Patents

Literature

45results about How to "Uniform flow velocity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

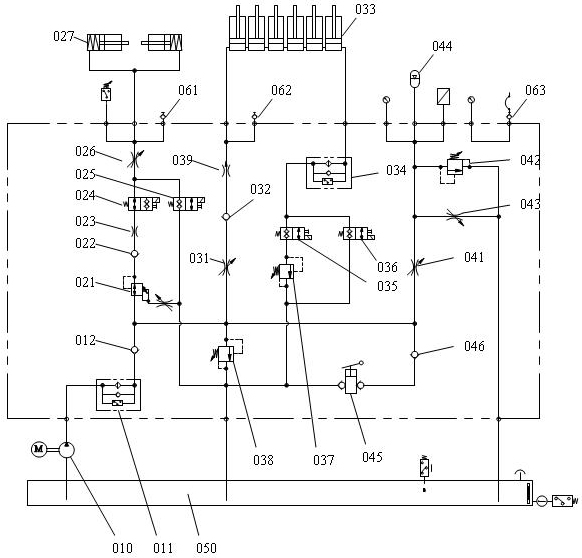

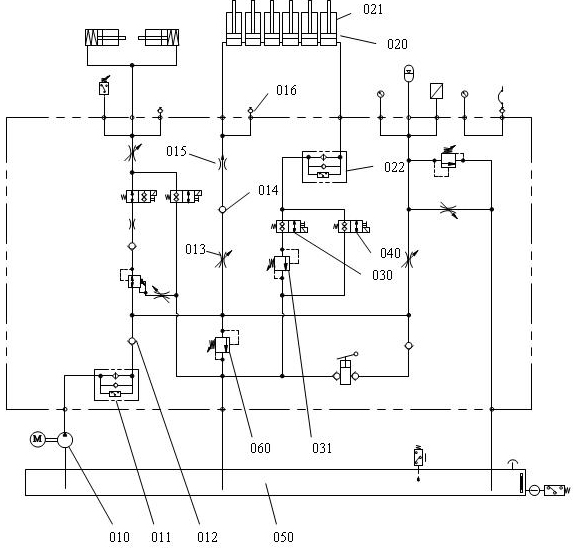

Wind power generation hydraulic system

InactiveCN101979870AUniform flow velocitySmooth brakingWind motor controlServomotorsSystem pressureFuel tank

The invention discloses a wind power generation hydraulic system, which comprises an oil pump, an external oil tank, a spindle brake unit, yawing brake unit and a safe pressure maintaining unit, wherein the oil pump is connected with a spindle brake oil cylinder group through a reducing valve and a first electromagnetic valve, connected with a yawing brake oil cylinder group through a first adjustable throttle, and connected with an energy accumulator through a second adjustable throttle by the same pipeline; the spindle brake oil cylinder group is connected with the external oil tank through a pipeline; the yawing brake oil cylinder group is connected with the external oil tank through a third electromagnetic valve and a first overflow valve by a pipeline; the energy accumulator is connected with the external oil tank through a third overflow valve by a pipeline; and the external oil tank is connected with the yawing brake oil cylinder group through a second overflow valve and the first adjustable throttle by a pipeline. The wind power generation hydraulic system can perform spindle brake and yawing brake, and is provided with the system pressure maintaining device.

Owner:SHANGHAI ELECTRICAL HYDRAULICS & PNEUMATICS

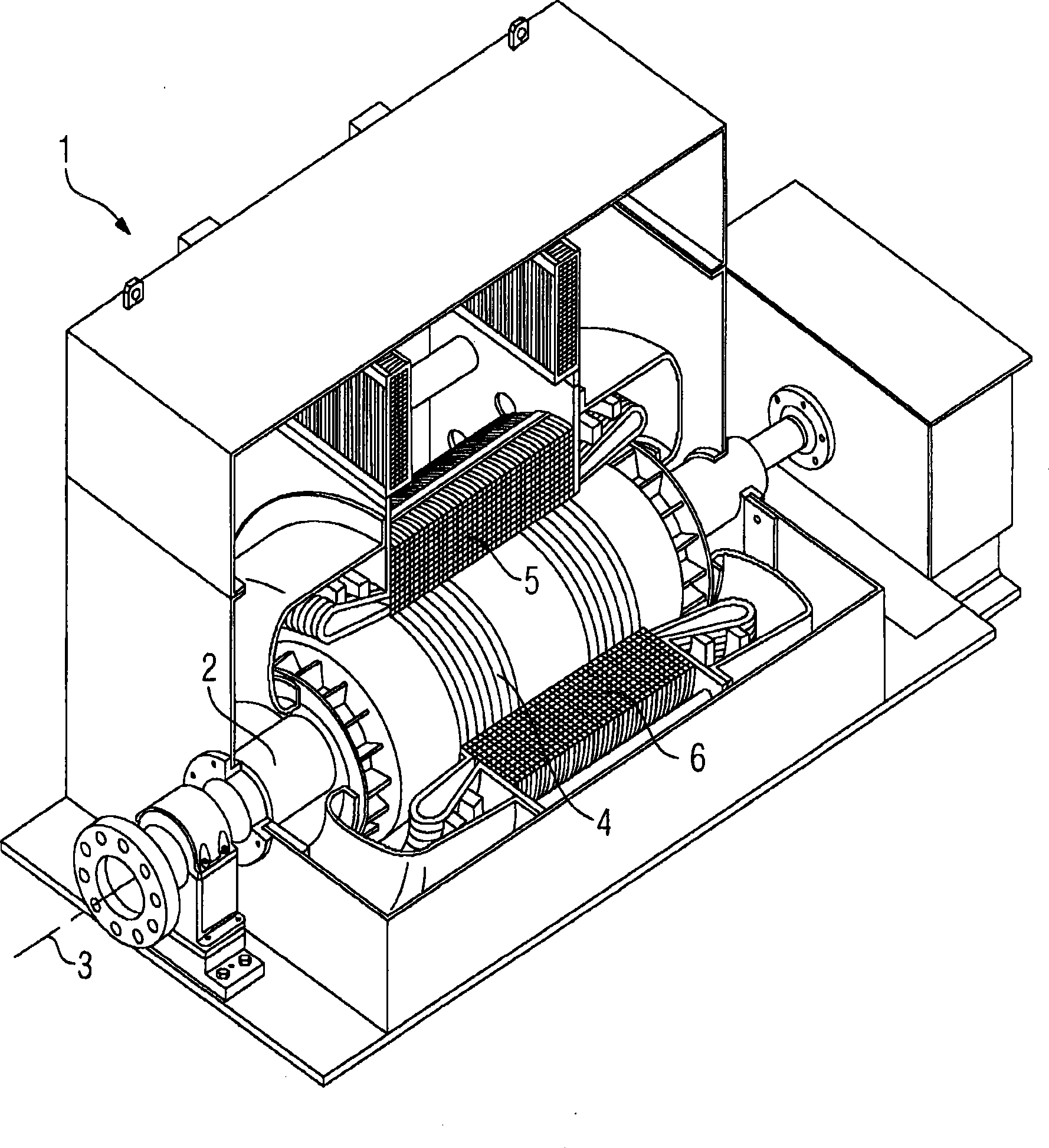

Gas distribution device

InactiveCN105597655ASpeed up the flowUniform flow velocityCatalytic gas-gas reactionChemical/physical/physico-chemical processesEngineering

Owner:BEIJING UNIV OF CHEM TECH

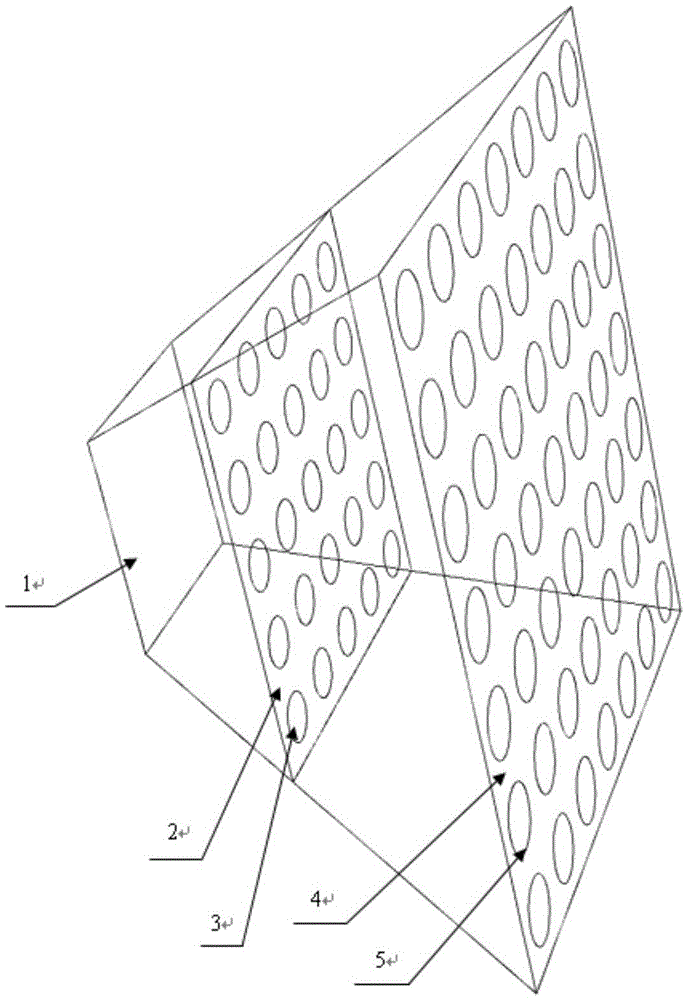

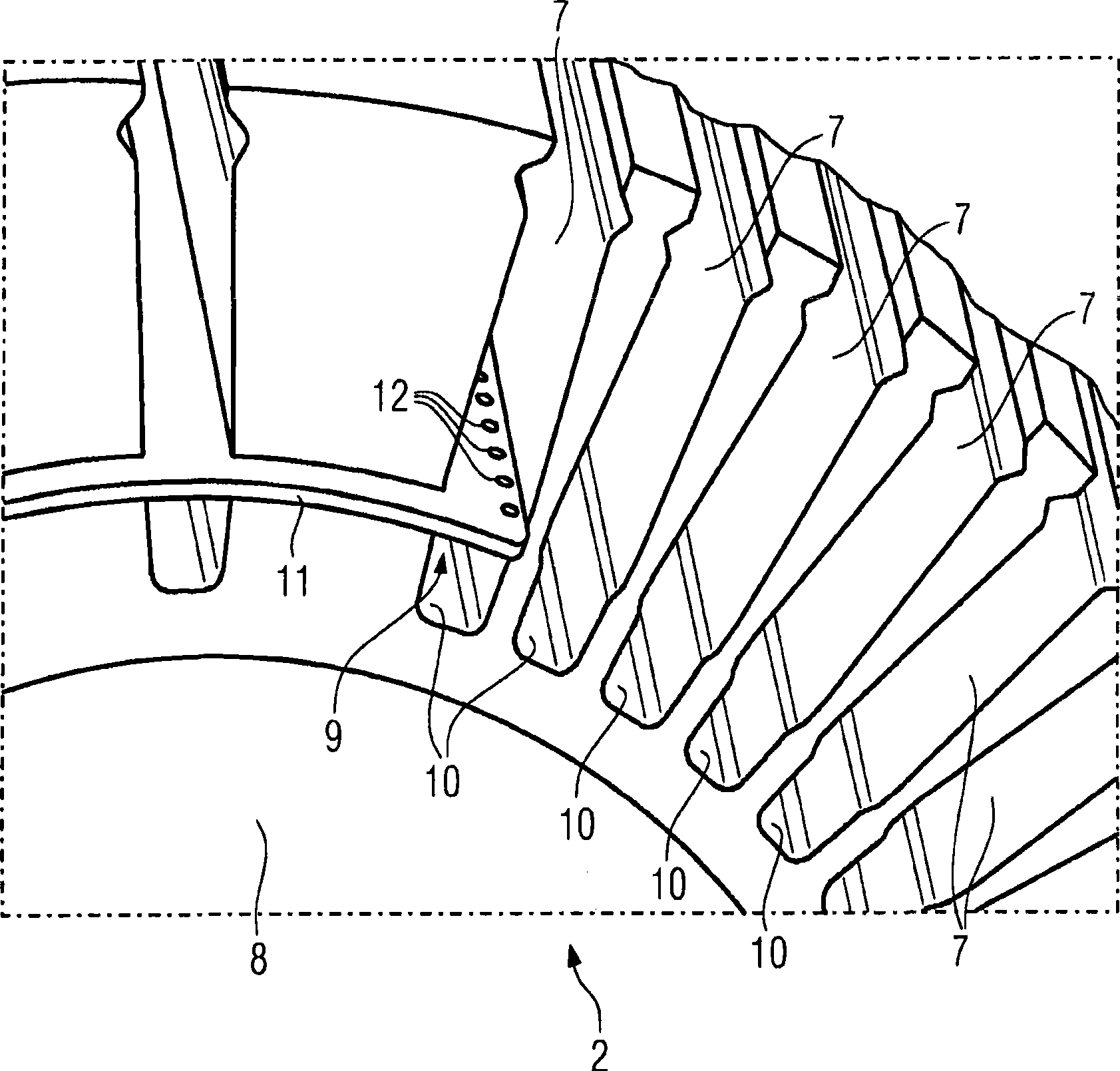

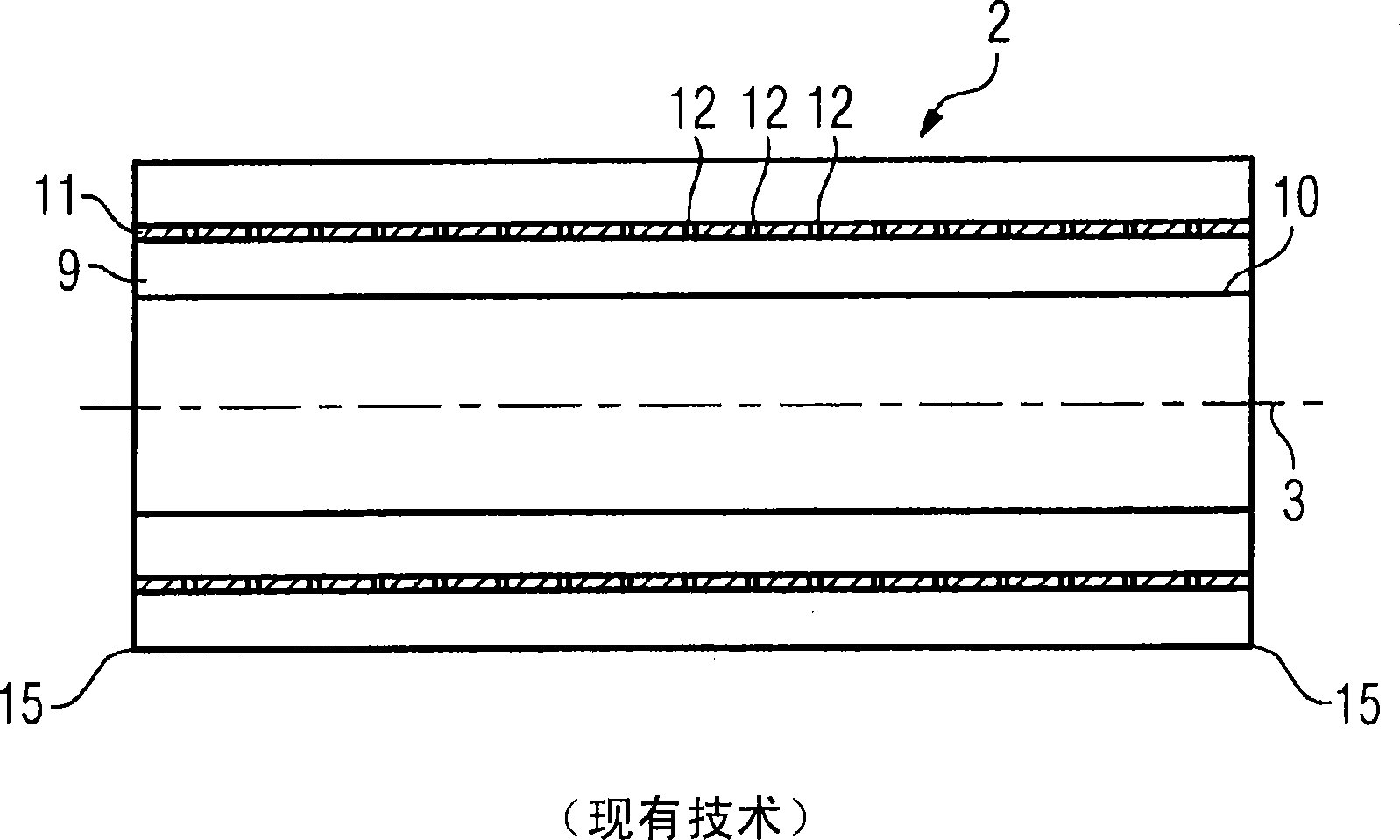

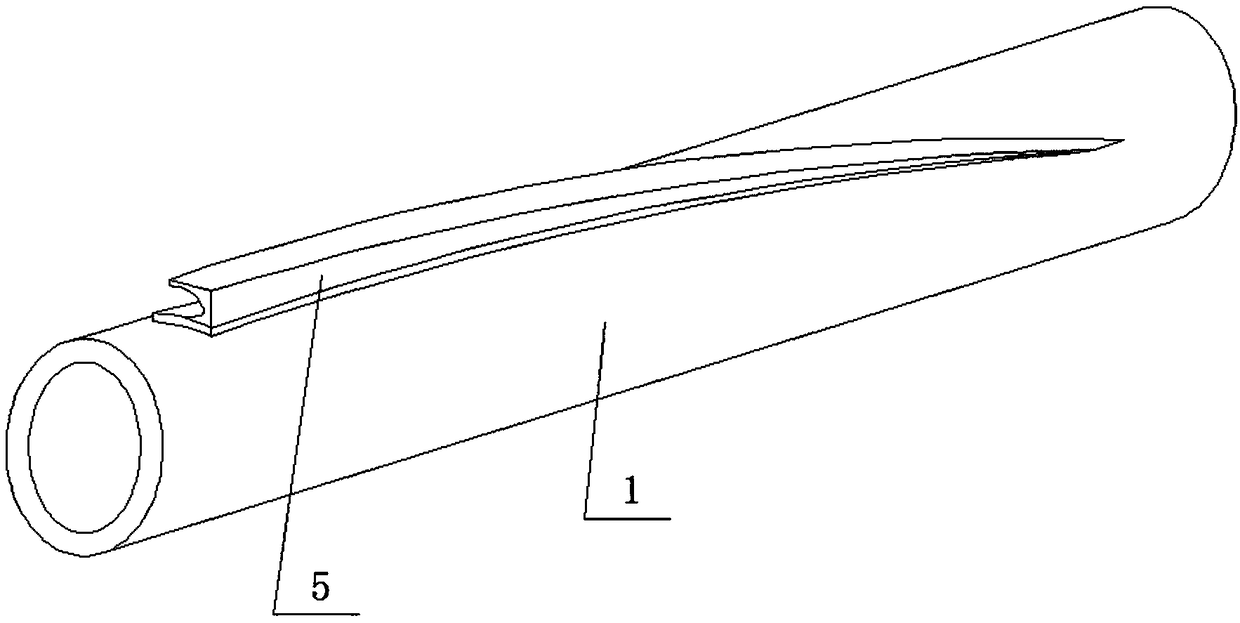

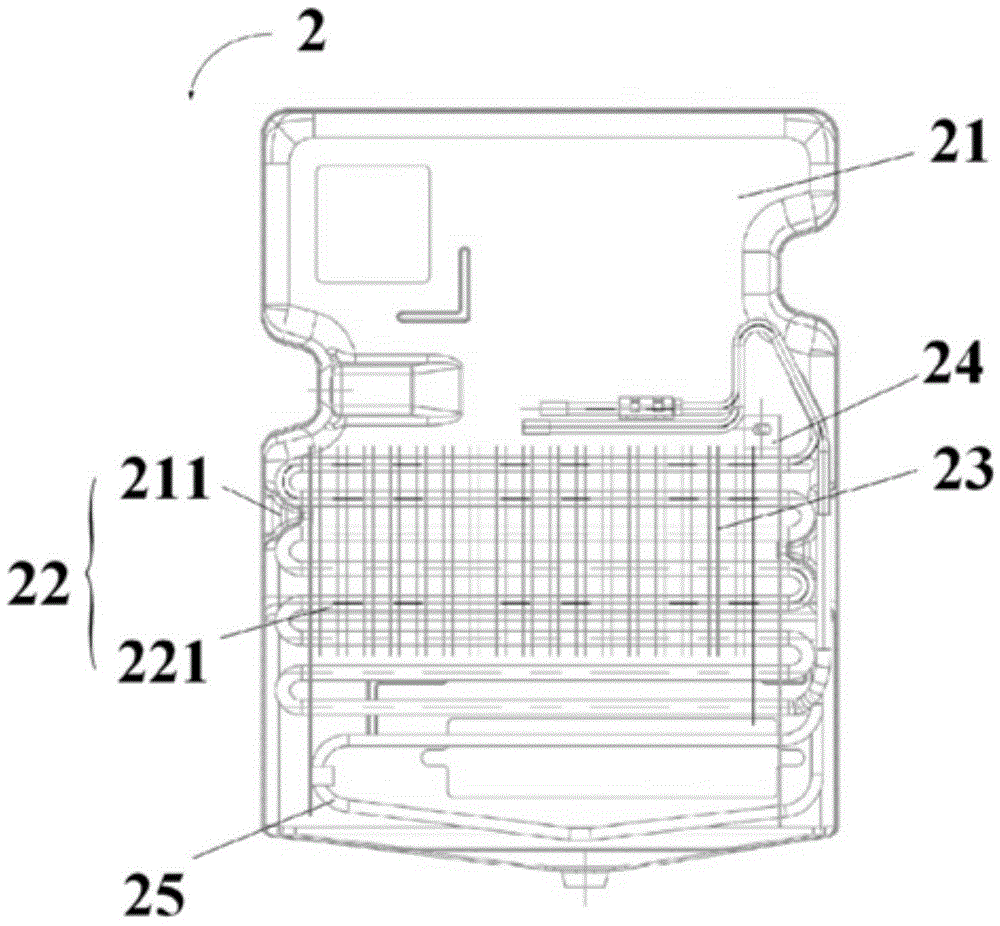

Rotor cooling for a dynamoelectrical machine

ActiveCN101512872AUniform flow velocityExtend your lifeMagnetic circuit rotating partsWindings conductor shape/form/constructionElectrical conductorCooling medium

The invention relates to a rotor (2) for a dynamoelectric machine. A bottom duct (9), through which a cooling medium flows and the conductors (4) are cooled via radial ducts (12) during operation, is disposed in the rotor (2). According to the invention, the bottom duct (9) is embodied such that the cross section thereof decreases towards the center of the rotor (2).

