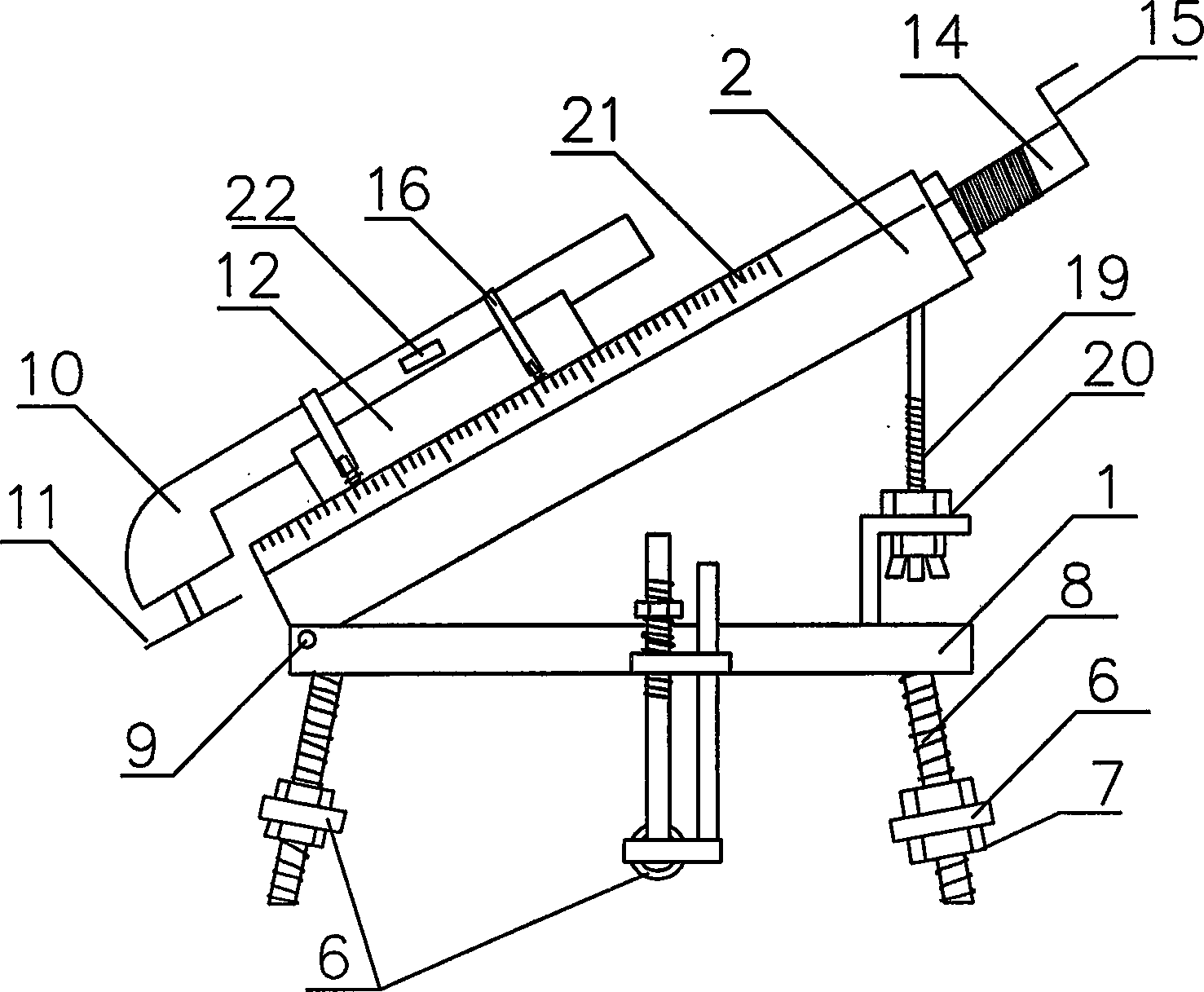

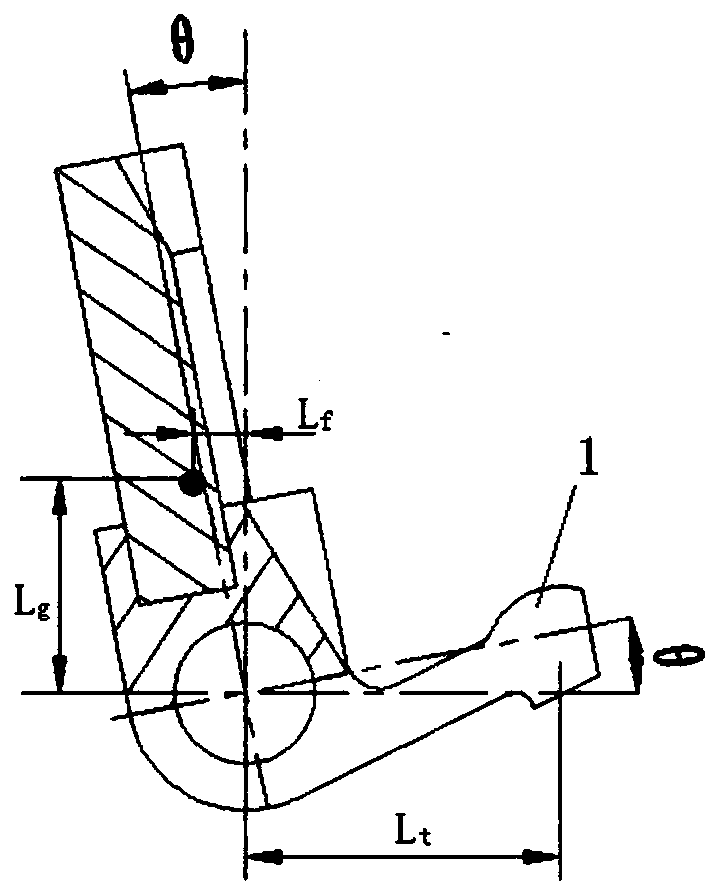

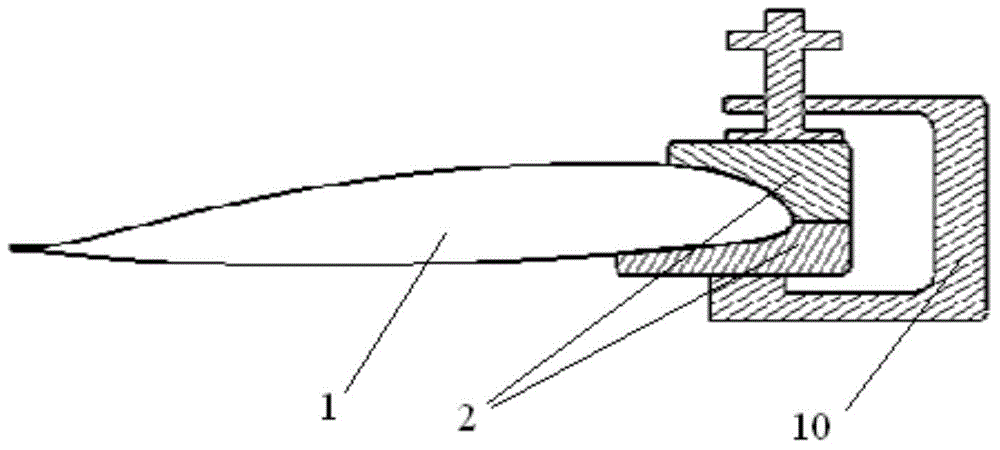

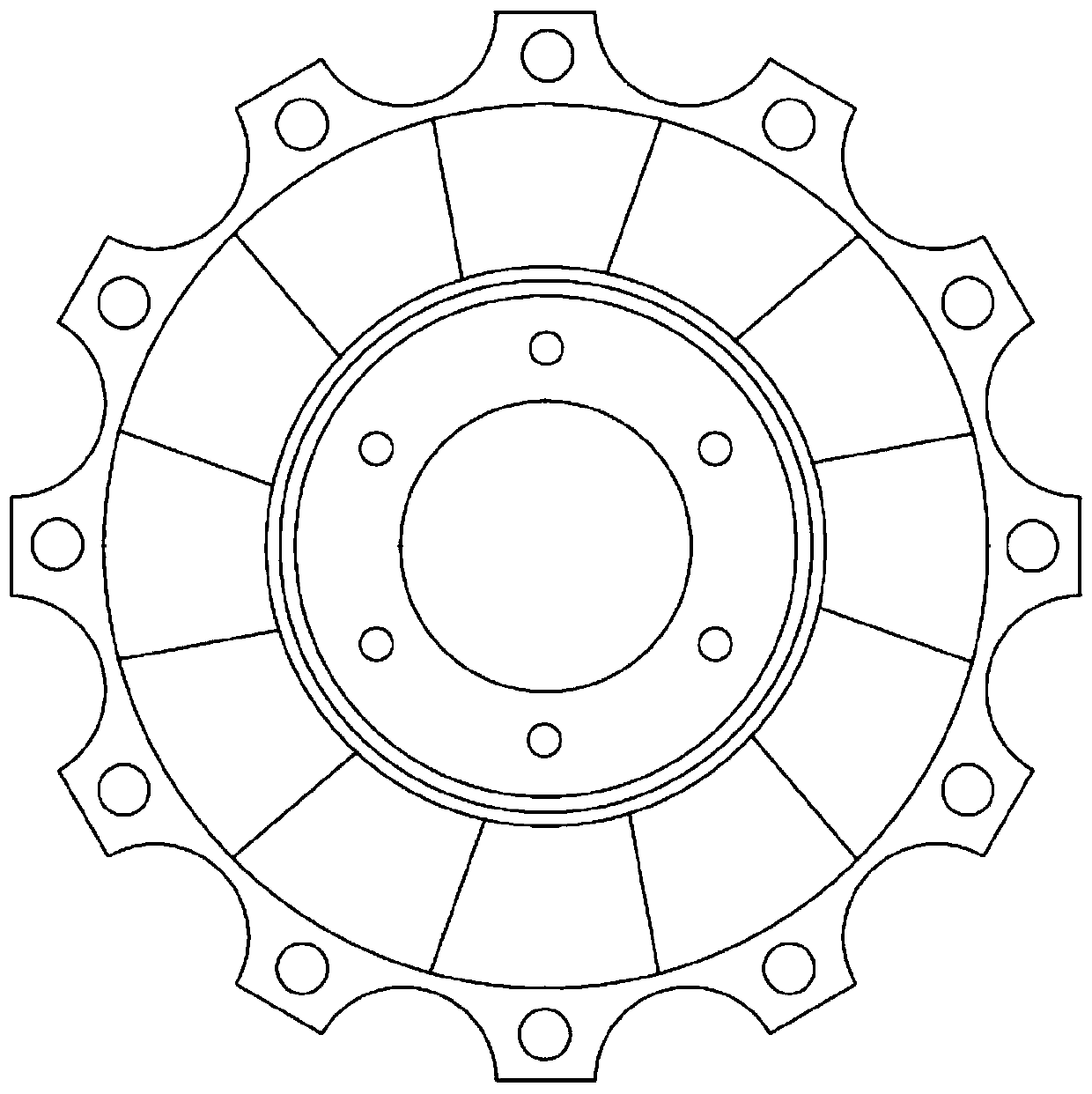

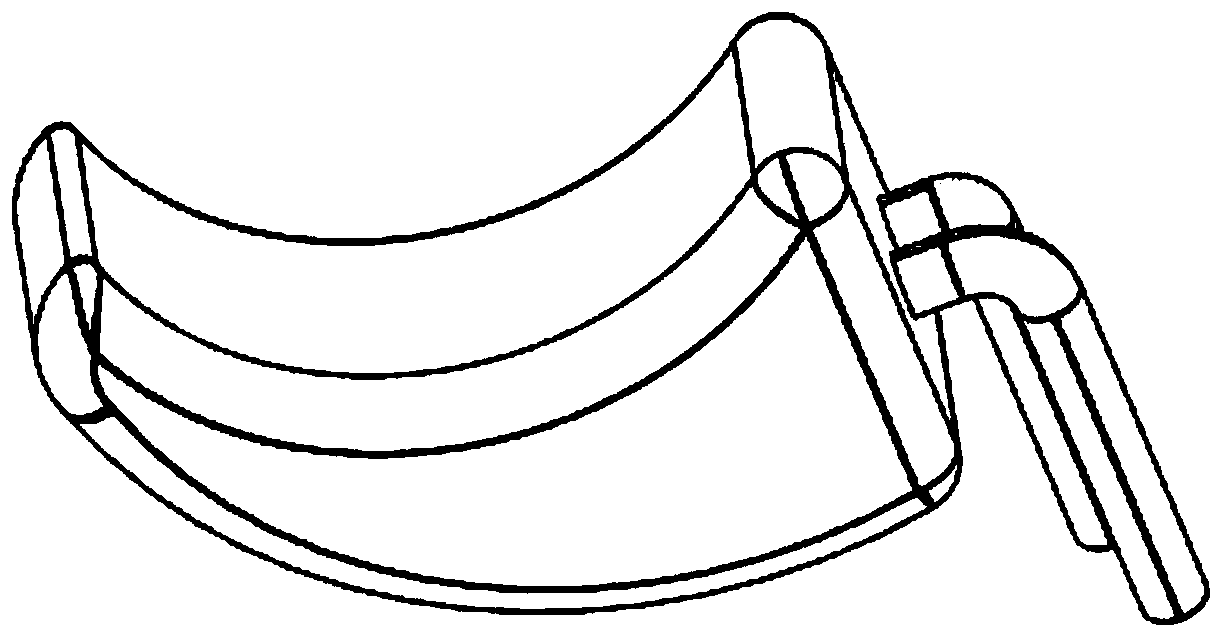

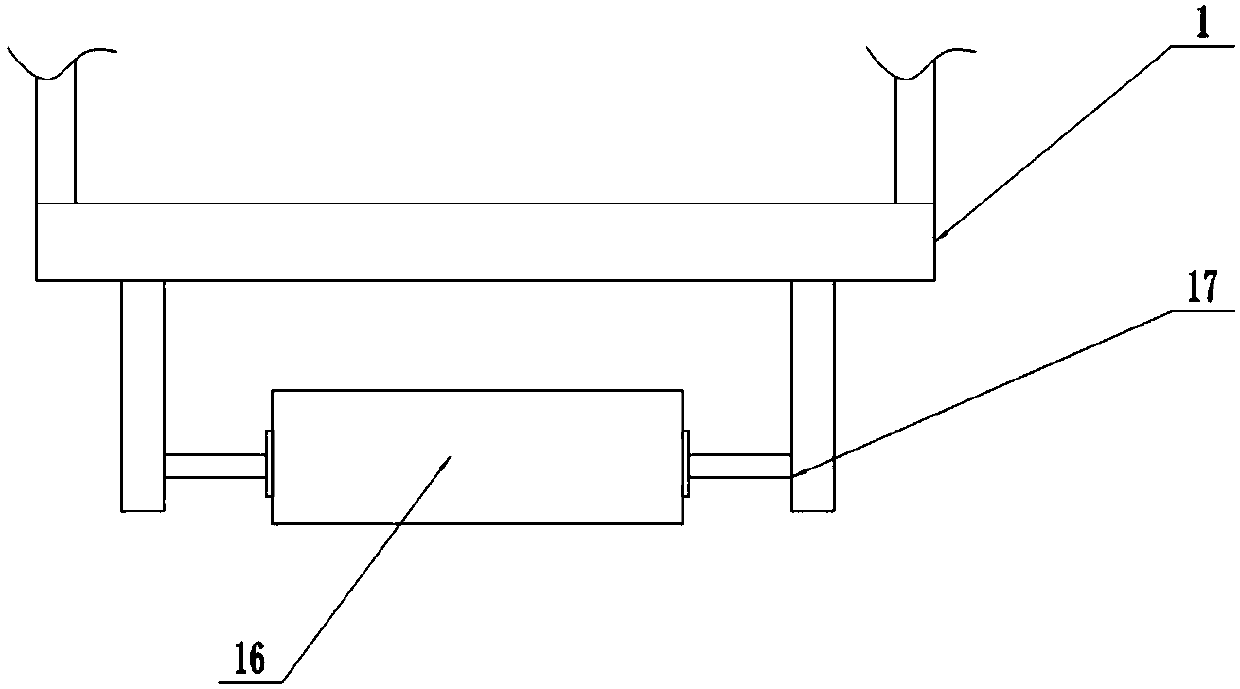

Technique for repairing surface damage on piston rod of hydraulic ram, and dedicated repairing tools

InactiveCN1872488AQuick fixQuick repairSpherical surface grinding machinesArc welding apparatusHydraulic cylinderHydraulic ram

A technology for repairing the surface damage of piston rod for hydraulic cylinder includes such steps as treating the surface at damaged position, build-up welding for filling the damaged recess, grinding and polishing. Its repair tool is composed of the hinged slide frame and grinding frame, an electric grinder with grinding wheel and fixed to the said grinding frame and a clamping arm with roller and arranged on said slide frame.

Owner:崔学斌

Carburization-like overloading tooth component tooth surface laser cladding powder material and repairing method thereof

InactiveCN101100746AImprove repair qualityImprove performanceMetallic material coating processesLaser beam welding apparatusLaser power densityAlloy

A process for laser powder-melting onto the surfaces of the teeth parts that are of heavily loaded cemented steel to be repaired is disclosed herewith. The powder of grains = (-140-+260 mesh) comprises (mass%): C 0.80-1.10, Mn 7.50-9.00, Cr 0.90-1.30, Mo 0.20-0.35, B 2.00-3.50, Si 2.50-3.50, and balanced with Fe with impurities of P not more than 0.06 and S not more than 0.04. Laser power density is equal to 1.0 X 108W-109W / m2 per unit of time. The said powder has good re-melting property, self-enhancing and fatigue-resistance performances, so that it can be used to repair worn gears.

Owner:ACADEMY OF ARMORED FORCES ENG PLA

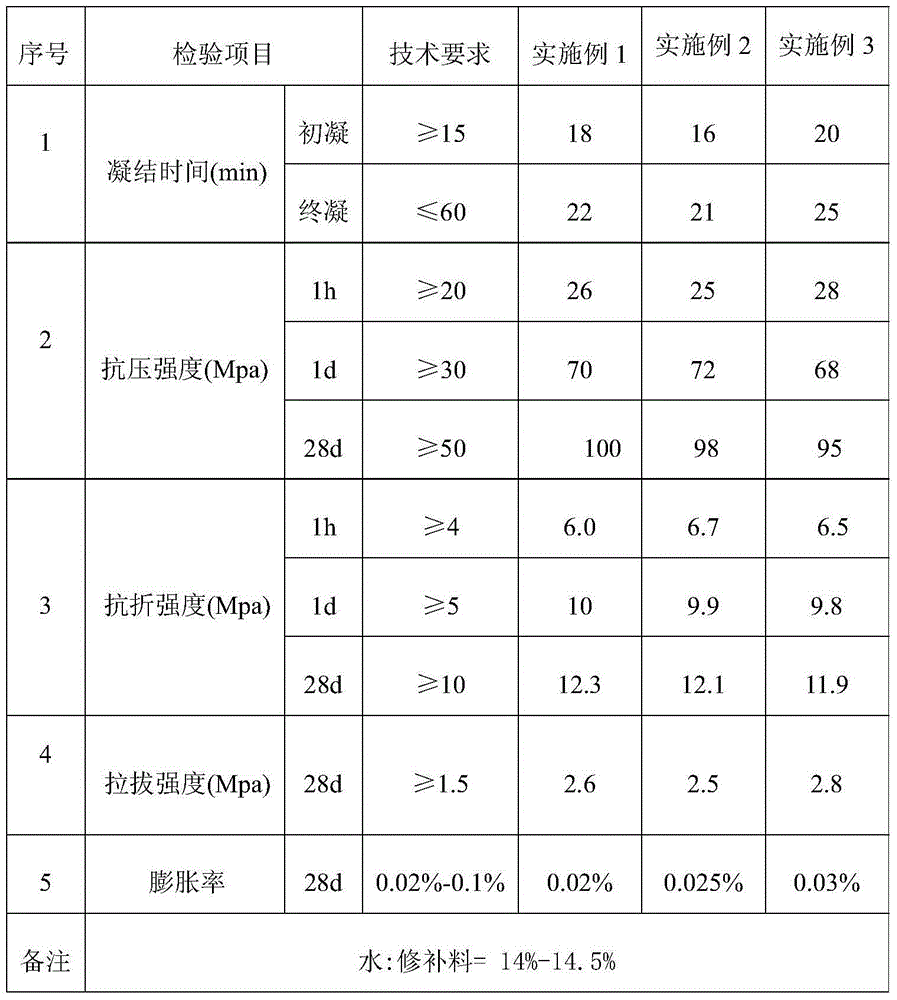

Pavement/bridge deck concrete fast mending material and application thereof

The invention relates to a pavement / bridge deck concrete fast mending material and application thereof. The mending material comprises the following raw materials by weight: 20 to 30 parts of sulphoaluminate cement, 8 to 10 parts of ordinary Portland cement 52.5, 5 to 10 parts of polymer powder, 0.5 to 1.5 parts of aluminium sulphate, 1 to 2 parts of water glass, 0.1 to 1 part of organic silicon, 1 to 2 parts of gypsum, 2 to 3 parts of slag, 0.1 to 0.5 part of silica micropowder, 0.5 to 1 part of an HPCA high-performance concrete expansive material, 3 to 5 parts of fly ash, 20 to 30 parts of washed-out and dried sand, 25 to 30 parts of corundum, 3 to 5 parts of composite fiber, 1 to 3 parts of a polycarboxylate superplasticizer, 0.1 to 0.5 part of boric acid, 0.1 to 0.3 part of sodium gluconate, and 0.2 to 1 part of lithium carbonate. The mending material is high in early strength, and has the advantages that traffic can be opened fast only 1 to 2 hours after mending is completed, so as to reduce traffic jams, and effectively reduce the generation of traffic accidents.

