Large-scale shallow water floating cofferdam

A cofferdam and shallow water technology, applied in construction, infrastructure engineering, caisson, etc., can solve the problems of large influence of floating navigation route, large filling area, deep water entry depth, etc., and meet the requirements of reducing ship tonnage and mechanical equipment, Guarantee the quality of perfusion and the effect of shallow water entry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings.

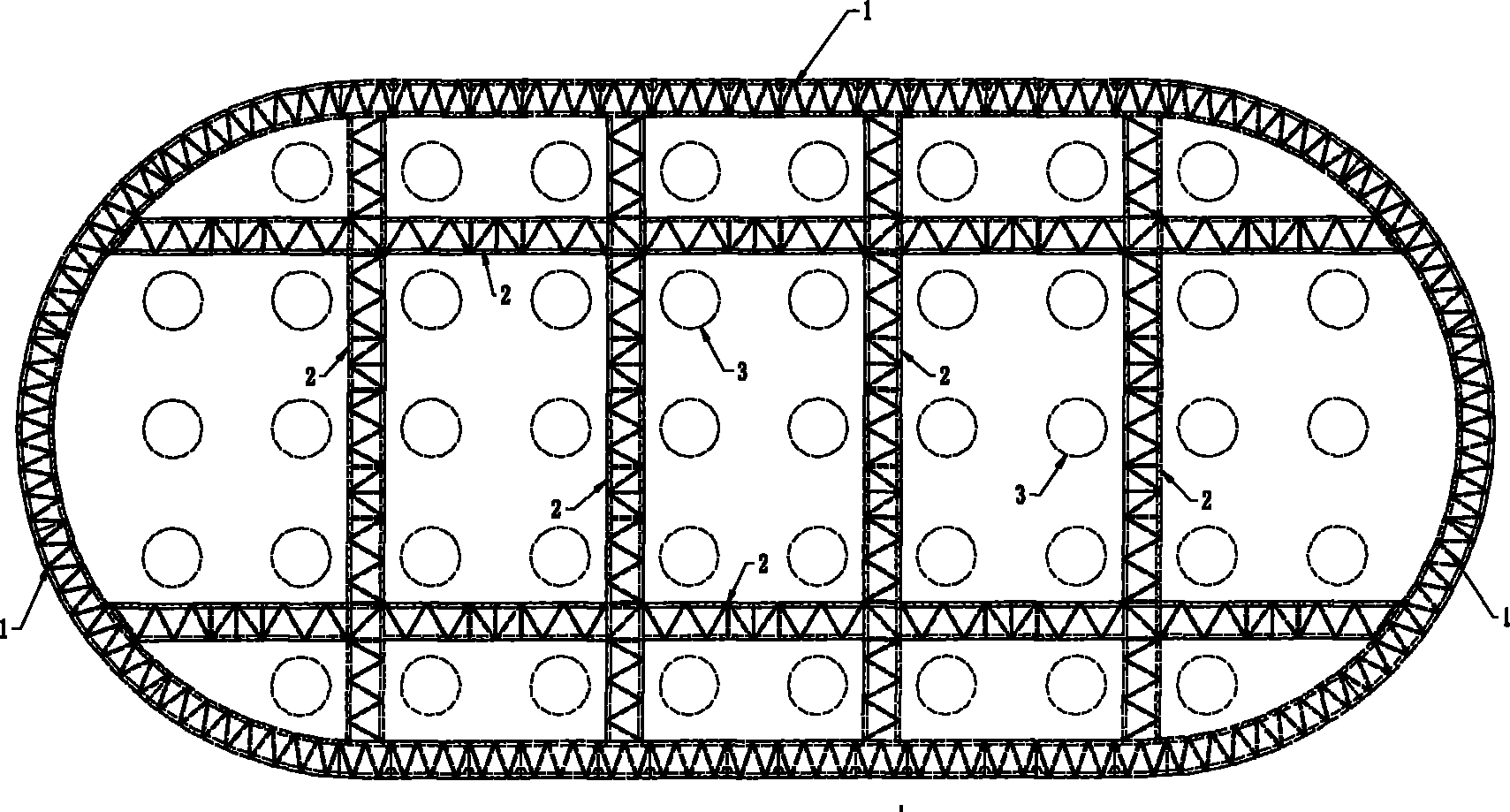