Owner:西门子能源全球两合公司

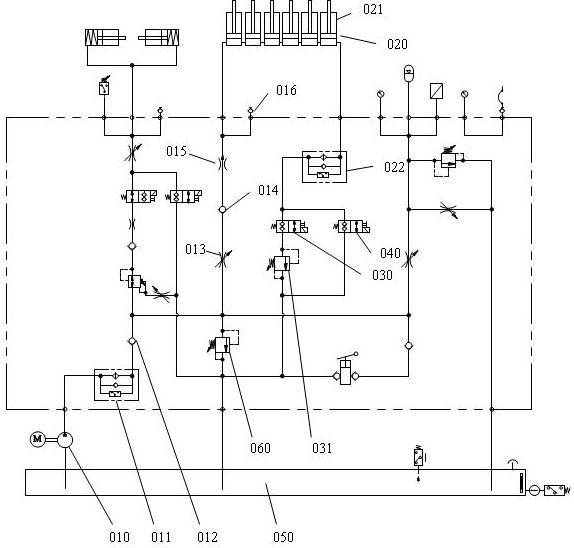

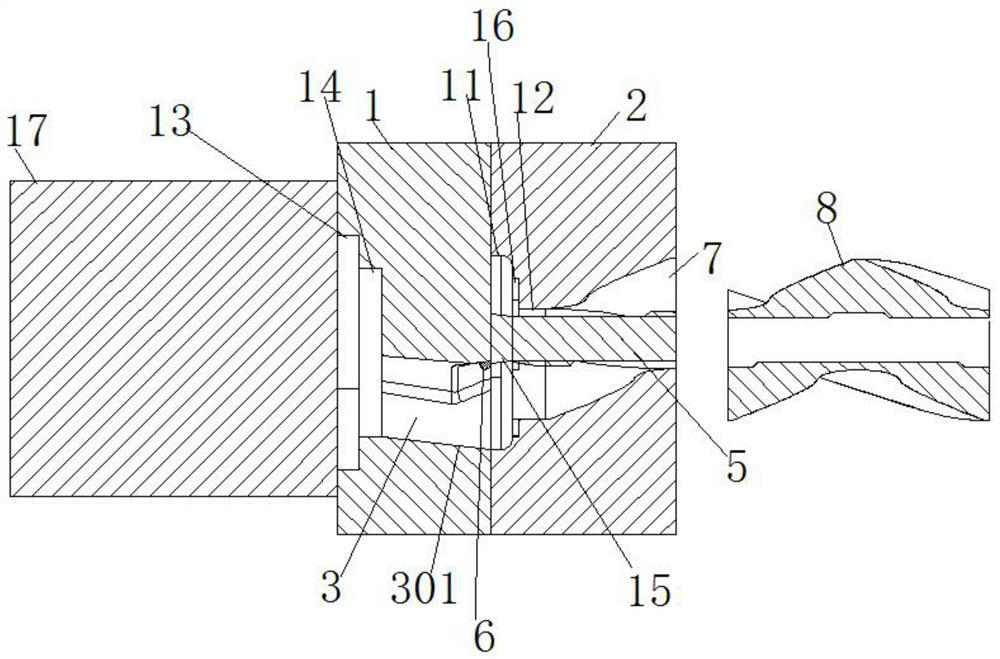

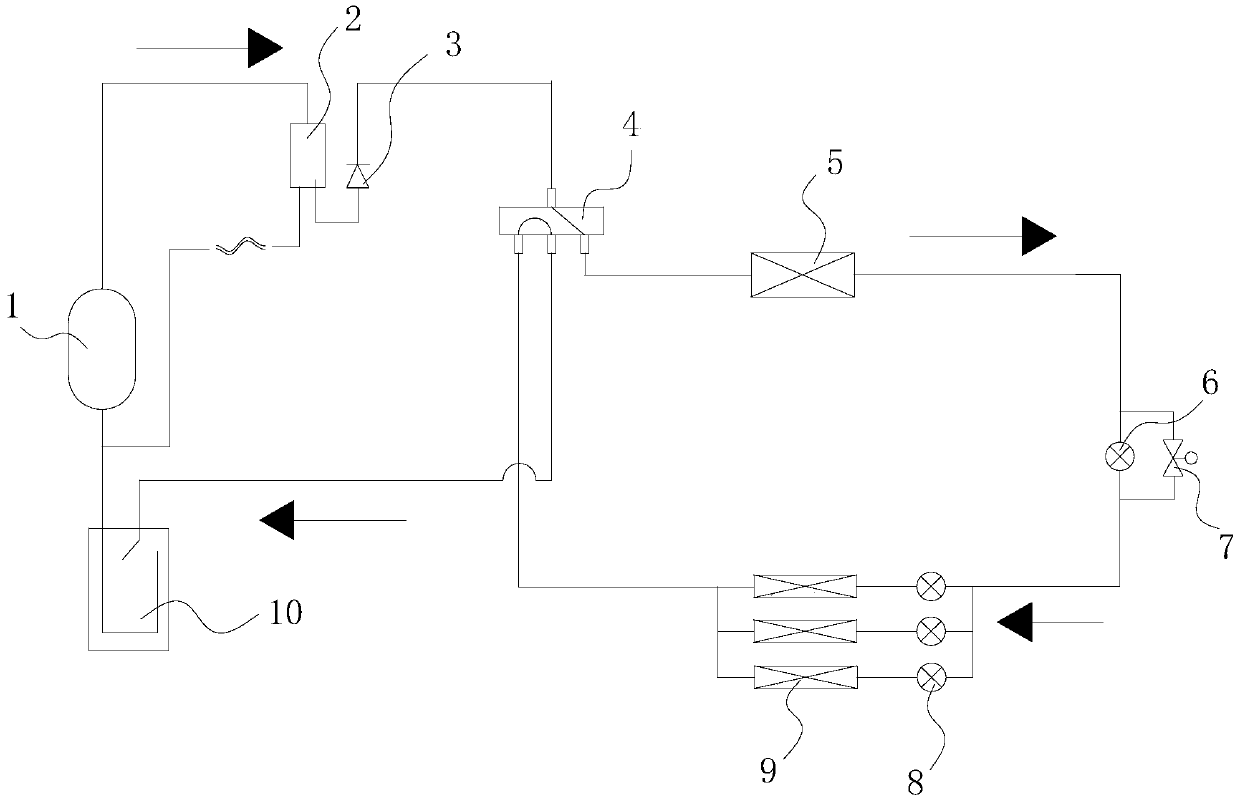

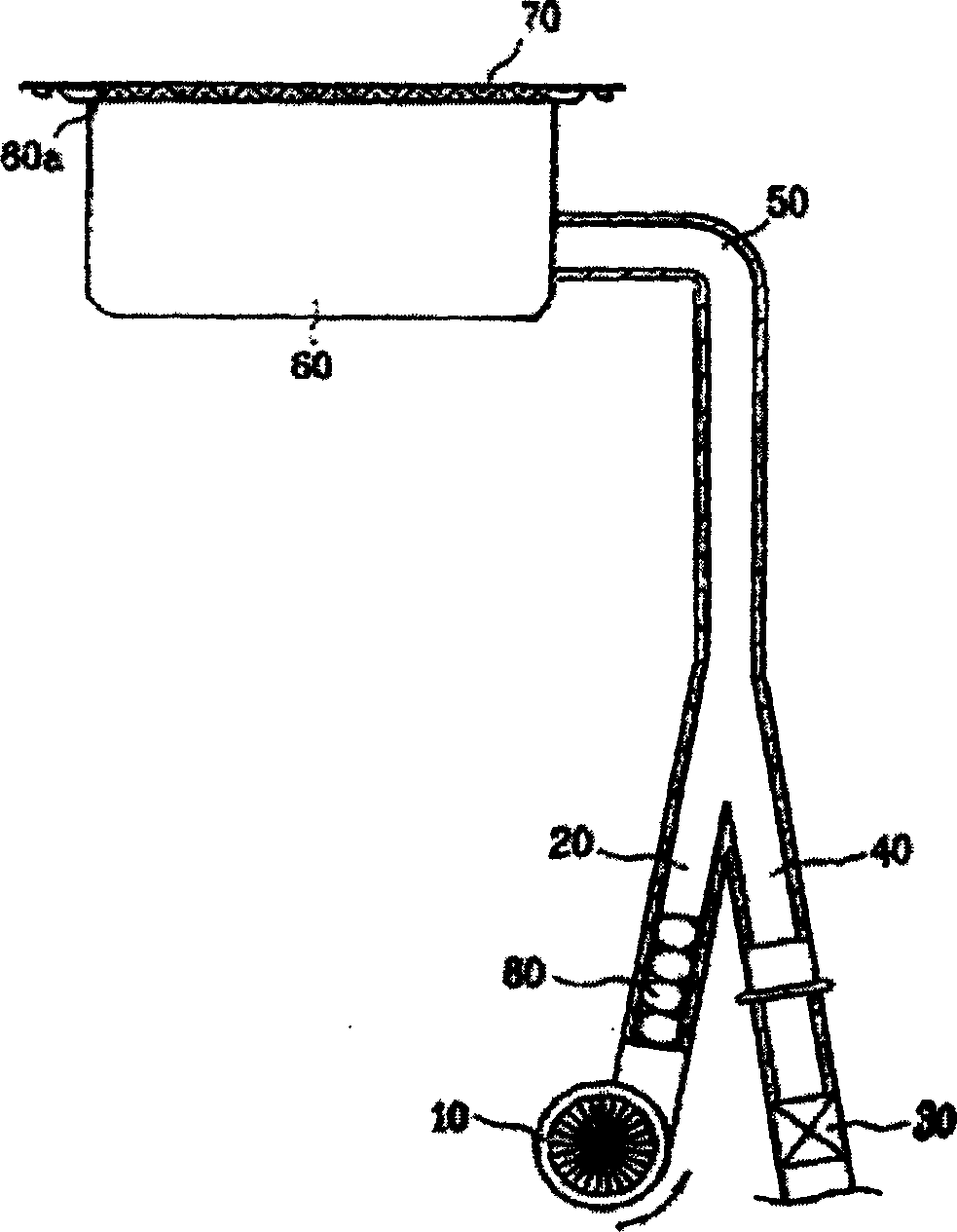

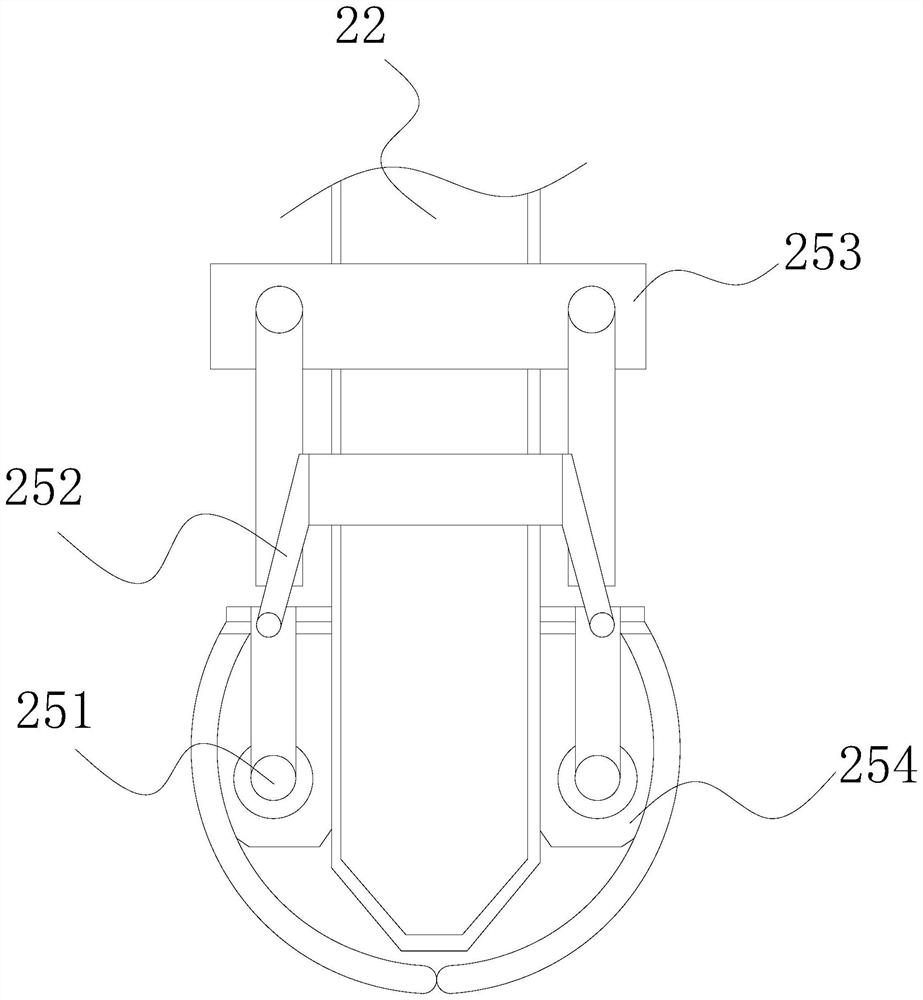

Yaw brake device of wind power generation hydraulic system

InactiveCN101979869AYaw braking smoothUniform flow velocityWind motor controlServomotorsFuel tankWind force

The invention discloses a yaw brake device of a wind power generation hydraulic system, which is applied to the technical field of wind power generation. The yaw brake device comprises an oil pump and an oil cylinder set connected with an oil pump pipeline, wherein the oil cylinder set is connected with an outside oil tank pipeline through a first electromagnetic valve and a first overflow valve in turn; oil cylinders are connected with the outside oil tank pipeline through a second electromagnetic valve; overflow branches connected with the outside oil tank pipeline through a second overflow valve are also arranged on the pipeline between the oil pump and the oil cylinder set; and the oil cylinder set consists of six oil cylinders which are connected in series. In the invention, the first electromagnetic valve is adopted, so that the hydraulic system realizes the yaw of a windmill generator under a backpressure condition, so that working energy consumption is reduced and working efficiency is improved; meanwhile, a throttling valve is adopted to control the pressure and flow rate of the hydraulic oil in a hydraulic pipeline, so that the normal and stable yaw brake of the hydraulic system is guaranteed.

Owner:SHANGHAI ELECTRICAL HYDRAULICS & PNEUMATICS

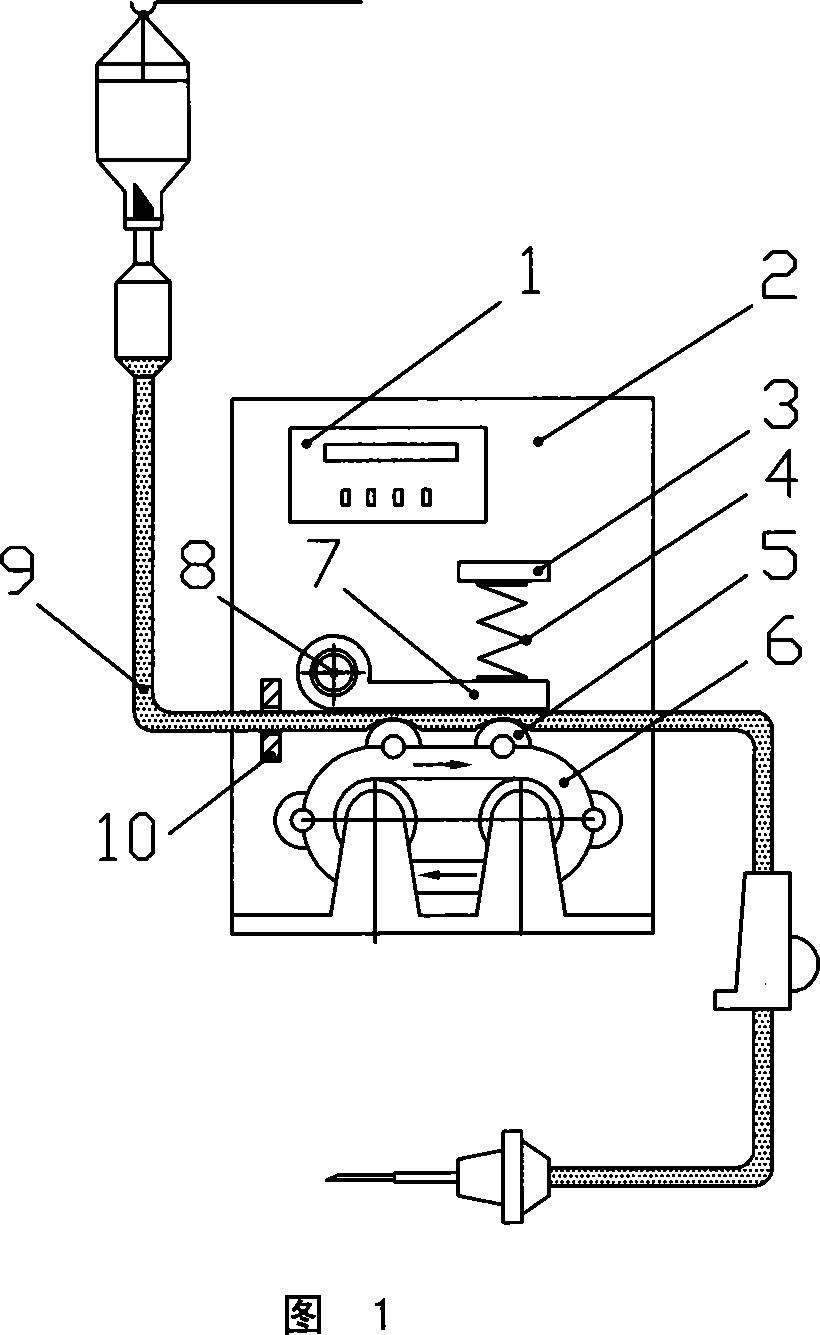

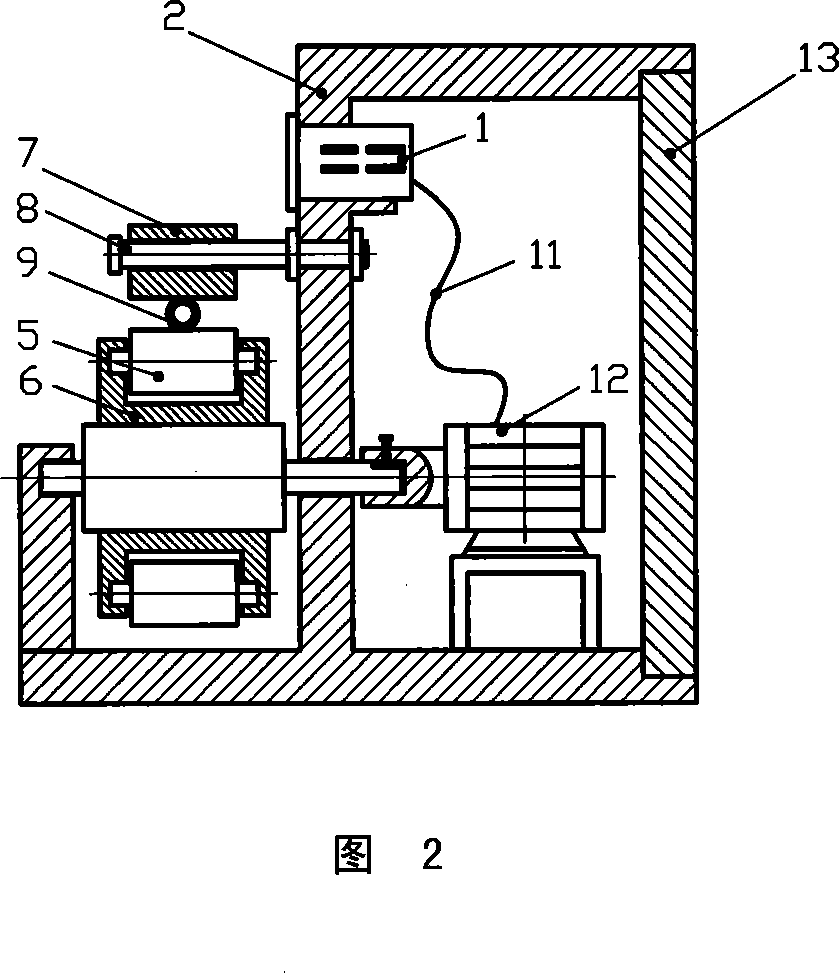

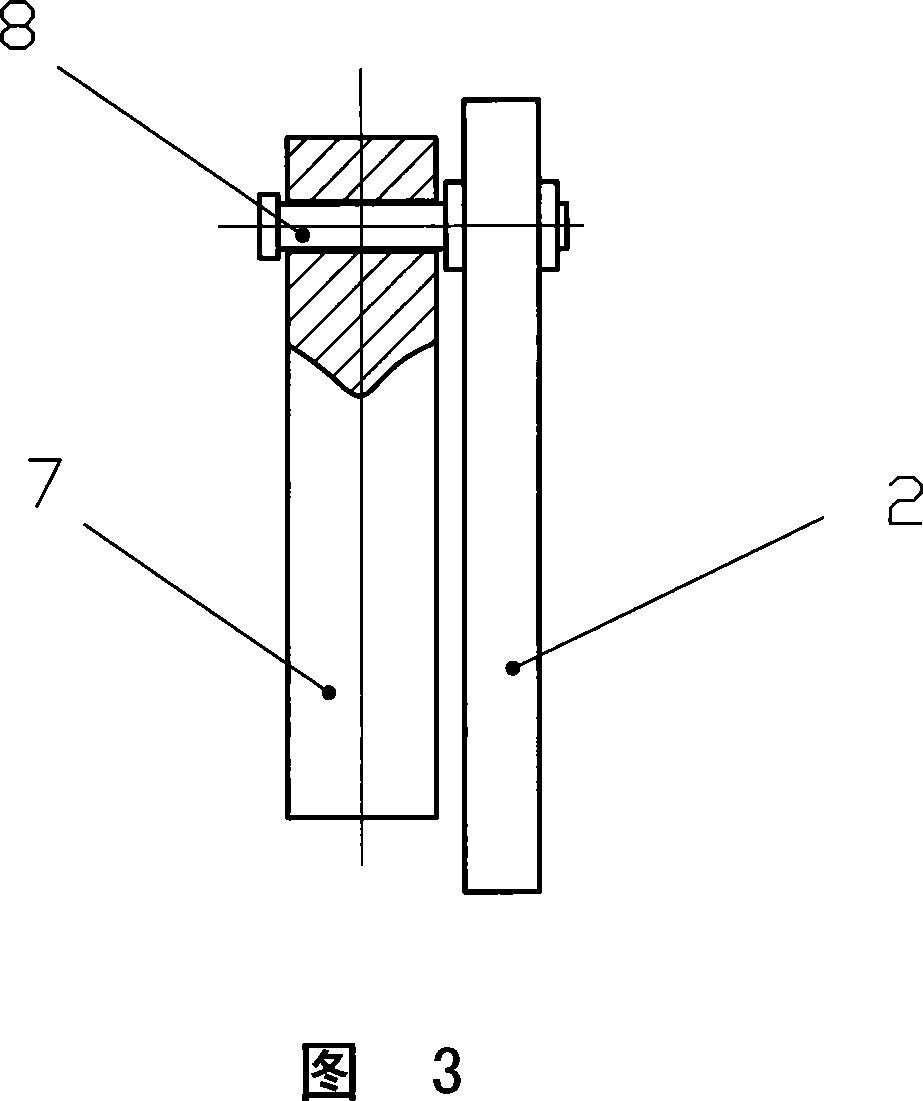

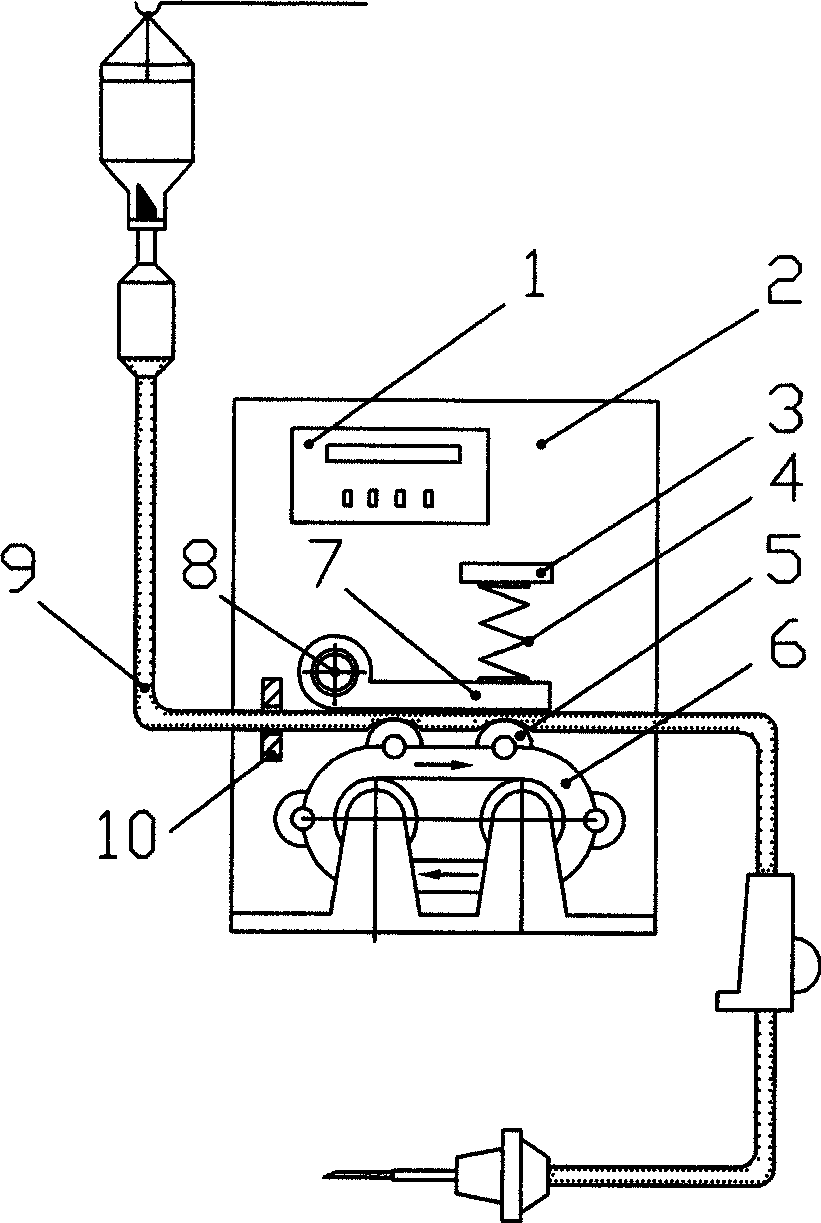

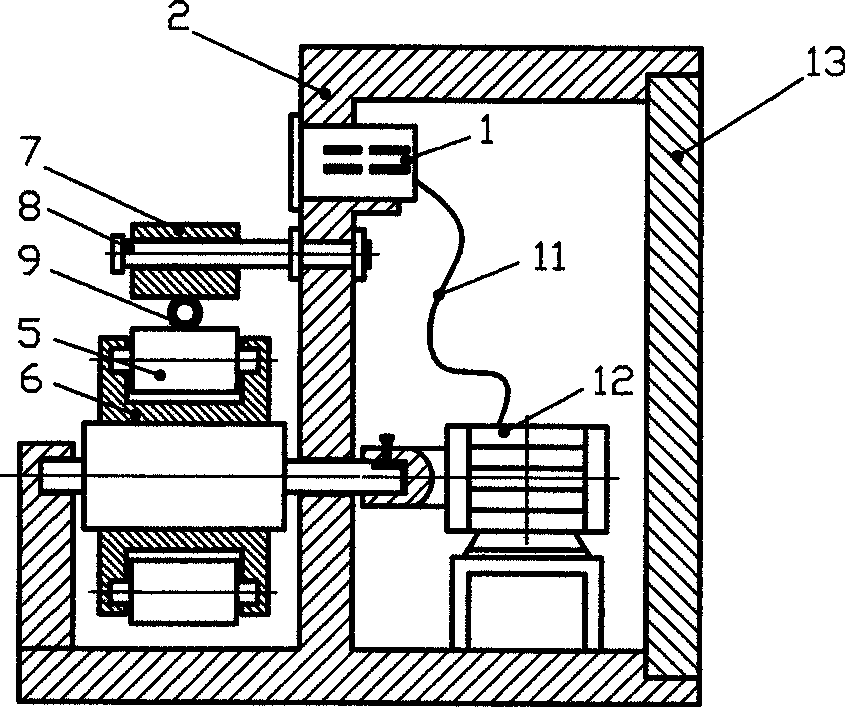

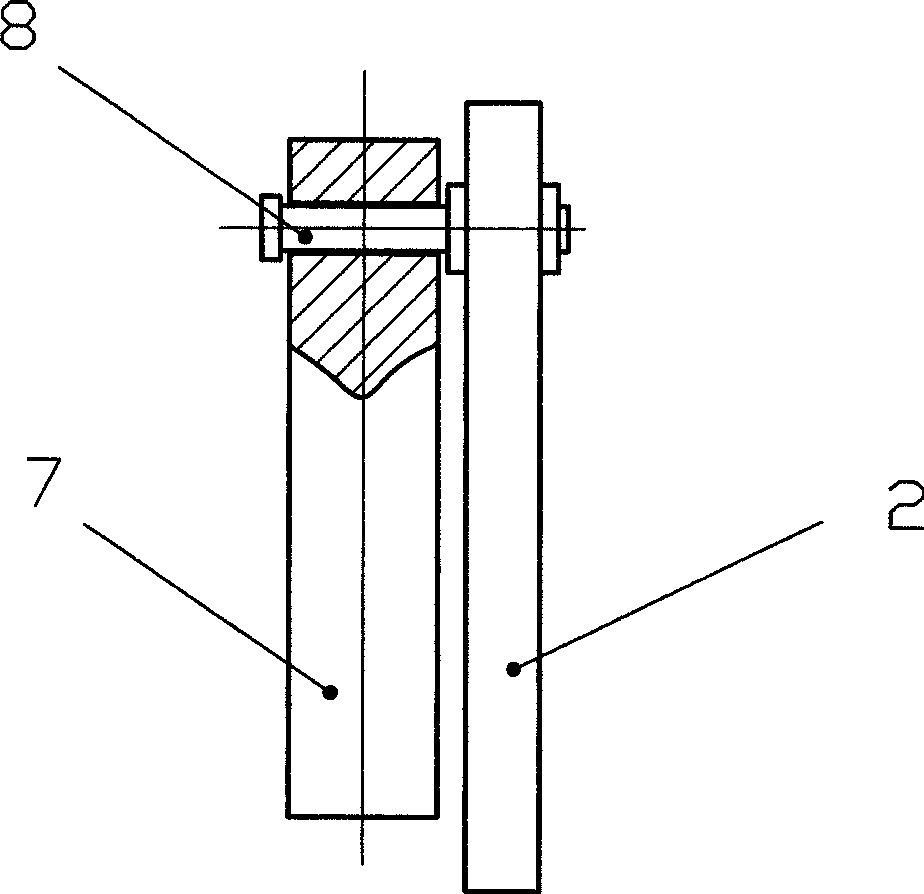

Medicine liquid flow rate controller for infusion set

InactiveCN101066482AGuaranteed equidistant extrusionAvoid Intermittent FluctuationsInfusion devicesFlow controlInfusion setEngineering

The medicine liquid flow rate controller for infusion set includes one casing, one flow pushing device on the casing and with roller, one extruding mechanism matching with the roller in the flow pushing device and mounted on to the casing via a locator for being parallel to the roller, and one elastic unit fixed on the casing and connected to the movable part of the extruding mechanism. The present invention has the features of simple operation, accurate metering, simple structure and low manufacture cost.

