Patents

Literature

30results about How to "Dense perfusion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

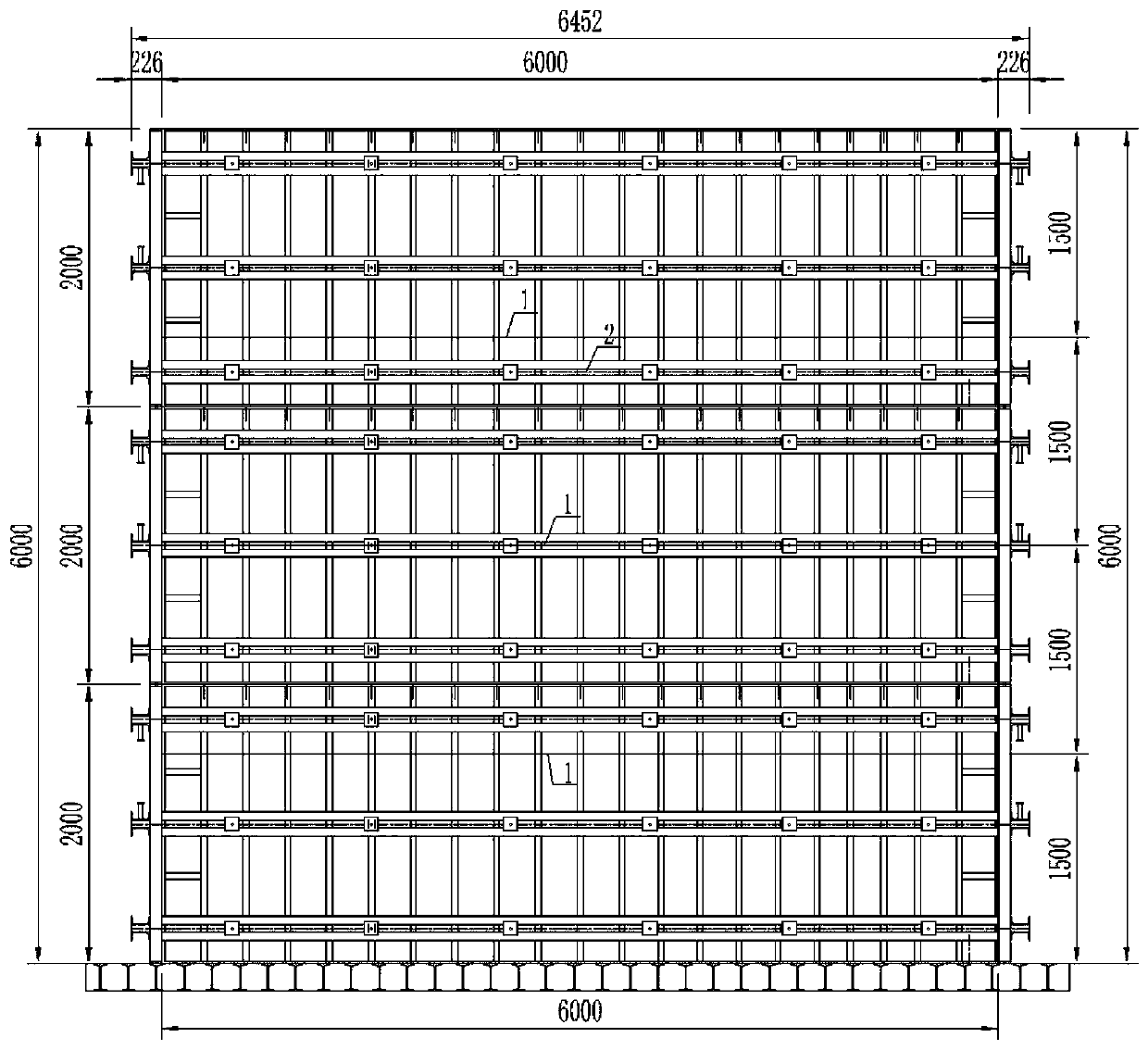

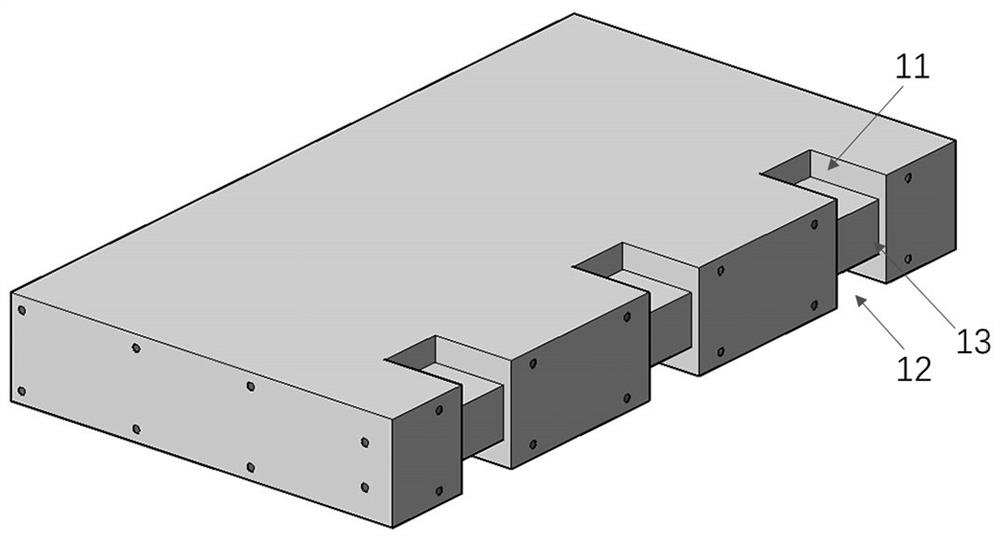

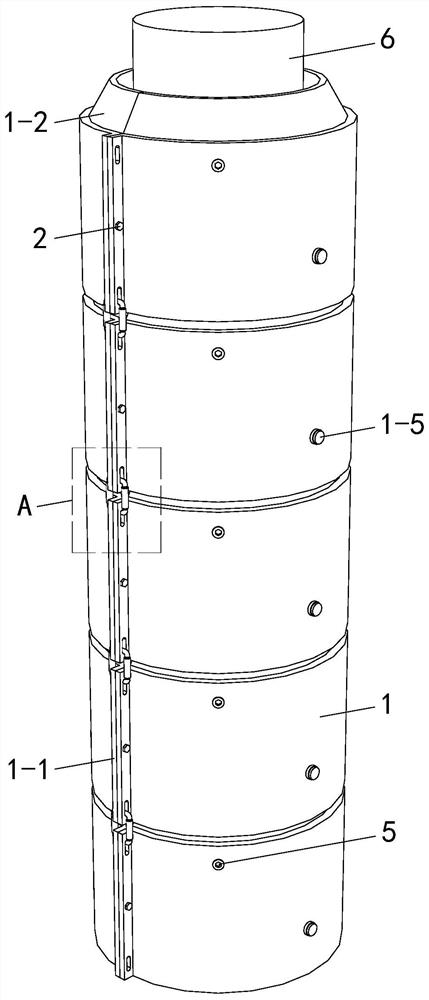

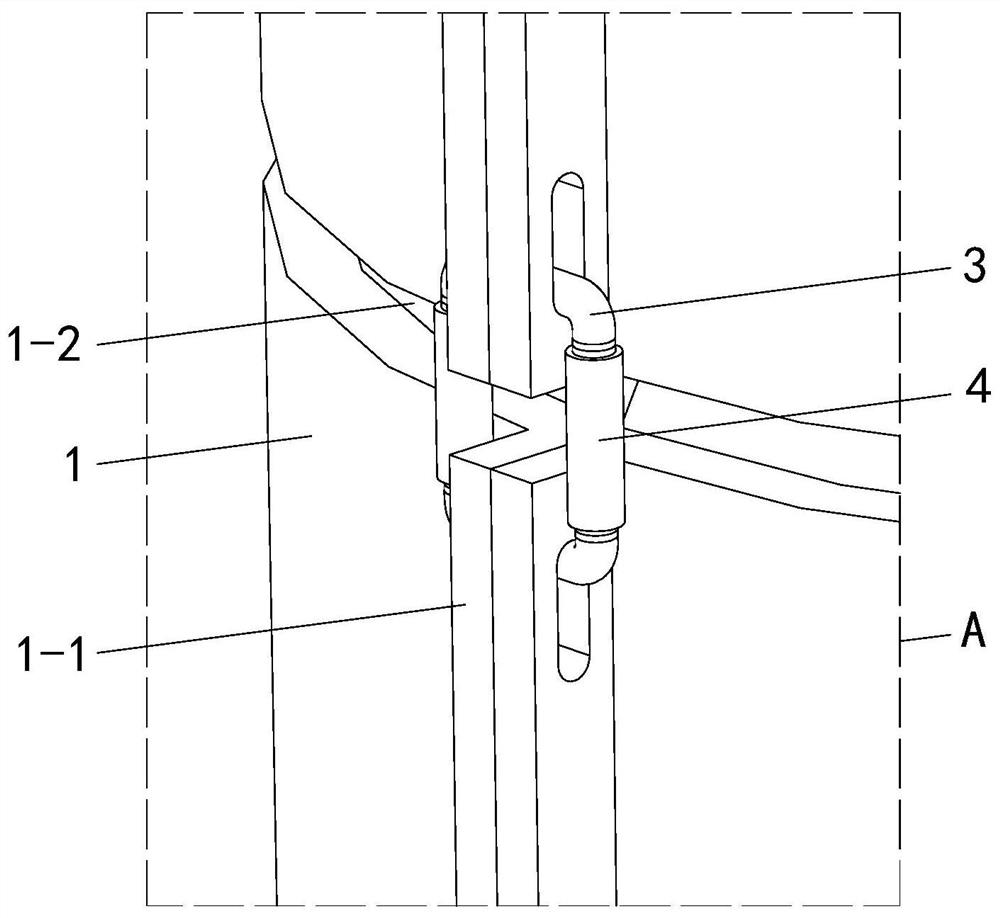

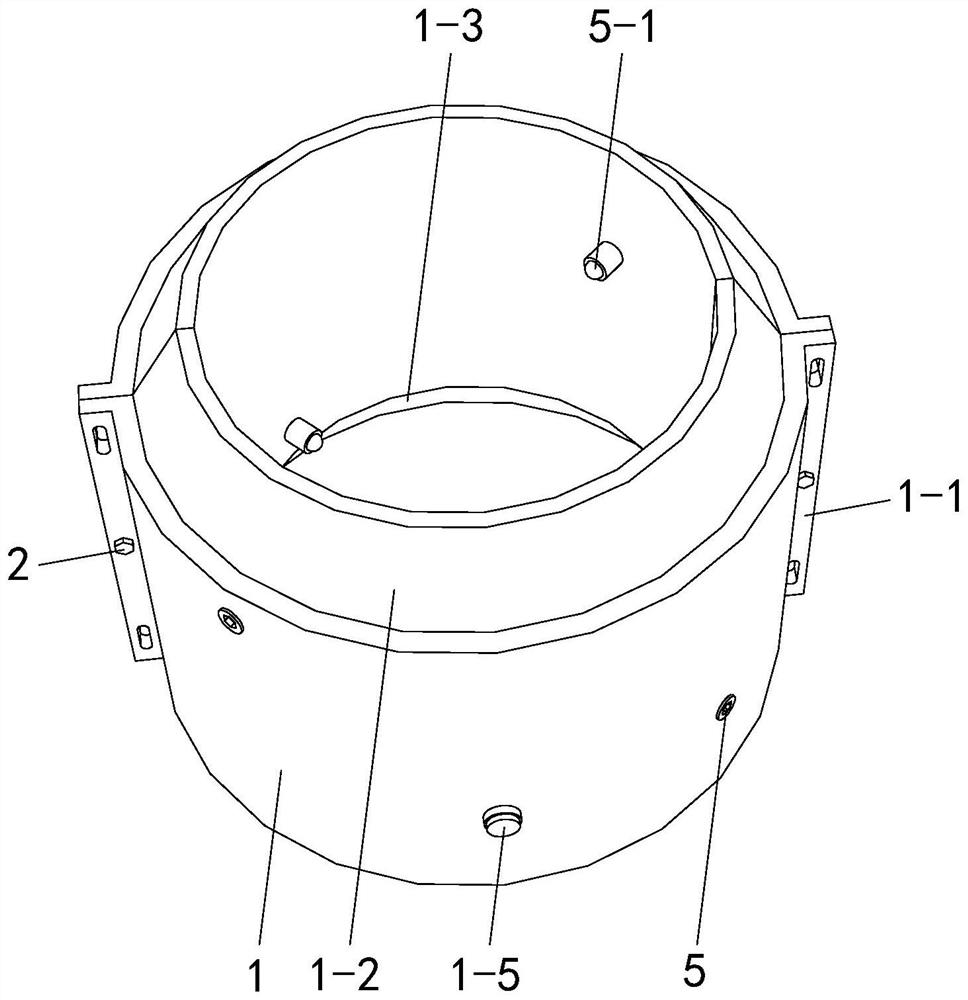

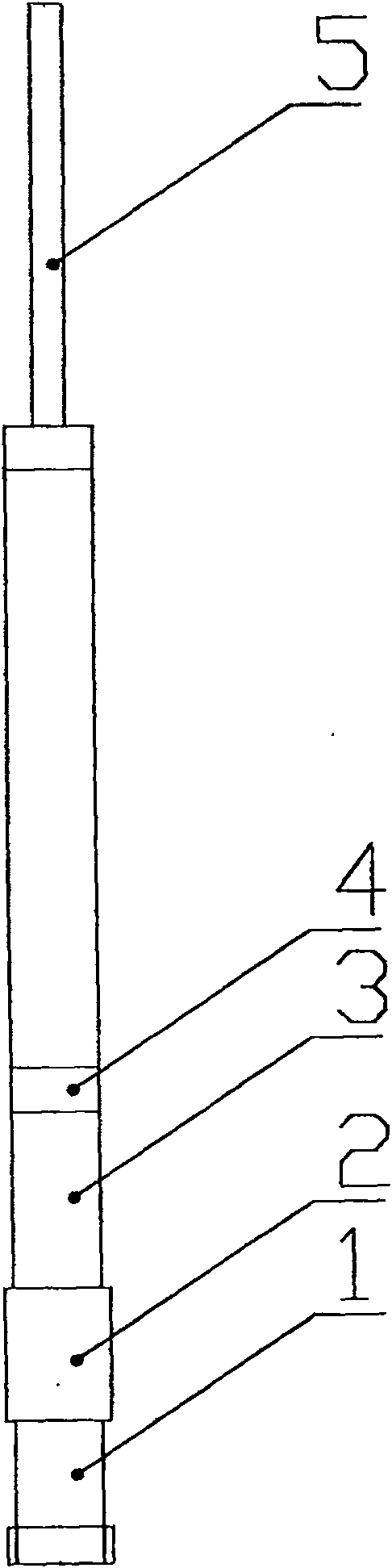

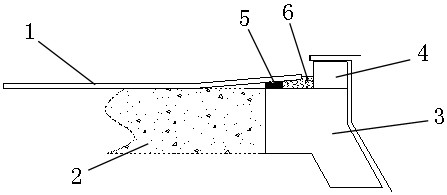

Prefabricated shear wall in cast-in-situ connection mode

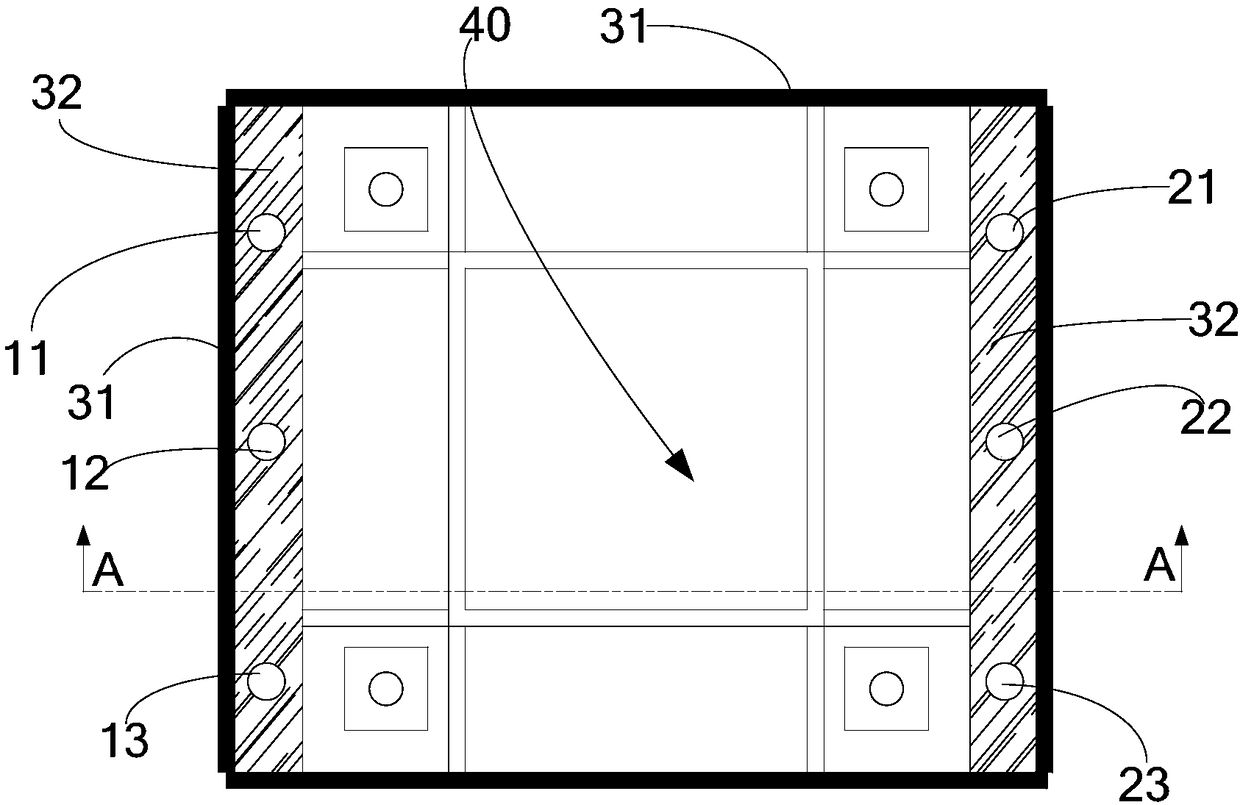

ActiveCN105604208AEasy constructionGuaranteed connection qualityConstruction materialWallsRebarThreaded pipe

