Patents

Literature

33results about How to "Guaranteed perfusion quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

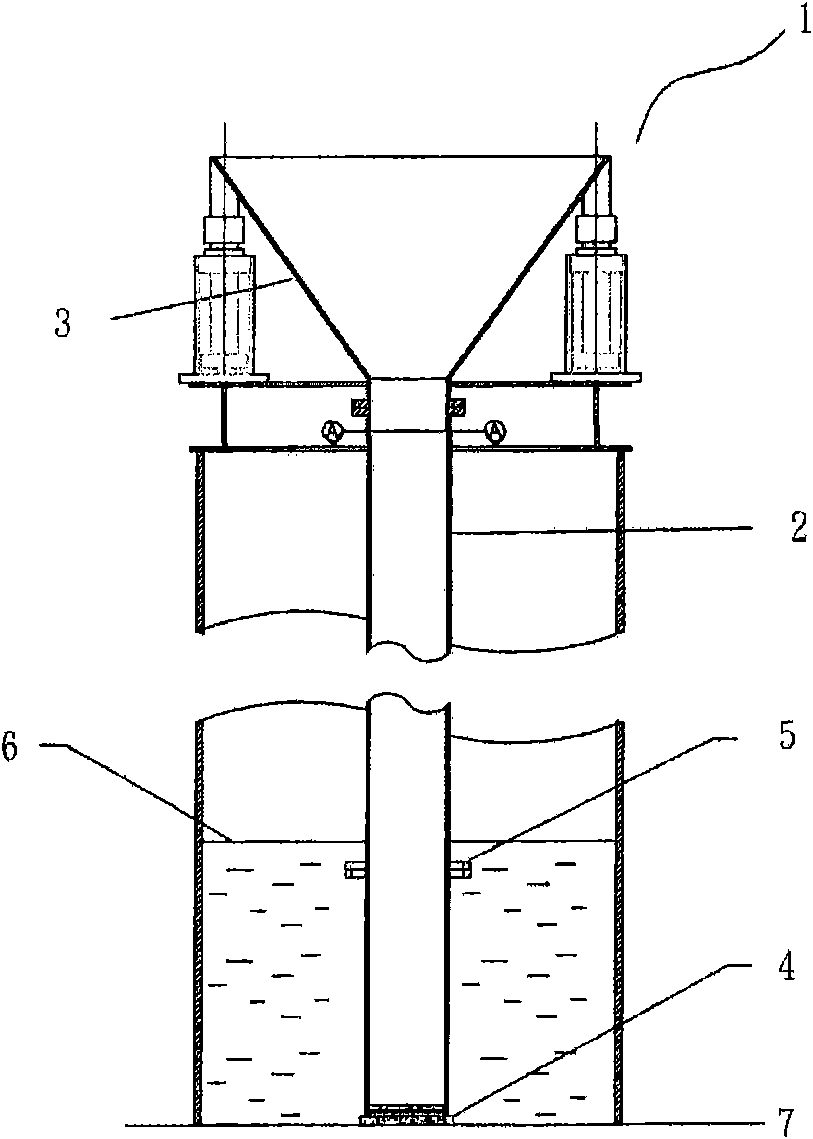

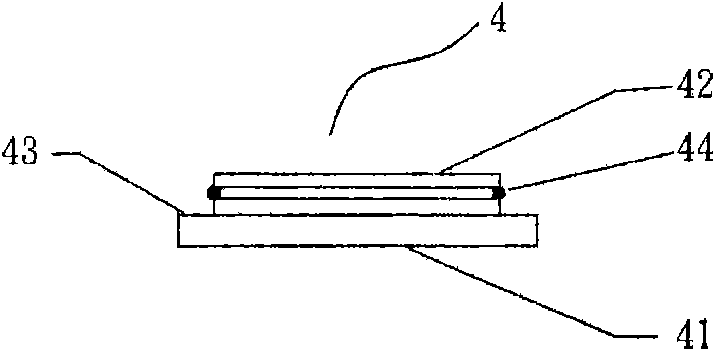

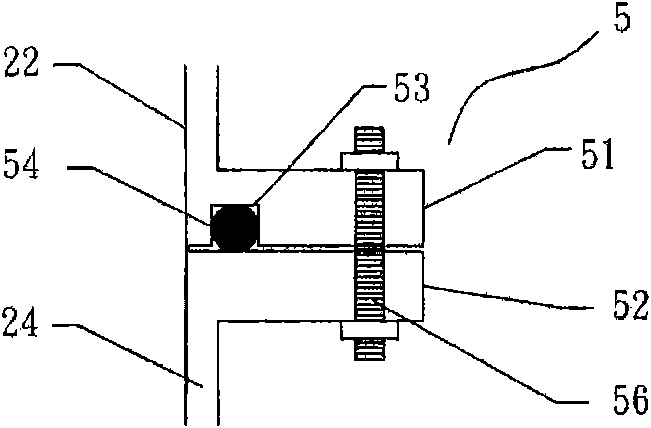

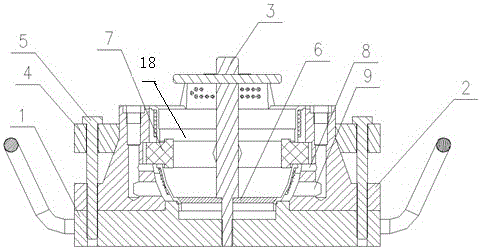

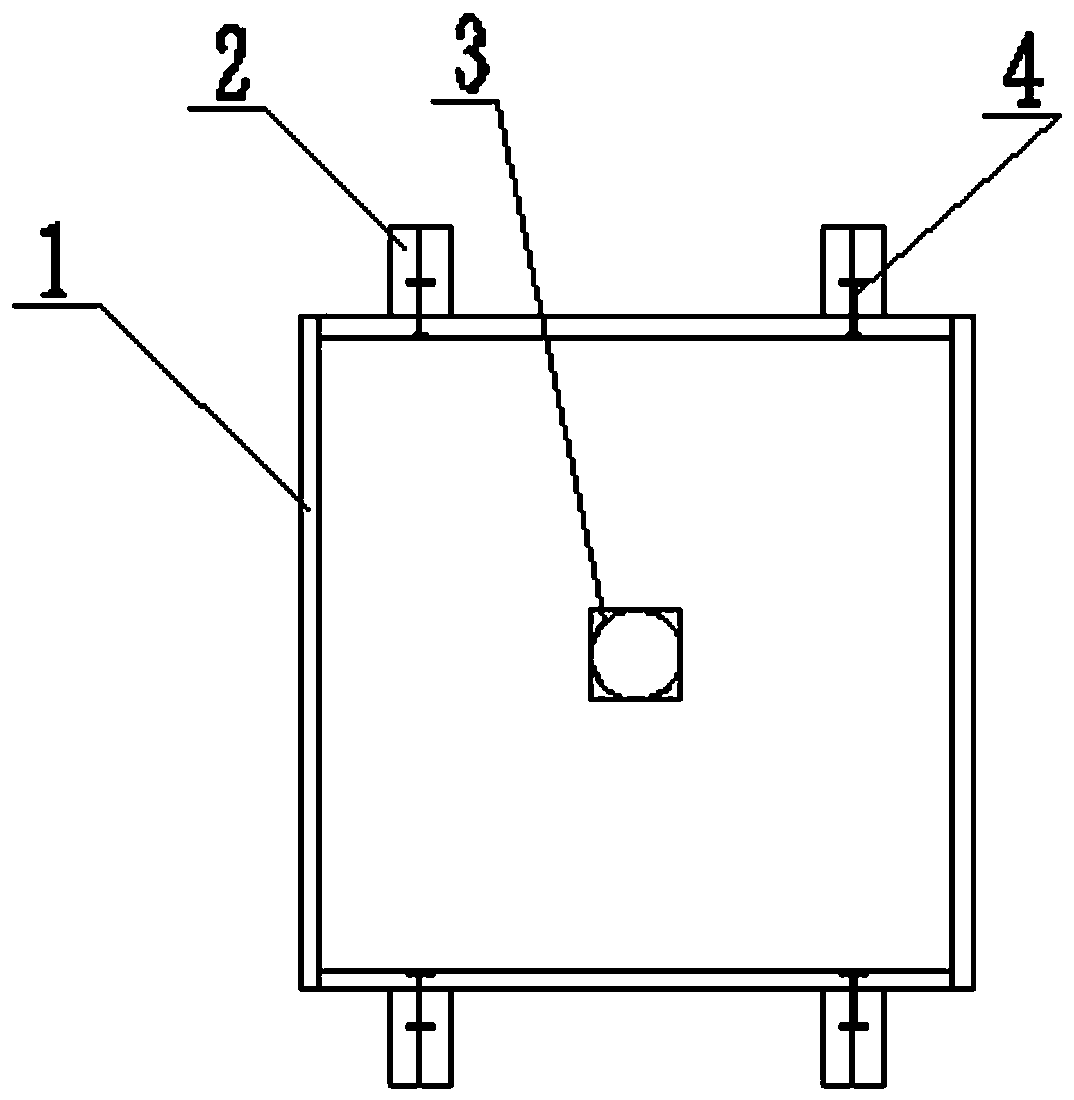

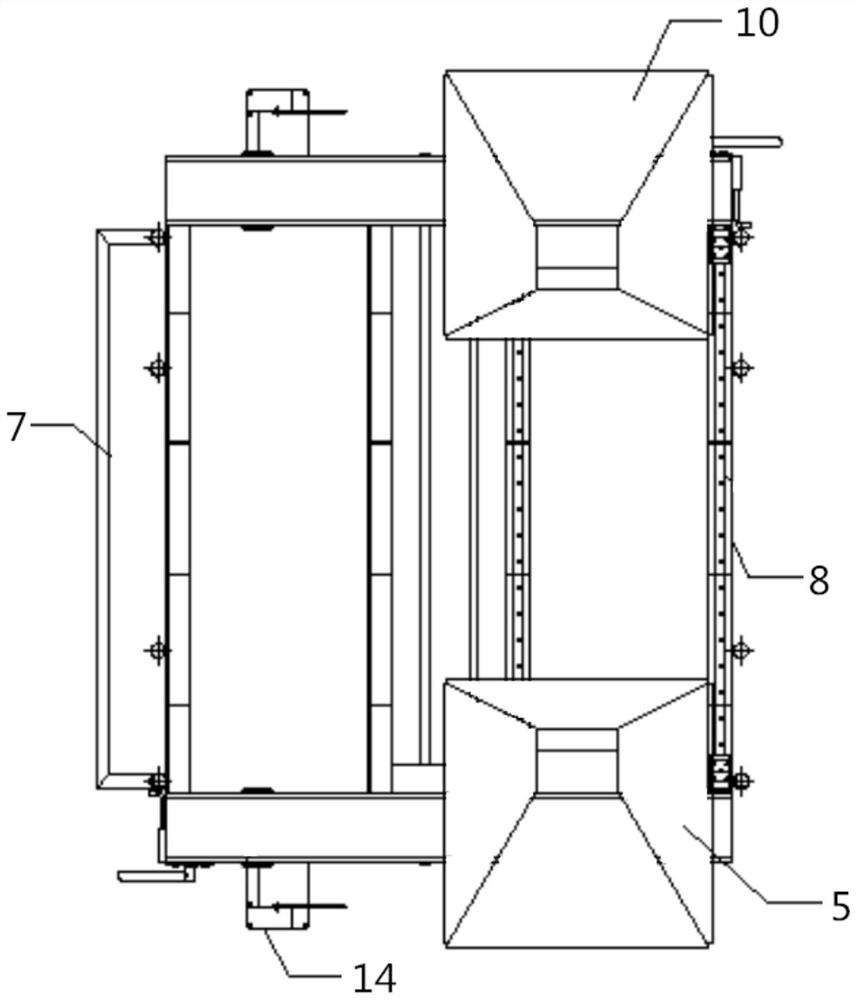

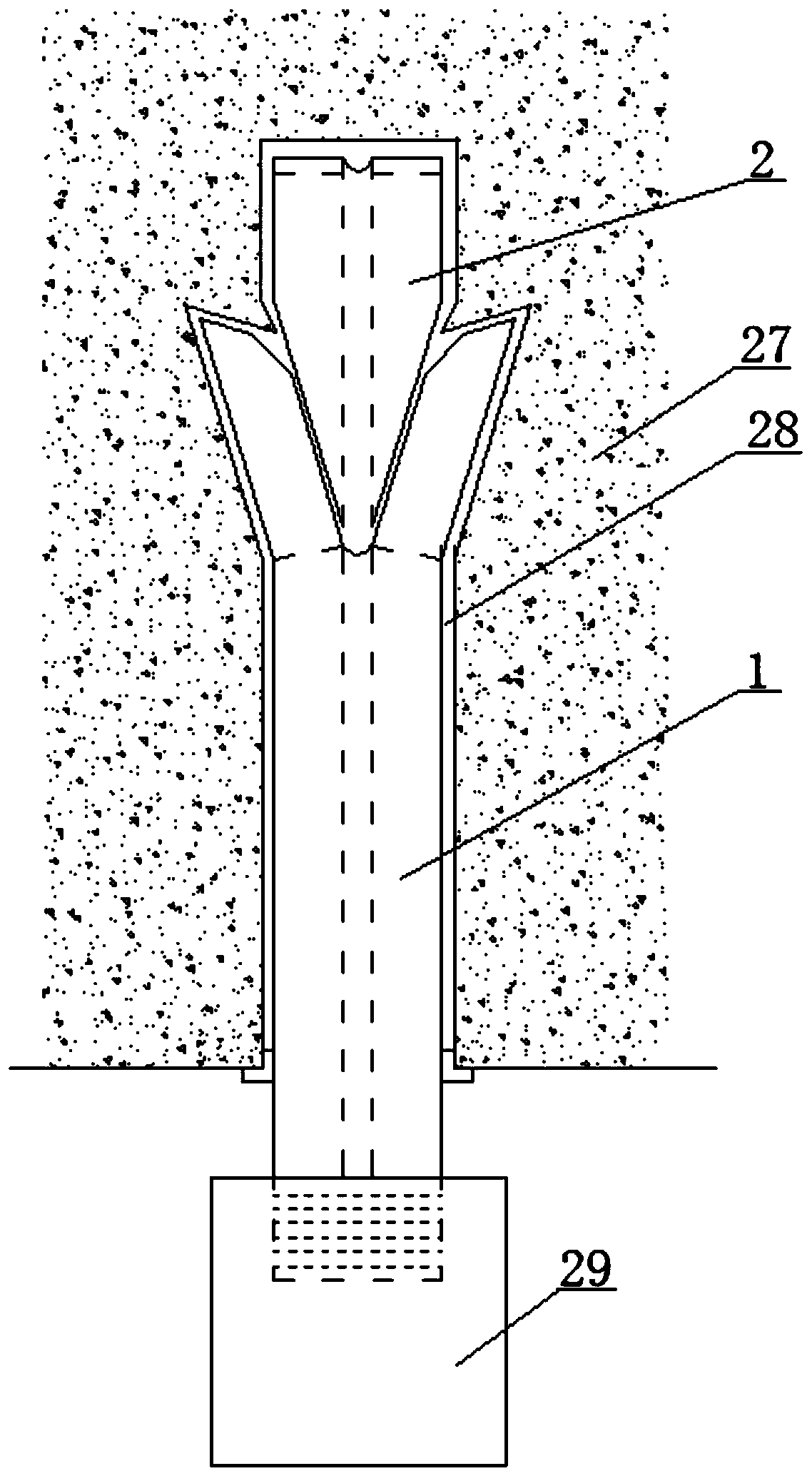

Concrete pouring device and method

ActiveCN102134852AGuaranteed perfusion qualitySolve the serious problem of mixing in waterFoundation engineeringGuide tubeUse equipment