Owner:闫云涛

Manufacturing process of X80 steel grade type DN1400 thick-wall tee

InactiveCN105081005AReduce the failure rateUniform flow velocityMeasurement devicesExtrusion diesThick wallThermal treatment

The invention relates to a manufacturing process of an X80 steel grade type DN1400 thick-wall tee. The manufacturing process comprises the following steps: preparing a base material steel tube; performing flaw inspection; performing finite element design for a bulging die; carrying out hot extrusion process; carrying out thermal treatment process; performing the flaw inspection again. With the adoption of the manufacturing process, tee tubes with high steel grade, large aperture and large wall thickness can be manufactured successfully; in addition, the tubes are high in strength, high in impact toughness, and high in resistance to low-temperature facture, and the actual demand on natural gas transportation can be met.

Owner:河北恒通集团宇鹏重工科技有限公司

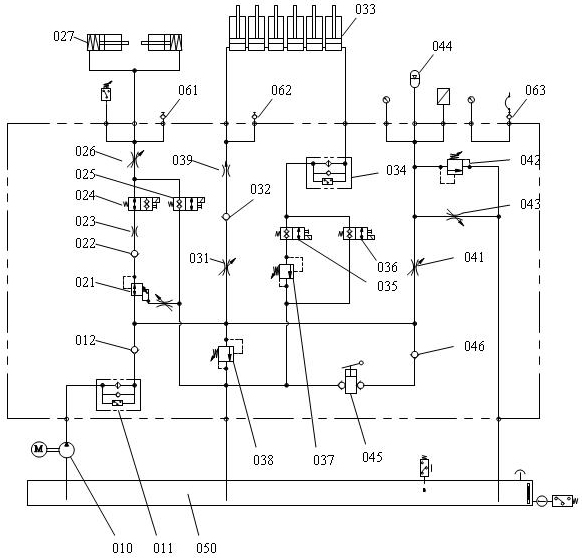

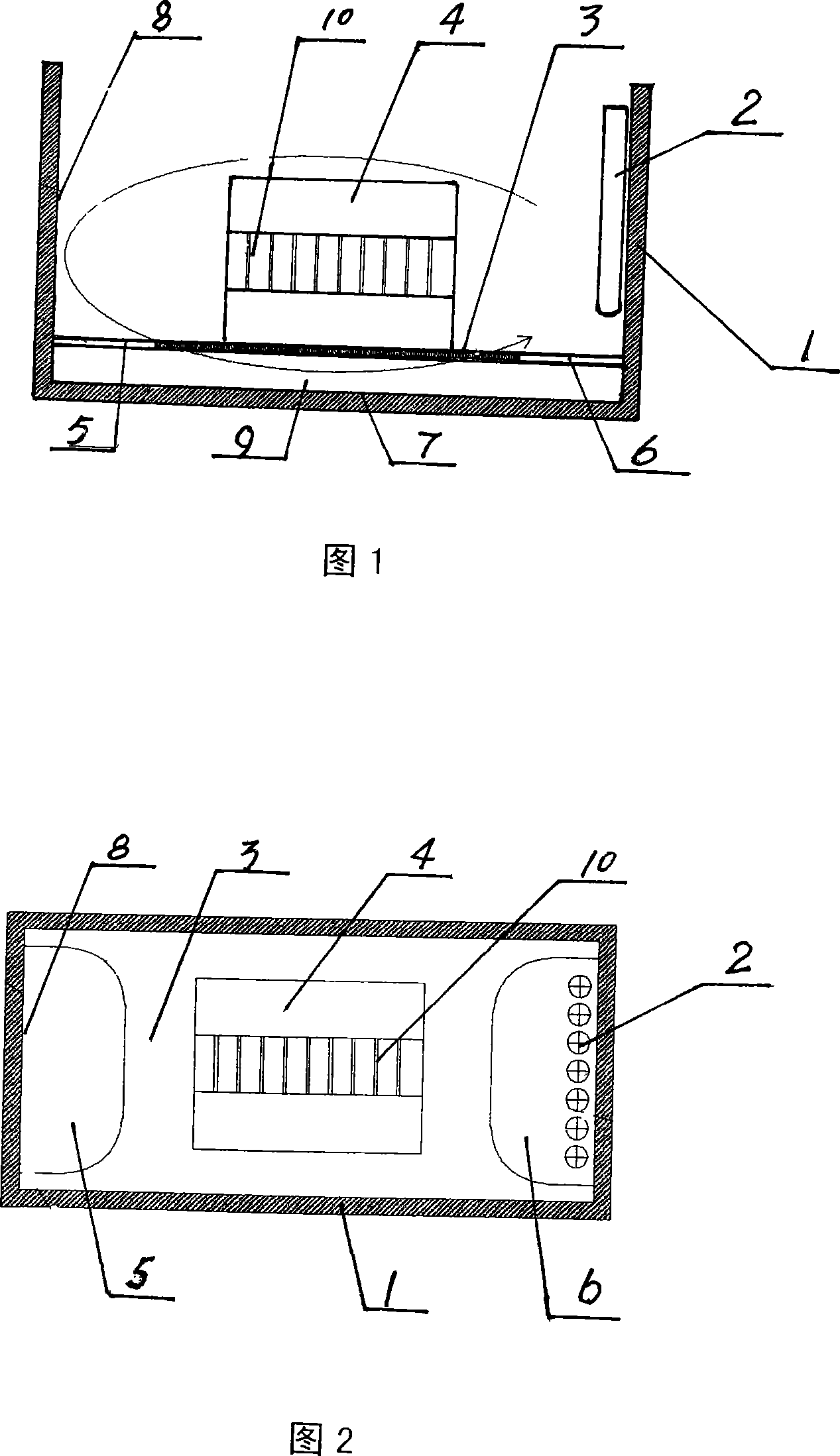

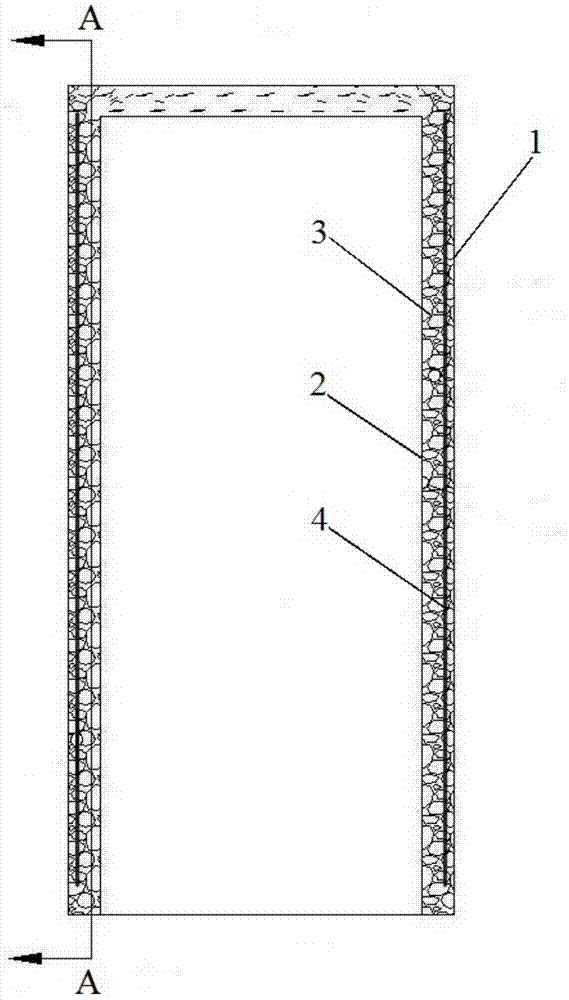

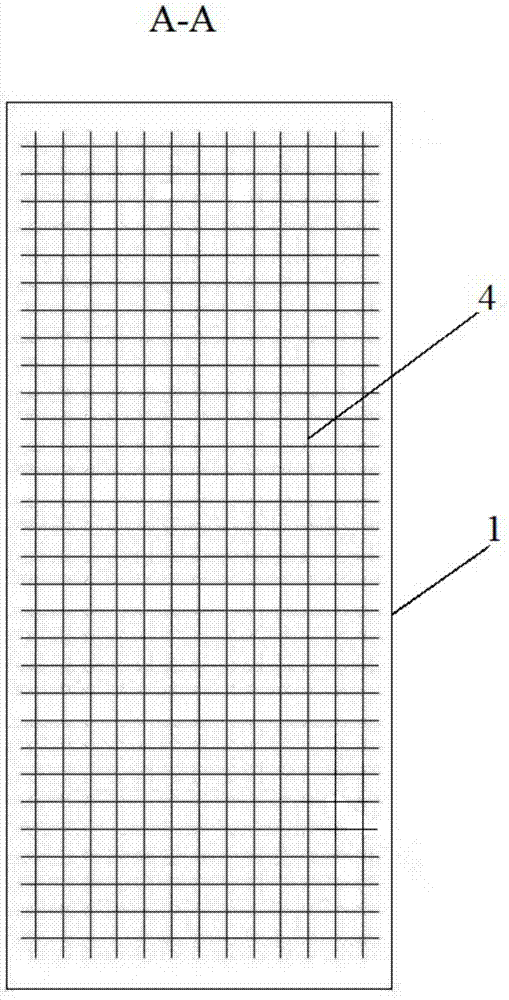

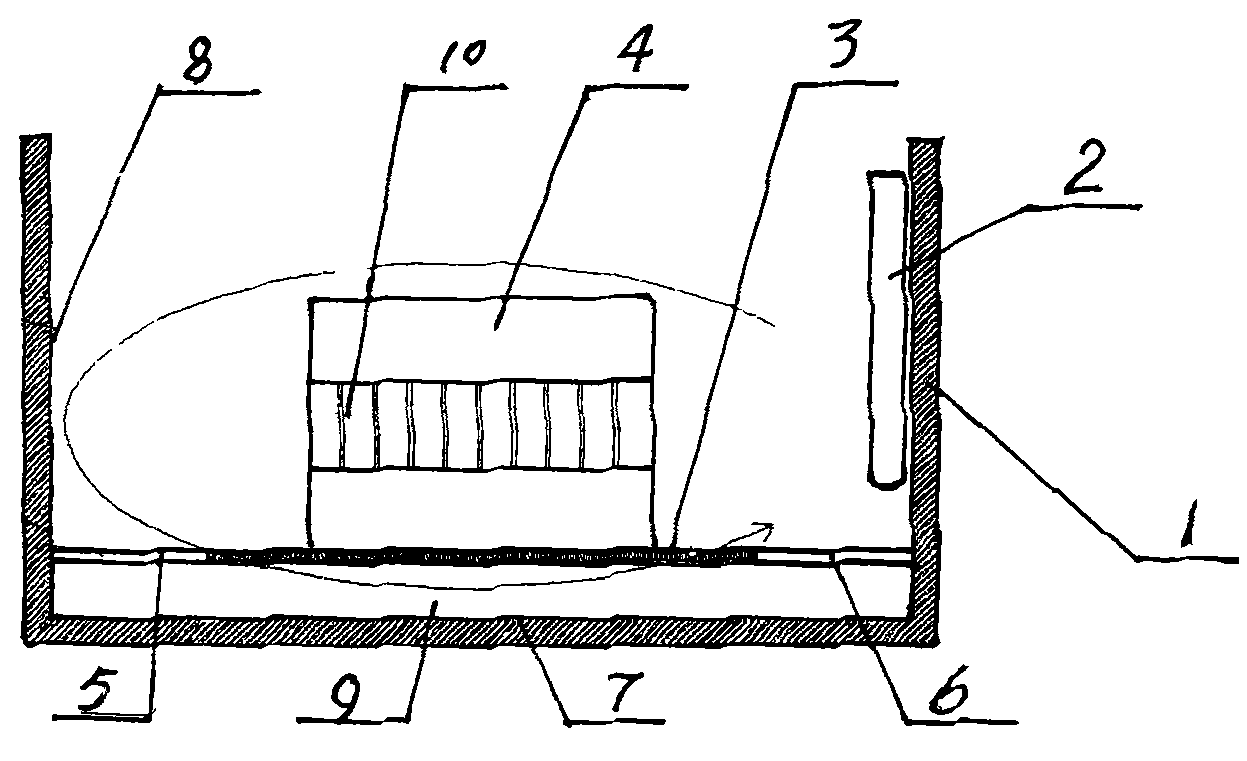

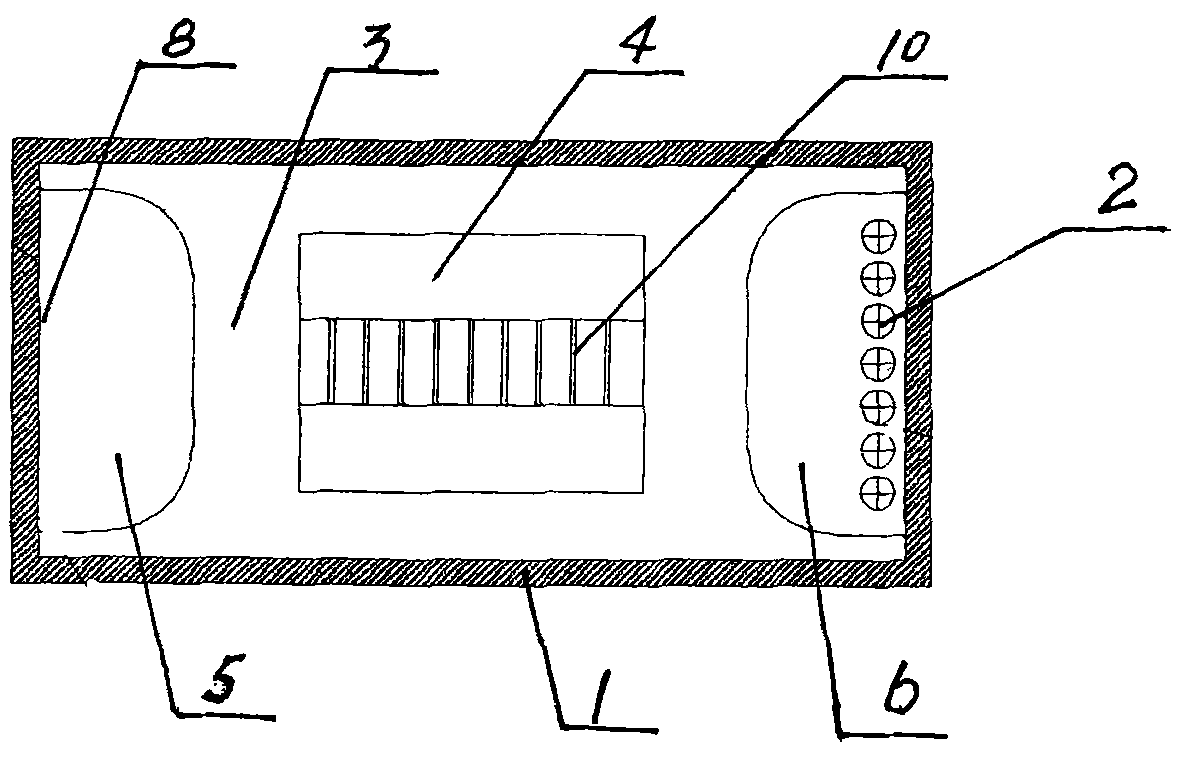

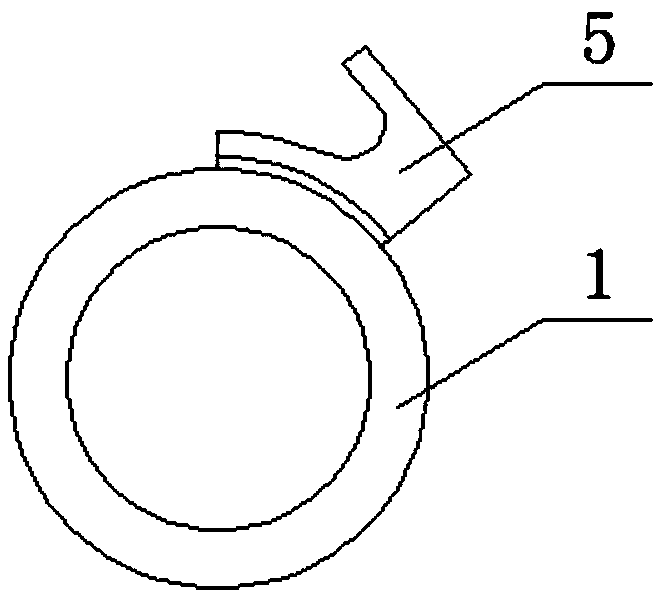

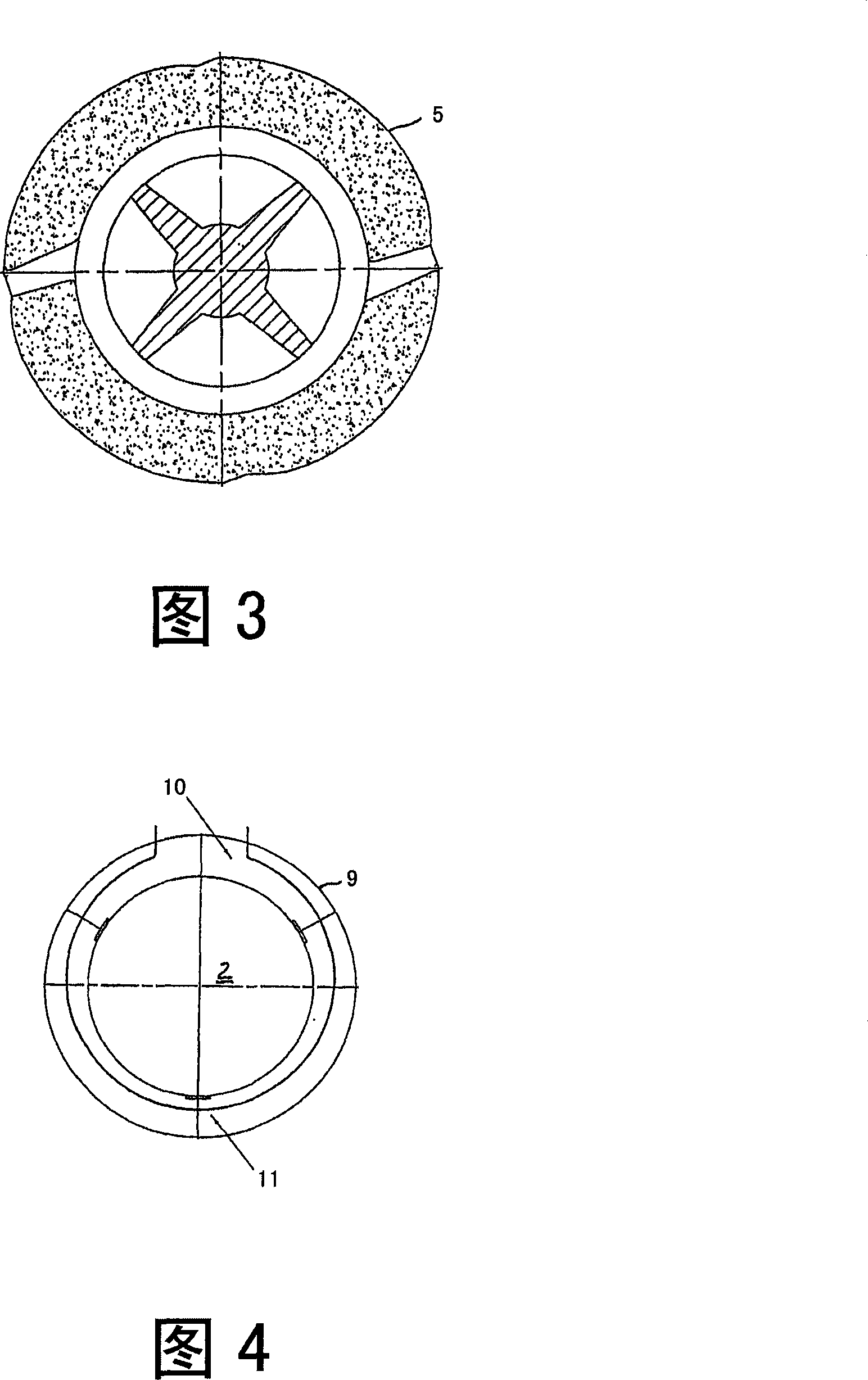

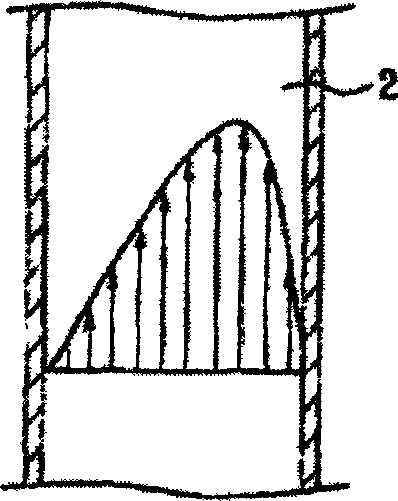

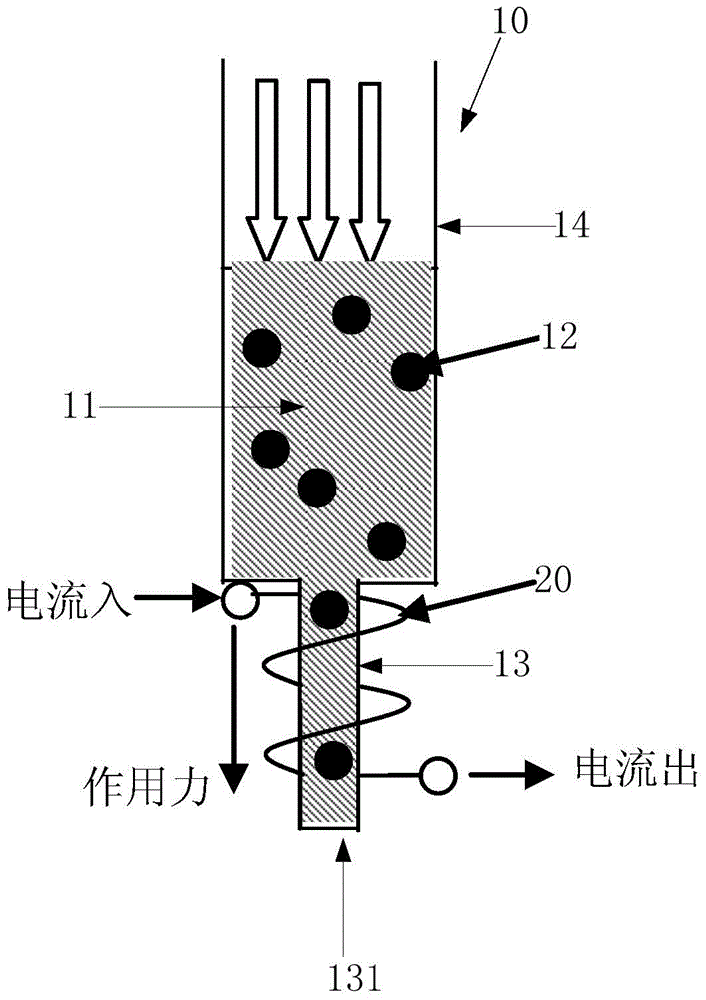

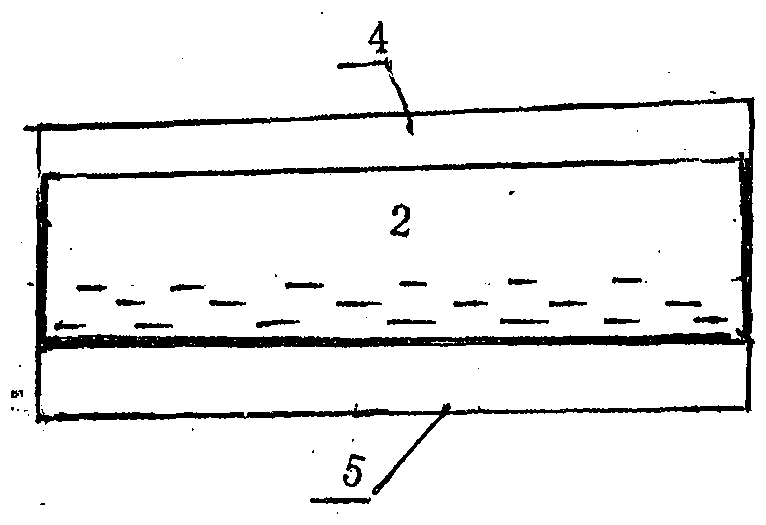

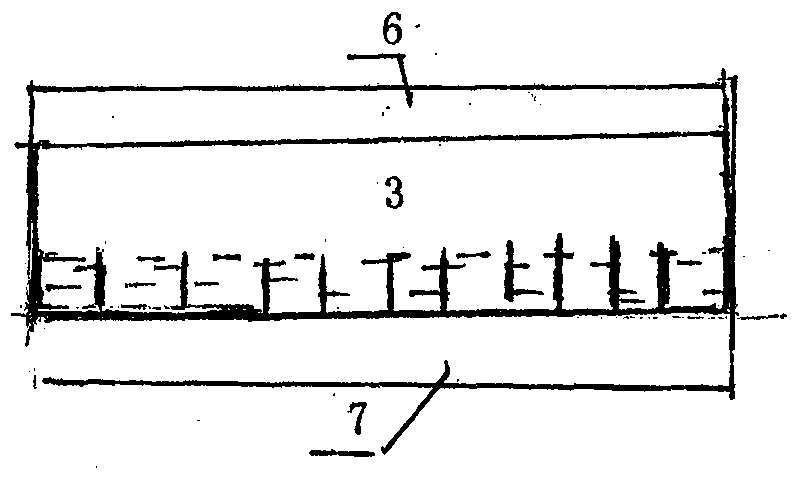

Monocrystaline silicon solar battery texture etching tank

InactiveCN101097971AUniform flow velocityEvenly heatedFinal product manufactureSemiconductor/solid-state device manufacturingElectrical batteryEngineering

A single-crystal silicon solar-energy battery velvet corrosion groove comprises a groove, a heating pipe, a support plate, and a silicon slice carrier, wherein the left and right ends of the support plate are respectively provided with a left curt an a right cut, the support plate is supported in the groove to form a chamber with the bottom of the groove, the heating pipe is mounted on the inner wall of the groove, above the left cut or the right cut, the silicon slice carrier is arranged on the support plate. When the corrosion groove is heated, the corrosion liquid will flow from the cut of the heating pipe vertically with the carrier, to lift up along the cuts of the support plate, to enter into the chamber under the support plate, to flow up along the cut near the heating pipe to be heated, as one circulation. Therefore, the surface of whole silicon slice is heated uniformly, the corrosion liquid flows uniformly, with uniform corrosion speed and uniform velvet structure.

