A small road repair device that is easy to operate

A road repair, small-scale technology, applied in the direction of road repair, roads, roads, etc., can solve the problems of low operation efficiency, high operation cost, relying on manual work, etc., to ensure the quality of perfusion, facilitate operation, and improve compaction efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

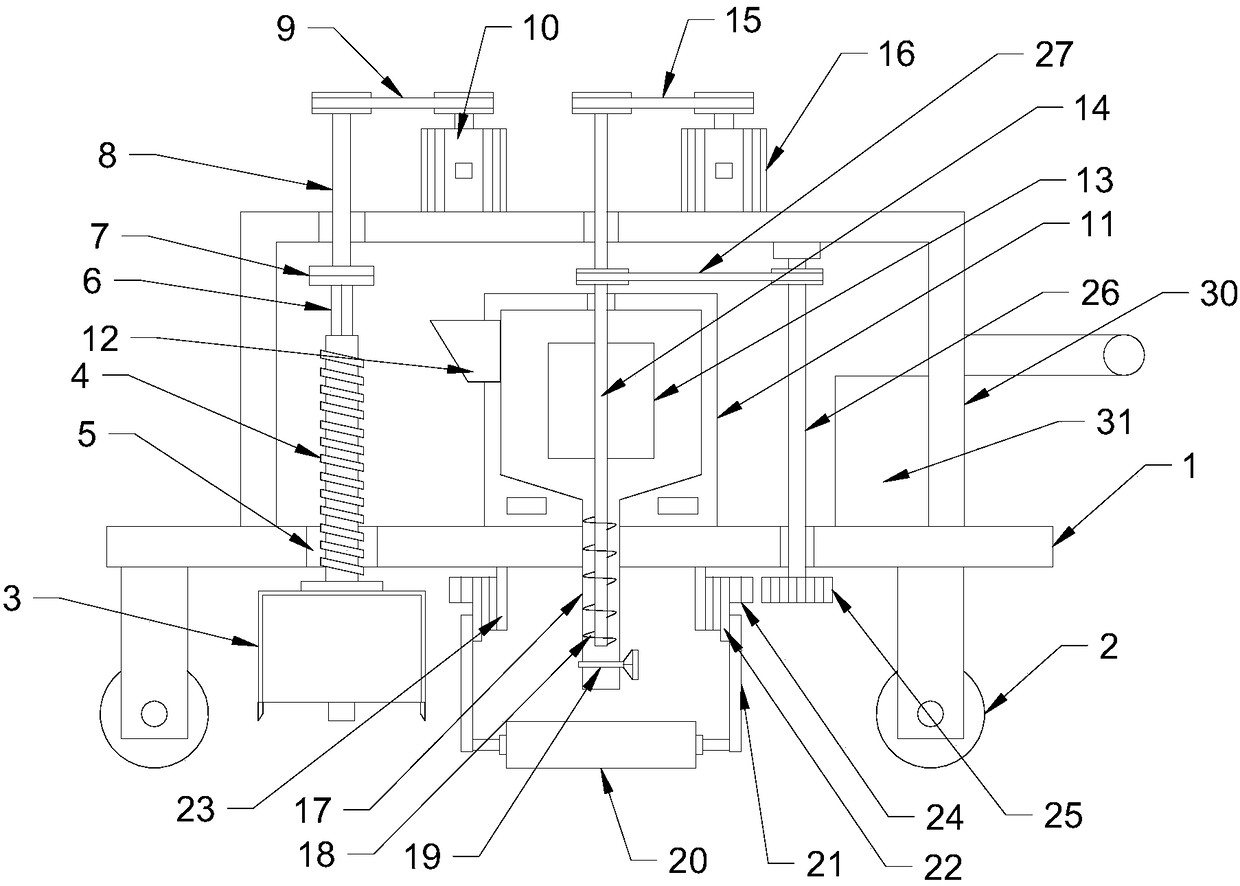

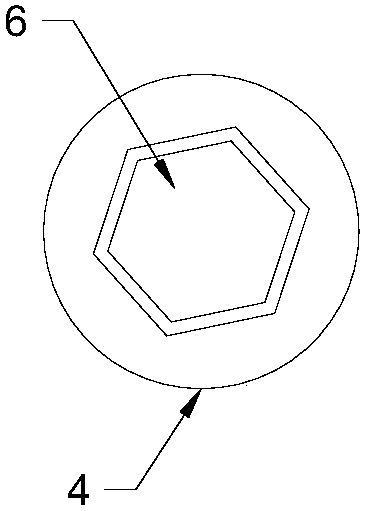

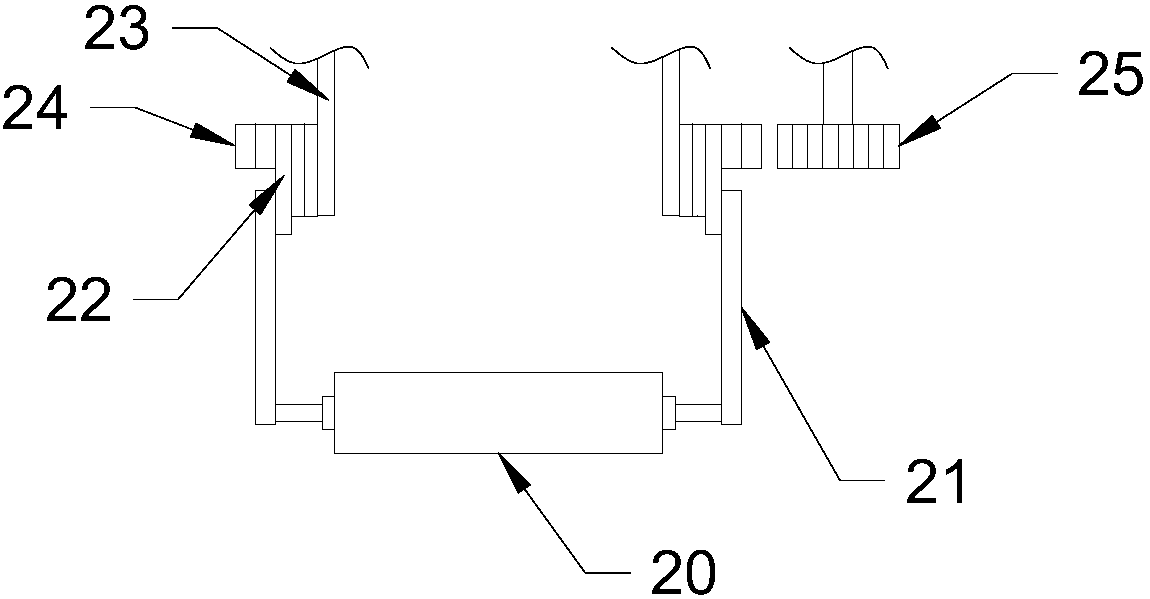

Embodiment 1

[0022] see Figure 1~3 , in the embodiment of the present invention, a kind of easy-to-operate small-sized road repairing device comprises vehicle body 1, drilling mechanism, pouring mechanism and compacting mechanism; Said drilling mechanism comprises drill tube 3, and the top of drill tube 3 is fixed by bolts The connection method is fixedly connected with a threaded sleeve 4, which can replace drill barrels of different diameters. The outer surface of the threaded sleeve 4 is provided with external threads, and the threaded sleeve 4 is provided with prismatic grooves; the threaded sleeve 4 runs through the car body 1 And threaded with the car body 1, the car body 1 is provided with a threaded hole 5; the threaded sleeve 4 is nested with a rotating rod 6, and the rotating rod 6 is nested in the threaded sleeve 4 and is slidably connected with the threaded sleeve 4 The rotating rod 6 is connected with a fixed shaft 8 through a shaft coupling 7, and the fixed shaft 8 is connec...

Embodiment 2

[0028] see Figure 4 The difference between this embodiment and Embodiment 1 is that: the car body 1 is provided with a roller 2 below, and the wheel shaft of the roller 2 is connected to the output shaft of the diesel engine 29 through the fourth transmission belt 28, which is convenient for the movement of the car body 1; A heating device is arranged in the mixing tank 11, and the heating device is a resistance wire, which stirs the asphalt and prolongs the asphalt pouring period.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com