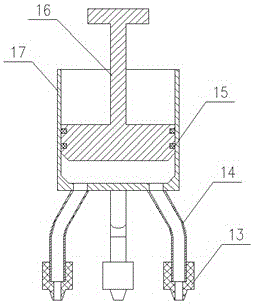

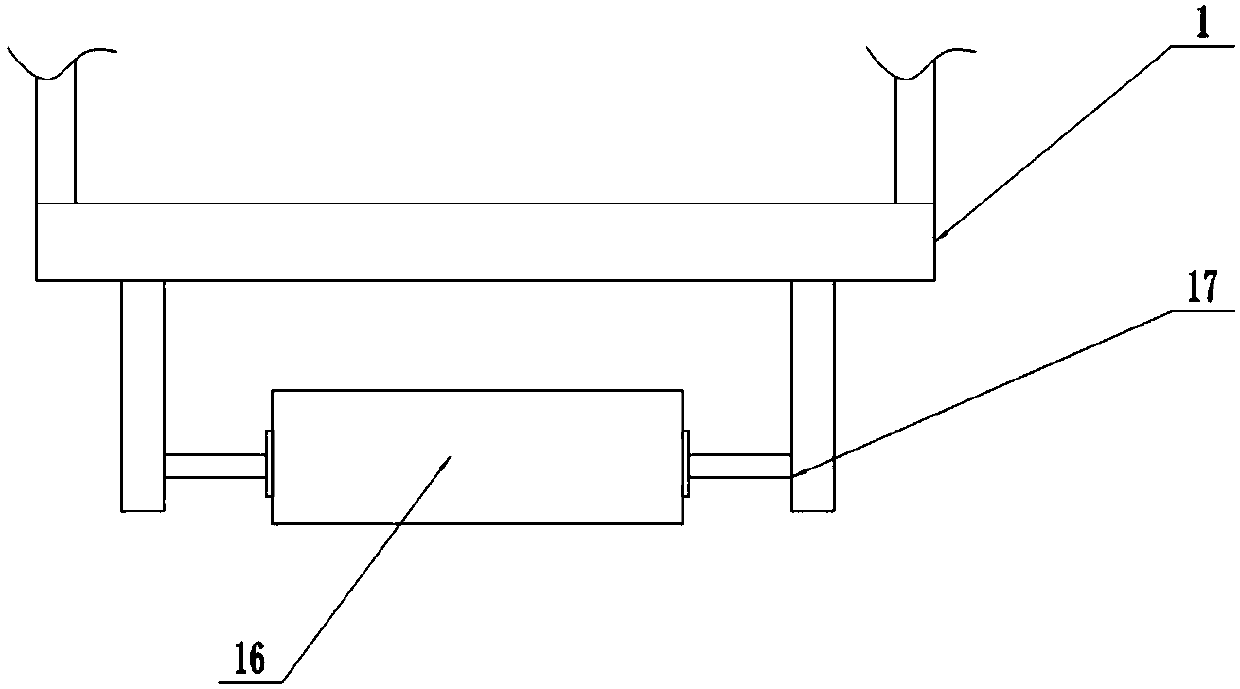

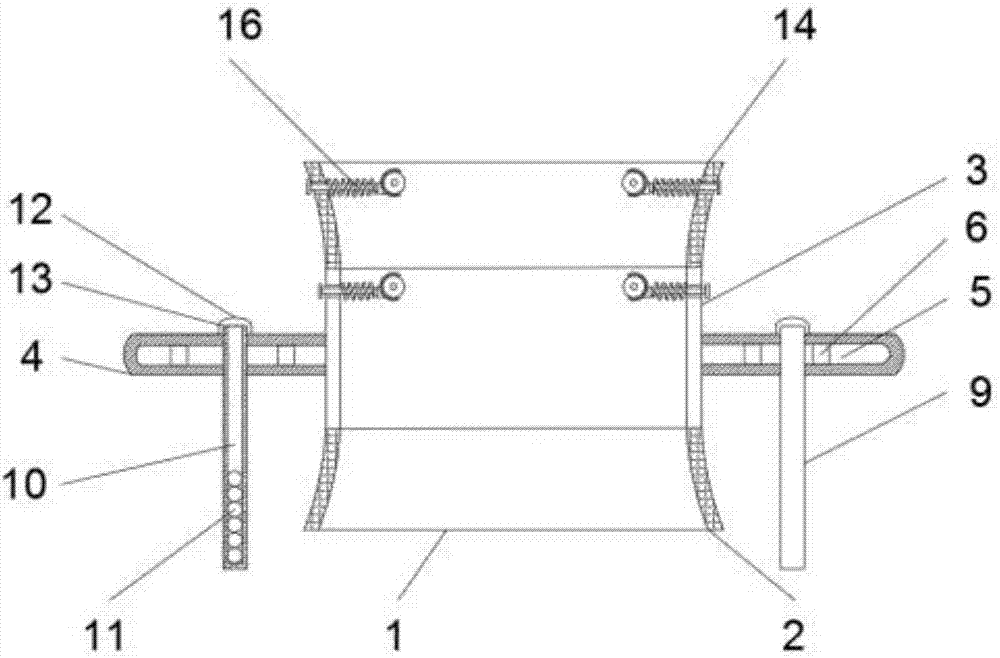

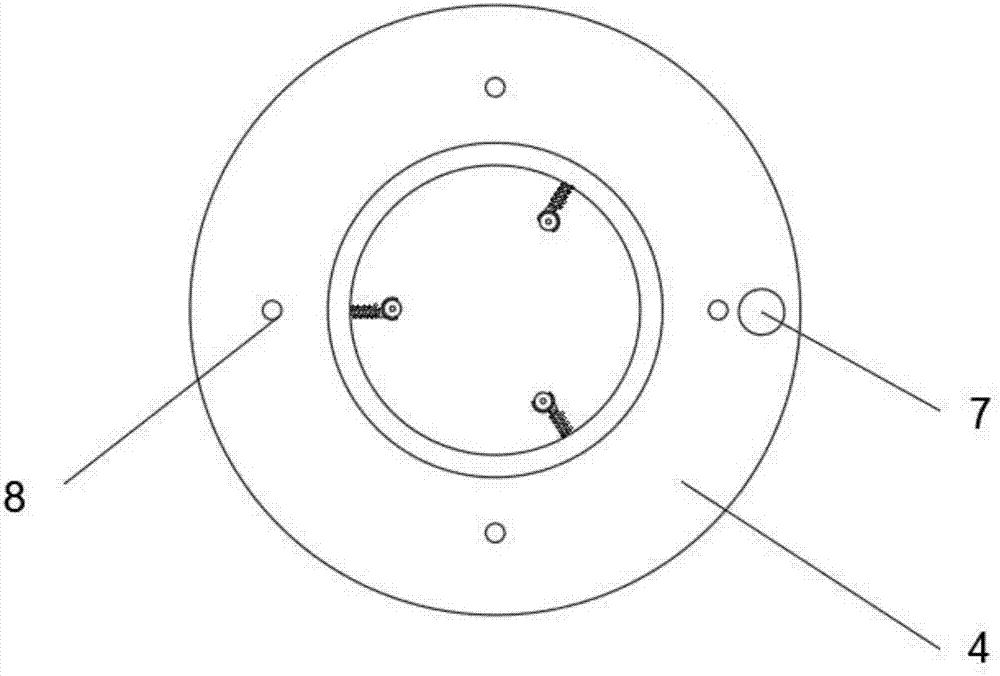

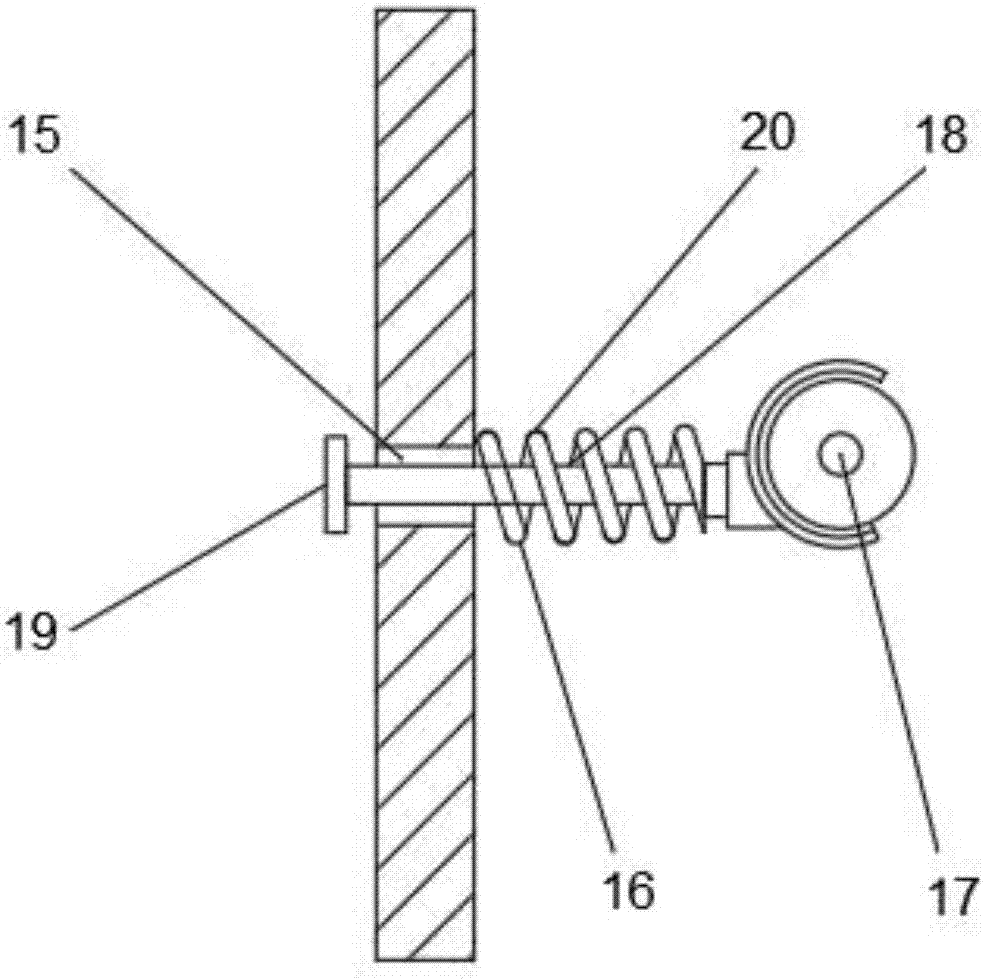

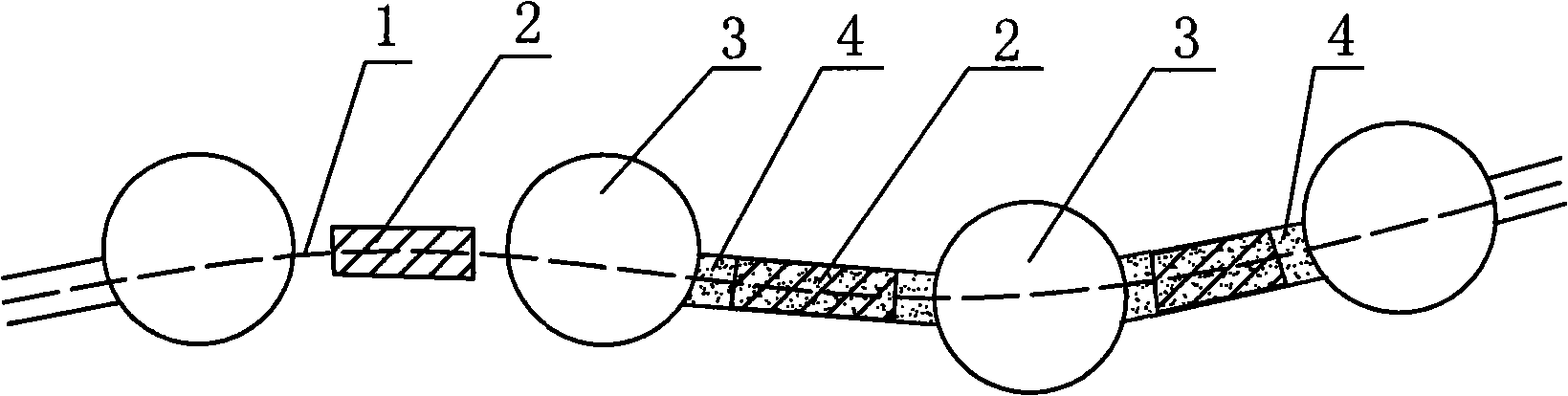

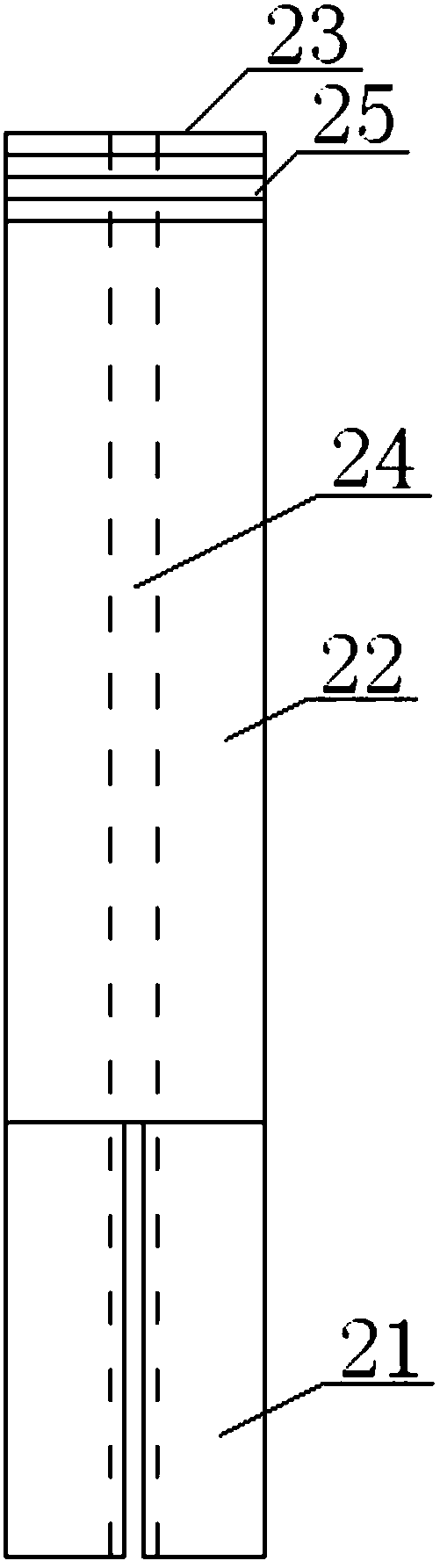

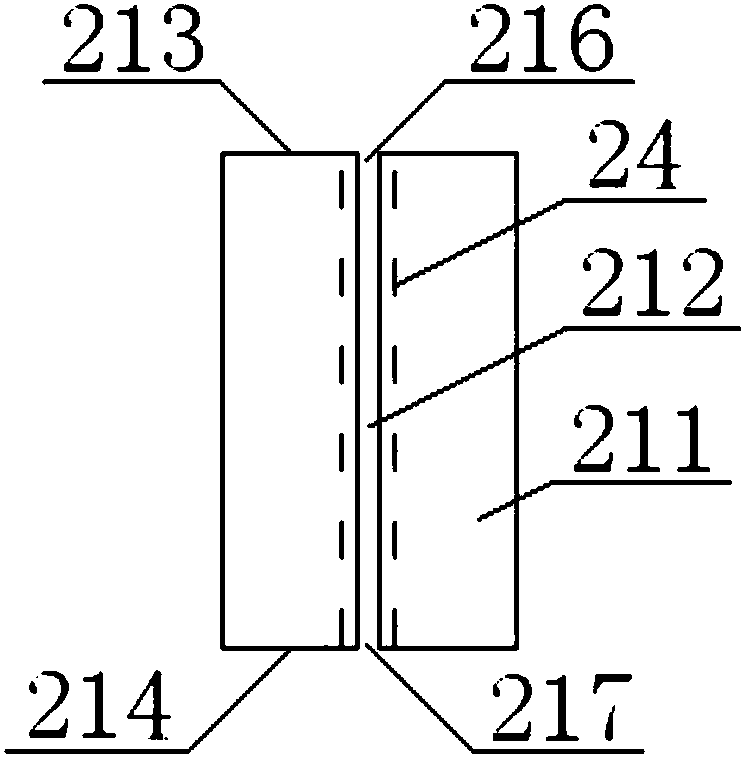

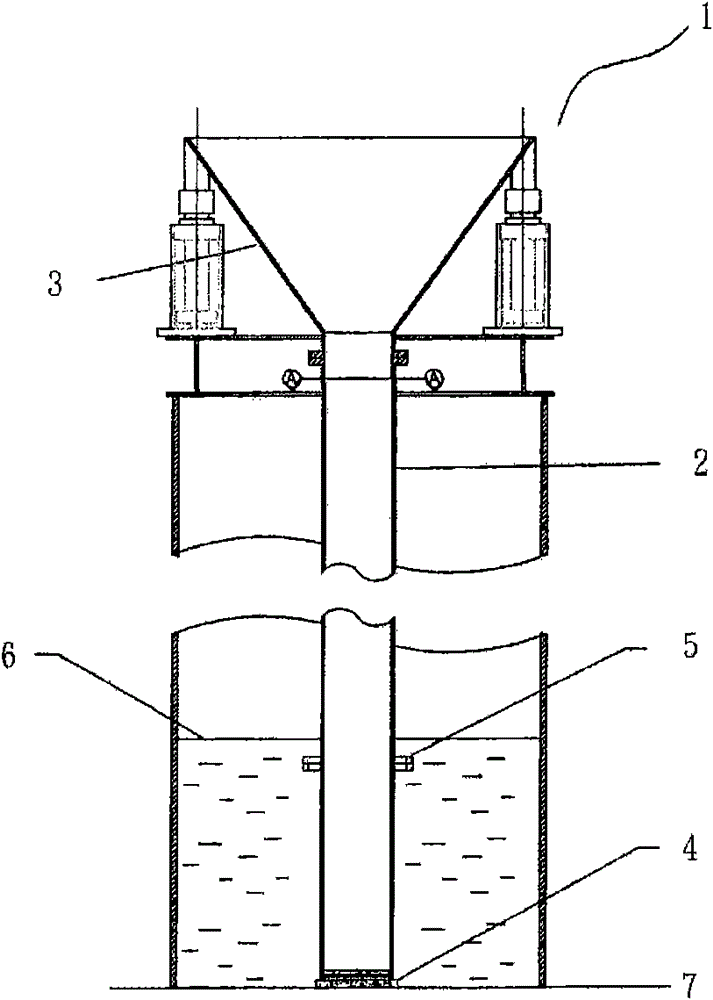

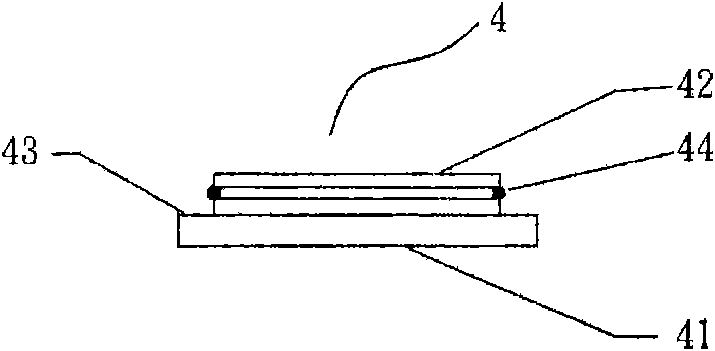

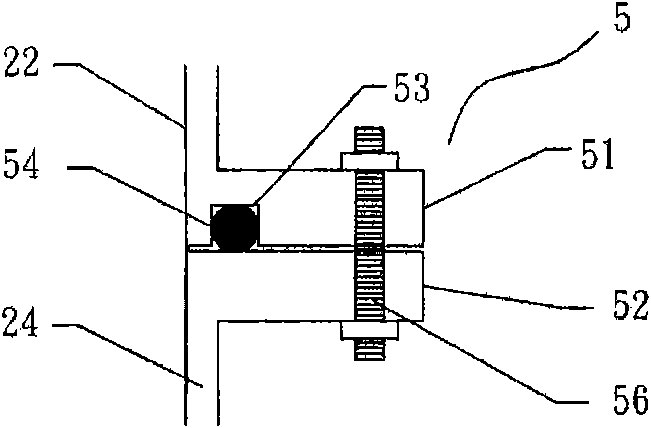

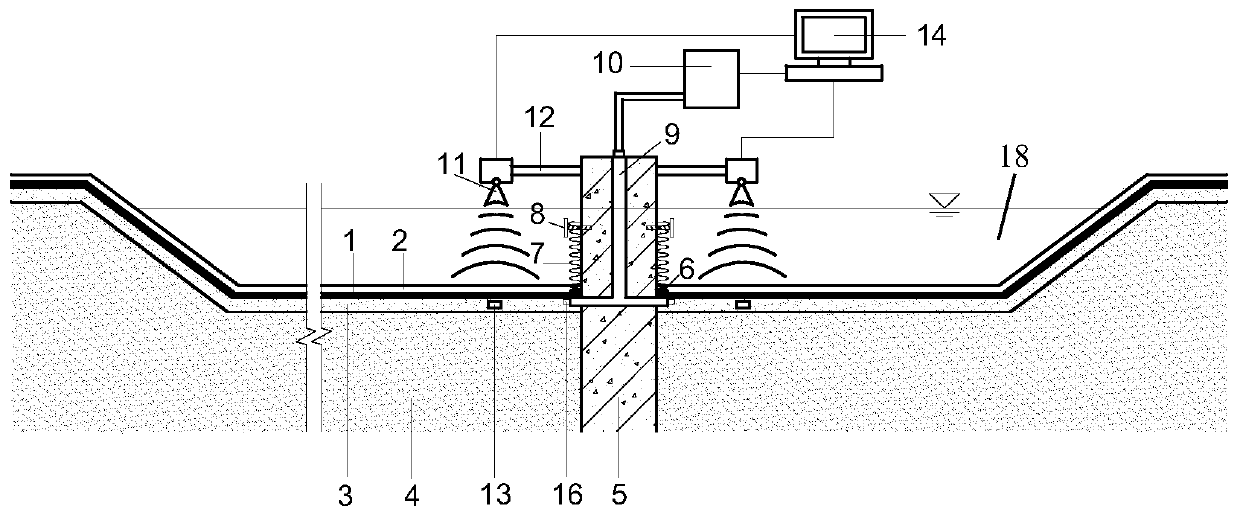

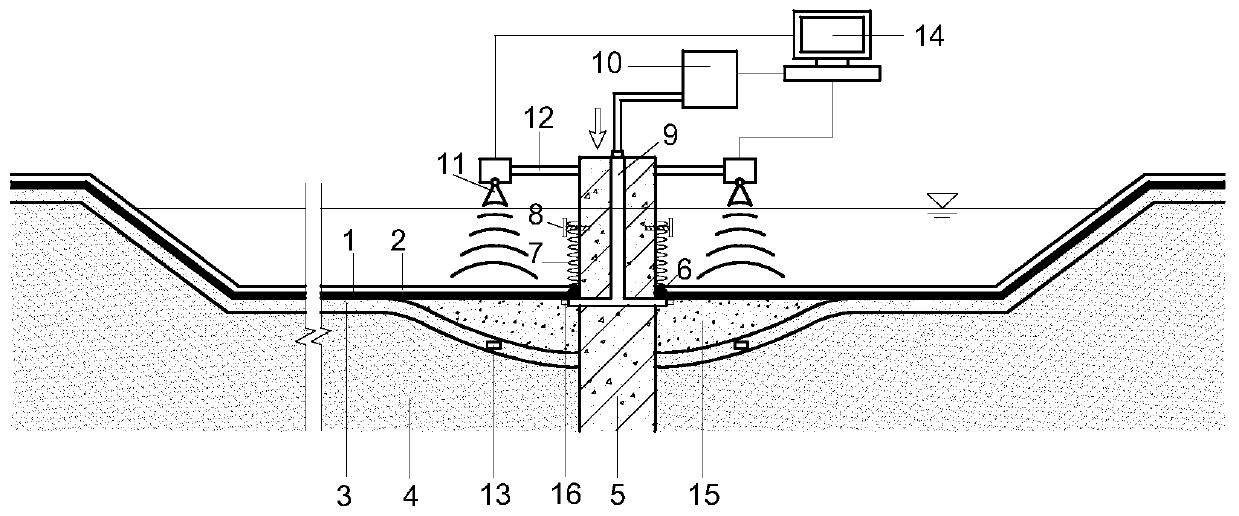

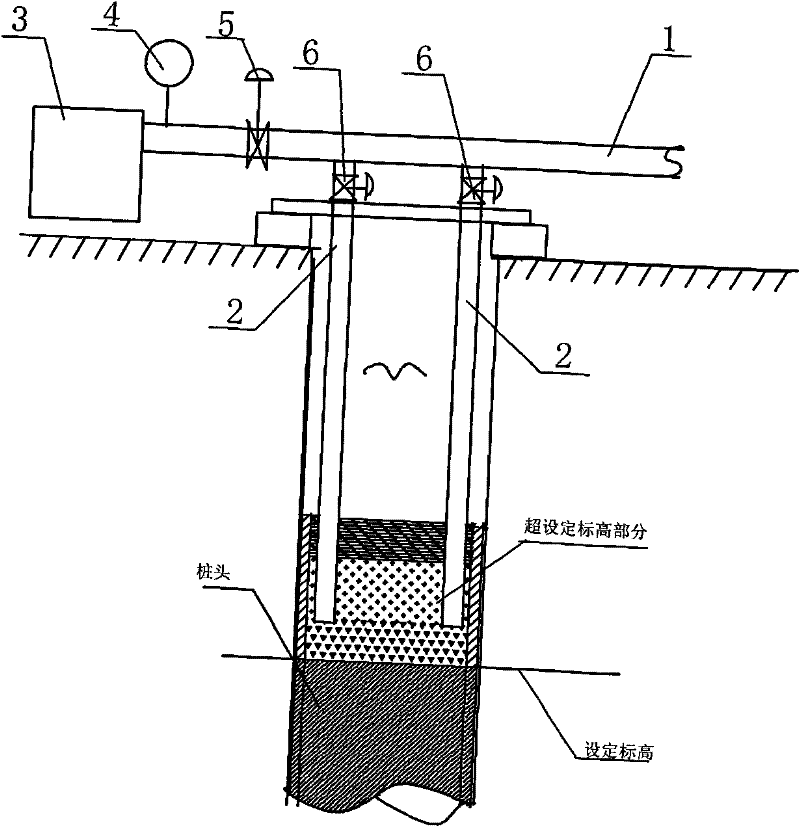

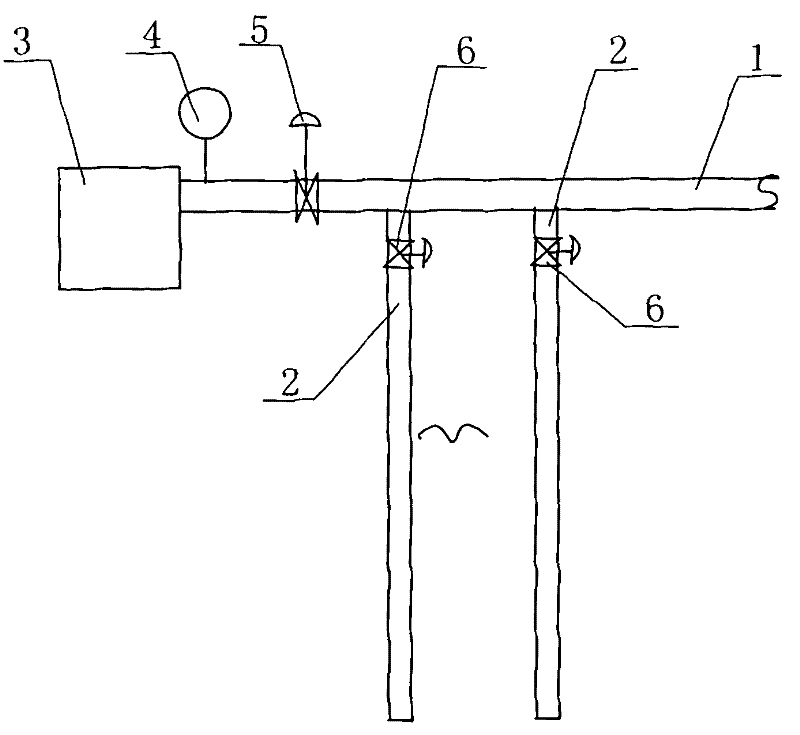

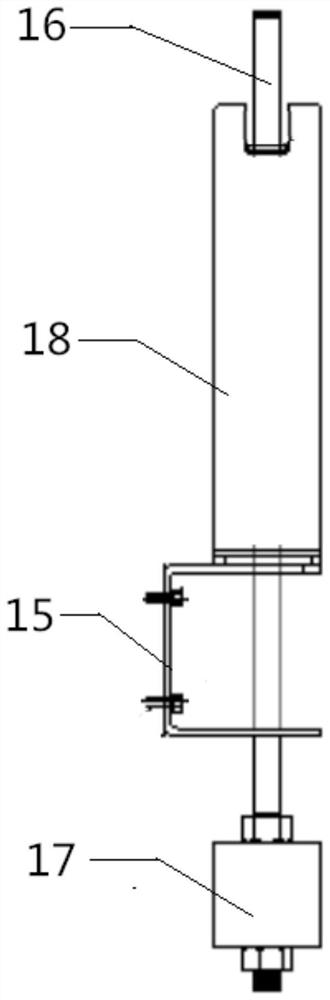

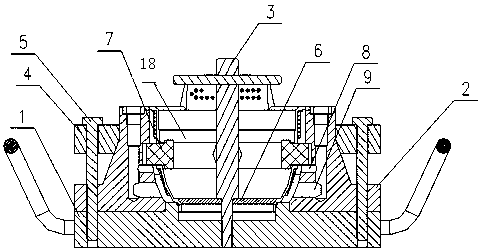

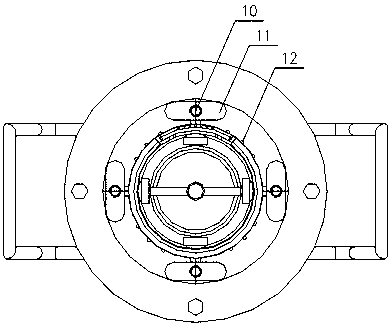

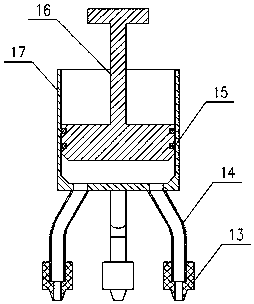

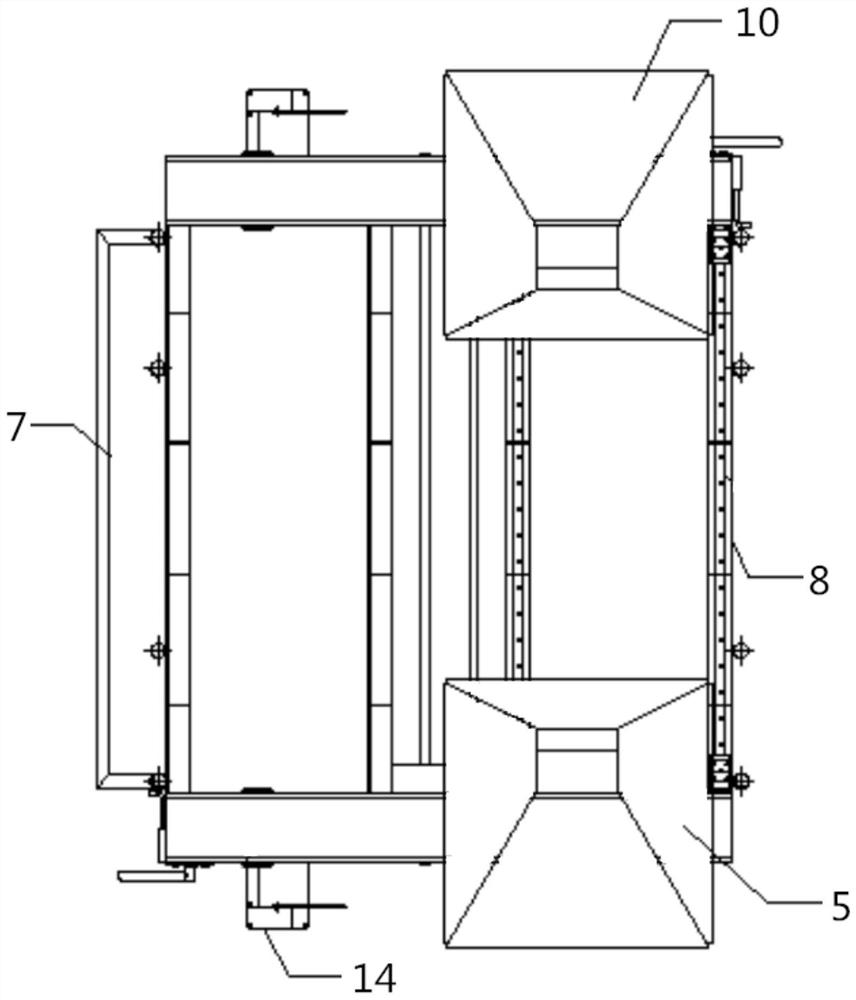

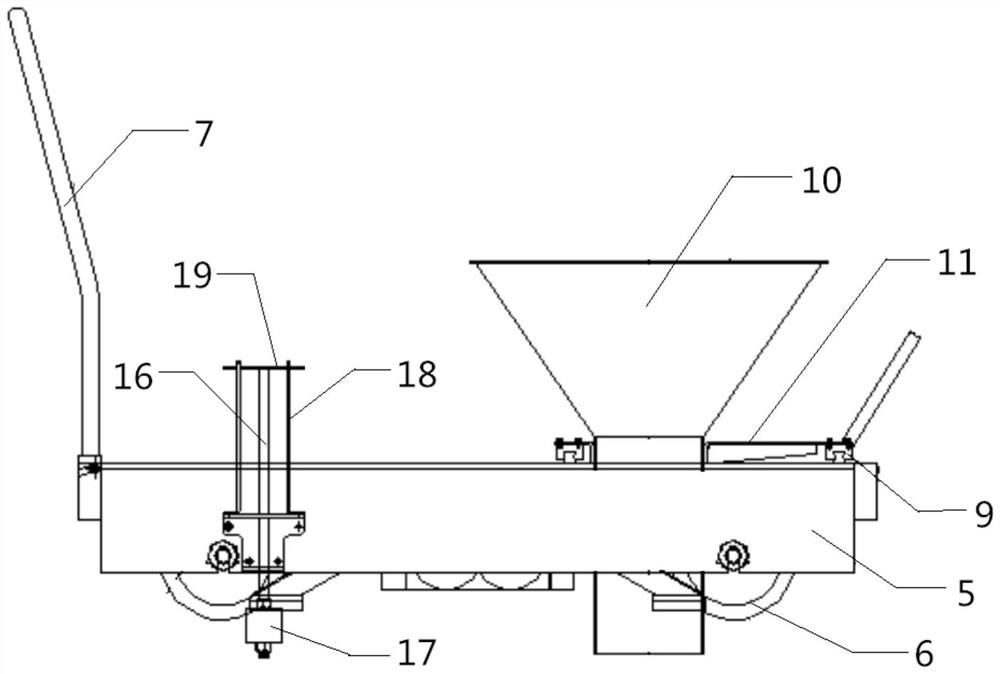

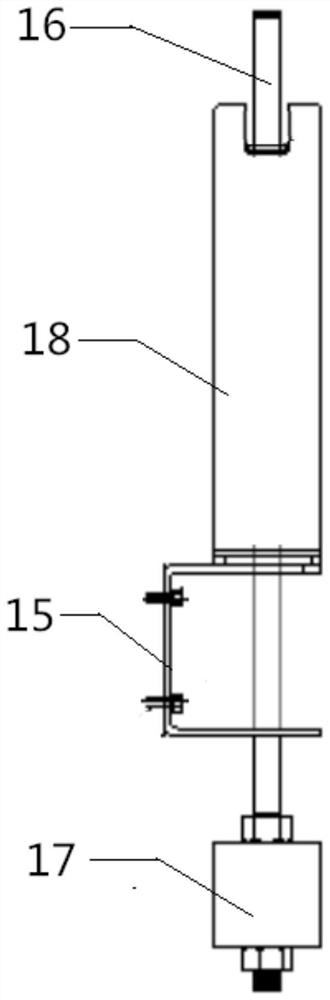

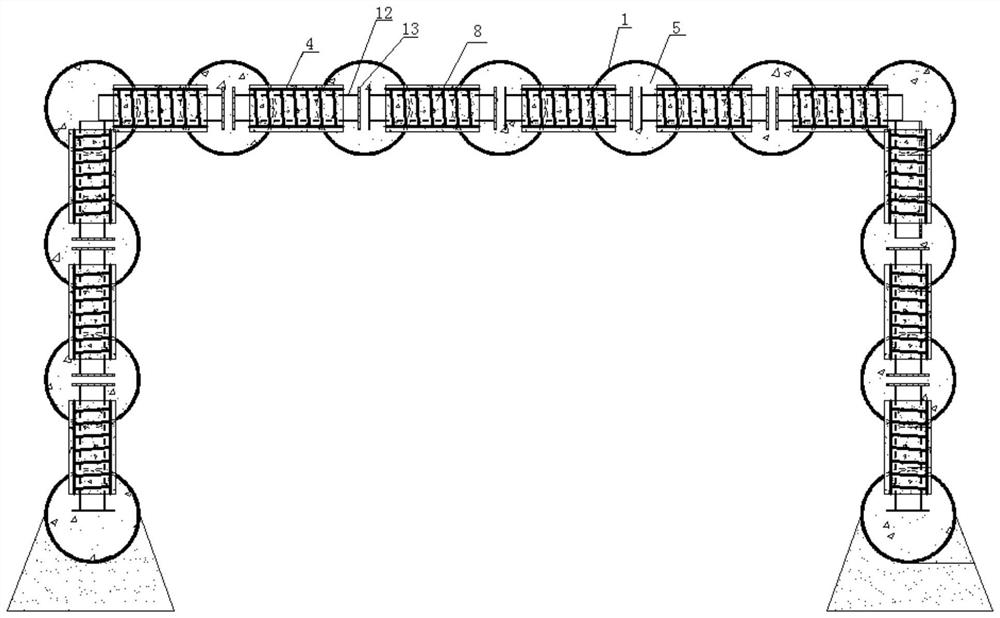

The invention relates to a concrete pouring device, which comprises a guide pipe for pouring concrete, a funnel-shaped pouring guide device connected with one end of the guide pipe and a lifting device of the guide pipe, wherein the guide pipe is formed by connecting multiple sections of short pipes together through a connecting device in a hermetical manner, and the other end of the guide pipe is sealed and closed by a pipe orifice closing device in a removable manner. The invention further relates to a guide pipe type concrete pouring method using equipment including the pipe orifice closing device, the pipe orifice closing device is mounted on the guide pipe before pouring, the pipe orifice closing device is placed on a foundation along with the guide pipe, and the pipe orifice closing device can be separated from the guide pipe after the beginning of the pouring of the concrete.

Owner:SAM WOO FOUND GRP

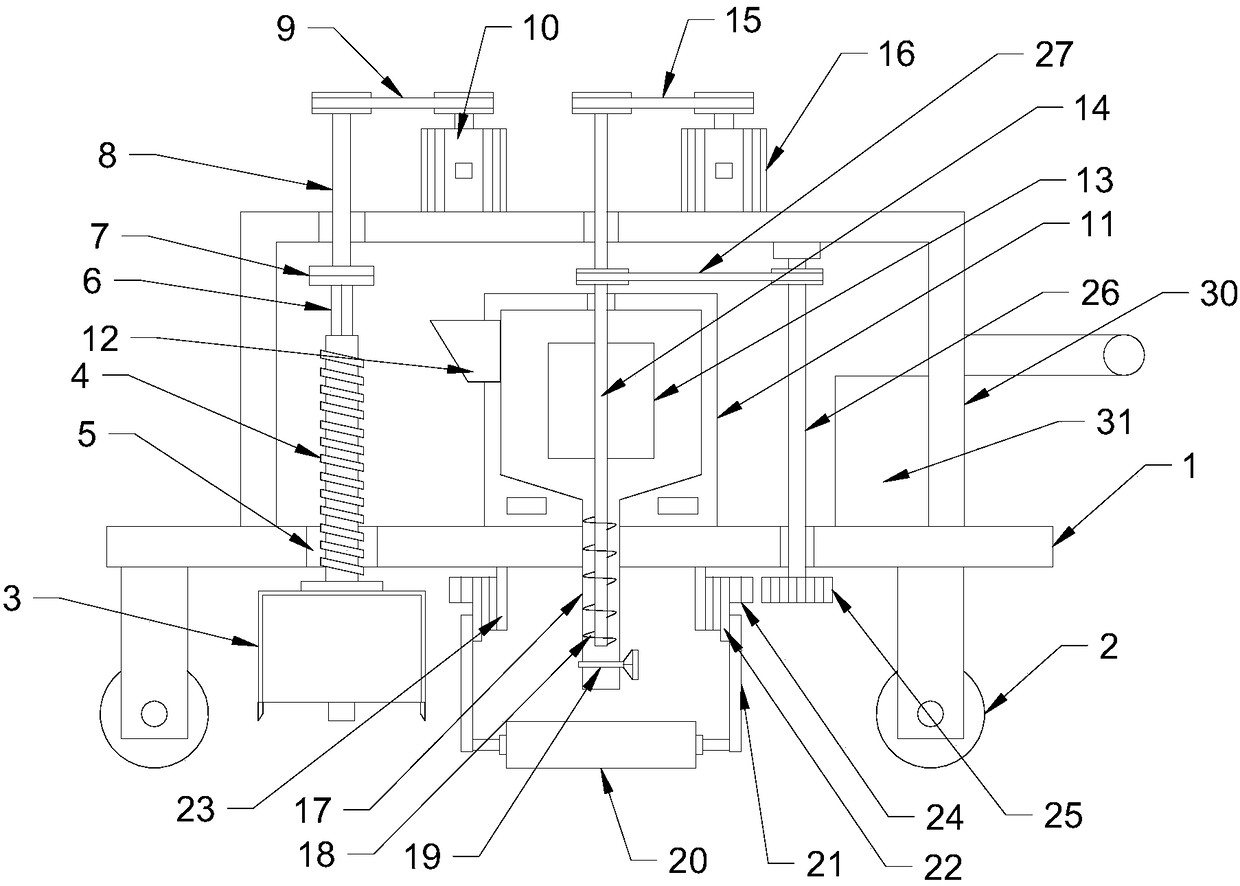

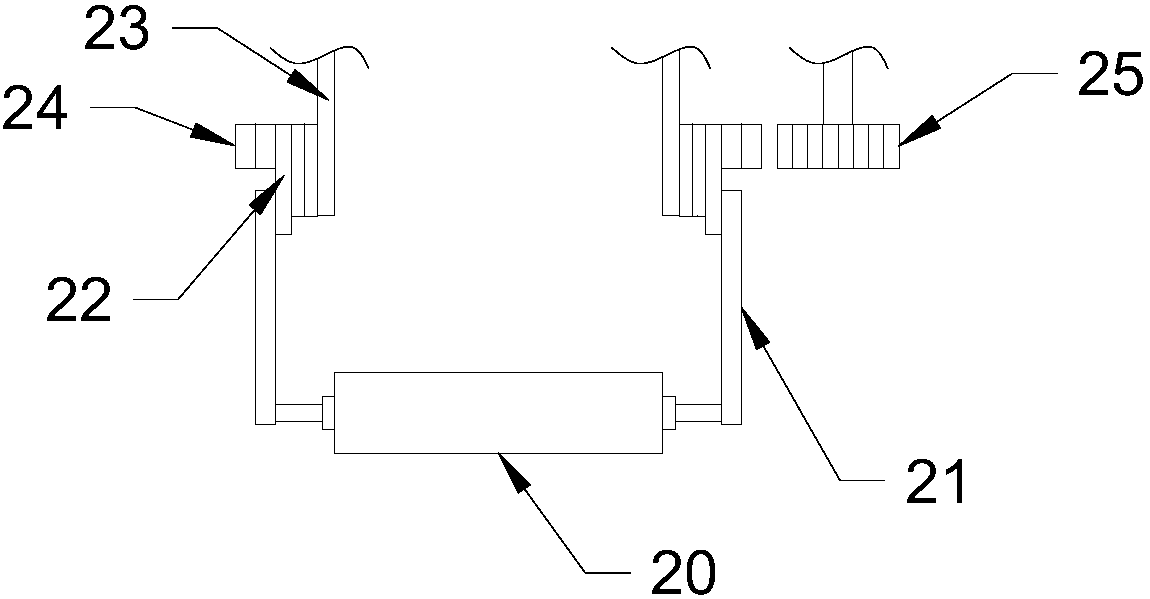

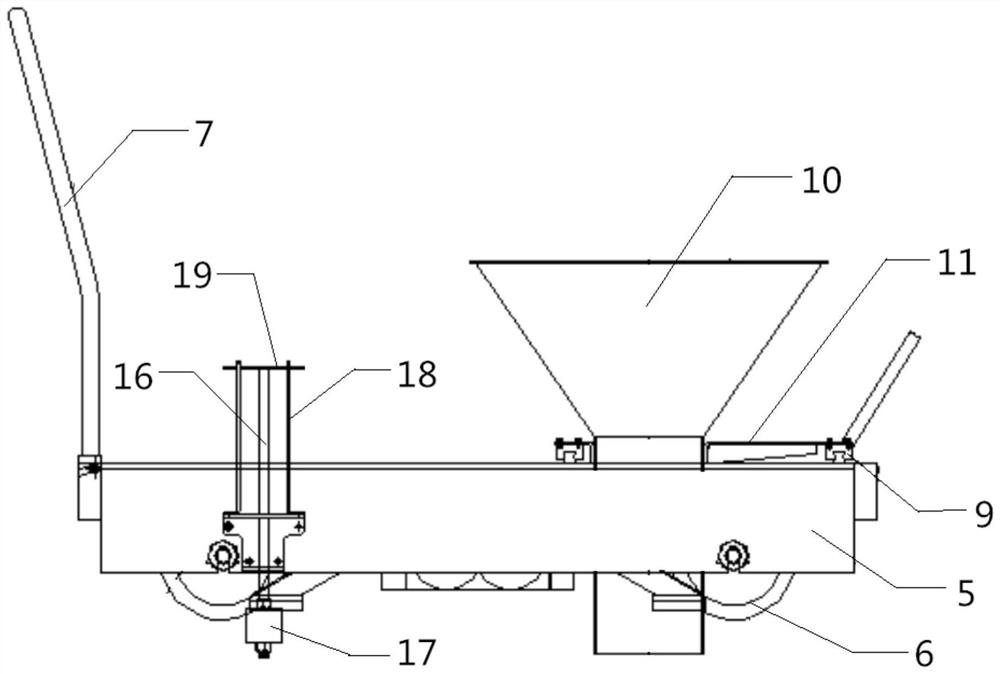

A small road repair device that is easy to operate

InactiveCN109056487AGuaranteed perfusion qualityImprove compaction efficiencyRoads maintainenceEngineeringAsphalt

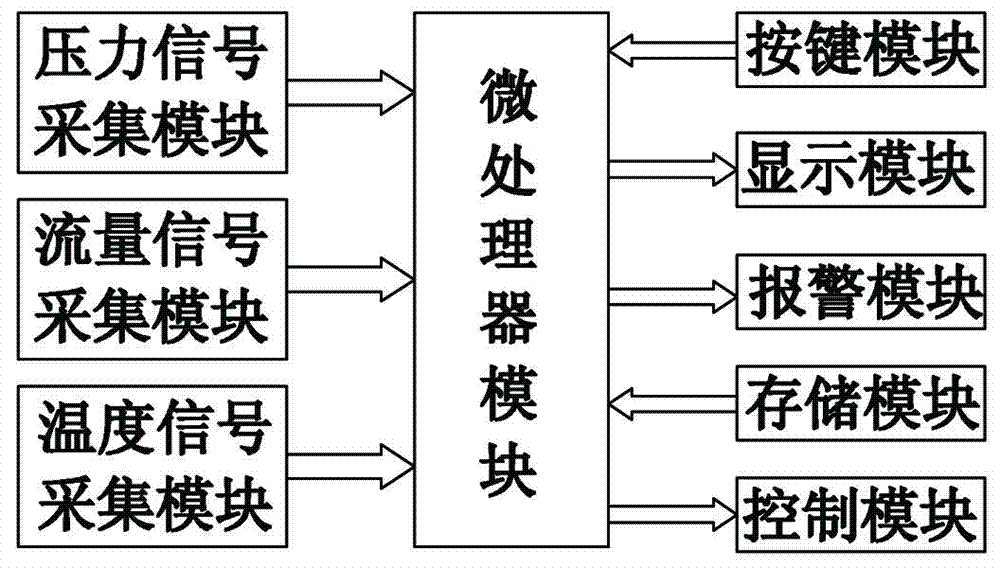

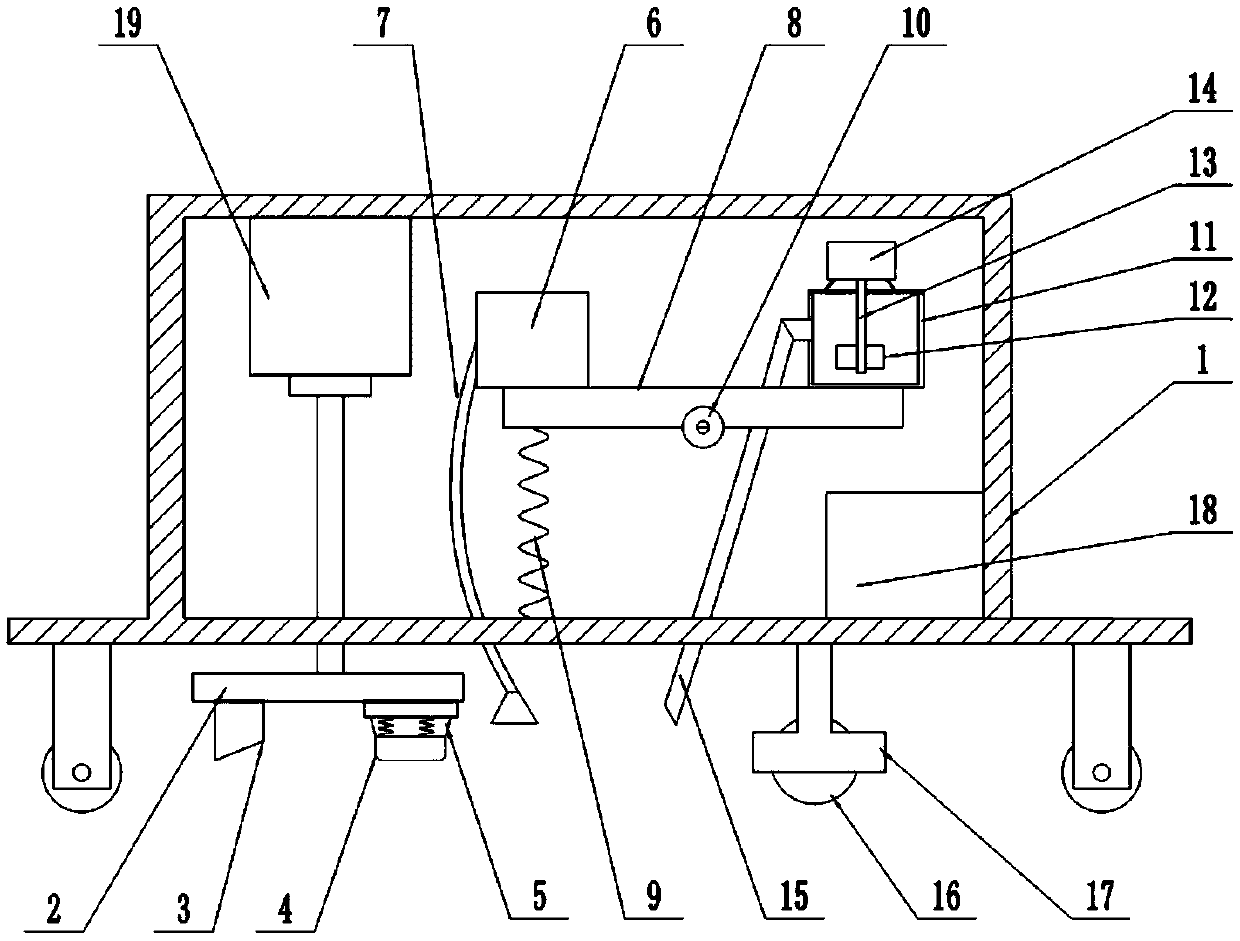

The invention discloses a small road repairing device convenient for operation, which comprises a vehicle body, a drilling mechanism, a filling mechanism and a compaction mechanism. The drilling mechanism comprises a drill barrel; The filling mechanism comprises a stirring barrel; A material discharge pipe is communicate with that lower part of the stir barrel, and the material discharge pipe extends to the lower part of the vehicle body and is provided with a manual valve; The compaction mechanism includes a compaction roller. As that drill barrel is fixedly connecte with an upper and lower rotate mechanism composed of a threaded sleeve and a rotating rod, the