Owner:EGING PHOTOVOLTAIC TECHNOLOGY CO LTD

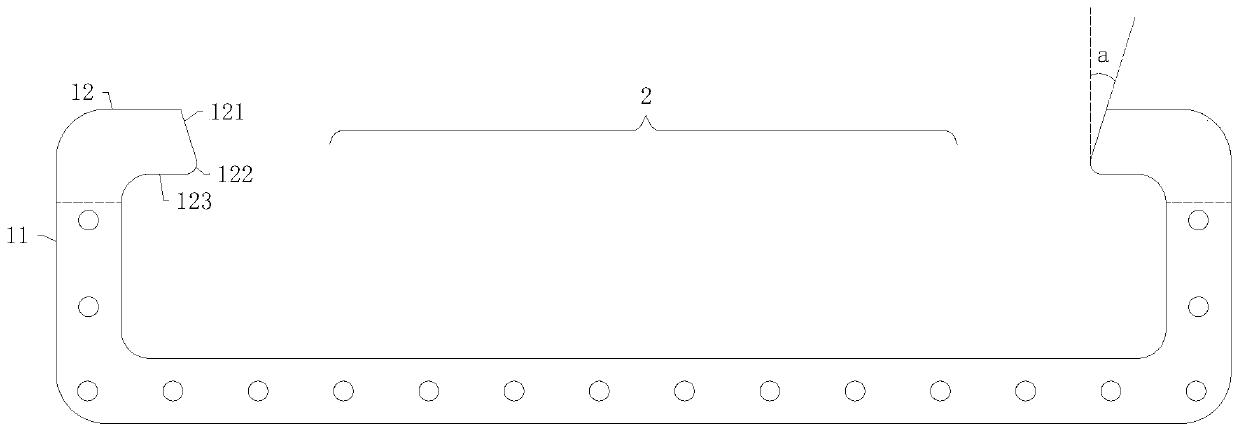

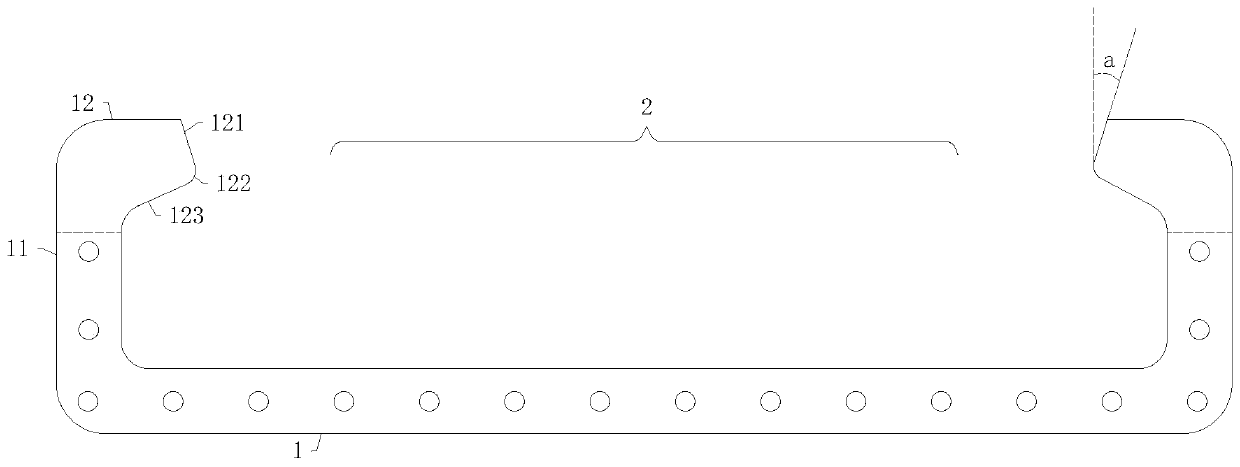

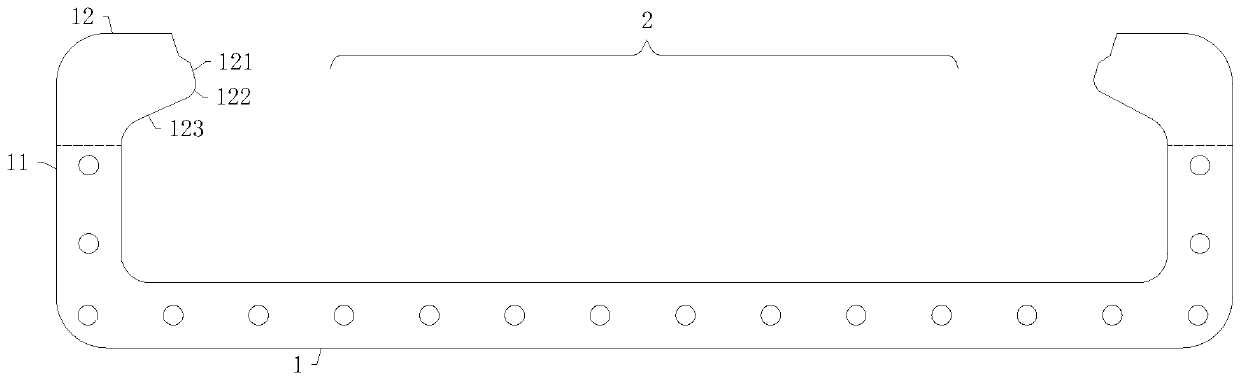

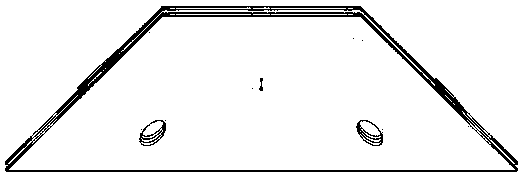

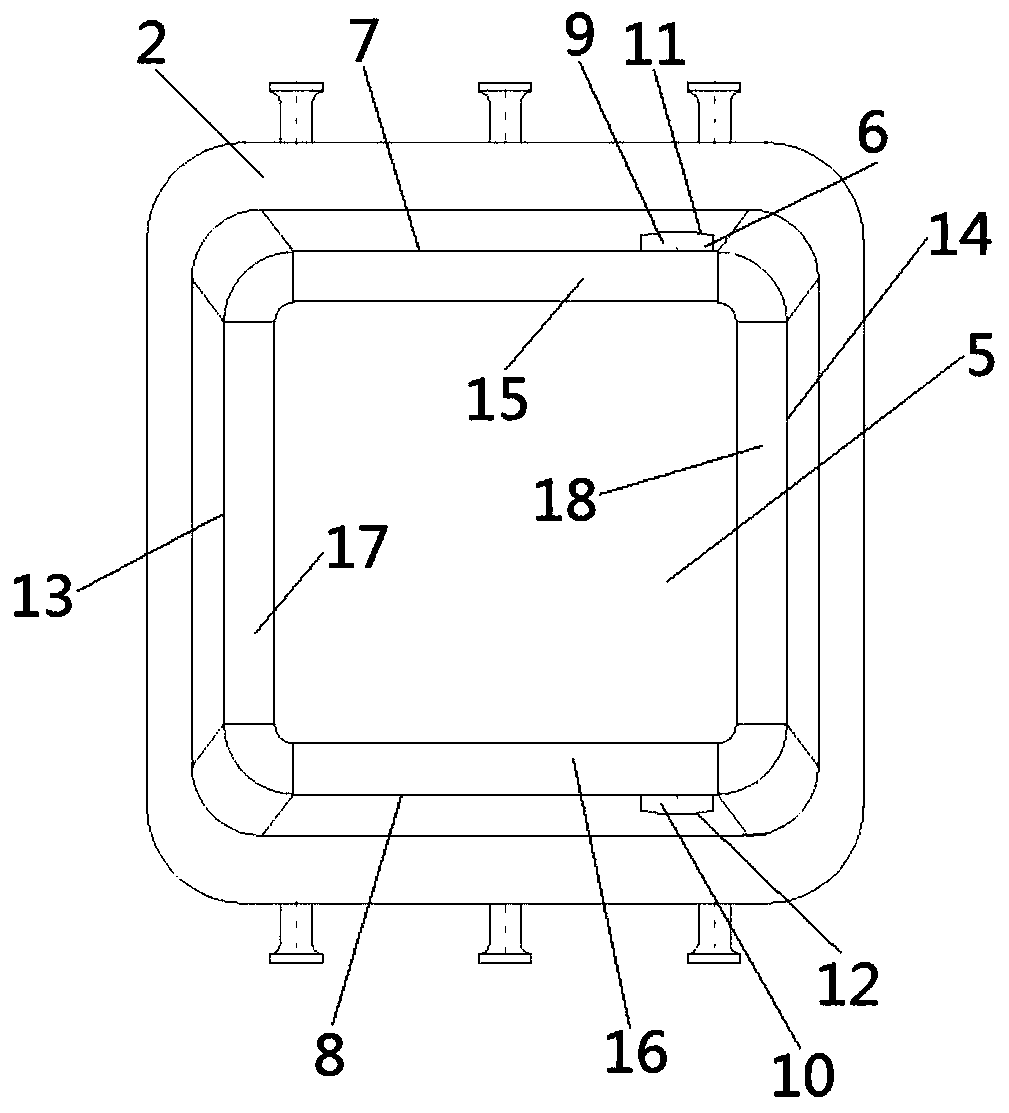

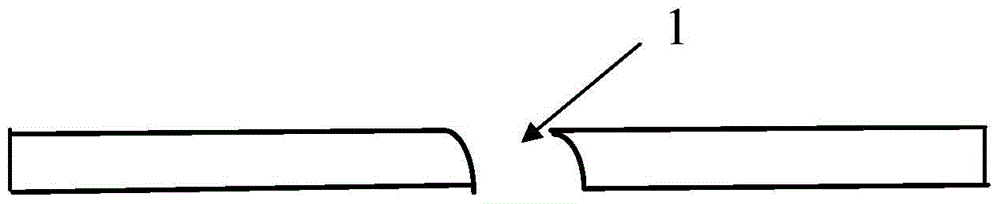

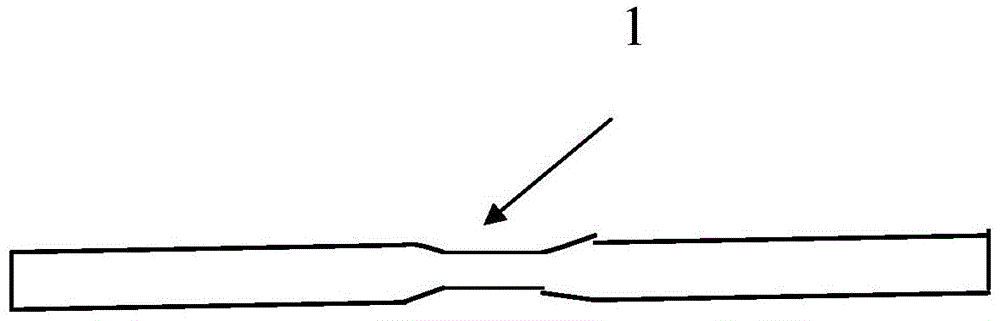

Extruding coating type die head gasket capable of eliminating coating edge effect

ActiveCN111250354AStable fluid pressureHigh thickness consistencyLiquid surface applicatorsElectrode collector coatingEngineeringLithium battery

The invention discloses an extruding coating type die head gasket capable of eliminating the coating edge effect and belongs to the technical field of lithium battery coating. The extruding coating type die head gasket comprises a die head gasket body, wherein a discharging hole is formed in the die head gasket body; the die head gasket body comprises a lower gasket and upper extending gaskets fixedly arranged at the left and right upper ends of the lower gasket; the space between the inner wall of the lower gasket and the two upper extending gaskets forms the discharging hole; and chamferingstructures for improving the fluid pressure when slurry flows to the edges of the upper extending gaskets via the discharging hole are arranged at mutually closed ends of the two upper extending gaskets, so that when the slurry is coated, the fluid pressure at the die head lip edge is stable, the speed of slurry extruded out of a slit is distributed uniformly, the edge thickness consistency of thecoated film surface is high, the coated edge film thickness and the range of the film edge abnormal area can be more effectively controlled to realize continuous coating of multiple films.

Owner:TIANNENG SAFT ENERGY JOINT CO

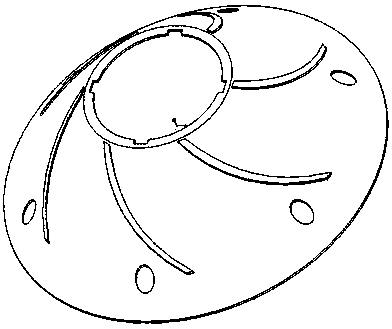

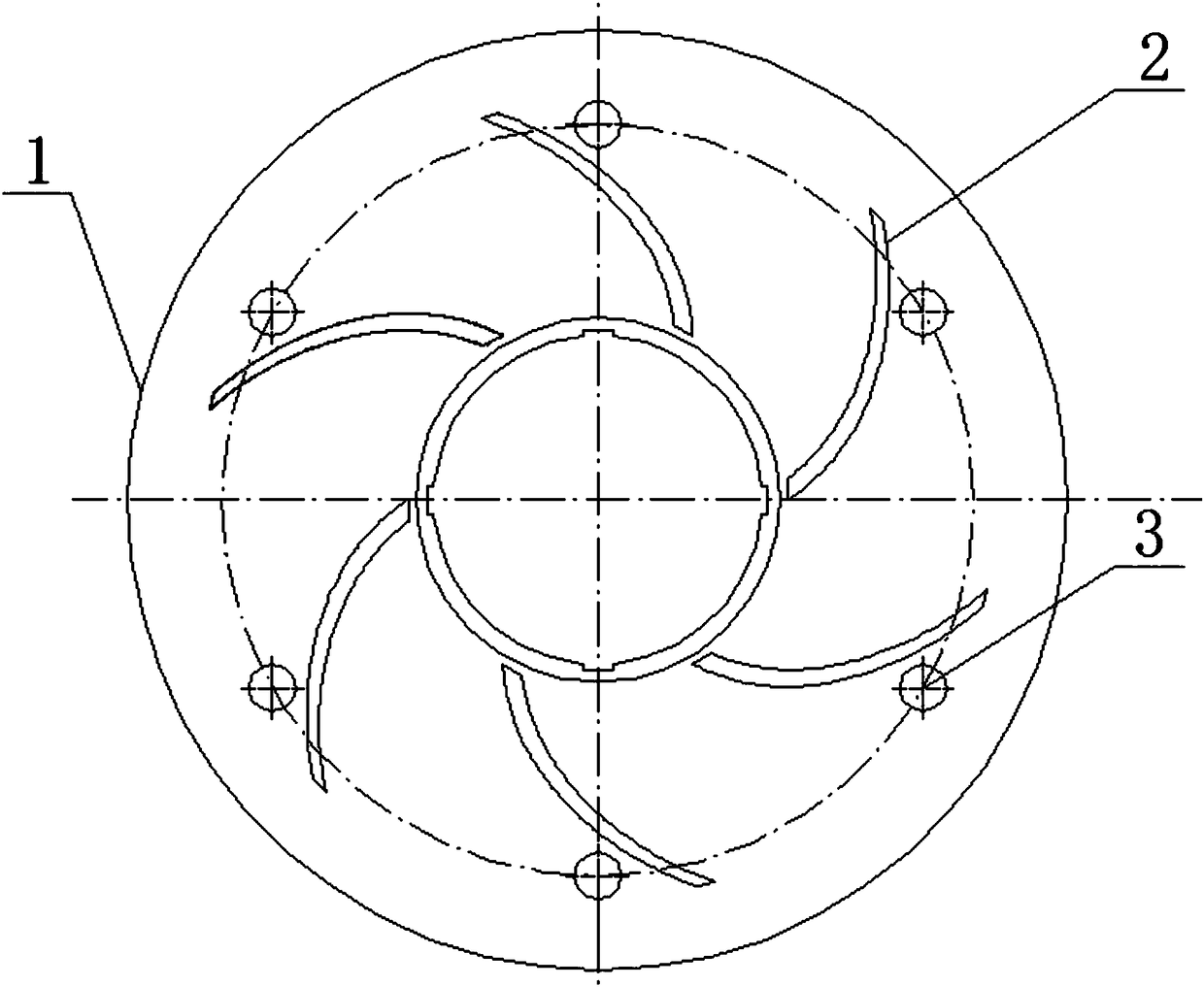

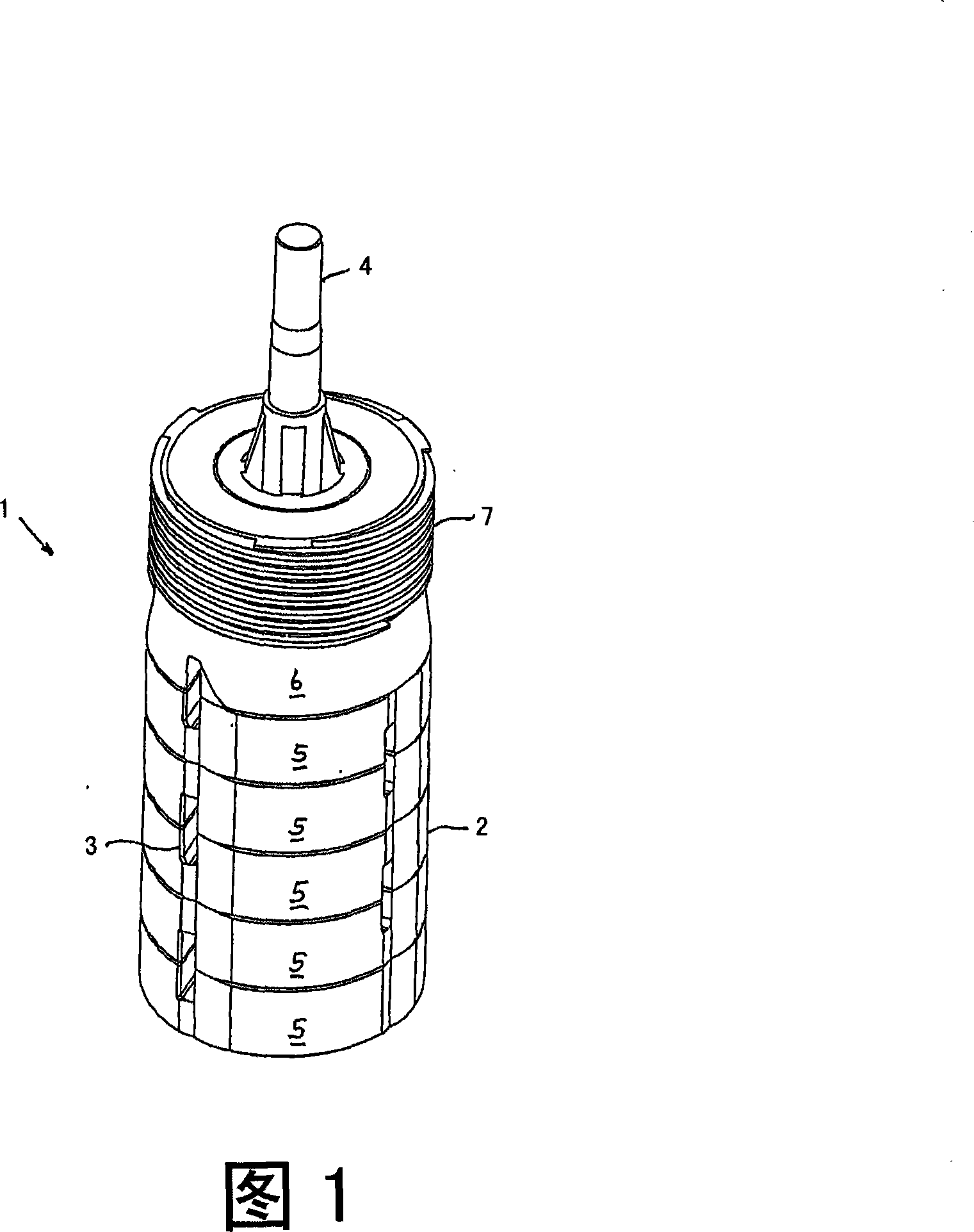

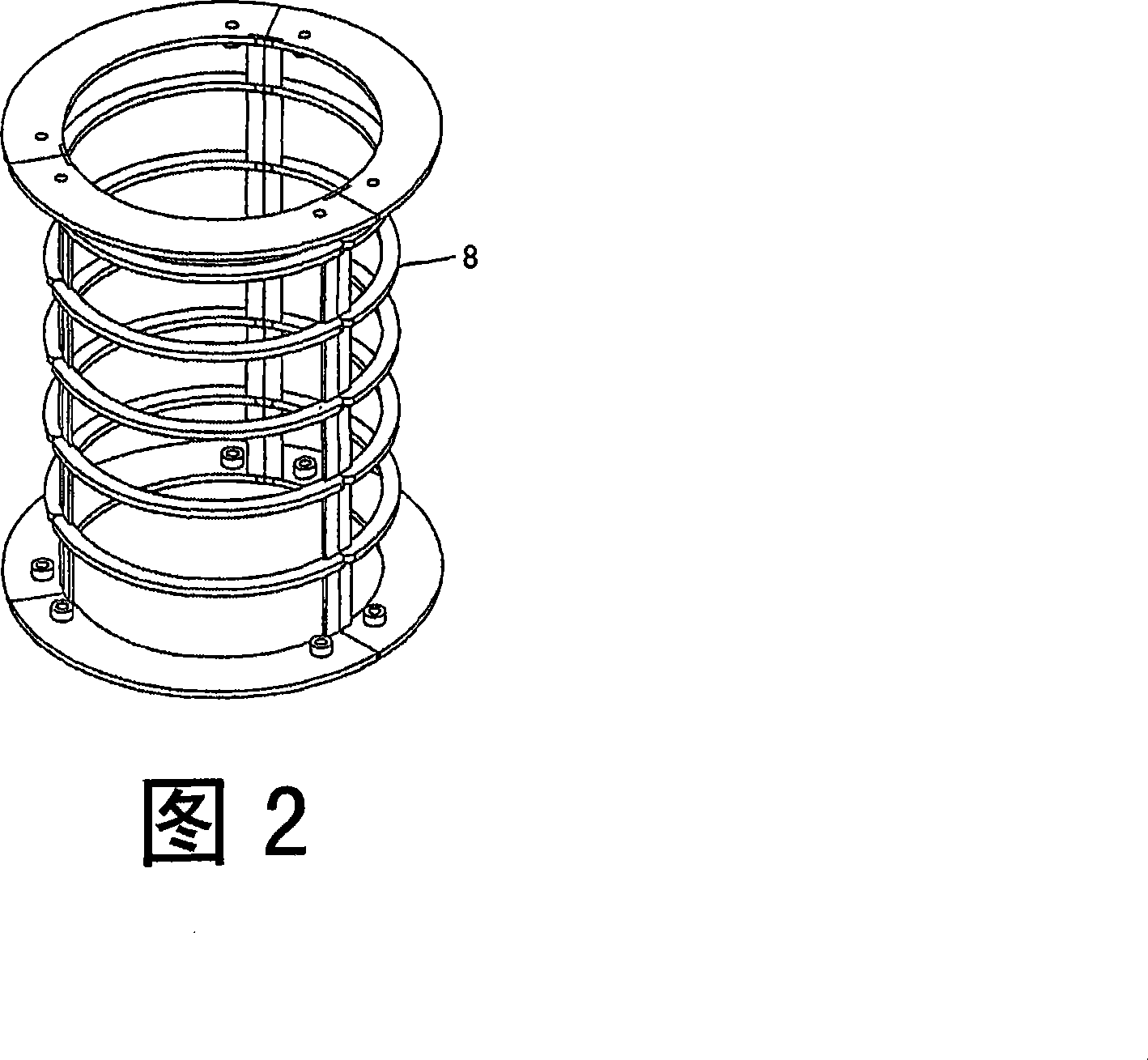

Disk of disk centrifuge

The invention relates to a disk of a disk centrifuge. The disk of the disk centrifuge includes a disk body, a plurality of distance ribbed strips and a plurality of feed openings. The disk of the diskcentrifuge is characterized in that the disk body is an upside-down cone dish with a small upper end and a big lower end; the distance ribbed strips are in a spiral shape, and the distance ribbed strips are distributed at the surface of a cone disk and extend backward in the opposite direction of the disk rotation from the small end to the big end of the disk; and axes of the feed openings are parallel to axis of the cone disk, the number of the axes is the same as that of the ribbed strips, and the axes are located above the distance ribbed strips. The distance ribbed strips and the feed openings are symmetrically distributed in the center. Flowing space is formed by a gap of the disk, materials flow into the flowing space from the feed openings of a first layer of disk at the bottom ofa disk set from bottom to top, the small end of the disk is a light phase outlet, and the big end of the disk is a heavy phase outlet. The disk of the disk centrifuge focus on the spiral structures ofthe distance ribbed strips, has the advantages that the affection of the material separation process through the disk structure is improved, and the hysteresis quality of flowing liquid in the gap ofthe disk is decreased, so that the separation efficiency of the disk centrifuge is effectively improved.