Owner:HENAN HUINENG ROAD & BRIDGE TECH CO LTD

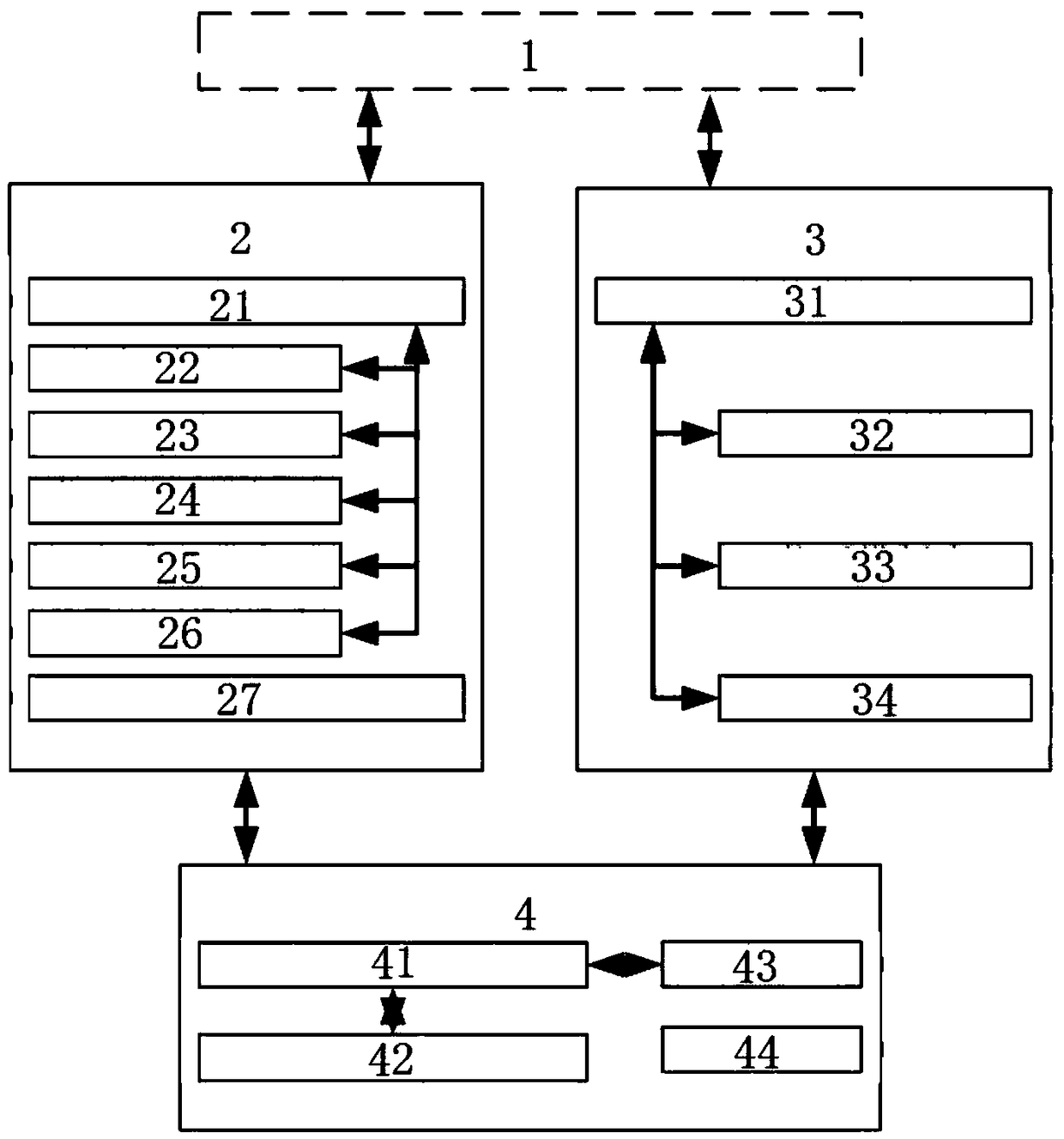

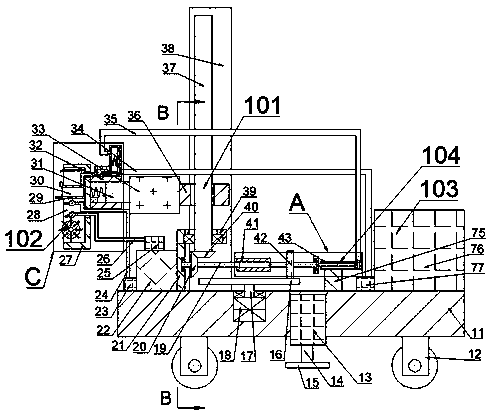

Ground comprehensive debugging verification platform for avionic flight control system

ActiveCN108983756ACross-link control implementationEasy to operateElectric testing/monitoringCombined testInteraction control

The invention relates to a ground comprehensive debugging verification platform for an avionic flight control system, and the platform comprises an avionic testing system for testing and simulation, aflight control testing system for simulating a real operation environment, and a crosslinking control system which enables the avionic testing system and the flight control testing system to be in interactive connection. The platform completes the comprehensive testing of the avionic system and flight control system of a tested object. The platform can be used for testing and maintenance of the avionic system and flight control system of an airplane, improves the comprehensive control and interaction control capability of the system, and improves the operability, test real-time responsiveness, test visuality and interaction of the verification platform.

Owner:国营芜湖机械厂

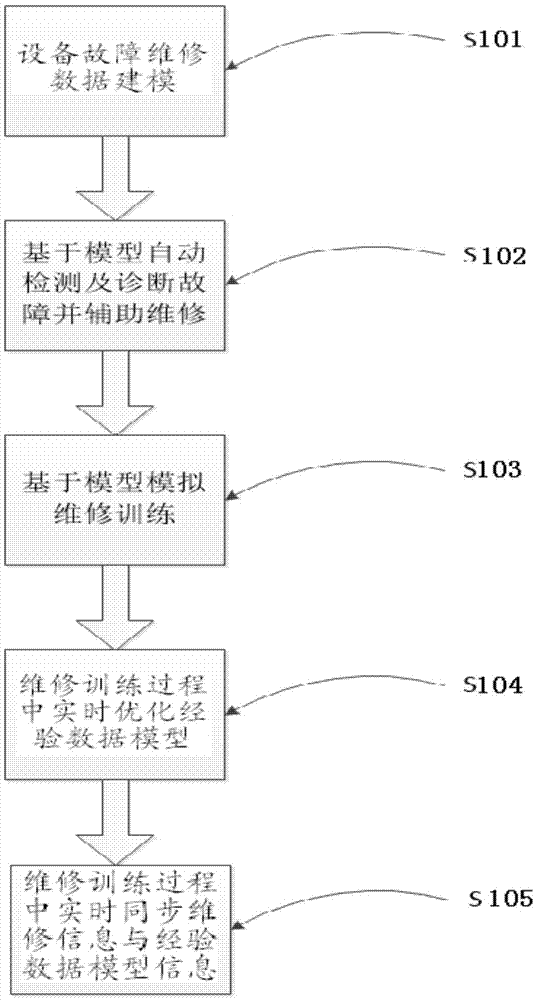

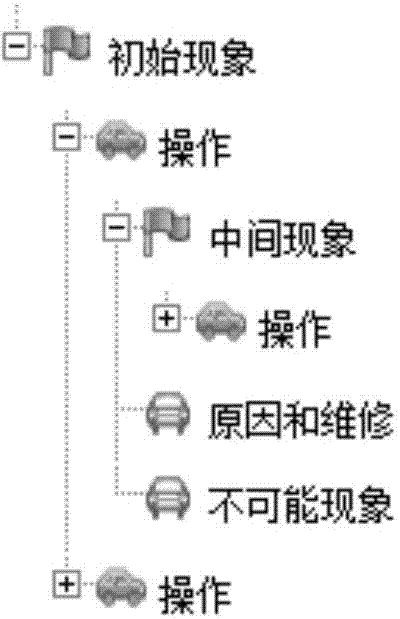

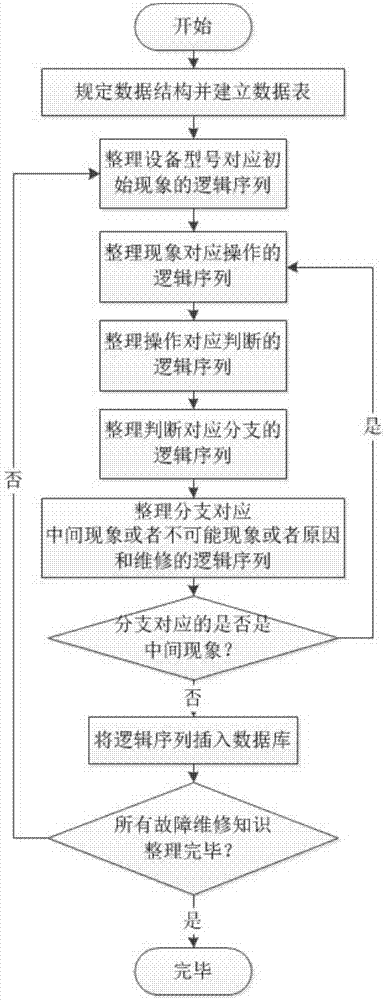

General fault detecting and maintenance method for equipment

InactiveCN103617576ARealize accumulationAchieve sharingDetecting faulty computer hardwareForecastingMaintenance strategySimulation training

The invention discloses a general fault detecting and maintenance method for equipment. The general fault detecting and maintenance method for the equipment comprises the following steps of carrying out modeling on maintenance knowledge of the equipment faults, automatically detecting and diagnosing the faults and carrying out auxiliary maintenance based on a model, simulating maintenance training based on the model, optimizing an experience knowledge model in real time in the maintenance training process, and synchronizing maintenance information and experience knowledge model information in the maintenance training process. Compared with an existing equipment maintenance method, the general fault detecting and maintenance method for the equipment enables the accumulation and the sharing of equipment maintenance experience knowledge and the automatic diagnosis of equipment faults to be achieved, and assistance can be provided for related maintenance strategies through the analysis and the exploitation of the maintenance record information. In addition, effective transmission of the experience of experts to primary maintainers is achieved through the step of simulation training. The general fault detecting and maintenance method for the equipment is especially suitable for chemical defense troops and other occasions where a large amount of complex equipment needs to be maintained frequently and where the turnover rate of maintenance personnel is high. Practice proves that the general fault detecting and maintenance method for the equipment can obvious improve equipment maintenance efficiency, promote maintenance levels and improve maintenance quality.

Owner:NANJING UNIV +1

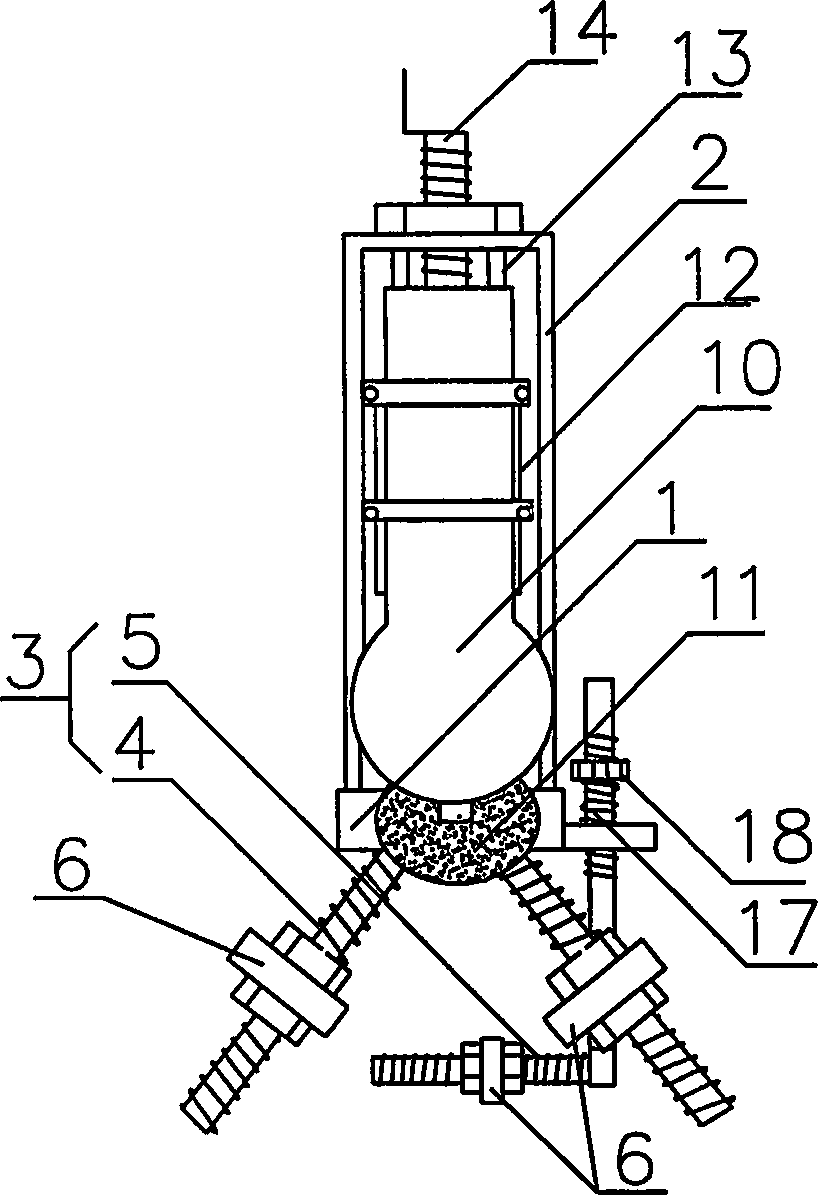

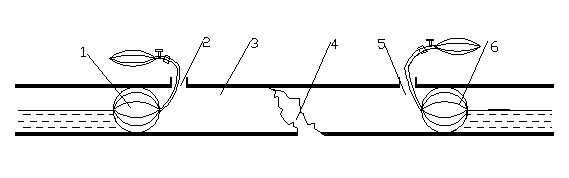

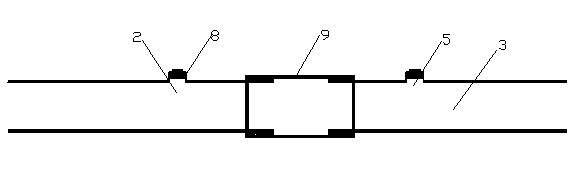

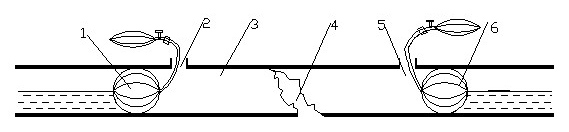

Under-water leakage blocking and repairing method of exterior line pipeline

The invention discloses an under-water leakage blocking and repairing method of an exterior line pipeline and belongs to a pipeline repairing method. The method is characterized in that the left position and the right position at the outer side of the damaged position of a pipeline are respectively provided with a threaded hole; the left threaded hole and the right threaded hole are big enough for a contracted rubber ball to be inserted; uninflated rubber balls are respectively plugged into the pipeline from each threaded hole; then, the uninflated rubber balls are inflated to seal the inner cavity of the pipeline so as to block water flow; and then the pipeline is repaired in a welding or bellmouth connecting mode to finish the repair work of the under-water leakage blockage of the pipeline. The under-water leakage blocking and repairing method of the exterior line pipeline is convenient to use and is low in cost, repairing time is shortened, and the working efficiency and the pipeline repairing quality are improved.

Owner:CHINA MCC17 GRP

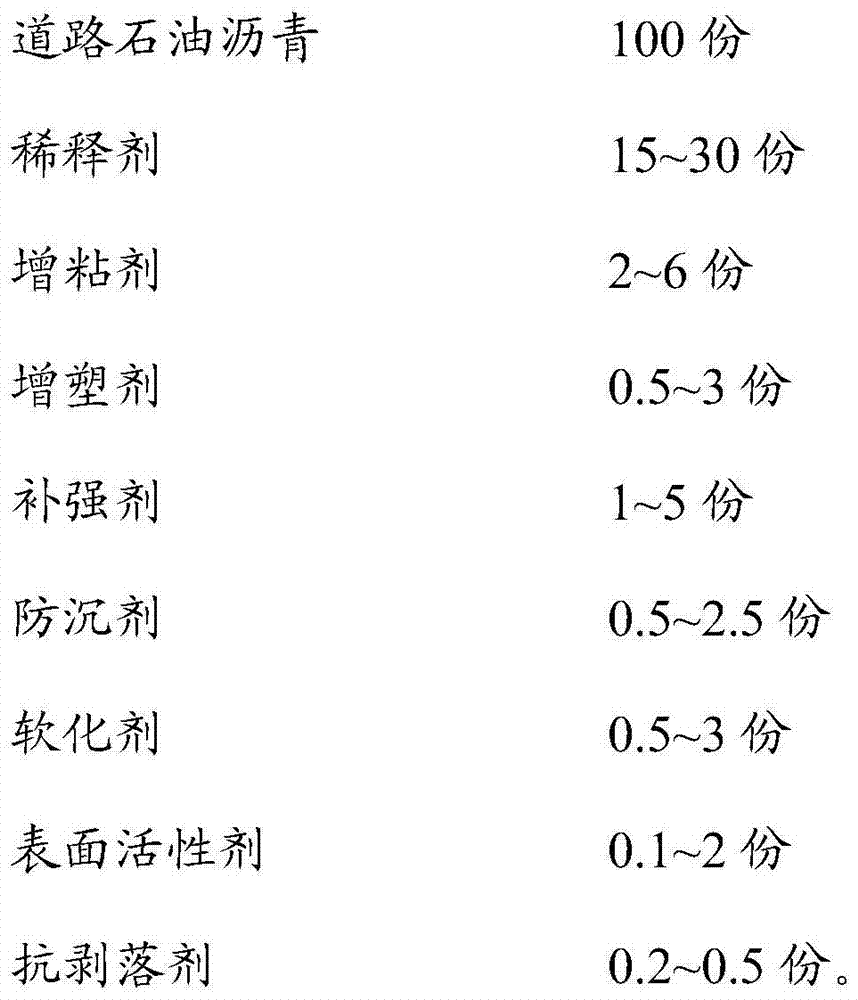

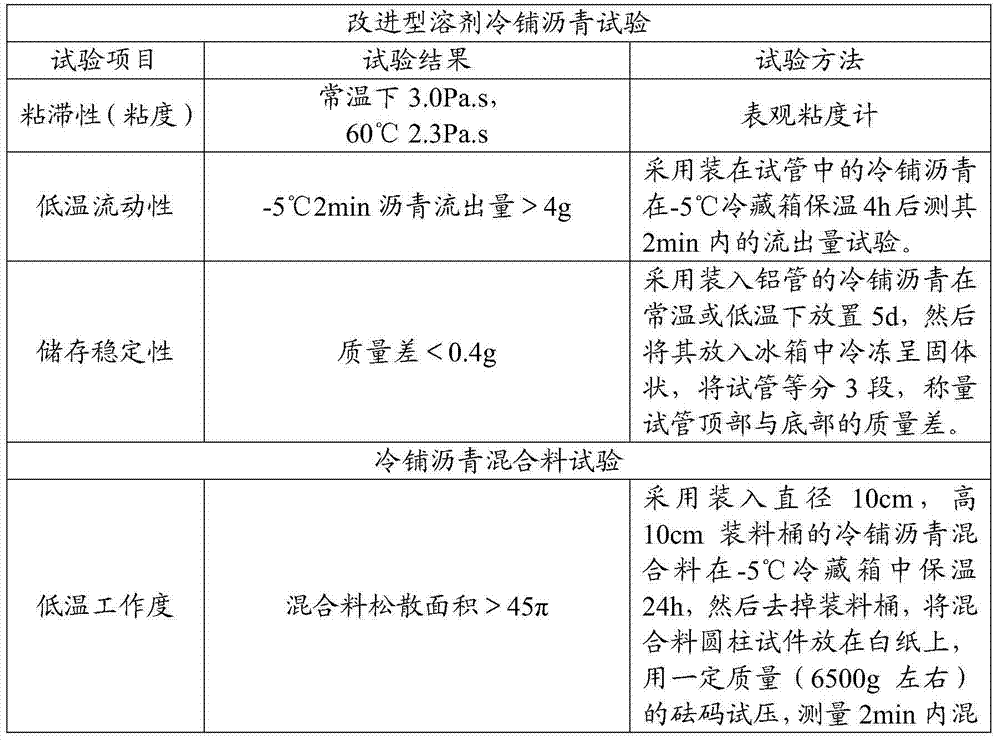

Improved solvent cold laid asphalt as well as preparation process and using method thereof

InactiveCN103923475AImprove adhesionImprove liquidityIn situ pavingsBuilding insulationsLiquid stateEngineering

The invention discloses an improved solvent cold laid asphalt as well as a preparation process and using method thereof. The improved solvent cold laid asphalt is at a liquid state under normal temperature or low temperature; cold oil and cold materials can be directly blended for construction on the spot without heating, and the construction can be carried out at high / low temperature seasons and rain / snow weather, and a large number of machinery and labor are not required in the construction process, the construction is simple and convenient and the repair effect is good; traffic can be immediately opened after repair without affecting the travel of people; the improved solvent cold laid asphalt is usually used for daily maintenance, such as pot slot repair and emergency repair; meanwhile, the improved solvent cold laid asphalt has the advantages of no deterioration, no layering and the like after being stored for a long time.