drill barrel is convenient to drill a hole at a place to be repaired of the road, the asphalt pouring interface is smoothed, and the pour quality is ensured; and the drill barrel is fixed on the upper and lower rotating mechanism composed of the threaded sleeve and the rotating rod. The rotary compaction of the poured asphalt iscarried out by means of a compaction roller which is linked with a rotary ring, so that the compaction efficiency is improved, and the operation is convenient compared with manual compaction.

Owner:孙同娟

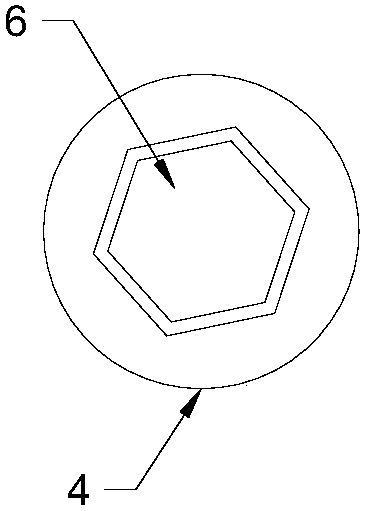

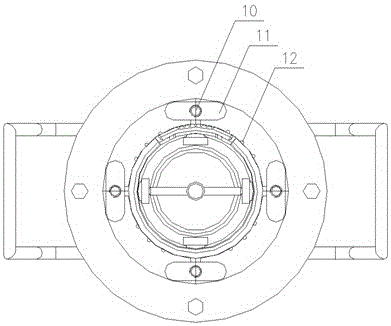

Pouring method for pouring molding of special-shaped coil former

The invention relates to a pouring method for pouring molding of a special-shaped coil former. The method includes the following steps that first, pretreatment of adhesives is performed, the adhesives are subject to defoaming treatment in stirring and pressure drop modes, and stirring under vacuumizing and stirring under ordinary pressure are carried out alternately; second, workpiece installation is conducted, and the coil former is placed into a molding tool; and third, filling and sealing are carried out, and a four-opening synchronous filling and sealing tool is used for pouring the four surfaces of the coil former at the same time. By the adoption of the tool and the pouring method thereof, the molding quality of coil pouring of a seeker product is guaranteed, reliable performance of the product is ensured, and production efficiency is improved.

Owner:XIAN NORTH ELECTRO OPTIC TECH DEFENSE

Organ transfer device

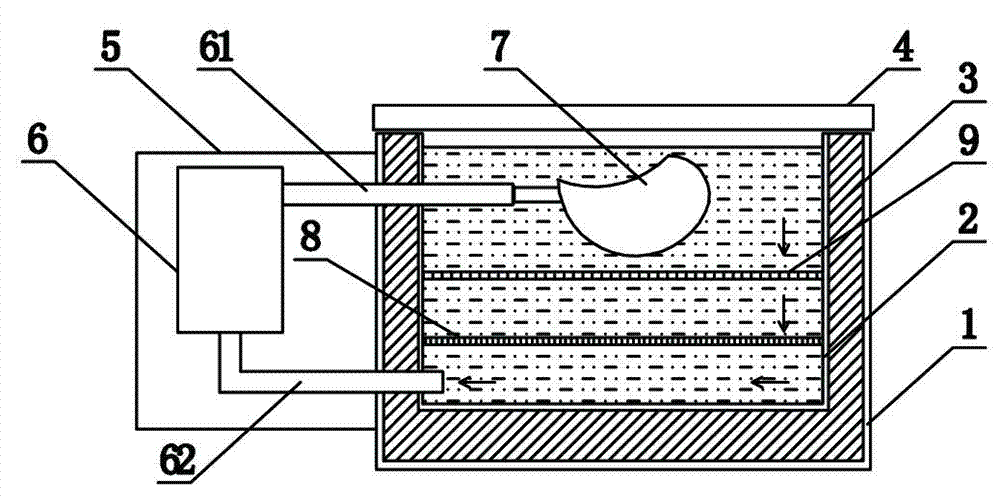

The invention provides an organ transfer device. The organ transfer device comprises an outer box body, an inner box body arranged in the outer box body and a perfusion system, wherein the inner box body is provided with a perfusion chamber the upper part of which is provided with an opening and a refrigeration cavity which is arranged between the inner box body and the outer box body and is used for placing a cold source; the perfusion chamber is internally horizontally provided with a filtering membrane, and the filtering membrane is used for dividing the perfusion chamber into an organ containing cavity and a filter liquor containing cavity which are respectively arranged above and below the perfusion chamber; the perfusion system comprises a peristaltic pump, wherein a liquid inlet of the peristaltic pump is communicated with the filter liquor containing cavity through a liquid inlet pipeline, and a liquid outlet of the peristaltic pump is communicated with a liquid outlet pipeline for communicating the organ liquid inlet to be transferred. The organ transfer device provided by the invention has the advantages that the design is scientific, the structure is reasonable, the operation is simple and the organ activity in a transferring process is guaranteed.