Owner:CHANGZHOU UNIV

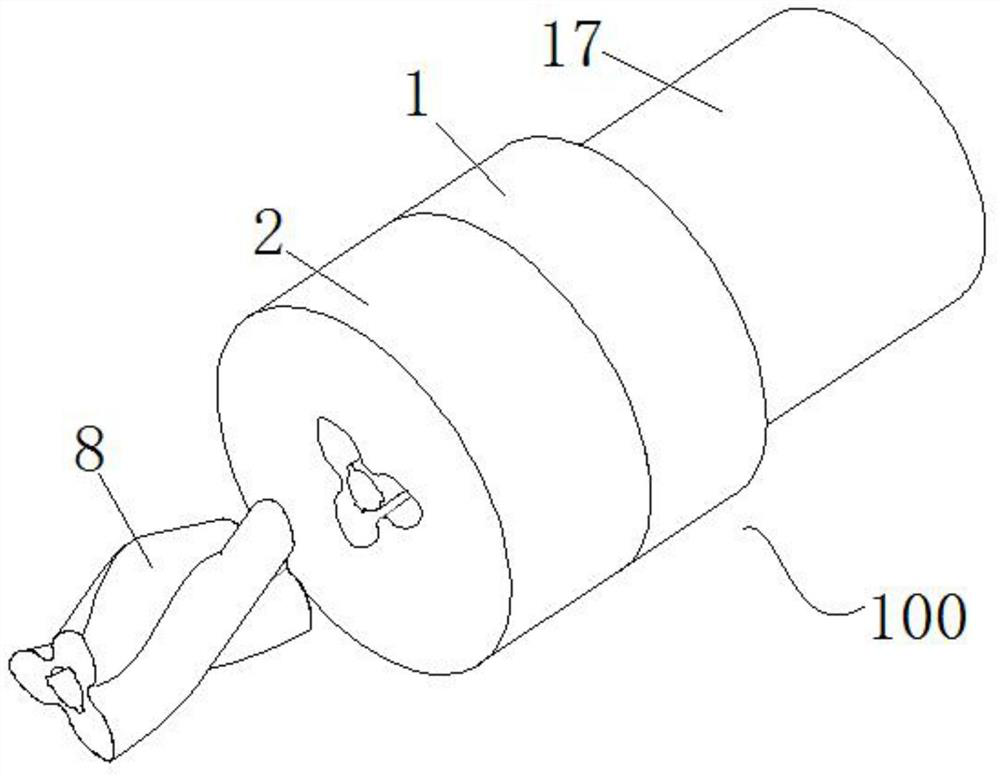

Extrusion device and extrusion method for hollow helicoid rotor profile with internal key groove

The invention discloses an extrusion device and an extrusion method for a hollow helicoid rotor profile with an inner key groove. The device comprises an upper die and a lower die, wherein one end of the upper die is provided with at least one diversion chamber, and the other end of the upper die is provided with at least two shunting holes communicating with the diversion chamber; a shunting bridge is arranged between every two adjacent shunting holes; a blocking table is arranged at the intersection of every two shunting bridges; the end, away from the diversion chamber, of the upper die is connected with a die core; the end, connected with the upper die, of the lower die is at least provided with a first-stage welding chamber, the end, far away from the upper die, of the welding chamber communicates with an orifice of the lower die, and the end, far away from the upper die, of the die core is sequentially inserted into the welding chamber and the orifice of the lower die; the diversion chamber, the shunting holes, the welding chamber and the orifice of the lower die communicate in sequence; and a transition key structure and a key structure which are connected in a matching manner are arranged on the outer wall of the die core. According to the extrusion method based on the device, light alloy is adopted for direct extrusion forming of the hollow rotor, the machining efficiency and blank utilization rate are high, and the production cost is low.

Owner:SHANDONG UNIV

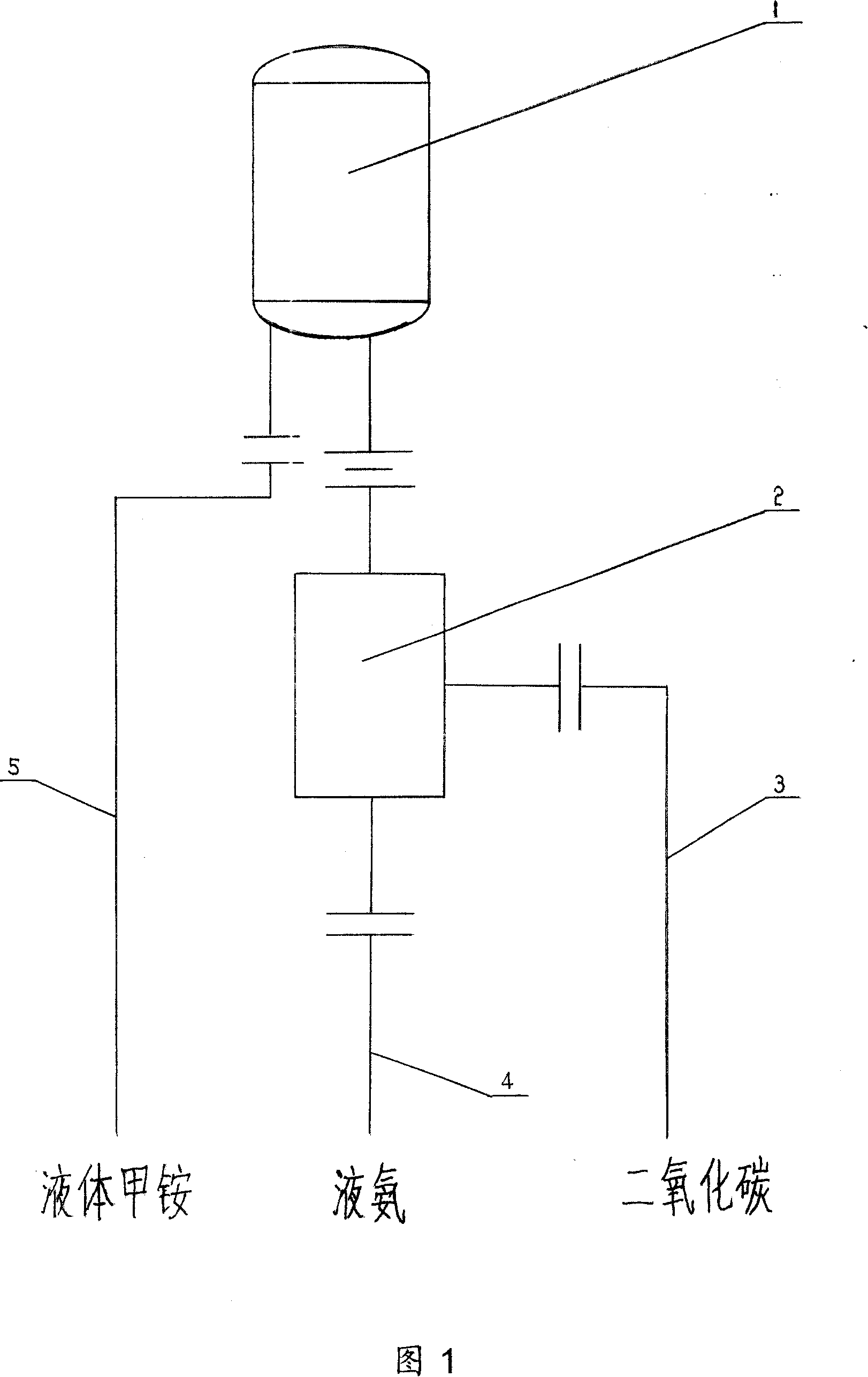

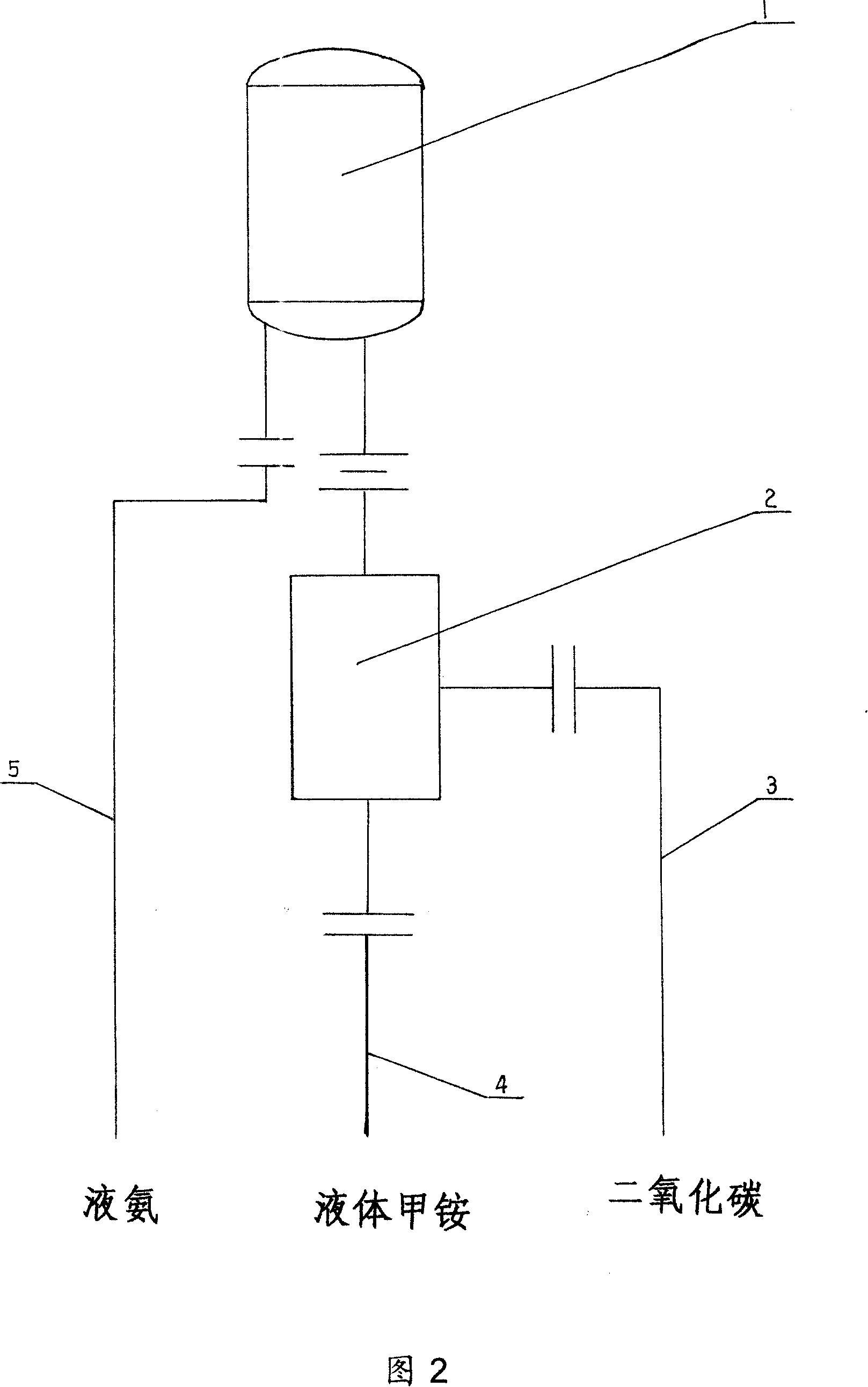

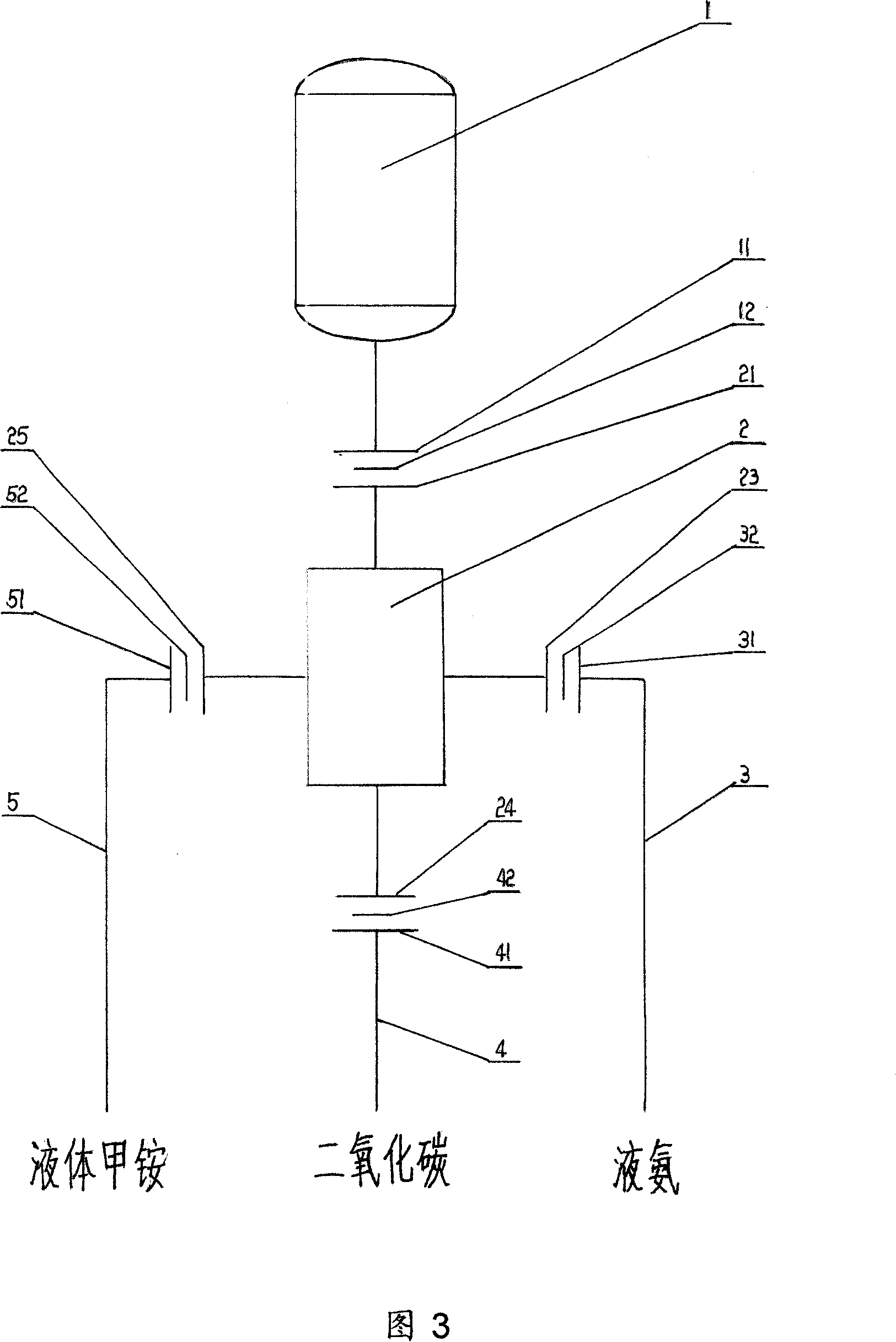

Synthesizing method for urea

ActiveCN101148425AAvoid backmixingPrevent reversible reactionsUrea derivatives preparationOrganic compound preparationUreaCarbon dioxide

The present invention provides one new urea synthesizing process. One high pressure tubular quick liquid-gas mixing reactor is set in the material inlet of urea synthesizing tower, liquid ammonia and liquid methyl amine are atomized to form 100-250 micron fog drops, and the fog drops are mixed with gaseous CO2 to form homogeneous two-phase flow into the urea synthesizing tower, where methyl amine is dewatered to produce urea. The improved urea synthesizing process has no back mixing of materials, short reaction period, high synthesis efficiency, raised CO2 converting rate, saving in energy, high yield and other advantages.

Owner:BEIJING HANGHUA ENERGY SAVING ENVIRONMENTAL PROTECTION TECH CO LTD

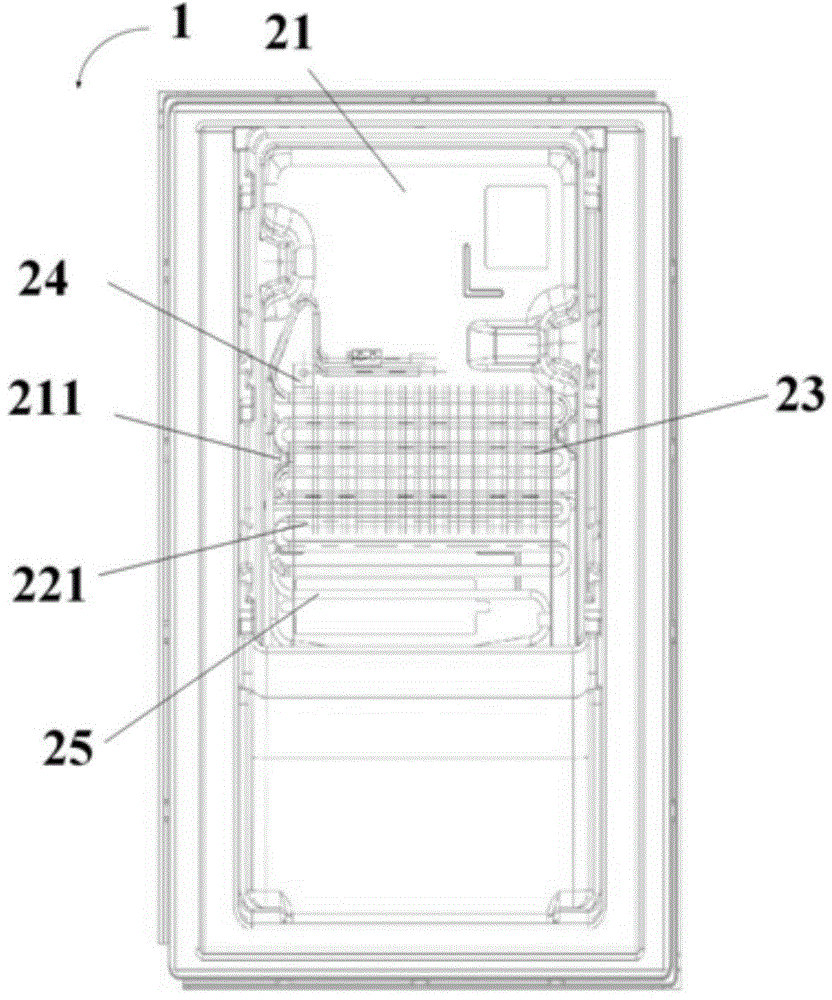

Box structure and refrigerator

ActiveCN104848641AAvoid scrappingImprove pass rateDomestic cooling apparatusLighting and heating apparatusMechanical engineeringRefrigerated temperature

Owner:GUANGZHOU MIDEA HUALING REFRIGERATOR +1

Monocrystaline silicon solar battery texture etching tank

InactiveCN101097971BUniform flow velocityEvenly heatedFinal product manufactureSemiconductor/solid-state device manufacturingElectrical batteryEngineering

A single-crystal silicon solar-energy battery velvet corrosion groove comprises a groove, a heating pipe, a support plate, and a silicon slice carrier, wherein the left and right ends of the support plate are respectively provided with a left curt an a right cut, the support plate is supported in the groove to form a chamber with the bottom of the groove, the heating pipe is mounted on the inner wall of the groove, above the left cut or the right cut, the silicon slice carrier is arranged on the support plate. When the corrosion groove is heated, the corrosion liquid will flow from the cut ofthe heating pipe vertically with the carrier, to lift up along the cuts of the support plate, to enter into the chamber under the support plate, to flow up along the cut near the heating pipe to be heated, as one circulation. Therefore, the surface of whole silicon slice is heated uniformly, the corrosion liquid flows uniformly, with uniform corrosion speed and uniform velvet structure.

Owner:EGING PHOTOVOLTAIC TECHNOLOGY CO LTD

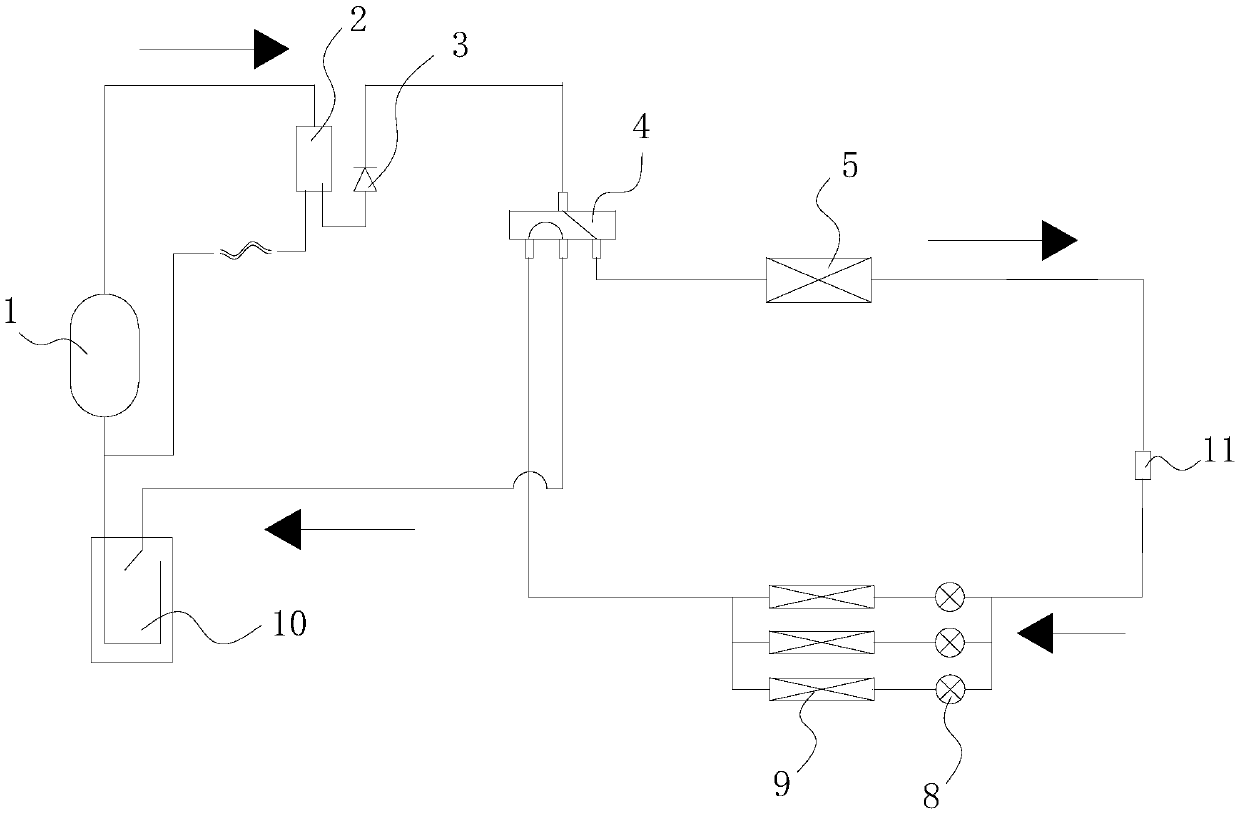

Condensate water reutilizing device for domestic air conditioner

InactiveCN109489234ASolve the problem of inability to completely absorb heat and evaporateWill not cause side spillCondensate preventionLighting and heating apparatusSufficient timeEngineering

The invention relates to the technical field of smart home equipment and discloses a condensate water reutilization device of a domestic air conditioner. The condensate water reutilization device comprises a condensation pipe, one end of the condensation pipe communicates with an exhaust opening of an air conditioner compressor, and the other end of the condensation pipe communicates with an air inlet of an electronic expansion valve. A preheating box is fixedly installed at the position, close to the exhaust opening of the air conditioner compressor, of the outer portion of the condensation pipe. By means of the condensate water reutilization device, inclined draining grooves are formed in the outer wall of the condensation pipe in an attached manner, the two draining grooves communicatewith each other end to end through a corrugated connecting pipe, condensate water is drained to the outer wall of the condensation pipe through the draining grooves and flows slowly in the length direction of the outer wall, under the flow guide effect of the multiple layers of draining grooves, the condensate water can make sufficient contact with the outer wall of the condensation pipe for a long time, and therefore the condensate water can have sufficient time to absorb heat to be evaporated. The problem that condensate water drops rapidly flow through the wall of a heat exchange pipe and cannot thoroughly absorb heat to be evaporated is solved, and the cooling capacity of the condensate water is sufficiently used for further cooling the heat exchange pipe of a condenser.

Owner:张永奇

Defrosting method of multi-split air conditioning system and multi-split air conditioning system

ActiveCN105509384AUniform flow velocityAvoid heat transfer dead endsMechanical apparatusCorrosion preventionLow speedFrost

The invention discloses a defrosting method of a multi-split air conditioning system and the multi-split air conditioning system, belongs to the field of air conditioning devices and defrosting methods thereof, and aims to solve such problems as incomplete defrosting of a traditional device. The defrosting method of the multi-split air conditioning system has the step of changing a heating mode to a refrigerating mode through reversing of a four-way valve, so that the flowing speeds of a refrigerant in an outdoor heat exchanger and at least one part of pipelines are nonuniform, and the alternation of high-speed flowing and low-speed flowing is generated. The multi-split air conditioning system is provided with a flowing speed control device on a pipeline between the outdoor heat exchanger and an indoor electronic expansion valve; and the flowing speed control device is communicated to a control device through signals. The defrosting method of the multi-split air conditioning system and the multi-split air conditioning system use alternation between high-speed flowing and low-speed flowing of the refrigerant for fully melting frost on the outdoor heat exchanger to prevent generation of heat exchange dead angles, so that the defrosting is faster and more thorough.