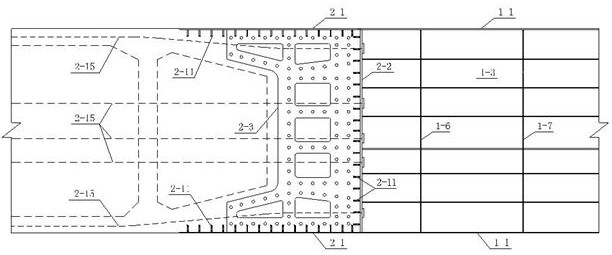

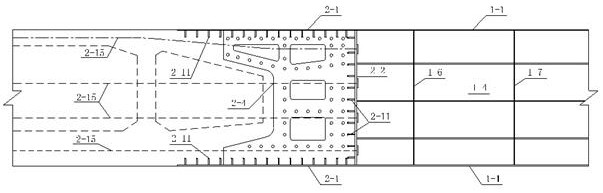

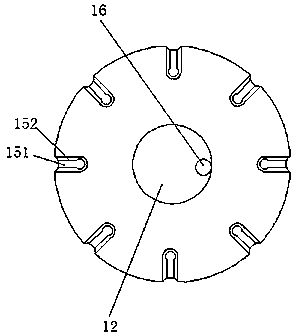

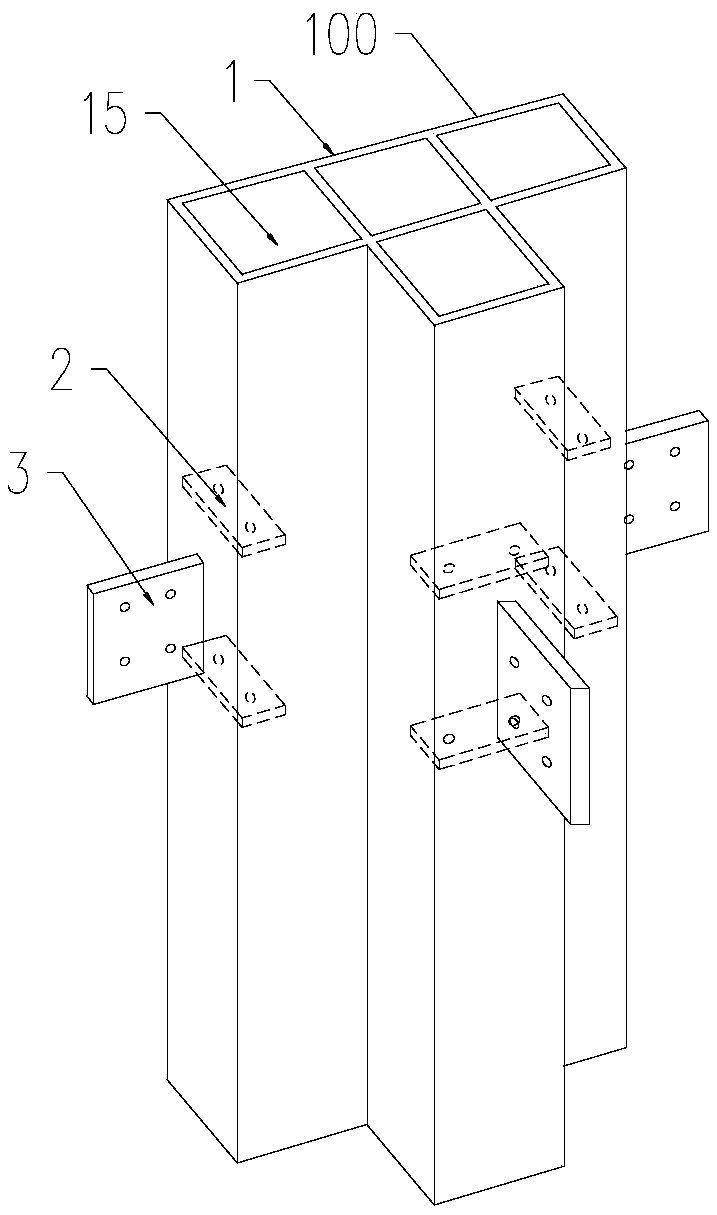

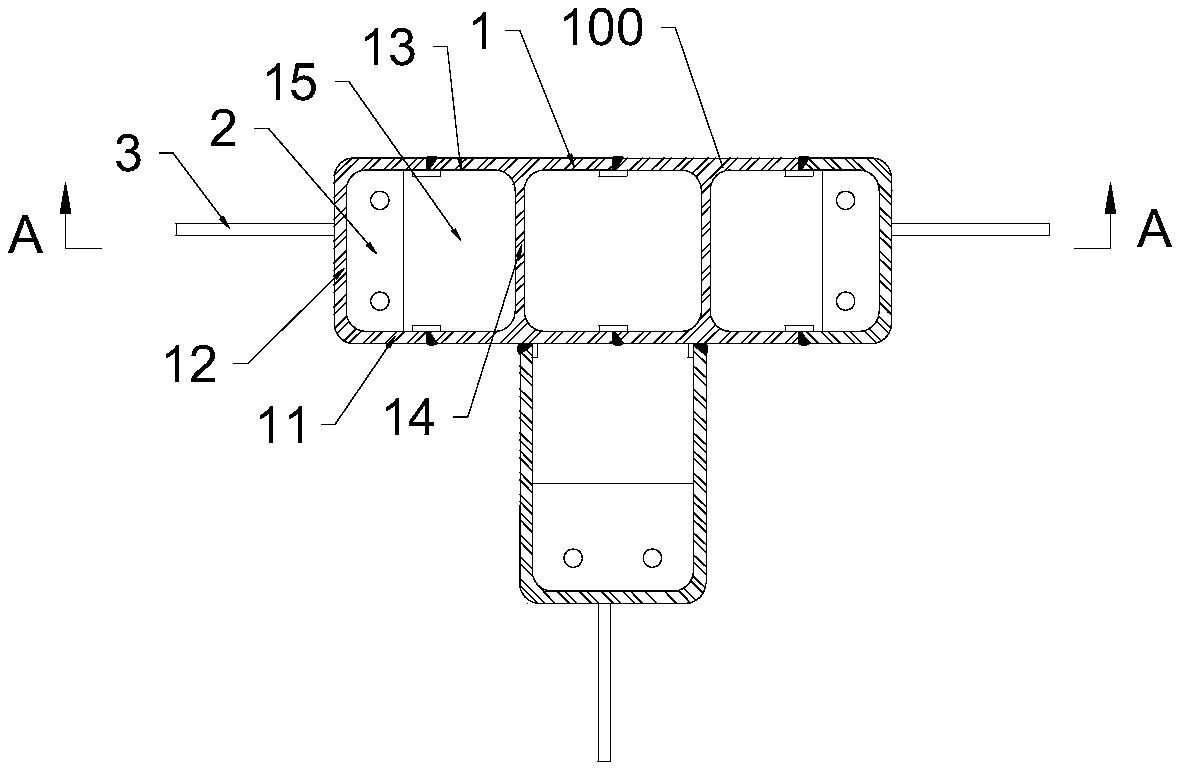

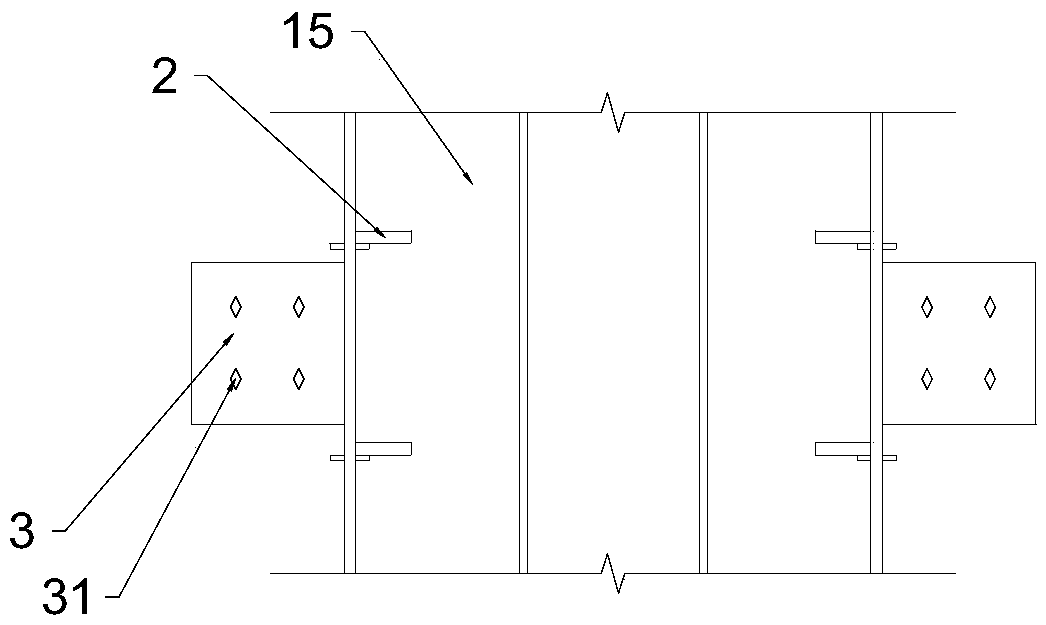

The invention relates to a prefabricated shear wall in a cast-in-situ connection mode. The prefabricated shear wall comprises a wall, pier heads, bottom upper concave sections and a bottom outer side plate. Side edges are respectively arranged on two sides of the wall, and a groove is formed in the middle of each side edge and is vertically perforated through the wall; wall vertical reinforcing bars are arranged in the wall; the bottom upper concave sections are uniformly distributed at the bottom of the wall; each pier head is arranged between the two corresponding adjacent bottom upper concave sections; air holes are formed in positions above the middles of the bottom upper concave sections; the air holes are communicated with the bottom upper concave sections via pipelines; the thicknesses of the pier heads are identical to the thickness of the wall, and holes are formed in the pier heads; the bottom outer side plate and the wall are integrated with each other, and the bottom outer side plate is positioned on the outer sides of the bottom upper concave sections; internally threaded pipes are embedded in positions close to the side edges of the wall, above the bottom upper concave sections and on the pier heads. The prefabricated shear wall in the cast-in-situ connection mode has the diversified advantages of firm structure, convenience in construction, reliability in connection and the like.

