Method for repairing turbine guide using laser additive

A turbine guide, laser additive technology, applied in the direction of additive processing, process efficiency improvement, energy efficiency, etc., can solve the problems of blade oxidation and corrosion, parts deformation, easy to burn out, etc., to achieve fast repair speed, Good repair quality and strong bonding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

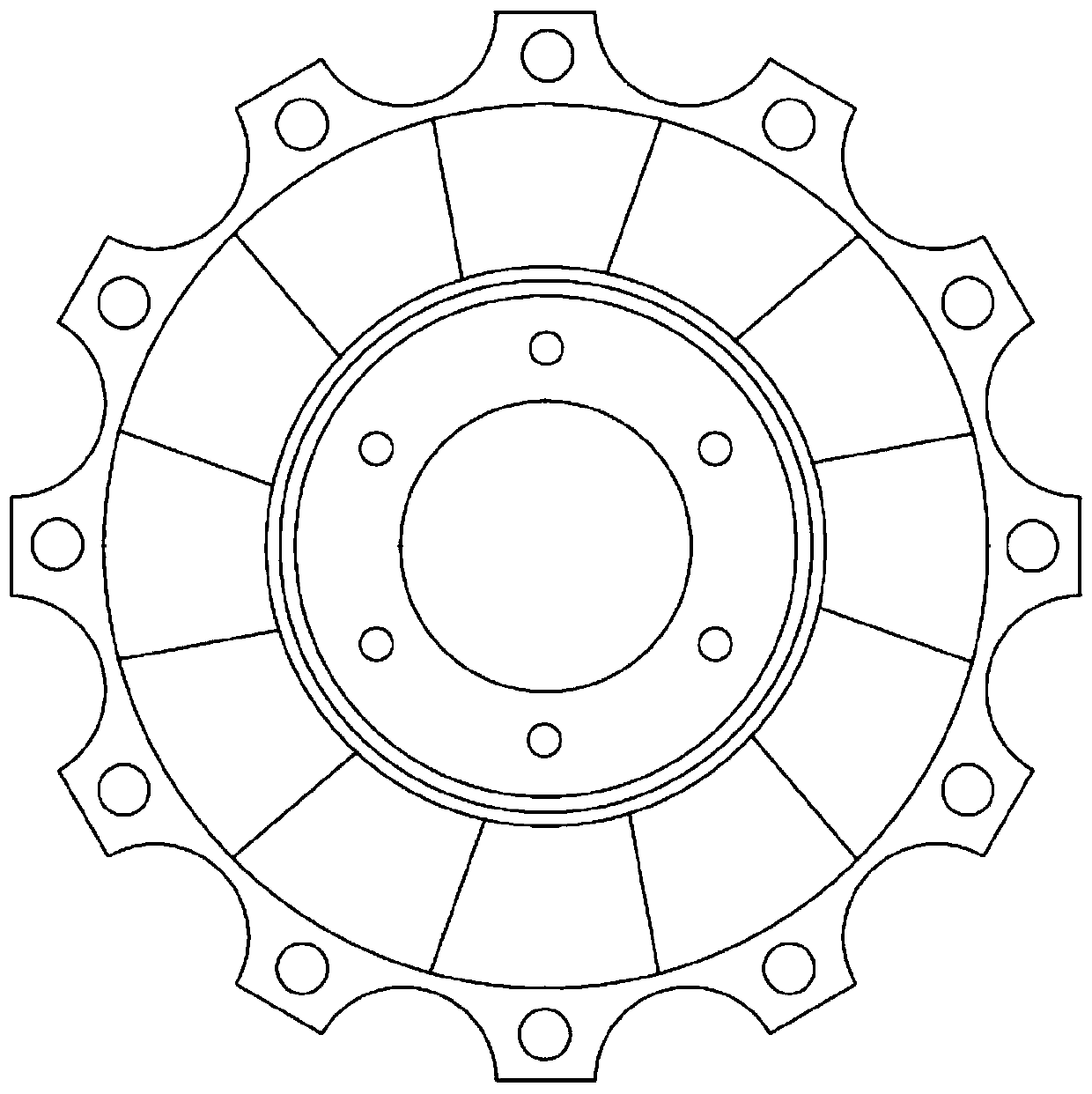

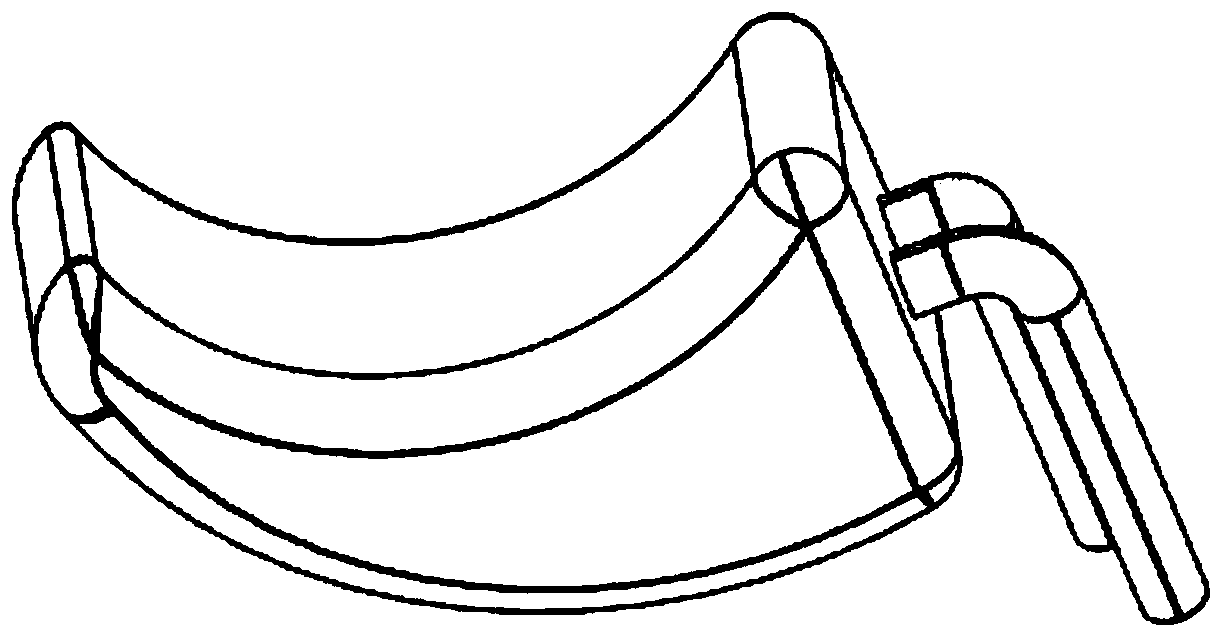

[0026] The turbine guider is repaired by laser additive repair method, and the matrix material is GH3536 alloy.

[0027] This embodiment includes the following steps:

[0028] After the repairable evaluation of the damaged part is determined to be repairable, laser additive repair is carried out, and the following specific steps are implemented:

[0029] S1. Perform fluorescence detection on the damaged guide and take pictures to record the defect location; specifically, use the fluorescence detection guide, focus on observing the blade wear and outer ring wear, and take pictures to record the defect position;

[0030] S2. Clean the surface of the guide, remove defects with a grinding gun under fluorescent light, polish off the wear layer and oxide layer with a file and sandpaper, and then put it into an ultrasonic cleaner for 10 minutes to remove oil stains and grinding debris that affect the repair quality , and possible residual fluorescent liquid, and then dried by compre...

Embodiment 2

[0041] The turbine guider is repaired by laser additive repair method, and the matrix material is GH3536 alloy.

[0042] This embodiment includes the following steps:

[0043] After the repairable evaluation of the damaged part is determined to be repairable, laser additive repair is carried out, and the following specific steps are implemented:

[0044] S1. Perform fluorescence detection on the damaged guide and take pictures to record the defect location; specifically, use the fluorescence detection guide, focus on observing the blade wear and outer ring wear, and take pictures to record the defect position;

[0045] S2. Clean the surface of the guide, remove defects with a grinding gun under fluorescent light, polish off the wear layer and oxide layer with a file and sandpaper, and then put it into an ultrasonic cleaner for 10 minutes to remove oil stains and grinding debris that affect the repair quality , and possible residual fluorescent liquid, and then dried by compre...

Embodiment 3

[0056] The turbine guider is repaired by laser additive repair method, and the matrix material is GH3536 alloy.

[0057] This embodiment includes the following steps:

[0058] After the repairable evaluation of the damaged part is determined to be repairable, laser additive repair is carried out, and the following specific steps are implemented:

[0059]S1. Perform fluorescence detection on the damaged guide and take pictures to record the defect location; specifically, use the fluorescence detection guide, focus on observing the blade wear and outer ring wear, and take pictures to record the defect position;

[0060] S2. Clean the surface of the guide, remove defects with a grinding gun under fluorescent light, polish off the wear layer and oxide layer with a file and sandpaper, and then put it into an ultrasonic cleaner for 10 minutes to remove oil stains and grinding debris that affect the repair quality , and possible residual fluorescent liquid, and then dried by compres...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com