Owner:GREE ELECTRIC APPLIANCES INC

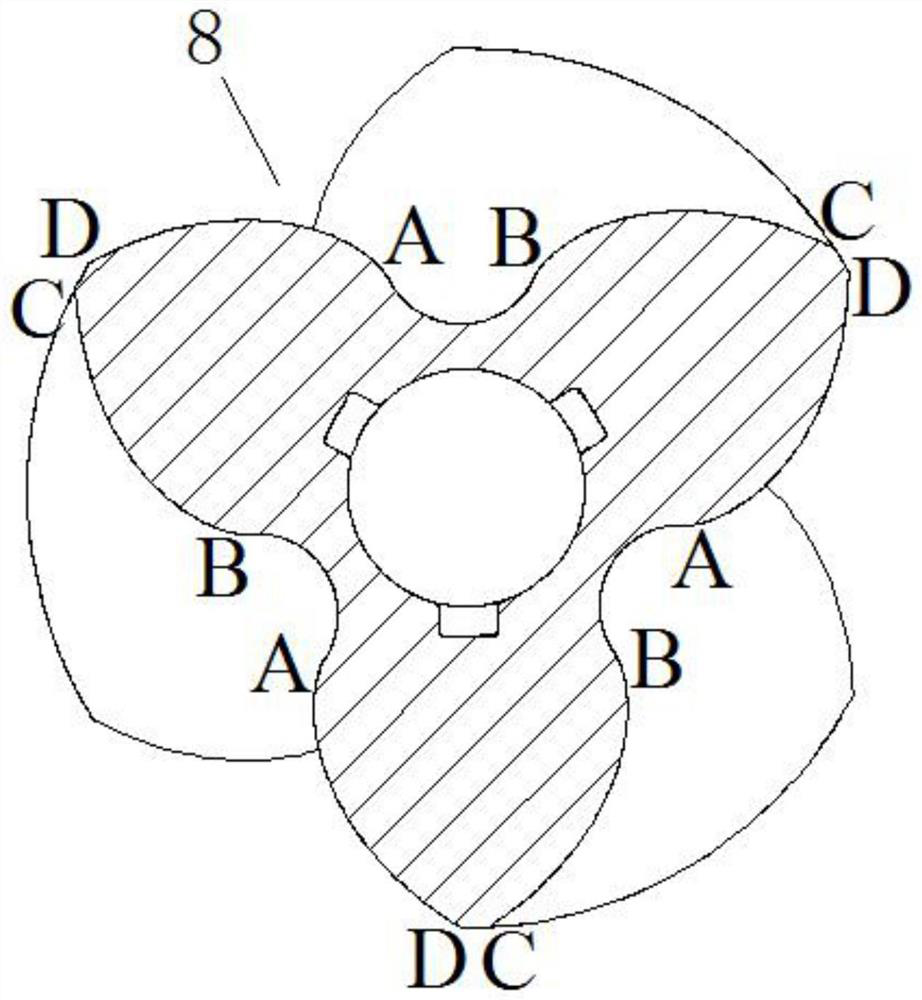

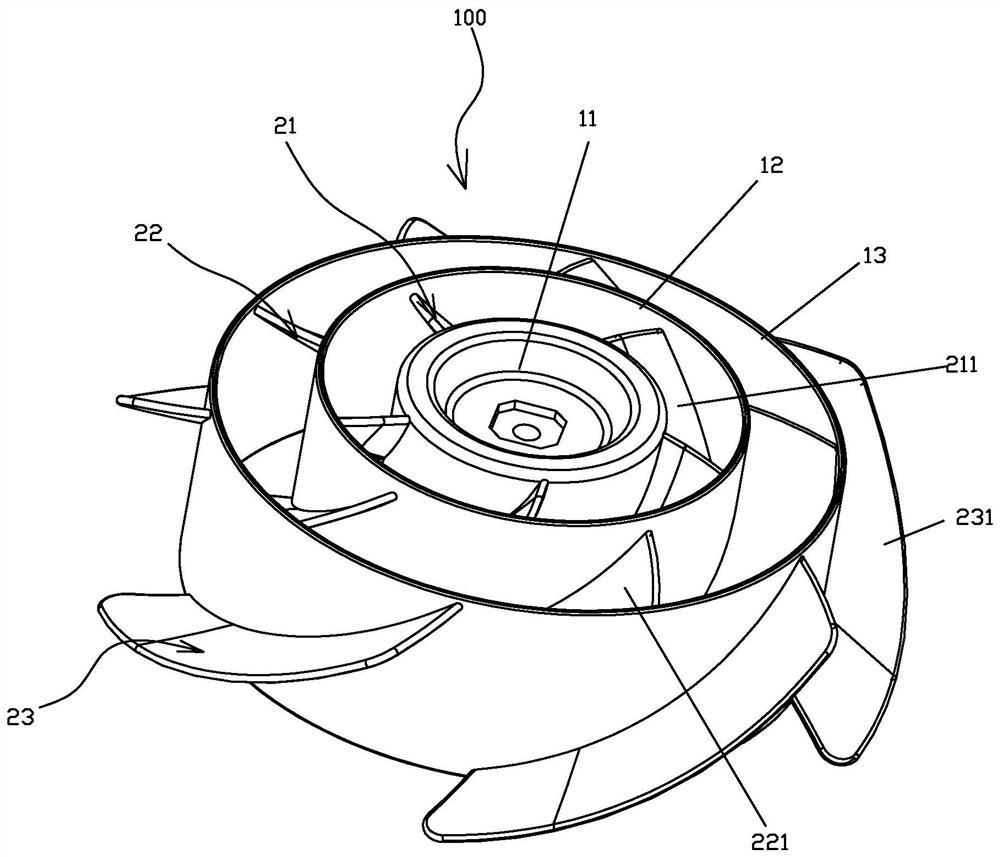

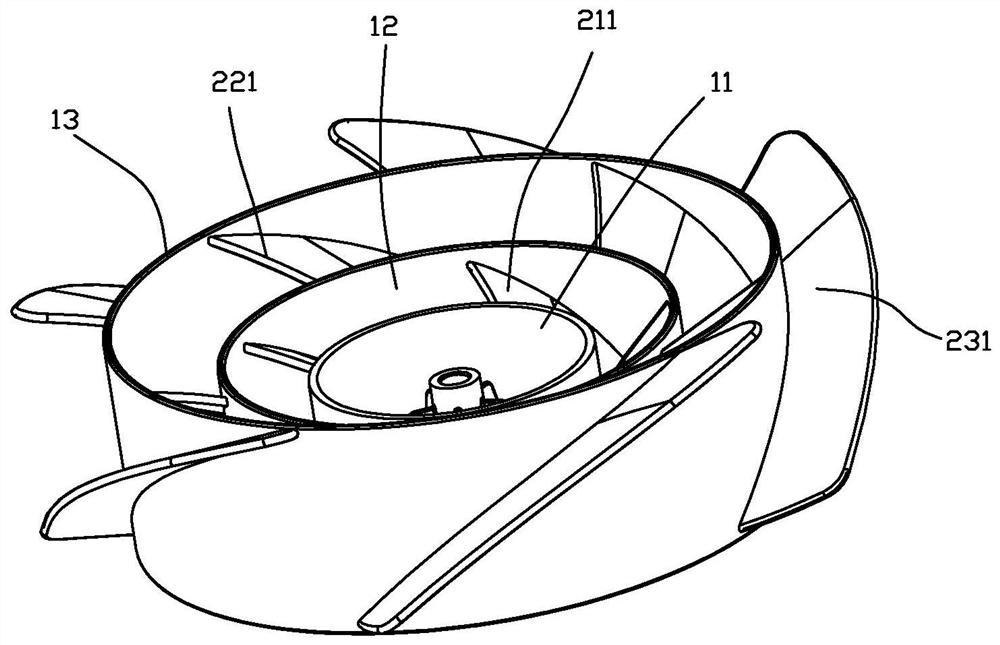

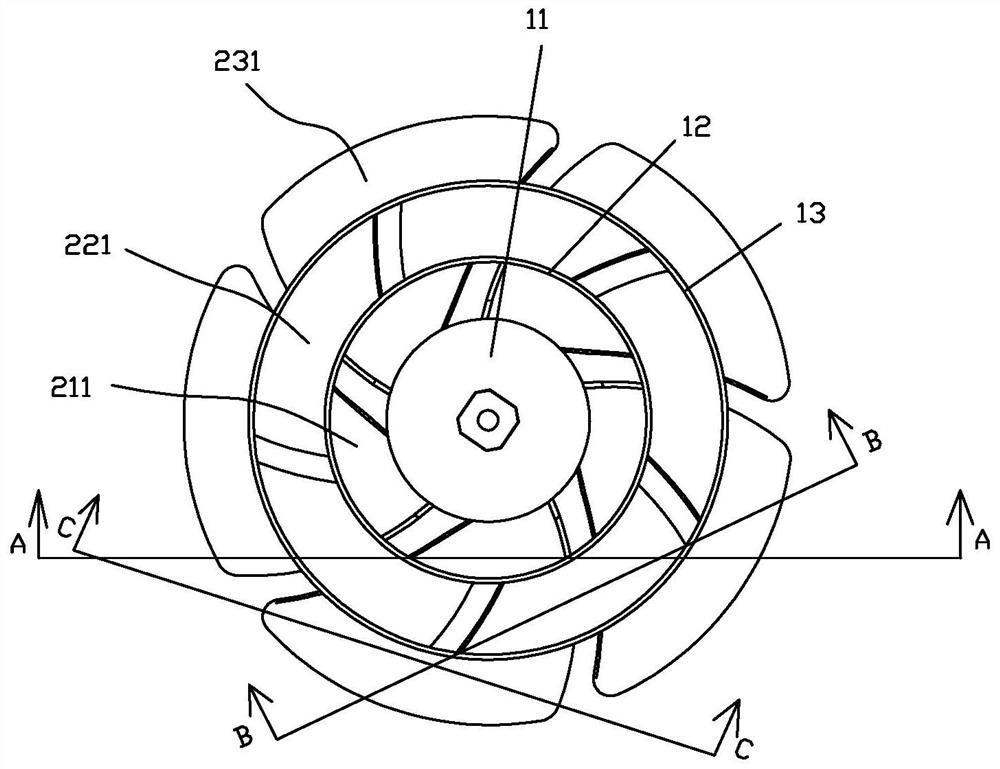

Three-layer fan blade and air circulation fan

PendingCN113090583AMeet design goalsImprove experiencePump componentsPump installationsAir cycleEngineering

The invention provides a three-layer fan blade and an air circulation fan. The three-layer fan blade comprises a blade shaft, an inner ring frame arranged on the periphery of the blade shaft and coaxial with the blade shaft, an outer ring frame arranged on the periphery of the inner ring frame and coaxial with the inner ring frame, a first-layer blade set arranged between the blade shaft and the inner ring frame, a second-layer blade set arranged between the inner ring frame and the outer ring frame and a third-layer blade set arranged on the periphery of the outer ring frame. The air outlet end part of the inner ring frame is higher than the air outlet end part of the outer ring frame. The blade shaft is assembled in the air circulation fan, and a slow air channel is formed by a channel between the blade shaft and the inner ring frame. A channel between the inner ring frame and the inner wall of a fan shell forms a fast air channel. Slow air blown out of the slow air channel can be focused and blown forwards more directionally, so that the interference loss of fast air blown out of the fast air channel to the slow air is reduced, and the air type is complete. The forward directivity of the air flow direction is effectively ensured, the concentration and uniformity of the air flow can still be kept at the position of 1 m blowing, and the air blown out of the circulation fan can penetrate farther.

Owner:XIAMEN VORK HEALTH IND CO LTD

Grinding machine for cereal grains

InactiveCN101203313AUniform flow velocityEconomic supplyGrain huskingGrain polishingEngineeringCereal grain

Owner:BUEHLER AG

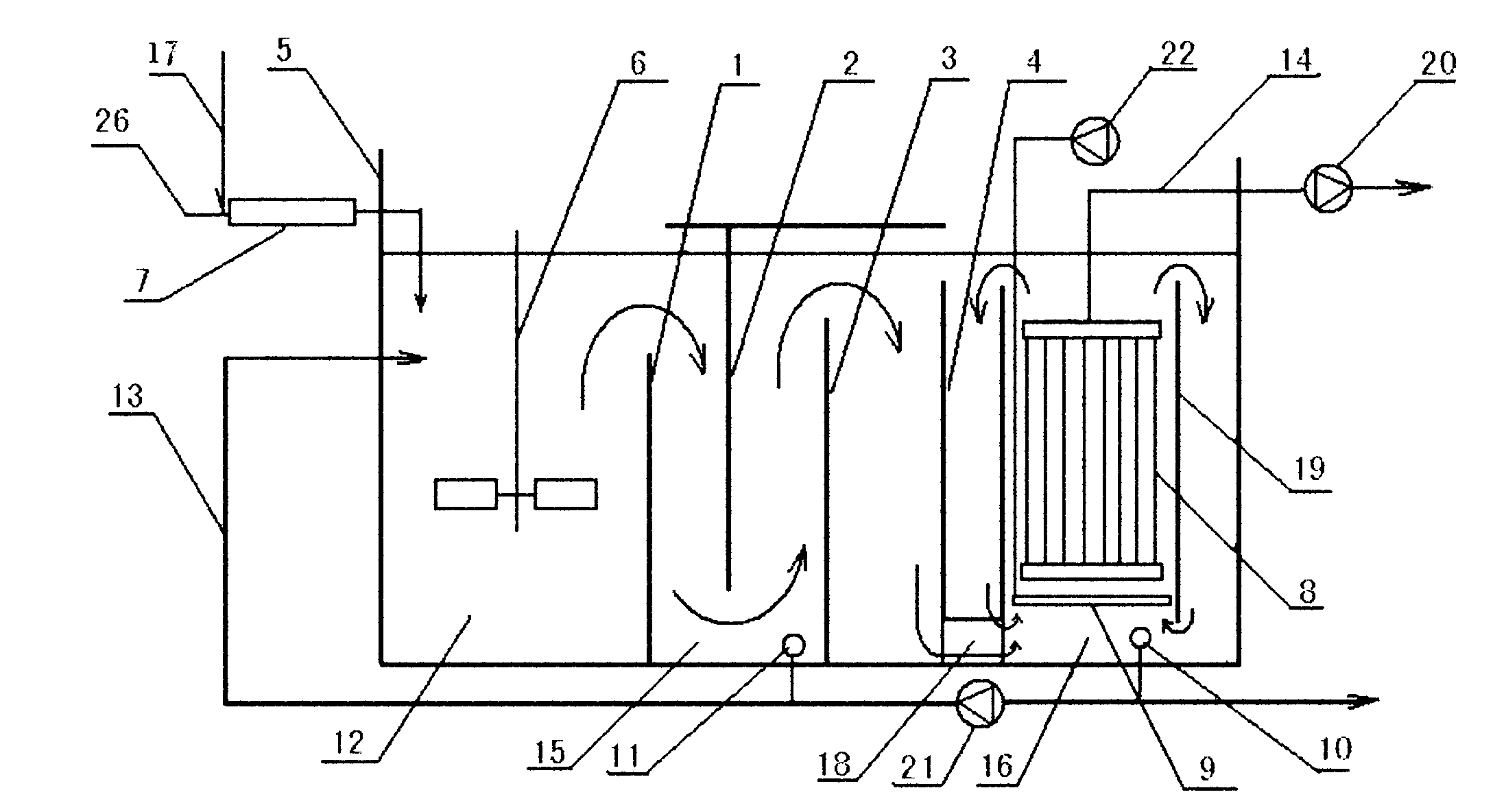

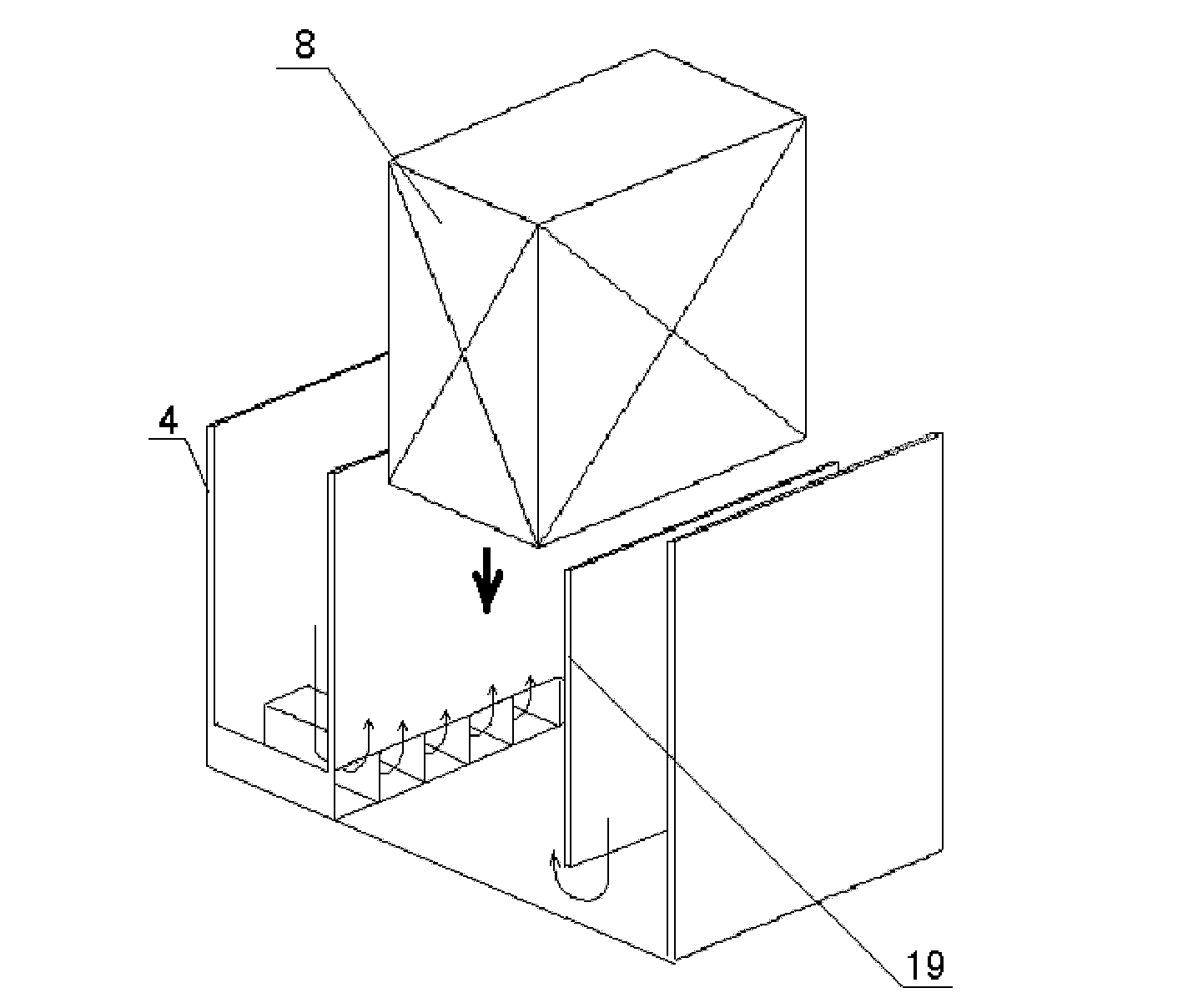

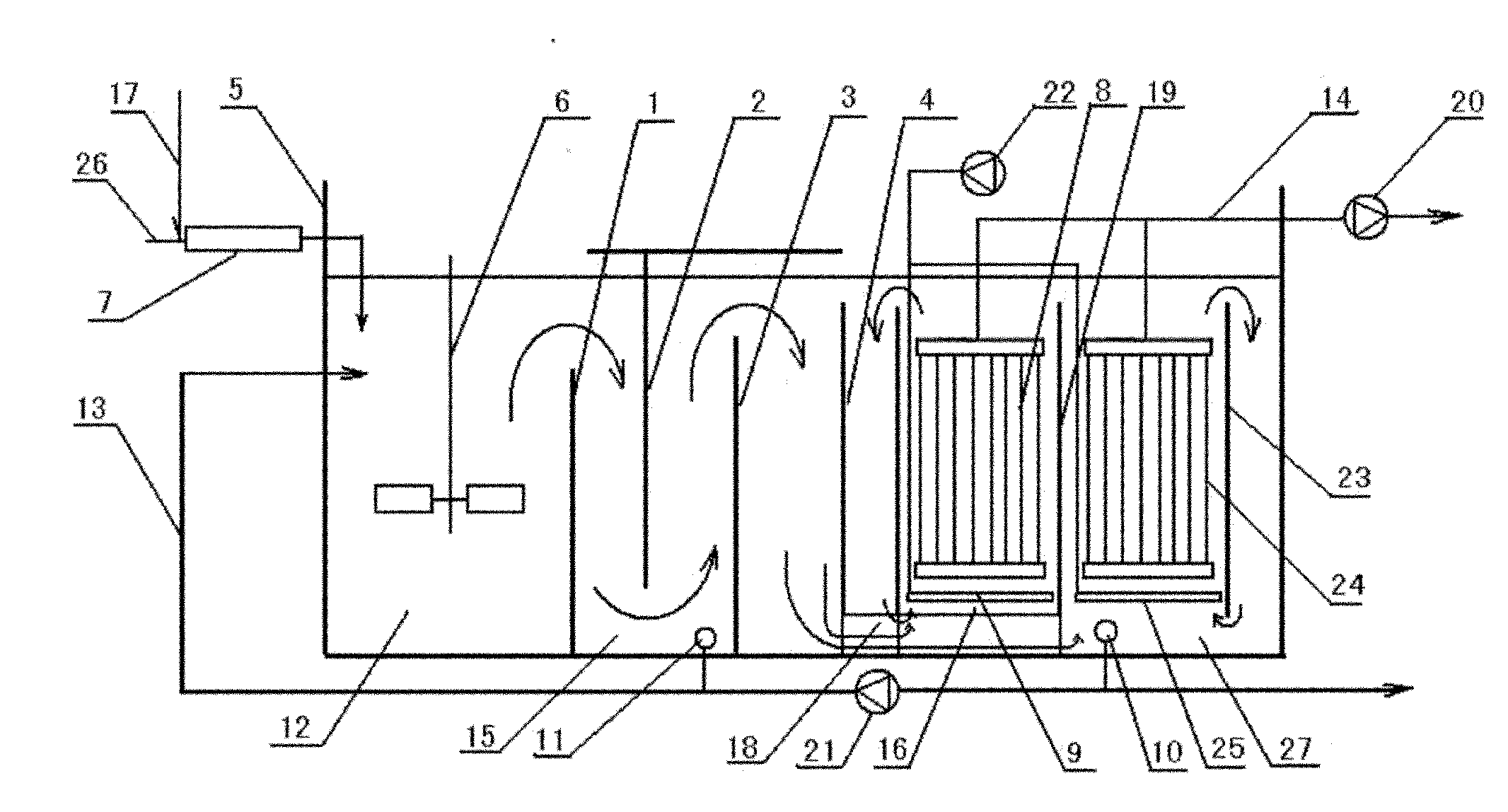

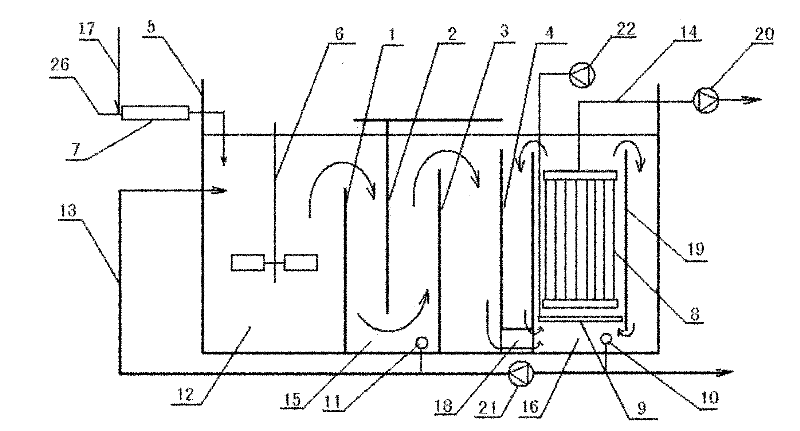

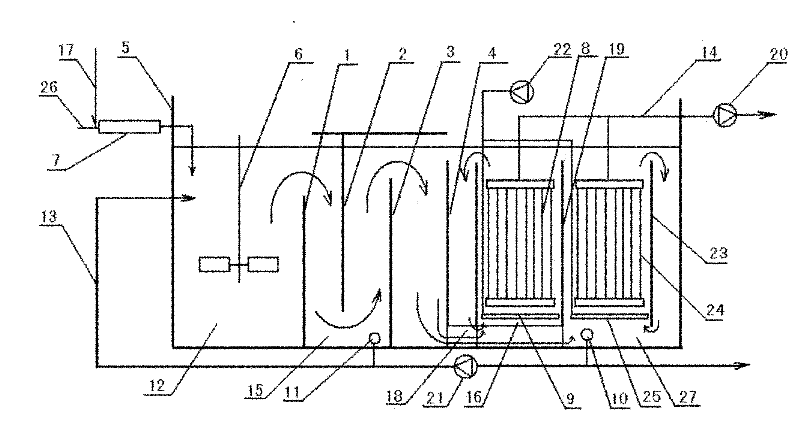

Enhanced phosphorus removal membrane bioreactor

InactiveCN102161552ATo achieve the effect of phosphorus removalSlow down the development of pollutionMultistage water/sewage treatmentPre doseFiltration

The invention discloses an enhanced phosphorus removal membrane bioreactor which comprises a reaction tank, a first guide wall, a second guide wall, a third guide wall, a sandwich type guide wall and a fifth guide wall; a blender is arranged in a facultative zone; the lower part of the inside of the sandwich layer guide wall is provided with a connecting device composed of a groove and a bulge; one end of the groove is communicated with a membrane filtration zone; the inside of the bulge is provided with a channel used for connecting an anaerobic zone and the membrane filtration zone; a raw water pipeline and a coagulant-dosing pipeline are separately connected with a static mixer and then connected with the reaction tank; and a first aerator is arranged below a first membrane component. The bioreactor disclosed by the invention adopts coagulant pre-dosing, thus the formation of sludge floc can be enhanced, the adsorption and capturing functions of sludge floc to the phosphorus in water can be enhanced, and the effect of removing phosphorus can be realized; after coagulant is dosed, the formed flocculent sludge is favorable for delaying membrane pollution and prolonging the cleaning period of the membrane; and the dissolved oxygen in the sludge can be consumed step by step, and the problem that the phosphorus release in the anaerobic zone is affected owning to the rich oxygen in the return sludge of the membrane filtration zone can be effectively avoided.

Owner:TIANJIN POLYTECHNIC UNIV

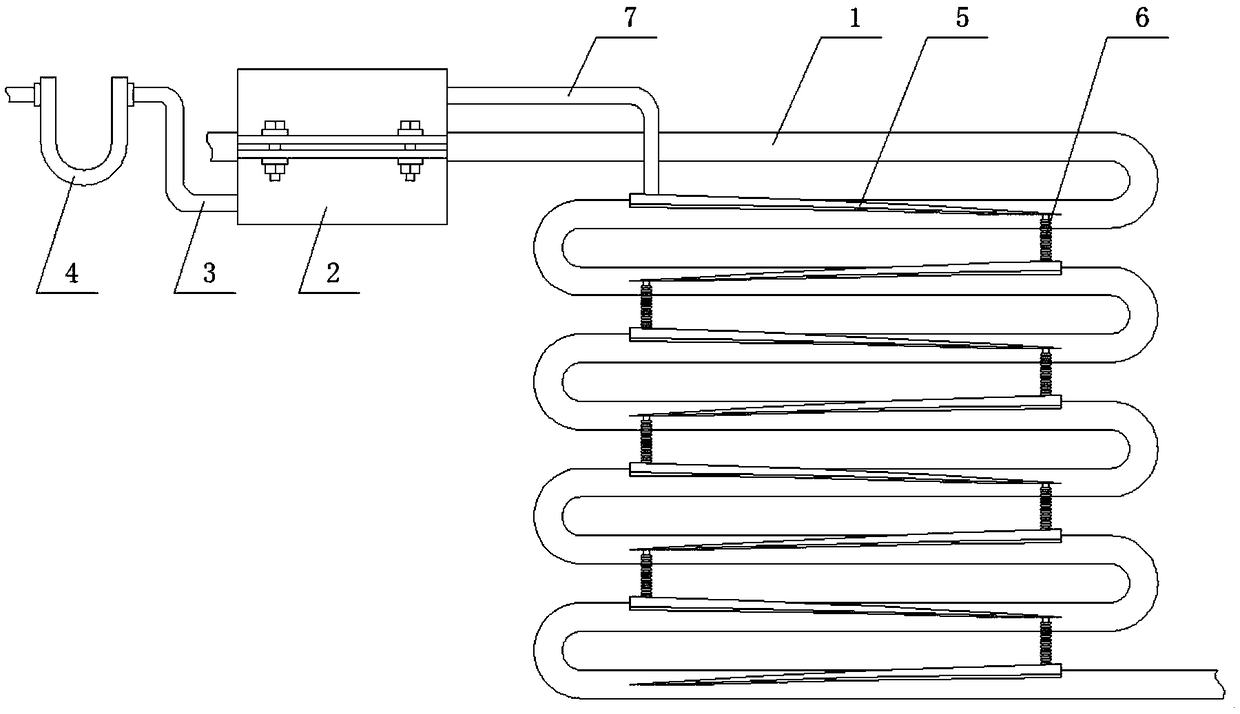

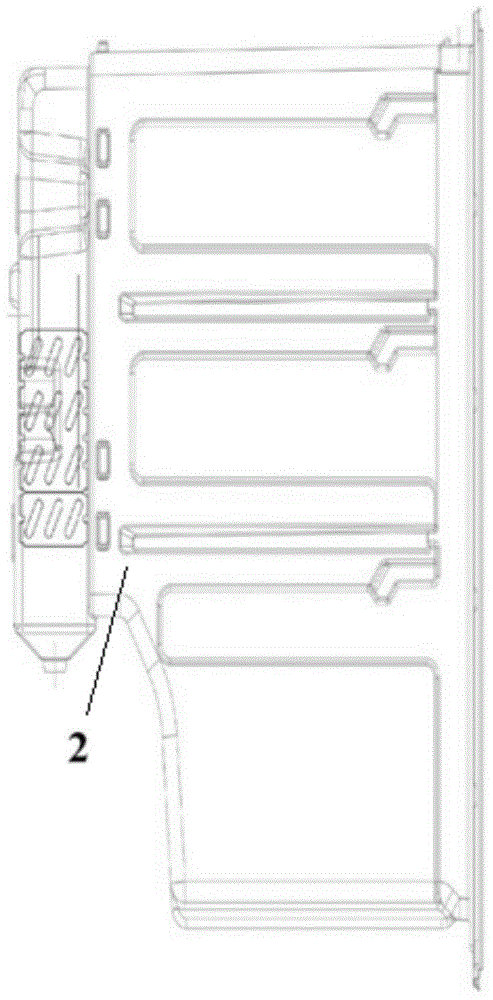

Refrigerator inner container and refrigerator

InactiveCN104864663AAvoid deformationLimit up and down movementLighting and heating apparatusRefrigeration devicesRefrigerator carRefrigerated temperature

The invention provides a refrigerator inner container and a refrigerator. The refrigerator inner container comprises an evaporator and a refrigerator inner container body; the evaporator comprises evaporating pipes; the inner wall of the refrigerator inner container body is provided with bosses which are located below the evaporating pipes and make contact with the outer walls of the evaporating pipes, wherein the bosses are used for supporting the evaporating pipes to enable the evaporator to be assembled on the refrigerator inner container body. According to the technical scheme, the bosses are arranged on the inner wall of the refrigerator inner container body, when the evaporator is installed on the refrigerator inner container body, the bosses can be clamped in the middles of the evaporating pipes of the evaporator to limit the evaporating pipes to move up and down, a role of supporting the evaporating pipes is played, therefore, the stability of the evaporator in the transportation process can be improved, the problems that the evaporating pipes at the bottom of the evaporator is too close to or makes contact with the bottom of the refrigerator inner container body due to the fact that the evaporator falls caused by road bumping can be avoided, then the problem that the refrigerator inner container body is deformed due to the too high temperature can be avoided, and the using safety of the refrigerator can be effectively improved.