Owner:华汇工程设计集团股份有限公司

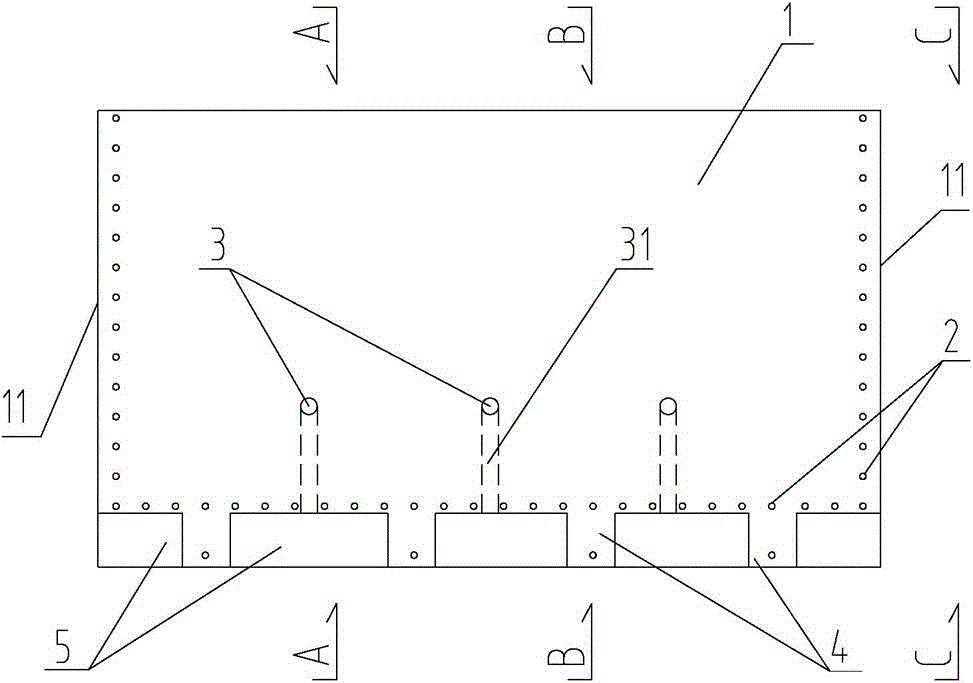

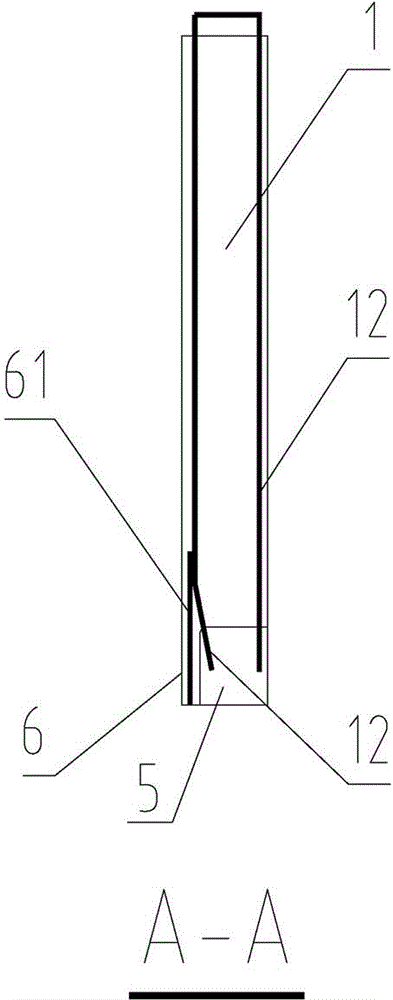

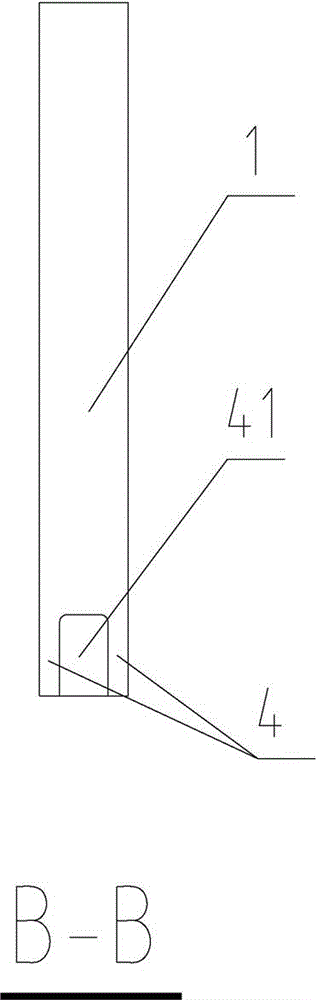

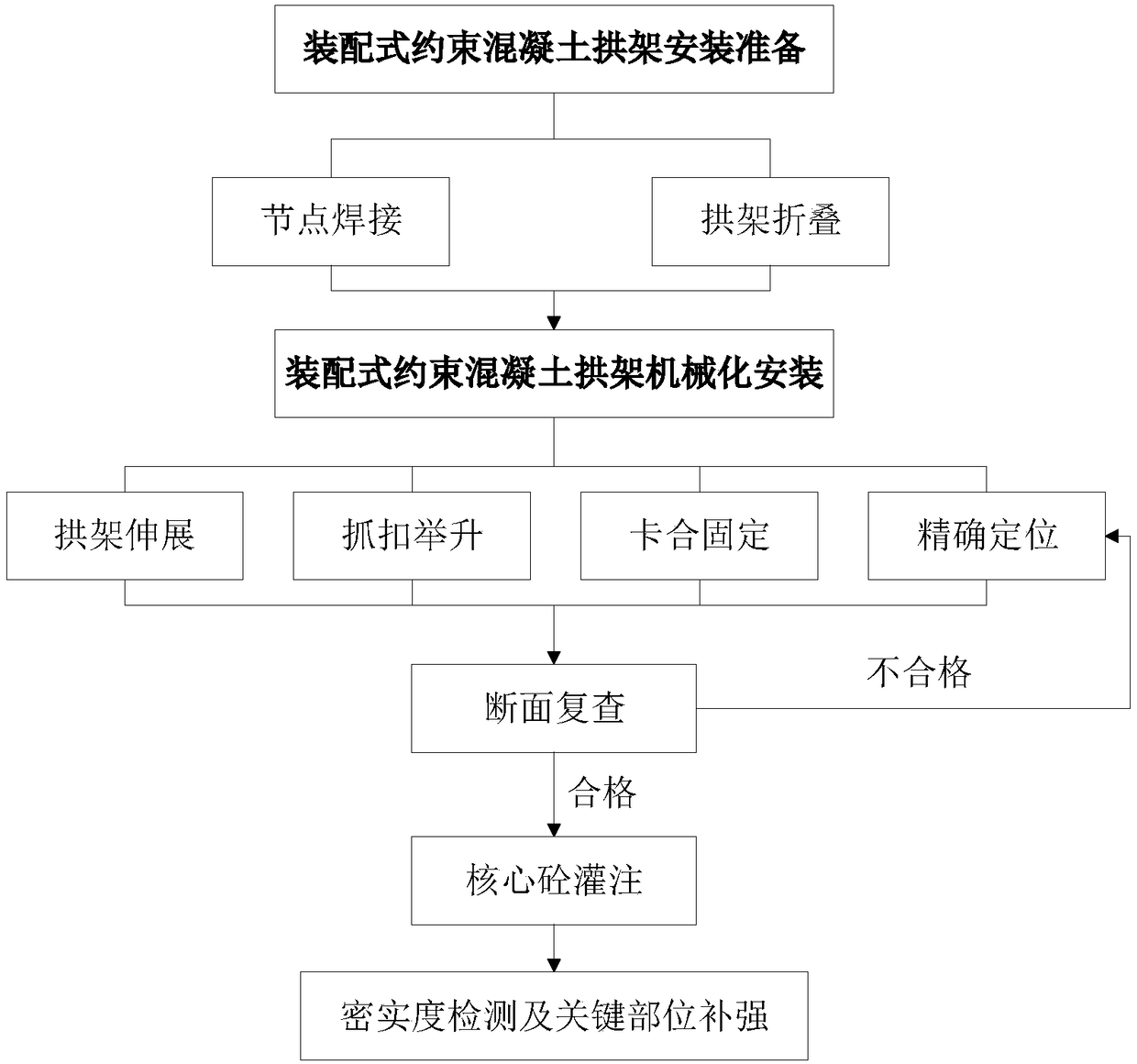

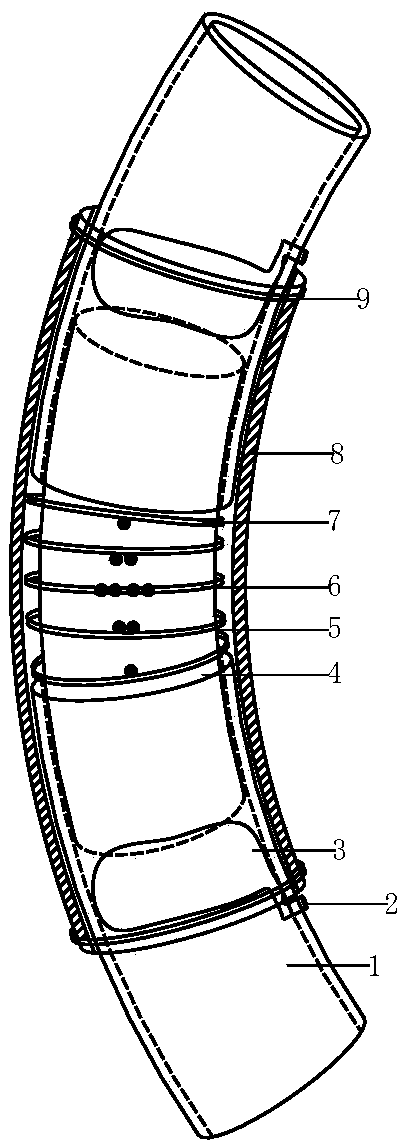

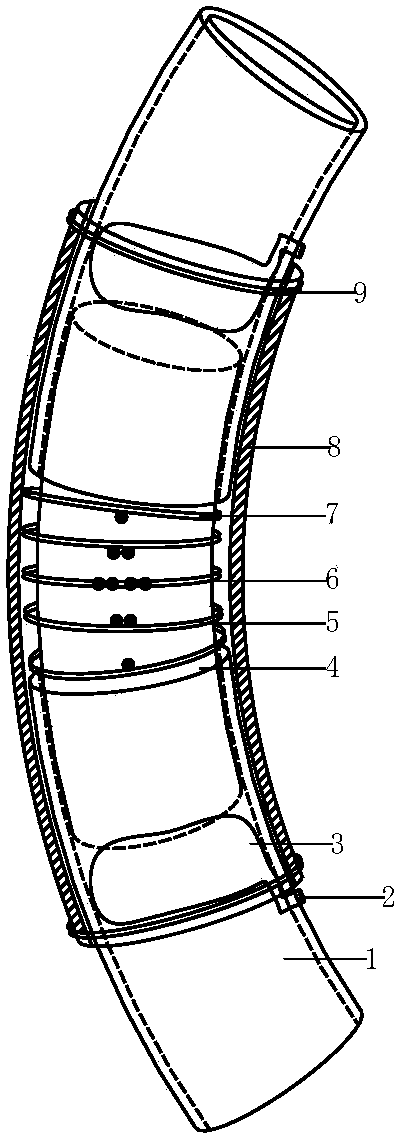

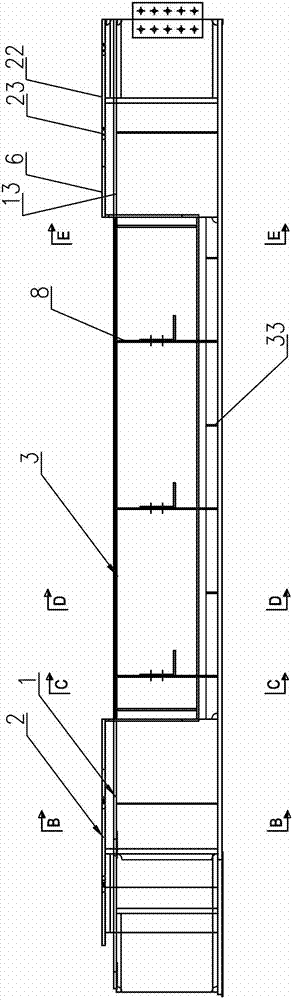

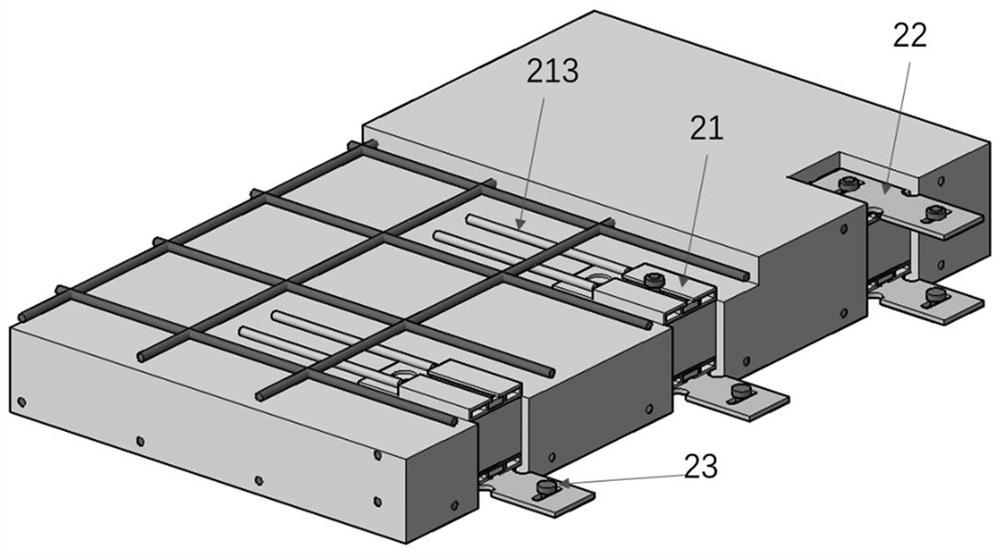

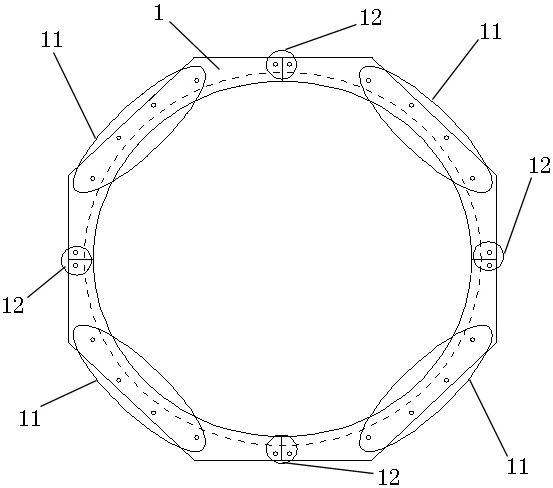

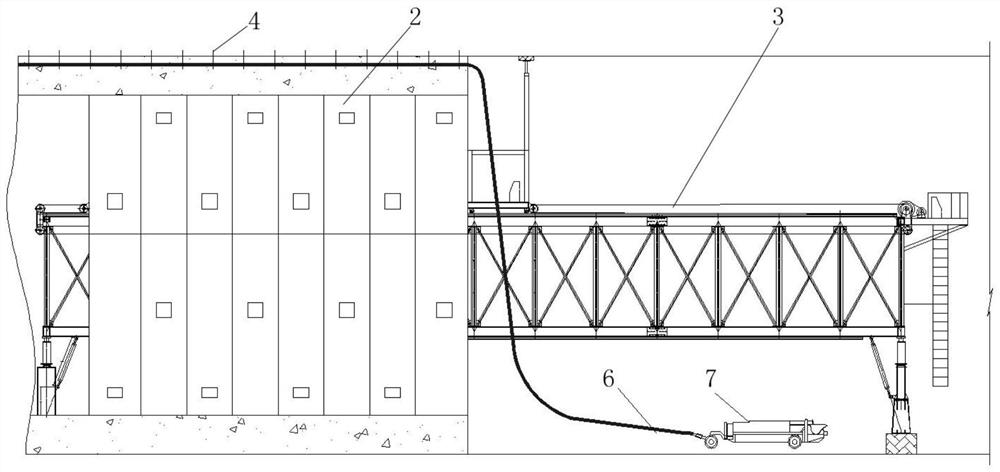

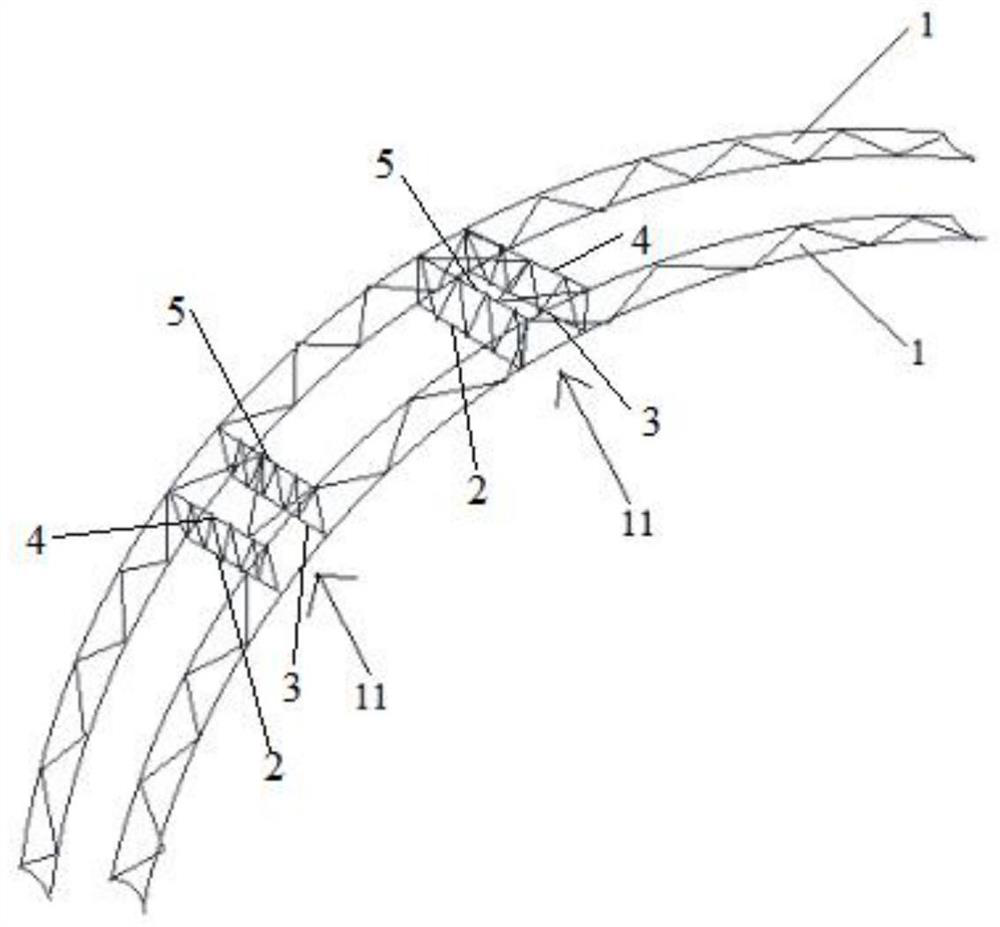

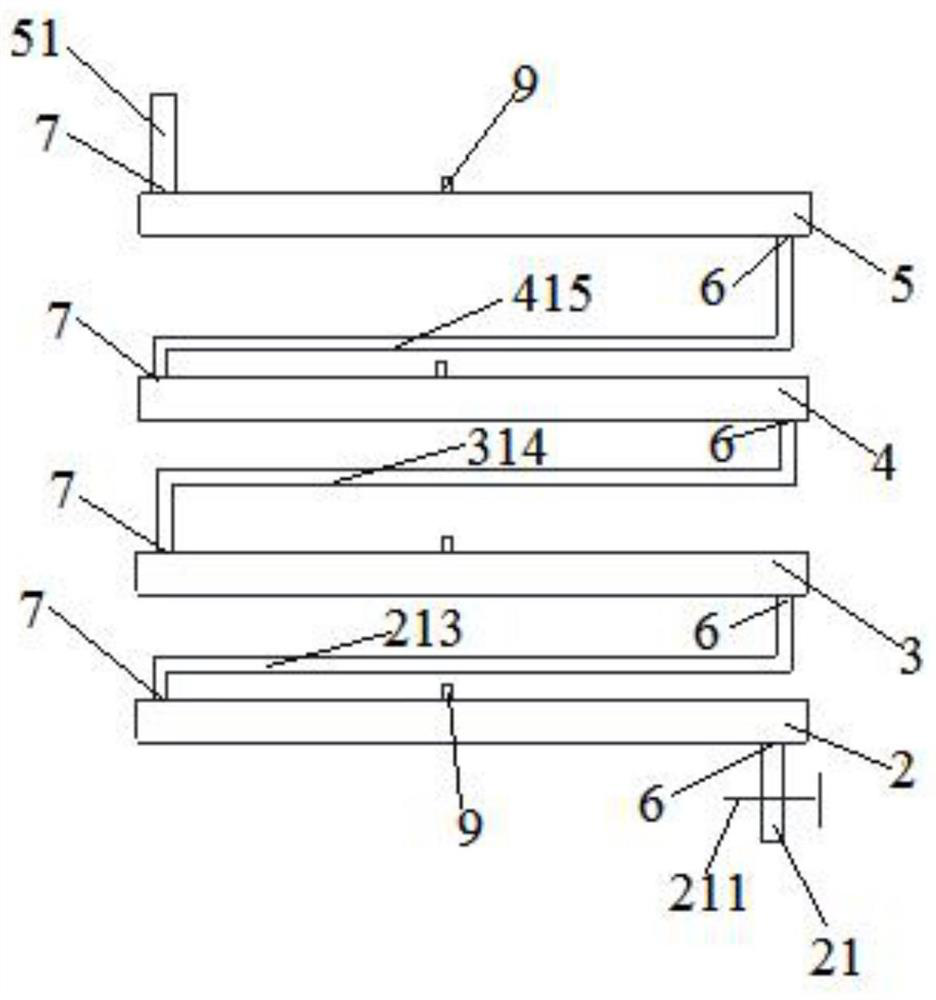

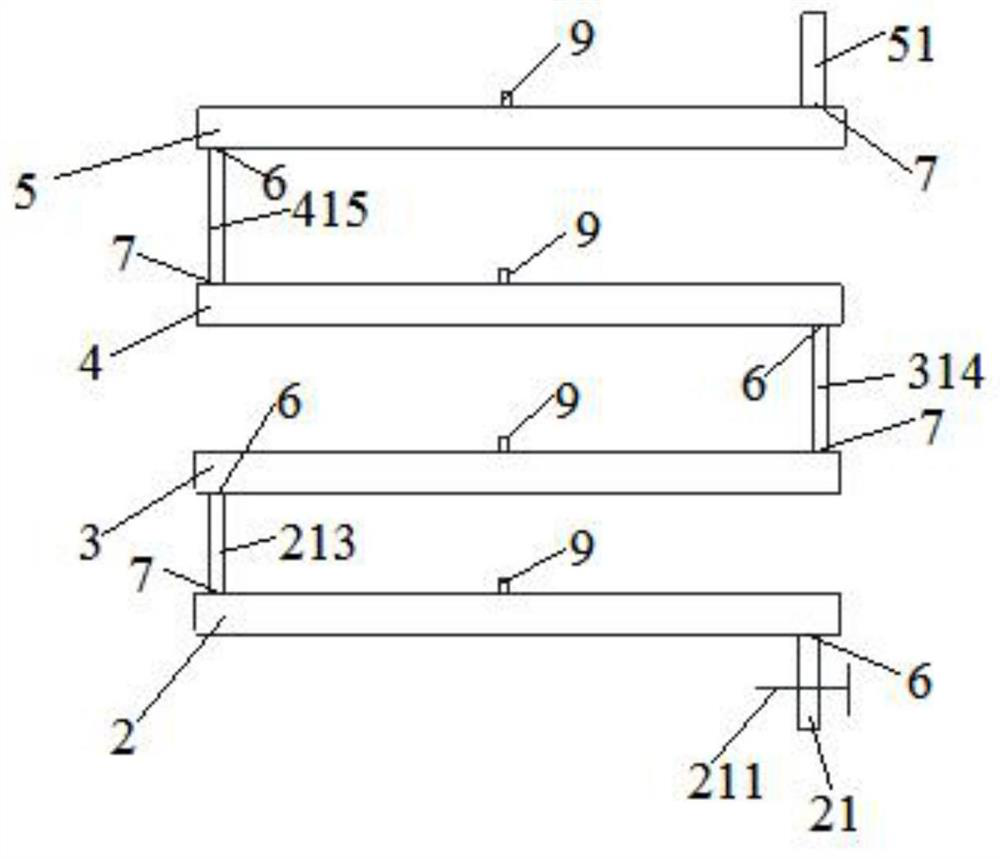

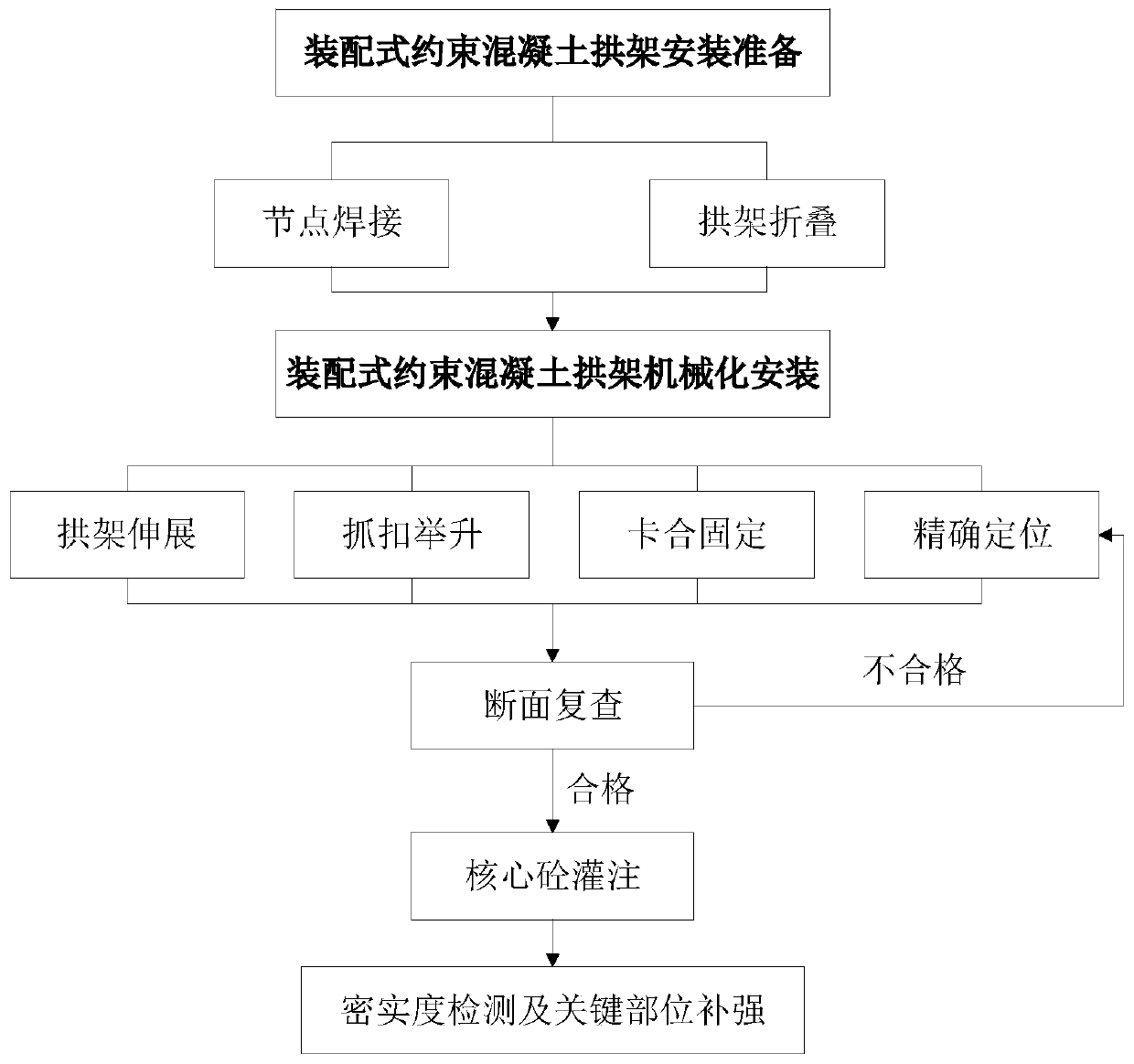

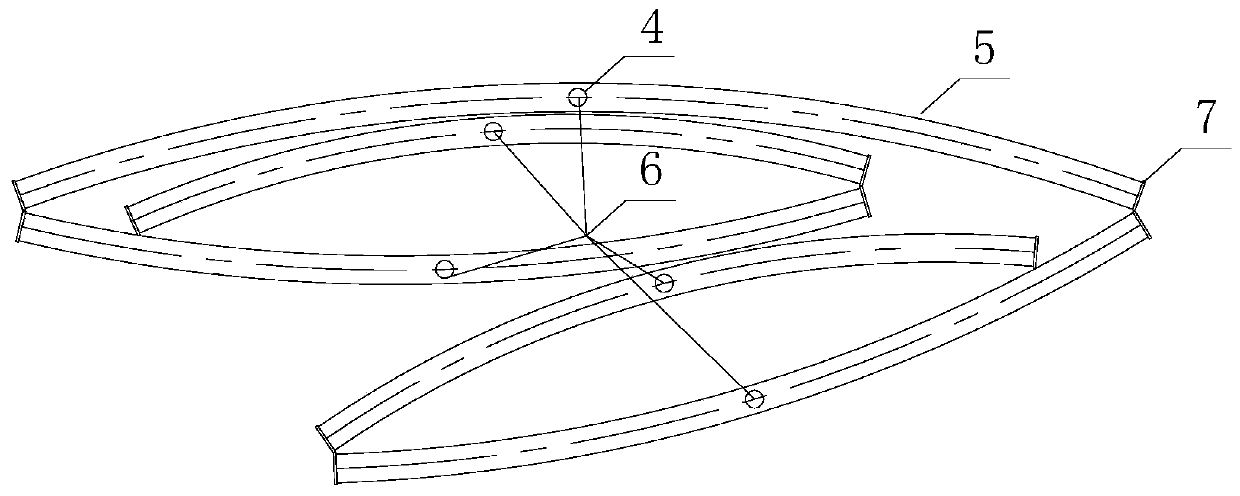

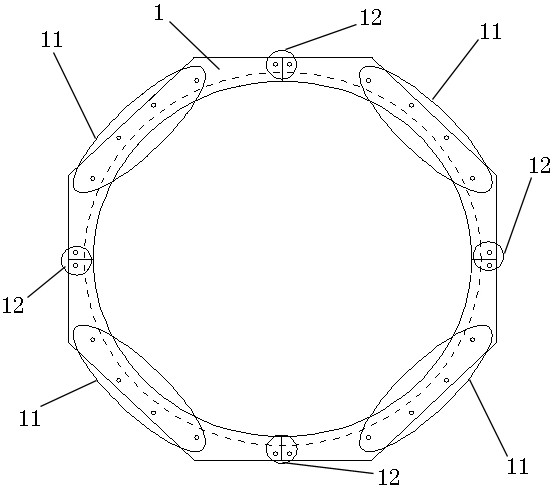

Underground construction fabricated confined concrete lagging jack and mechanized construction method

ActiveCN108104832AHigh strengthSafe and efficient constructionUnderground chambersTunnel liningEngineeringTunnel construction

The invention discloses an underground construction fabricated confined concrete lagging jack and a mechanized construction method. In order to be matched with lagging jack intelligent mounting equipment to conduct tunnel construction, the fabricated confined concrete lagging jack is researched and developed, the relevant technologies of folded hoisting, mechanized assembly, accurate positioning,fracture surface reexamination and the like of the lagging jack are broken through, the lagging jack being lifted manually to be split is not needed in the tunnel construction process, and the whole set of construction process can be conducted through a mechanized manner, and is safer and more efficient. The mechanized construction method specifically comprises the construction steps that (1), thelagging jack is folded and hoisted; (2), the lagging jack intelligent mounting equipment is utilized to conduct sequential extending on the lagging jack, fabricated joints are automatically clamped,and a longitudinal connection device is mounted in advance; (3), clamping buckle lifting, accurate positioning and clamping fixing are conducted; (4) fracture surface reexamination is conducted; (5) core concrete is poured; and (6) the compactness is detected and a key part is reinforced.

Owner:SHANDONG UNIV +1

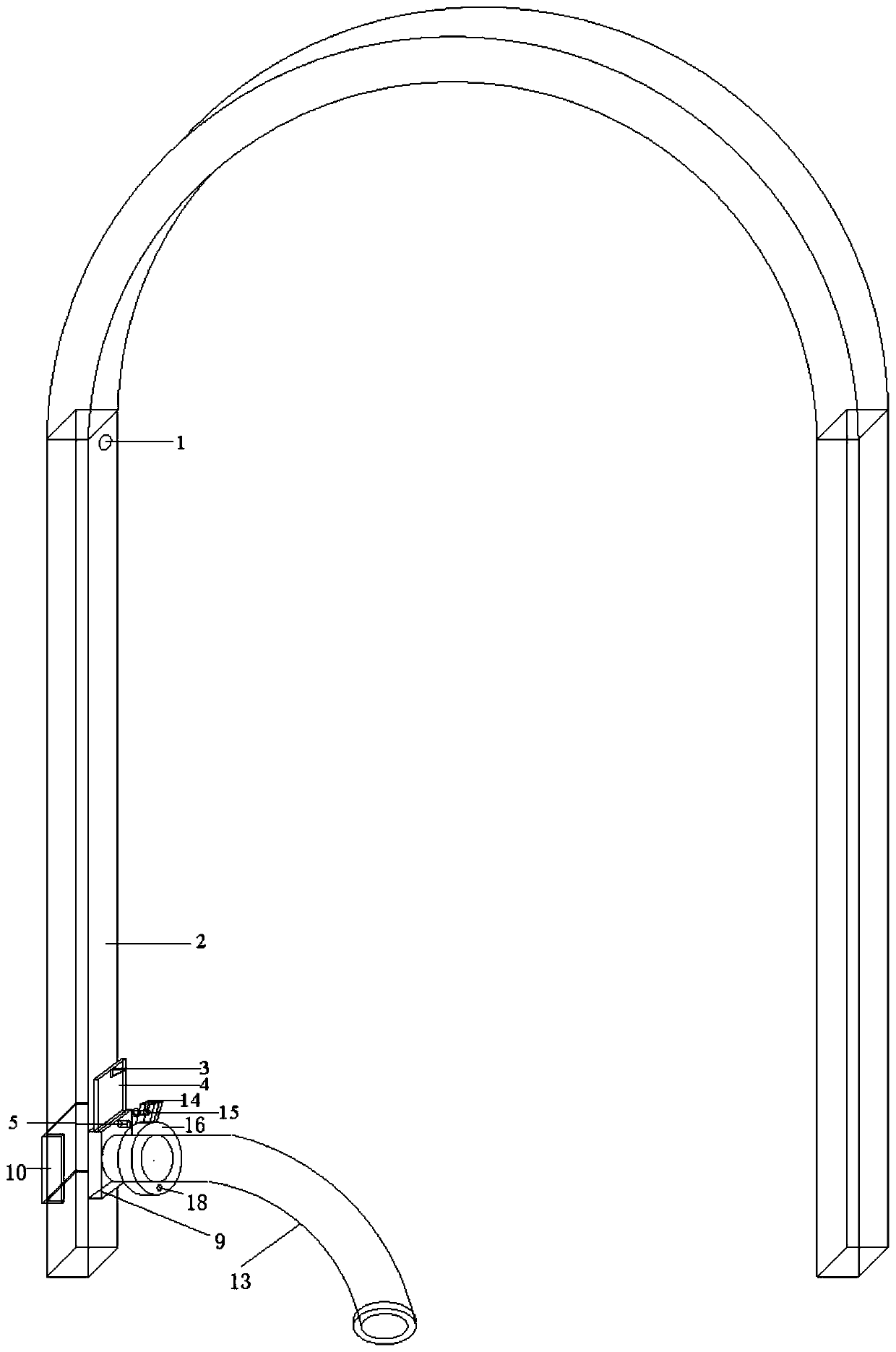

Retractable joint of steel pipe concrete arch bracket and arch bracket

PendingCN108397216ASolve the problem that can not be compressedAvoid damageUnderground chambersTunnel liningVoltageBearing capacity

The invention discloses a retractable joint of a steel pipe concrete arch bracket and the arch bracket. The problem that a rigid connection joint in the arch bracket is prone to causing damage to thearch bracket is solved. The bearing capacity of an initial support of the steel pipe concrete arch bracket is ensured, and a support body has the retractable performance. When the load of surroundingrocks is enlarged, the arch brackets can be retracted to achieve the yield moderately and reduce the load acting on the support body, and the long-term stability of the support body is achieved. According to the technical scheme, the retractable joint of the steel pipe concrete arch bracket comprises an internally-inserted steel pipe, wherein the two ends of the internally-inserted steel pipe areinserted into a joint of the arch bracket. The outer portion of the internally-inserted steel pipe is sleeved with a joint sleeve. A compression limiting part is arranged on the outer side of the pipein the middle of the internally-inserted steel pipe in a sleeving mode. The compression limiting part is arranged between the arch bracket on the two ends of the internally-inserted steel pipe. Whenthe force of the arch brackets exceeds the voltage endurance capability of the compression limiting part, the compression limiting part displaces, then the joint of the arch brackets displaces, and the overall size of the arch brackets is reduced to achieve the yield.

Owner:SHANDONG JIANZHU UNIV

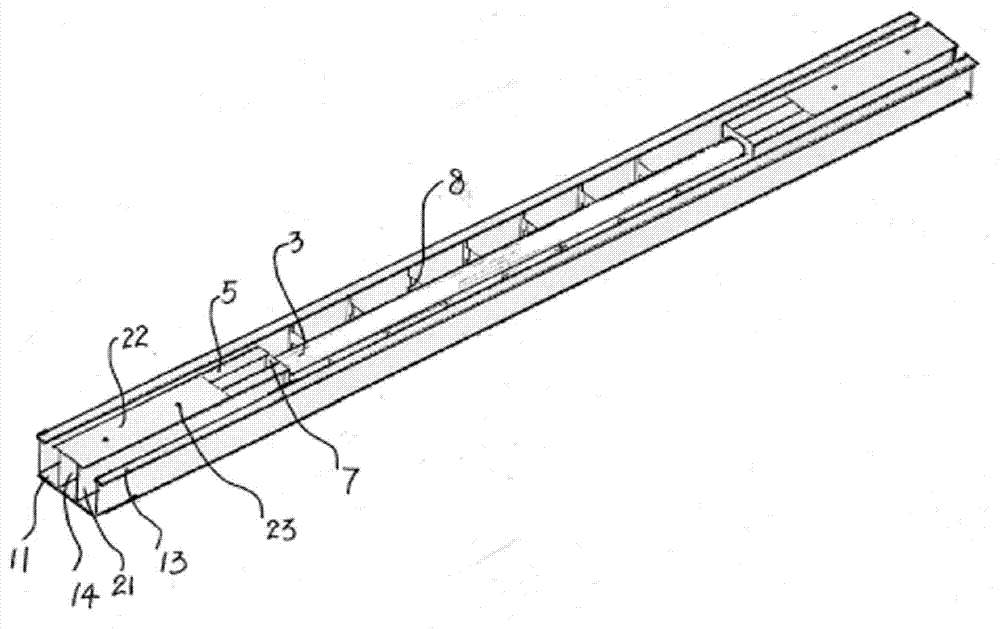

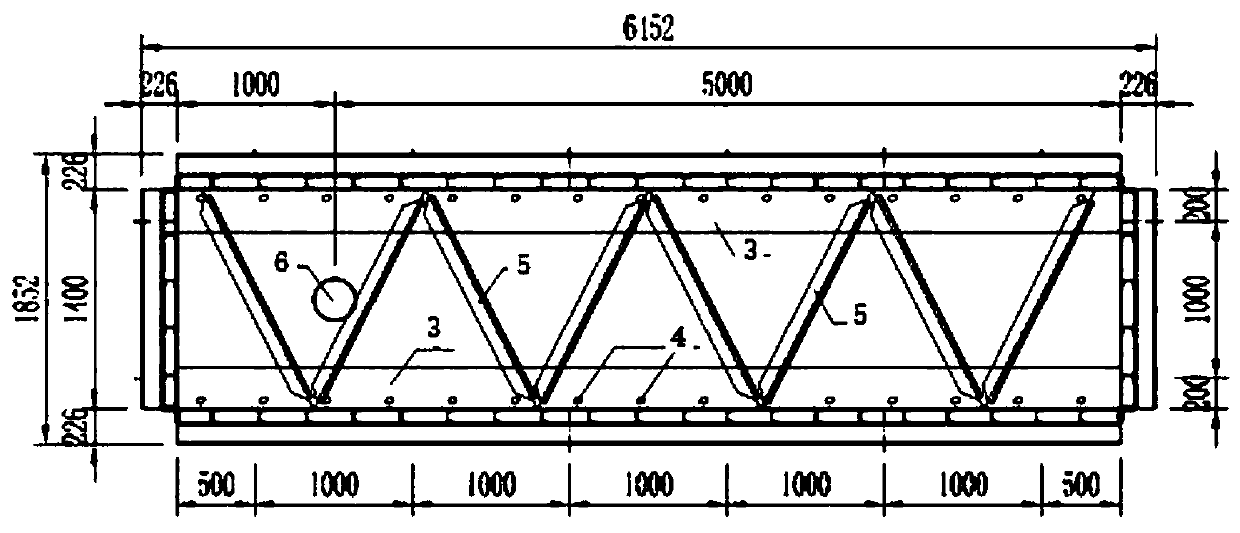

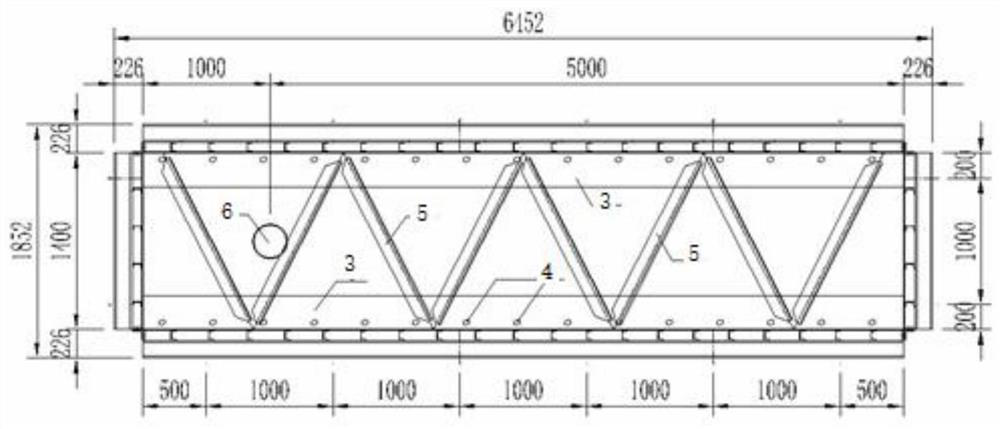

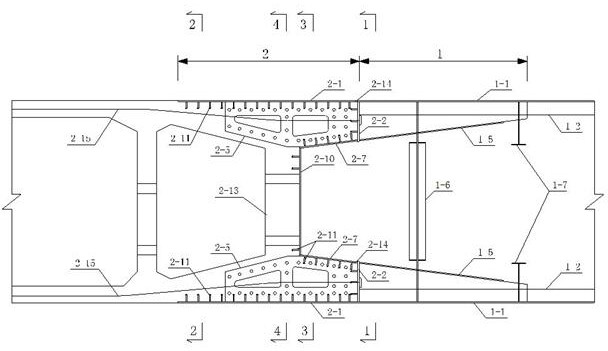

Steel box component and steel box-concrete combined U-shaped girder composed of same