Owner:CHANGAN UNIV

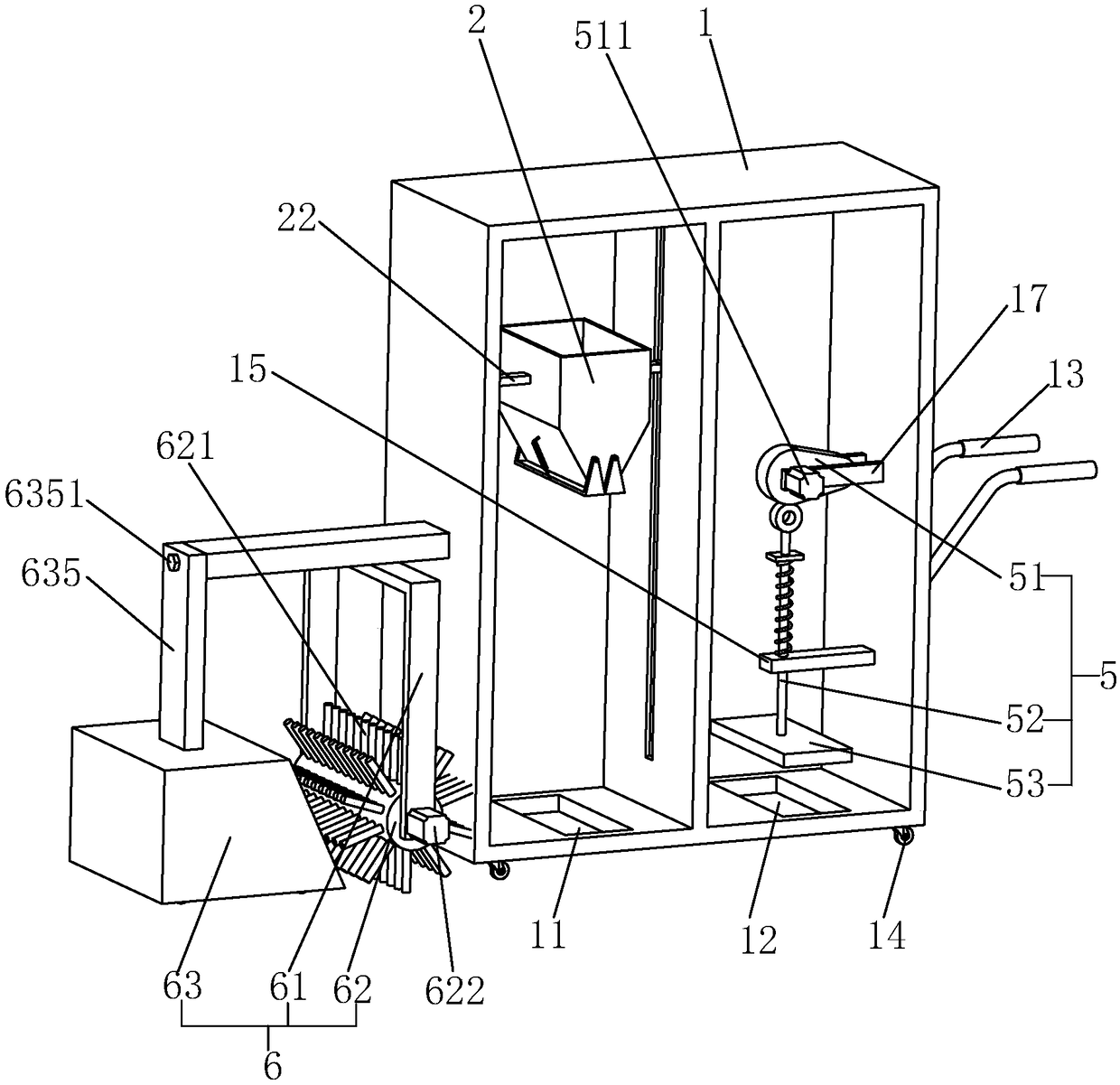

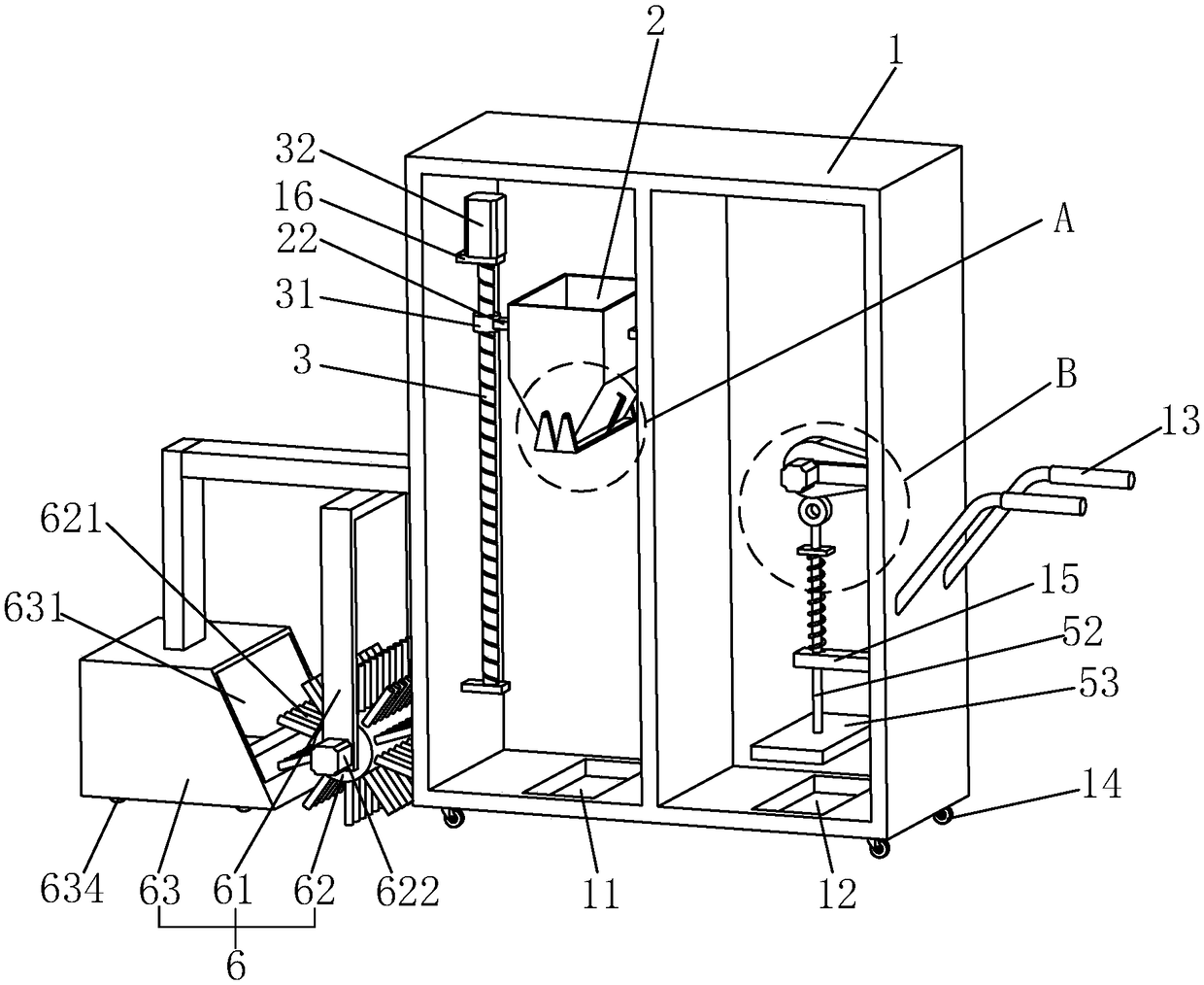

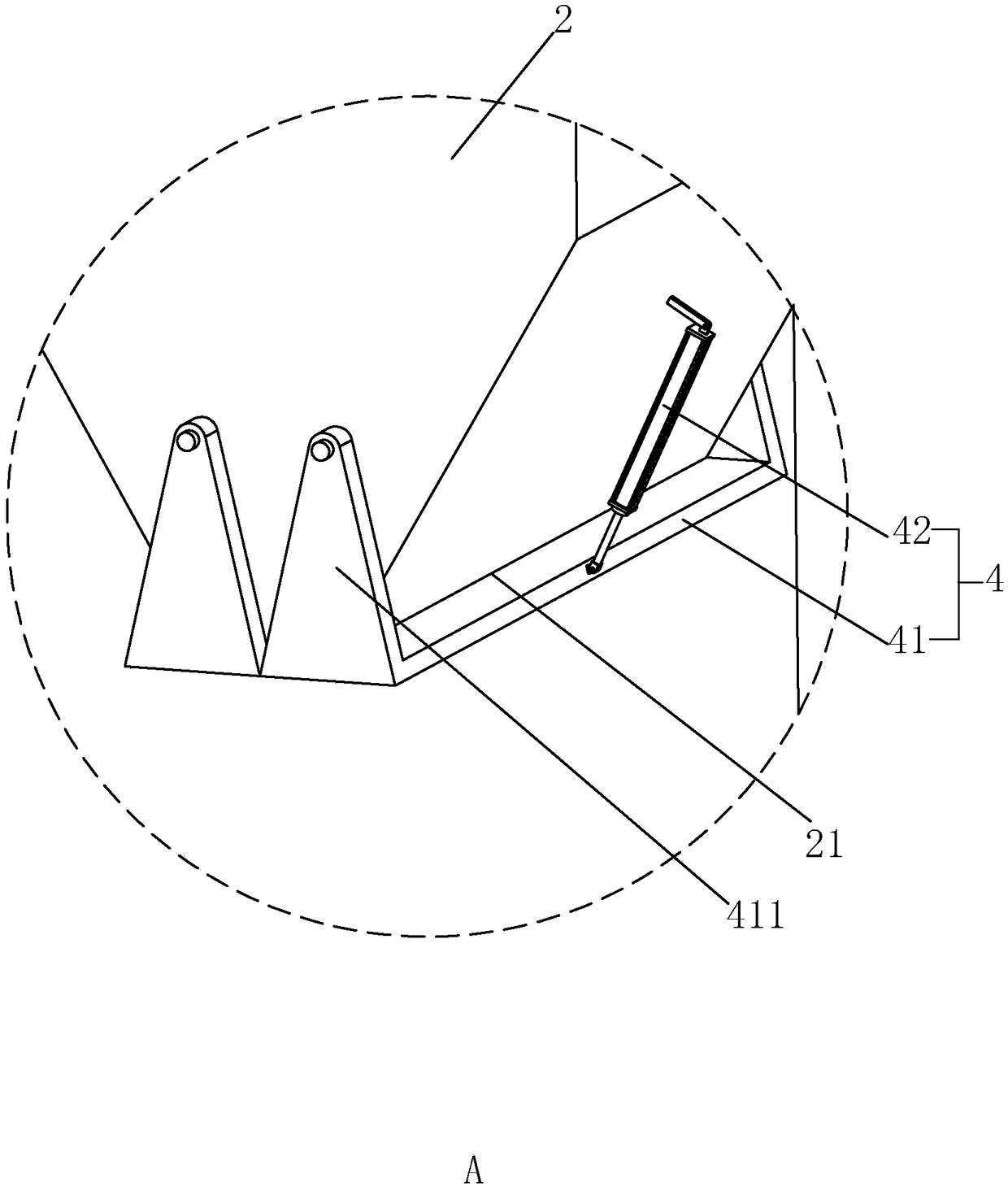

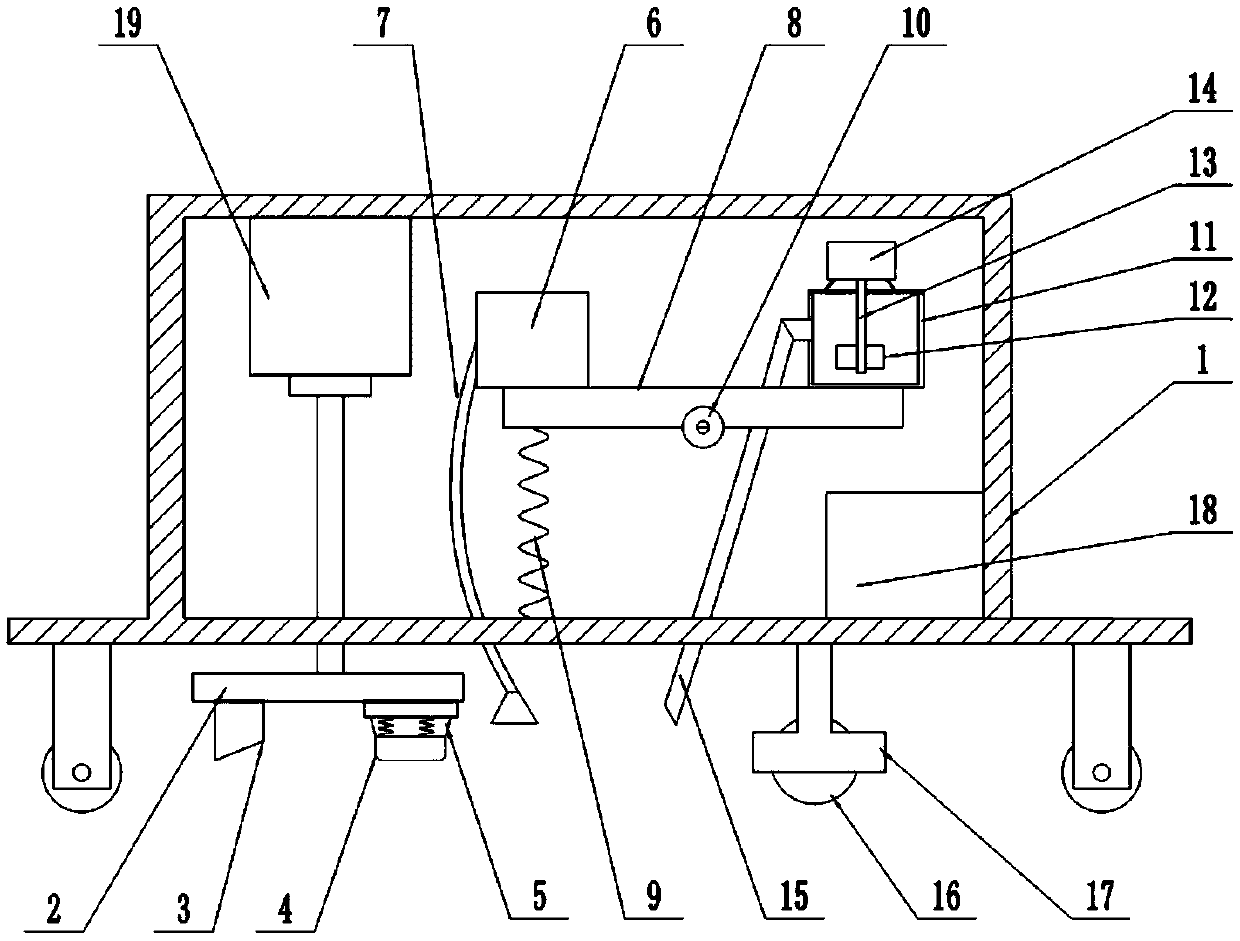

Asphalt pavement repair device for municipal engineering

InactiveCN109487672AImprove repair efficiencyImprove repair qualityRoads maintainenceEngineeringRoad surface

The invention relates to an asphalt pavement repair device for municipal engineering and belongs to the technical field of pavement repair devices. The key point of the technical scheme is as follows:the asphalt pavement repair device for municipal engineering comprises a repair box. A charging assembly and a planishing assembly are arranged in the charging assembly. The charging assembly comprises a charging box, a discharge port is formed in the bottom of the charging box, and a discharge hole is formed in the lower side of the discharge port at the bottom of the repair box; the planishingassembly comprises a can, a slide bar and a pressing plate. The rotating axis of the cam is horizontal and a planishing motor is arranged on the cam; a fixed plate is fixedly arranged in the repair box and is slidably connected to the slide bar, a horizontal adjusting plate is fixedly arranged at the top end, close to the cam, of the slide bar, a spring winding the circumferential surface of the slide bar is arranged between the adjusting plate and the fixed plate, the pressing plate is fixedly connected to the bottom of the slide bar, and a pressure hole aligned to the pressing plate is formed in the bottom of the repair box. An effect of improving the pavement repair efficiency is achieved.