Owner:HEFEI MIDEA REFRIGERATOR CO LTD +1

Air and gas supply structure of gas radiant furnace

An air and gas supply structure for the gas radiant furnace comprises a mixing tube, an air supply tube and a gas supply tube. The air supply tube and the gas supply tube are disposed axially along the mixing tube. A gas mixing device disposed in the air supply tube can make the air flowed into the tube have the uniform flow rate. The uniform flow rate of the air can minimize the flow resistance of the air and gas to reduce the flowing noise while mixing the air and gas fully and uniformly.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

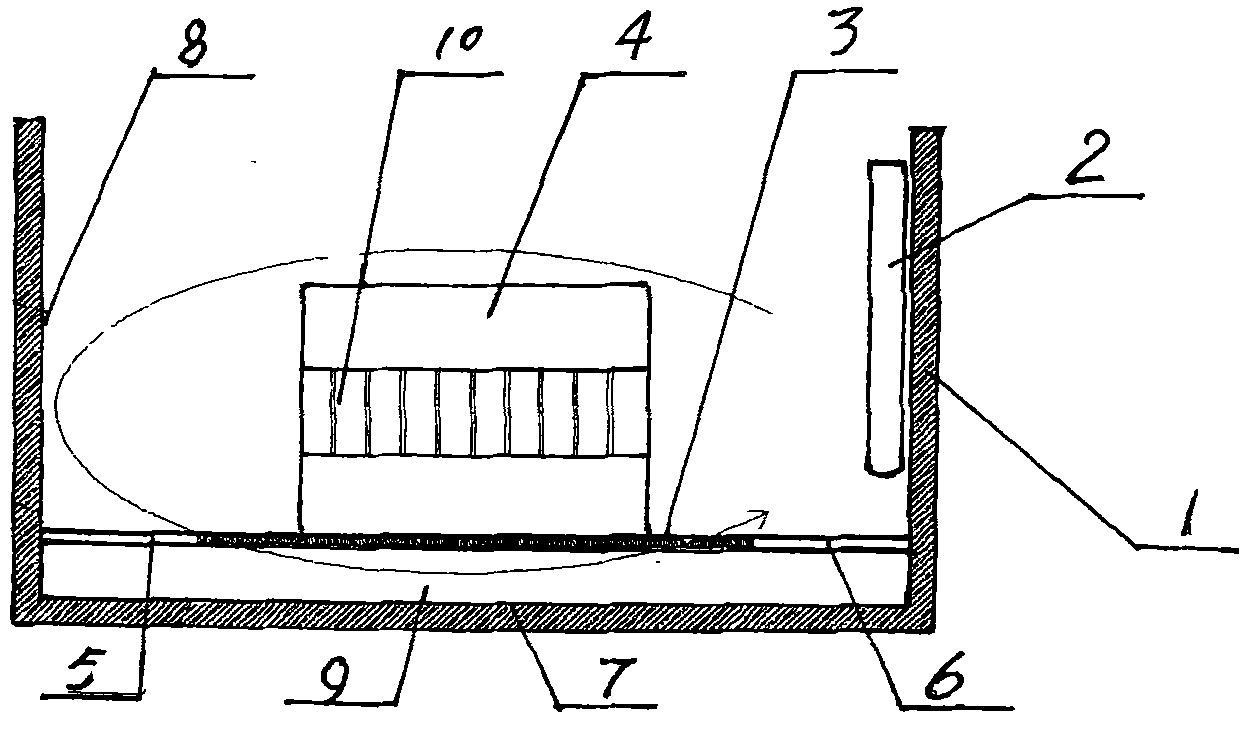

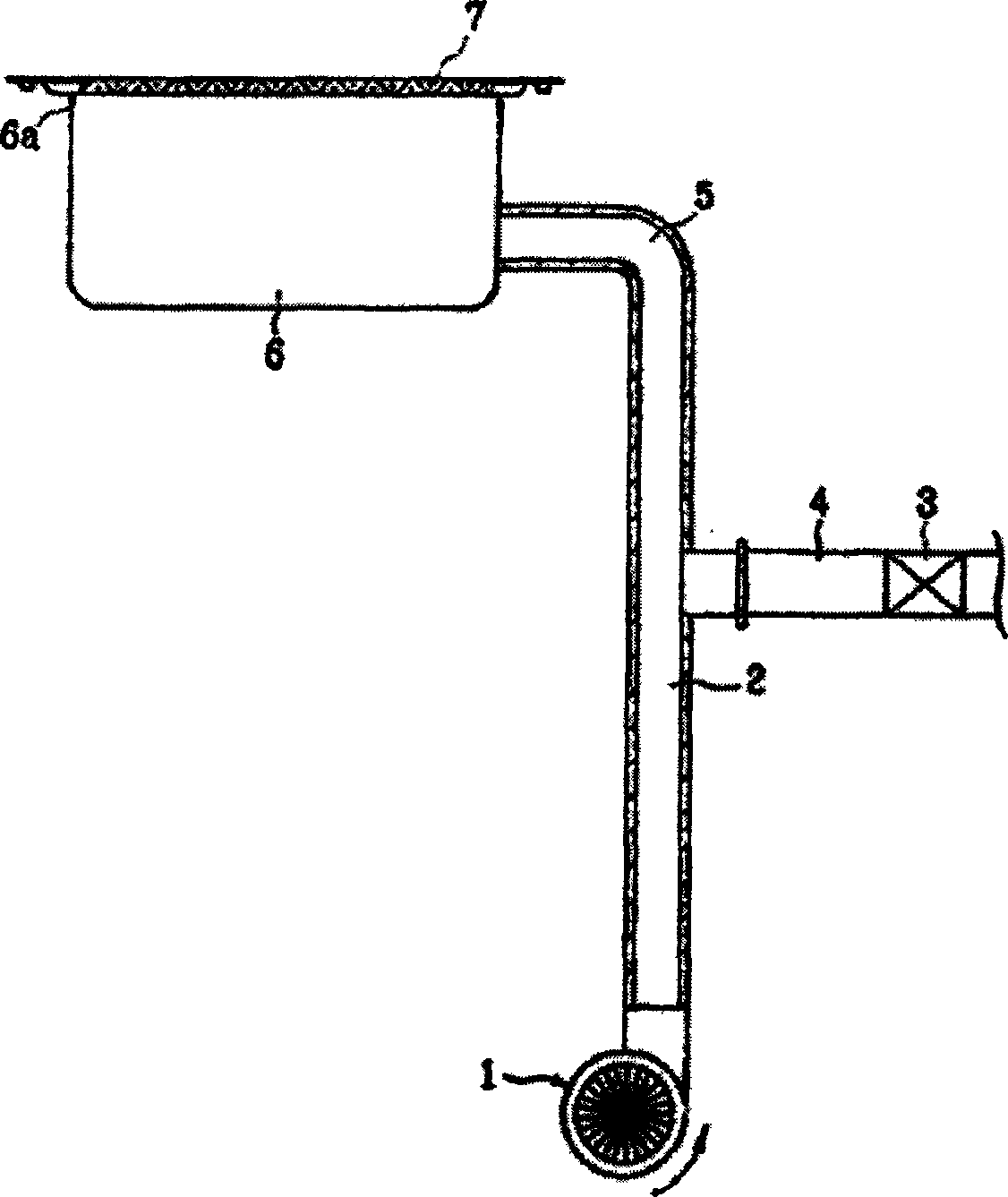

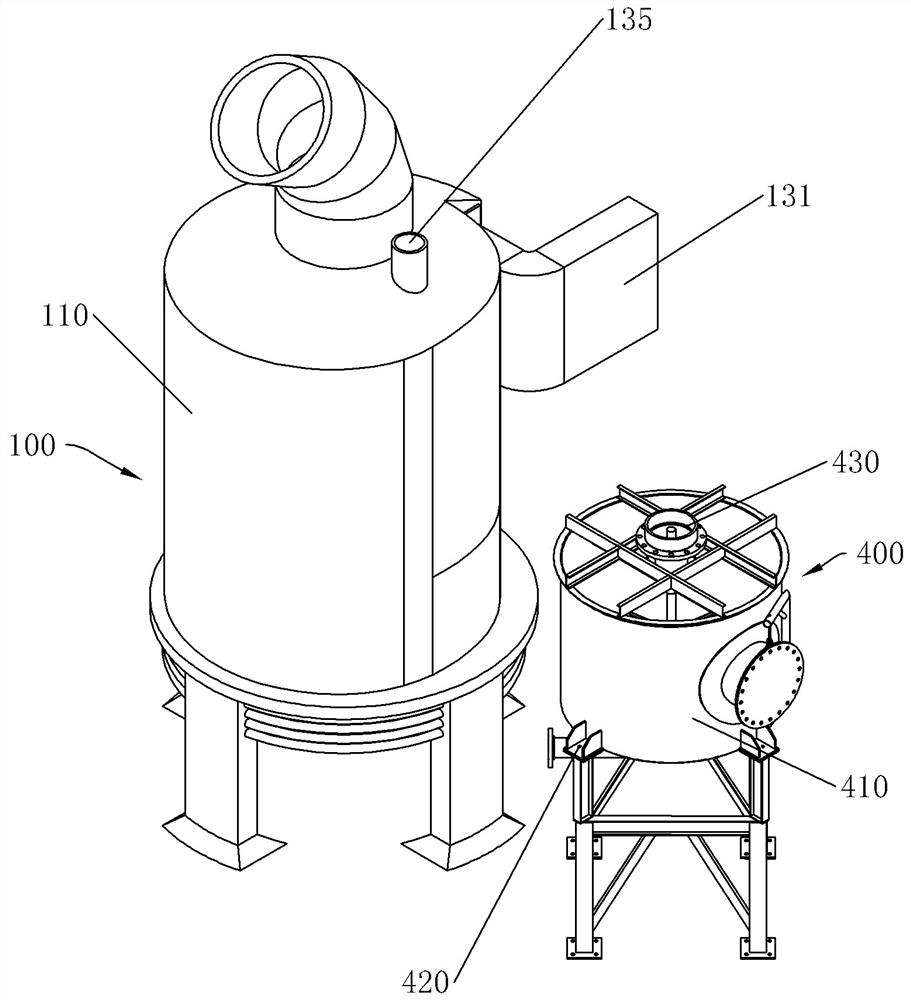

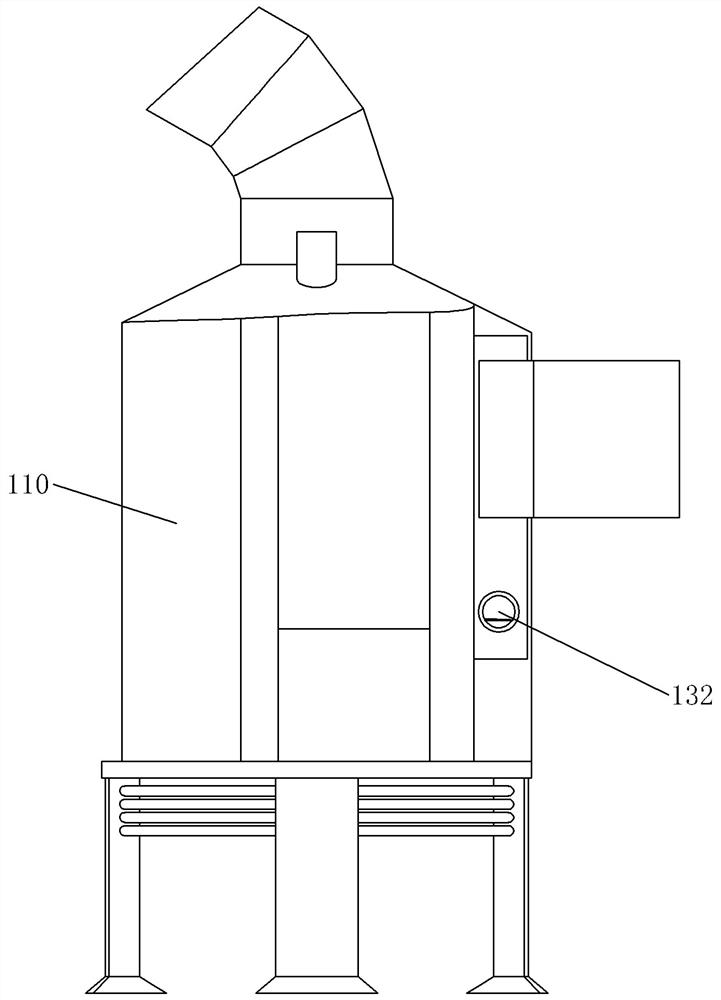

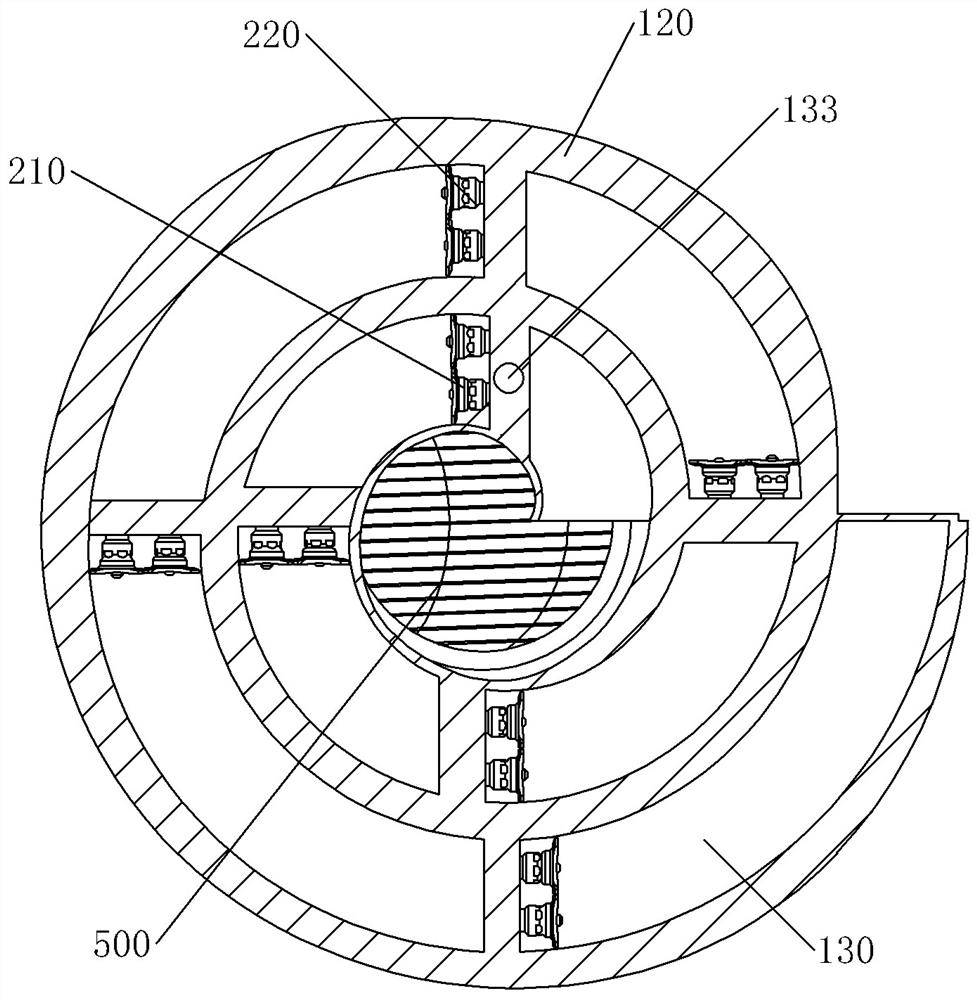

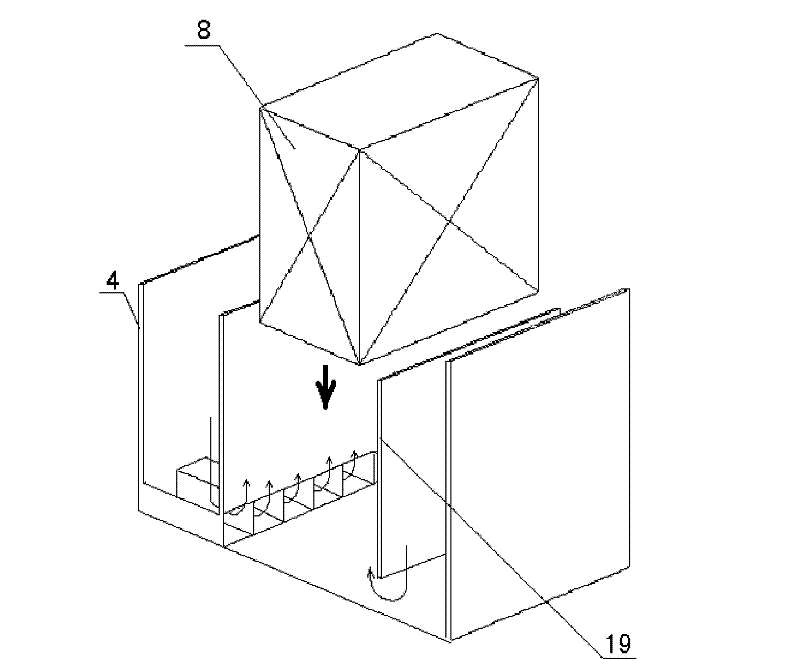

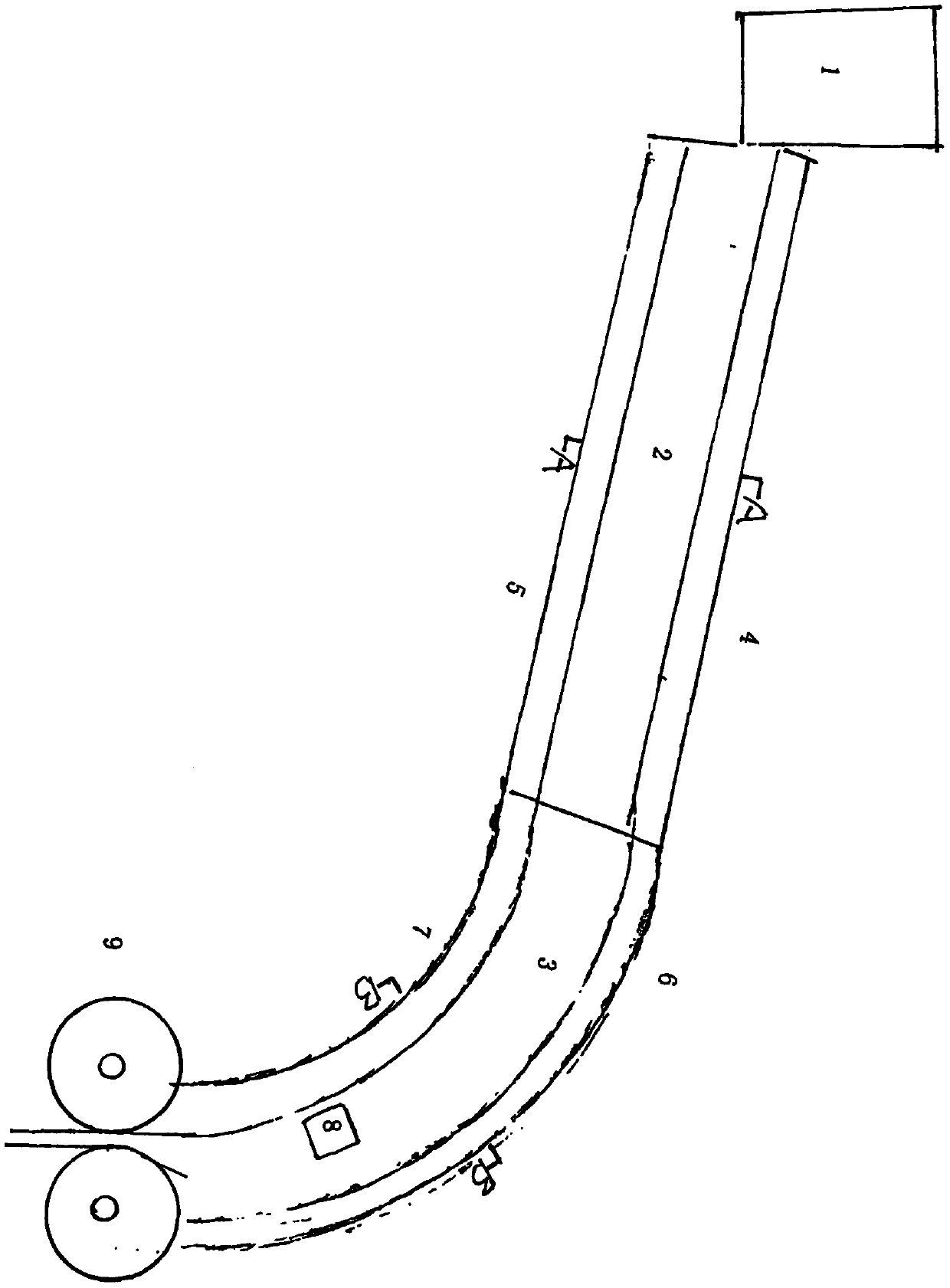

Air chopped slag treatment device for steelmaking slag treatment

PendingCN110628970AImproved granulationImprove flow trajectoryRecycling and recovery technologiesProcess efficiency improvementSlag

The invention provides an air chopped slag treatment device for steelmaking slag treatment applied to the energy-saving and environment-friendly steel slag technical field. A middle slag ladle (2) ofthe air chopped slag treatment device for steelmaking slag treatment is located below a large slag ladle (1), the lower portion of the middle slag ladle (2) communicates with a deslagging launder (3),a granulator (4) is located below the deslagging launder (3), a middle slag tank passing pipeline (5) is located in the middle slag ladle (2), the inner wall of the middle slag tank passing pipeline(5) is provided with slag launders (6) which are vertically arranged, and each slag launder (6) extends to the lower portion of the middle slag tank passing pipeline (5) from the upper portion of themiddle slag tank passing pipeline (5). The air chopped slag treatment device for steelmaking slag treatment can effectively guide the flowing state and the flowing speed of the steel slag in the middle slag tank, it is ensured that the slag flow is uniform and stable before passing through the granulator, the stability of the slag flow in front of the granulator can be improved, the slag flow evenly passes through the position in front of the granulator, and the steel slag granulation effect is ensured.

Owner:MAANSHAN IRON AND STEEL COMPANY

Acid-making tail gas purifying and white-removing device

ActiveCN114870606AEasy to purify and absorbAvoid disturbanceGas treatmentDispersed particle separationFlue gasPhysical chemistry

The invention relates to the field of flue gas purification, in particular to an acid-making tail gas purification and white gas removal device. Comprising a purification device, a stirring device and a demister, the purification device comprises a purification cylinder, a flow guide plate, a spraying structure and a precipitation structure, the flow guide plate is a vertical plate with a vortex-shaped cross section, and a limestone solution enters a reaction cavity from a liquid inlet in the center of the reaction cavity after being stirred by the stirring device and flows in a vortex shape from inside to outside along the flow guide plate; tail gas enters the reaction cavity from the gas inlet in the outer side of the reaction cavity, advances in a vortex shape from outside to inside along the guide plate, is subjected to purification reaction with a sprayed limestone solution and then is discharged from the gas outlet, and the vortex-shaped reaction cavity increases the space and stroke of gas-liquid reaction under the condition of the same equipment and the same volume. And purification and absorption of sulfur dioxide and other substances in the tail gas are promoted. Meanwhile, the reacted limestone solution flows back to the stirring device to be stirred again, disturbance to precipitates is avoided, and generation of precipitate crystallization is facilitated.

Owner:CANGZHOU CHINA RAILWAY EQUIP MFG MATERIALS CO LTD

Gluing device and gluing method

ActiveCN103909040BControl flow speedUniform flow velocityNon-macromolecular adhesive additivesMagnetsEngineeringGlue line

The present invention provides a gluing device and a gluing method, the gluing device comprises: a drip nozzle for guiding the adhesive along the dripping direction, the adhesive is added with a magnetic material; a magnetic field generating structure, It is used to apply an induced magnetic field to the dripping head, and the magnetic material exerts the same or opposite force to the dripping direction through the induced magnetic field. The present invention adds a magnetic material to the adhesive to be dripped, and uses the induced magnetic field applied to the dripping head to apply the same or opposite force to the magnetic material in the dripping direction, so that the magnetic material acts on the adhesive to achieve the purpose of controlling the flow rate of the adhesive in the dripping direction, so that the adhesive in the gluing device can drip out smoothly, and the flow rate is more uniform, which solves the problem of air pressure or pressure when gluing in the prior art. Insufficient glue breaking and glue line thinning.