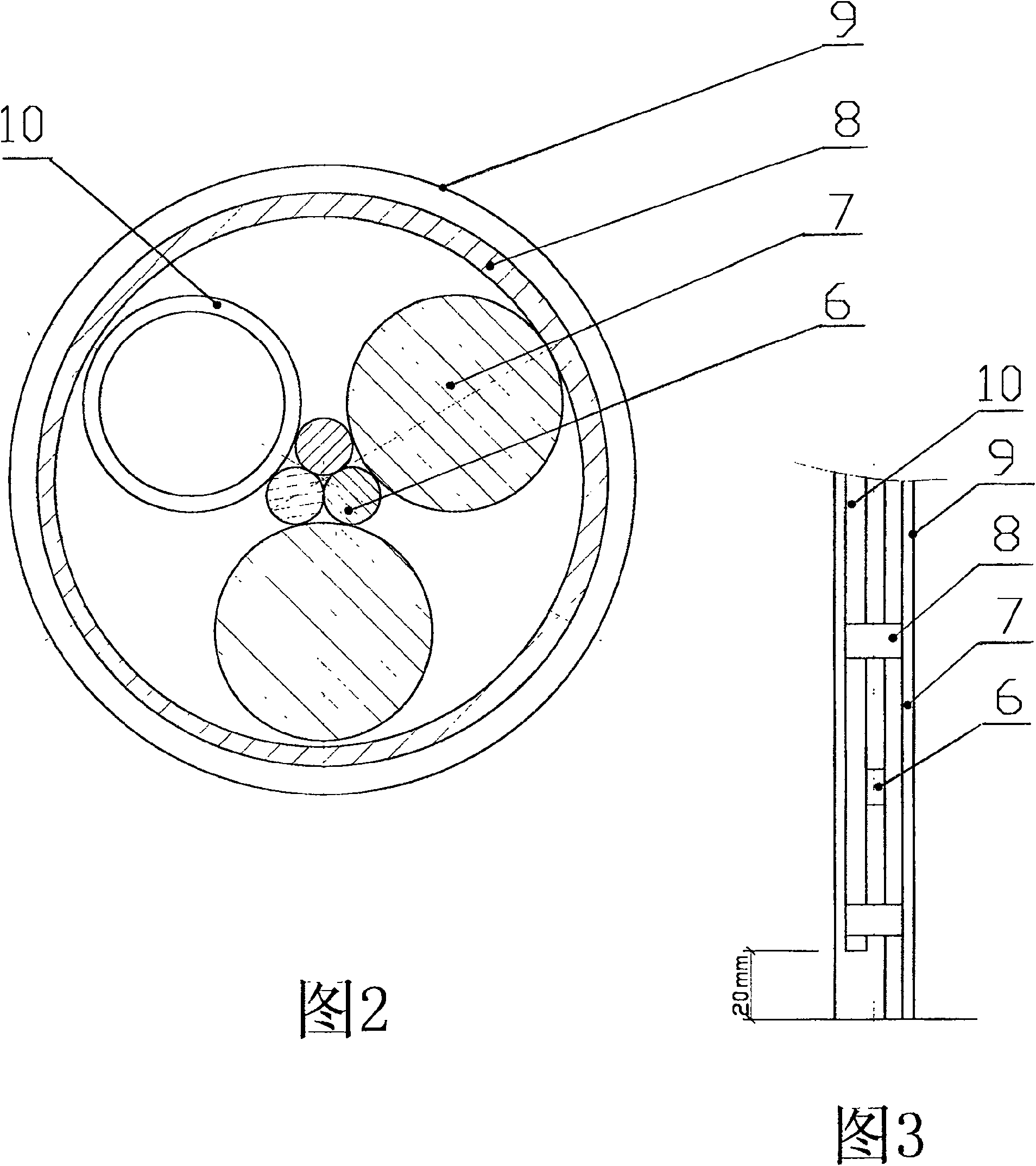

ActiveCN103046462AImprove bearing capacityDense perfusionLoad-supporting elementsBridge structural detailsMaterials scienceSteel tube

The invention discloses a steel box component. The component is mainly composed of a U-shaped steel piece, n-shaped steel pieces and a steel tube which is arranged at a mid-span position of the U-shaped steel piece. The n-shaped steel pieces are arranged in U-shaped space at two ends of the U-shaped steel piece, the length directions of the n-shaped steel pieces are consistent with the longitudinal direction of the U-shaped steel piece, the lower ends of inner side plates of the n-shaped steel pieces are fixed on a bottom plate of the U-shaped steel piece and surround with the bottom plate of the U-shaped steel piece to form hollow pouring chambers with inner and outer ports, and pouring holes are opened on top plates of the n-shaped steel pieces. Vertical sealing plates are arranged at inner end openings of the pouring chambers, the steel tube is arranged in a suspension mode, steel openings at the two ends of the steel tube are connected onto the sealing plates respectively and blocked by the sealing plates; and gaps are arranged between the U-shaped steel piece and the n-shaped steel pieces and between the U-shaped steel piece and the steel tube. The invention further discloses a steel box-concrete combined U-shaped girder composed of the steel box component. By means of the steel box component and the steel box-concrete combined U-shaped girder composed of the same, the construction cost is saved, the construction period is shortened, the bearing capacity and the bending resistance at the girder support position are improved, and the reinforcement area and about 25% of dead-weight are reduced.

Owner:ARCHITECTURAL DESIGN RES INST OF GUANGDONG PROVINCE

Underwater concrete pouring device, underwater concrete construction method and application of construction method in ultra-large deep water open caisson foundation

ActiveCN111364469AGuarantee perfusion qualityReduce impactCaissonsArchitectural engineeringUltimate tensile strength

The invention discloses an underwater concrete pouring device, an underwater concrete construction method and application of the construction method in an ultra-large deep water open caisson foundation. The underwater concrete pouring device is composed of a plurality of pouring conduits, and the pouring conduits are provided with side openings or oblique openings. The underwater concrete construction method comprises the following steps: pouring anti-dispersion concrete at first to cover the shaft wall and the bottom of a base, and stopping for 5-10 min after pouring is completed; and pouringself-compacting concrete. The underwater concrete construction method is suitable for the construction of the ultra-large deep water open caisson foundation, the problems that underwater concrete ofthe ultra-large deep water open caisson foundation is quite prone to washing separation, the strength is obviously reduced and pouring is not compact can be effectively solved, and the engineering construction quality is guaranteed.