Owner:尚文俊 +1

Road repairing and breaking device

InactiveCN109629386AWeight increaseImprove repair qualityRoads maintainenceCrushed stoneRoad surface

The invention belongs to the field of road equipment, and particularly discloses a road repairing and breaking device. The road repairing and breaking device comprises a cart body, a breaking mechanism, a dust collection pump and a pouring mechanism, wherein the breaking mechanism, the dust collection pump and the pouring mechanism are located in the cart body; a lever is arranged in the cart body, the dust collection pump and the pouring mechanism are fixedly connected to the two ends of the level respectively, an elastic piece is fixedly connected to the bottom of the level on one side of the dust collection pump, the dust collection pump is communicated with a sucker for absorbing road gravel particles, the sucker penetrates through the bottom of the cart body, and a sucker opening faces the lower portion of the cart body; the pouring mechanism comprises a discharging hopper containing padding, the side wall, towards one side of the dust collection pump, of the discharging hopper iscommunicated with a discharging pipe, and the discharging pipe penetrates through the bottom of the cart body to face the lower portion of the cart body. After the technical scheme is adopted, the road repairing and breaking device can automatically pour padding into road surface cracks in the road repairing process.

Owner:CHONGQING VOCATIONAL INST OF ENG

Rock-fill dam deformation control technology

InactiveCN102493403APotableControllableFoundation engineeringEarth-fill damsSlurryDeformation control

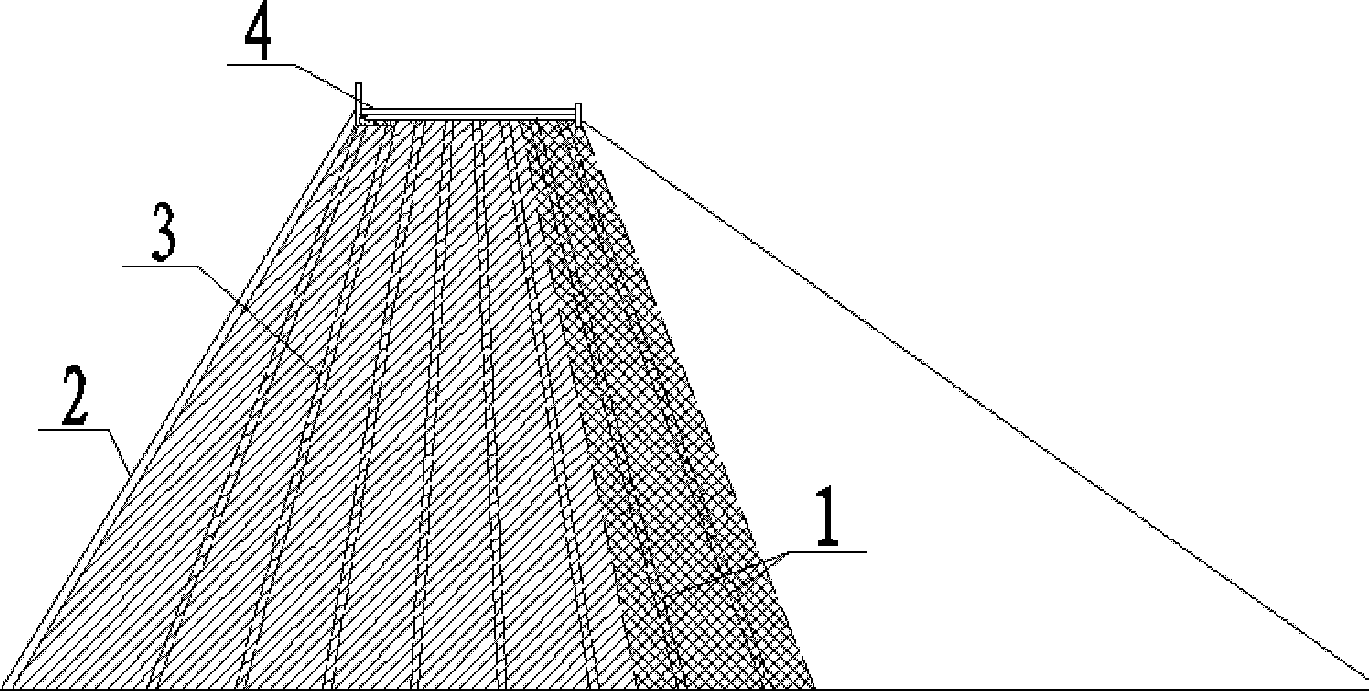

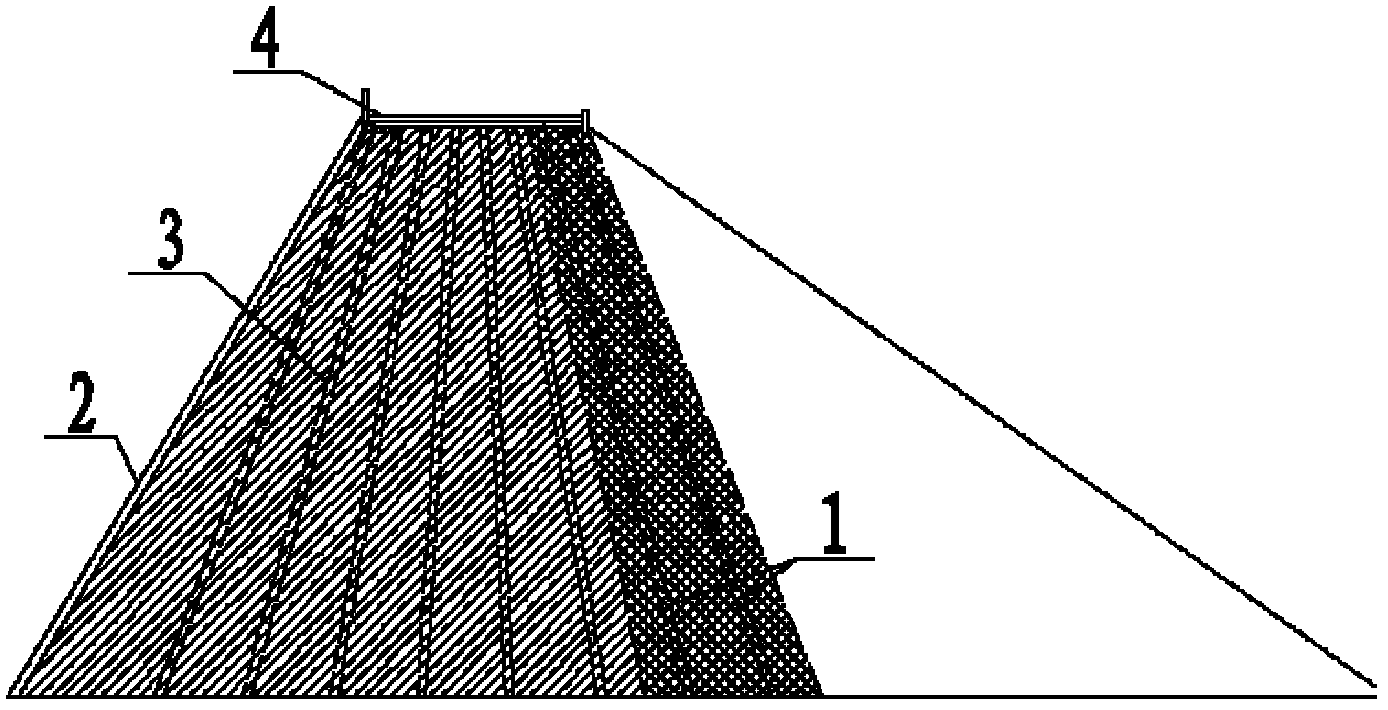

The invention belongs to the technical field of hydraulic and hydro-power engineering, and discloses a rock-fill dam deformation control technology which can be applied to diseased rock-fill dams or rockfill deformation control in the hydraulic and hydro-power engineering. The rock-fill dam deformation control technology comprises the following steps of: 1, preparing a pasty stable grouting liquid and cement mortar; 2, drilling holes in the dam body of the rock-fill dam, wherein the holes comprise stable grouting liquid grouting holes for sealing, and filling grouting holes; and 3, grouting: injecting the pasty stable grouting liquid into two rows of holes around a filling grouting area to make the pasty stable grouting liquid and a concrete panel on the upstream side of the rock-fill dam form an enclosed area, injecting the cement mortar into holes in the grouting area in an orifice filling mode after the pasty stable grouting liquid has been injected for 14 days, and controlling the rock-fill dam deformation after the grouting area has been grouted for 28 days. By the rock-fill dam deformation control technology, the deformation resistance of the rock-fill dam can be improved, the deformation of the dam body can be controlled, the grouting quality can be guaranteed, and the rock-fill dam deformation control technology has the advantages of short construction period, high work efficiency and the like.

Owner:CHANGJIANG SURVEY PLANNING DESIGN & RES

Large-diameter drilled pile construction method

The invention discloses a large-diameter drilled pile construction method. The large-diameter drilled pile construction method comprises the following steps: (1) a drilling platform is built; (2) a steel protection cylinder is constructed; the top surface of the steel protection cylinder is higher than the top surface of the drilling platform by 50 cm; (3) a down-hole drill is used for construction; 28-30 small holes are drilled in the pile foundation plane range; gaps between the small holes are controlled within 35-40 cm; and the drilling depth is above the pile bottom elevation by 30 cm; (4) finished holes are constructed; (5) the holes are cleaned through reverse circulation, so that the residue thicknesses at the bottoms of the finished holes are lower than 5 cm, the mud weights in the holes are 1.03-1.1, and the sand contents are not higher than 2%; (6) a reinforcement cage is placed; and (7) concrete is poured. The large-diameter drilled pile construction method can overcome theconstruction difficulties of high-strength rock layers, improves the quality of drilled piles, and guarantees the stability of a bridge main tower.

Owner:SHANGHAI CIVIL ENG GRP FIFTH

Post-grouting bored pile construction method

The invention discloses a post-grouting bored pile construction method. The post-grouting bored pile construction method comprises the following steps of hole forming: measuring a pile position first,and then vertically burying a pile aligning the center of a steel protective cylinder with the center of a pile hole, and finally, drilling to form a hole; after the hole is drilled to a designed depth, using a hole cleaning drill bit to clean the hole once; transporting a made steel reinforcement cage to the site through a cage transporting vehicle; lowering the steel reinforcement cage in place; after a guide pipe is lowered, carrying out secondary hole cleaning; pouring concrete to the pile depth within half an hour of secondary hole cleaning; when the pouring is performed to the top of the pile, measuring the elevation of the top of the pile by using a heavy hammer or a measuring rod in real time; and finally, carrying out post-grouting construction, wherein in post-grouting construction, grouting is carried out on the pile side first; and after a grouting liquid is initially set, the grouting liquid is grouted to the bottom of the pile. By using the post-grouting bored pile construction method to construct, harmful effects on adjacent buildings and surrounding environments are small, the length and diameter of the pile can be freely changed according to design requirements, the end of the pile can enter a supporting layer or can be embedded into a rock stratum; and the bearing capacity of a single pile is large.

Owner:POWER CHINA HENAN ENG CO LTD

Measuring device of pouring pile concrete surface

InactiveCN107514019AGuaranteed perfusion qualityWaste controlFoundation testingElectric machineArchitectural engineering

Owner:中地君豪高科股份有限公司

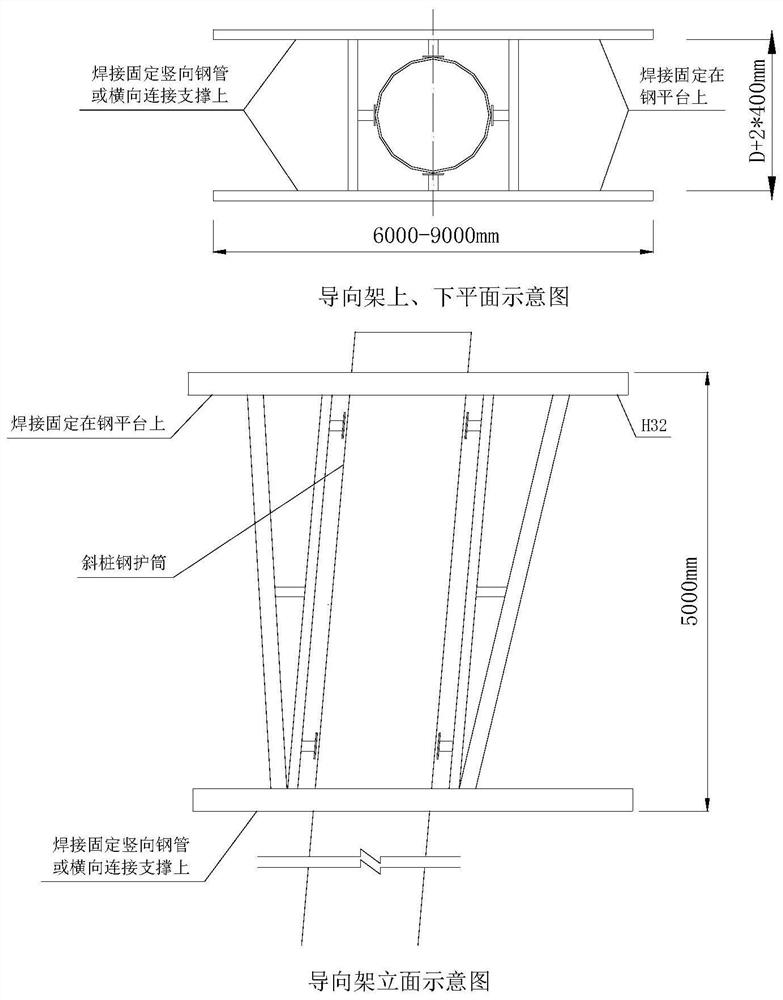

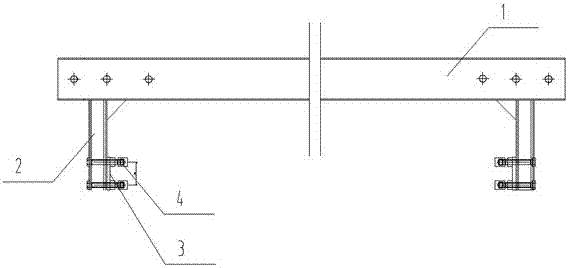

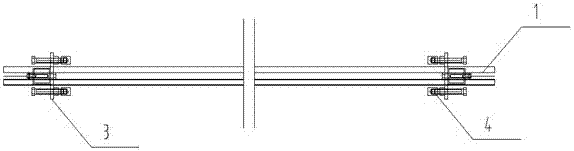

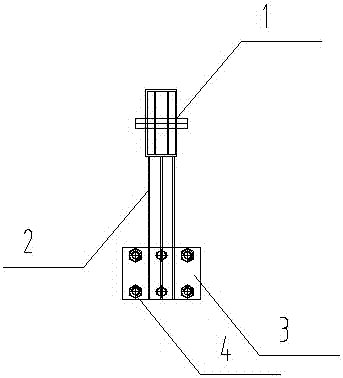

Rock-socketed oblique pile impact-drilling and pile-forming construction process

InactiveCN111663892ASolve construction technical problemsGuarantee the pile qualityEarth drilling toolsReciprocating drilling machinesRebarGuide tube

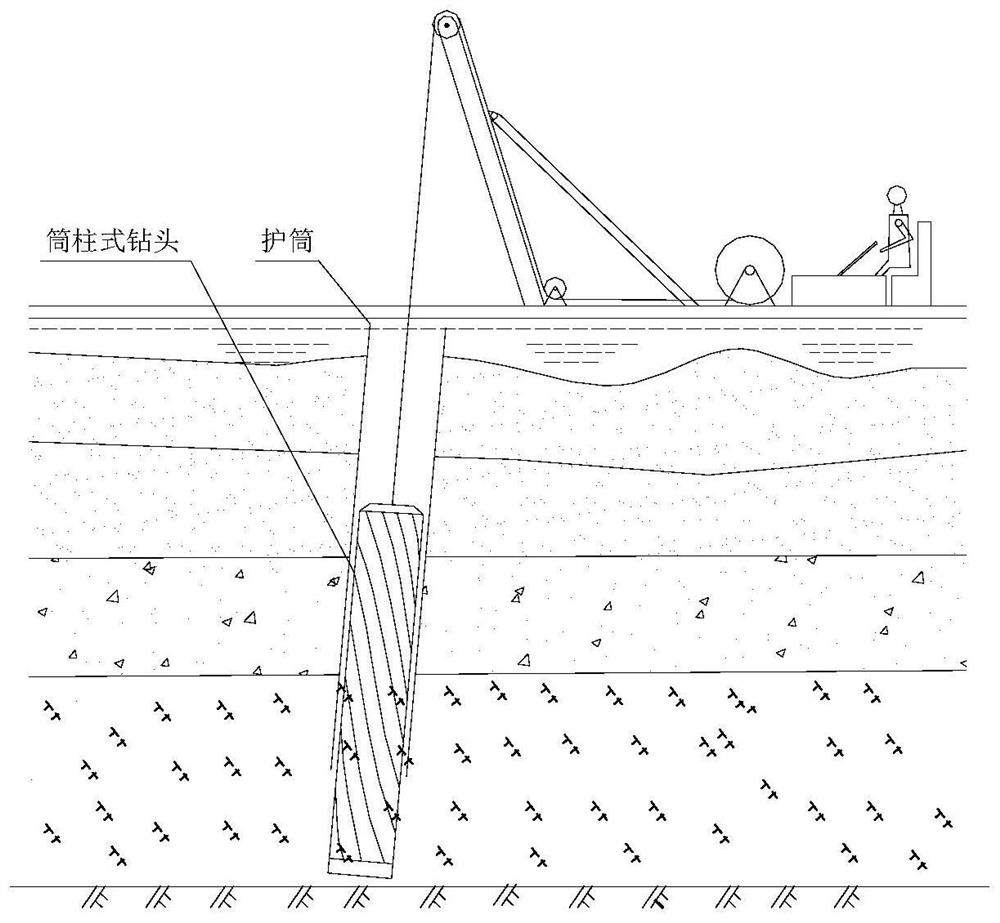

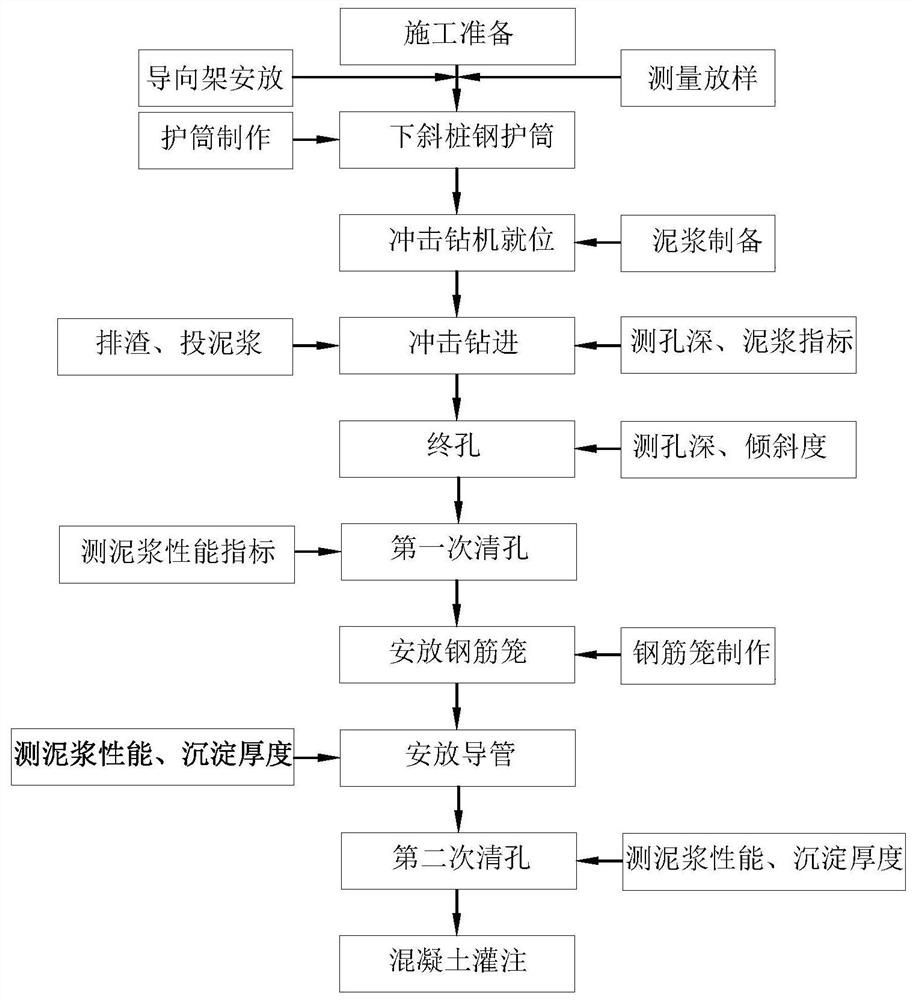

The invention discloses a rock-socketed oblique pile impact-drilling and pile-forming construction process which belongs to the technical field of port wharf tubular pile construction. The rock-socketed oblique pile impact-drilling and pile-forming construction process comprises the following steps: S1, performing a construction preparation stage; S2, mounting a steel casing guide frame; S3, performing impact holing; S4, clearing holes for the first time; S5, mounting a reinforcement cage; S6, mounting guide tubes; S7, clearing the holes for the second time; and S8, pouring concrete. Accordingto the rock-socketed oblique pile impact-drilling and pile-forming construction process disclosed by the invention, self-innovation equipment and a process are combined to solve oblique pile construction technical problems, so that oblique pile inclination and the pile-forming quality are guaranteed, and oblique pile design requirements are met.

Owner:江西省地质工程集团有限公司

High-speed railway aluminium alloy track plate pressing device

InactiveCN106988170AGuaranteed perfusion qualityGuaranteed fixed effectRailway track constructionEngineeringRebar

The invention relates to a high-speed railway aluminium alloy track plate pressing device. The device comprises a tie down block, landing legs, side fixing plates, pressing pull rods and pushing screws; the device is characterized in that the tie down block and the landing legs are welded perpendicularly to form a shape of a door; the side fixing plates are arranged at the lower ends of the landing legs in parallel and connected with the landing legs through bolts; the pressing pull rods are connected with a track base plate and the tie down block and connected with reserved openings of the track base plate in a suspended mode through rebar; the pushing screws push an edge sealing formwork through the side fixing plates; the landing legs and the side fixing plates are made from aluminum alloy materials. Accordingly, it is guaranteed that ballastless track construction is conducted smoothly, the self-compacting concrete pouring quality is guaranteed, and the working efficiency is improved; construction installation and transportation are convenient, operation is easy, learning is fast, and the self-compacting concrete pouring quality and the fixed track plate space position are guaranteed; turnover is conducted many times, and the phenomena of track plate floating, the self-compacting concrete layer open joint and the like are avoided.

Owner:湖南天象建筑科技有限公司

Crack pouring treating method for crack of construction

InactiveCN101338585AConvenient self-checkEasy to check and acceptBridge structural detailsBuilding constructionsAdhesive beltScotch tape

The invention discloses a crack pouring processing method for a building structure crack. The method comprises processing the crack base plane, installating an injection seat, sealing the surface of the crack, injecting crack pouring sealant, hardening maintenance and shaping and leveling. The method is characterized in that firstly scotch tapes are adopted to seal the crack surface, and two 5 to 8 cm of blank spaces without scotch tapes are reserved on the both sides of the injection seat along the crack direction, then transparent joint sealant is used to seal the crack surface (the parts adhered with scotch tapes are included), the sealing width is 4 to 6 cm, the sealed cross section of the transparent joint sealant on the crack surface is in arc, and the middle part is slightly thicker; empty injection seats without injectors are reserved among three to five injection seats as exhaust passages; red pigment is mixed in the joint sealant. The method has the advantages that the method is scientific and simple, the implementation is convenient and easy, the cost is low, the self-checking is convenient for the constructer, the full degree and the length of the crack pouring can be accurately confirmed, and the supervision and the acceptance of the construction are convenient, thus the crack pouring quality is guaranteed, simultaneously, the measurement control is convenient, and the construction cost is saved.

Owner:江苏京沪高速公路有限公司

Construction method for underwater non-dispersing self compact concrete

InactiveCN109763491AImprove liquidityHigh technical content in construction technologyFoundation engineeringUnderwaterEngineering

The invention discloses a construction method for underwater non-dispersing self compact concrete. Poured and bottom-sealed concrete formed by inputting an underwater protecting agent into a water body and preparing pouring concrete is good in flowability, a construction process is high in technical content, and a construction operation is simple. The concrete can be bottom-sealed and formed primarily and is water-tight. The construction process is safe and reliable, the construction workload is reduced, the risk of unsuccessful bottom sealing is reduced, the integrity of the concrete is guaranteed and a construction period is conducted smoothly. Compared with self compact concrete, the underwater non-dispersing self compact concrete has obvious advantages on the aspect of underwater construction and can ensure the underwater pouring quality of the concrete, the bottom-sealing effect reaches a predicted target, and various potential safety hazards probably induced by bottom sealing defects are reduced. The construction method is applied to the field of concrete construction.

