Mounting method of concrete hollow anchor rod tool

An installation method and concrete technology, which is applied in the fields of earthwork drilling, installation of bolts, foundation structure engineering, etc., can solve the problems that horizontal bolts and inverted bolts cannot solve the problem of grouting outflow, etc., achieve high reliability and improve durability And reliable performance, the effect that the durability is high

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

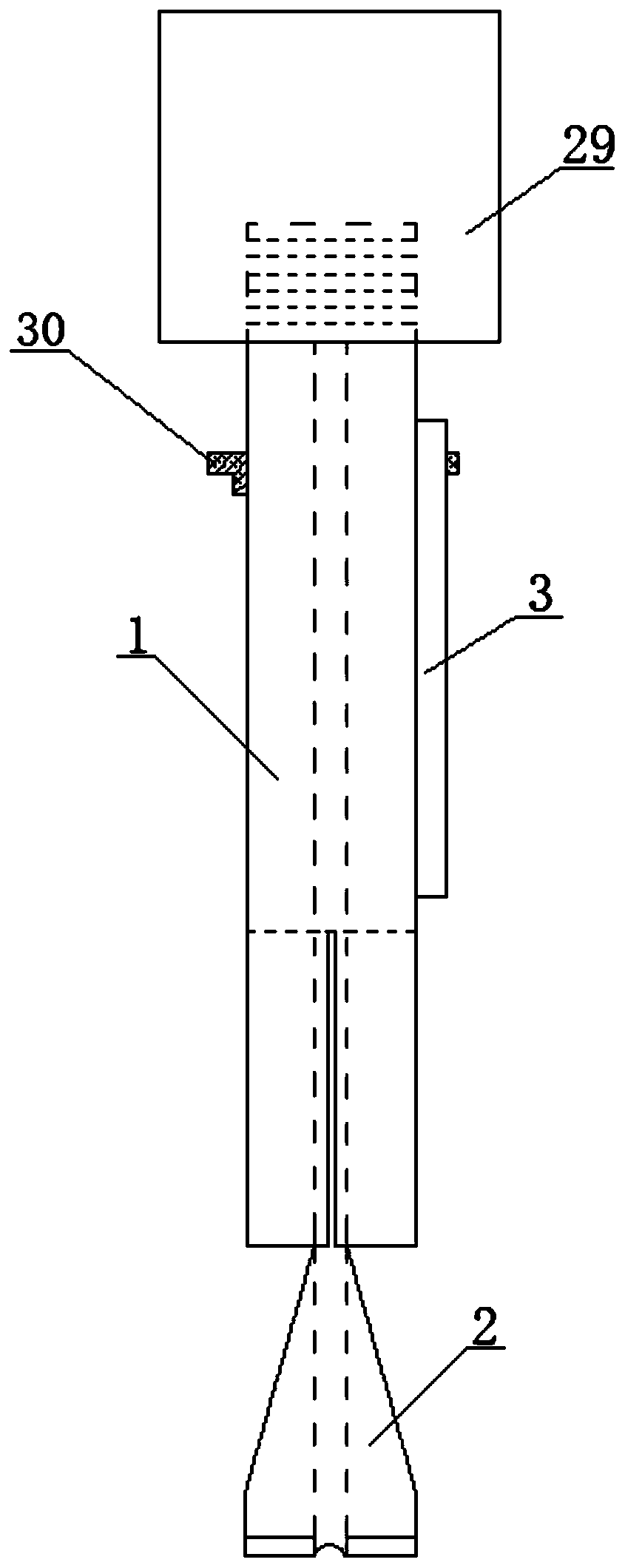

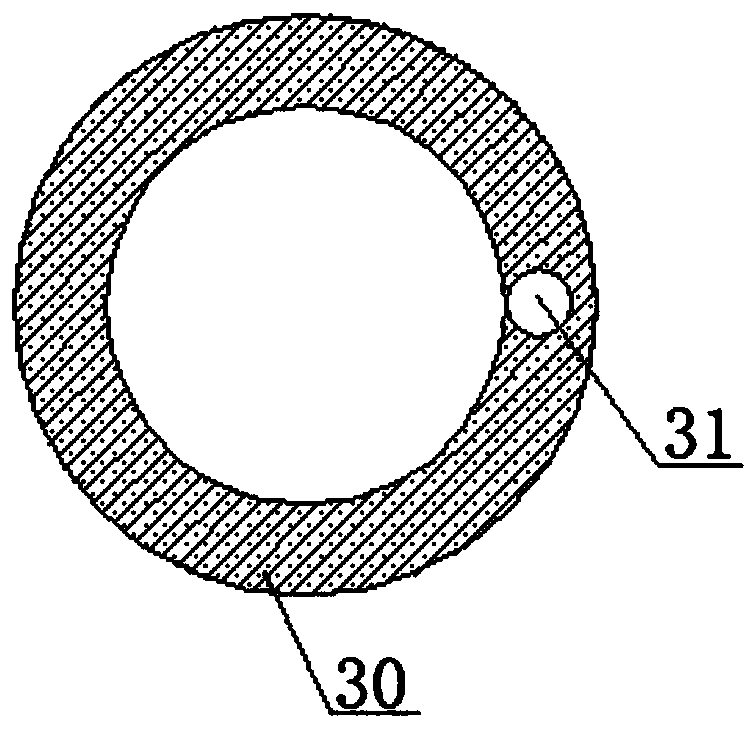

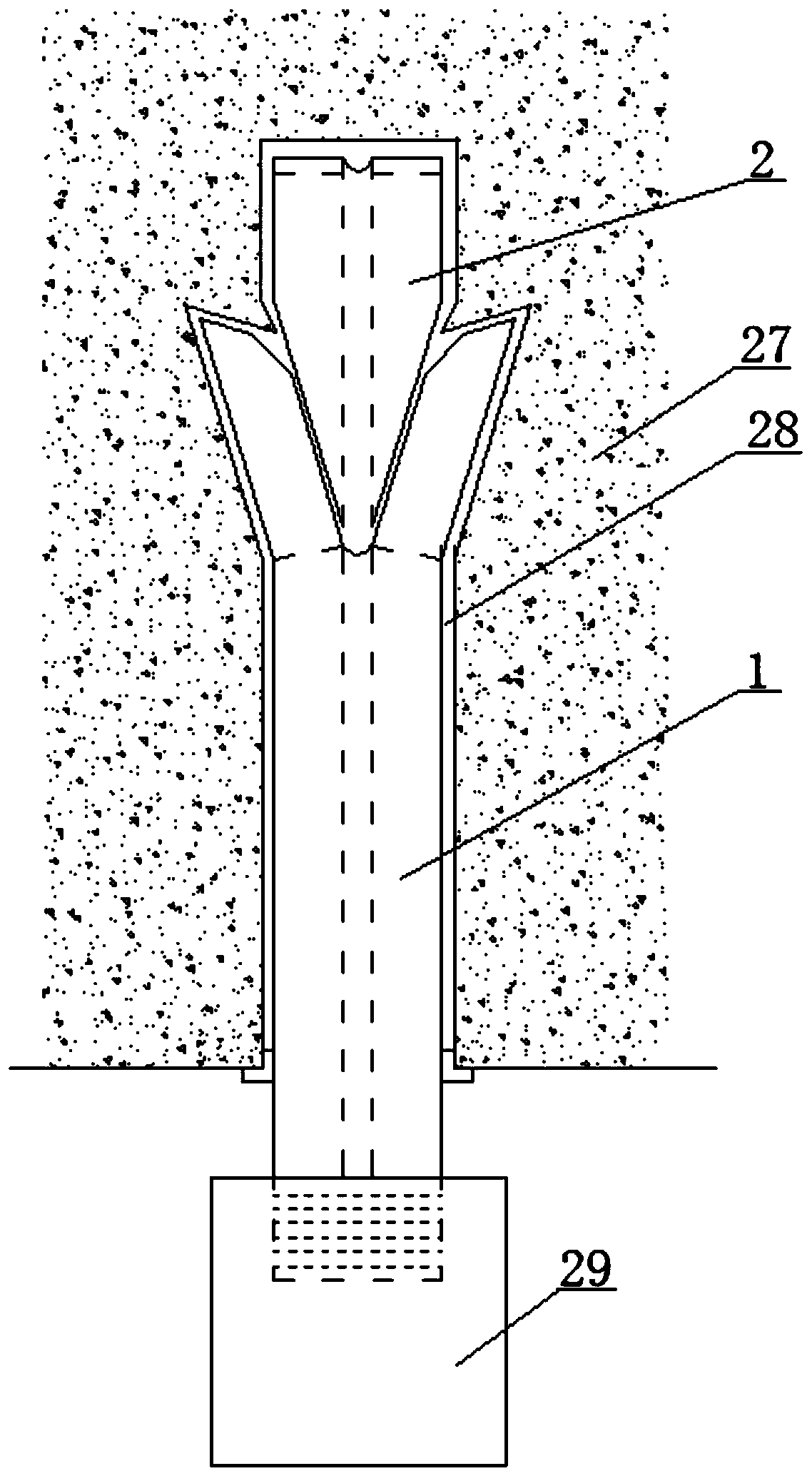

[0023] see Figure 3 to Figure 11 , a hollow bolt installation tool, wherein the hollow bolt includes a rod body 1 and a wedge 2. The rod body 1 includes a bottom end 4, an intermediate rod 5 and an exposed end 6 connected in sequence, and the wedge block 2 includes a connected wedge head 7 and a base 8; the center of the rod body 1 is provided with a rod inner hole 9, One end of the shaft inner hole 9 extends to the end surface of the exposed end 6 , and the other end of the shaft inner hole 9 extends to the end surface of the bottom end 4 . Described bottom end 4 comprises cutter head 10 and slit 11, and the quantity of described cutter head 10 is at least two, and cutter head 10 comprises upper end 12, lower end 13 and peripheral surface 14; The quantity of described slit 11 and cutter head 10 are equal in number, and the slit 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com