Owner:SOUTHEAST UNIV +1

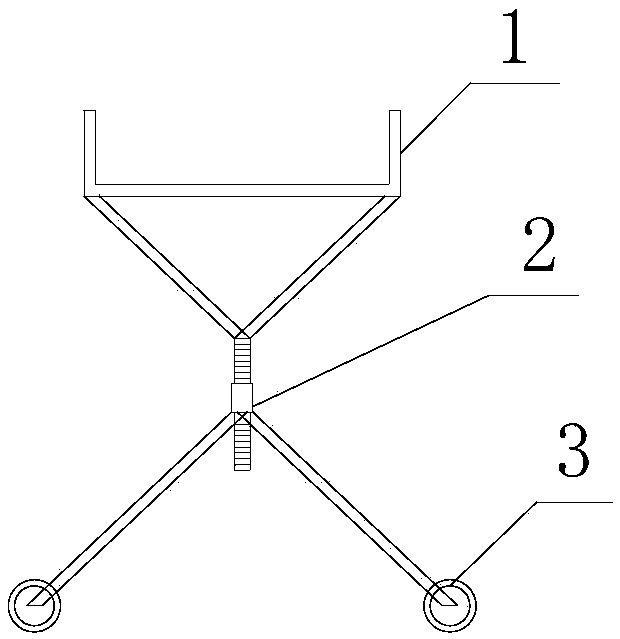

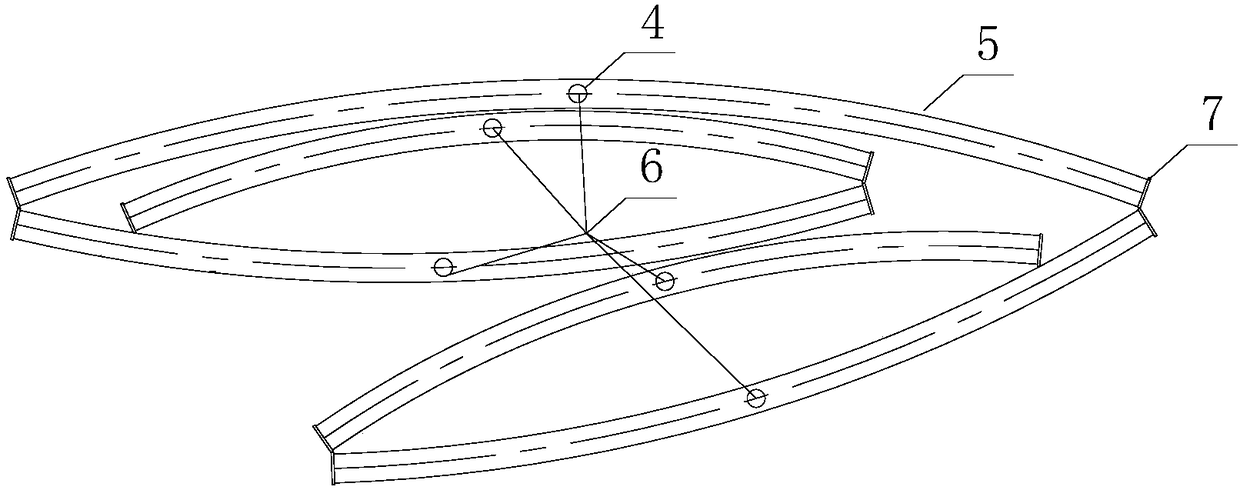

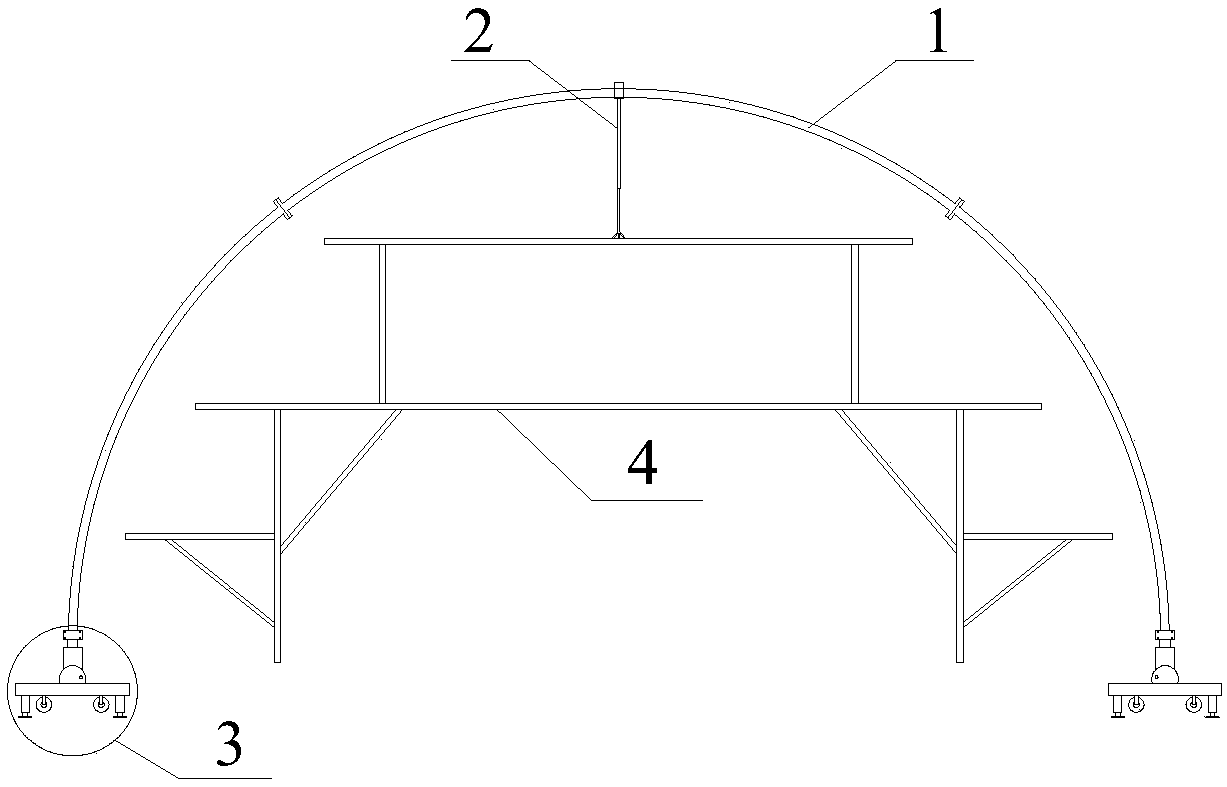

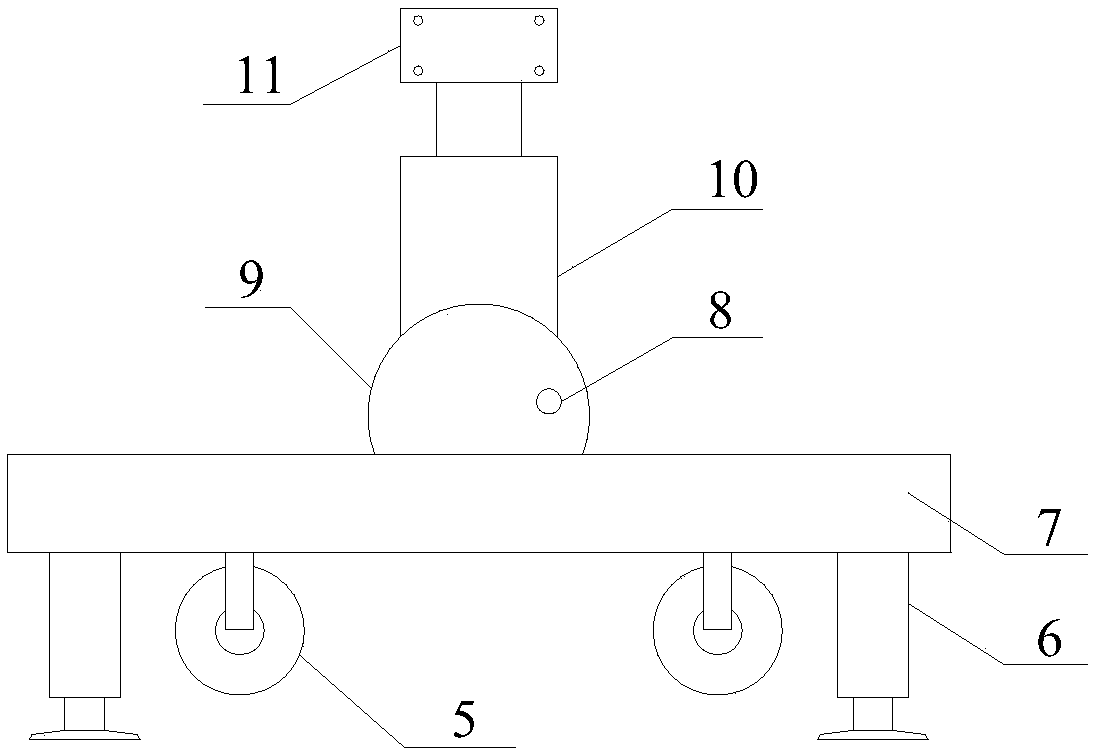

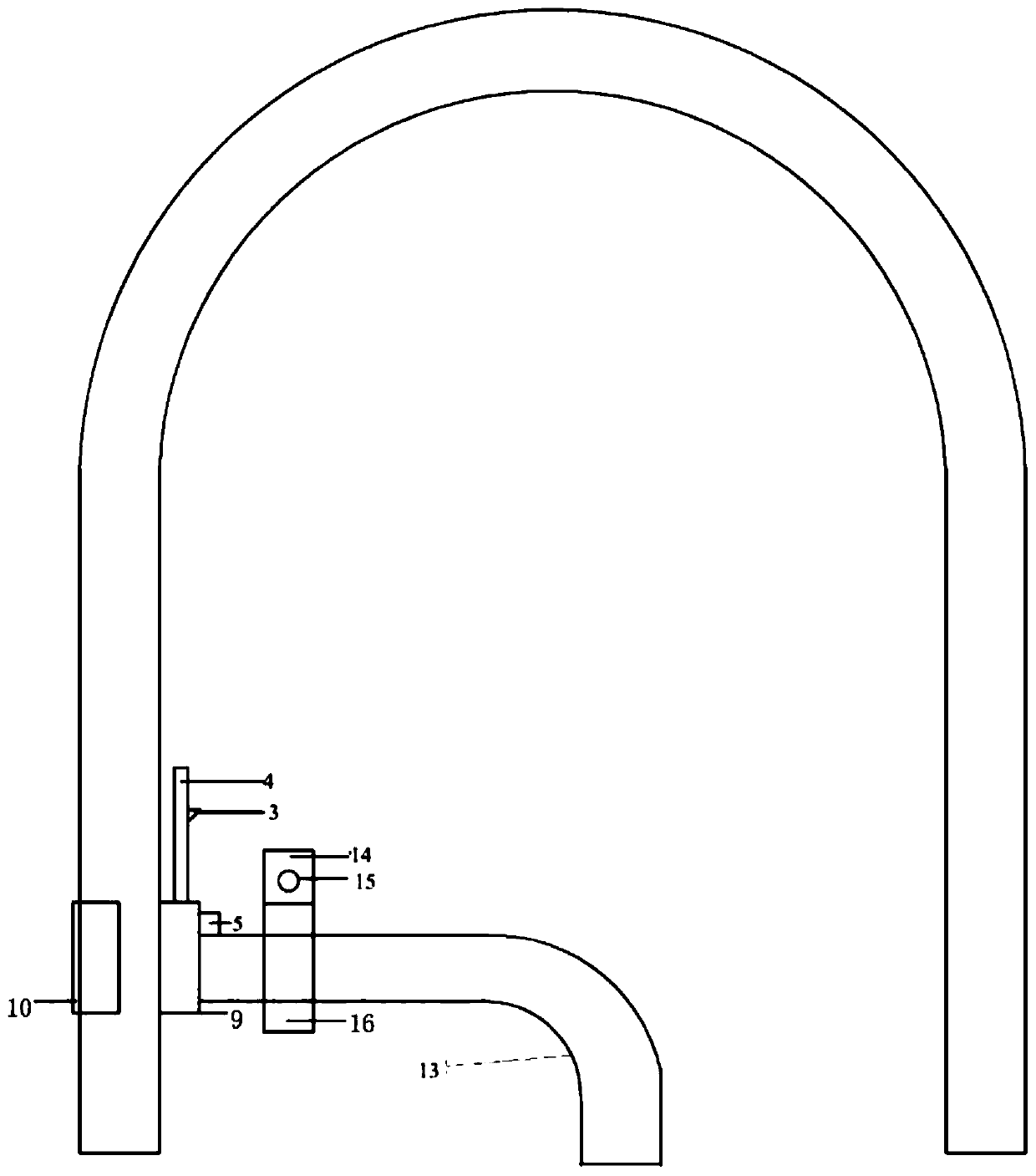

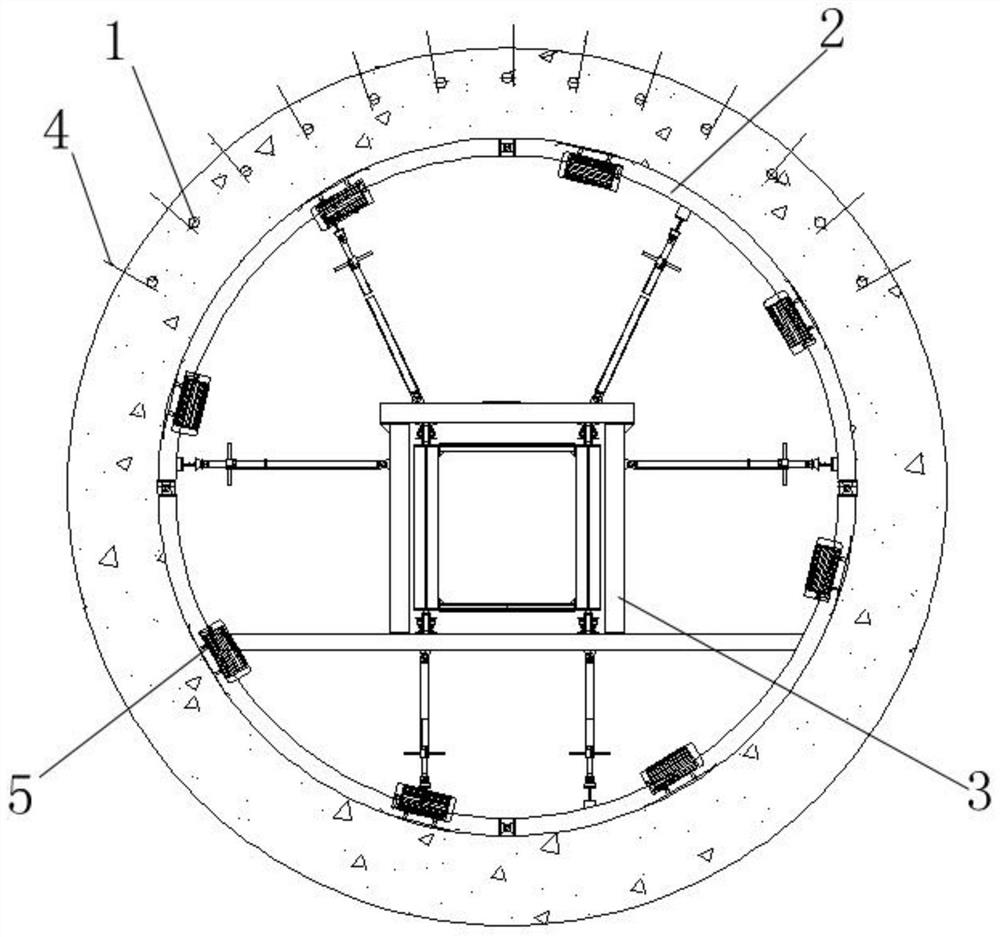

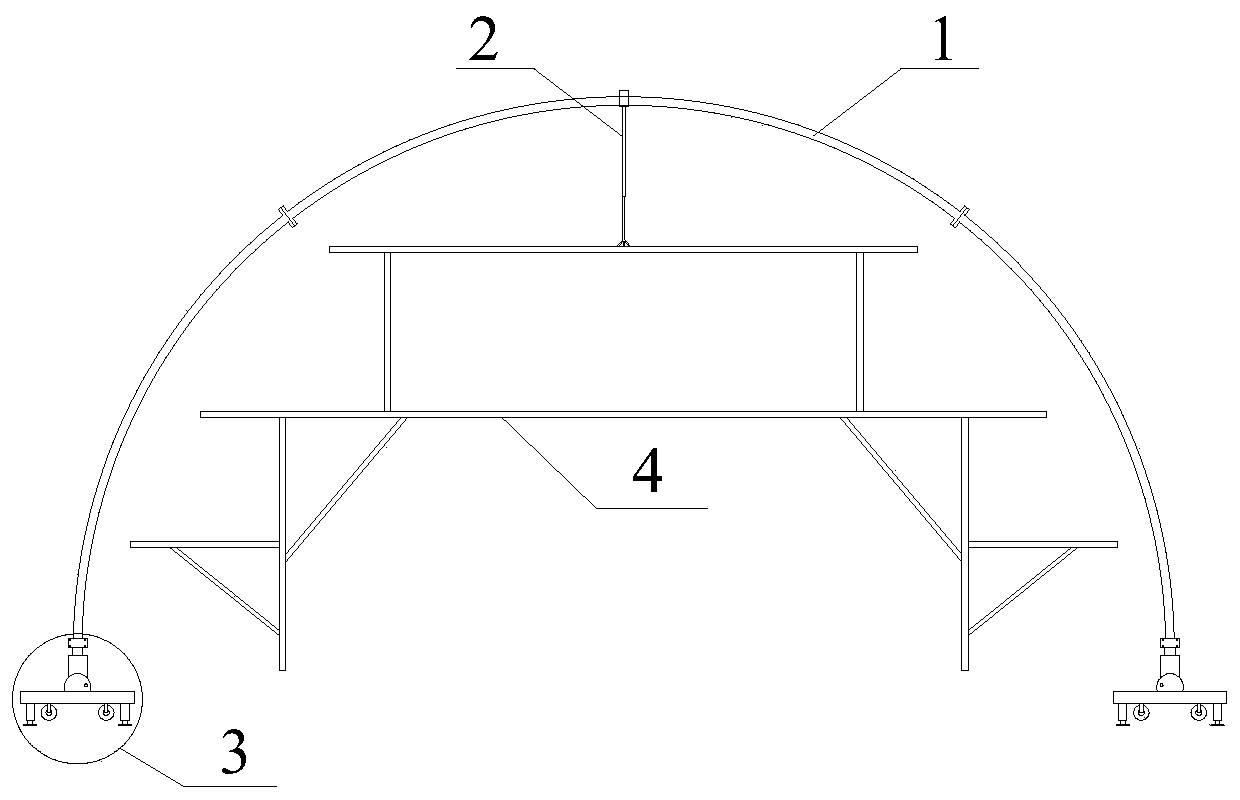

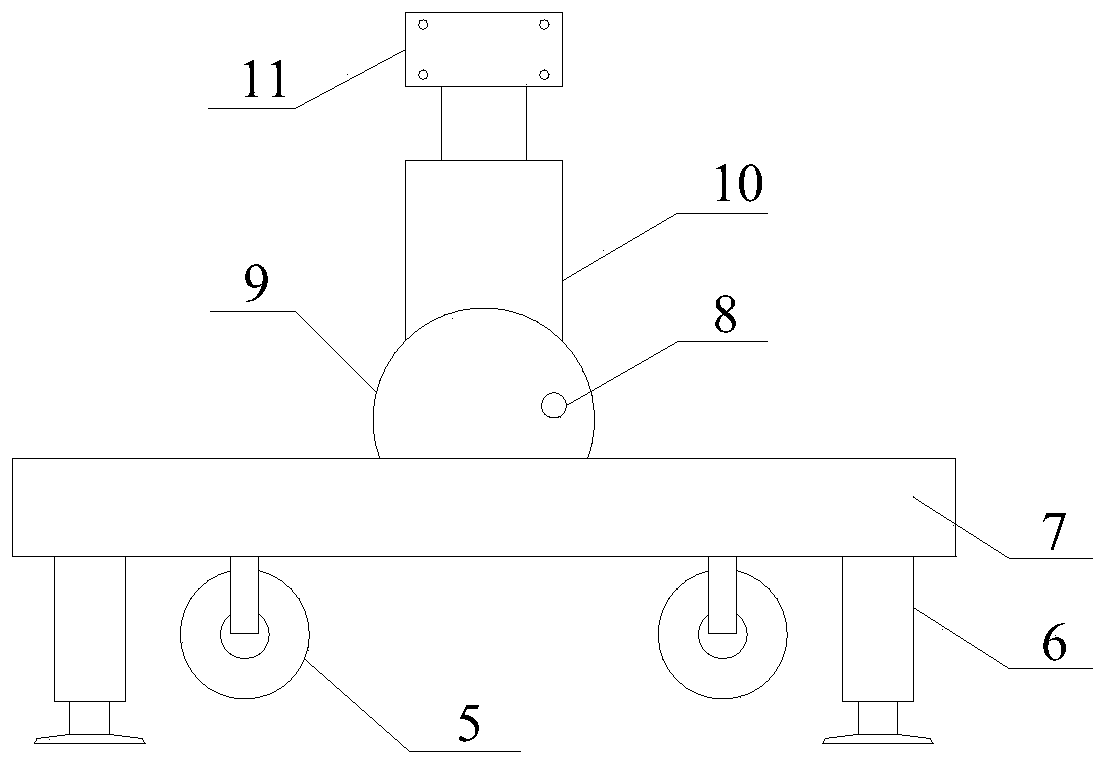

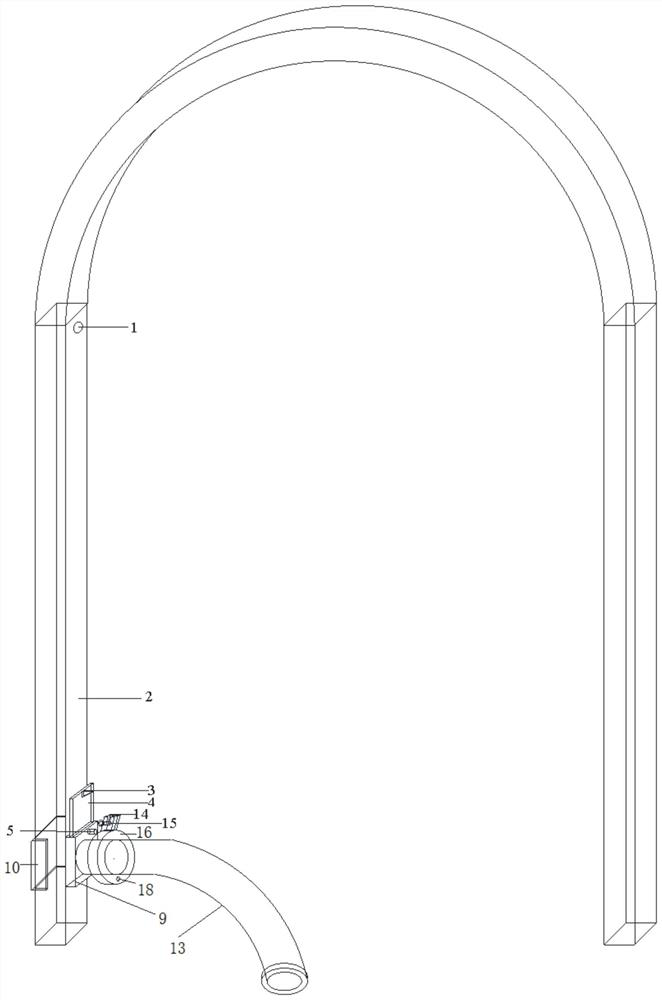

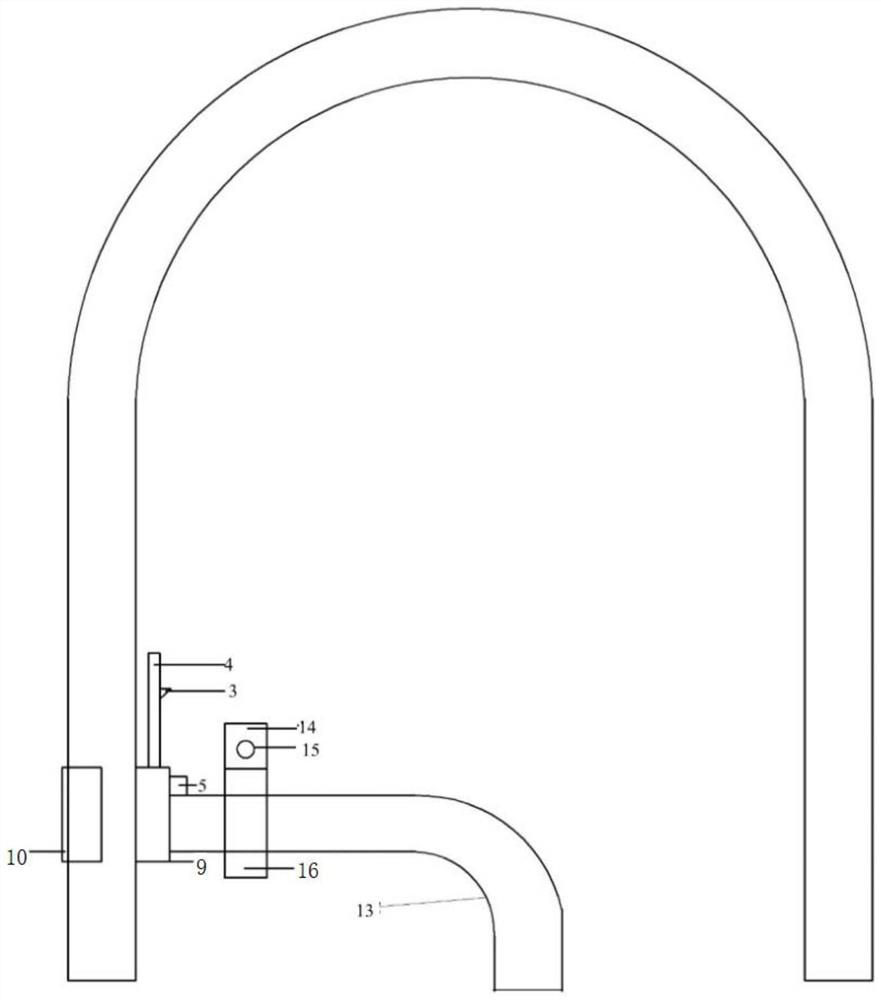

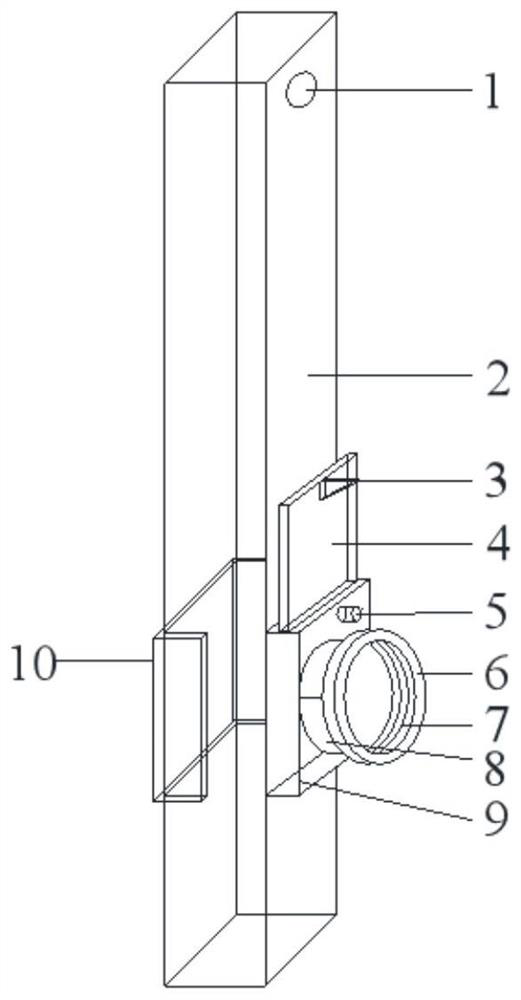

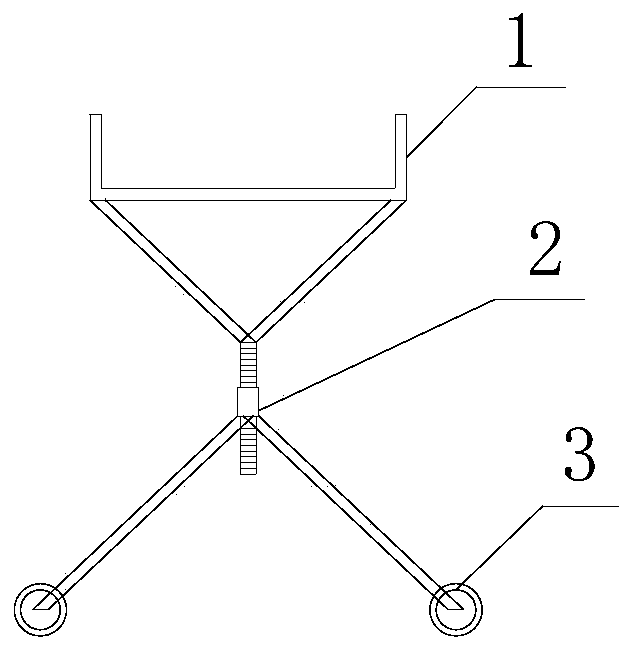

Assembly device and construction technology for restrained concrete arch frame

ActiveCN108240228APrecise positioningReduce face instabilityUnderground chambersTunnel liningClerestoryLaser

The invention discloses an assembly device and construction technology for a restraining concrete arch frame. The assembly device comprises a restrained concrete arch frame formwork, a vault adjustingdevice, two adjusting trolleys, and a laser aligning system. A sealed space for pouring concrete is formed in the restrained concrete arch frame formwork, and the vault adjusting device is arranged at the vault position of the restrained concrete arch frame formwork. The two adjusting trolleys are separately used for adjusting and locating two arch legs of the restrained concrete arch frame formwork, the two adjusting trolleys specifically comprise upper clamping components and adjusting supporting components, wherein the upper clamping components are provided with upward opening parts used for clamping the arch legs; and the adjusting supporting components can stretch and retract in the axial direction, the tops of the adjusting supporting components are fixedly connected with the bottoms of the upper clamping components, and the bottoms of the adjusting supporting components is fixedly connected with a load-bearing platform in a rotating mode along the vertical plane. The laser aligning system comprises laser launching receiving devices which are separately arranged on the vault adjusting device and the adjusting trolleys, and the degree of accuracy of the locating of the arch frame is determined based on laser receiving states of each laser launching receiving device and the relationship between the laser receiving states and a vertical positioning hammer arranged on the arch frame.