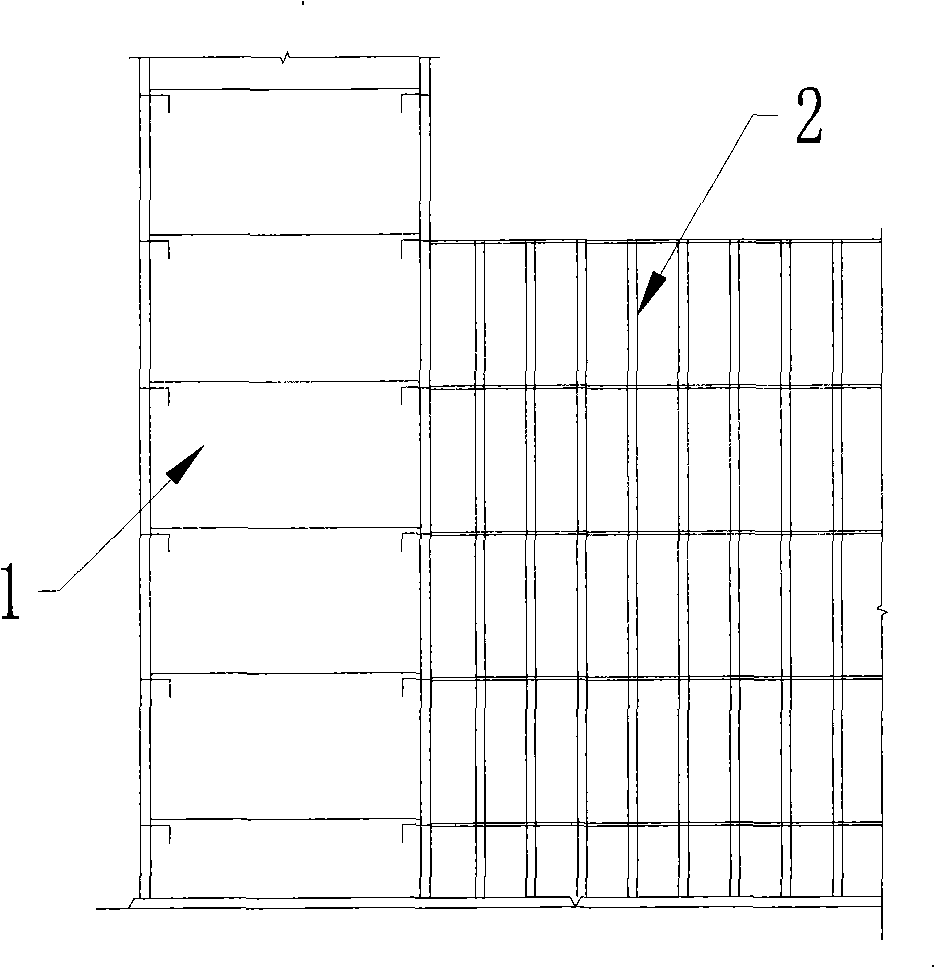

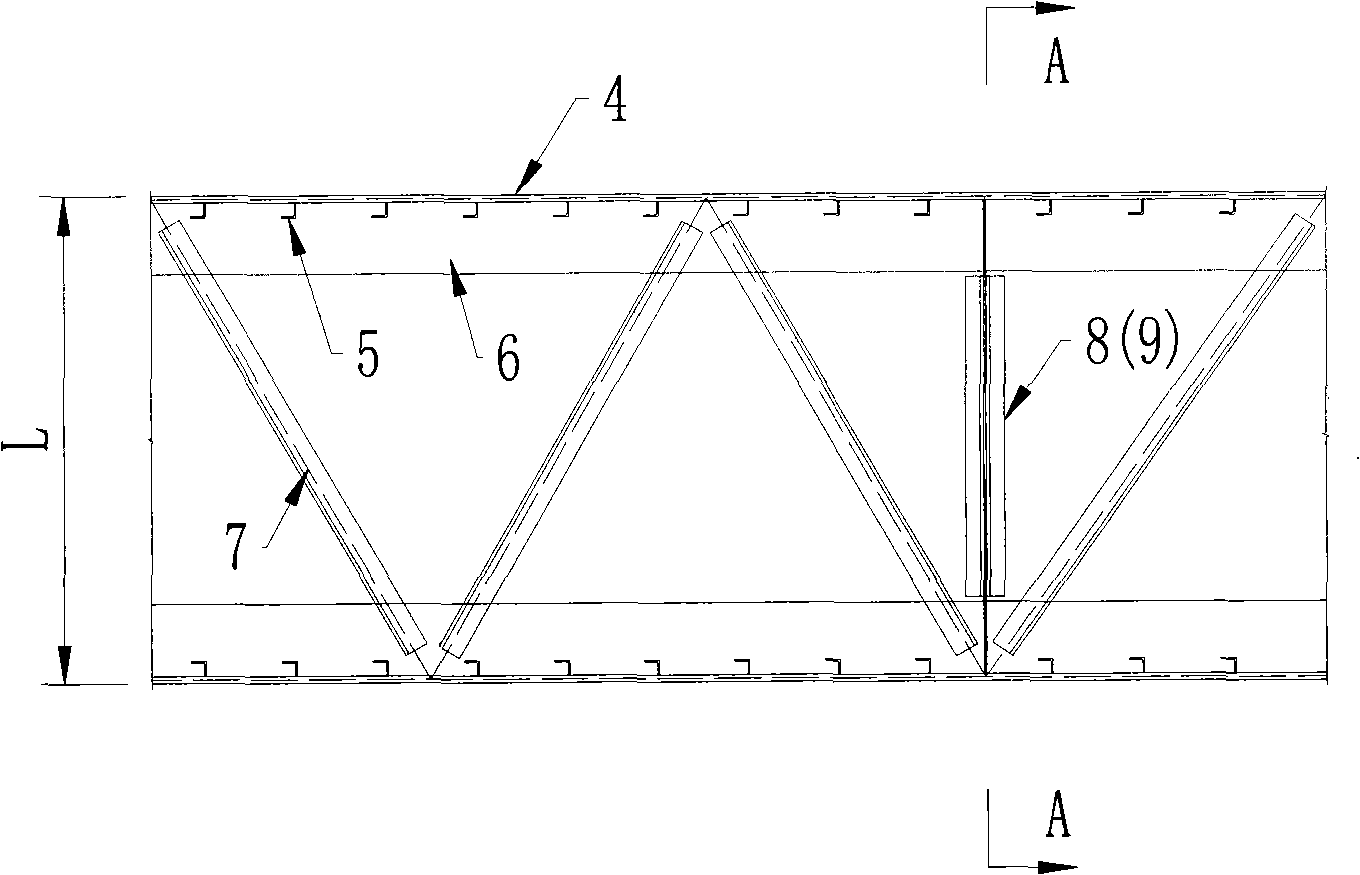

[0021] figure 1 It is a structural schematic diagram of the large-scale shallow water floating cofferdam described in the present invention, figure 2 It is a side view diagram of a cofferdam side plate and a closed bottom compartment, including an annular structure composed of two parallel cofferdam side plates 1, and is characterized in that: the bottom between the two parallel cofferdam side plates 1 and The side plate 1 of the cofferdam constitutes an impermeable closed area, and a number of closed bottom compartments 2 for reducing the water entry depth of the cofferdam and a number of bored piles 3 adapted to the pier pile positions are arranged in the annular structure. The cabins 2 are connected to each other into several horizontal and vertical rows, and their two ends are connected with the cofferdam side plate 1 to divide the cofferdam into severa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com