Owner:BOE TECH GRP CO LTD +1

Enhanced phosphorus removal membrane bioreactor

InactiveCN102161552BTo achieve the effect of phosphorus removalSlow down the development of pollutionMultistage water/sewage treatmentPre doseFiltration

The invention discloses an enhanced phosphorus removal membrane bioreactor which comprises a reaction tank, a first guide wall, a second guide wall, a third guide wall, a sandwich type guide wall and a fifth guide wall; a blender is arranged in a facultative zone; the lower part of the inside of the sandwich layer guide wall is provided with a connecting device composed of a groove and a bulge; one end of the groove is communicated with a membrane filtration zone; the inside of the bulge is provided with a channel used for connecting an anaerobic zone and the membrane filtration zone; a raw water pipeline and a coagulant-dosing pipeline are separately connected with a static mixer and then connected with the reaction tank; and a first aerator is arranged below a first membrane component. The bioreactor disclosed by the invention adopts coagulant pre-dosing, thus the formation of sludge floc can be enhanced, the adsorption and capturing functions of sludge floc to the phosphorus in water can be enhanced, and the effect of removing phosphorus can be realized; after coagulant is dosed, the formed flocculent sludge is favorable for delaying membrane pollution and prolonging the cleaning period of the membrane; and the dissolved oxygen in the sludge can be consumed step by step, and the problem that the phosphorus release in the anaerobic zone is affected owning to the rich oxygen in the return sludge of the membrane filtration zone can be effectively avoided.

Owner:TIANJIN POLYTECHNIC UNIV

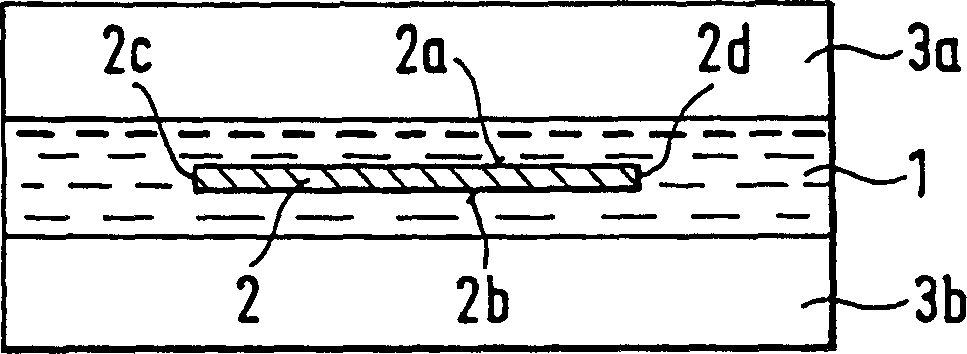

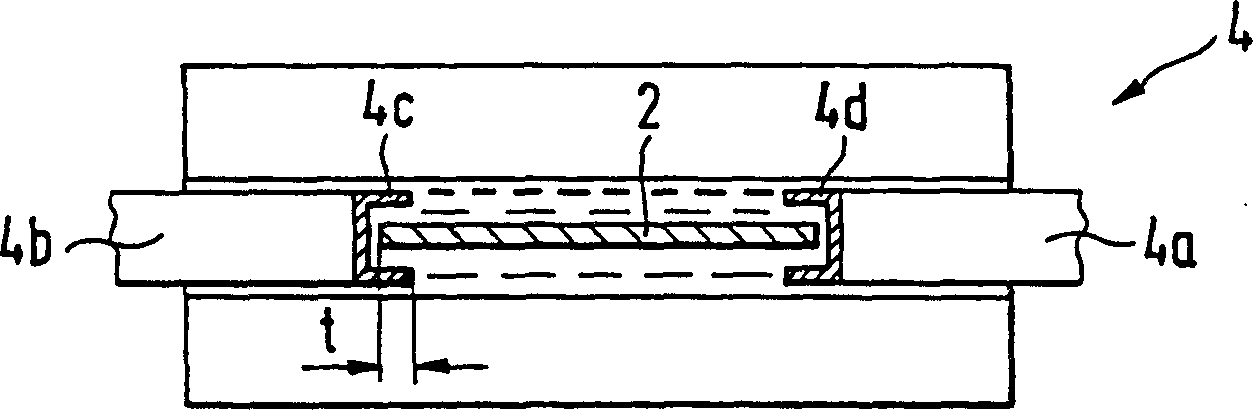

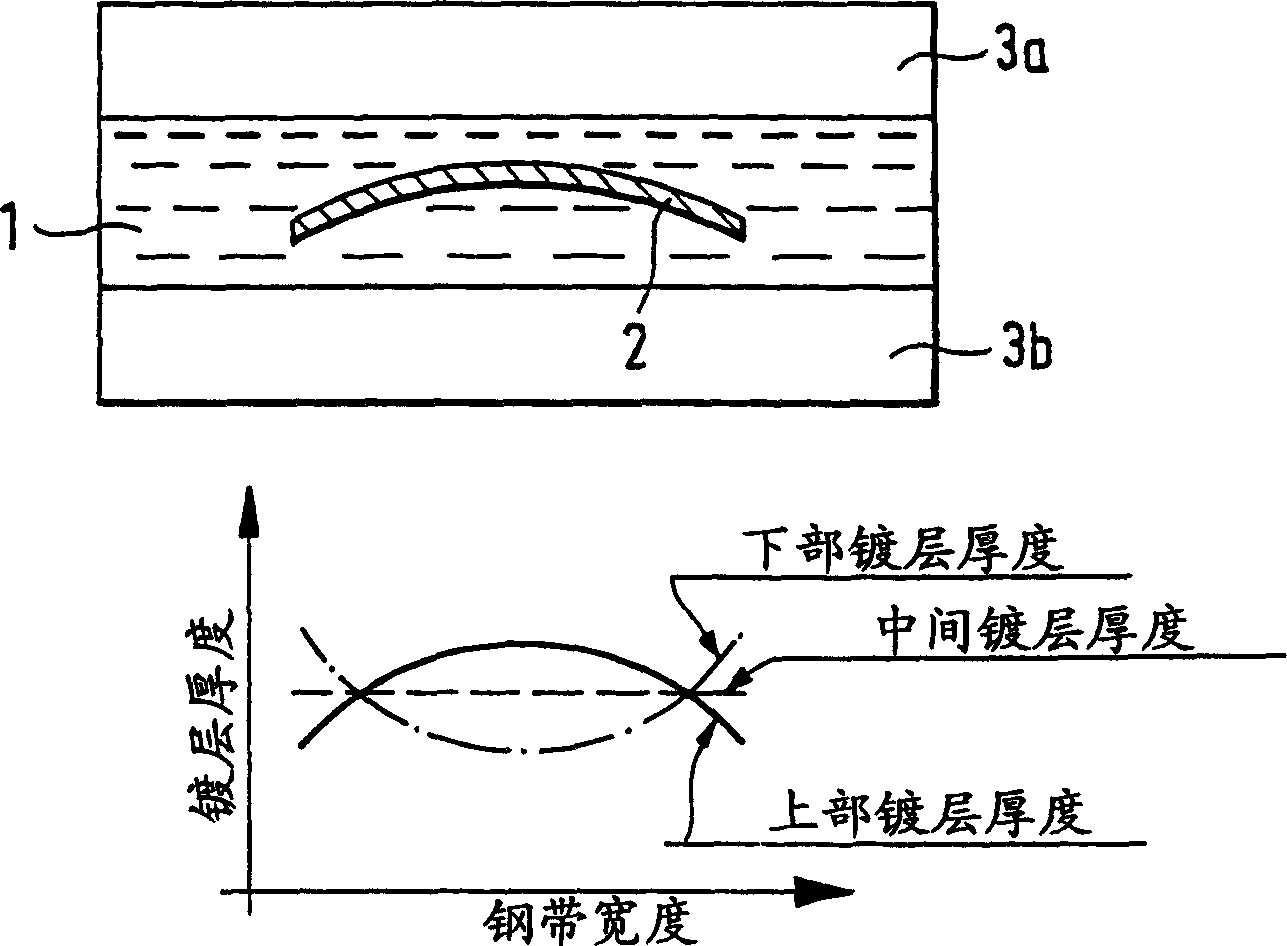

Device for electroplating steel band coating

The invention provide an apparatus for electrogalvanic coating which surely prevents the edge excessly depositing of the separate metal, simultaneously eliminates the difficulties of the apparatus to be used for edge masks. The solution with the above project is that: in the said type apparatus, the respective anodes are divided to several anode stripes in parallel with the moving direction of the band plate and these anode stripes are insulated from each other. A current is passed discretely through each of the respective anode stripes.

Owner:SMS SCHLOEMANN SIEMAG AG

Medicine liquid flow rate controller for infusion set

InactiveCN100509070CGuaranteed equidistant extrusionAvoid Intermittent FluctuationsInfusion devicesFlow controlInfusion setChassis

The invention relates to a device for controlling the liquid flow rate of an infusion set. It consists of a casing and a pusher with rollers installed on the casing. The extrusion mechanism that cooperates with the roller of the flowmeter is installed on the casing through a positioner that is parallel to the roller. The movable part is connected with an elastic object fixedly connected with the casing at one end. The invention has the characteristics of simple operation, accurate measurement, simple overall structure and low manufacturing cost.

Owner:闫云涛

Semi-solid steel rolling equipment and control method thereof

The invention discloses semi-solid steel rolling equipment and a control method thereof. The molten steel from a converter or an electric furnace flows into a flow guide tank, water steam or air enters into an upper cooling flat tube and a lower cooling flat tube, the molten steel in the flow guide tank is cooled, and the molten steel in the flow guide tank is reduced to the melting point and thenflows into an arc tank. The water steam or air enters into an upper arc cooling flat tube and a lower arc cooling flat tube, the molten steel with the temperature at the melting point is cooled on the arc tank to release heat, the molten steel is cooled and crystallized to form crystal nucleuses, the crystal nucleuses stretch out of crystal branches, vibrating devices installed on the two sides of the arc tank work to vibrate the arc tank, the molten steel with the temperature at the melting point is stirred as the molten steel flows over an even ceramic nail bed of the arc tank, the crystalbranches are broken to form new crystal nucleuses, and the number of the crystal nucleuses increases constantly. The crystallinity degree of the molten steel at the rear end of the arc tank reaches 60%-80%, and the molten steel with the crystallinity degree reaching 60%-80% enters a rolling mill and is rolled into steel with set shapes. The water stream or hot air from the cooling flat tubes is collected and fed into a waste heat generator.

Owner:张英华

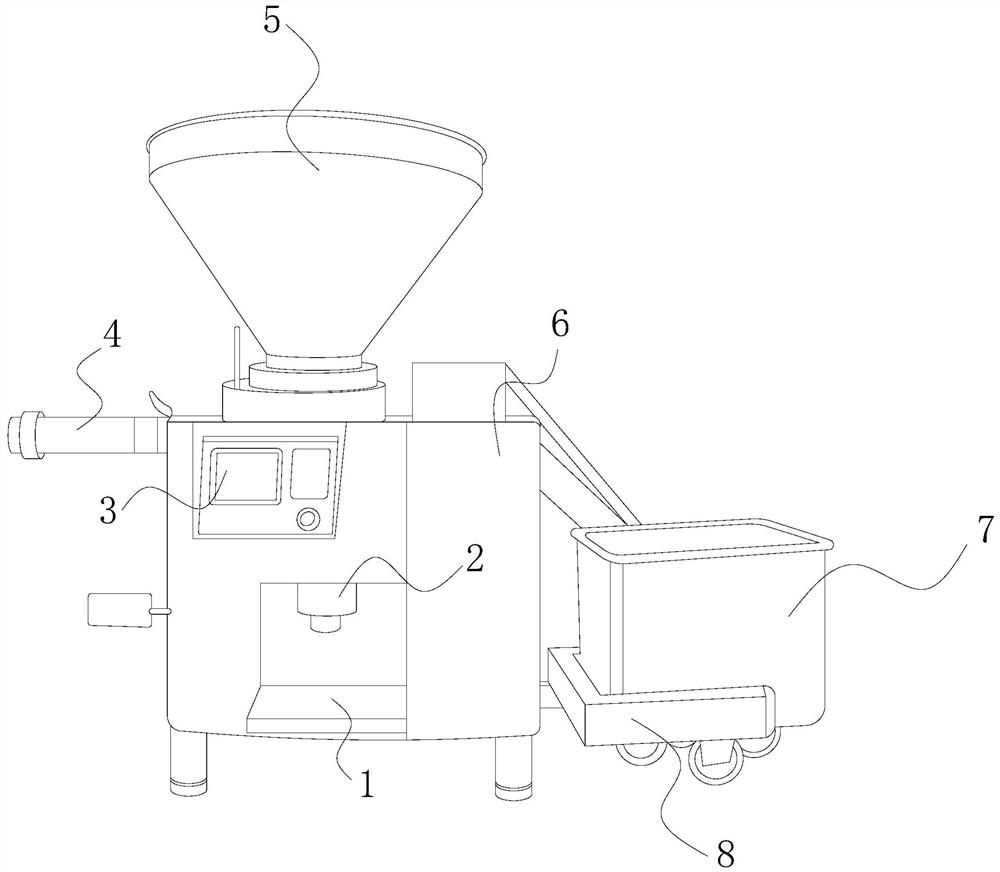

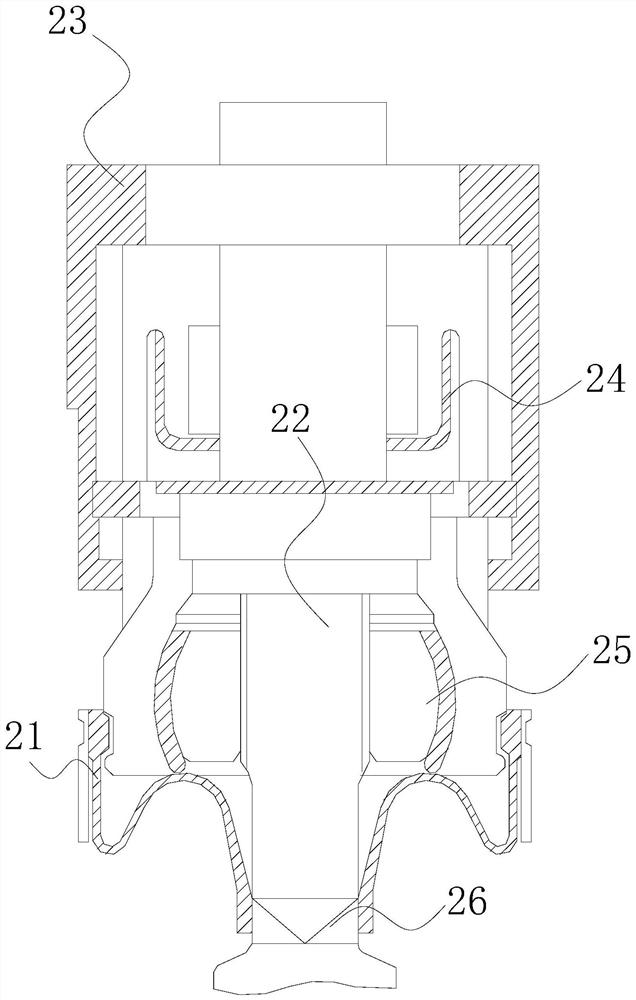

A valve bag vacuum filling equipment

ActiveCN111874290BEasy to fillQuality assuranceLiquid materialStructural engineeringMechanical engineering

The invention discloses a valve bag vacuum filling equipment, the structure of which includes a filling table, a protective device, a control panel, an evacuation valve, a hopper, a main body, a placement cavity, and a card holder. Cooperate with the wave guard to open the dust cover to the outside, which is convenient for valve pocket filling. When the filling is completed, the winding reel drives the wave guard to retract the dust cover to the inside. The dust cover is pulled inward, so that the dust cover fits on both sides of the filling head to protect the filling head and ensure the purity and quality of the beverage filling; when the beverage enters the diversion tank, the impact bullet The block blocks the filled beverage to reduce the impact of the beverage. The buffered beverage flows into the swirl plate through the impact bullet. , to prevent beverages from spilling and falling on the ground, and improve the filling efficiency of beverages.

Owner:郑州宝腾科技有限公司

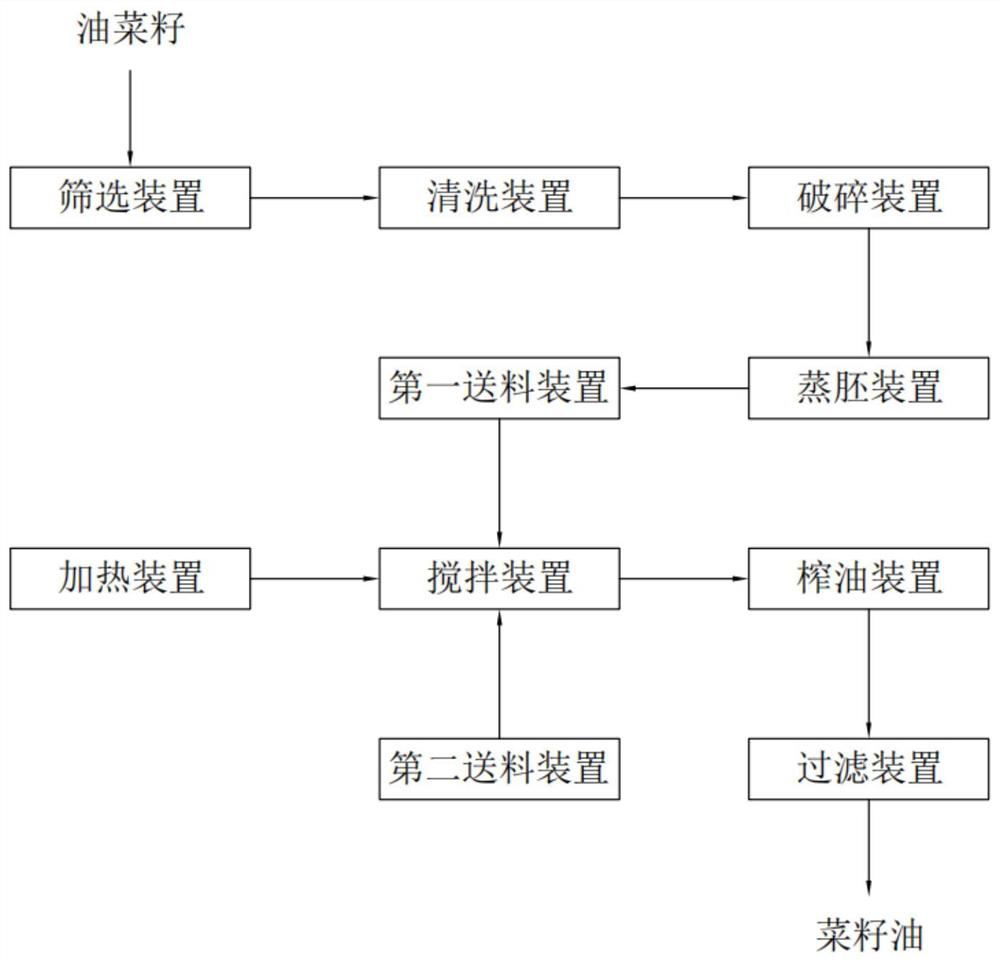

Rapeseed oil processing equipment

InactiveCN114032136AOil out evenlyReduce the temperatureFatty-oils/fats productionOil processingProcess engineering

The invention discloses rapeseed oil processing equipment, and relates to the technical field of rapeseed oil processing. The rapeseed oil processing equipment comprises a screening device, a cleaning device, a crushing device, a blank steaming device, an oil squeezing device and a filtering device which are sequentially arranged; a first feeding device is arranged at the bottom of the blank steaming device, and a stirring device is arranged on the oil squeezing device; the first feeding device feeds rapeseeds in the blank steaming device into the stirring device, a second feeding device is connected to the stirring device and used for feeding cavings or tea seeds into the stirring device, and the evenly-mixed materials in the stirring device are fed into the oilsqueezing device; and a heating device for heating the stirring device is arranged outside the stirring device, oil squeezed by the oil squeezing device enters the filtering device, and the filtering device filters the oil. By guaranteeing the temperature of the rapeseeds and reducing the flowing speed of the rapeseeds in the squeezer, the oil extraction rate is increased, the function is practical, and use is convenient.

Owner:上海明鹤实业有限公司

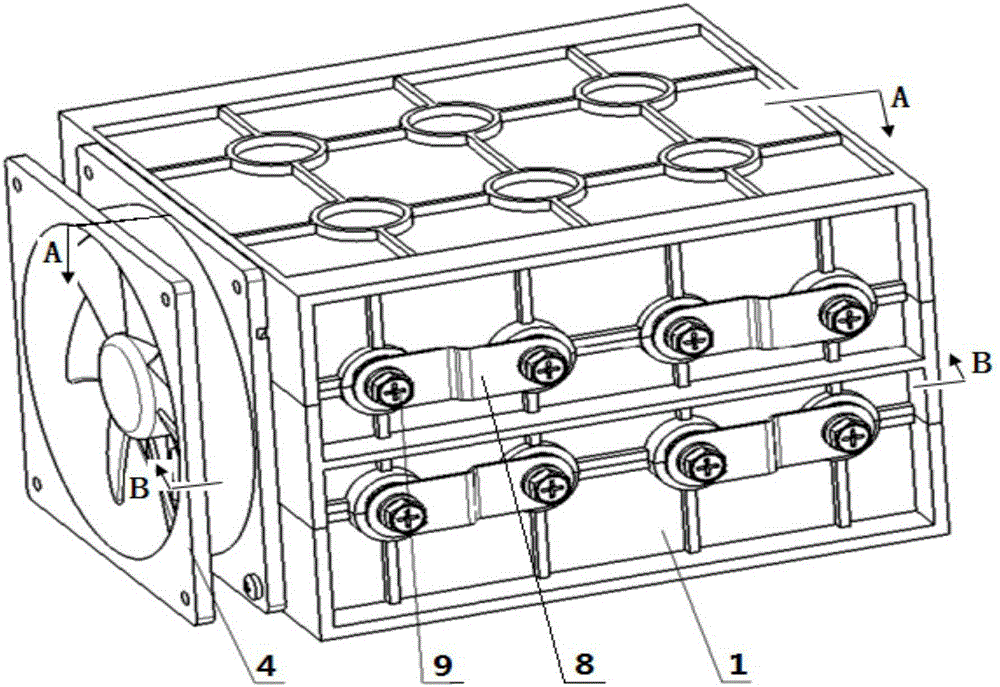

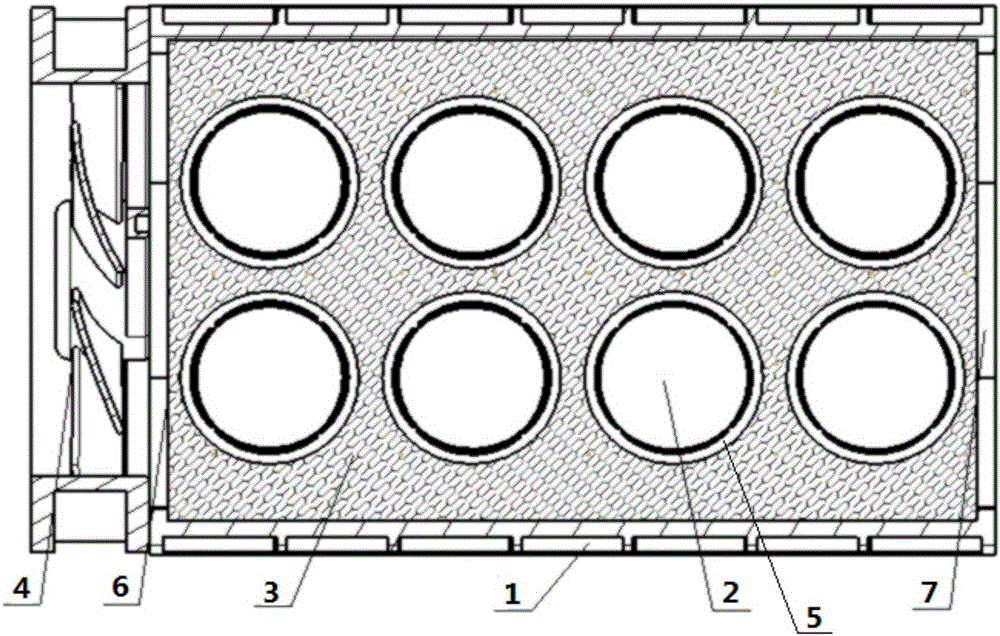

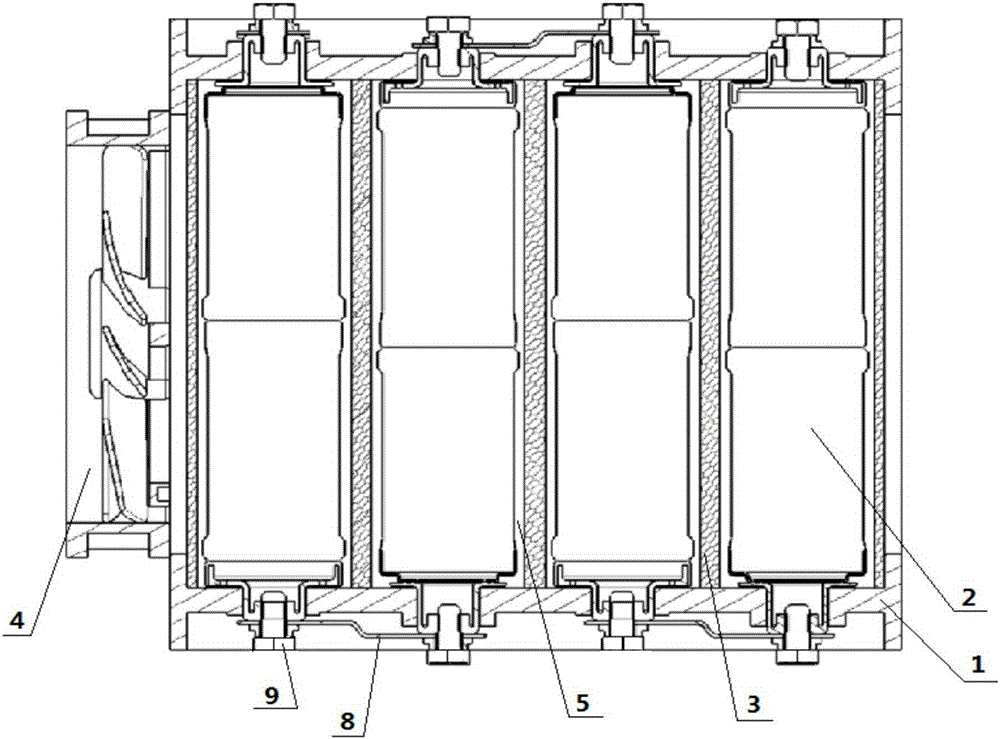

a battery pack

ActiveCN103606638BExtend your lifeEasy to placeBattery isolationSecondary cellsMetallic materialsProcess engineering

Owner:湖南科霸汽车动力电池有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com