Owner:CHINA RAILWAY GUANGZHOU ENG GRP CO LTD +1

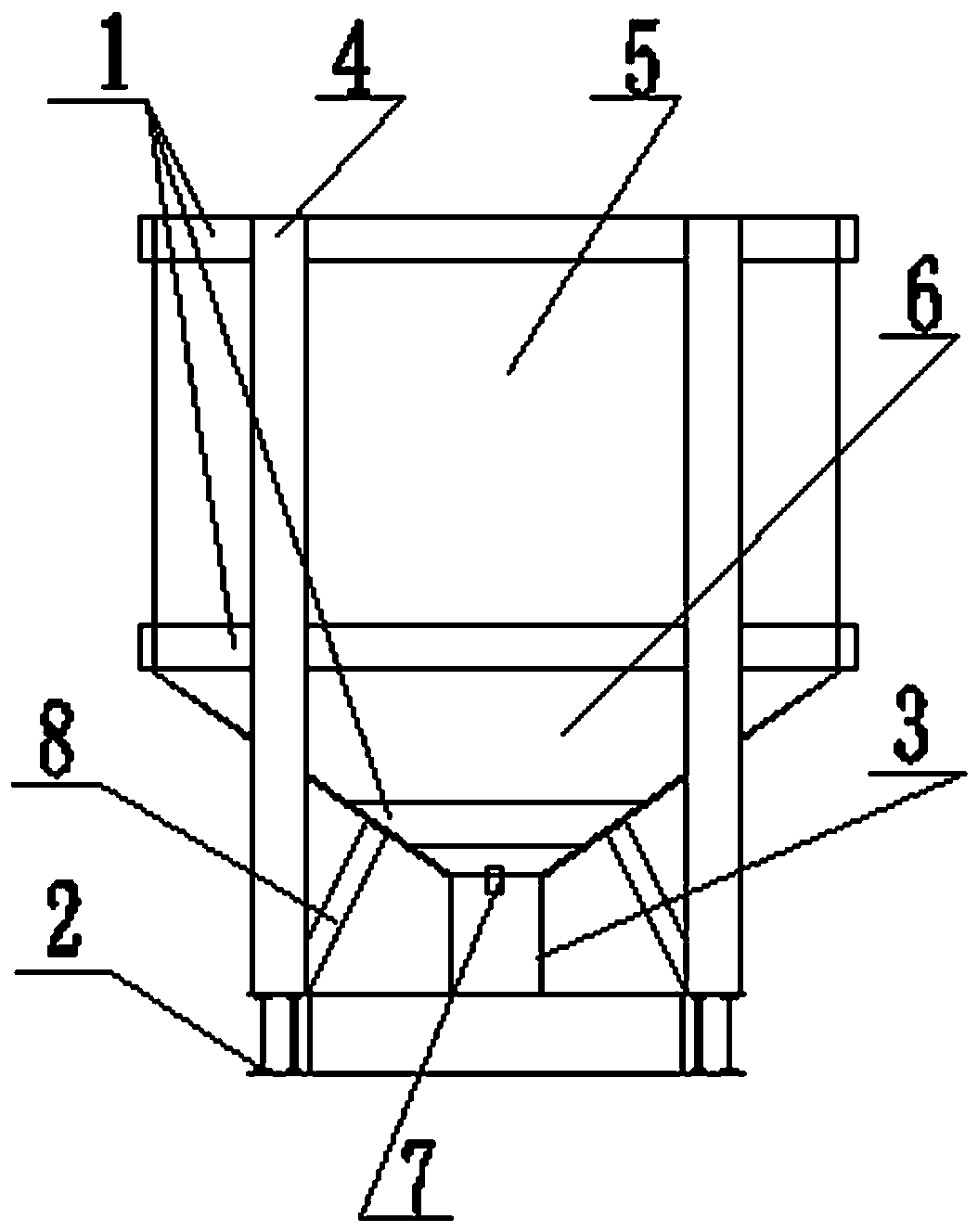

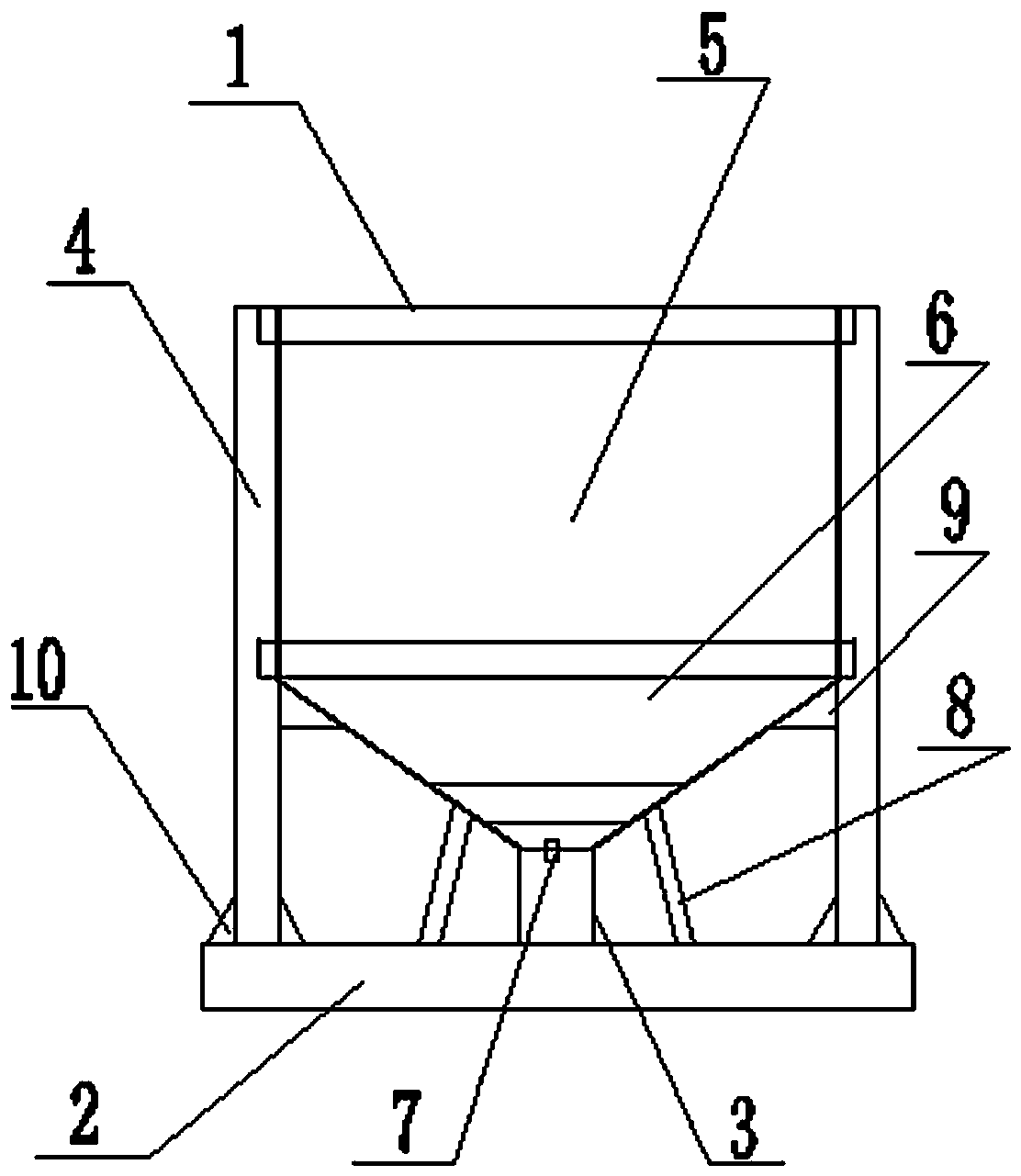

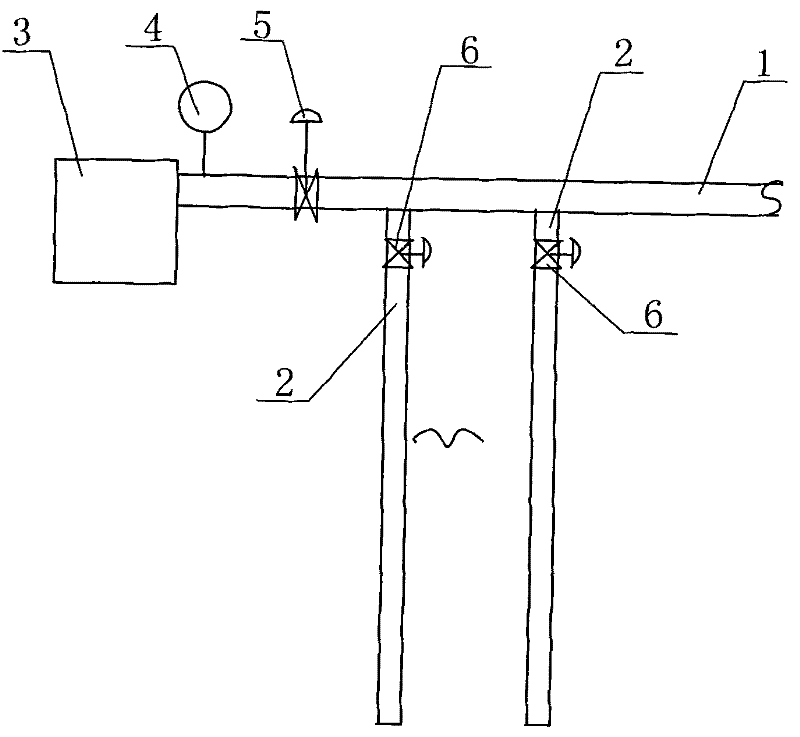

A grouting method for underwater large-diameter bored piles in corrosion geology

ActiveCN106245628BUniform and stable deliveryGuaranteed perfusion qualityBulkheads/pilesTank truckEngineering

The invention discloses a grouting method for a corrosion geological underwater large-diameter drilled pile. The grouting method comprises the following steps of: (1) hole opening; (2) drilling to form the hole; (3) hole cleaning; (4) steel reinforcement cage placement, (5) guide tube lowering; (6) first batch concrete grouting, namely hoisting a large hopper, which is connected to the guide tube, onto a guide tube platform; arranging 2-4 concrete tank trucks and 2-4 ground pumps on the shore, wherein pump lines of the ground pumps are connected to the large hopper by means of a temporary floating bridge; the concrete tank trucks deliver concrete to the ground pumps, and the ground pumps pump concrete into the large hopper; after the large hopper is full of concrete, a ball is pulled out; and 2-4 ground pumps are employed to feed concrete at the same time; and (7) subsequent concrete grouting, namely after the completion of first batch concrete grouting, replacing the large hopper by a small hopper having the capacity of 2-5 m3 for grouting to a designed elevation. By means of the grouting method for a corrosion geological underwater large-diameter drilled pile, the construction difficulties of the corrosion geological condition and a wide river channel can be overcome, and the quality of the drilled pile can be improved so as to ensure the stability of the main tower of a bridge.

Owner:SHANGHAI CIVIL ENG GRP FIFTH +1

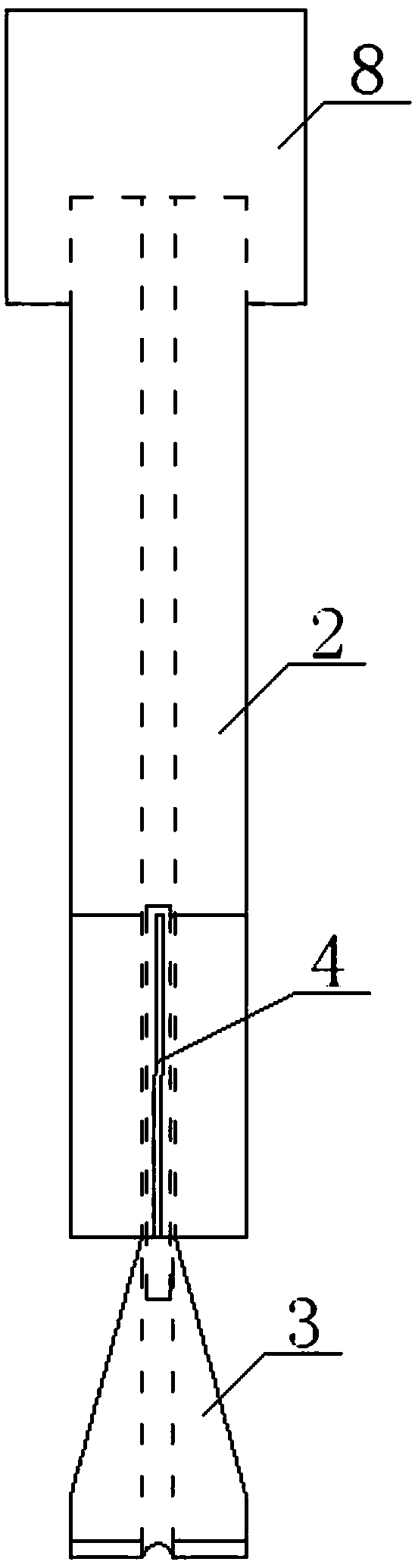

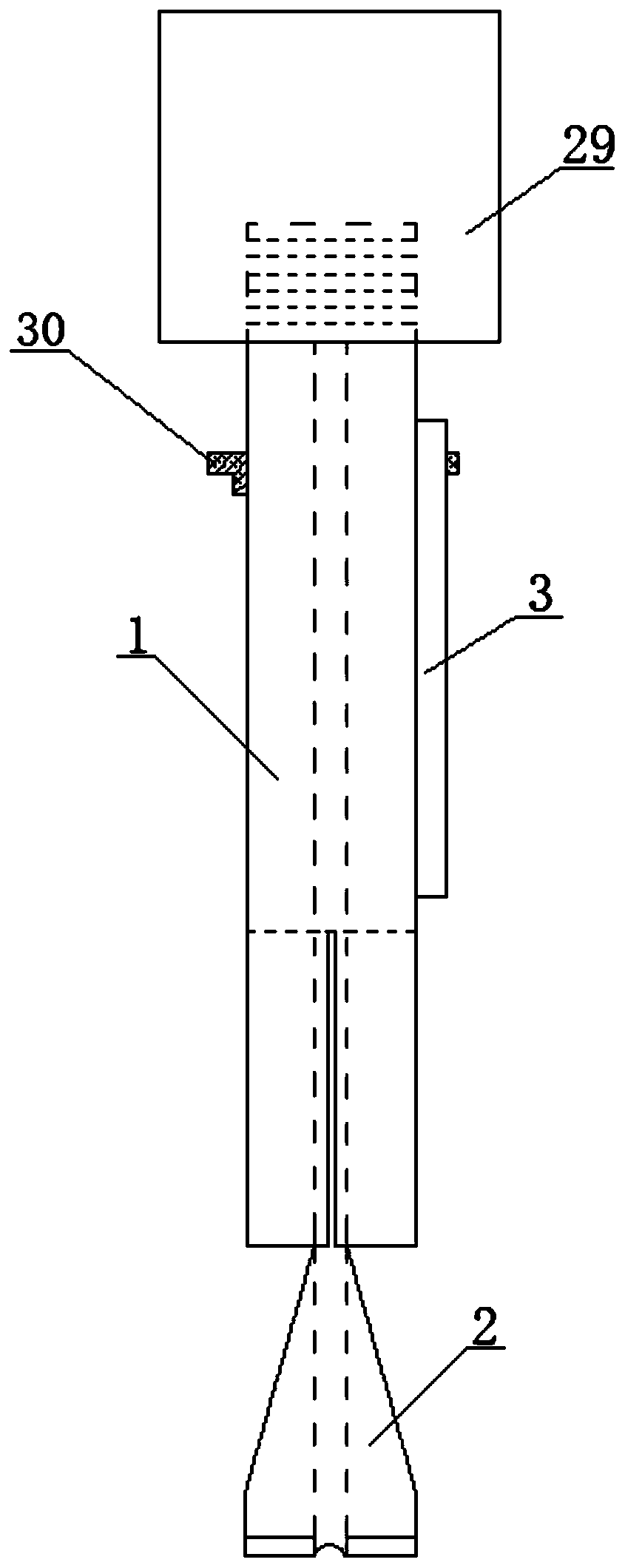

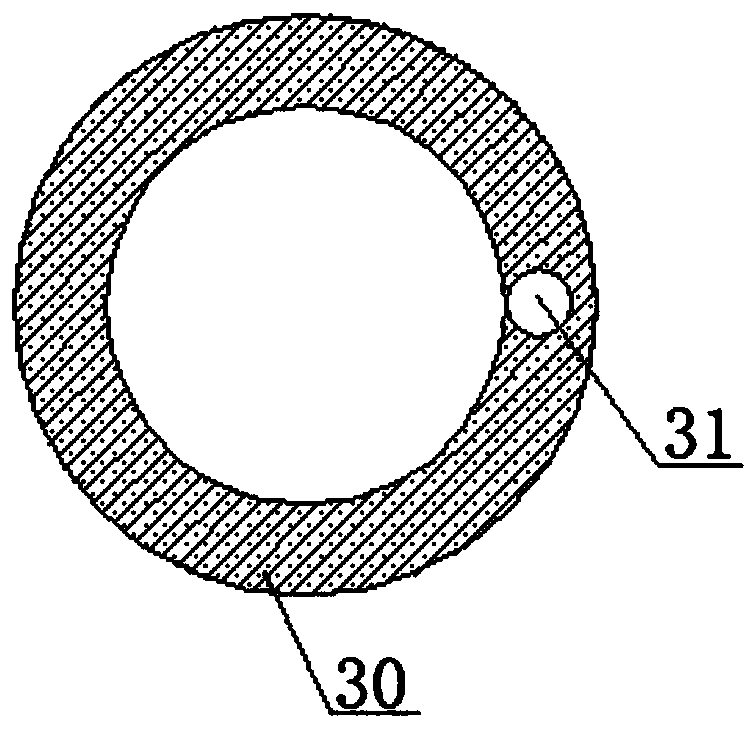

A hollow self-expanding bottom anchor bolt and its installation method

ActiveCN105951825BImprove bottoming effectBottom expansion is beneficialBulkheads/pilesAnchoring boltsEngineeringSlurry

A hollow self-expanding bottom anchor bolt, including a rod body, a wedge, and a liner pipe. The center of the rod body is provided with a hole in the rod body. The rod body includes a bottom end, a middle rod, and an exposed end. There is a wedge inner hole in the center of the center, the wedge includes a wedge head and a base, the outer peripheral surface of one end of the inner liner is connected with the inner peripheral surface of the inner hole of the rod, and the outer peripheral surface of the other end of the inner liner is connected with the inner hole of the wedge. The inner peripheral surface is connected, and the inside of the lining pipe is connected with the inner hole of the rod and the inner hole of the wedge; when installing, insert the above-mentioned anchor bolt into the bottom of the straight hole, hammer or impact the installation cap, so that the wedge pushes the cutter head toward the The hole wall is expanded, and the cutter head is inserted into the straight hole wall to chisel out the broken pieces. While hammering or impacting the installation cap, use the installation cap to input compressed air to blow out the broken pieces. The grout overflows, and the anchor bolts are installed after the grout solidifies. This design not only has good bottom expansion effect, but also has good grouting quality, high durability and high reliability.

Owner:WUDA JUCHENG STRUCTURE CO LTD

Concrete pouring device and method

ActiveCN102134852BGuaranteed perfusion qualitySolve the serious problem of mixing in waterFoundation engineeringGuide tubeUse equipment

The invention relates to a concrete pouring device, which comprises a guide pipe for pouring concrete, a funnel-shaped pouring guide device connected with one end of the guide pipe and a lifting device of the guide pipe, wherein the guide pipe is formed by connecting multiple sections of short pipes together through a connecting device in a hermetical manner, and the other end of the guide pipe is sealed and closed by a pipe orifice closing device in a removable manner. The invention further relates to a guide pipe type concrete pouring method using equipment including the pipe orifice closing device, the pipe orifice closing device is mounted on the guide pipe before pouring, the pipe orifice closing device is placed on a foundation along with the guide pipe, and the pipe orifice closing device can be separated from the guide pipe after the beginning of the pouring of the concrete.

Owner:SAM WOO FOUND GRP

A multifunctional organ transplant vehicle and its usage method

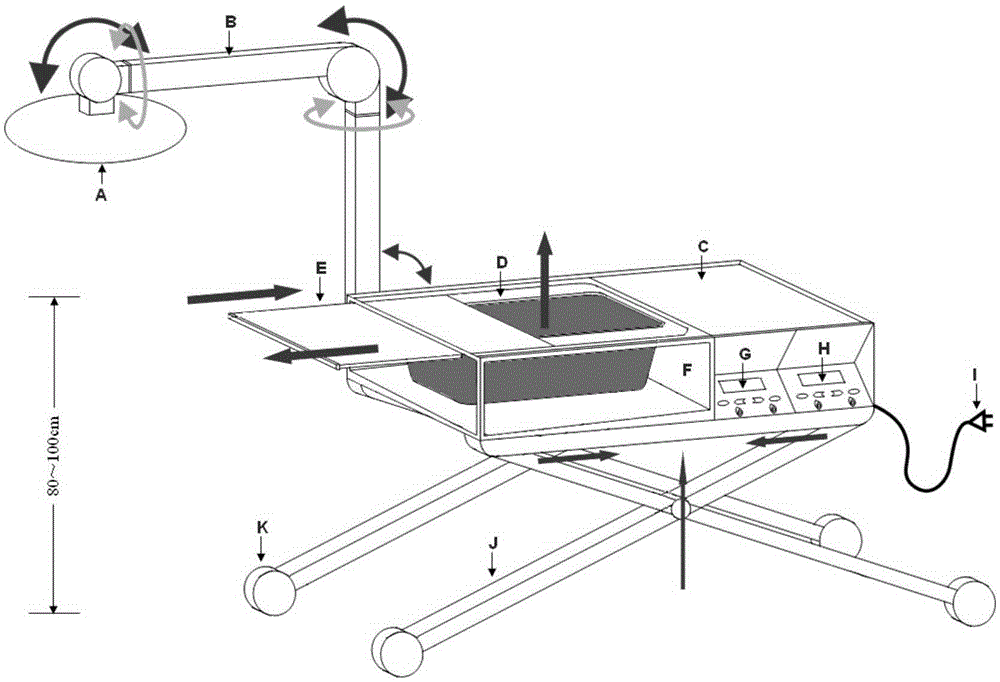

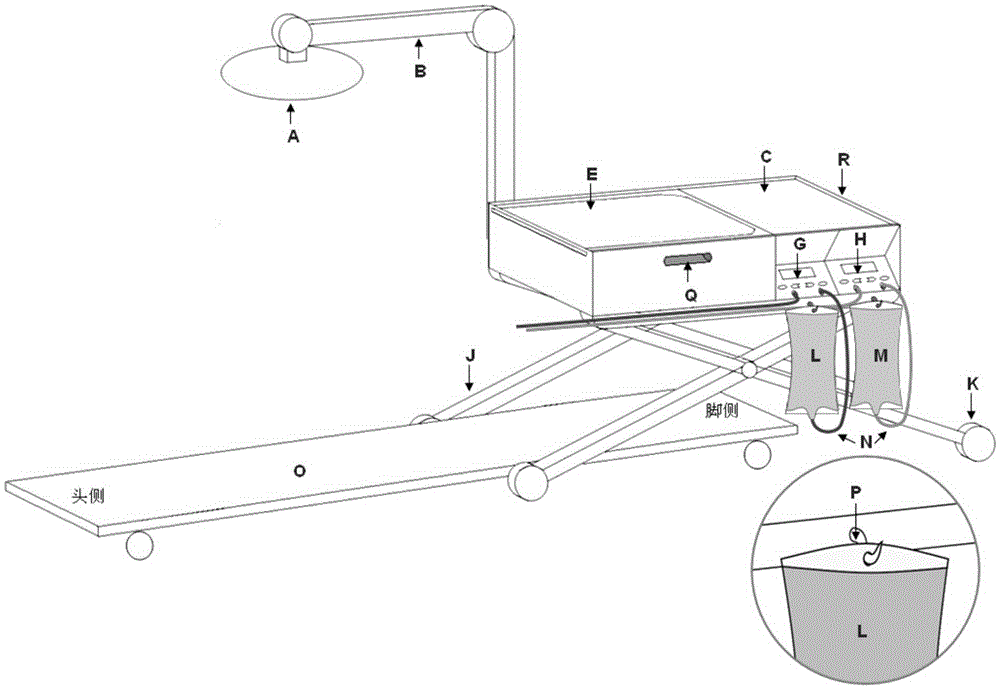

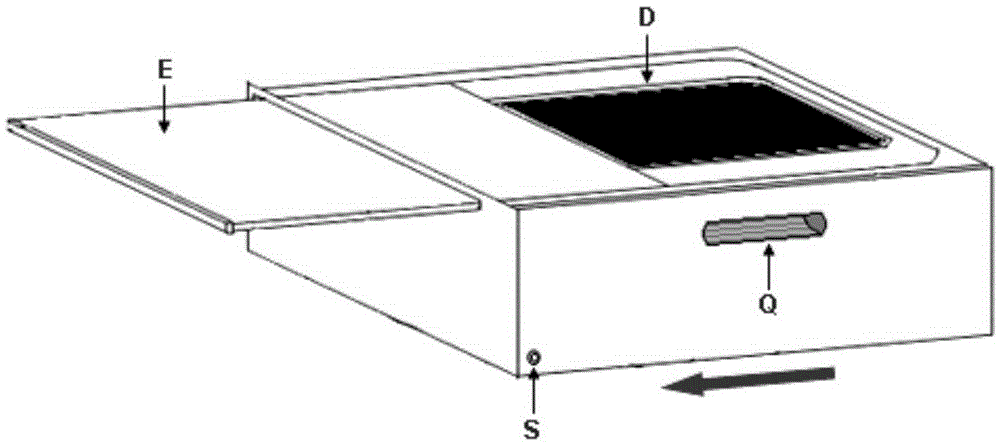

InactiveCN103800160BReduce volumeEasy to moveSurgical furnitureOperating tablesPeristaltic pumpLeft half

The invention discloses a multifunctional organ transplantation working vehicle and an application method thereof. The working vehicle comprises a main vehicle body, wherein a support is arranged below the main vehicle body, an operating platform is arranged at the upper end of the main vehicle body, a thermal-insulation box is arranged at the left half part of the main vehicle body, and an upper end cover of the thermal-insulation box is used as the left half part of the operating platform; a first peristaltic pump and a second peristaltic pump are arranged at the right half part below the operating platform; a lamp arm is arranged on one side of the main vehicle body, and an operation lamp is arranged at the upper end of the lamp arm; a stretcher is arranged below the main vehicle body; and a negative-pressure suction device is also arranged below the operating platform of the main vehicle body. By means of the working vehicle, on the premise that an existing operation vehicle is not required to be transformed, the peripheral space can be fully utilized, cleanliness of an operation area can be guaranteed, and the requirement for accurate regulation of organ perfusion pressure can be met; and meanwhile, smooth obtaining of donor organs and repairing of the organ operating platform for operations are guaranteed, the blank of the lack of professional operating equipment at present is filled up, and a lot of problems during operations are solved.

