Disk of disk centrifuge

A disc centrifuge and disc technology, applied to centrifuges, centrifuges with rotating drums, etc., can solve problems that are not conducive to improving hysteresis, uneven material distribution, and affecting the separation performance of disc centrifuges. , to achieve the effect of improving fluid flow hysteresis, uniform liquid flow velocity, and favorable slag discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings.

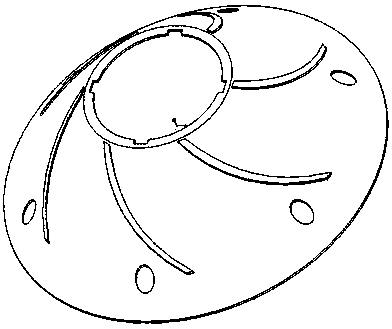

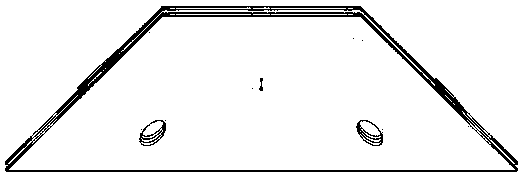

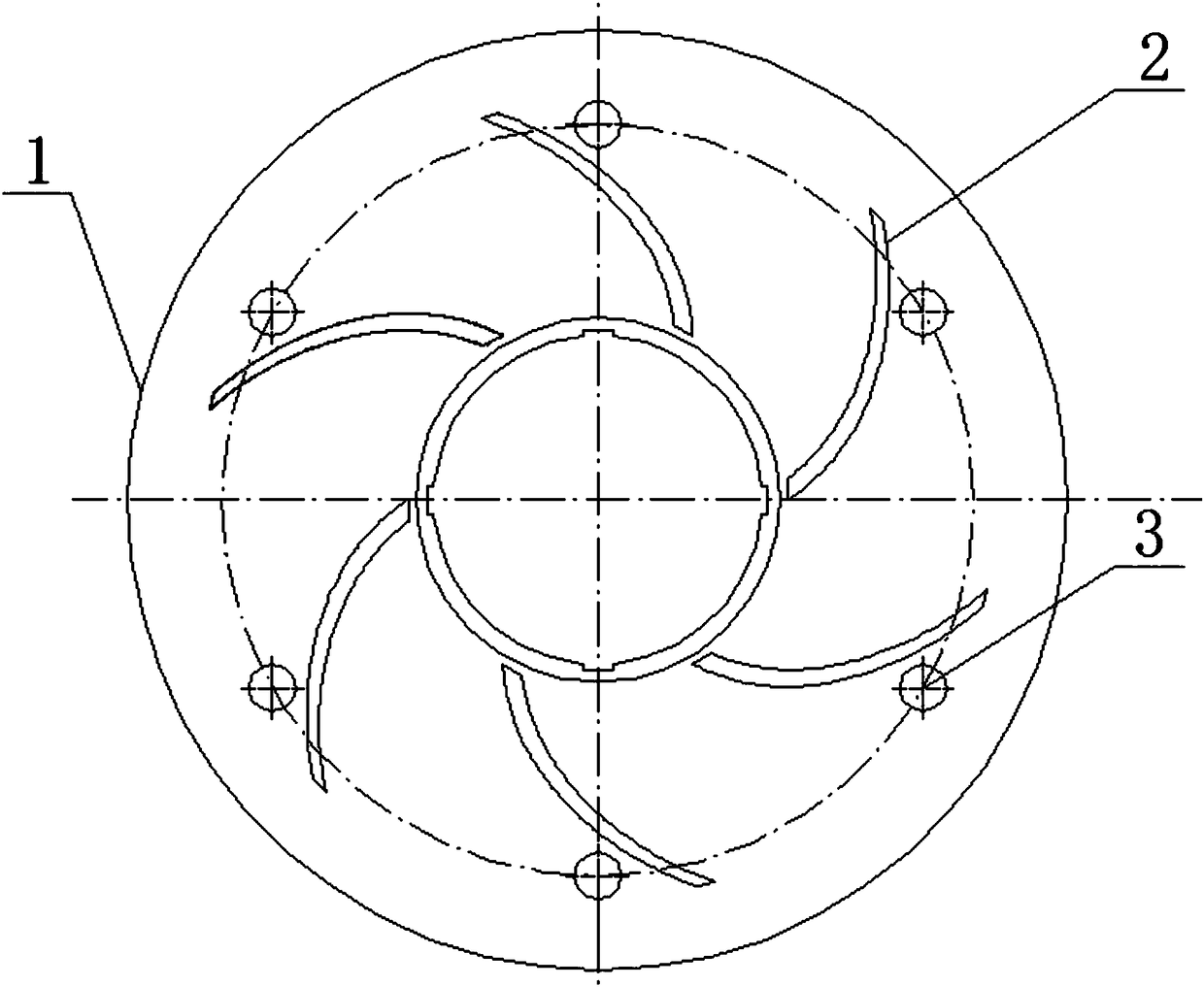

[0020] A disc centrifuge disc provided in this example includes a disc body (1), several spacer ribs (2) and several feeding holes (3). It is characterized in that: the disc body (1) is an inverted conical disc with a small upper end and a larger lower end; the fixed-distance ribs (2) are in a spiral shape, extending from the small end of the disc to the surface of the conical disc. The big end extends backward against the direction of disc rotation; the axis of the feed hole (3) is parallel to the axis of the conical disc, the number of which is equal to the number of ribs, and is located upstream of the fixed-distance ribs. The spacer ribs (2) and feed holes (3) are symmetrically distributed about the center.

[0021] The above disc centrifuge disc is characterized in that the ratio of the distance between the spacer ribs at the small end of the disc to the diameter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com