Owner:温州建源建设有限公司

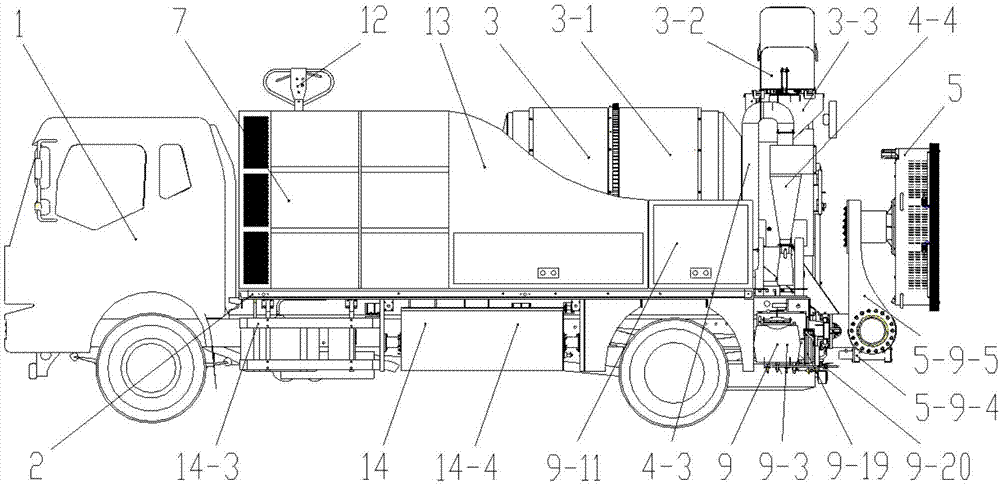

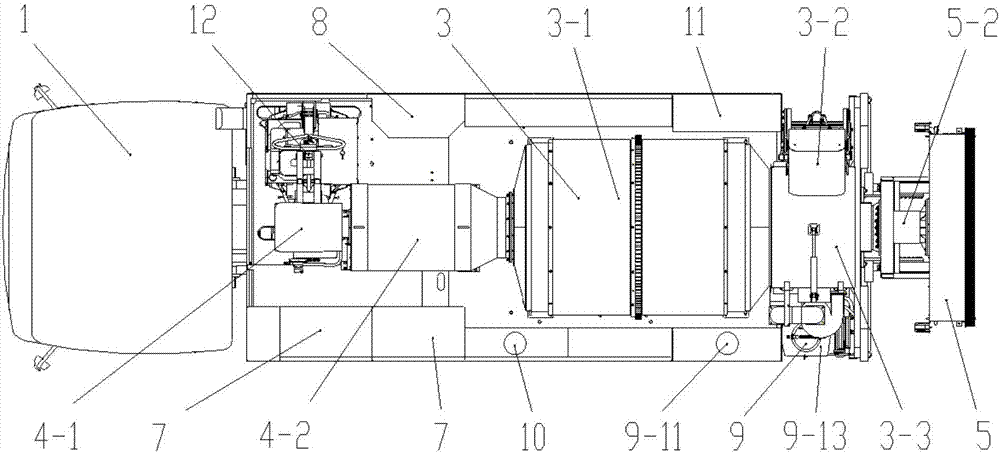

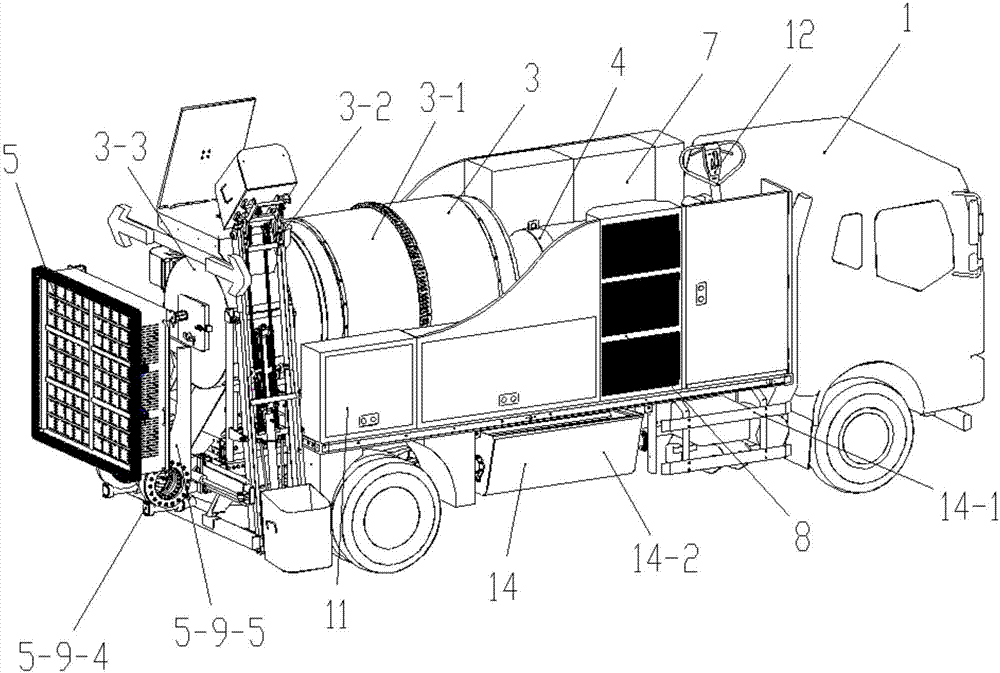

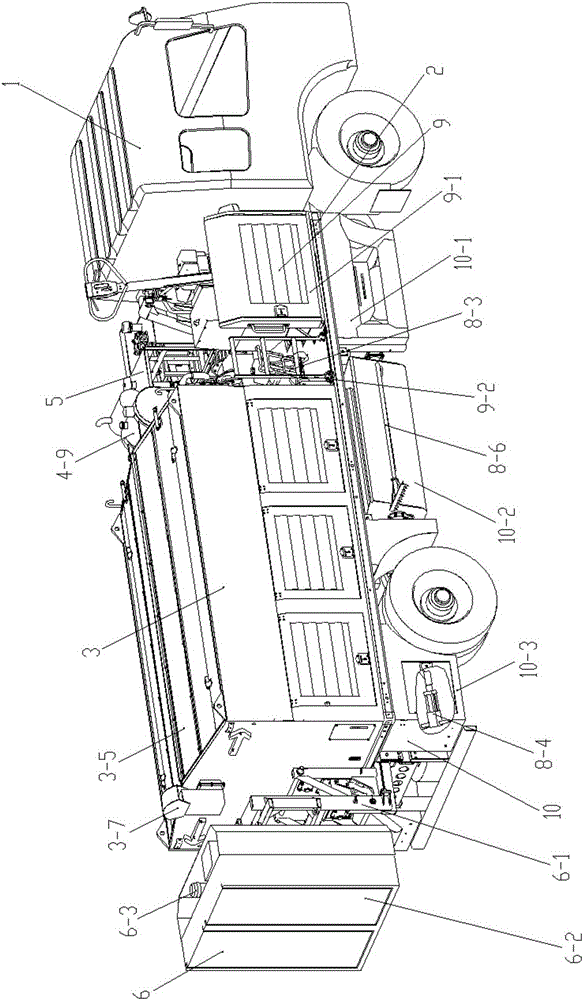

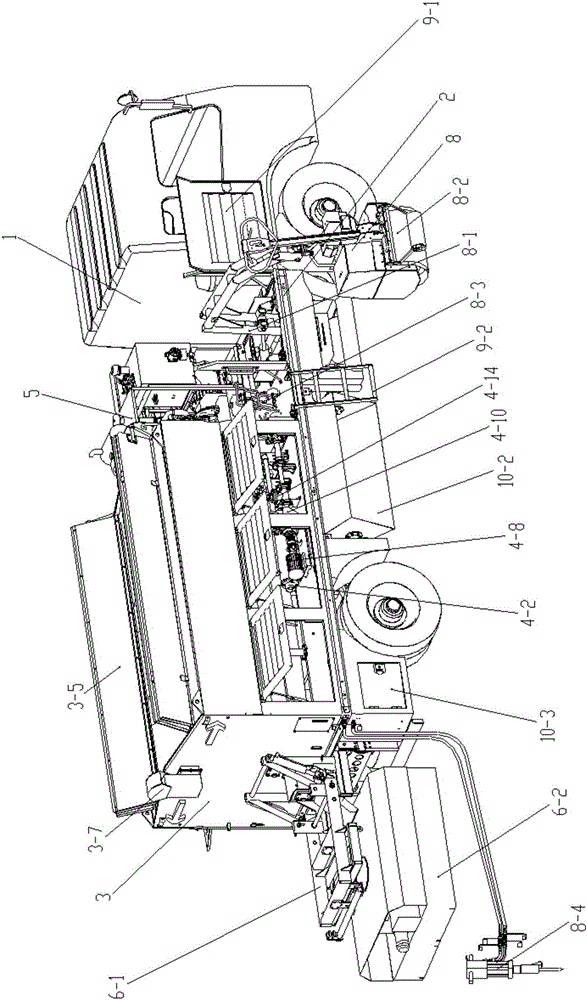

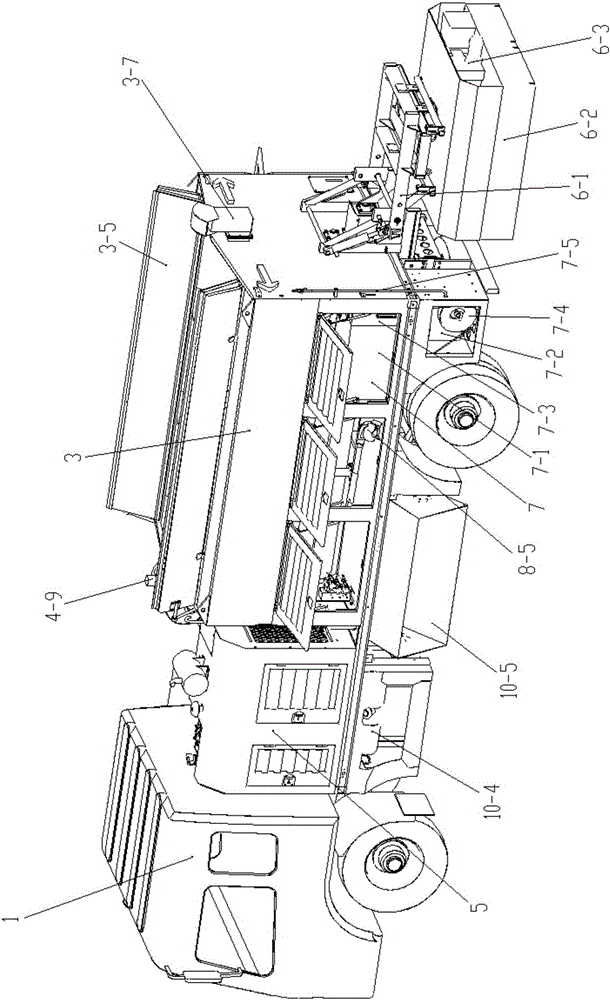

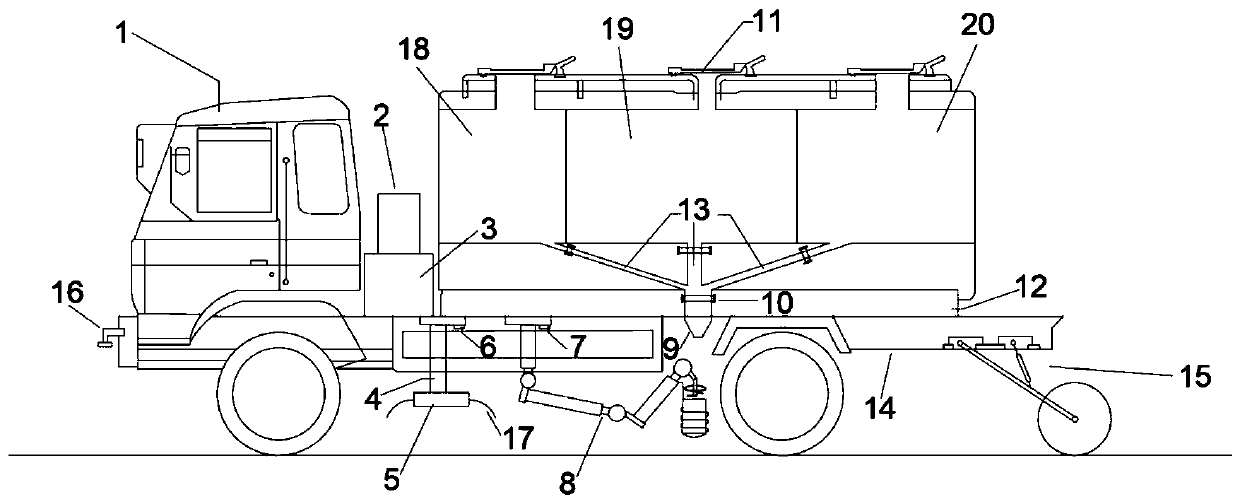

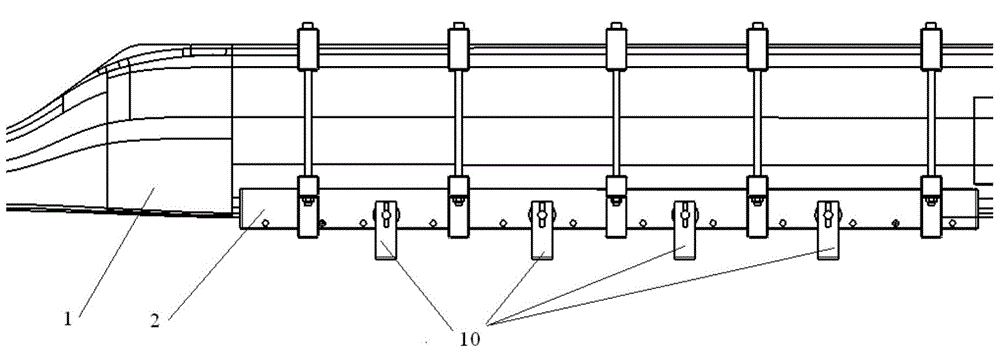

Microwave in-situ regenerative asphalt pavement maintenance vehicle and construction method

ActiveCN107254827ASolve heating and insulationSolve construction problemsRoads maintainenceVehicle frameTransformer

The invention discloses a microwave in-situ regenerative asphalt pavement maintenance vehicle. The microwave in-situ regenerative asphalt pavement maintenance vehicle comprises an automobile chassis, a frame, a drum stock bin, a heating system, a microwave heating wall system, a generator set, a transformer cubicle, a cooling system, an emulsified asphalt system, a hydraulic system, an electrical system and a road rolling tool. The microwave in-situ regenerative asphalt pavement maintenance vehicle has the advantages of high efficiency, energy conservation, environment friendliness, moderate heating depth, small interlayer temperature gradient and uniform heating; microwave magnetron heating is utilized as a heat source, heating and heat preservation of emulsified asphalt are realized, and cooling of a microwave generating magnetron self is also realized, so that working stability of the microwave generating magnetron is improved, and the aims of saving energy and reducing consumption are achieved; multilayered shielding combination is adopted, and a shielding effect on high frequency and low frequency electromagnetic fields is good; overturning of more than 90 degrees of a microwave heating wall can be realized, working condition adaptability is good, and the difficulty of construction of a ramp of an asphalt pavement is solved; and the complete machine adopts multi-functional integration and has strong disease adaptability, high repairing efficiency and good repairing quality.

Owner:JIANGSU JITRI ROAD ENG TECH & EQUIP RES INST CO LTD

Thermal-insulation storage type bituminous pavement comprehensive maintenance vehicle

ActiveCN105200902ASolve the problem that the construction cannot be carried out due to abnormal heatingAvoid coolingRoads maintainenceVehicle frameThermal insulation

The invention discloses a thermal-insulation storage type bituminous pavement comprehensive maintenance vehicle which is characterized in that the vehicle comprises an automotive chassis, a vehicle frame, a thermal-insulation bunker, a heating system, a generator set, a heating wall system, an emulsified asphalt system, an auxiliary tool, an upper enclosure and a lower vehicle fence. As for electrical heating, the generator set can output electric energy or mains supply as two modes of heating. The thermal-insulation bunker is provided with an anti-caking device capable of realizing positive and negative rotating and stirring and preventing a bituminous mixture from being cooled, arched and separated, and a spiral feeder assists to discharge materials. Discharge of materials is continuous, fast and free of blocking materials. The vehicle of the invention has two disease repairing technologies. Different repairing technologies can be selected according to the disease degree of the pavement. The vehicle of the invention has strong adaptability, high repairing efficiency and good repairing quality. The vehicle of the invention adopts a double-heat-source series circulatory heating mode and has three selection modes, namely diesel oil heating, electrical heating by the generator set and mains supply heating. The vehicle is energy-saving and efficient and has strong adaptability. By the use of the vehicle, the problem that a single heat source used for heating causes abnormity and construction failure is solved.

Owner:XUZHOU XCMG MAINTENANCE MACHINERY CO LTD

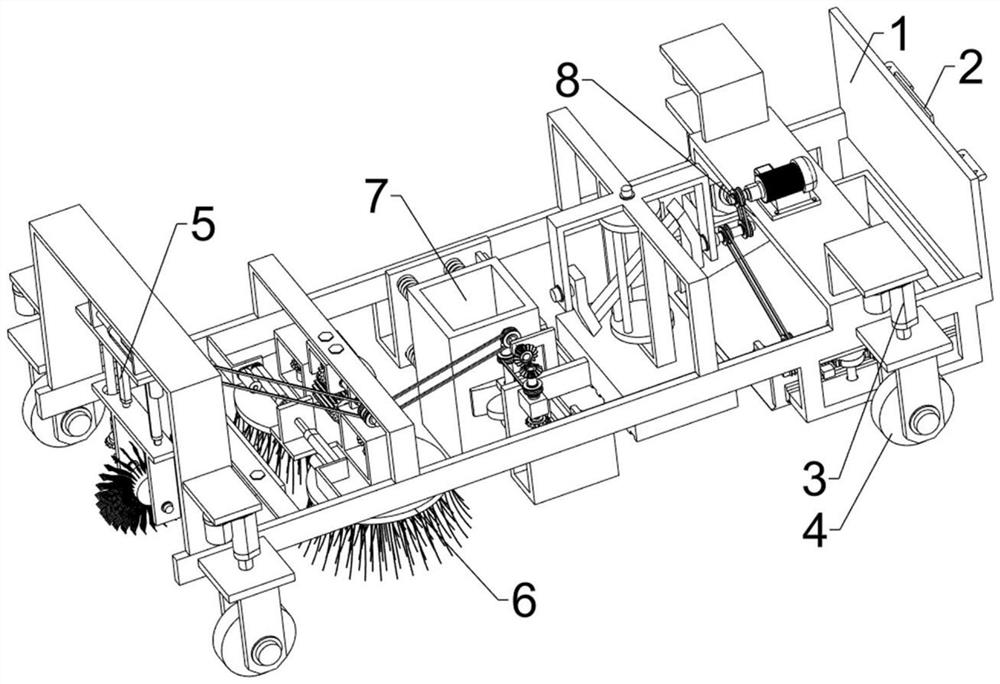

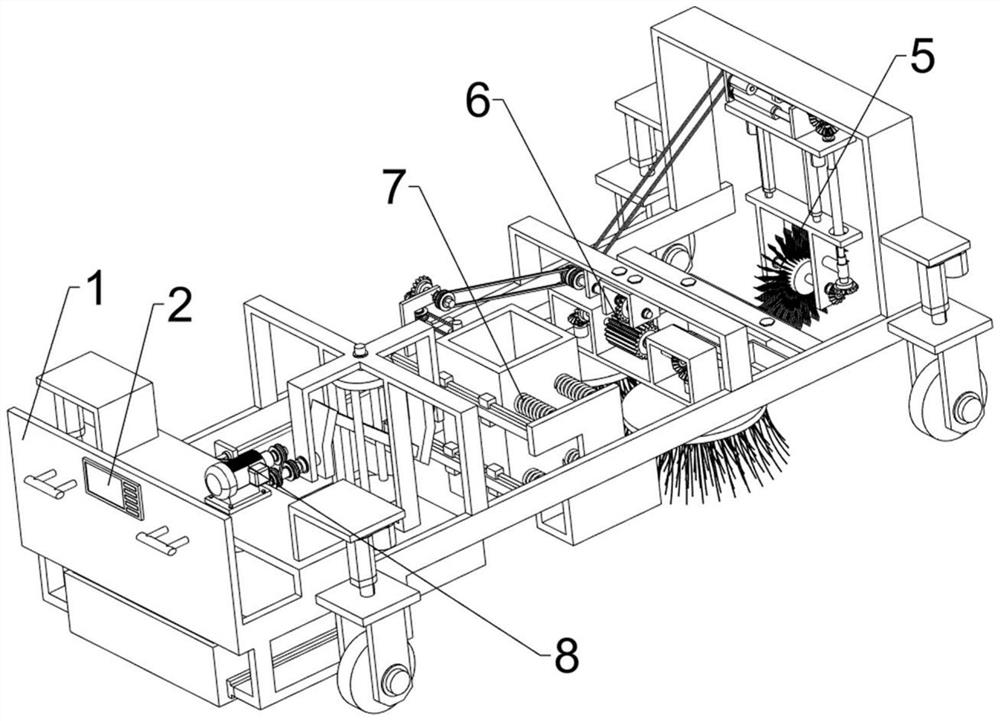

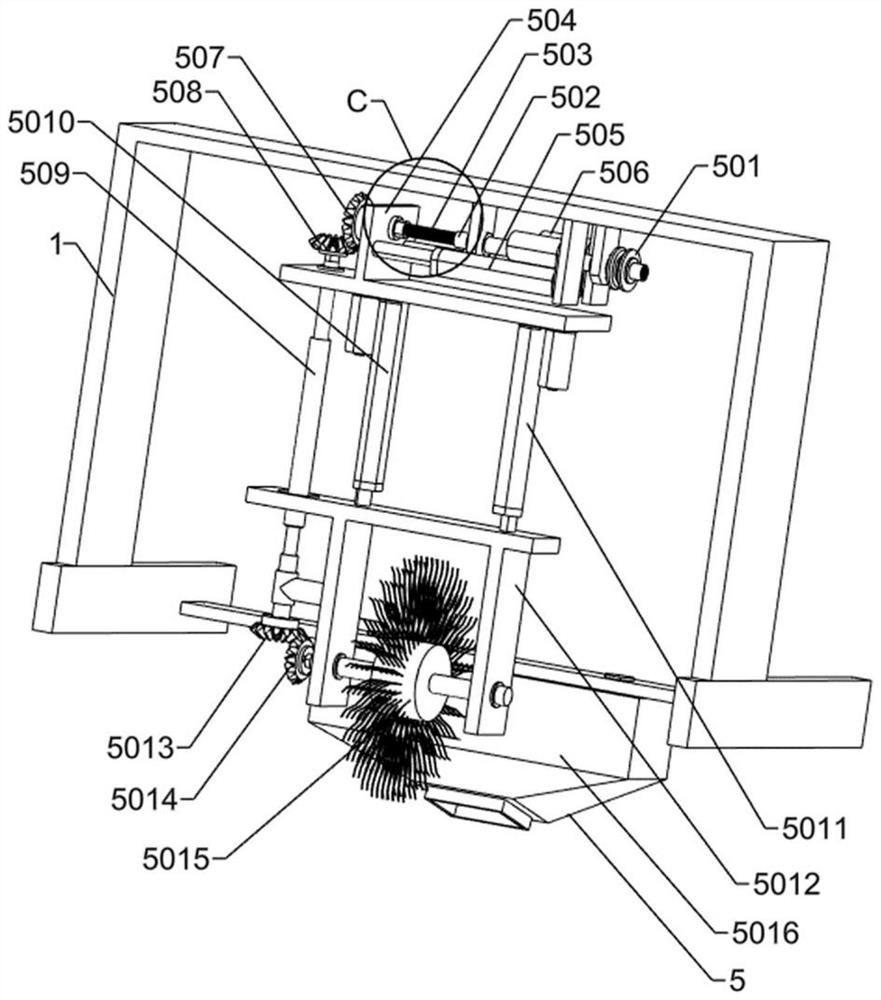

Asphalt road repairing device capable of filling bending cracks

The invention relates to the field of asphalt, in particular to an asphalt road repairing device capable of filling bending cracks. The technical problem to be solved by the invention is to provide the asphalt road repairing device capable of filling the bending cracks. According to the asphalt road repairing device, the asphalt road repairing device capable of filling the bent cracks comprises asupporting frame plate, a control display screen, a first electric push rod, a steering wheel, a crack cleaning mechanism, a road surface cleaning mechanism, an asphalt adding mechanism and a finishing mechanism. A control display screen is arranged on the side face of the supporting frame plate. According to the device, broken-line-shaped road cracks can be effectively swept, the purity of filledasphalt is improved, the road surface is synchronously cleaned, secondary pollution is prevented, meanwhile, asphalt filling is conducted through a machine, repeated manual taking is replaced, the working efficiency is improved, the finished road is located on the same horizontal plane. An effect of improving repairing quality is realized.

