A pouring method of concrete in the cross brace tube between arch ribs of steel pipe bridge

A technology of concrete and cross braces, which is applied in the construction of arch bridges, bridges, bridges, etc., can solve the problems of long construction period and poor safety, and achieve the effect of reducing operation steps, improving safety and facilitating on-site construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

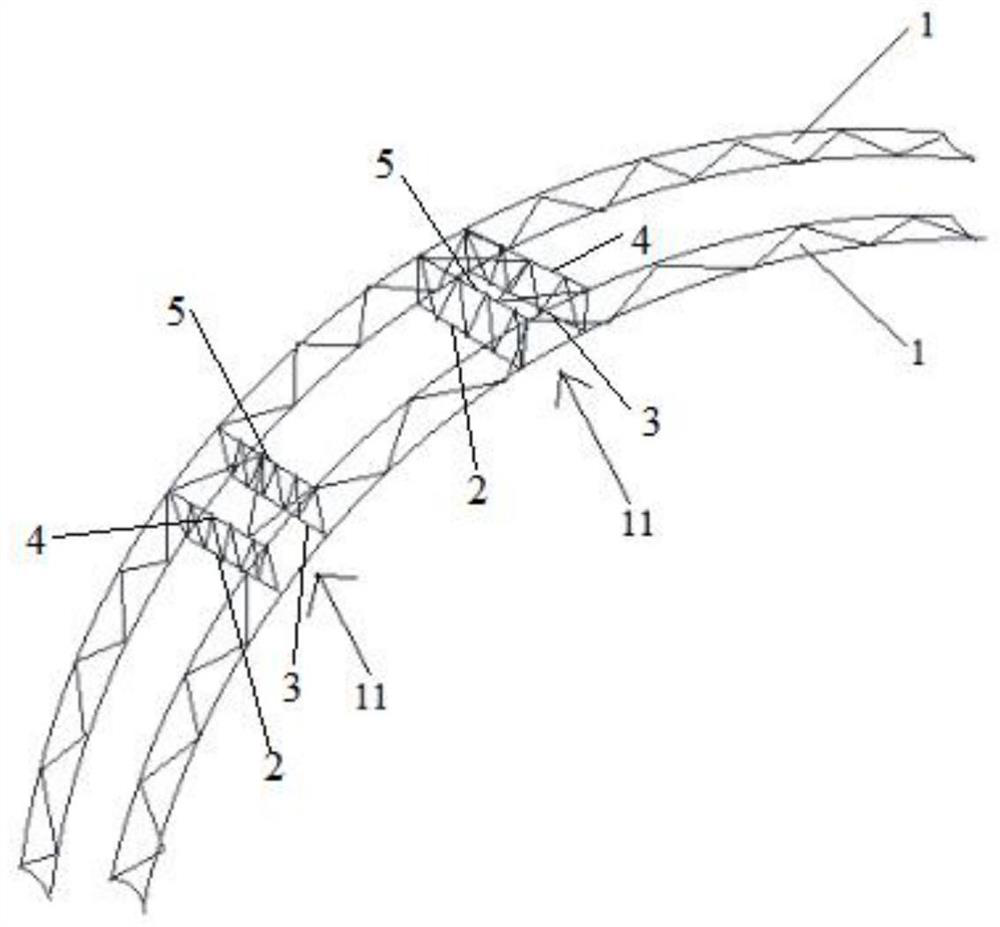

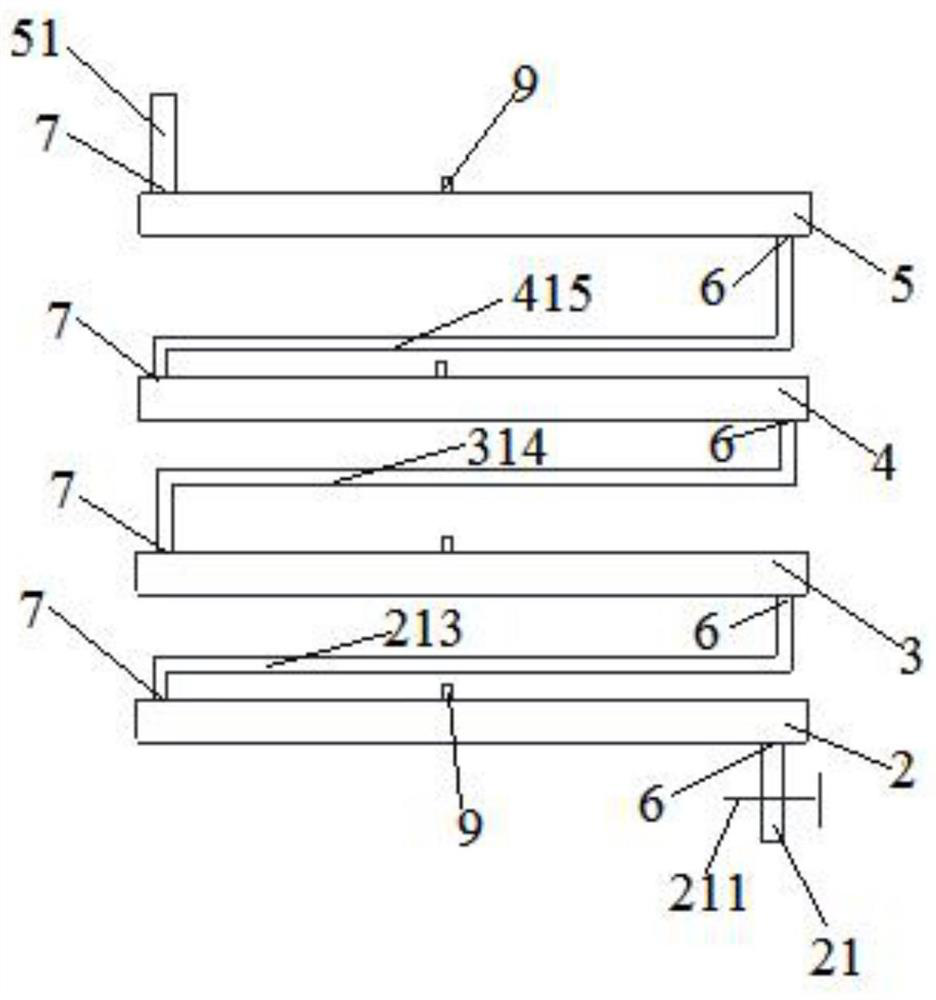

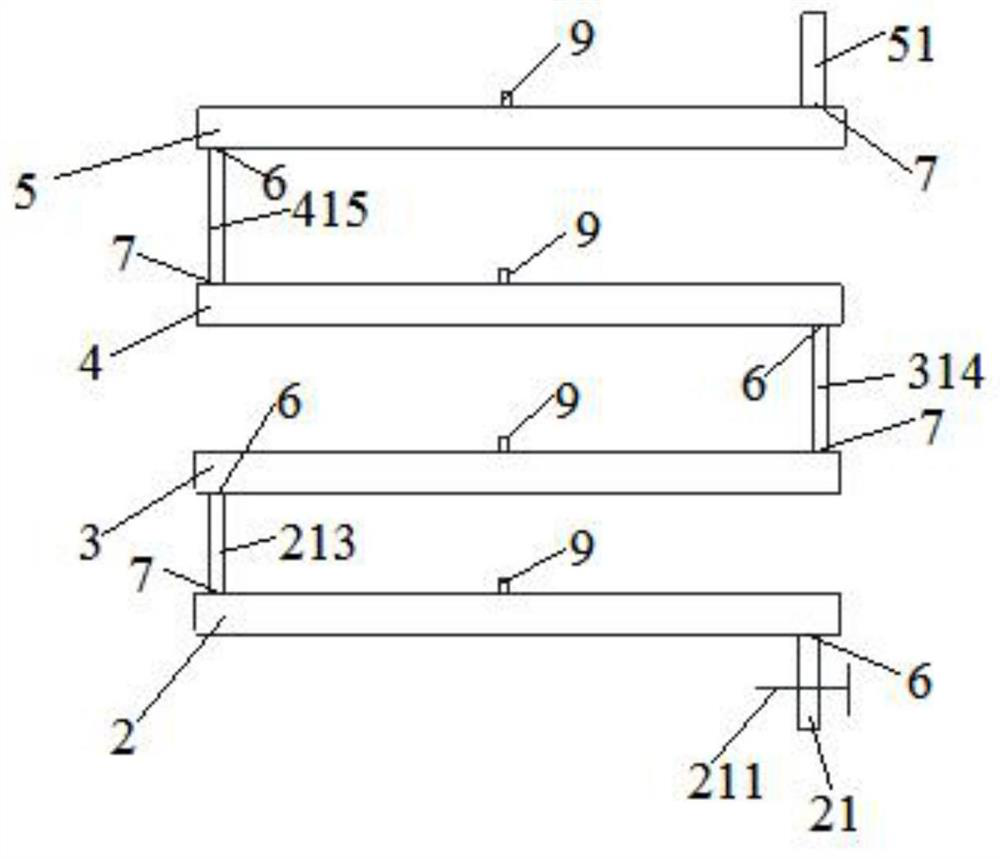

[0042] A steel pipe arch bridge has a total of nine cross-bracing tube assemblies between two arch ribs. The cross-bracing pipe assembly is composed of four cross-bracing pipes. The two ends of the cross-bracing pipes are respectively connected to the two arch ribs 1 of the steel pipe bridge; The four horizontal tubes in each horizontal tube assembly are the first horizontal tube 2, the second horizontal tube 3, the third horizontal tube 4 and the fourth horizontal tube 5 according to the elevation from bottom to top. The bridge has a total of thirty-six transverse braces. Such as figure 1 As shown, it is a structural schematic diagram of the environmental position relationship of the transverse brace tubes between the arch ribs of some steel pipe bridges. figure 2 and image 3 The elevation position relationship of four cross-stay pipes in one cross-stay pipe assembly can be shown in .

[0043] The bridge site of a steel pipe arch bridge construction project is located di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com