Owner:XI AN JIAOTONG UNIV

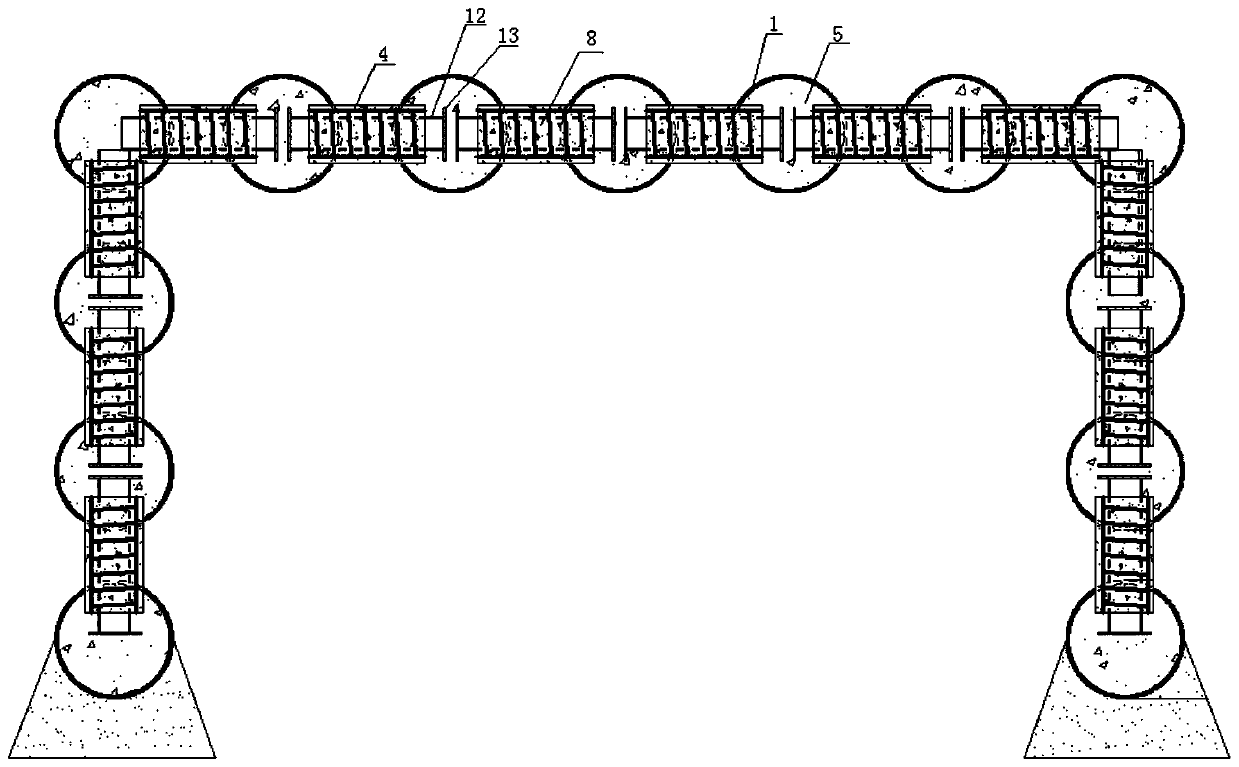

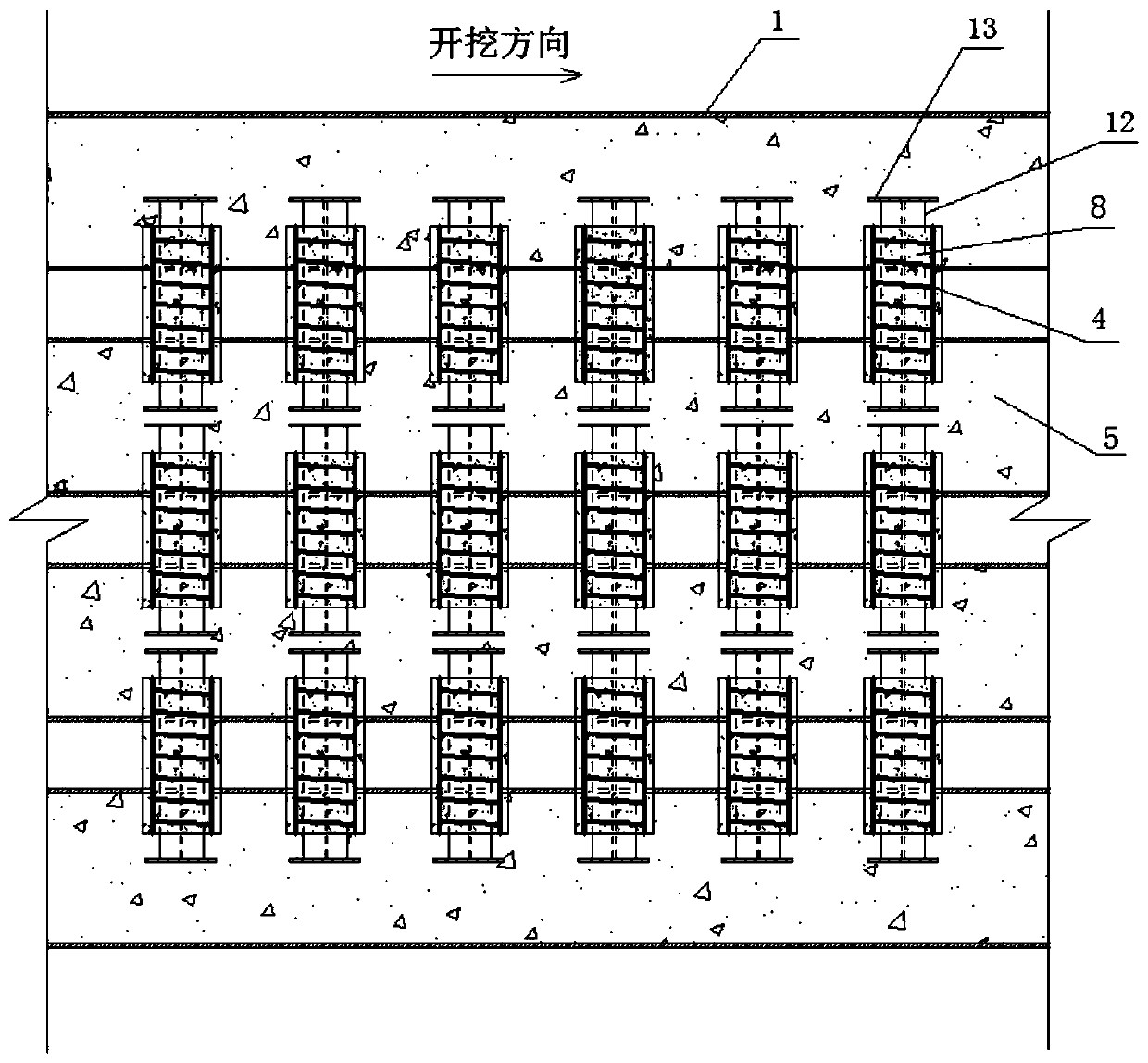

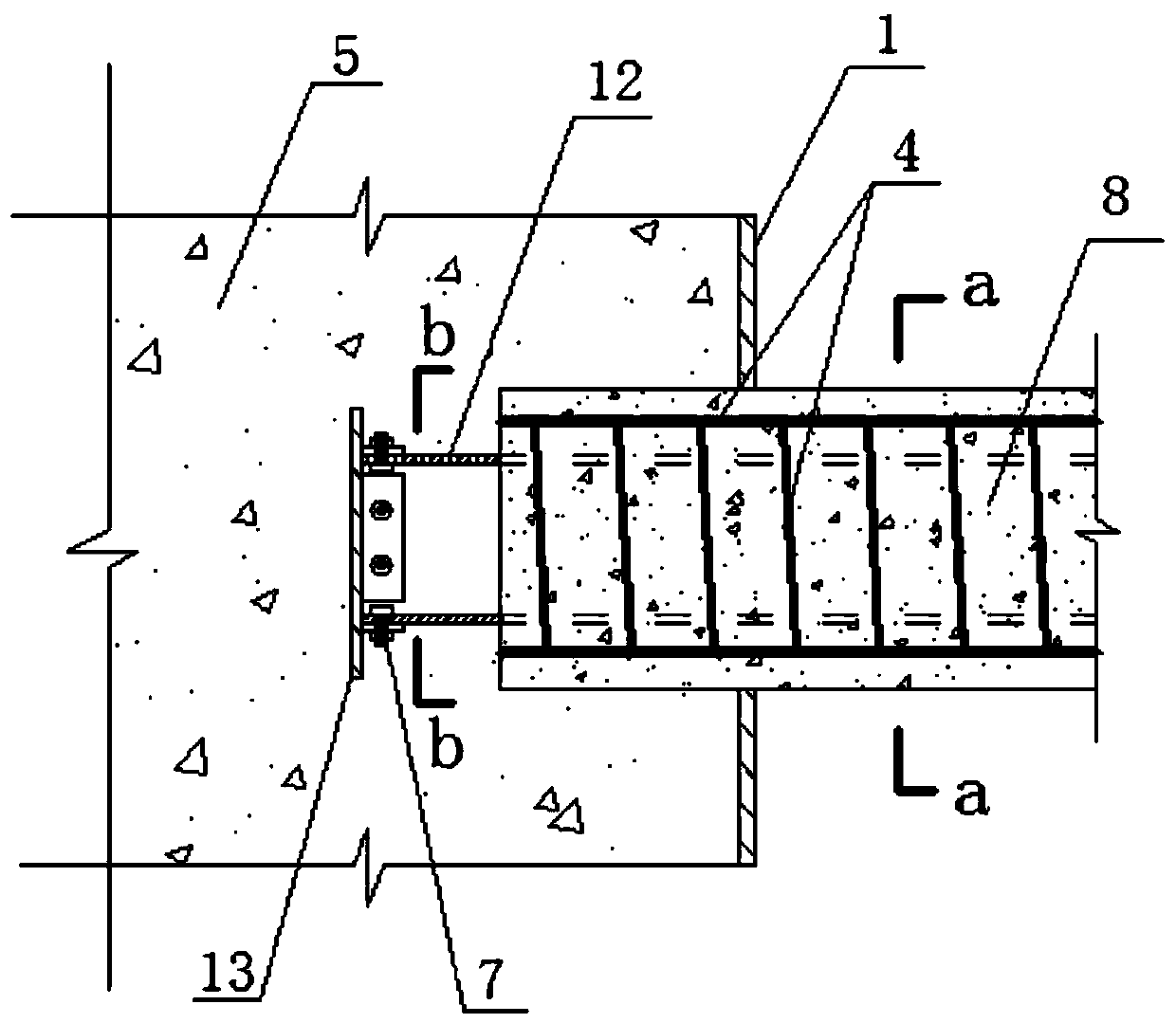

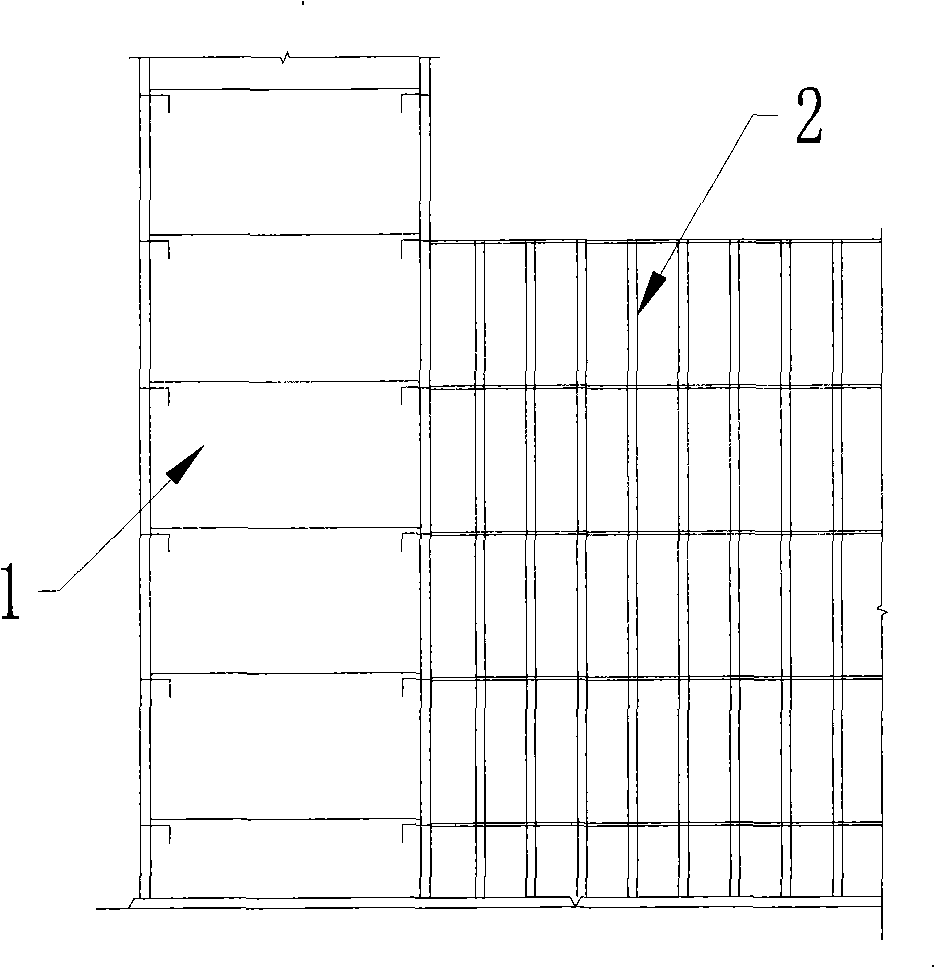

Semi-assembled pipe curtain structure based on steel reinforced concrete connection and construction process

ActiveCN110952993ARealize semi-fabricated constructionEasy constructionUnderground chambersTunnel liningReinforced concreteArchitectural engineering

The invention discloses a semi-assembled pipe curtain structure based on a steel reinforced concrete connection. The semi-assembled pipe curtain structure comprises lateral supporting structures and atransverse supporting structure, wherein the lateral supporting structures are used for supporting lateral surrounding rock, the transverse supporting structure is used for supporting the ground, thelateral supporting structures are connected through the transverse supporting structure, each of the lateral supporting structure and the transverse supporting structure comprise a plurality of largesteel pipes, the adjacent large steel pipes are connected through a prefabricated connecting component, and concretes I are filled in the large steel pipes for packaging the prefabricated connectingcomponent. The construction process of the semi-assembled pipe curtain structure based on the steel reinforced concrete connection comprises the following steps of 1, manufacturing a working well; 2,prefabricated connecting members outside the field; 3, installing a pipe curtain; 4, forming a pipe curtain structure; and 5, grouting reinforcement treatment and building a building. The manufacturing process of the prefabricated connecting component is standardized, the concrete pouring quality of the prefabricated connecting component is guaranteed, and the phenomena of insufficient concrete pouring compactness and internal concrete missing are avoided.

Owner:NORTHEASTERN UNIV

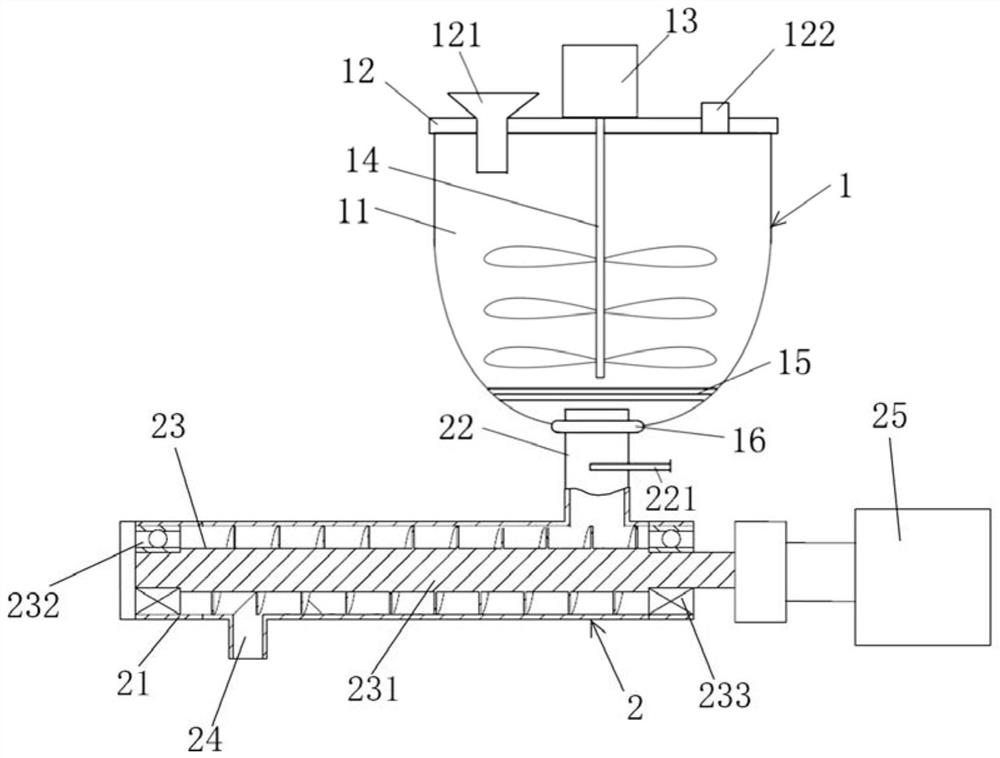

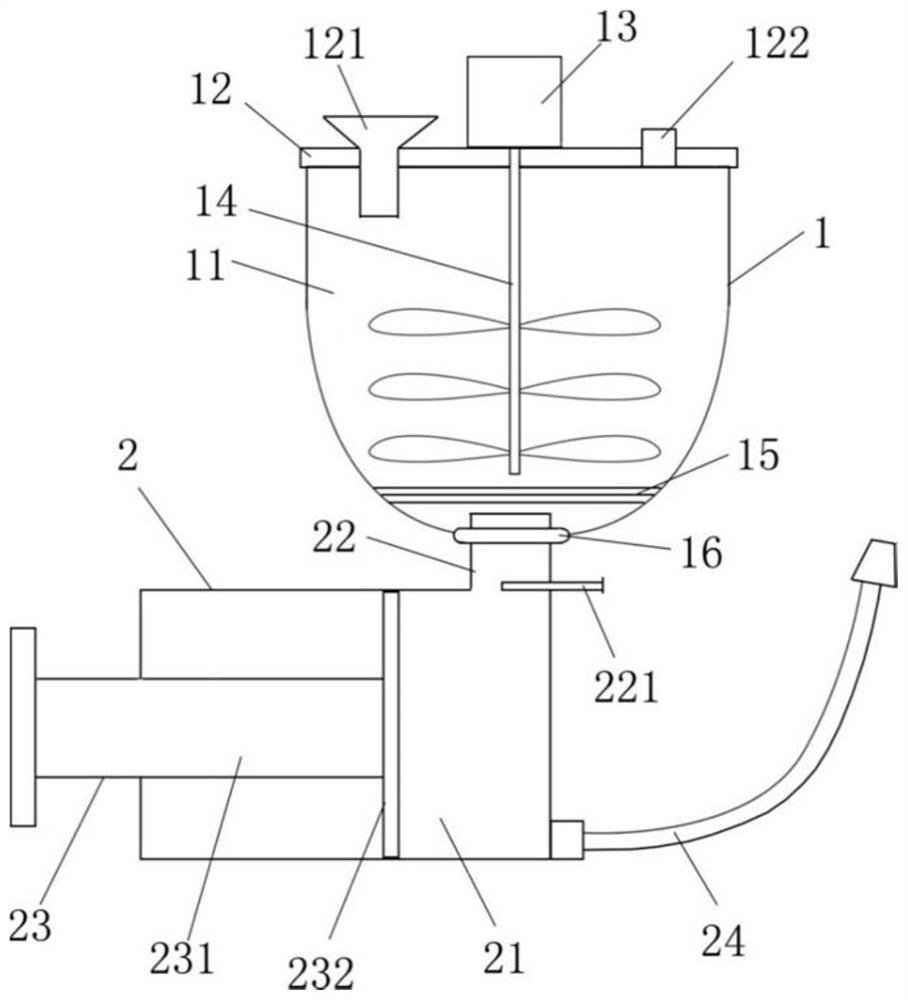

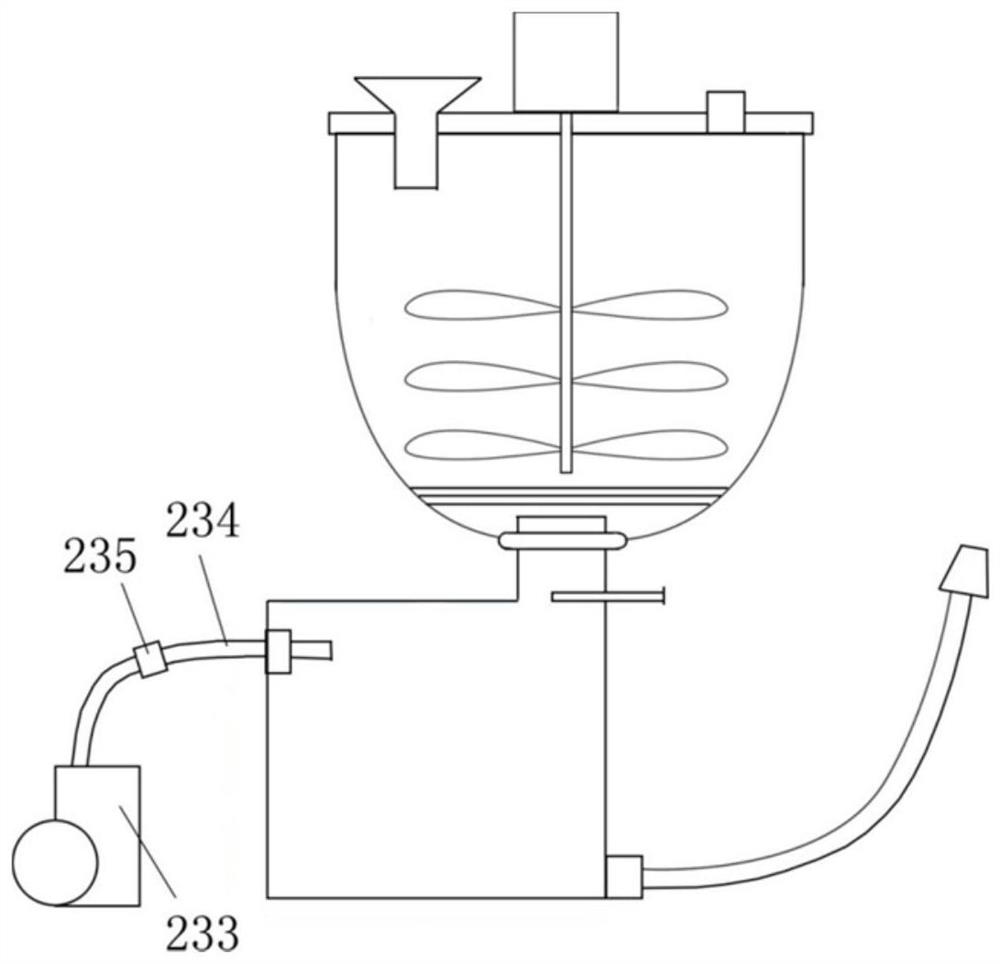

Gypsum slurry stirring and pouring device

PendingCN112619477AEasy to makeRapid perfusionRotary stirring mixersTransportation and packagingMining engineeringSlurry

The invention relates to a gypsum slurry stirring and pouring device, which comprises a stirring module and a pouring module, the stirring module comprises a stirring container and a stirring mechanism, the pouring module comprises a tubular container, a connecting pipe, a pressurizing mechanism and a liquid outlet, the bottom of the stirring container is communicated with the lower tubular container through the connecting pipe, and the pressurizing mechanism is mounted in the tubular container, the pressurizing mechanism comprises a first bearing, a second bearing, a spiral shaft and a first motor, the first bearing is located at the closed end of the tubular container, the second bearing is located at the open end of the tubular container, and one end of the spiral shaft is connected with the first bearing while the other end penetrates the second bearing to be connected with the first motor. Compared with the prior art, gypsum powder and water are mixed through the stirring module to generate the gypsum slurry, so that the gypsum slurry is convenient and rapid to prepare; gypsum slurry can be injected between lining cloth of a novel gypsum device through the pressurizing mechanism, rapid pouring is achieved, and the pouring quality is ensured.