Owner:吴皎阳

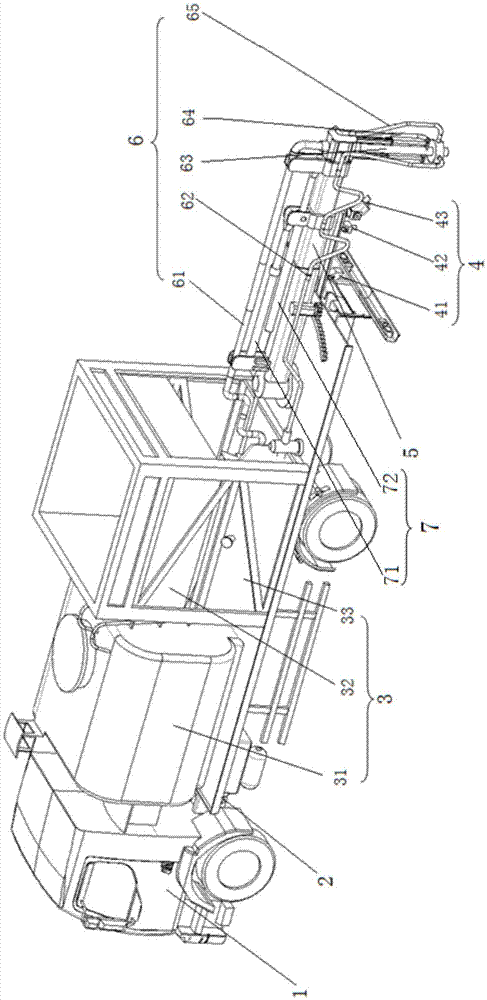

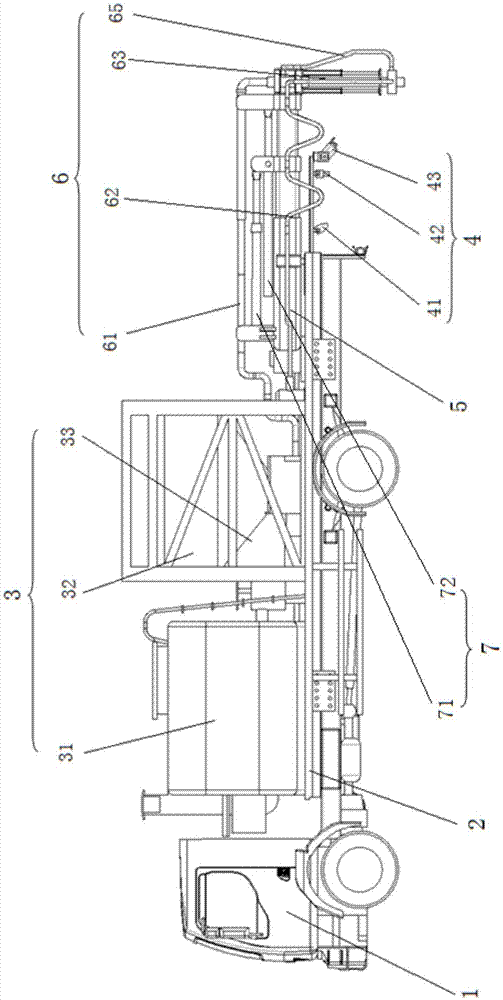

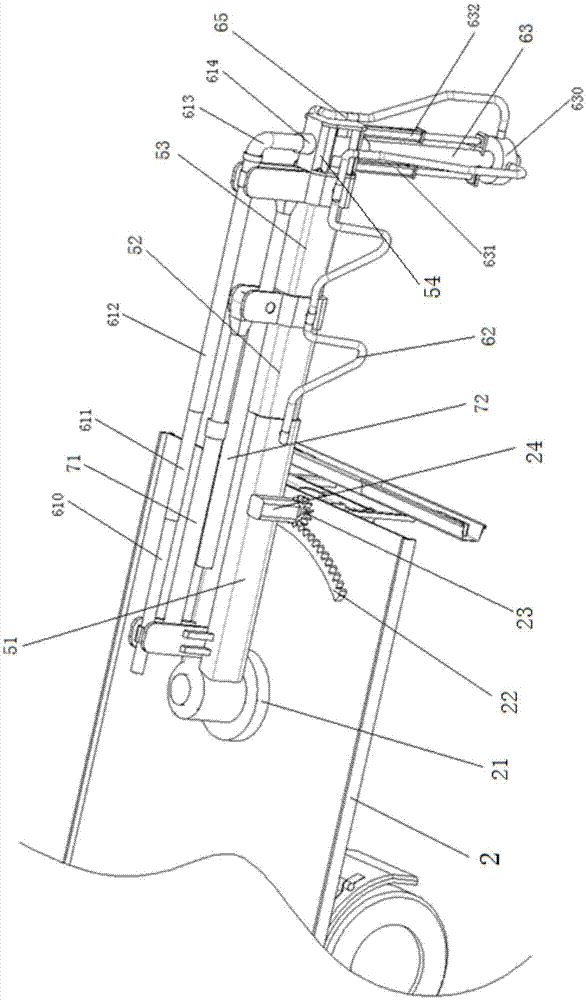

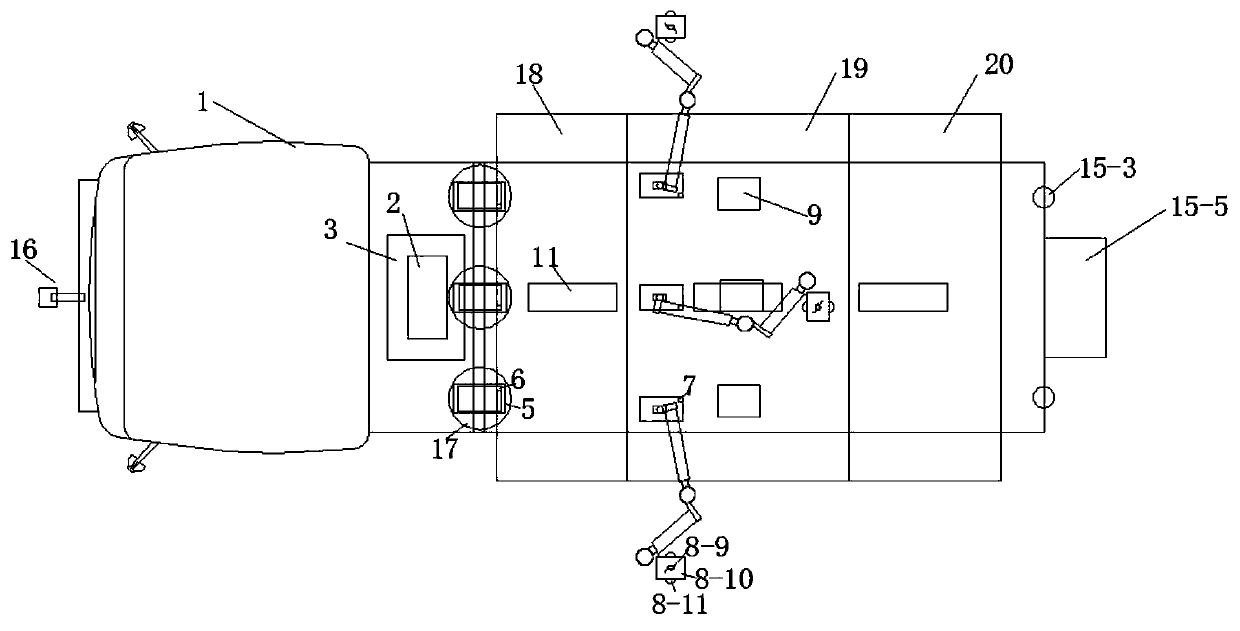

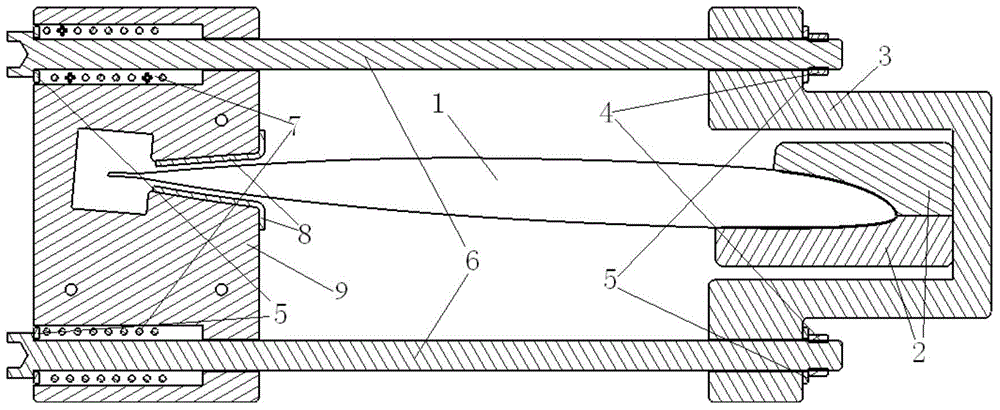

Full-automatic jet type pavement pit repairing vehicle

The invention provides a full-automatic jet type pavement pit repairing vehicle. A frame bottom plate is arranged on a chassis; a material storing assembly, an arm support assembly, a material conveying assembly and a position adjusting assembly are arranged on the frame bottom plate; the arm support assembly is installed on the frame bottom plate through a plane rotating component, and the arm support assembly is adjusted to rotate in a plane through the plane rotating component; the material conveying assembly comprises material collecting and conveying pipes and a vertical telescopic material conveying pipe communicated with the material collecting and conveying pipes along the vertical direction; the material collecting and conveying pipes are installed on the arm support assembly in parallel along the vertical direction through an axial telescopic component; the axial telescopic component drives the arm support assembly and the material collecting and conveying pipes to make telescopic motion together along the axial direction; and the vertical telescopic material conveying pipe can stretch along the vertical direction. The full-automatic jet type pavement pit repairing vehicle provided by the invention can completely replace artificial operation and fills in the blank of the field of a pit repairing machine which adopts a jet type repairing process, is based on the three-dimensional reconstruction technology, has high precision and can realize full automation.

Owner:CHANGAN UNIV

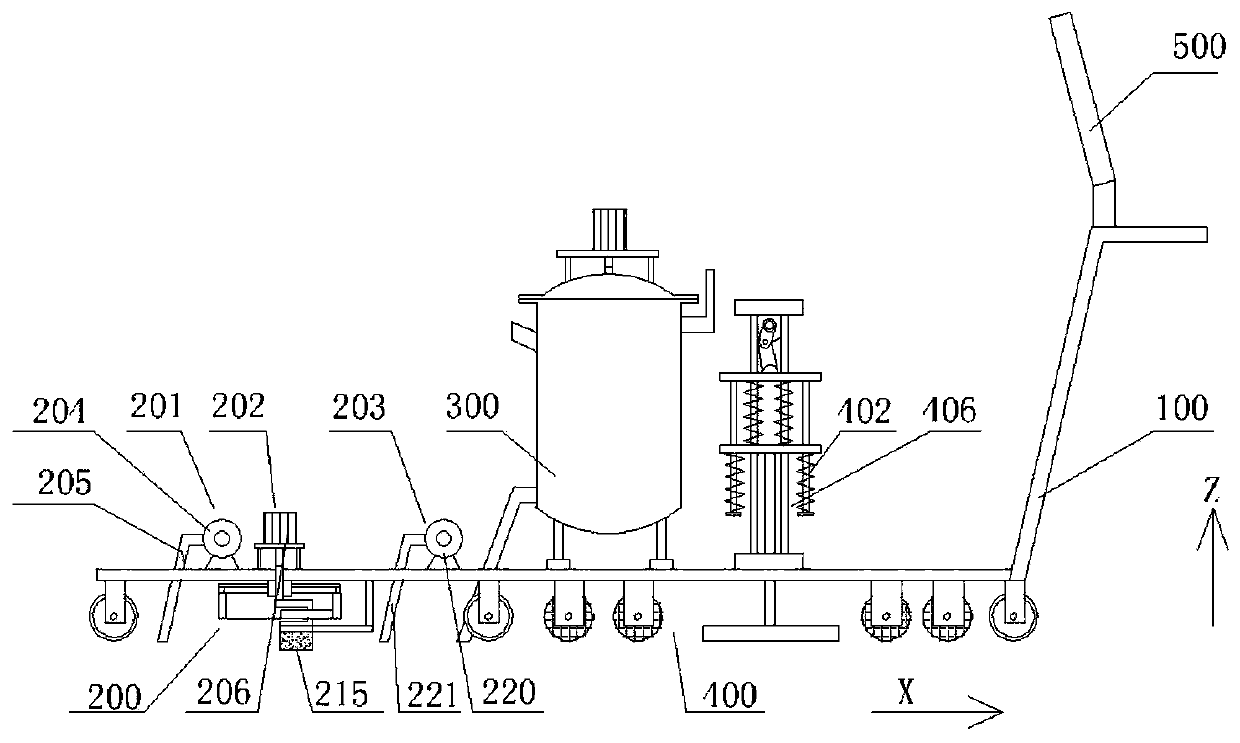

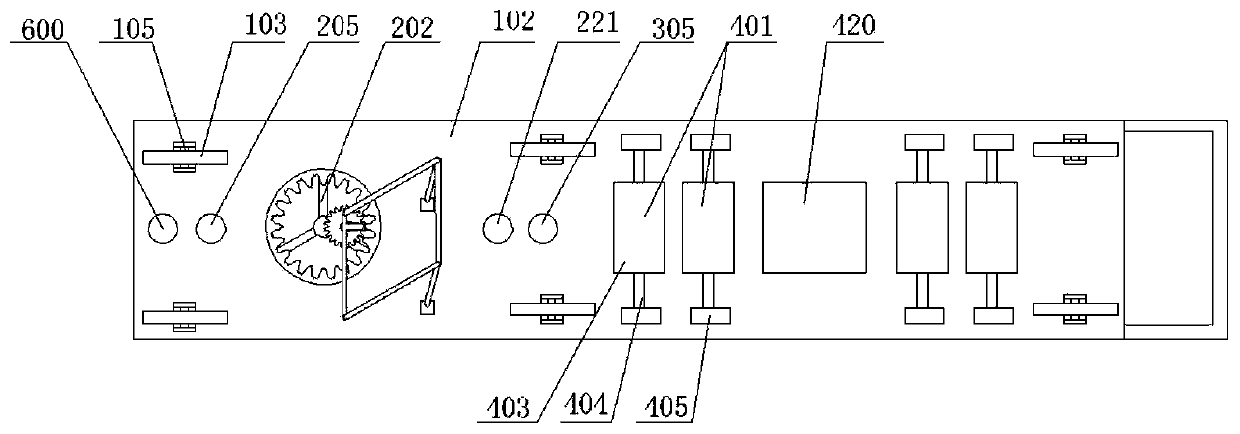

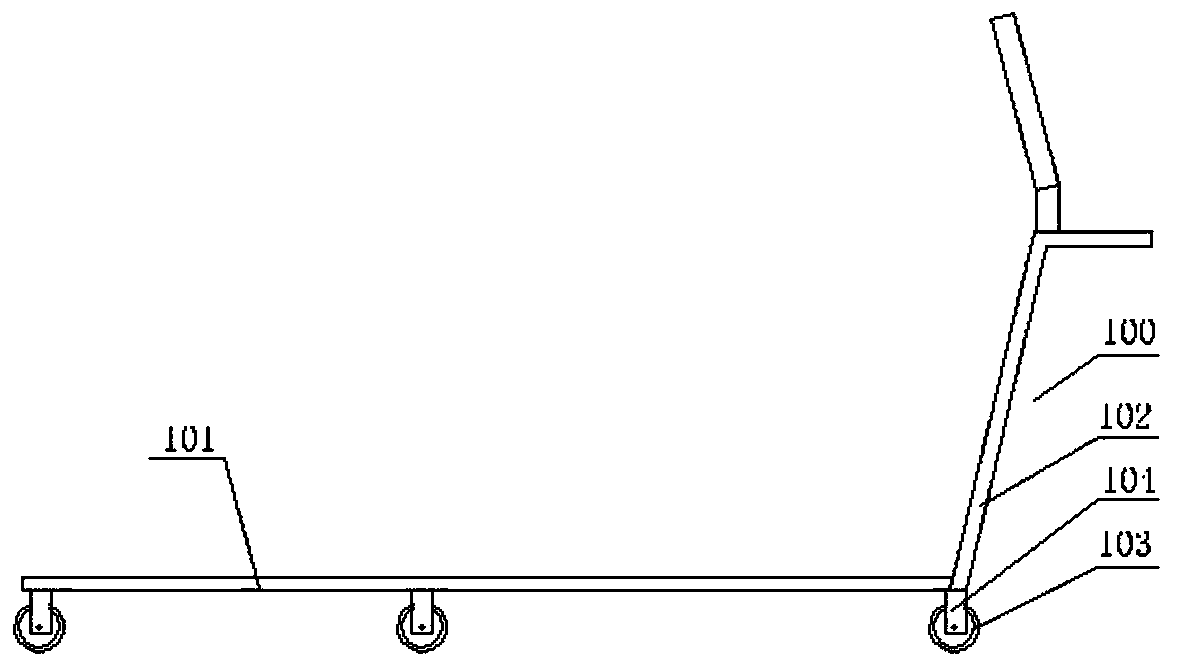

Municipal road asphalt concrete pavement maintenance structure and construction method thereof

ActiveCN110258277AReasonable structureGood potting effectRoads maintainencePavement maintenanceRoad surface

The invention discloses a municipal road asphalt concrete pavement maintenance structure. The municipal road asphalt concrete pavement maintenance structure comprises a trolley used for moving, a cleaning device arranged on the trolley and used for cleaning dust and impurities of a slot seam, a melting kettle used for heating and stirring the asphalt and a leveling device used for flattening and compacting the asphalt; the cleaning device comprises a dust collection assembly used for removing dust and removing impurities of the slot seam, a scrubbing assembly used for scrubbing the slot seam and a drying component used for drying the slot seam which are sequentially distributed along the X-axis direction; the melting kettle comprises a kettle body used for temporarily storing the asphalt, a kettle cover and a stirring assembly used for stirring the asphalt; and the leveling device comprises a plurality of flattening assemblies used for flattening the asphalt in the slot seam and a compaction assembly used for compacting the asphalt in the slot seam. The municipal road asphalt concrete pavement maintenance structure is specially designed for a highway pouring seam, and is reasonable in structure, good in pouring effect and high in repairing quality.

