Road repairing and breaking device

A technology of crushing device and road repair, applied in the direction of road repair, roads, roads, etc., can solve the problems of reducing repair efficiency, high operation cost, low operation efficiency, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The following is further described in detail through specific implementation methods:

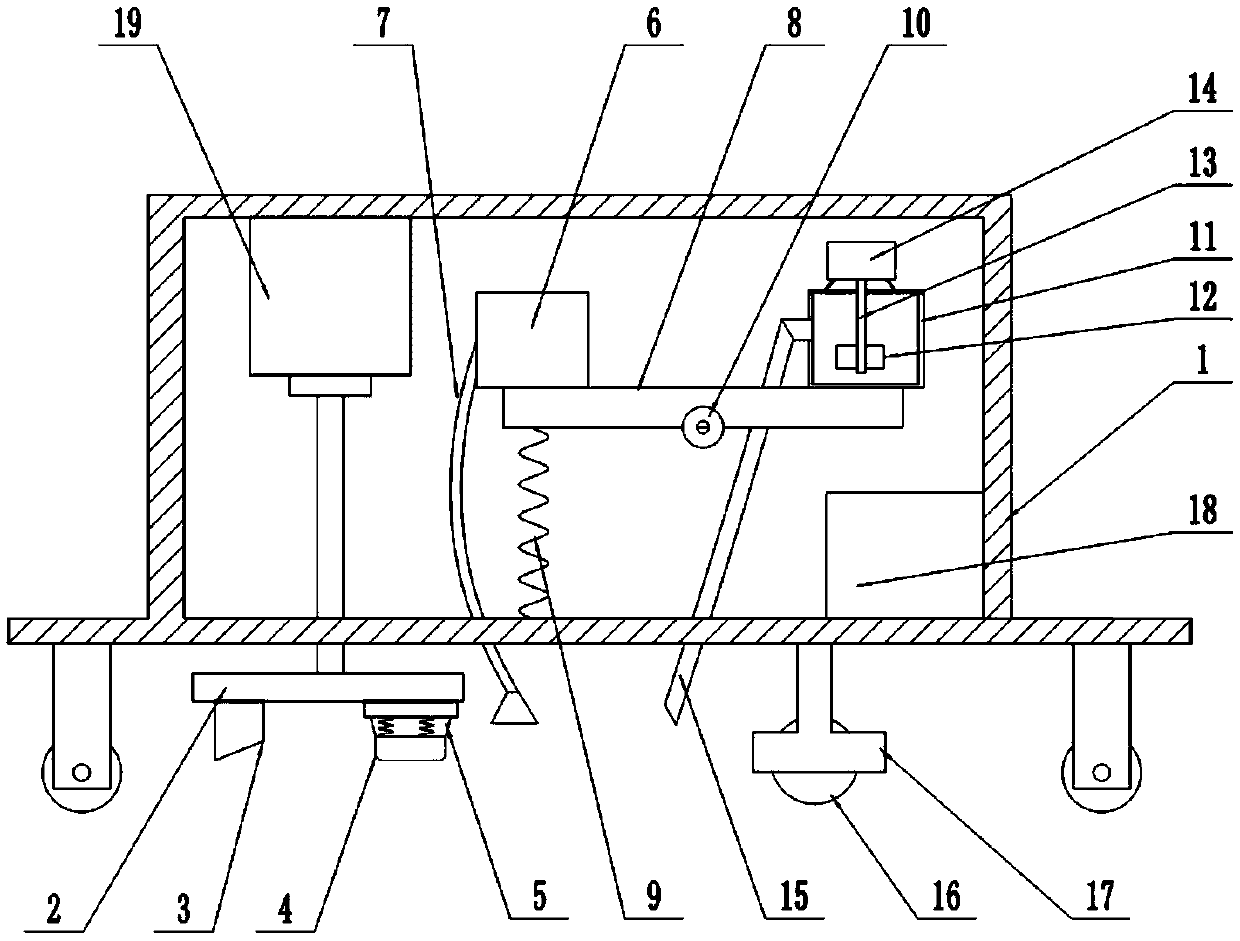

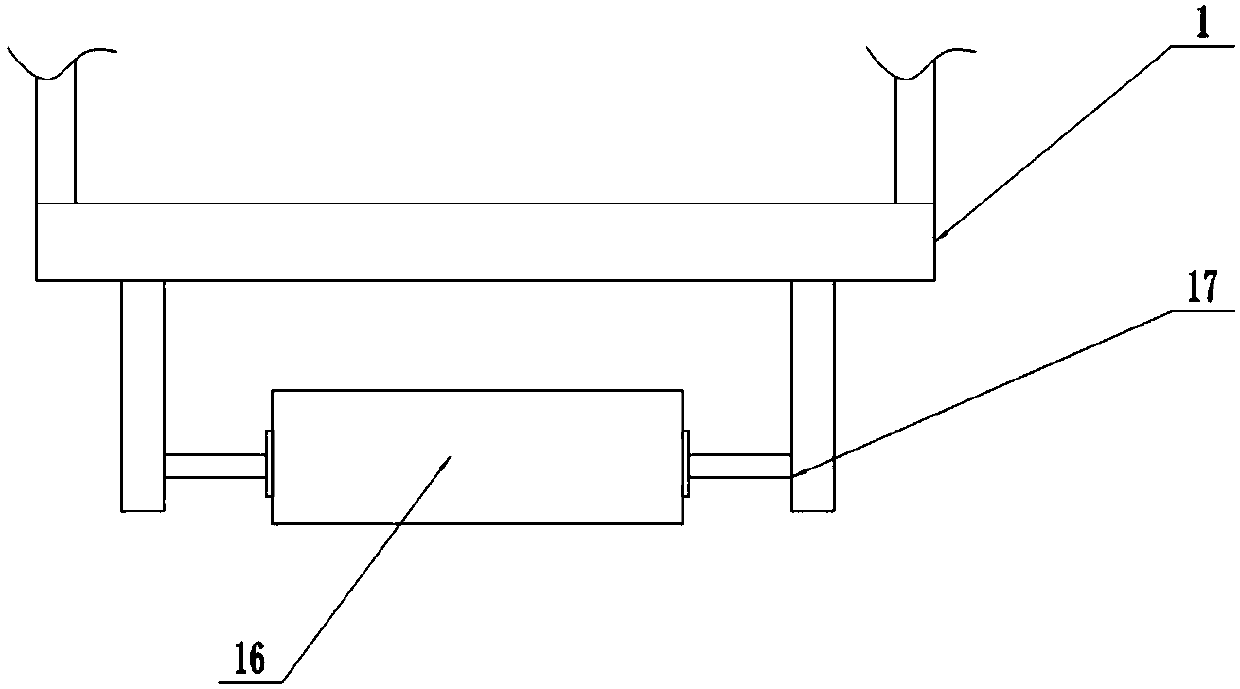

[0019] The reference signs in the drawings of the specification include: car body 1, mounting plate 2, cutting head 3, breaking hammer 4, vibrator 5, dust suction pump 6, suction pipe 7, lever 8, spring 9, support rod 10, hopper 11. Stirring plate 12, central shaft 13, driving motor 14, feeding pipe 15, compacting roller 16, connecting rod 17, vehicle power supply 18, cylinder 19.

[0020] The embodiment is basically as attached figure 1 and figure 2 Shown:

[0021] The orientation words such as "left, right" described in this embodiment are only limited to the appended figure 1 and figure 2 , a road repair breaking device, such as figure 1 As shown, it includes a car body 1, a crushing mechanism, a pouring mechanism and a compacting mechanism; a lever 8 and a transverse strut 10 are installed in the car body 1, and the strut 10 is welded on both side walls of the car body 1, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com