Owner:UNIV OF JINAN +1

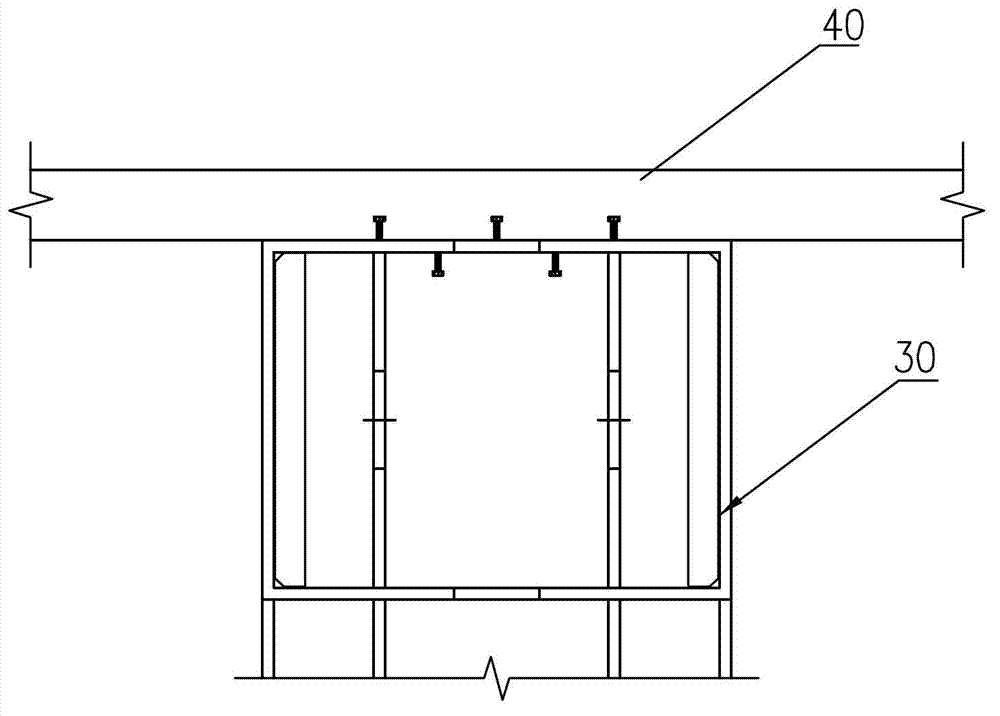

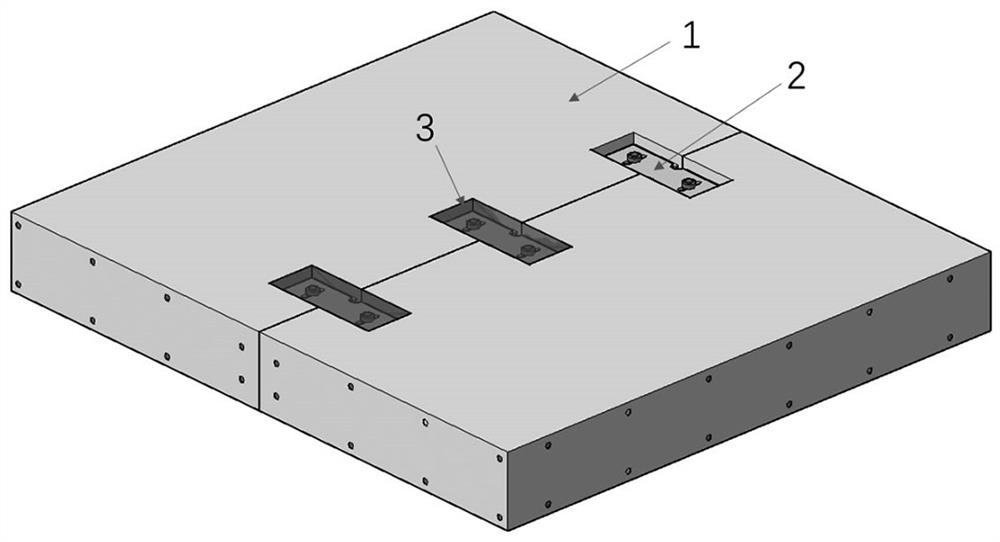

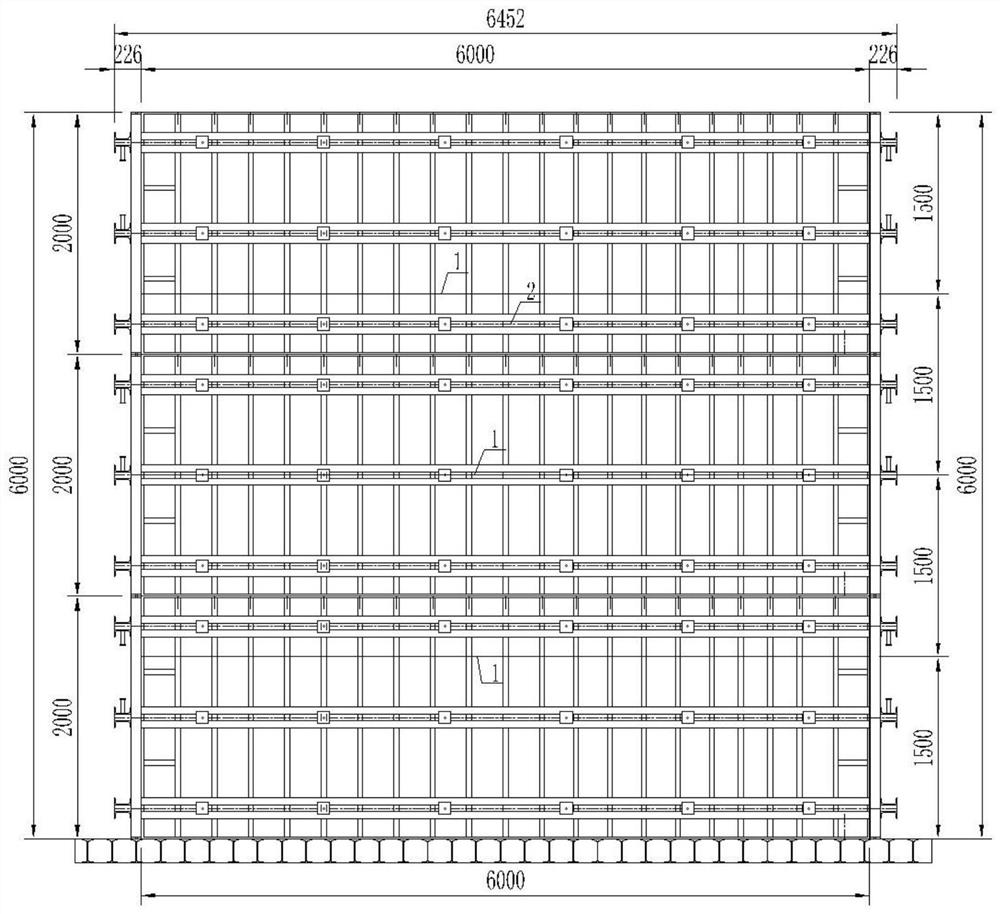

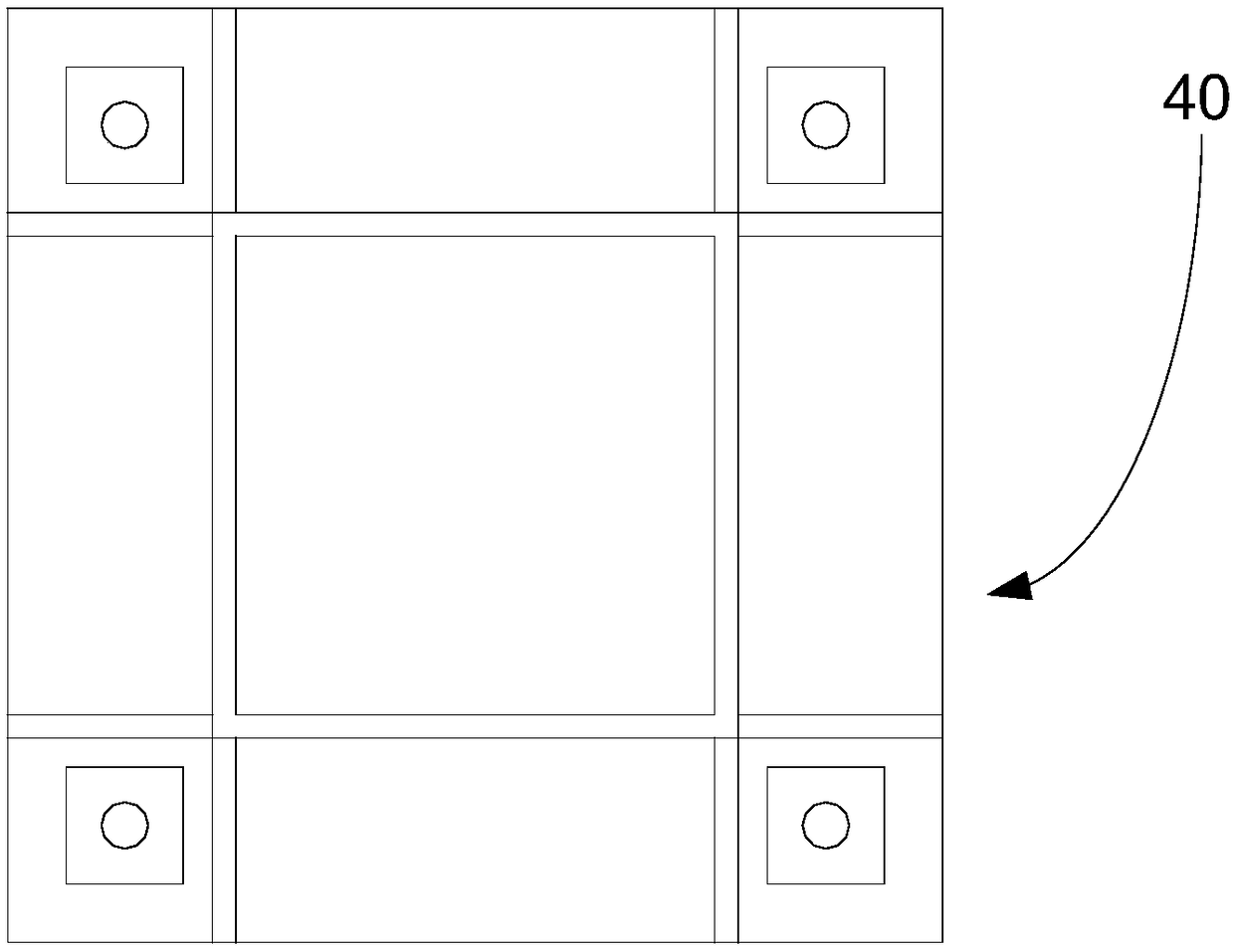

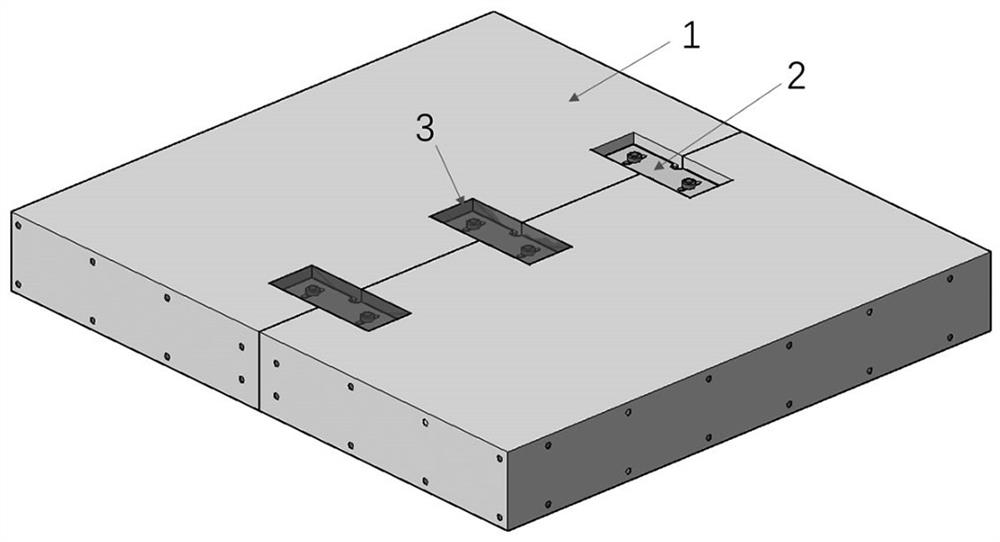

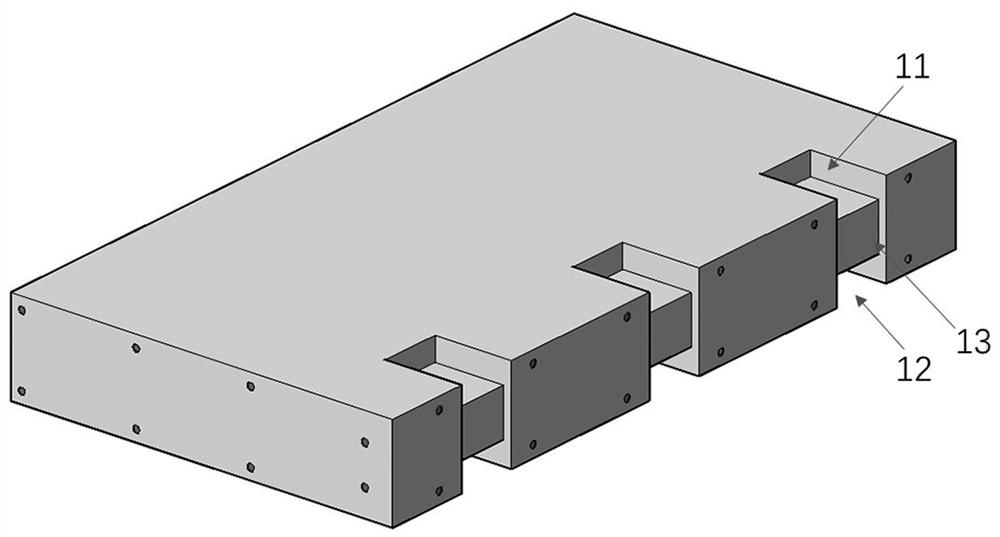

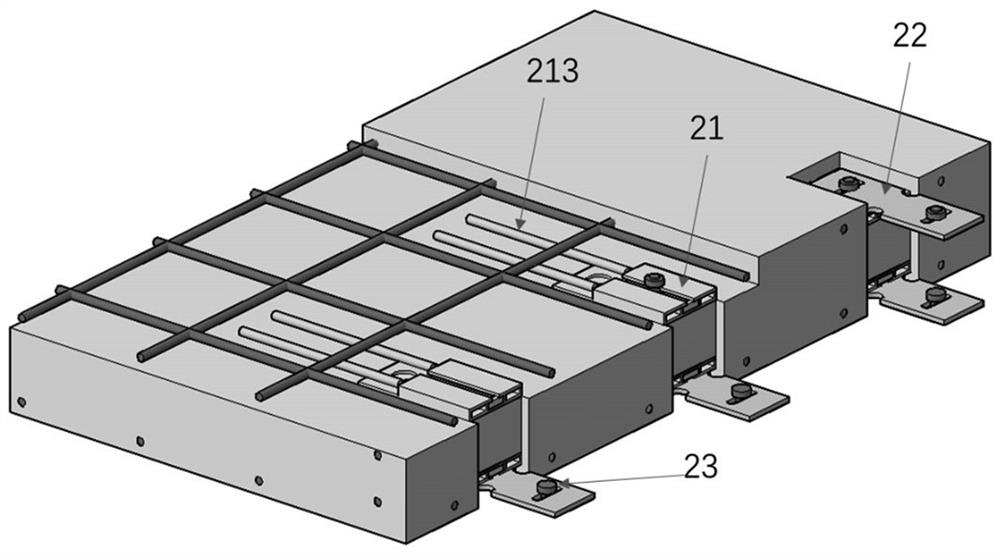

Full-prefabricated concrete floor slab connecting joint

ActiveCN114517551AImprove shear resistanceIncreased bending stiffnessFloorsHydro energy generationFloor slabArchitectural engineering

The invention discloses a full-prefabricated concrete floor slab connecting joint which comprises a prefabricated concrete floor slab, a plurality of sets of connecting grooves are preset in the connecting side at intervals, each connecting groove is composed of an upper plate face horizontal groove, a lower plate face horizontal groove and a side face vertical groove, and the upper plate face horizontal grooves communicate with the lower plate face horizontal grooves through the side face vertical grooves; the connecting piece comprises a pre-embedded steel connecting piece and a connecting steel plate, a steel sliding groove perpendicular to the connecting side direction is formed in the pre-embedded steel connecting piece, and the steel sliding groove at least allows the adjacent prefabricated concrete floor slabs to transversely slide; and the grouting materials are poured in the connecting joints after the adjacent prefabricated concrete floor slabs are spliced. According to the connecting joint, the in-plane shear resistance, the bending rigidity and the tensile bearing capacity of the fully-prefabricated floor slab can be remarkably improved, and deformation coordination of slab joints is guaranteed when vertical loads and explosive impact loads are borne. The full-prefabricated assembly type floor slab has the advantages of being reliable in performance, simple in structure, rapid in construction, environmentally friendly and the like.

Owner:CENT RES INST OF BUILDING & CONSTR CO LTD MCC GRP

An underwater concrete pouring device and construction method and its application in super large deep water caisson foundation

ActiveCN111364469BImprove cohesionImprove mechanical propertiesCaissonsUltimate tensile strengthCaisson

The invention discloses an underwater concrete pouring device and construction method and its application in super large deep water caisson foundations. The underwater concrete pouring device of the present invention is composed of several pouring conduits, and the pouring conduits are provided with side openings or oblique openings. The steps of the underwater concrete construction method are as follows: first pour anti-dispersion concrete, cover the well wall and the bottom of the base, and then stop for 5-10 minutes; then pour self-compacting concrete. The underwater concrete construction method of the present invention is suitable for the construction of super large deep water caisson foundations, and can effectively solve the problems that the underwater concrete of super large deep water caisson foundations is easily washed and segregated, the strength is significantly reduced, and the pouring is not compact, so as to ensure the construction quality of the project.

Owner:SOUTHEAST UNIV +1

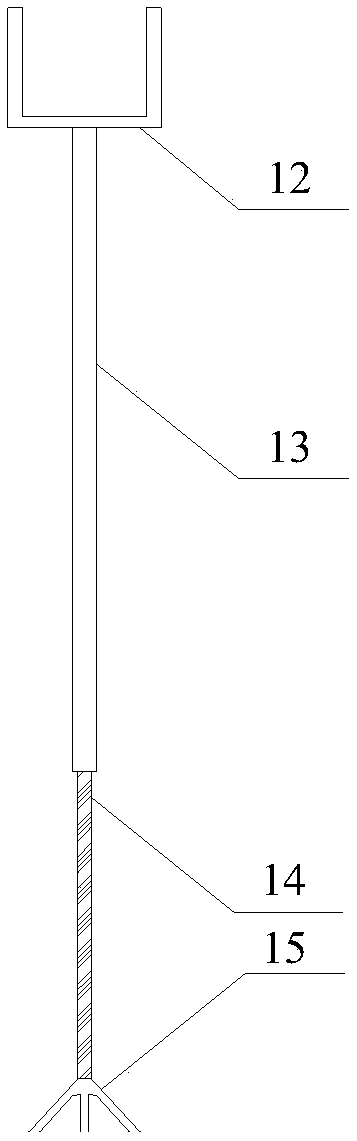

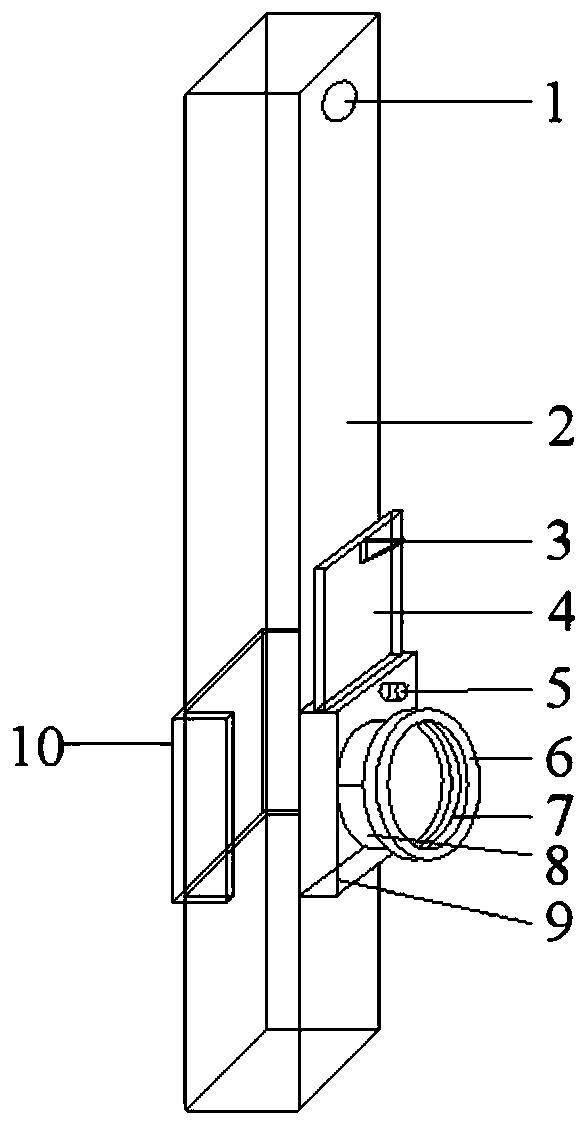

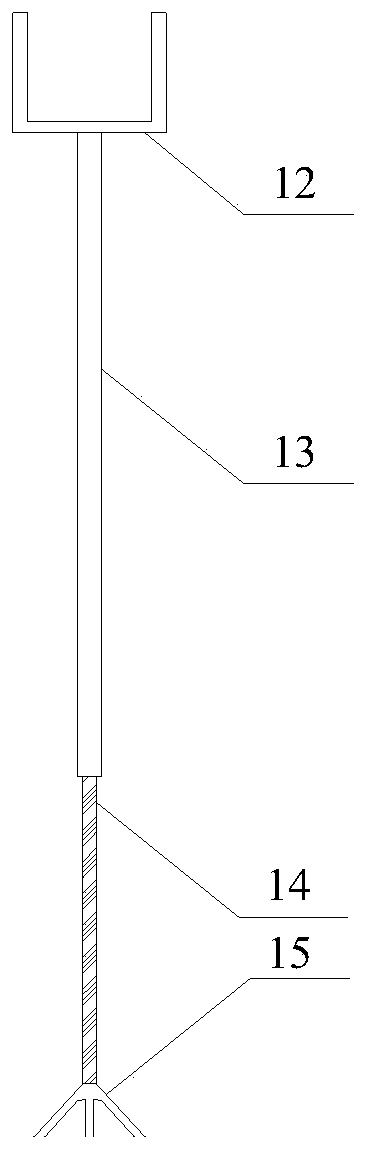

Confined concrete arch frame precise filling device and efficient construction method

ActiveCN110939462AGuarantee the quality of pouring constructionImprove construction efficiencyUnderground chambersTunnel liningGroutPipe

The invention discloses a confined concrete arch frame precise filling device and an efficient construction method. The device comprises a core filling component, a high-strength conveying pipe and ajoint ring buckle device; the core filling component comprises a joint plate; the high-strength conveying pipe is in embedded connection with the joint plate, and the connected place of the two is locked and fastened through the joint ring buckle device; an internal conveying pipeline is arranged in the joint plate for communicating with a grouting injection port of an arch frame; an opening is formed in the top of the joint plate; a pulp stop insertion plate capable of moving up and down is arranged in the opening; and the pulp stop insertion plate can fall to the bottom of the joint plate toblock the grouting injection port. In the filling device, the pulp stop insertion plate can be inserted in the filling component to block the injection port after completion of filling for timely pulp stop, so that the filling quality is guaranteed, the filling efficiency is improved, and the confined concrete arch frame supporting effect is improved.

Owner:王琦 +1

Rear plate type steel-concrete combined section with semi-open grid chamber

PendingCN111979912AShorten the lengthInclined arrangement facilitatesBridge structural detailsBridge materialsStructural engineeringMechanical engineering

The invention discloses a rear plate type steel-concrete combined section with a semi-open grid chamber. The rear plate type steel-concrete combined section with the semi-open grid chamber comprises asteel-concrete combined area. The steel-concrete combined area comprises combined-section peripheral steel plates, steel-grid-chamber force transfer partition plates in the bridge direction are arranged on the inner sides of the combined-section peripheral steel plates, and rear pressure-bearing steel plates in the transverse direction of a bridge are further arranged on the inner sides of the combined-section peripheral steel plates. Grid-chamber inner side plates are arranged at the ends of the steel-grid-chamber force transfer partition plates and the rear pressure-bearing steel plates, asteel grid chamber is defined by the combined-section peripheral steel plates, the steel grid chamber force transfer partition plates, the rear pressure-bearing steel plates and the grid-chamber innerside plates, and concrete is poured in the steel grid chamber. The length of a closed section of the combined-section grid chamber is greatly reduced, the overall arrangement is simpler, the open space is enlarged, the grid-chamber inner side plates are obliquely arranged, and construction operation of workers is facilitated. The length of the combined section is greatly reduced compared with that of a front and rear plate type combined section, the local rigidity of a main beam is prevented from being too high, stress and deformation of the main beam are more uniform, the grid-chamber innerside plates are obliquely arranged, concrete pouring compaction is facilitated, and the engineering quality is guaranteed.

Owner:CHINA RAILWAY DESIGN GRP CO LTD

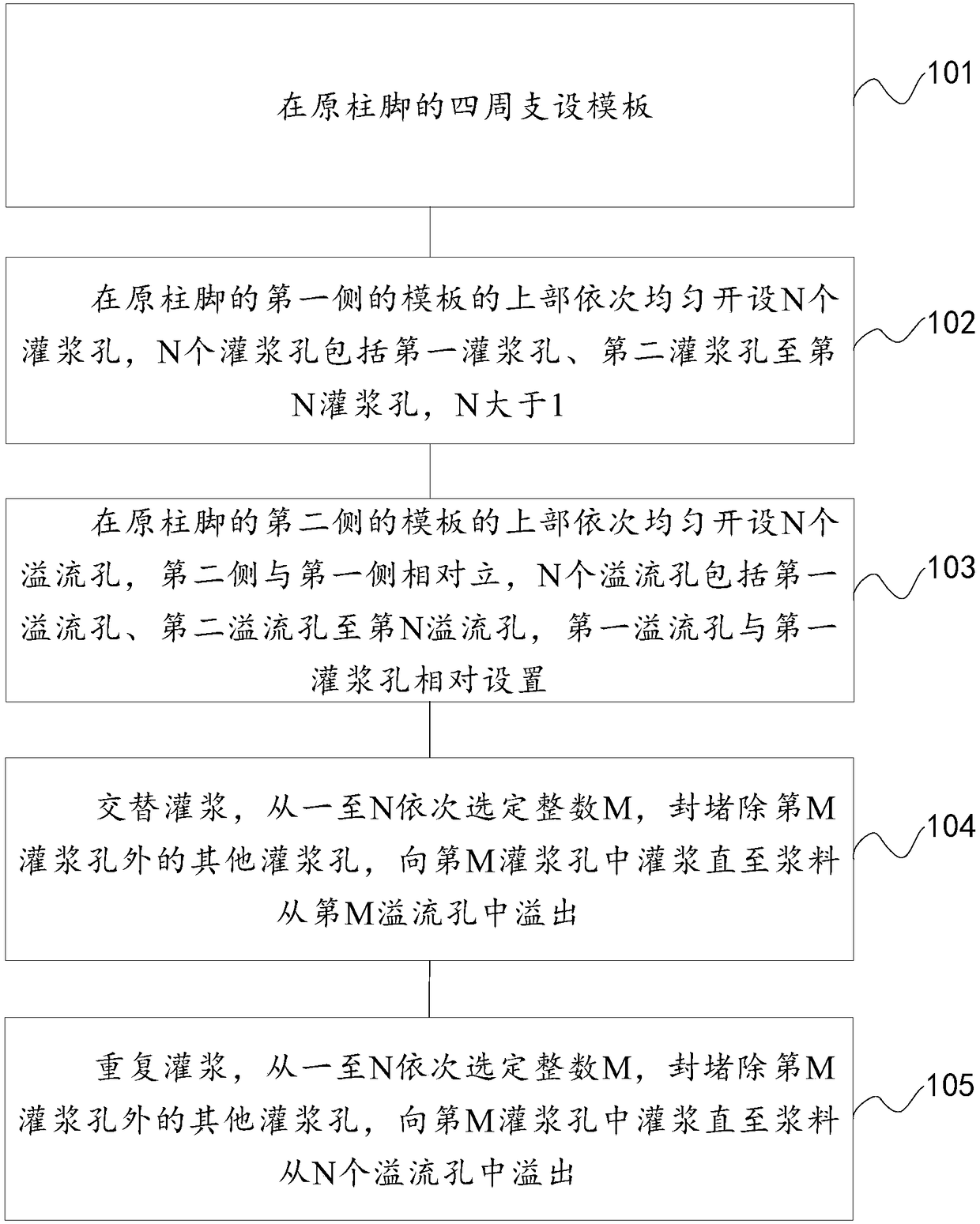

Alternative grouting method for steel-structure column feet

The invention discloses an alternative grouting method for steel-structure column feet. The alternative grouting method comprises the following steps: arranging a template; sequentially and uniformlyforming N grouting holes in the upper part of the template at the first side of the original column feet, wherein N grouting holes comprise first grouting hole to N-th grouting holes, and N is greaterthan 1; sequentially and uniformly forming N overflow holes in the upper part of the template at the second side of the original column feet, wherein the N overflow holes comprise first overflow holeto N-th overflow hole, and the first overflow hole and the first grouting hole are oppositely formed; alternatively grouting, selecting an integer M from one to N sequentially, sealing other groutingholes except from the M-th grouting hole, grouting the M-th grouting hole until slurry overflows from the M-th overflow hole; repeatedly grouting, selecting the integer M from one to N sequentially,sealing other grouting holes except from the M-th grouting hole, grouting the M-th grouting hole until the slurry overflows from the N-th overflow hole. The alternative grouting method is used to sequentially grout the grouting holes until the corresponding overflow holes overflow, so that the grouting is more compact. The more stable and safer structure is guaranteed.