Owner:克孜勒苏柯尔克孜自治州第一建筑安装工程有限责任公司

Use method of high-temperature ceramic welding material

The invention provides a use method of a high-temperature ceramic welding material. The high-temperature ceramic welding material comprises 35-43 wt% of Al2O3, 35-45 wt% of SiO2 and 19-30 wt% of ZrO2. The high-temperature ceramic welding material is sprayed to a breakage part of an industrial stove from a welding gun under the current carrying action of combustion-supporting gas, fuel particles of the high-temperature ceramic welding material combust at the breakage part to produce high temperature so as to soften and fuse refractory material particles of the high-temperature ceramic welding material and the refractory material at the breakage part, so that the breakage part and the refractory material of the high-temperature ceramic welding material are firmly welded together so as to achieve the purpose of stove recovery. Compared with the traditional siliceous high-temperature ceramic welding material, the high-temperature ceramic welding material has better corrosion resistance, better thermal shock resistance, better thermal stability and firmer welding; the invention reduces the use cost of the industrial stove, reduces the loss caused by the breakage of the industrial stove and is suitable for large-scale popularization and application.

Owner:上海杰汇炉窑新技术有限公司

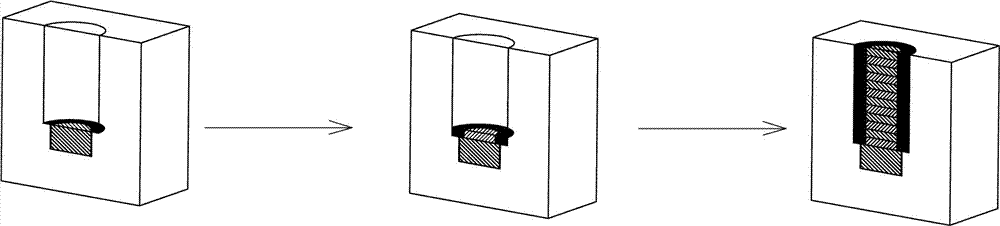

Threaded hole welding and repairing process

ActiveCN107498262AImprove repair efficiency and qualityReduce welding height and welding volumeSheet steelSurface finishing

The invention provides a threaded hole welding and repairing process. The threaded hole welding and repairing process comprises the following steps of material preparation, chambering, welding, surface treatment, drilling and tapping. According to the process, circular steel sheets are laid in an inner hole subjected to chambering to replace the bead welding quantity, bead welding in the small diameter of a thread is replaced with the circular sheets, the welding quality of the large diameter of the thread and the small diameter of the thread is guaranteed, and meanwhile it is guaranteed that the small diameter of the thread is filled with the circular steel sheets, so that positioning and construction are performed conveniently when redrilling is performed. By means of the process, the quality and efficiency of repair of a threaded hole can be improved, meanwhile welding deformation is lowered, and the threaded hole welding and repairing process is particularly suitable for welding and repairing of the deep threaded hole.

Owner:中国船舶重工集团柴油机有限公司

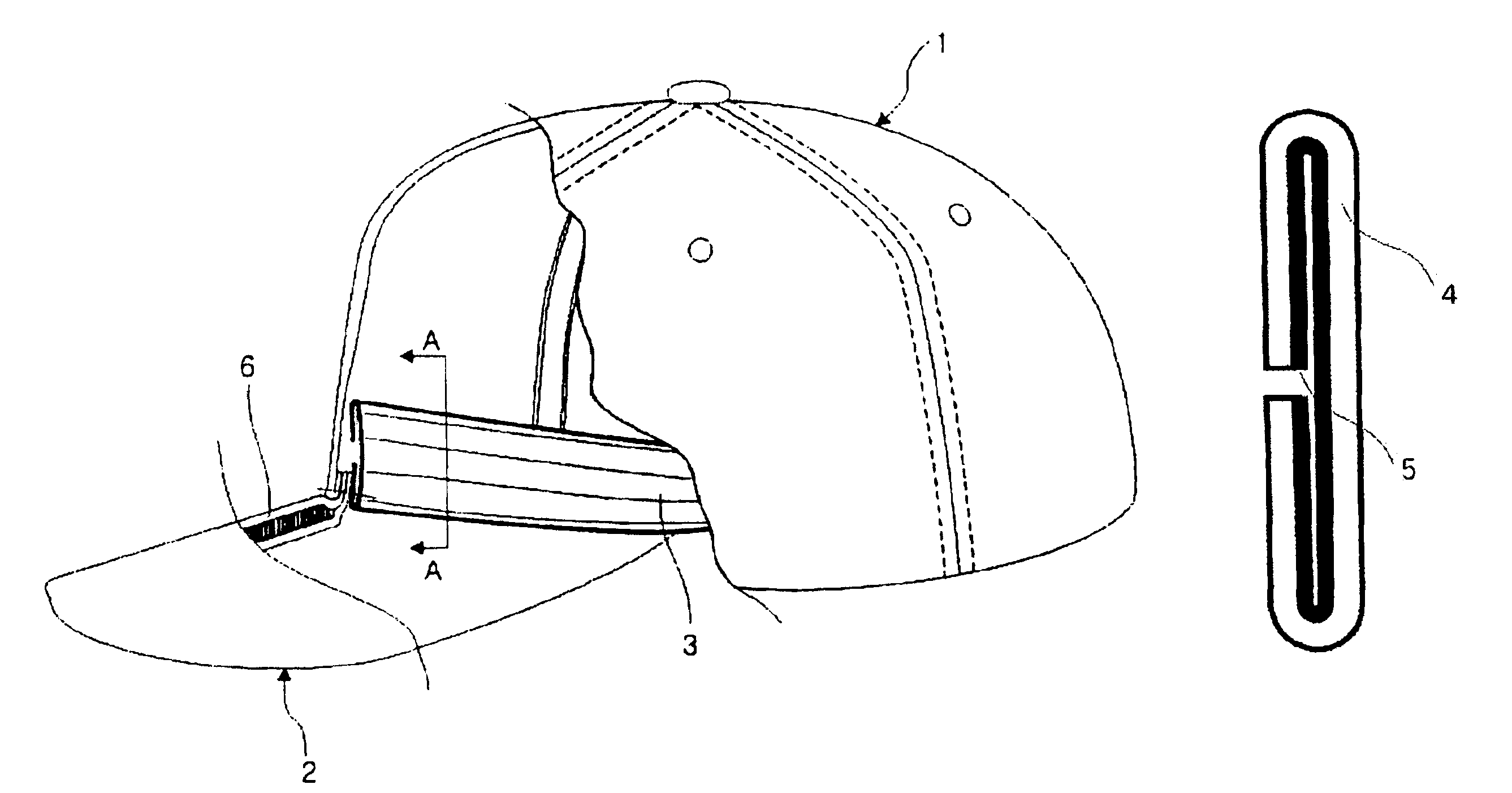

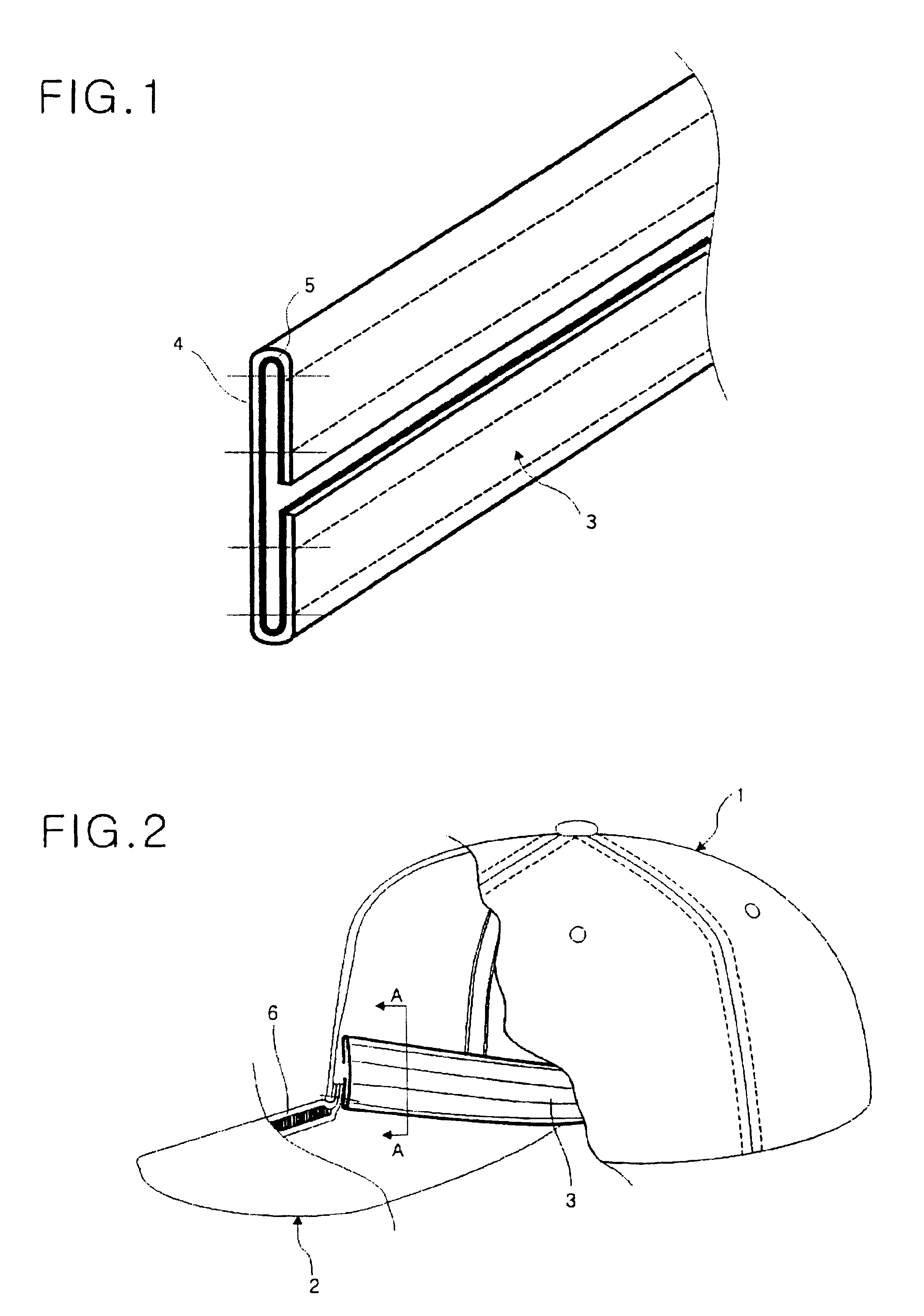

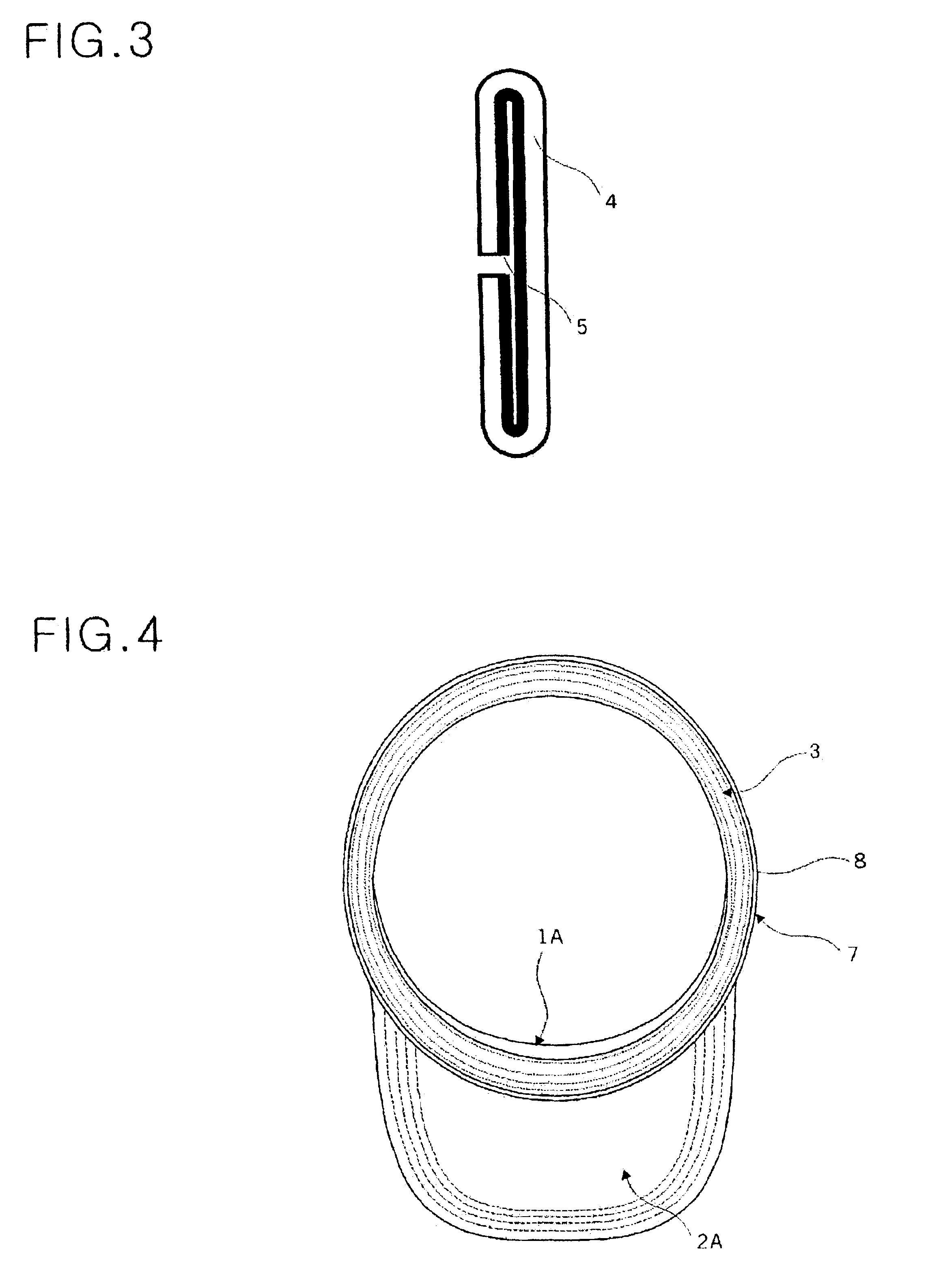

Coated headband for a cap

Headwear having a two-ply headband coated with a layer of polyurethane. The headwear includes a crown main body, a visor, and the headband which is preferably connected to the lower peripheral edge of the crown main body. The two-ply headband is created by folding a strip of knitted fabric, coated on one side with polyurethane, so that the polyurethane is inside the folds and then stitching the folds to secure the shape of the headband. The knitted portion of the headband demonstrates good moisture absorbency while the polyurethane layer prevents the conveyance of sweat to the crown main body and any accompanying staining that might otherwise occur. The headband stretches to fit the wearer comfortably without undue pressure during use, while also exhibiting good resilience when removed.

Owner:DADA CO LTD

Damaged wall surface scraping and repairing device

InactiveCN111379431AQuality assuranceImplement automatic repairBuilding repairsMechanical engineeringComposite material

The invention discloses a damaged wall surface scraping and repairing device. The device comprises a moving trolley, wherein a moving lifting device is arranged on the moving trolley and used for providing lifting motion needed for scraping and repairing wall surface, and a wall surface scraping device is arranged on the left side of the moving lifting device; a wall body repairing device is arranged on the wall surface scraping device, wherein the wall body repairing device is used for spraying an interface agent and wall repairing paste to the wall surface with impurities scraped away so asto repair a wall body; and a lifting speed adjusting device is arranged on the upper side of the moving trolley, wherein the lifting speed adjusting device can adjust the downward moving speed of themoving lifting device according to the damage condition of the wall body, so that the wall body repairing device is sprayed the sufficient wall repairing paste onto the wall surface, and accordingly the repaired wall body has good quality. According to the damaged wall surface scraping repairing device, the damaged wall surface can be automatically repaired, the automation degree is high, the repairing quality is easily guaranteed, and the repairing quality is good.

Owner:宁波暮春自动化科技有限公司

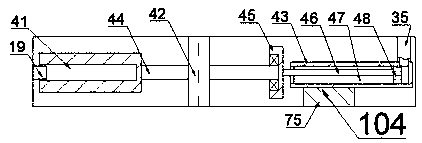

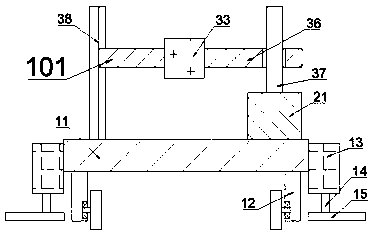

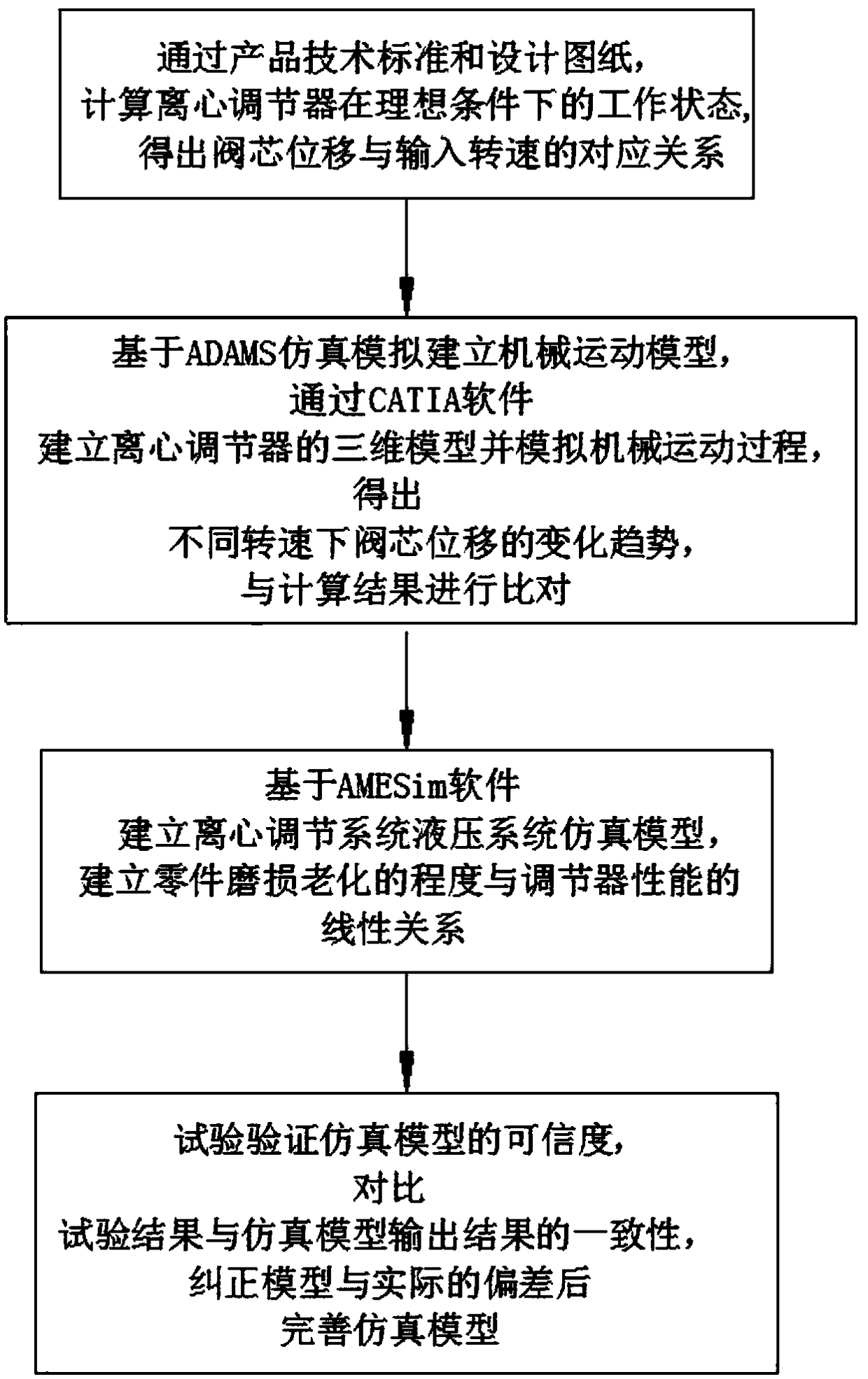

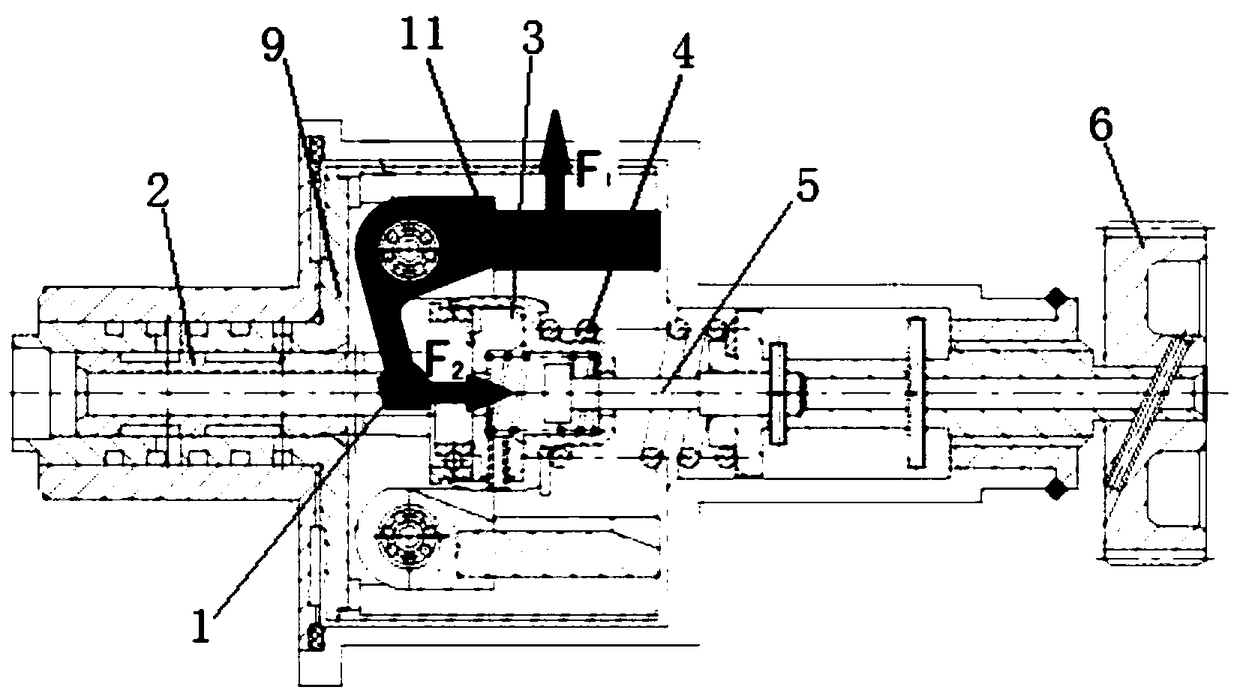

Repair tolerance analysis method based on computational simulation of constant speed transmission regulating system