Owner:SHANGHAI NINTH PEOPLES HOSPITAL SHANGHAI JIAO TONG UNIV SCHOOL OF MEDICINE

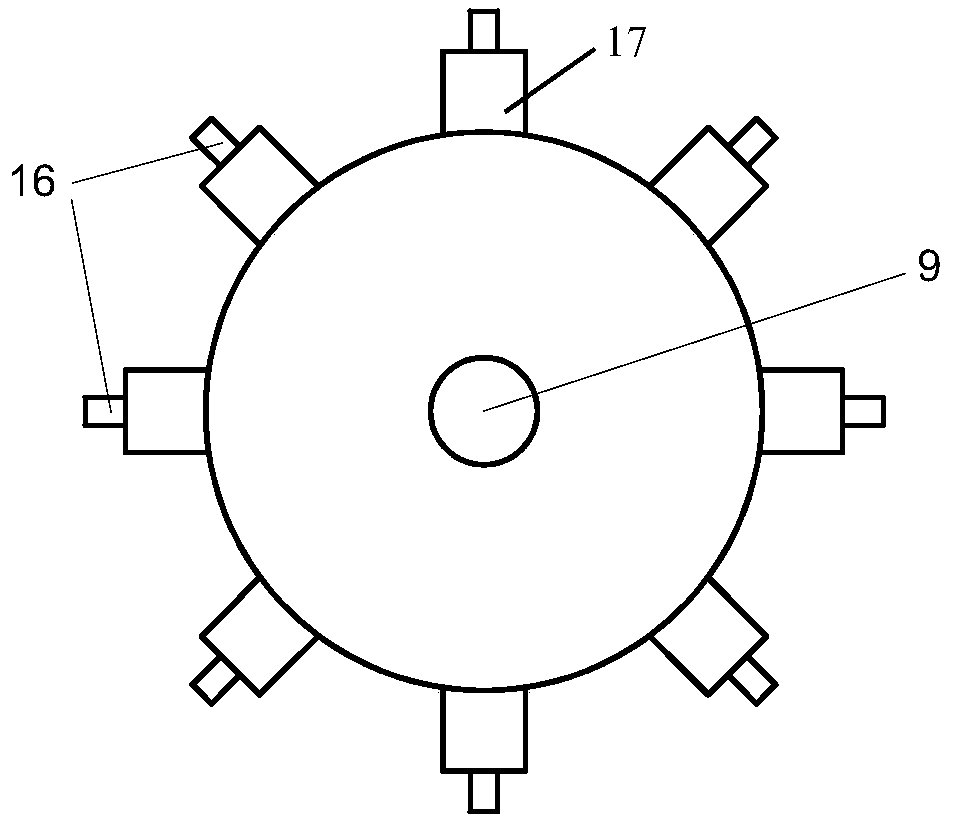

A facility and method for preventing geomembrane damage caused by subsidence around a water inlet tower

ActiveCN109518728BSolve the problem of tension damageCause damageFoundation testingProtective foundationTransceiverGeomembrane

The invention discloses a facility and method for preventing peripheral settlement of an intake tower from causing geomembrane damage. The facility comprises a grouting device and a settlement amountdetection device. The grouting device comprises a grouting machine, a grouting main pipe and multiple grouting branch pipes. The grouting main pipe is vertically arranged in the intake tower, the topof the grouting main pipe stretches out of the intake tower and is connected with the grouting machine, and the multiple grouting branch pipes are arranged at the bottom of the grouting main pipe in aradial shape. The settlement amount detection device is used for detecting the settlement amount of a reservoir around the intake tower and comprises an ultrasonic transceiver and a reflection plate.By means of the facility and method, the settlement amount detection device monitors differential settlement of a foundation around the intake tower regularly, once it is found that the settlement difference exceeds the allowable value, the grouting device carries out grouting on the settlement area in time, and differential settlement is eliminated; and if it is found that large settlement happens to the foundation again, the settlement area can be subjected to grouting repeatedly, and the problem of pulling destroying caused by too large geomembrane deformation due to foundation differential settlement around the intake tower is thoroughly solved.

Owner:HOHAI UNIV

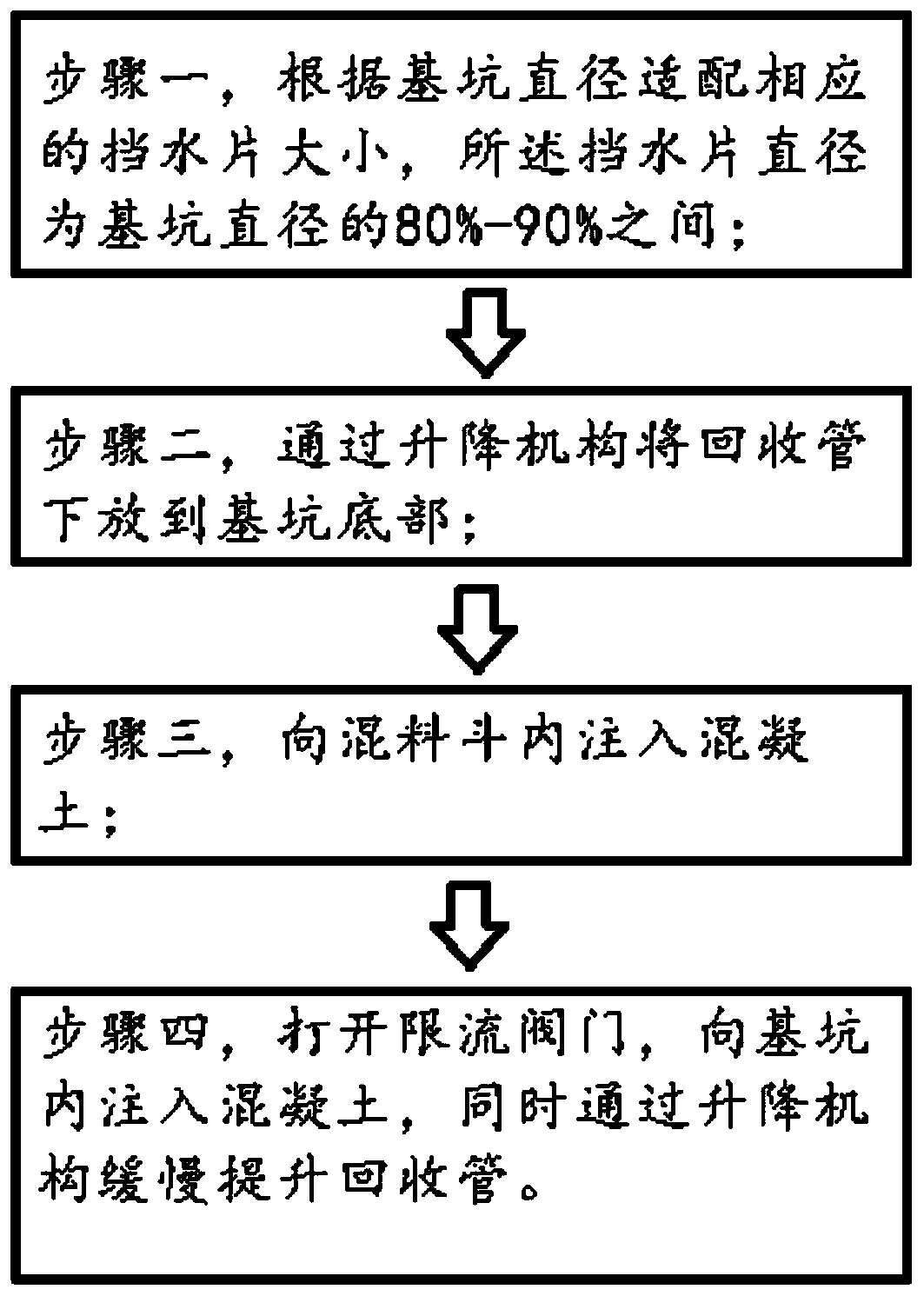

Treatment method of elevation-exceeding part of concrete pouring pile head

The invention relates to a treatment method of an elevation-exceeding part of a concrete pouring pile head. The method comprises the following steps of: within 10 minutes after a pouring pipe is pulled out, inserting a branch compressed gas pipe of a concrete pouring pile head treatment device into concrete and ensuring that a distance of 100-500 millimeters is reserved between the bottom end of the branch compressed gas pipe and a required elevation of the pouring pile head; successively opening a regulating valve and a master regulating valve of the concrete pouring pile head treatment device to ensure that the compressed gas is ejected out from the bottom of the branch compressed gas pipe; within 3-10 minutes after slurry bubbles appear on the surface layer of the concrete, successively closing the master regulating valve and the regulating valve and stopping inputting the compressed gas; pulling the branch compressed gas pipe out; and chipping off a set elevation part exceeding the pouring pile head. In the invention, materials in different proportions in the concrete material are separated in the presence of the action of gas by adopting the compressed gas so that the strength of a redundant concrete part is greatly reduced, thus the part is easy to treat, and the main reinforcing steel bar of the pouring pile head and the quality of the pile head concrete are not easy todamage.

Owner:CHINA FIRST METALLURGICAL GROUP

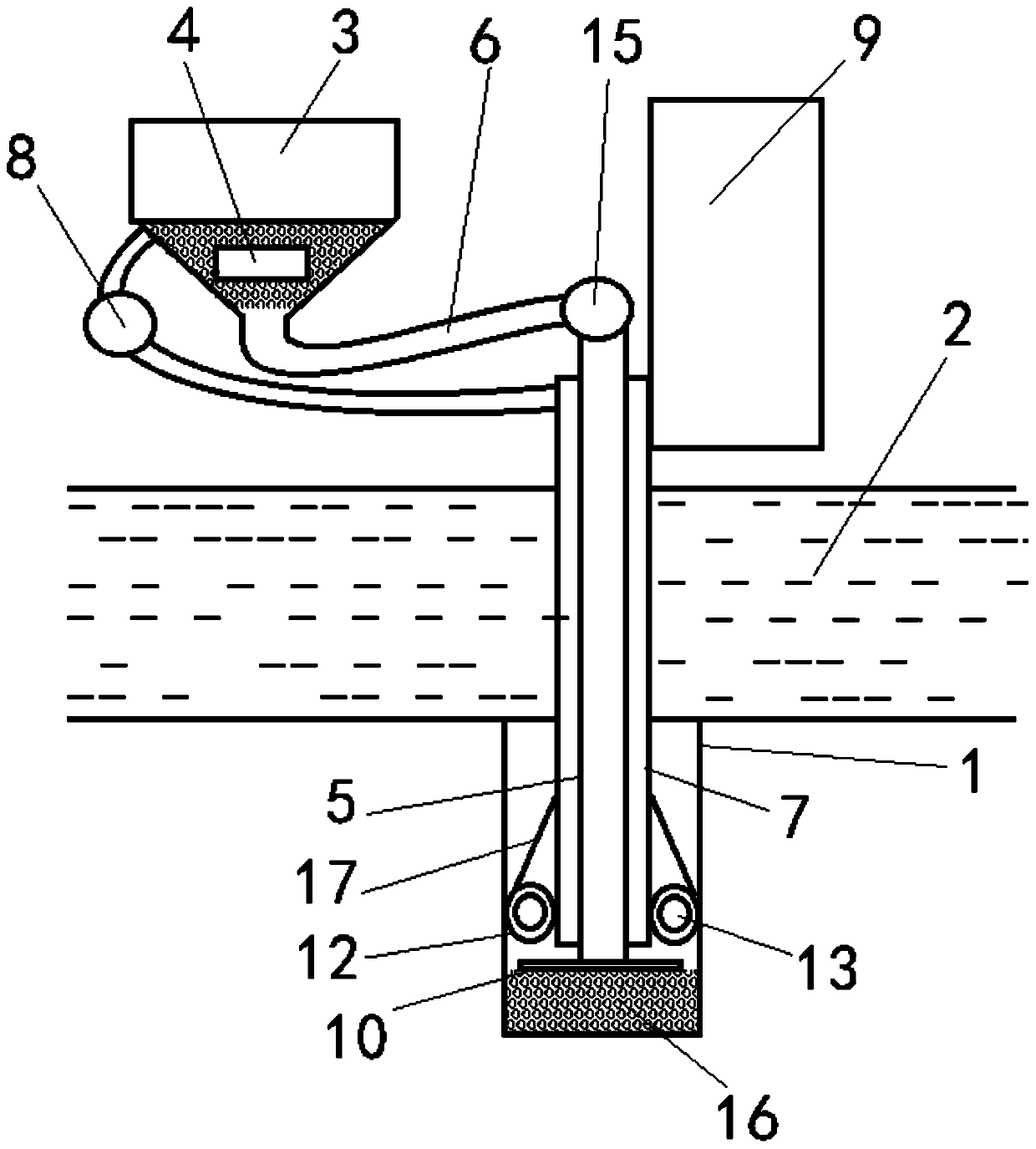

Bridge pile foundation concrete pouring equipment and process applied to water accumulated area

ActiveCN111364468AAvoid buryingAvoid runningFoundation engineeringCement mixing apparatusArchitectural engineeringStructural engineering

The invention relates to the technical field of bridge crossing construction, in particular to bridge pile foundation concrete pouring equipment and process applied to a water accumulated area. The equipment comprises a material mixing hopper, a grouting pipe and a recycling pipe; the material mixing hopper is fixedly arranged above the water surface of a foundation pit area; a stirring mechanismis arranged in the material mixing hopper; the grouting pipe is a section of vertical pipeline arranged rigidly; the top of the grouting pipe communicates with the bottom of the material mixing hopperthrough a high-pressure hose; the recycling pipe is arranged outside the grouting pipe in an nesting manner; the top of the recycling pipe is connected with the outer wall of the grouting pipe in a sealing manner; and the top of the recycling pipe communicates with the interior of the material mixing hopper through a sucking pump. The bridge pile foundation concrete pouring equipment and processapplied to the water accumulated area aim to grout concrete into a foundation pit with accumulated water from bottom to top by means of the special equipment, and perform targeted treatment on dilutedconcrete, so that the grouting difficulty of the foundation pit of the accumulated area is simplified, and meanwhile, the grouting quality is also ensured.

Owner:CHONGQING COMM CONSTR GRP

Gypsum slurry stirring and perfusion device

PendingCN112618171AEasy to makeRapid perfusionRotary stirring mixersTransportation and packagingEngineeringSlurry

The invention relates to a gypsum slurry stirring and perfusion device. The gypsum slurry stirring and perfusion device comprises a stirring module and a perfusion module connected in a vertical direction; the stirring module includes a stirring container and a stirring mechanism; the stirring mechanism is installed in the stirring container; the perfusion module includes a perfusion container, a connecting pipeline, a pressurizing mechanism and a liquid outlet guide pipe; a bottom inner cavity of the stirring container is a cambered surface; the cambered surface is connected with the perfusion container below the stirring container through the connecting pipeline; the pressurizing mechanism is connected with one end of the perfusion container; the liquid outlet guide pipe is connected with the other end of the perfusion container; and a switch valve is arranged in the connecting pipeline. Compared with the prior art, the gypsum slurry stirring and perfusion device has the advantage that gypsum powder and water are mixed by the stirring module to generate gypsum slurry, so that the gypsum slurry is made conveniently and rapidly; through the vertical structural design of the stirring module and the perfusion module, the generated gypsum slurry automatically enters the perfusion module; and the gypsum slurry can be injected between lining cloth of a novel gypsum device through the pressurizing mechanism, so that rapid perfusion is realized, and the perfusion quality is guaranteed.

Owner:SHANGHAI NINTH PEOPLES HOSPITAL AFFILIATED TO SHANGHAI JIAO TONG UNIV SCHOOL OF MEDICINE

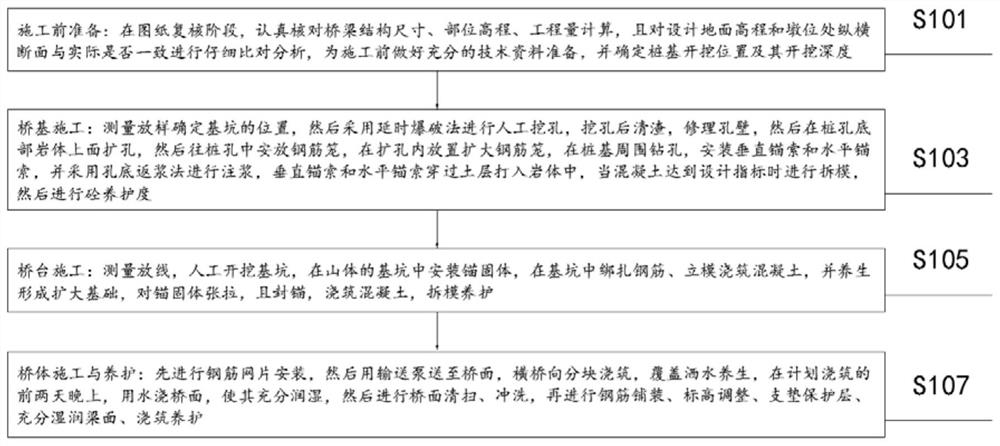

Mountainous area bridge construction method with large water volume change

PendingCN113502747AGuaranteed perfusion qualityLow costBridge erection/assemblyBulkheads/pilesArchitectural engineeringMechanical equipment

The invention discloses a mountainous area bridge construction method with large water volume change, which comprises the following steps: preparation before construction: in a drawing rechecking stage, carefully checking the bridge structure size and the part elevation, calculating the engineering quantity, and carefully comparing and analyzing whether the design ground elevation and the longitudinal and transverse sections at the pier position are consistent with the reality; making sufficient technical data preparation before construction, and determining the excavation position and the excavation depth of the pile foundation; and bridge foundation construction: measuring and setting out to determine the position of a foundation pit, then carrying out manual hole digging by adopting a delayed blasting method, removing slag after hole digging, repairing a hole wall, then expanding a hole in a rock mass at the bottom of a pile hole, placing a reinforcement cage in the pile hole, and placing an expanded reinforcement cage in the expanded hole. The method has the beneficial effects that the concrete follow-up retaining wall is adopted, the construction safety and the pouring quality of pile foundation concrete are ensured, the number of used mechanical equipment is small, the construction investment is reduced, the engineering cost is reduced, the professional degree of construction is small, the construction face is wide, the number of excavation points is large, and the construction progress is accelerated.