Owner:CHINA CONSTR EIGHT ENG DIV CORP LTD

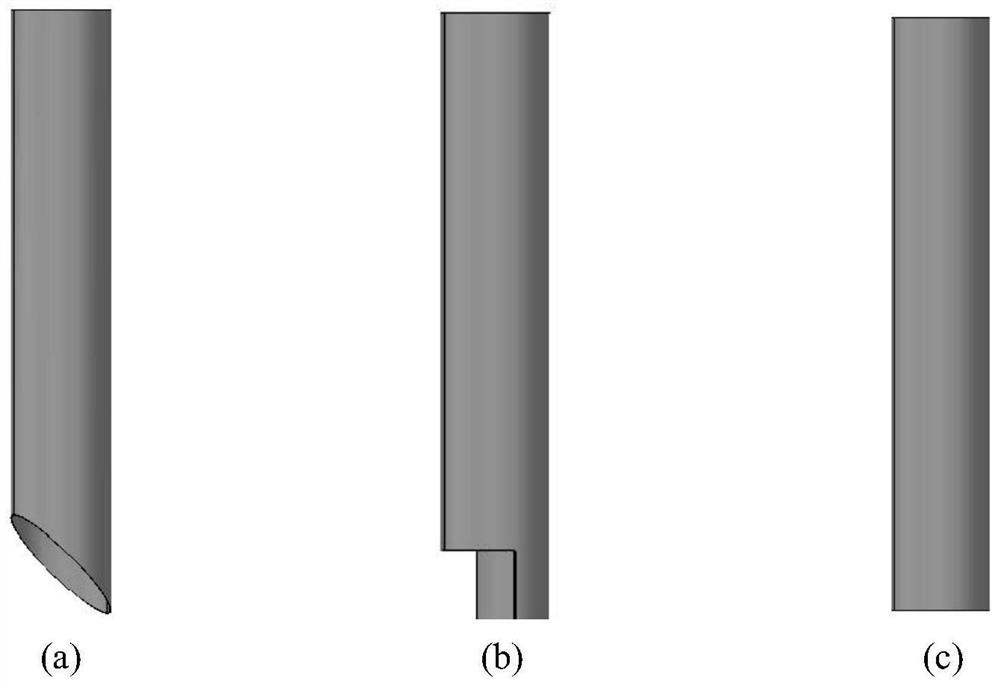

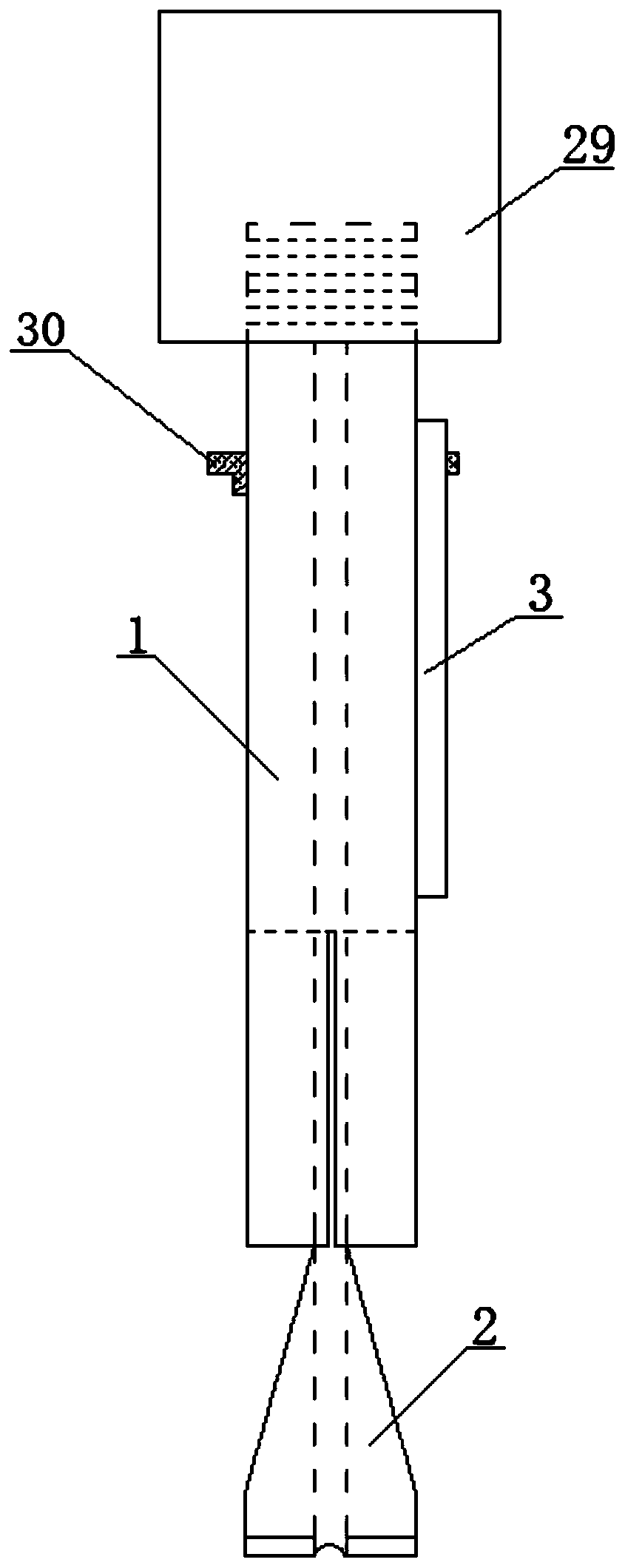

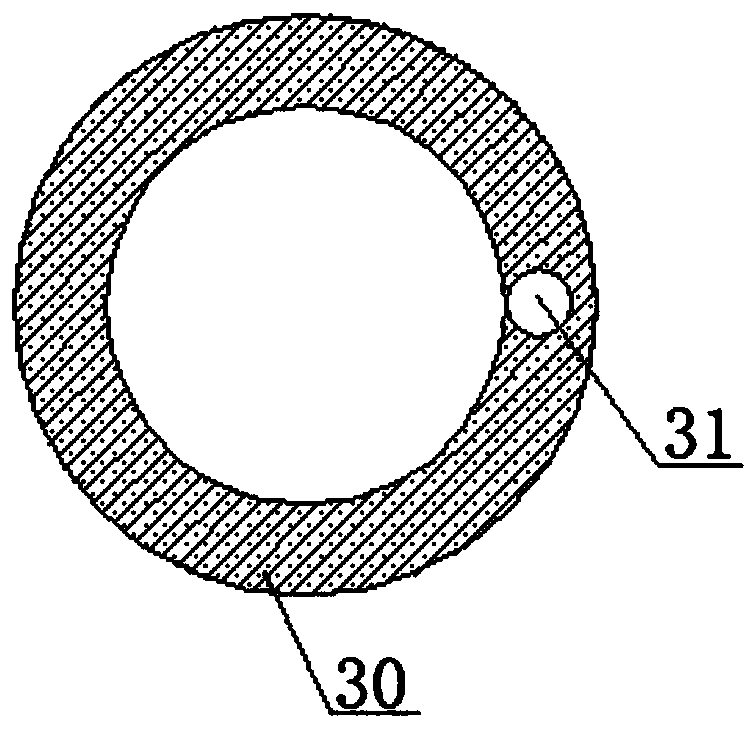

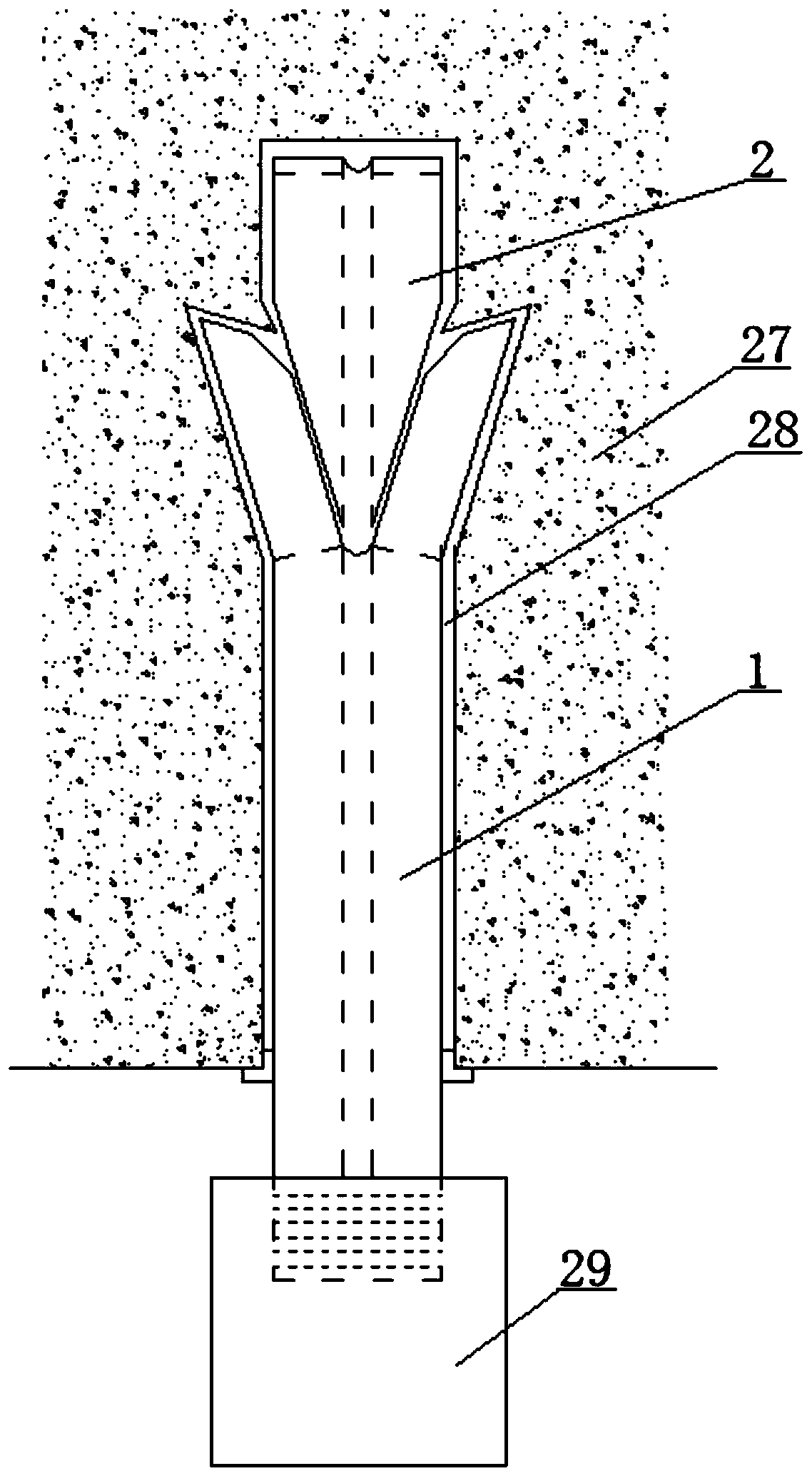

Mounting method of concrete hollow anchor rod tool

InactiveCN110117957AGuaranteed perfusion qualityImproved durability and reliabilityBulkheads/pilesAnchoring boltsSyringeInjector

The invention discloses a mounting method of a concrete hollow anchor rod tool. When used for inverted mounting of a hollow anchor rod, the mounting method comprises the following steps: 1, a hole isformed and cleared, specifically, the straight hole (28) is drilled in rock or concrete (27) through a drilling rig, then the hole is broached through broaching equipment, and then the hole is clearedthrough a hole clearing device; 2, mounting is conducted, specifically, hollow self-bottom-expanding anchor bolts are assembled firstly, a rubber sleeve (30) sleeves a rod body (1) and is located ona middle rod (22) part, then the rubber sleeve (30) is glued to the rod body (1) through glue, and then the assembled hollow self-bottom-expanding anchor bolts are inserted into the straight hole (28); and 3, grouting is conducted, specifically, through an injector, a grouting material sequentially passes through a rod body inner hole (9) and a wedge block inner hole (24) and then is injected intothe hole bottom of the straight hole (28), after the grouting material overflows from an air guiding pipe (32) on a large scale, grouting is stopped, an anchor rod cap (29) is mounted at the exposedend (6) to block the rod body inner hole (9) to prevent the grouting material from flowing out, and after the grouting material is solidified, the hollow self-bottom-expanding anchor bolts are mounted.

Owner:WUDA JUCHENG STRUCTURE CO LTD

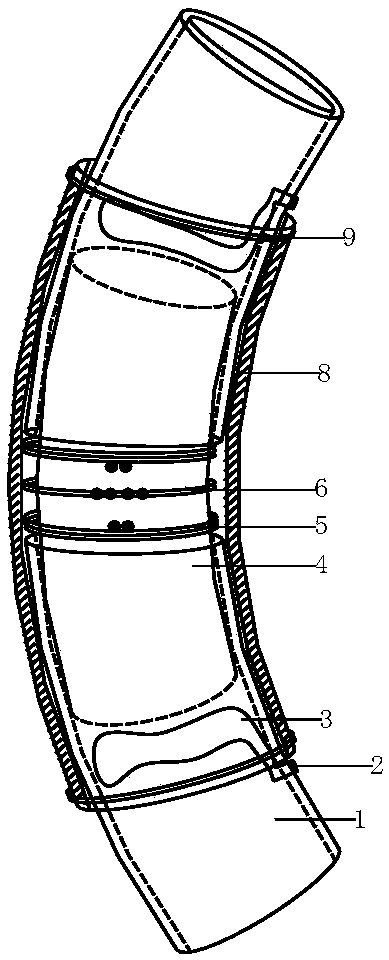

Pier reinforcing device and construction method thereof

InactiveCN111733690AEfficient reinforcementEasy to adjust the positionBridge structural detailsBridge erection/assemblyButt jointArchitectural engineering

The invention discloses a pier reinforcing device and a construction method thereof, and relates to a reinforcing device and a construction method. The hoop units are vertically stacked to be cylindrical and arranged outside a pier cylinder in a sleeving mode. Every two adjacent hoop units are connected through two hoop connecting pieces. Each hoop unit is formed by butting two semicircular protection walls, the upper ends are in butt joint to form a conical connectorand the lower ends are in butt joint to form a conical slot; the hoop connecting piece comprises two U-shaped screw rods and twointernal thread connecting pipes; the opening ends of the two U-shaped screw rods are oppositely arranged, the hoop unit is hung at the connecting end, the two U-shaped screw rods are relatively close to or far away from each other when the internal thread connecting pipe rotates, a grouting hole and four thread through holes are formed in the side wall of the hoop unit, fine adjustment bolts arescrewed in the thread through holes, and the fine adjustment bolts are arranged in the radial direction of the hoop unit. The upper ends and the lower ends of the hoop units are provided with the conical connectors and the conical slots correspondingly, non-rigid connection is achieved, energy dissipation and shock absorption are facilitated, and layer-by-layer grouting from bottom to top is morereasonable.

Owner:HEILONGJIANG COLLEGE OF CONSTR

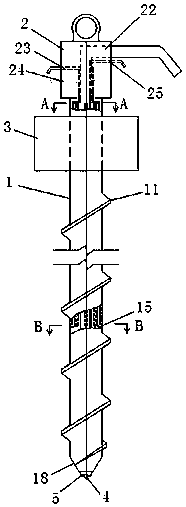

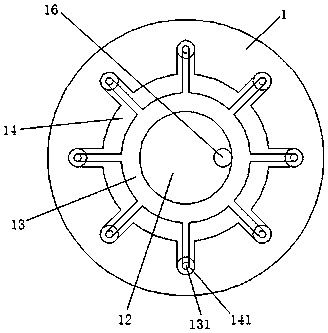

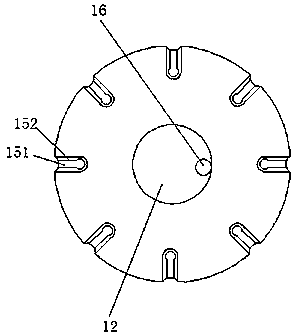

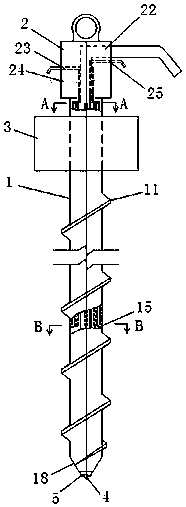

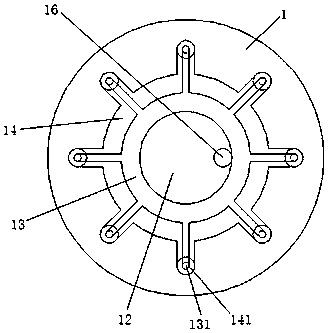

Threaded pile drill pipe for reinforcing local silt layer and method for pile formation of foundation threaded pile including silt layer

The invention discloses a threaded pile drill pipe for reinforcing local silt layer and a method for pile formation of a foundation threaded pile including a silt layer. Threads are arranged on the surface of a pipe body of the drill pipe, the internal axis communicates with a pouring cavity up and down, the top end of the drill pipe is rotatably connected with a rotary jet grouting drilling rig distributing device, a power device sleeves the upper pipe body of the drill pipe, a powder ring cavity and an air ring cavity which are on the same axis with the pouring cavity are formed in the uppersection in the drill pipe, the rotary jet grouting drilling rig distributing device is internally provided with channels communicating with the drill pipe pouring cavity, the powder ring cavity and the air ring cavity correspondingly, and external inlets of the channels are used for being connected with a high-pressure flow concrete pump, a high-pressure powder pump and a high-pressure air pump correspondingly; and a round of spaced radial nozzles are formed in the circumferential surface of the pipe body in the middle of the drill pipe, concentric central powder spraying holes on the end faces of the nozzles externally surround air spraying holes, the powder spraying hole communicate with the powder ring cavity, and the air spraying holes communicate with the air ring cavity. The specialdrill pipe is used for reinforcing a silt sandwich layer during hole forming, and the threaded pile with the integral structure is formed.

Owner:HUAIYIN INSTITUTE OF TECHNOLOGY

Threaded pile drill pipe for reinforcing local silt layer and pile forming method thereof

The invention discloses a threaded pile drill pipe for reinforcing a local mud layer and a threaded pile forming method for a foundation thread pile containing a mud layer. Spray drilling tool splitter, the upper part of the drill pipe is socketed with the power unit, the inner upper part of the drill pipe is provided with a powder ring cavity and an air ring cavity coaxial with the filling cavity, and the rotary jet drilling tool splitter is equipped with a corresponding connected drill pipe The passages of the pouring chamber, the powder ring chamber and the air ring chamber are respectively used to connect the high-pressure fluid concrete pump, the high-pressure powder pump, and the high-pressure air pump at the outer entrances of each passage. The radial nozzle, the end face of the nozzle is a concentric central powder injection hole and an outer ring air injection hole, the powder injection hole is connected with the powder ring cavity, and the air injection hole is connected with the air ring cavity. Use this special drill pipe to reinforce the silt sandwich layer when forming a hole to form a threaded pile with an overall structure.

Owner:HUAIYIN INSTITUTE OF TECHNOLOGY

Special-shaped column assembly and beam column connecting joint structure

PendingCN109322440AGuaranteed structural strengthReduce weld lengthStrutsPillarsProject areaEngineering

The embodiment of the invention provides a special-shaped column assembly and a beam column connecting joint structure. The special-shaped column assembly comprises a special-shaped column and separating plates of a preset number, and the special-shaped column comprises at least one lateral plate. All the lateral plates enclose to form at least one cavity, or at least one lateral plate integrallyforms at least one cavity. A part of cavities is internally provided with at least one separating plate, and projected areas of the separating plates along lengths of the cavities are smaller than base areas of the cavities. The fact that the projected areas of the separating plates of the special-shaped column assembly along the lengths of the cavities are smaller than base areas of the cavitiesindicates that at least one marginal area existing in the separating plates is in a separating condition with one corresponding lateral plate or a part of thecorresponding lateral plate, and the marginal area and the corresponding lateral plate or the part of the corresponding lateral plate have intervals of certain distance and do not need to be connected in a weld mode, so that lengths of welding lines between the separating plates and the lateral plates which enclose to form the cavities are shortened, and welding workloads are reduced; and margins which are not connected with the lateral plates of the separating plates and the inner walls of the lateral plates enclose to form through holes used for pouring concrete, therefore, the separating plates do not need to be provided with pouring holes, and the own structural intensity of the separating plates is ensured.

Owner:北京和筑科技有限公司

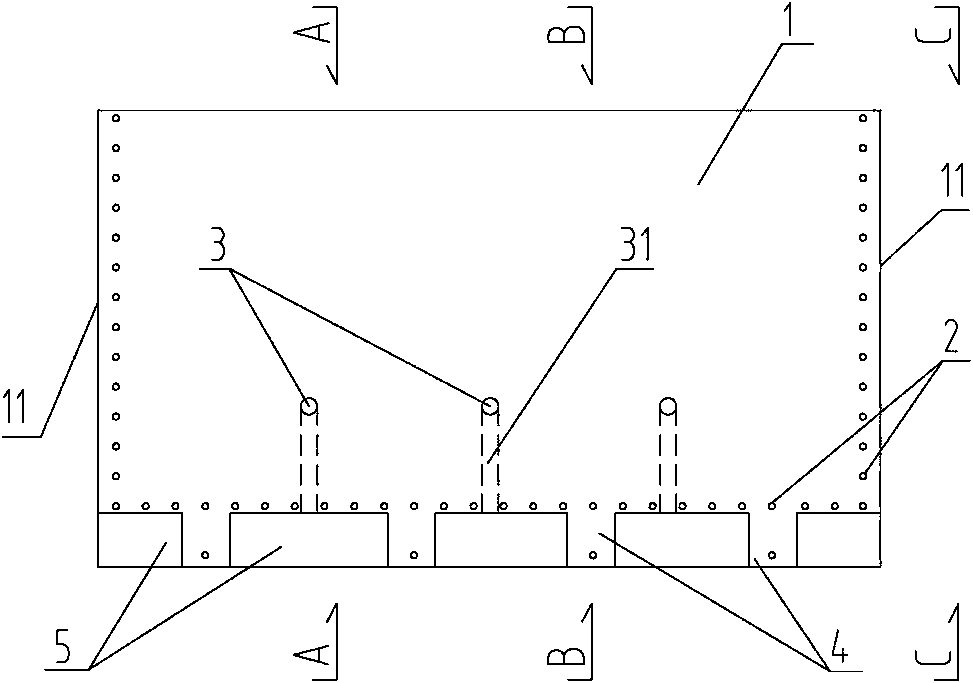

A method for arching treatment of steel cladding panels in refueling pools of nuclear power plants

ActiveCN112196269BGuaranteed to workAvoid deformationBuilding material handlingIndustrial buildingsNuclear plantNuclear power

Owner:SANMEN NUCLEAR POWER CO LTD

Strength delayed concrete and application thereof to A/B occlusive piles

ActiveCN107285683APromote growthWorkability is goodBulkheads/pilesUltimate tensile strengthMaterials science

The invention provides strength delayed concrete and an application thereof in A / B occlusive piles. In terms of dosage per cubic meter, the strength delayed concrete is prepared from components as follows: 150-350 kg of cement, 180-190 kg of water, 600-900 kg of sand, 1100-1250 kg of pebbles, 50-100 kg of an admixture and 3-7 kg of a retarder. The strength of the strength delayed concrete is increased slowly at the early stage, 7d strength is just 30%-50% of designed strength value under the natural curing condition, 28d strength can reach 100% or higher of the designed strength value, workability is good, and pouring is compacter. With application of the strength delayed concrete to the A / B occlusive piles, a pile A can be subjected to rotary excavating and cutting smoothly, and requirements of the pile A for soil blocking and water stopping can be met.