InactiveCN109388849AGuaranteed credibilityImprove repair qualityGeometric CADDesign optimisation/simulationTechnical supportThree dimensional model

The invention relates to a repairing tolerance analysis method based on the calculation and simulation of a constant speed transmission device regulating system, which comprises the following steps: firstly, calculating the working state of a centrifugal regulator under an ideal condition through a product technical standard and a design drawing, and obtaining a corresponding relationship betweena valve core displacement and an input rotational speed; Secondly, based on ADAMS simulation, the mechanical motion model is established, and the three-dimensional model of the centrifugal regulator is established to simulate the mechanical motion process, and the change trend of the valve spool displacement at different rotational speeds is obtained, which is compared with the calculated results.thirdly, establishling a simulation model of that hydraulic system of the centrifugal regulating system, and establish a linear relationship between the wear and aging degree of the parts and the performance of the regulator; Fourthly, the credibility of the simulation model is verified by experiments, and the simulation model is perfected after the deviation between the model and the reality iscorrected. Fifthly, Determining Repair Tolerance. The invention can provide the technical support for the repair of the constant speed transmission device through the calculation and simulation analysis of the centrifugal regulator and the determination of the repair tolerance.

Owner:WUHU SHUANGYI AERO TECH

Construction method of asphalt pavement pit slot repairing vehicle based on electromagnetic heating

ActiveCN110700065AImprove repair qualityAffect the repair effectRoads maintainenceRepair materialStructural engineering

The invention discloses a construction method of an asphalt pavement pit slot repairing vehicle based on electromagnetic heating. The construction method comprises the following steps: detecting a pavement pit slot; starting the bituminous pavement pit slot repairing vehicle to move on the pavement, and scanning the road condition of the pavement by a pavement scanner at the front part of the vehicle body; preheating the pavement; processing, and adding a repairing material and flattening; the asphalt pit slot repairing capsule in the storage bin is discharged from a discharge port, the material falls into a stirring container in the repairing mechanical arm structure, then the material is subjected to induction heating through an induction coil wound on the stirring container, and then the position of the preheated pit slot is inducted through a temperature inductor to be filled and flattened; vibrating and compacting; cleaning and acceptance. The asphalt pavement pit slot repairing vehicle based on electromagnetic heating is combined with the pit slot repairing capsule to conduct electromagnetic induction repairing on the pit slot in the asphalt concrete pavement, and rapid repairing of the asphalt concrete pavement is achieved.

Owner:HEFEI UNIV OF TECH

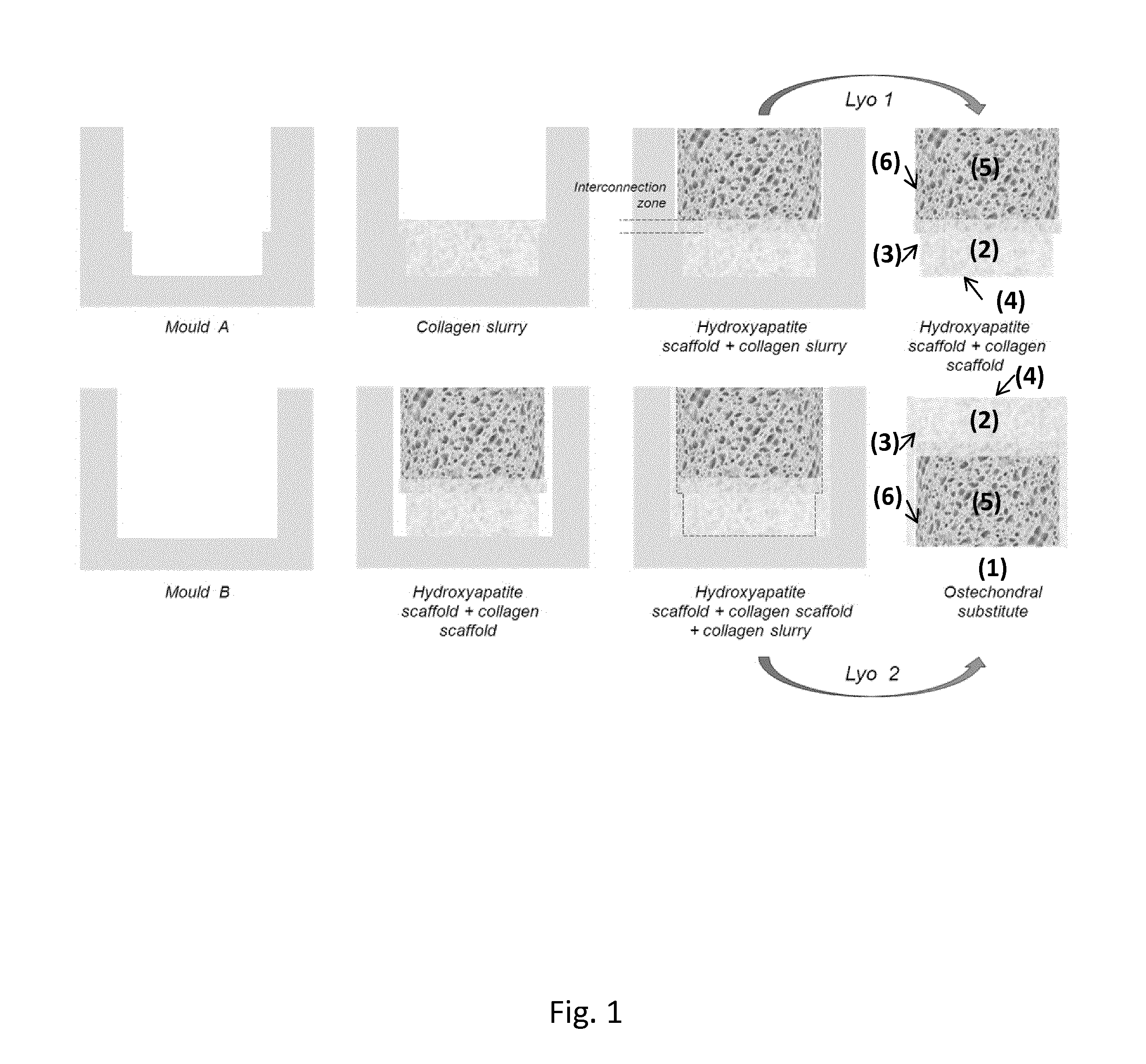

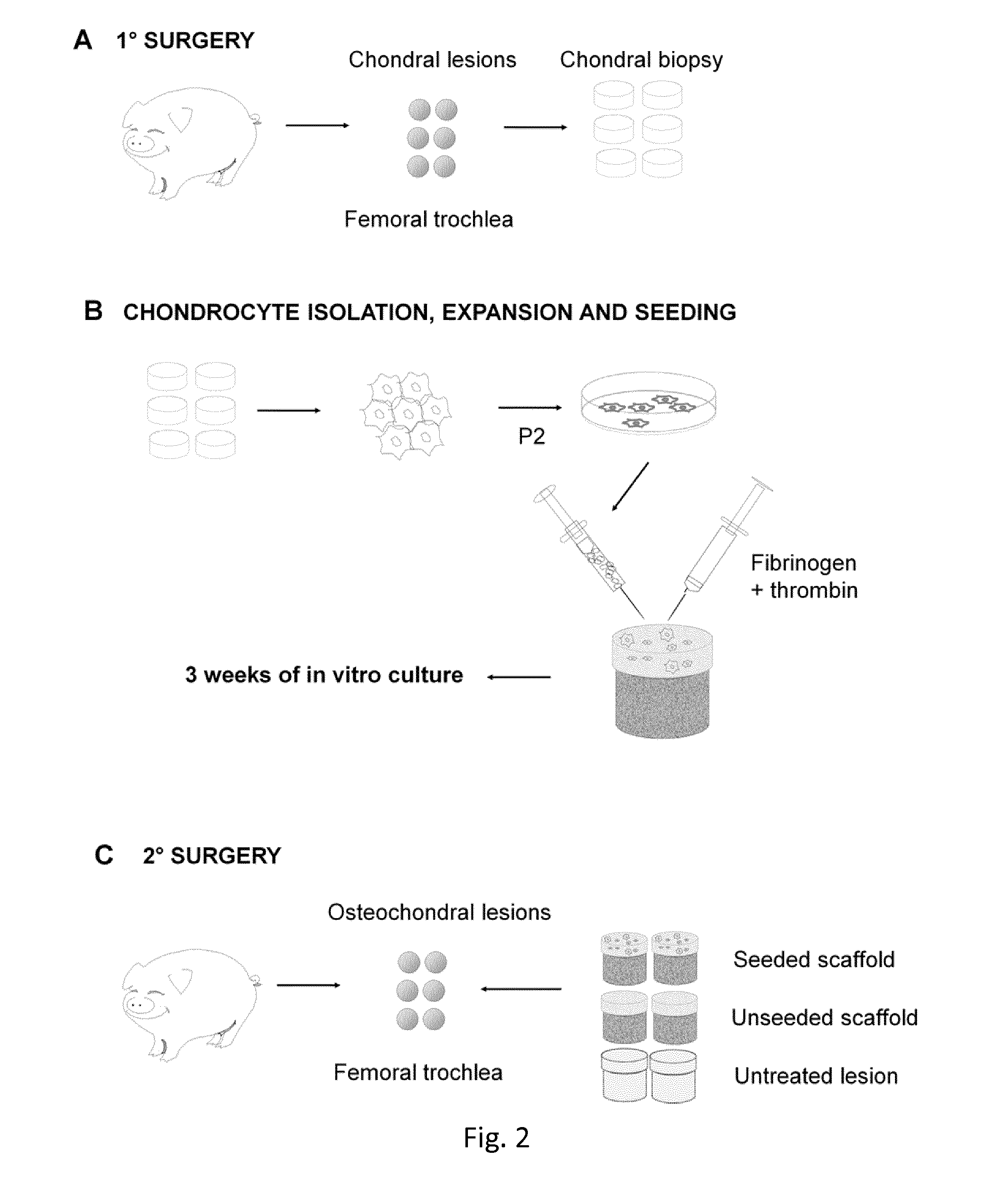

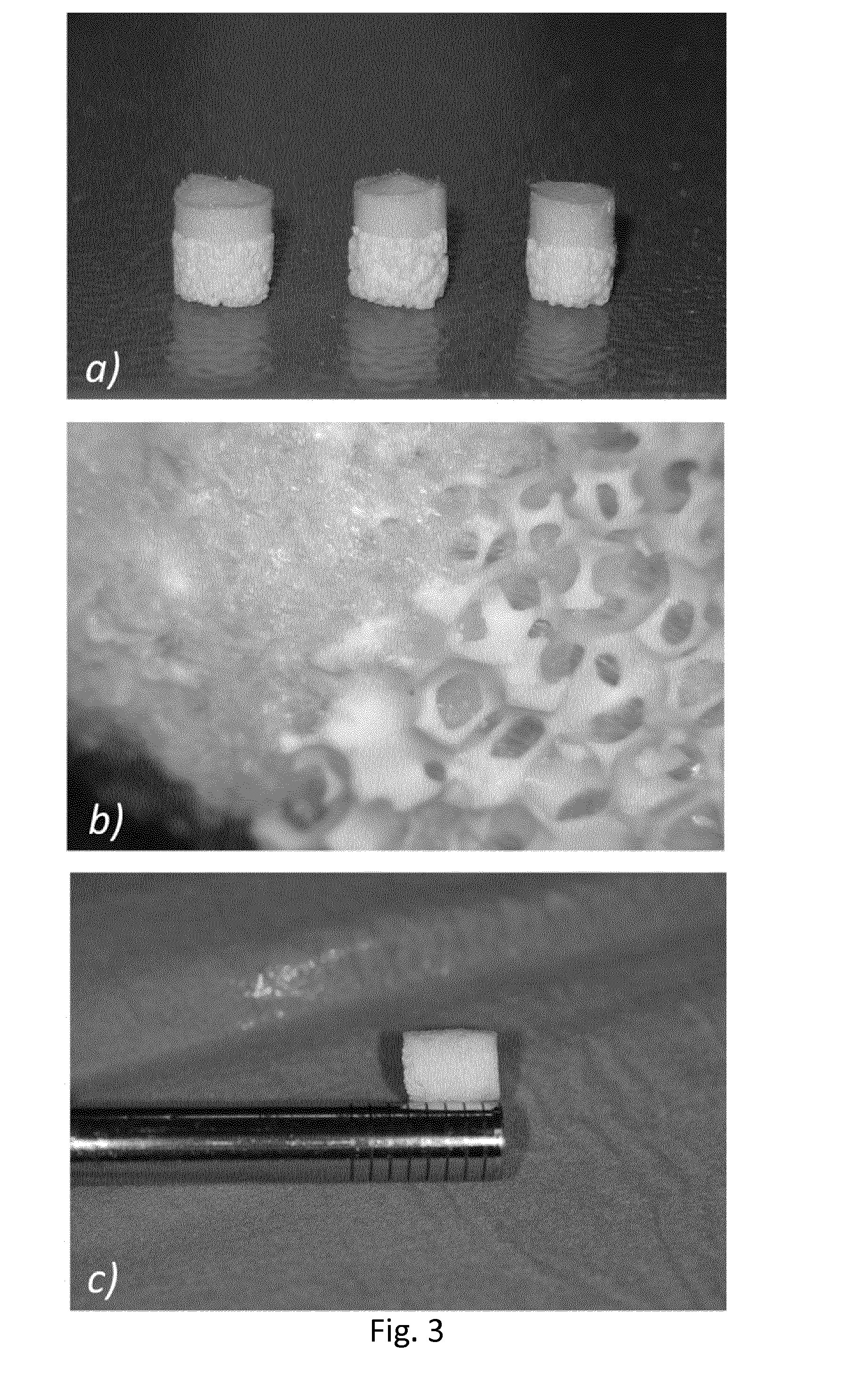

Composite scaffold for tissue repair

ActiveUS20160106885A1Efficient repairIncrease the number of cellsBiocidePeptide/protein ingredientsSecondary layerBiomedical engineering

A synthetic composite material for tissue repair is disclosed which includes a first layer having an organic material and having side walls and external surface; and a second porous layer comprising an inorganic material and having side walls; wherein the first layer is in direct contact with the second layer and wherein the side walls of the first layer and the side walls of the second layer are coated with a third layer of the organic material.

