A slow-strength concrete and its application in a/b occlusal piles

A concrete and retarder technology, applied in sheet pile walls, foundation structure engineering, construction, etc., can solve the problem that the initial setting time of ultra-retarded concrete cannot meet the expected requirements, and the A pile rotary excavation is difficult to cut and cannot reach Concrete strength growth and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

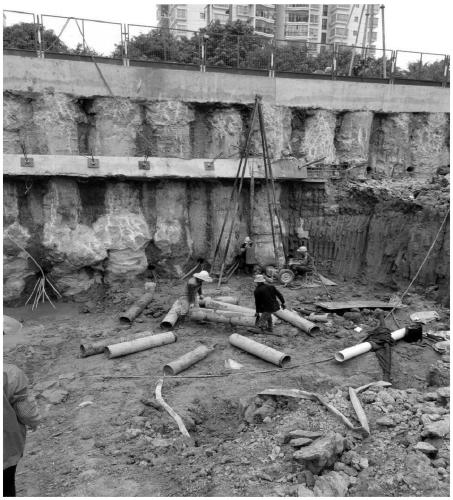

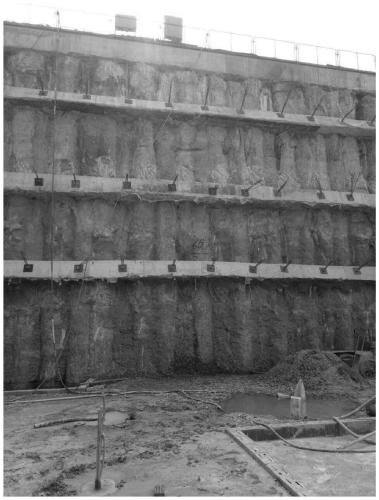

Image

Examples

Embodiment 1

[0072] On a unilateral basis, cement 199kg, water 185kg, river sand (0.25mm in diameter) 850kg, stones (5mm in diameter) 1126kg, retarder (purchased from Guangxi Dahai Building Materials Co., Ltd., model CX-1 efficient retarding water reducing Mixing agent) 3.98kg, bentonite 50kg, mix evenly to get slow-strength concrete with strength grade C10.

Embodiment 2

[0074] On a unilateral basis, according to 253kg of cement, 185kg of water, 750kg of river sand (0.5mm in particle size), 1172kg of stones (8mm in particle size), retarder (purchased from Guangxi Dahai Building Materials Co., Ltd., model CX-1 high-efficiency retarding and water-reducing 5.06kg of bentonite and 65.78kg of bentonite are mixed, and the strength grade is C15 slow-strength concrete after mixing evenly.

Embodiment 3

[0076] On a unilateral basis, according to cement 330kg, water 185kg, sea sand (particle size 0.5mm) 641kg, gravel (particle size 10mm) 1244kg, retarder (purchased from Guangxi Dahai Building Materials Co., Ltd., model CX-1 efficient retarding water reducing Mixing agent) 6.6kg, bentonite 85.8kg, and after mixing evenly, the strength grade is C20 slow-strength concrete.

[0077] The slow-strength concrete obtained in Examples 1-3 is naturally cured, and its strength grade, 7d and 28d compressive strength, slump, density and setting time are measured, and the obtained results are shown in Table 1;

[0078] Table 1 Example 1 ~ 3 obtained slow strength concrete detection data

[0079]

[0080] According to the data in Table 1, it can be seen that the 7d strength of the slow-strength concrete provided by the present invention is relatively small, only 30% to 50% of the design strength value, and the 28d strength can reach more than 100% of the design value, and the slump is sma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com