Owner:GUANGXI METALLURGICAL CONSTR

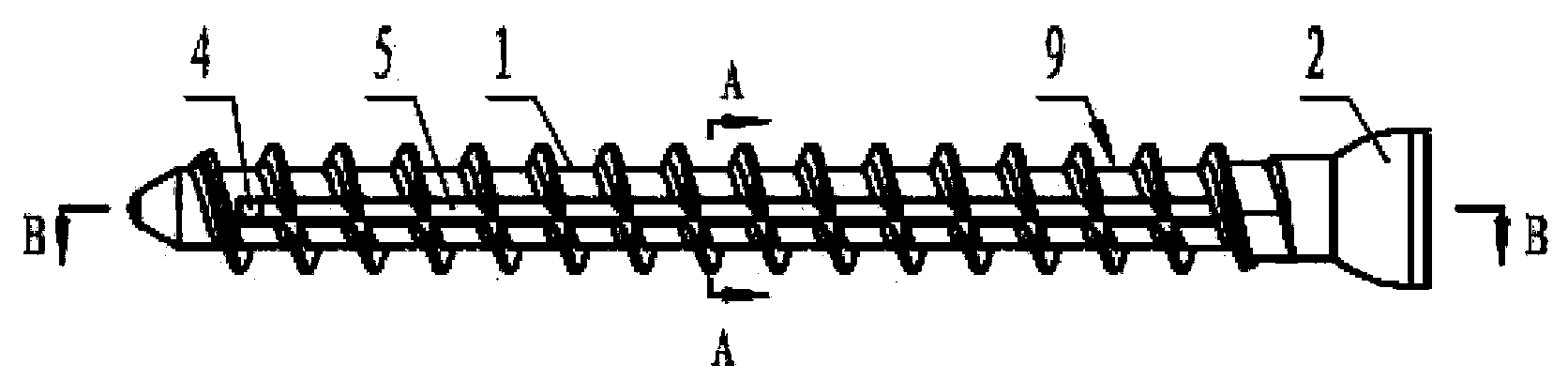

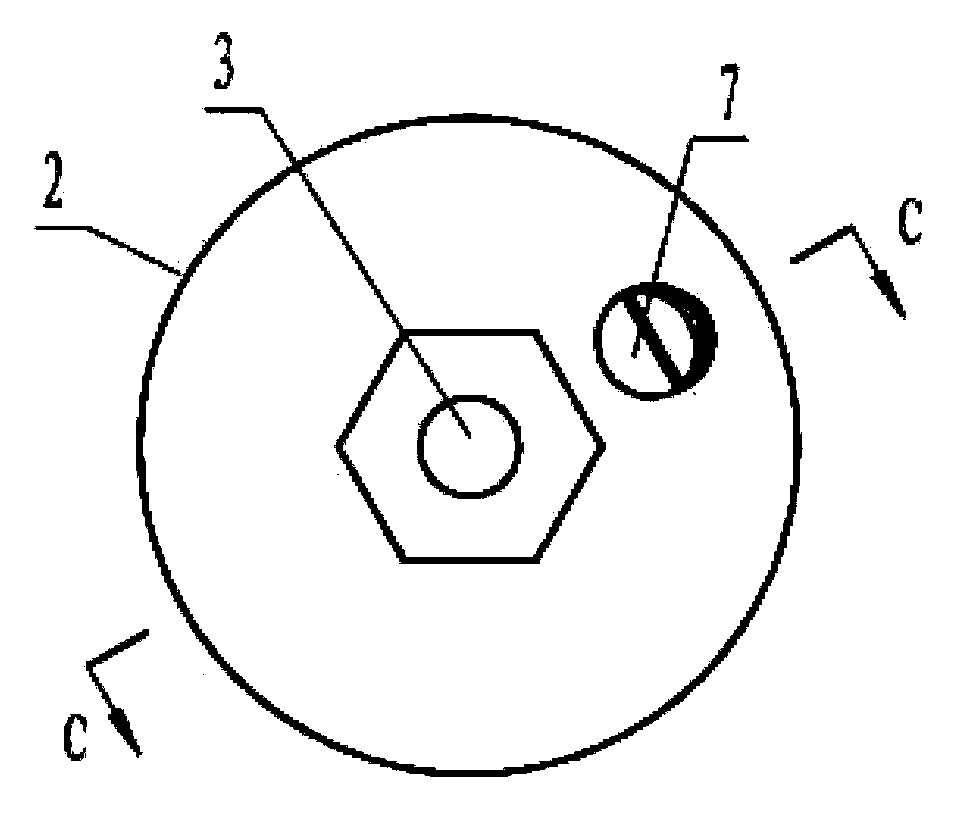

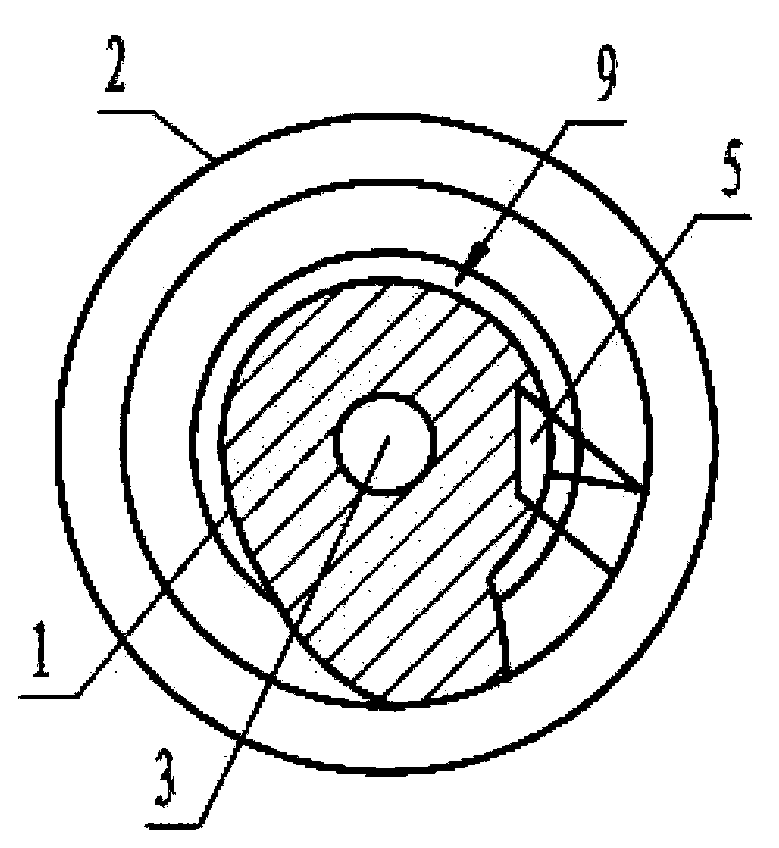

Improved pourable pedicle screw

ActiveCN102715941BEasy accessAvoid contaminationInternal osteosythesisFastenersEngineeringIliac screw

The invention relates to a surgical instrument, in particular to an improved pourable pedicle screw. At least one axial groove (5) communicated with a seepage hole (4) is arranged on the outer surface of a screw body (1) of the pedicle screw. The improved pourable pedicle screw is characterized in that an exhaust hole (6) enabling a thread groove (9) to be communicated with the air is arranged on the periphery of a blind hole (3) and on a screw end (2) of the pedicle screw, and a flow adjusting valve is arranged in an outlet of the exhaust hole(6). The flow adjusting valve is formed by an outlet portion (8) of the exhaust hole (6) and a valve core (7) matched with the outlet portion (8), wherein the valve core (7) is formed by a cylinder and a cone with the gradually-reduced section in sequence from the port of the outlet portion (8) of the exhaust hole (6), and the cylinder is in threaded connection with the outlet portion (8) of the exhaust hole (6). The improved pourable pedicle screw has the advantages of achieving fully pouring and having good fixing effect.

Owner:SOUTHERN MEDICAL UNIVERSITY

A Construction Method of Concrete Vibration for Tunnel Vault

ActiveCN110374630BWill not affect the construction progressEasy to operateUnderground chambersTunnel liningArchitectural engineeringStructural engineering

Owner:CHINA HYDROPOWER ELEVENTH ENG BUREAU ZHENGZHOU CO LTD +1

A fully precast concrete floor connecting node

ActiveCN114517551BImprove shear resistanceIncreased bending stiffnessFloorsHydro energy generationFloor slabArchitectural engineering

The invention discloses a fully prefabricated concrete floor connection node. The connection node comprises: a prefabricated concrete floor slab, a plurality of groups of connection grooves are preset at intervals on the connection side, and the connection grooves are composed of a horizontal groove on an upper board surface, a horizontal groove on a lower board surface and a side surface. It is composed of vertical grooves, and the horizontal grooves on the upper board surface and the horizontal grooves on the lower board surface are connected through the side vertical grooves; the connecting pieces include embedded steel connecting pieces and connecting steel plates. Steel chute, the steel chute at least allows the adjacent precast concrete floor slabs to produce lateral sliding; the grouting material is poured in the connection node after the adjacent precast concrete floor slabs are spliced. The connecting node of the invention can significantly improve the in-plane shear resistance, bending stiffness and tensile bearing capacity of the fully prefabricated floor slab, and ensure the deformation coordination of the slab joints when bearing vertical loads and explosion impact loads. The invention relates to a fully prefabricated assembled floor slab, which has the advantages of reliable performance, simple structure, rapid construction, green environmental protection and the like.

Owner:CENT RES INST OF BUILDING & CONSTR CO LTD MCC GRP

Assembly equipment and construction technology for a restrained concrete arch frame

ActiveCN108240228BSatisfy the positioning problemEasy to operateUnderground chambersTunnel liningVertical planeClerestory

Owner:UNIV OF JINAN +1

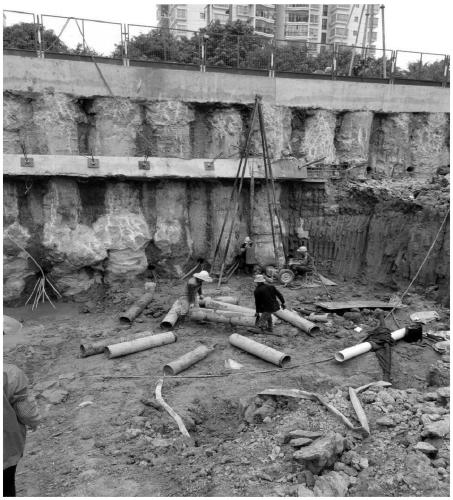

Mass concrete structure deep pore reinforced construction method

ActiveCN100596318CHigh strengthPracticalBridge erection/assemblyMarine site engineeringEngineeringRebar

The present invention discloses a construction method for planting reinforcement bars in deep holes by a massive concrete structure, and relates to a construction method for the reinforcement and compensation project of the massive concrete structure. The utility model has the embodiment that: firstly, the plane position for embedding the reinforcing steel bars is determined in accordance with thedesign requirement, holes are drilled by a drilling machine, the hole wall is smoothed and the holes are cleaned, and the two pre-embedded reinforcing steel bars, an infusion tube and a centering supporting frame are bond, an outer ring positioning ring is suited outside, the bond reinforcing steel bars are arranged inside the drilling holes, and the reinforcing steel bars and the centering supporting frame are contacted with a bottom hole, the grouting material is perfused into the drilling holes through the infusion tube by using an injection pump; in the injection process, the infusion tube is extracted out upward gradually, the infusion is operated continuously until the hole is fully filled, the reinforcing steel bars can be disturbed within 24 hours, and the bar planting is completed after 48 hours. The present invention can improve the strength of the massive concrete structure without changing the former section size of the concrete structure, and the additionally arranged reinforcing steel bars are firmly connected with the former structure. The invention method is simple, and has strong practicability and lower construction cost; the continuous pressure perfusion is adopted to ensure that the grouting material is compact without holes.

Owner:WUDA JUCHENG STRUCTURE CO LTD

Precise pouring device and efficient construction method for constrained concrete arch

ActiveCN110939462BWill not cause slurry leakageImprove construction efficiencyUnderground chambersTunnel liningArchitectural engineeringPipe

The invention discloses a precise pouring device and a high-efficiency construction method for constrained concrete arches, including a core pouring component, a high-strength delivery pipe, and a joint buckle device; The connection between the two is locked and fastened by the joint ring buckle device; the connecting plate has an internal delivery pipeline to communicate with the grouting inlet of the arch frame, an opening is set on the top of the connecting plate, and a grout blocking plate that can move up and down is arranged in the opening , The grout blocking plate can drop to the bottom of the connecting plate to block the grouting inlet. With this pouring device, after the pouring is completed, the grout blocking plate can be inserted into the pouring member to seal the pouring port, the grout can be stopped in time, the pouring quality can be ensured, the pouring efficiency can be improved, and the support effect of the confined concrete arch can be improved.

Owner:王琦 +1

A pouring method of concrete in the cross brace tube between arch ribs of steel pipe bridge

ActiveCN112709148BShorten the perfusion timeImprove securityBridge erection/assemblyBuilding material handlingSlurryPipe

The invention relates to a pouring method of concrete in a cross-stay tube between arch ribs of a steel pipe bridge. The two ends of the brace tube, wherein, the hole at the bottom of the brace tube is a grouting hole, and the hole at the top of the brace tube is a grout hole; step 2, the first brace tube The grout hole is connected to the grouting hole of the second brace pipe with a pump pipe ..., and the grout hole of the n-1th brace pipe is connected to the grouting hole of the nth brace pipe hole; step 3, connect the concrete delivery pump pipe with the grouting hole of the first cross-bracing pipe, perform concrete pouring, and stop pumping when the concrete flowing out of the grouting hole of the n-th cross-bracing pipe contains aggregate , close the valve of the pump pipe, the pouring of one horizontal support pipe assembly is completed, and the concrete pouring of the next horizontal support pipe assembly is performed. The pouring method can effectively shorten the construction period and improve the safety of construction and environment.

Owner:CHINA RAILWAY NO 2 ENG GRP CO LTD +1

Prefabricated Confined Concrete Arch Frame and Mechanized Construction Method for Underground Engineering

ActiveCN108104832BHigh strengthSafe and efficient constructionUnderground chambersTunnel liningEngineeringTunnel construction

The invention discloses an underground construction fabricated confined concrete lagging jack and a mechanized construction method. In order to be matched with lagging jack intelligent mounting equipment to conduct tunnel construction, the fabricated confined concrete lagging jack is researched and developed, the relevant technologies of folded hoisting, mechanized assembly, accurate positioning,fracture surface reexamination and the like of the lagging jack are broken through, the lagging jack being lifted manually to be split is not needed in the tunnel construction process, and the whole set of construction process can be conducted through a mechanized manner, and is safer and more efficient. The mechanized construction method specifically comprises the construction steps that (1), thelagging jack is folded and hoisted; (2), the lagging jack intelligent mounting equipment is utilized to conduct sequential extending on the lagging jack, fabricated joints are automatically clamped,and a longitudinal connection device is mounted in advance; (3), clamping buckle lifting, accurate positioning and clamping fixing are conducted; (4) fracture surface reexamination is conducted; (5) core concrete is poured; and (6) the compactness is detected and a key part is reinforced.

Owner:SHANDONG UNIV +1

A slow-strength concrete and its application in a/b occlusal piles

ActiveCN107285683BPromote growthWorkability is goodBulkheads/pilesStructural engineeringUltimate tensile strength

The invention provides strength delayed concrete and an application thereof in A / B occlusive piles. In terms of dosage per cubic meter, the strength delayed concrete is prepared from components as follows: 150-350 kg of cement, 180-190 kg of water, 600-900 kg of sand, 1100-1250 kg of pebbles, 50-100 kg of an admixture and 3-7 kg of a retarder. The strength of the strength delayed concrete is increased slowly at the early stage, 7d strength is just 30%-50% of designed strength value under the natural curing condition, 28d strength can reach 100% or higher of the designed strength value, workability is good, and pouring is compacter. With application of the strength delayed concrete to the A / B occlusive piles, a pile A can be subjected to rotary excavating and cutting smoothly, and requirements of the pile A for soil blocking and water stopping can be met.

Owner:GUANGXI METALLURGICAL CONSTR

A prefabricated shear wall with cast-in-place connection

ActiveCN105604208BEasy constructionNo increase in costConstruction materialWallsThreaded pipeEngineering

The invention relates to a prefabricated shear wall in a cast-in-situ connection mode. The prefabricated shear wall comprises a wall, pier heads, bottom upper concave sections and a bottom outer side plate. Side edges are respectively arranged on two sides of the wall, and a groove is formed in the middle of each side edge and is vertically perforated through the wall; wall vertical reinforcing bars are arranged in the wall; the bottom upper concave sections are uniformly distributed at the bottom of the wall; each pier head is arranged between the two corresponding adjacent bottom upper concave sections; air holes are formed in positions above the middles of the bottom upper concave sections; the air holes are communicated with the bottom upper concave sections via pipelines; the thicknesses of the pier heads are identical to the thickness of the wall, and holes are formed in the pier heads; the bottom outer side plate and the wall are integrated with each other, and the bottom outer side plate is positioned on the outer sides of the bottom upper concave sections; internally threaded pipes are embedded in positions close to the side edges of the wall, above the bottom upper concave sections and on the pier heads. The prefabricated shear wall in the cast-in-situ connection mode has the diversified advantages of firm structure, convenience in construction, reliability in connection and the like.

Owner:HUA HUI ENGINEERING DESIGN GROUP CO LTD

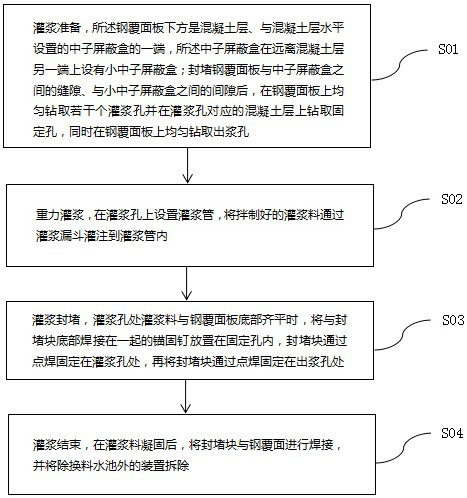

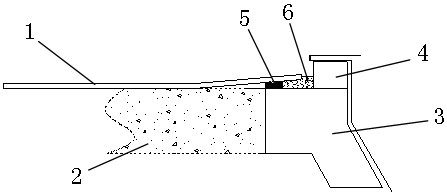

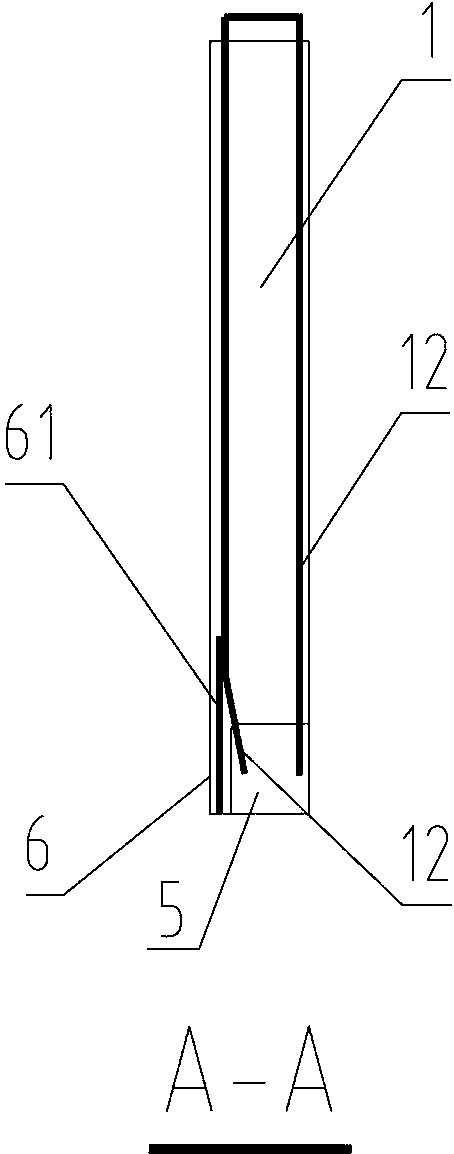

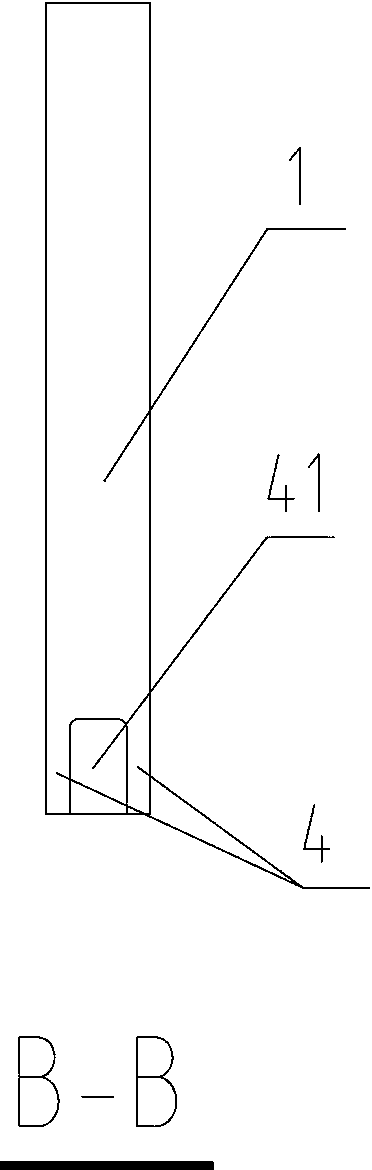

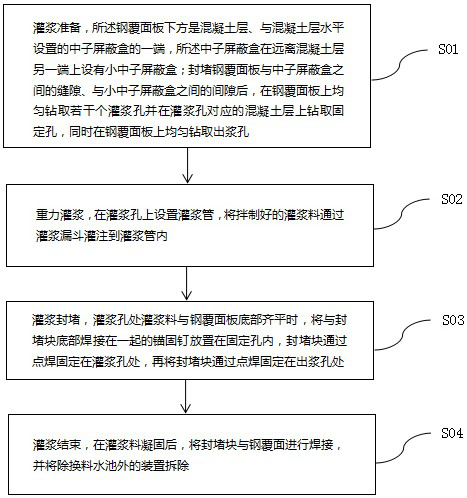

Method for arching treatment of steel clad panel of refueling pool of nuclear power plant

ActiveCN112196269AAchieve drillingPrecise drillingBuilding material handlingIndustrial buildingsNuclear plantSlurry

The invention provides a method for arching treatment of a steel clad panel of a refueling pool of a nuclear power plant, and relates to the field of nuclear power plant maintenance. The method specifically comprises the steps that S01, grouting preparation is carried out, specifically, a plurality of grouting holes are uniformly drilled in the steel clad panel and fixing holes are drilled in a concrete layer corresponding to the grouting holes, and slurry holes are uniformly drilled at the same time; S02, gravity grouting is carried out, specifically, grouting pipes are arranged on the grouting holes, and mixed grouting materials are poured into the grouting pipes through grouting funnels; S03, grouting plugging is carried out, specifically, anchoring nails welded to the bottoms of plugging blocks are placed in the fixing holes, and the plugging blocks are fixed to the grouting holes and grout outlet holes through spot welding; and S04, grouting is finished, after the grouting materials are solidified, the plugging blocks and the steel covering surface are welded, and devices except the refueling pool are disassembled. The gap between the steel clad panel and the concrete layer below the steel clad panel due to arching is evenly filled, and it is ensured that the steel clad panel does not deform and is good in sealing performance.

Owner:SANMEN NUCLEAR POWER CO LTD

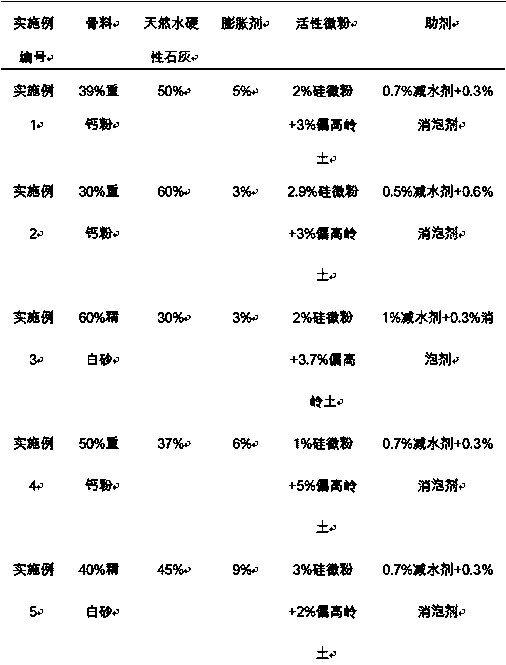

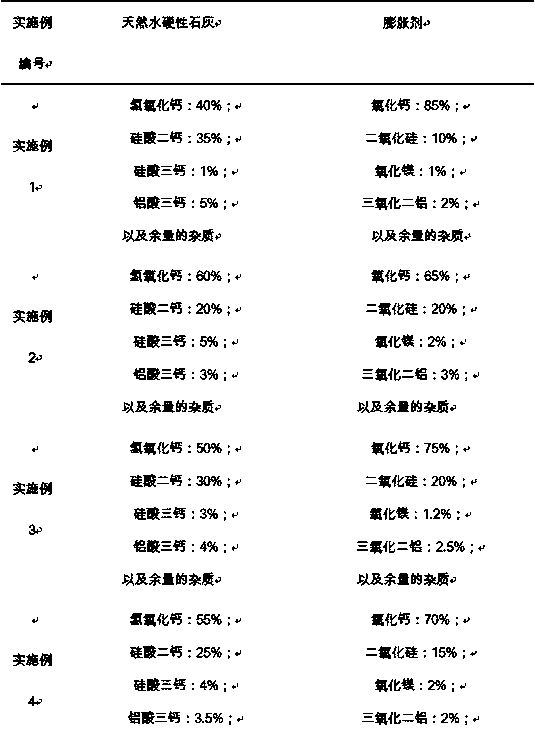

A kind of lime-based micro-shrinkage grouting material composition and preparation method thereof

The invention discloses lime-based micro-contraction grouting material composition and relates to the technical field of materials for brick and stone historical relic protection. The composition is prepared from components in percentage by weight as follows: 30%-60% of aggregate, 30%-60% of natural hydraulic lime, 3%-9% of an expanding agent, 3%-8% of active micropowder and 0.8%-1.6% of an auxiliary. The micro-contraction grouting material has good compatibility with traditional brick and stone materials in physical and chemical property as well as relatively high strength, besides, micro volume expansion can be produced after the grouting material is poured into gaps due to reasonable introduction of the expanding agent, so that the grouting material can be closely combined with bricks and stone serving as a base material, and more compact grouting is realized.

Owner:浙江德赛堡建筑材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com