Owner:OSPEDALE SAN RAFFAELE SRL +1

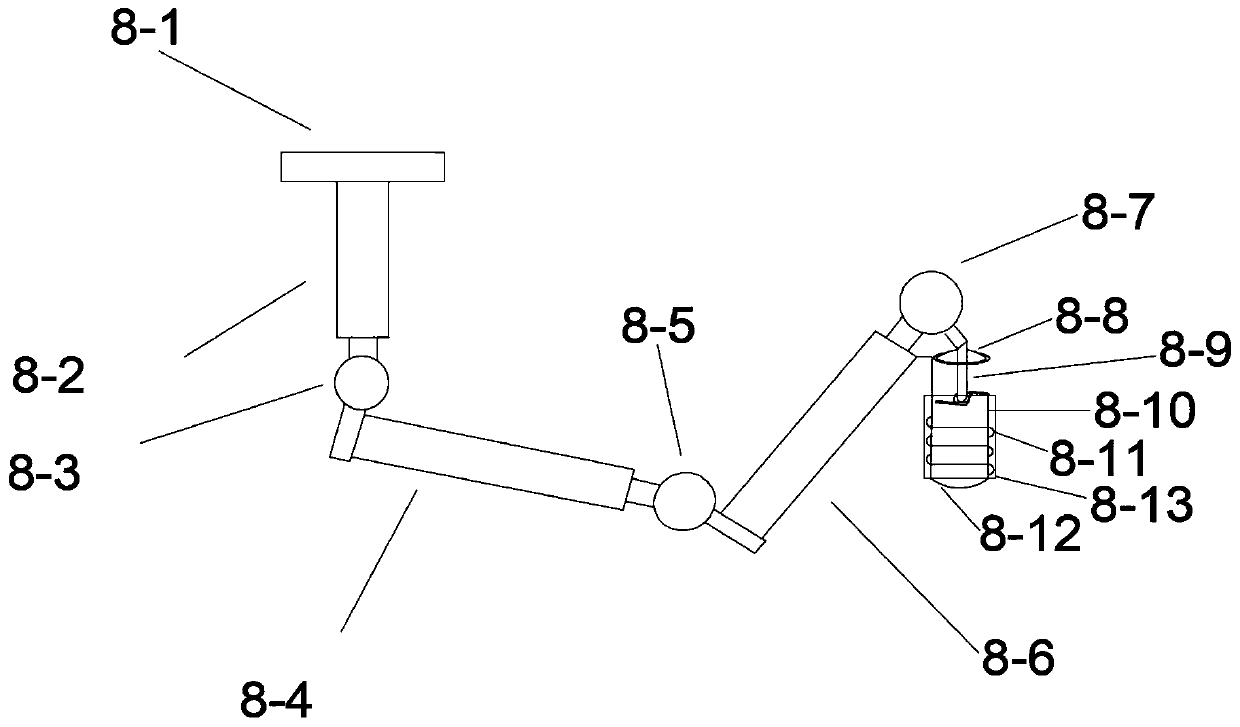

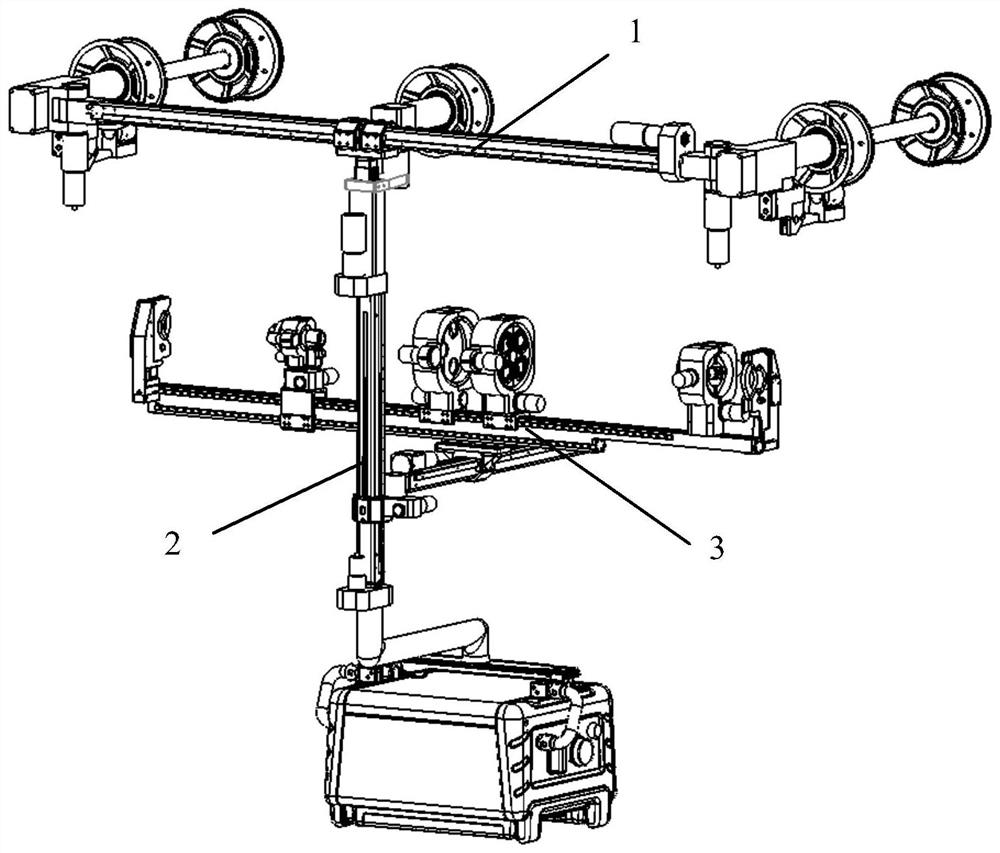

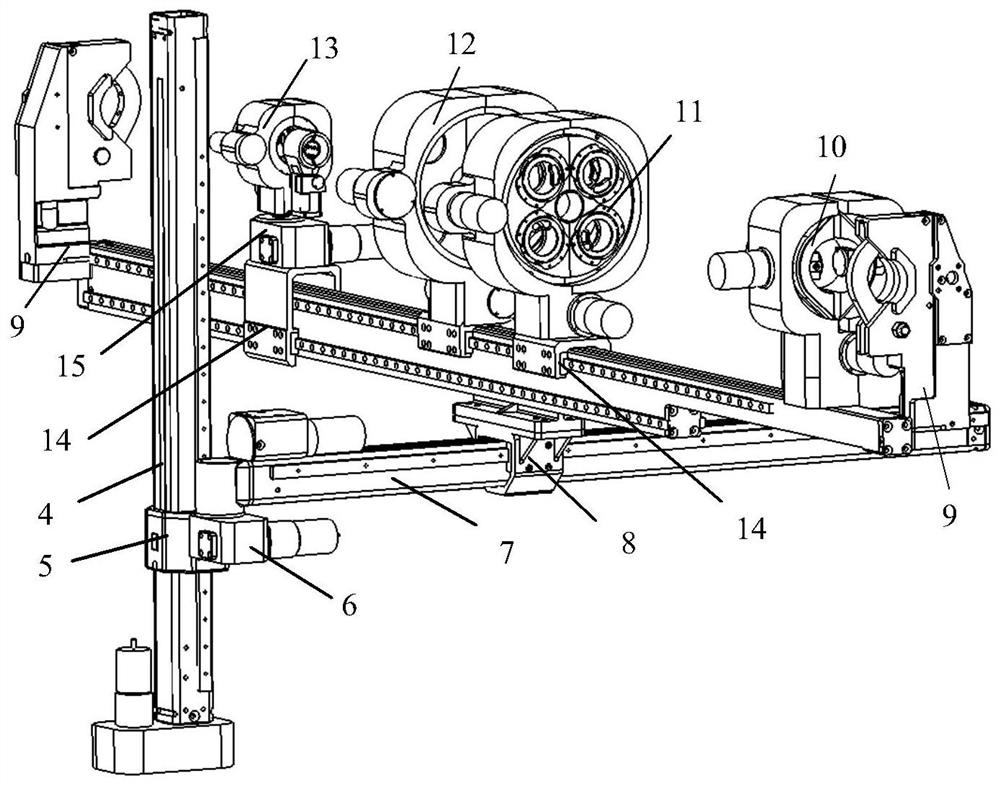

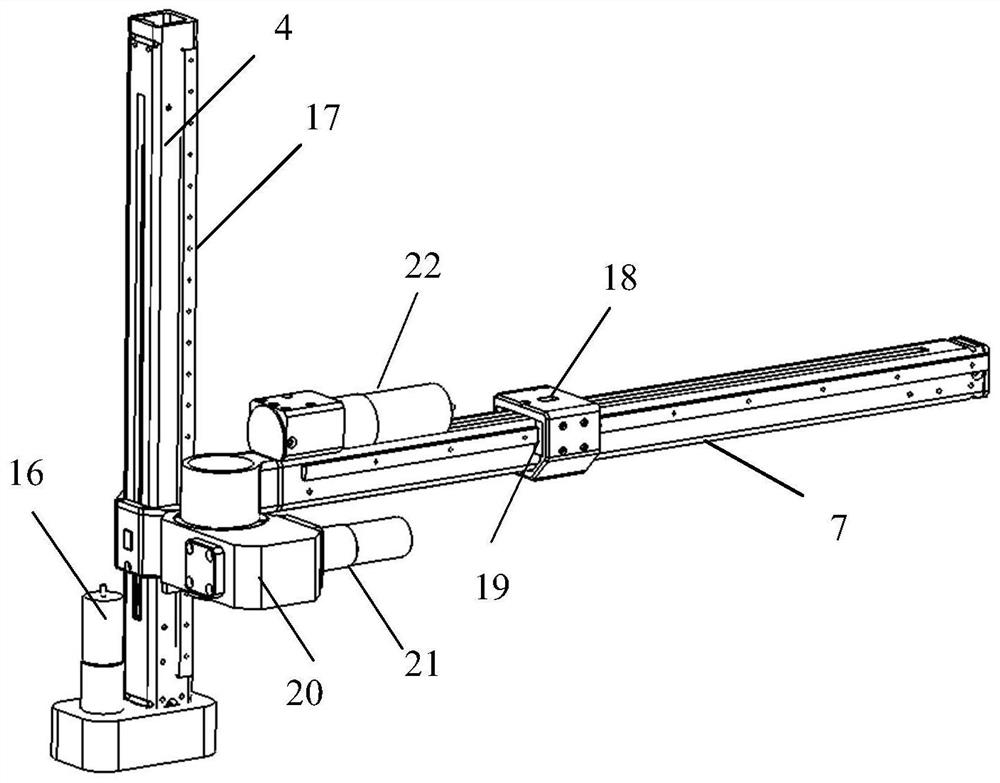

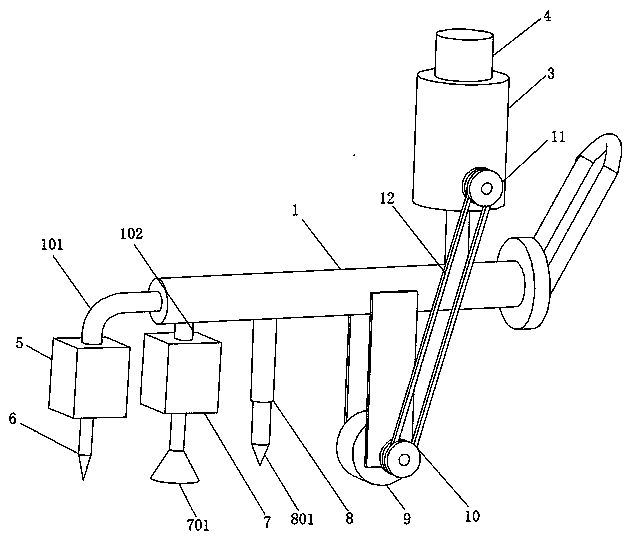

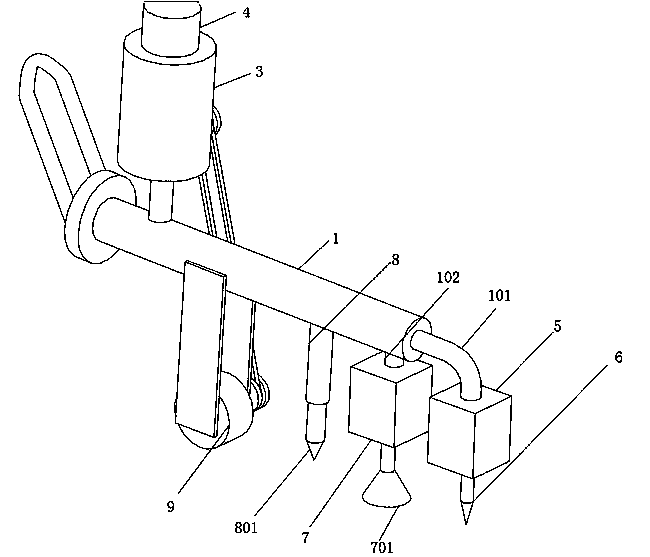

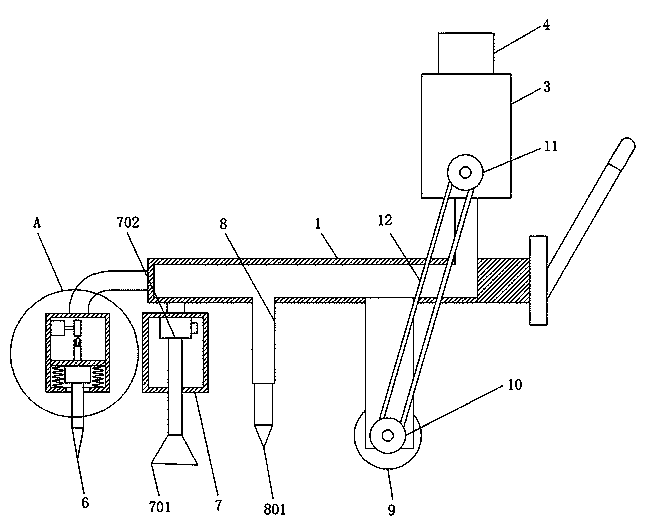

Live-line work robot for repairing broken strand lead by protecting line

ActiveCN113067291AExpand the range of working spaceHigh feasibilityApparatus for joining/termination cablesEngineeringStructural engineering

The invention discloses a live-line work robot for repairing a broken strand lead by a protecting line, and the robot comprises a walking carrier, an obstacle avoidance mechanism and a broken strand repairing working device; the obstacle avoidance mechanism comprises a vertical arm and a transverse arm I; the vertical arm is provided with an up-down longitudinal moving mechanism, the transverse arm I is connected with the up-down longitudinal moving mechanism through a rotary joint, and the upper end of the vertical arm is connected with the walking carrier; the broken strand repairing operation device comprises a left-right translation mechanism, a front-back translation mechanism is arranged on the first cross arm, the left-right translation mechanism is installed on the front-back translation mechanism in a sliding mode through a front-back translation joint and is perpendicular to the transverse arm I, and clamping mechanisms are installed at the two ends of the left-right translation mechanism. A limiting mechanism is fixedly mounted in the middle; a winding mechanism, a guide mechanism and a compounding mechanism are slidably mounted; and the composite mechanism carries out wire stroking, wire wiping, greasing and crimping operations on the wire and the wire pressing strip. According to the invention, full-coverage and integrity repair operation for the multi-split line conductor can be realized, and meanwhile, the surface of the conductor is cleaned, greased and repaired to ensure that the conductor maintains good conductivity.

Owner:WUHAN UNIV

Composite roller repairing method using laser rapid prototyping

InactiveCN103614731AAvoid crackingEasy to operateFurnace typesMetallic material coating processesX-rayOptoelectronics

The invention relates to a composite roller repairing method using laser rapid prototyping. The method is characterized in that a scrap roller is repaired by a laser to form a working layer; when a coaxial powder delivery laser rapidly forms the working layer, an X-ray online detection system performs detection in real time and diagnoses whether the working layer has a defect; if so, the coaxial powder delivery laser is started to re-repair the defect; after the repaired or re-repaired working layer is qualified, the working layer is subjected to thermal treatment by a plasma trigger; finally, the working layer is subjected to finish machining to obtain a finished product of the roller. In the method provided by the invention, by adopting two groups of lasers, X-ray online detection and plasma thermal treatment, the pores and cracks easily generated in the existing laser rapid prototyping repairing process are avoided, the process is relatively simple to operate, the production period is short, the repairing quality is good, and the labor productivity is high.

Owner:湖州市银鑫轧辊有限公司

Process method for replacement and repair of iron clad of main blade made of composite material

InactiveCN104691779AImprove repair efficiencyIncrease success rateAircraft maintainanceAdhesion strengthPolyresin

The invention belongs to the technique of repair of aircrafts, and relates to a process method for replacement and repair of an iron clad of a main blade made of a composite material. The surface of the blade is marked in a spanwise position where the iron clade needs to be replaced, and the iron clad is separated from the main blade; an original resin system is selected and used, dry glass cloth is dipped in glue with 45% glue content, the glass cloth after glue dipping is cut according to the size of the glass cloth, and the layers of the laid glass cloth are one more than those of the stripped glass cloth; a tooling is fixed by adhesive tape and vacuumized, and a upper wing surface and a lower wing surface of the iron clad are pressurized; finally, the method that the blade is fully packaged with a vacuum bag is adopted, so that the iron clad of the blade can be replaced and repaired. The repair quality of the iron clad of the main blade is improved after ungluing, the theoretical appearance and the adhesion strength of the blade are guaranteed, the blade scrap rate caused by faults of the iron clade is effectively reduced, the repair efficiency and the repair success rate of the blade are increased, and the repair quality and the product stability are guaranteed.

Owner:HARBIN

Bumpy cement concrete road surface mending agent

The invention relates to road construction field, in particular to a bumpy cement concrete road surface mending agent, aiming at solving such problems of mending materials adopted in current cement concrete road surface mending as slow strength development, poor combination with original cement concrete layer, easy contraction and cracking and the like. The invention comprises 15-25% of acrylic ester elastic latex, 5-20% of 108 adhesive, 5-10% of AKD latex, 8-15% of polyvinyl alcohol fiber, 0.5-2% of common silicate cement, 1-3% of sand and balance water. The mending agent has good tenacity and anti-deformation capability, reduces drying shrinkage, has higher cementing strength with the old concrete interface, good compatibility, enhanced rupture strength and antifatigue property, increased fatigue life and good mechanical property, satisfies the requirement of fast mending the cement concrete road surface, improves use property of the road surface, prolongs service life of the road surface, saves project cost, shortens construction period and is beneficial for enhancing mending quality and speed of cement road surface.

Owner:亢吉田

Method for repairing turbine guide using laser additive

InactiveCN110666168AImprove repair qualityFast repairAdditive manufacturing apparatusIncreasing energy efficiencyFluorescenceStructural engineering

The invention provides a method for repairing a turbine guide using laser additive. The method comprises the following steps of S1, carrying out fluorescence detection on a damaged guide and photographing and recording a defect position; S2, cleaning the surface of the guide, grinding an area to be repaired, removing a wear layer, a fatigue layer, an oxide layer and other impurities; S3, confirming the size of the area to be repaired according to three-dimensional scanning and combining a drawing; S4, analyzing and confirming the material of the repairing area by an alloy analyzer; S5, developing a repairing process, specifically, confirming the repairing sequence, designing a reasonable tool, repairing parameters of the laser additive and powder type; S6, carrying out machining and quality inspection, specifically, machining the repaired area to make the size, shape precision and surface quality to meet the technical requirements, and carrying out X-ray detection on the repaired areato detect whether a defect exists or not. According to the method for repairing the turbine guide using the laser additive, the repairing quality is good, the repairing speed is high, the efficiency is high, an interface between the repairing area and a base body is metallurgically bonded, the binding force is strong, and the deformation is small.

Owner:航发优材(镇江)增材制造有限公司

Road repairing and breaking device

InactiveCN109629386AWeight increaseImprove repair qualityRoads maintainenceCrushed stoneRoad surface

The invention belongs to the field of road equipment, and particularly discloses a road repairing and breaking device. The road repairing and breaking device comprises a cart body, a breaking mechanism, a dust collection pump and a pouring mechanism, wherein the breaking mechanism, the dust collection pump and the pouring mechanism are located in the cart body; a lever is arranged in the cart body, the dust collection pump and the pouring mechanism are fixedly connected to the two ends of the level respectively, an elastic piece is fixedly connected to the bottom of the level on one side of the dust collection pump, the dust collection pump is communicated with a sucker for absorbing road gravel particles, the sucker penetrates through the bottom of the cart body, and a sucker opening faces the lower portion of the cart body; the pouring mechanism comprises a discharging hopper containing padding, the side wall, towards one side of the dust collection pump, of the discharging hopper iscommunicated with a discharging pipe, and the discharging pipe penetrates through the bottom of the cart body to face the lower portion of the cart body. After the technical scheme is adopted, the road repairing and breaking device can automatically pour padding into road surface cracks in the road repairing process.

Owner:CHONGQING VOCATIONAL INST OF ENG

Die core repairing process

The invention provides a die core repairing process. The die core repairing process includes the following steps that a, detection is carried out, and specifically the damage conditions of a dire core are examined; b, repairing and analysis are carried out, and a repairing scheme is made according to the examined damage conditions; c, repairing welding is carried out on a die core with a small damage area, and a numerical control milling machine is used for machining the repairing welding position to meet the size requirement; d, an insert is used for repairing the die core with a large damage area in a filling mode, and the numerical control milling machine is used for machining the insert filling position to meet the size requirement; and e, a new die core is machined to replace the die core with a too large damage area. The die core repairing process is convenient and rapid to operate, good in repairing quality and capable of reducing the machining cost.

Owner:鲁一军

Wood floor repairing agent and using method thereof

InactiveCN106883802AImprove the efficiency of manual patchingImprove adhesionEpoxy resin adhesivesSolid woodAdhesive

The invention belongs to the technical field of chemical adhesives, and relates to a wood floor repairing agent and a using method thereof. The wood floor repairing agent is prepared by compounding and blending epoxy resin and an epoxy resin curing agent, wherein the epoxy resin is bisphenol A-type epoxy chloropropane with low molecular weight; the epoxy resin curing agent is polyethylenimine, wherein the weight ratio of the epoxy resin to the epoxy resin curing agent is 100: (50-70). The invention further discloses the using method of the repairing agent. By adopting the wood floor repairing agent disclosed by the invention, the efficiency of manual repair of a solid wood composite floor can be improved, and when the veneer floor with low repair grade is repaired, compared with the repairing efficiency of the quick-drying putty, the efficiency is improved by about 100%; the repairing agent is firmly adhered to the surrounding wood, cracking and detachment between the repairing agent with knots and the wood are avoided, and the detection requirements of 6.2.5 surface hot-cold cycle resistant test in the standard LY / T1700-2007 of wood based flooring for ground with a heating system can be met. The improvement of the repairing quality of the material species rich in the medullary spot and resin pocket is more obvious, and the repairing agent has a good application prospect.

Owner:DAYA JIANGSU FLOOR

Asphalt additive for cold repair of road surface

InactiveCN1810885AImprove road performanceImprove anti-aging propertiesIn situ pavingsBuilding insulationsPetroleum resinPolyamide

The asphalt additive material for cold repair of road surface consists of: styrene-butadiene-styreene block copolymer 2-5 weight portions, petroleum resin 1-3 weight portions, terpene resin 1-3 weight portions, polyamide 0.3-0.7 weight portions, N-cyclohexyl-Níõ-phenyl-phenylenediamine 0.3-0.7 weight portions, mineral oil 1-3 weight portions, styrene 3-7 weight portions, diesel oil 3-7 weight portions and asphalt 70-90 weight portions. It is prepared through mixing the materials at 170- 200 deg.c via high speed stirring for mutual reaction. The present invention has reasonable preparation process, and the asphalt additive material for cold repair of road surface has simple application, long storage period, high repair quality, wide use, environment friendship and low cost.

Owner:SHENYANG URBAN CONSTR ASPHALT CONCRETE FACTORY

Portable efficient building asphalt road maintenance crack repairing gun

InactiveCN109914211AImprove work efficiencyEasy to achieve reciprocating motionRoads maintainenceEngineeringAsphalt

The invention discloses a portable efficient building asphalt road maintenance crack repairing gun and belongs to the field of building construction. The portable efficient building asphalt road maintenance crack repairing gun comprises an asphalt storage cylinder, wherein a pressurizing pump acting on the asphalt storage cylinder is connected with the top of the asphalt storage cylinder; a conveying tube is connected with the discharge hole of the asphalt storage cylinder; a cleaning mechanism, a dust collection mechanism and a guide tube are sequentially connected at one end, far away from the asphalt storage cylinder, of the conveying tube in a horizontal direction; a stirring rod is connected inside the asphalt storage cylinder. When being used, the repairing gun is pushed, in case ofcracks, irregular cracks are cleaned by using the cleaning mechanism, cleaned dust and soil are collected by using the dust collection mechanism, finally asphalt in the asphalt storage cylinder is injected into cleaned cracks through the conveying tube, and thus the working efficiency can be improved.

Owner:董佑军

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com