Owner:杭州市城市建设基础工程有限公司

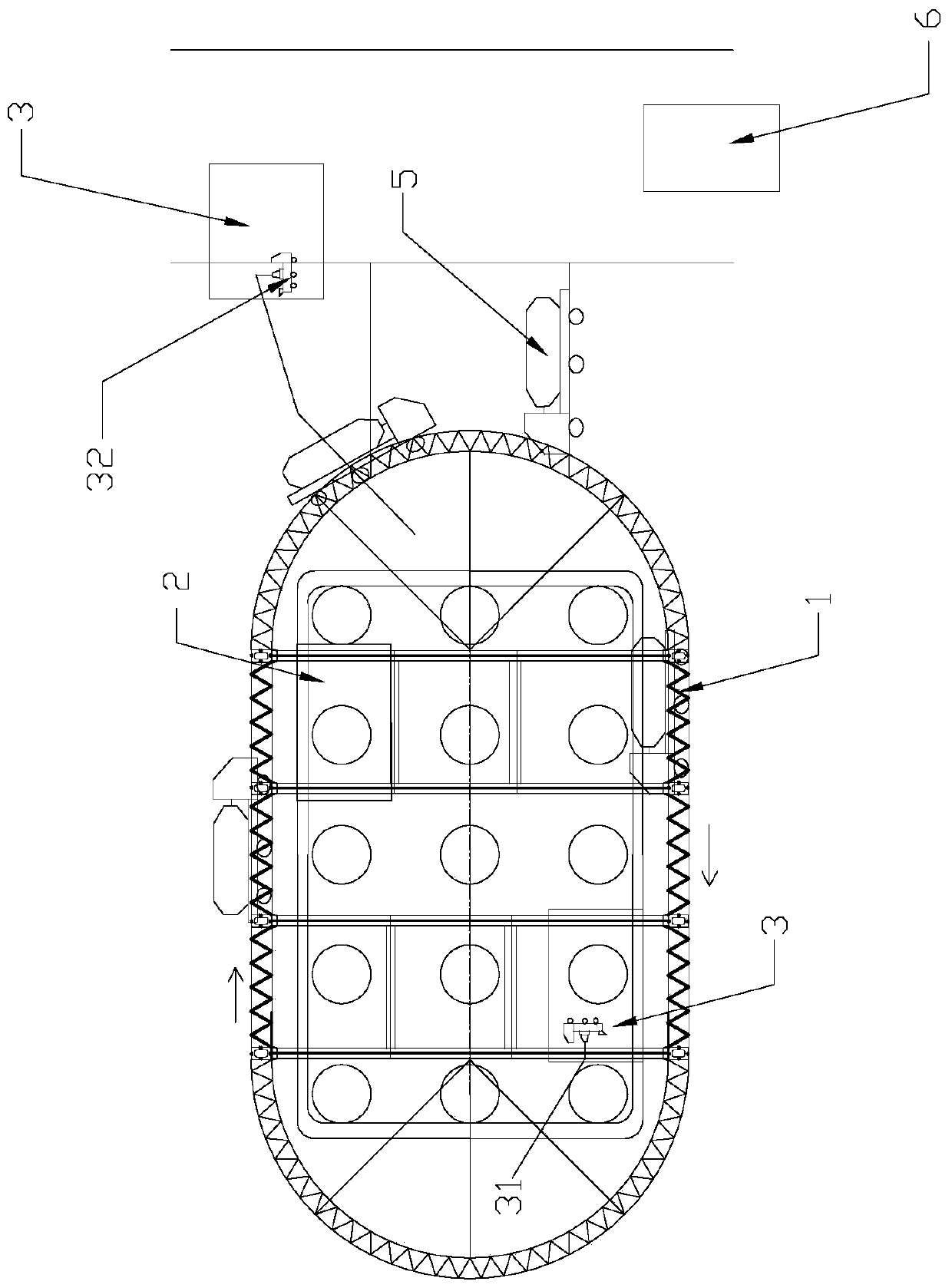

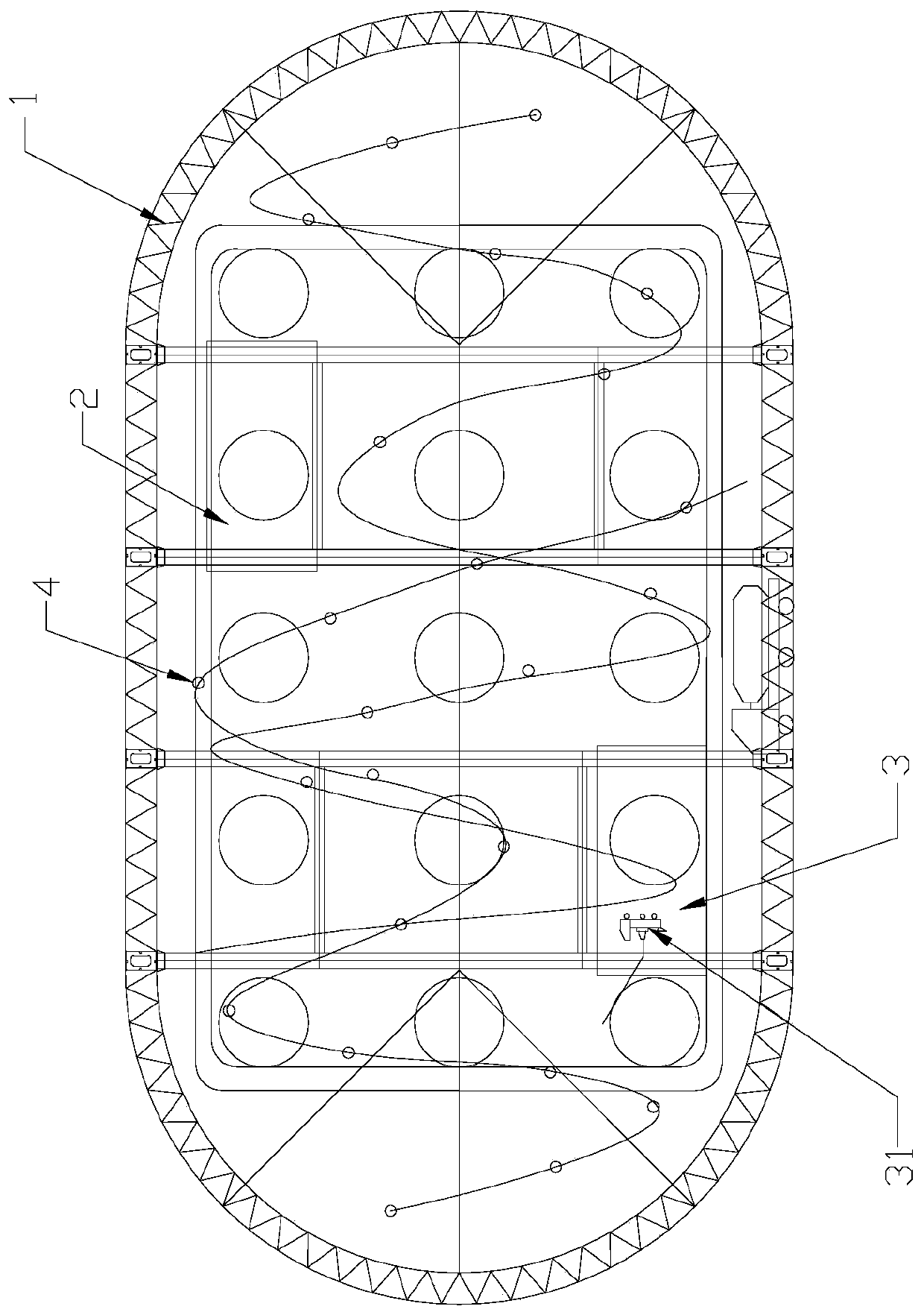

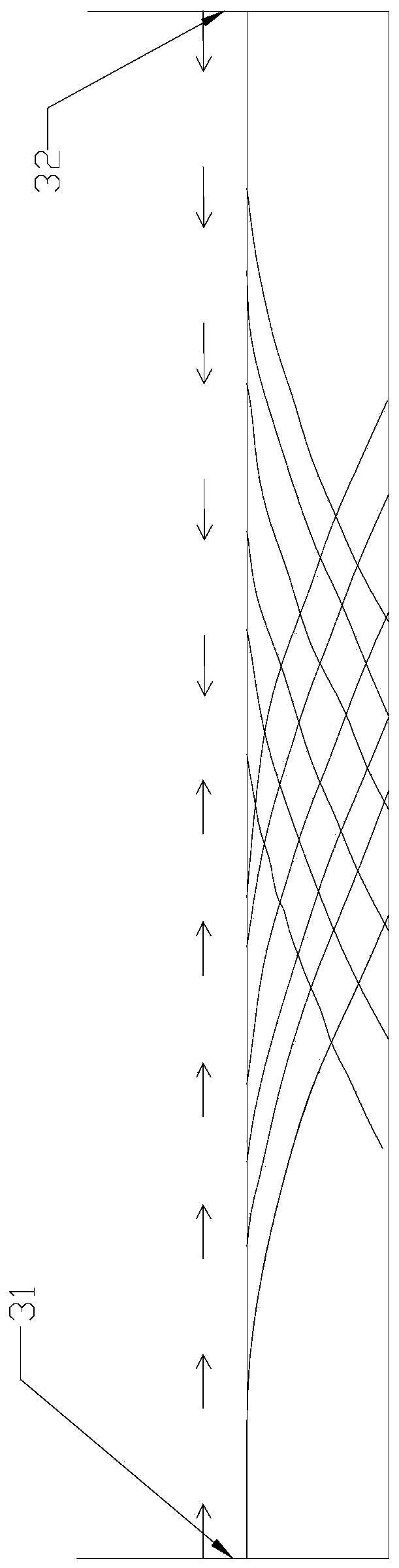

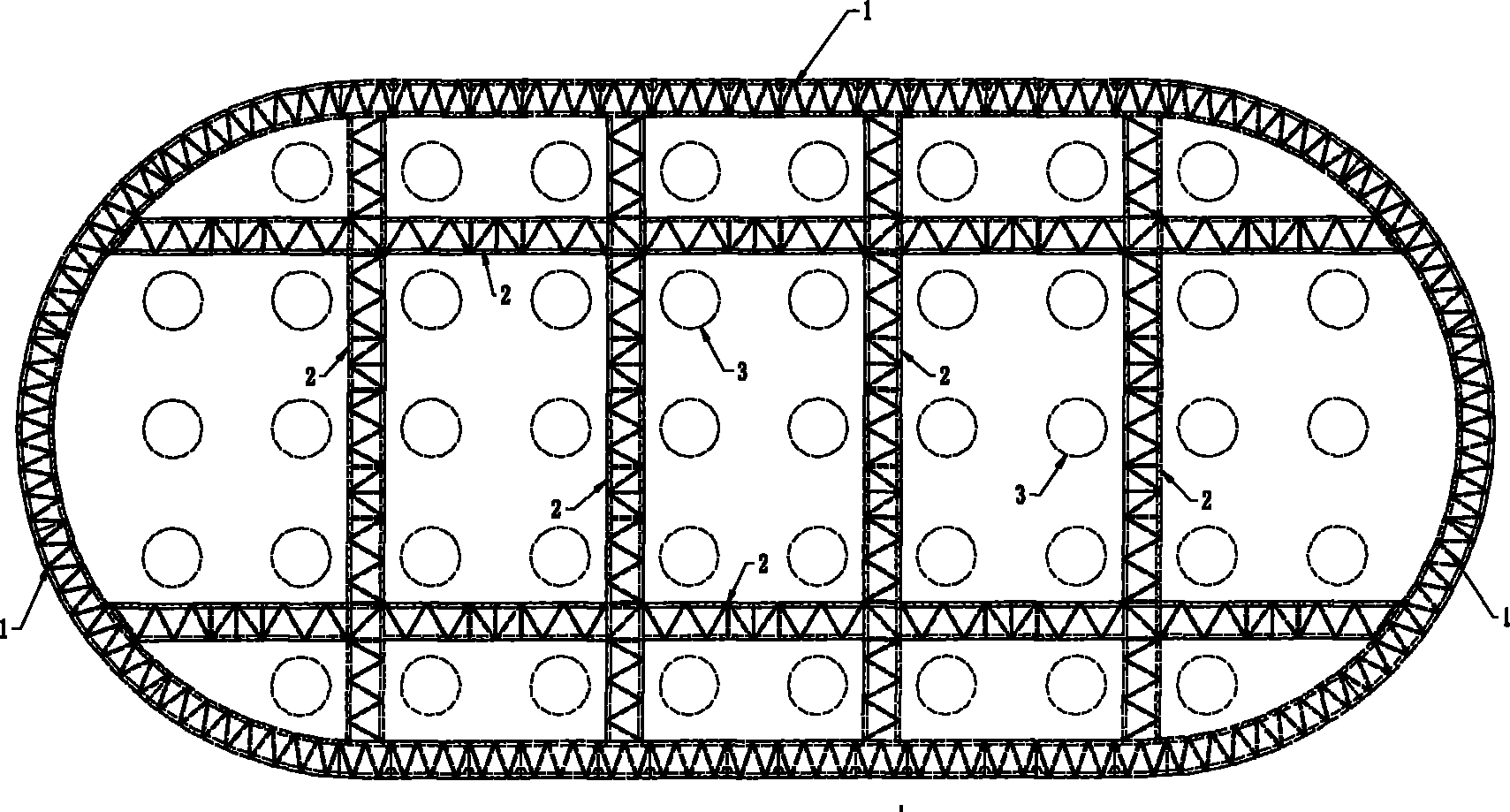

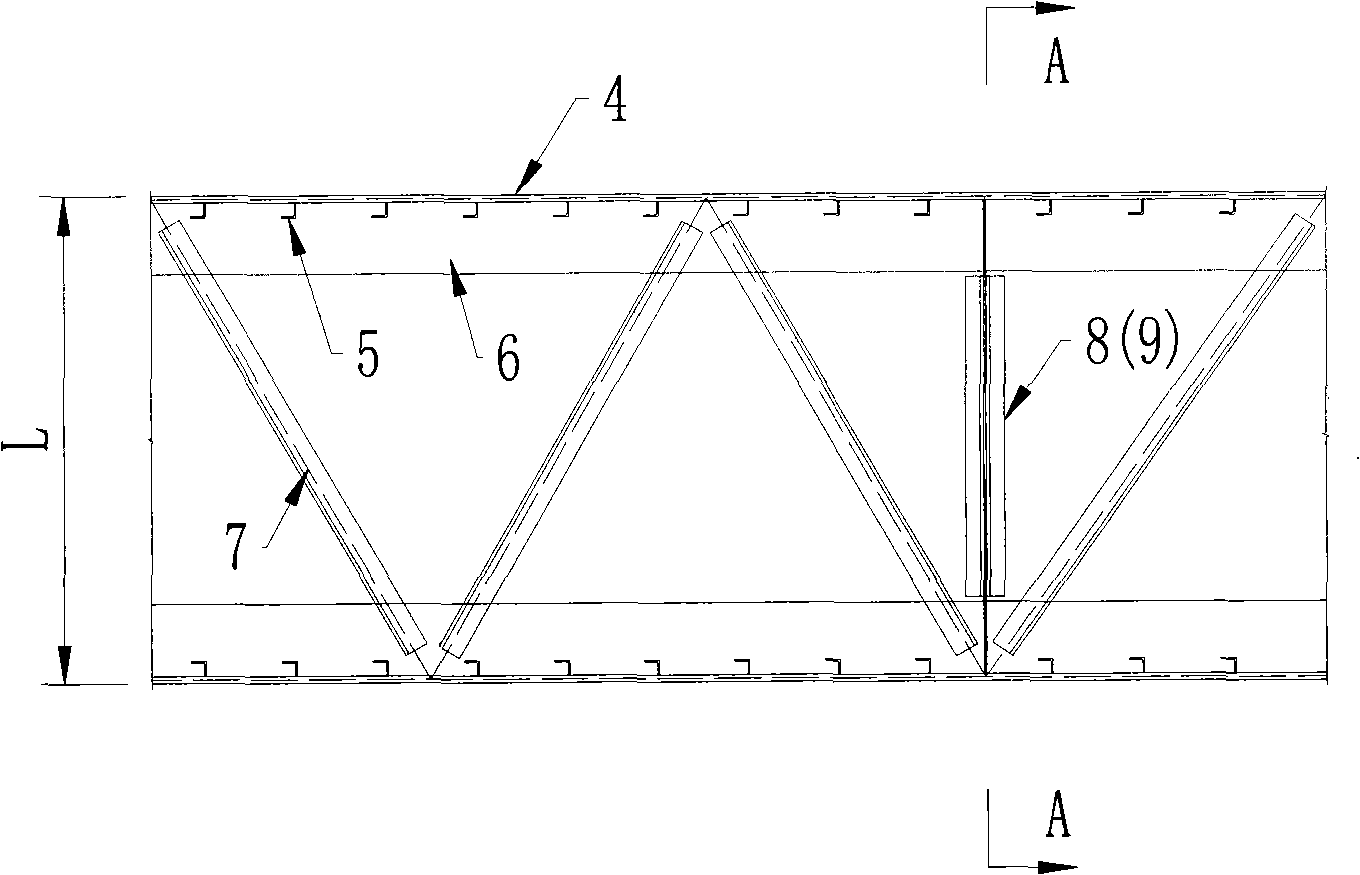

Large-scale shallow water floating cofferdam

ActiveCN101435201BLower requirementLittle effect of water levelCaissonsBridge engineeringMarine engineering

Disclosed is a large-scale shallow water floating cofferdam, relating to the large-scale cofferdam in bridge engineering. The cofferdam comprises an annular structure composed of two parallel cofferdam side plates, and is characterized in that the bottom part between the parallel cofferdam side plates and the parallel cofferdam side plates form a waterproof closed area, the inside of the annular structure is provided with a plurality of closed bottom compartments for reducing the underwater depth of the cofferdam and a plurality of bored piles which are matching with the pile positions of bridge pier, the closed bottom compartments are interconnected into a plurality of transverse and longitudinal columns, the two ends of the closed bottom compartments and the cofferdam side plates are connected to divide the cofferdam into a plurality of symmetrical work areas and avoid the position of bored piles, and the height of the closed bottom compartment is lower than that of the cofferdam side plate. The large-scale shallow water floating cofferdam of the invention has shallow underwater depth during cofferdam floating, reduces the requirement of the ship tonnage and mechanical equipment, has little water level influence to the floating navigation route, reduces cost, and has little perfusion area during the perfusion process of underwater back cover concrete and can guarantee the perfusion quality of the concrete.

Owner:CHINA RAILWAY MAJOR BRIDGE ENG GRP CO LTD

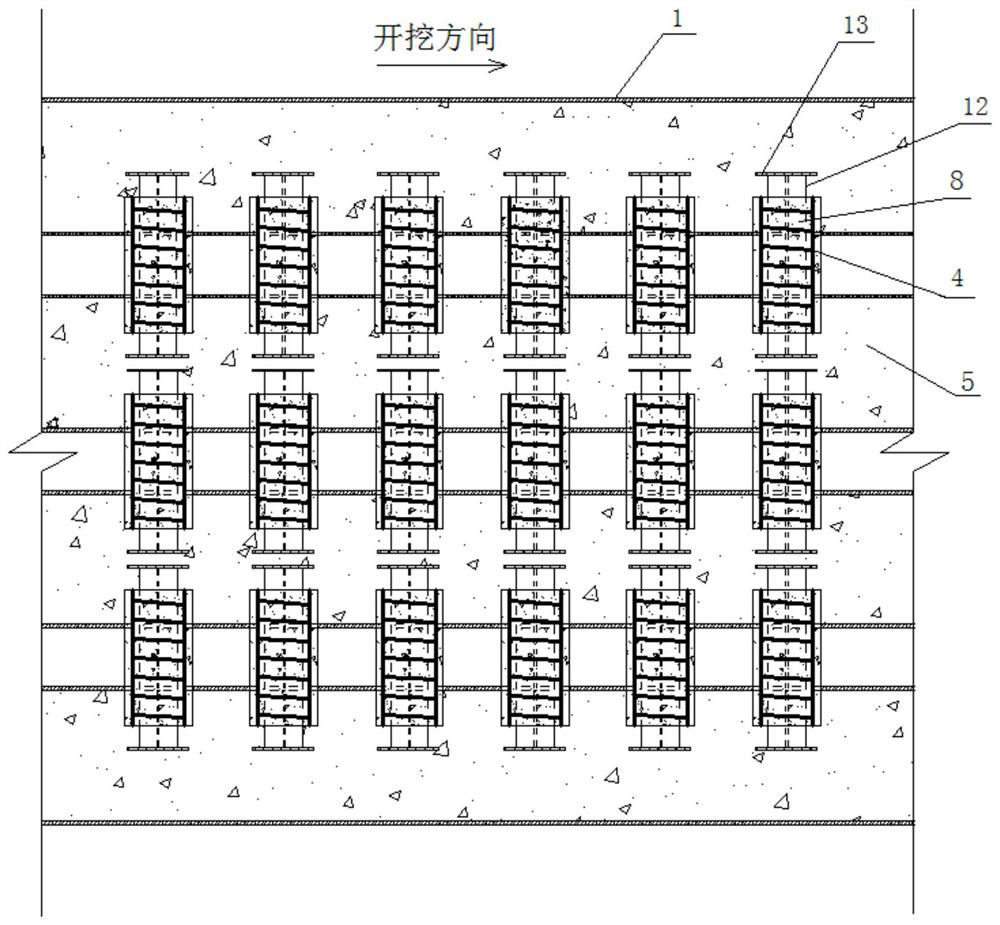

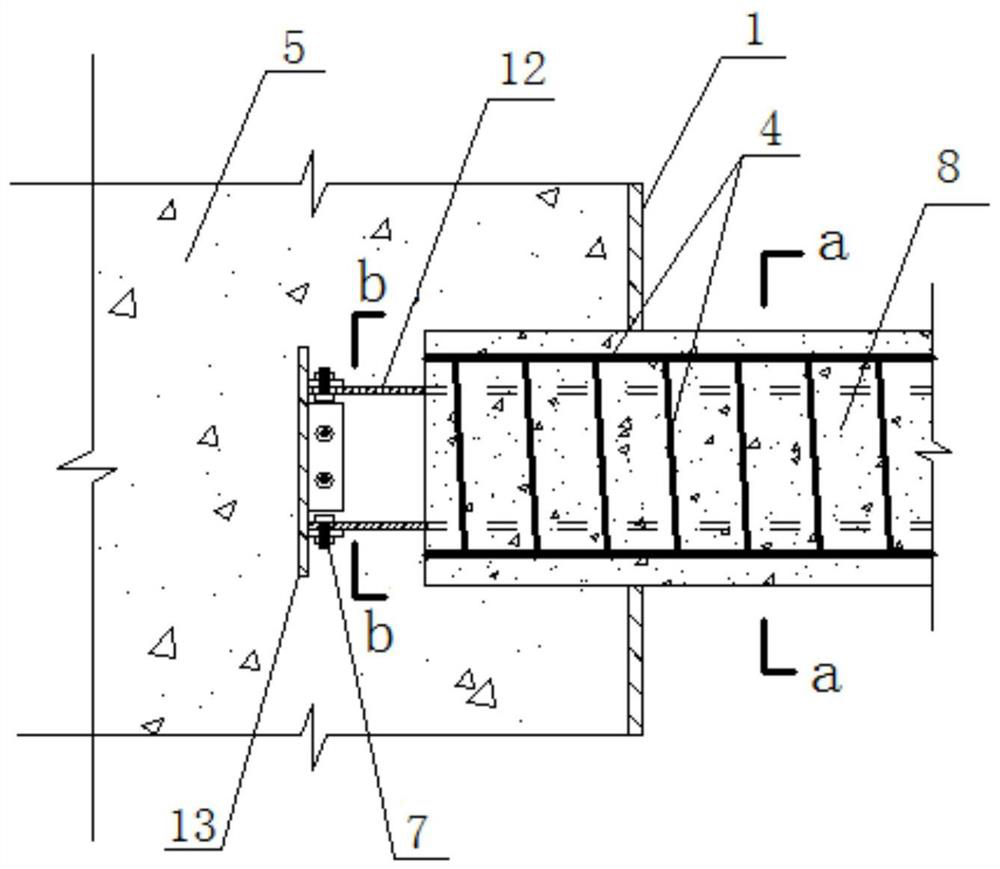

Novel concrete fractionation device for subway slab track construction and construction method

ActiveCN113389096ASolve construction difficultiesAccurateRailway track constructionTrackwayArchitectural engineering

The invention provides a novel concrete fractionation device for subway slab track construction and a construction method. The fractionation device is installed on a steel rail above a track slab through walking wheels, the fractionation device can freely slide on the steel rail, and two fractionation chutes capable of freely moving are symmetrically arranged on the fractionation device through a sliding rail beam and a sliding block, so that accurate alignment of the fractionation chutes, a discharging opening and pouring holes is achieved, continuous pouring can be achieved, the problem of procedure interruption in a traditional construction technology is solved, and the construction efficiency is higher. Limiting devices are further arranged on the two sides of the fractionation device, the limiting devices are clamped with the pouring holes of the track slab through stopping blocks capable of moving up and down, then braking of the fractionation device is achieved, the risk that the fractionation device slides in the discharging process of an ash hopper and the pouring process of the fractionation chutes is avoided, operation is convenient, and use is safe and reliable.

Owner:CHINA CONSTR IND & ENERGY ENG GRP CO LTD

A perfusion method for perfusion molding of special-shaped coil skeleton

The invention relates to a pouring method for pouring molding of a special-shaped coil former. The method includes the following steps that first, pretreatment of adhesives is performed, the adhesives are subject to defoaming treatment in stirring and pressure drop modes, and stirring under vacuumizing and stirring under ordinary pressure are carried out alternately; second, workpiece installation is conducted, and the coil former is placed into a molding tool; and third, filling and sealing are carried out, and a four-opening synchronous filling and sealing tool is used for pouring the four surfaces of the coil former at the same time. By the adoption of the tool and the pouring method thereof, the molding quality of coil pouring of a seeker product is guaranteed, reliable performance of the product is ensured, and production efficiency is improved.

Owner:XIAN NORTH ELECTRO OPTIC TECH DEFENSE

New Concrete Separating Device and Construction Method for Subway Slab Track Construction

ActiveCN113389096BSolve construction difficultiesAccurateRailway track constructionTrackwayStructural engineering

Owner:CHINA CONSTR IND & ENERGY ENG GRP CO LTD

Semi-fabricated pipe curtain structure and construction technology based on steel-concrete connection

ActiveCN110952993BRealize semi-fabricated constructionEasy constructionUnderground chambersTunnel liningReinforced concreteArchitectural engineering

A semi-fabricated pipe curtain structure based on profiled steel-concrete connections, including a lateral support structure and a lateral support structure. The lateral support structure is used to support lateral surrounding rocks. The lateral support structure is used to support the ground. The lateral support structure They are connected through a lateral support structure. The lateral support structure and the lateral support structure include a number of large steel pipes. The adjacent large steel pipes are connected through prefabricated connecting members. The large steel pipes are filled with concrete I for packaging prefabricated Connecting components. The construction process of a semi-fabricated pipe curtain structure based on profiled steel-concrete connections includes the following steps: Step 1, making a working shaft; Step 2, off-site prefabricated connection components; Step 3, installation of the pipe curtain; Step 4, forming the pipe curtain structure; Step 5: grouting reinforcement and masonry construction; the standardization of the production process of prefabricated connecting components ensures the quality of concrete pouring of prefabricated connecting components and avoids the phenomenon of insufficient concrete pouring and missing internal concrete.

Owner:NORTHEASTERN UNIV LIAONING

Mounting method of concrete hollow anchor rod tool

InactiveCN110117957AGuaranteed perfusion qualityImproved durability and reliabilityBulkheads/pilesAnchoring boltsSyringeInjector

The invention discloses a mounting method of a concrete hollow anchor rod tool. When used for inverted mounting of a hollow anchor rod, the mounting method comprises the following steps: 1, a hole isformed and cleared, specifically, the straight hole (28) is drilled in rock or concrete (27) through a drilling rig, then the hole is broached through broaching equipment, and then the hole is clearedthrough a hole clearing device; 2, mounting is conducted, specifically, hollow self-bottom-expanding anchor bolts are assembled firstly, a rubber sleeve (30) sleeves a rod body (1) and is located ona middle rod (22) part, then the rubber sleeve (30) is glued to the rod body (1) through glue, and then the assembled hollow self-bottom-expanding anchor bolts are inserted into the straight hole (28); and 3, grouting is conducted, specifically, through an injector, a grouting material sequentially passes through a rod body inner hole (9) and a wedge block inner hole (24) and then is injected intothe hole bottom of the straight hole (28), after the grouting material overflows from an air guiding pipe (32) on a large scale, grouting is stopped, an anchor rod cap (29) is mounted at the exposedend (6) to block the rod body inner hole (9) to prevent the grouting material from flowing out, and after the grouting material is solidified, the hollow self-bottom-expanding anchor bolts are mounted.

Owner:WUDA JUCHENG STRUCTURE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com