An underwater concrete pouring device and construction method and its application in super large deep water caisson foundation

A technology of underwater concrete and construction methods, which is applied in basic structure engineering, caissons, buildings, etc., can solve the problems of no strength, economic decline of underwater structure construction, limited impact of post-poured concrete, etc., and achieve good fluidity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

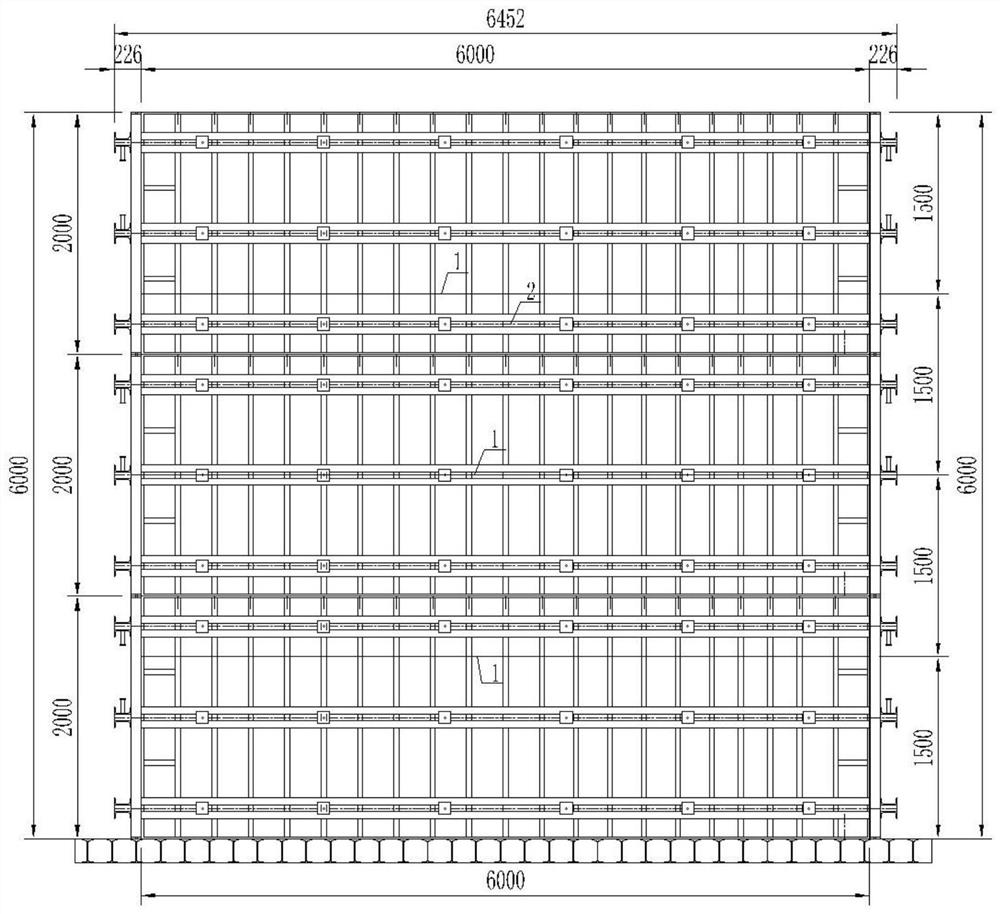

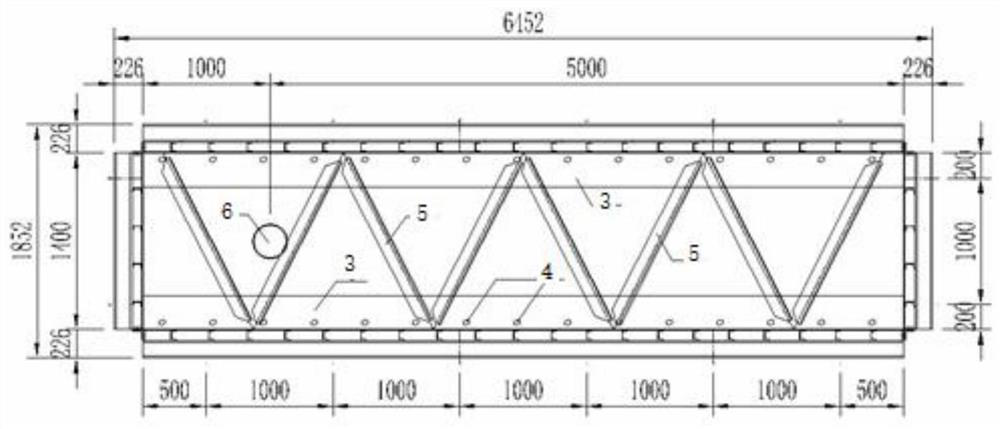

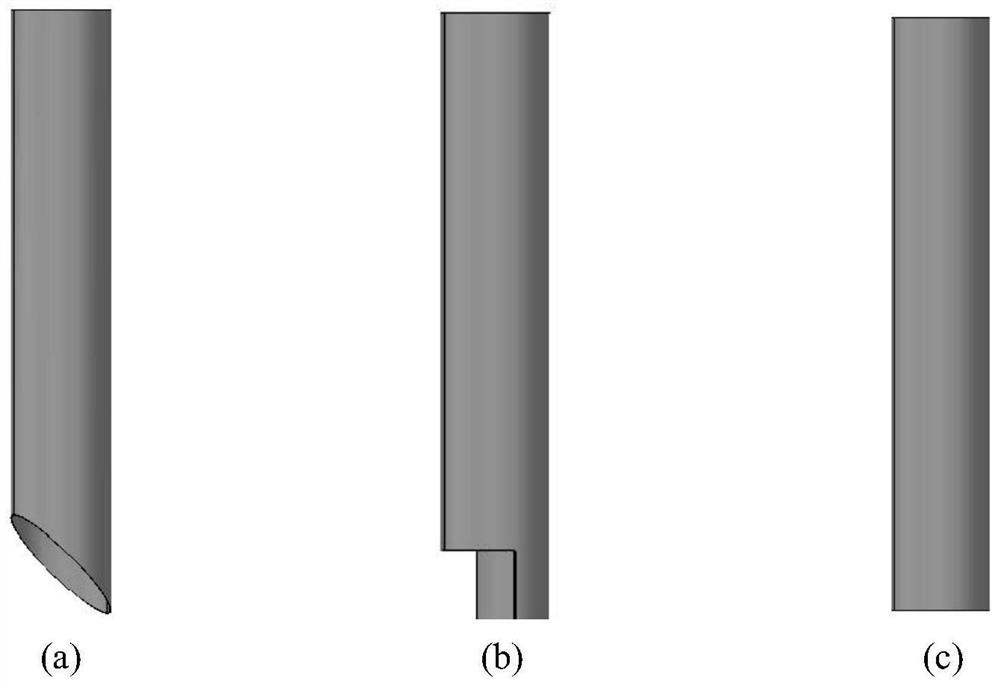

[0044] Such as figure 1 and figure 2 As shown, a full-scale model test simulating an actual project is carried out to evaluate the implementation effect of the underwater concrete construction method for the ultra-large deep-water caisson foundation provided by the present invention. The net size of the model is 6m (length) × 6m (height) × 1.4m (width). The interior is equipped with a horizontal truss composed of an 8mm thick ring plate with a 55mm@400mm overflow hole and an angle steel plate of ∠75×6mm. It is temporarily welded with side forms to form an integral structure. A total of 3 horizontal trusses are arranged in the height direction of the model, with a spacing of 1500mm. One side of the ring plate is welded to the formwork panel, and the other side of the ring plate is not welded to the formwork panel. A 325mm perfusion catheter is set on one side of the model, and the opening at the bottom of the catheter is as follows: image 3 As shown in (a), it is the obliq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com