Two-section type entrained-flow bed gasification device for biomasses and gasification method

A gasification device, two-stage technology, applied in the direction of granular/powdered fuel gasification, combustible gas manufacturing, petroleum industry, etc., can solve environmental pollution, increase greenhouse effect and other problems, achieve strong controllability, single Furnace gas production increased, the effect of promoting combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

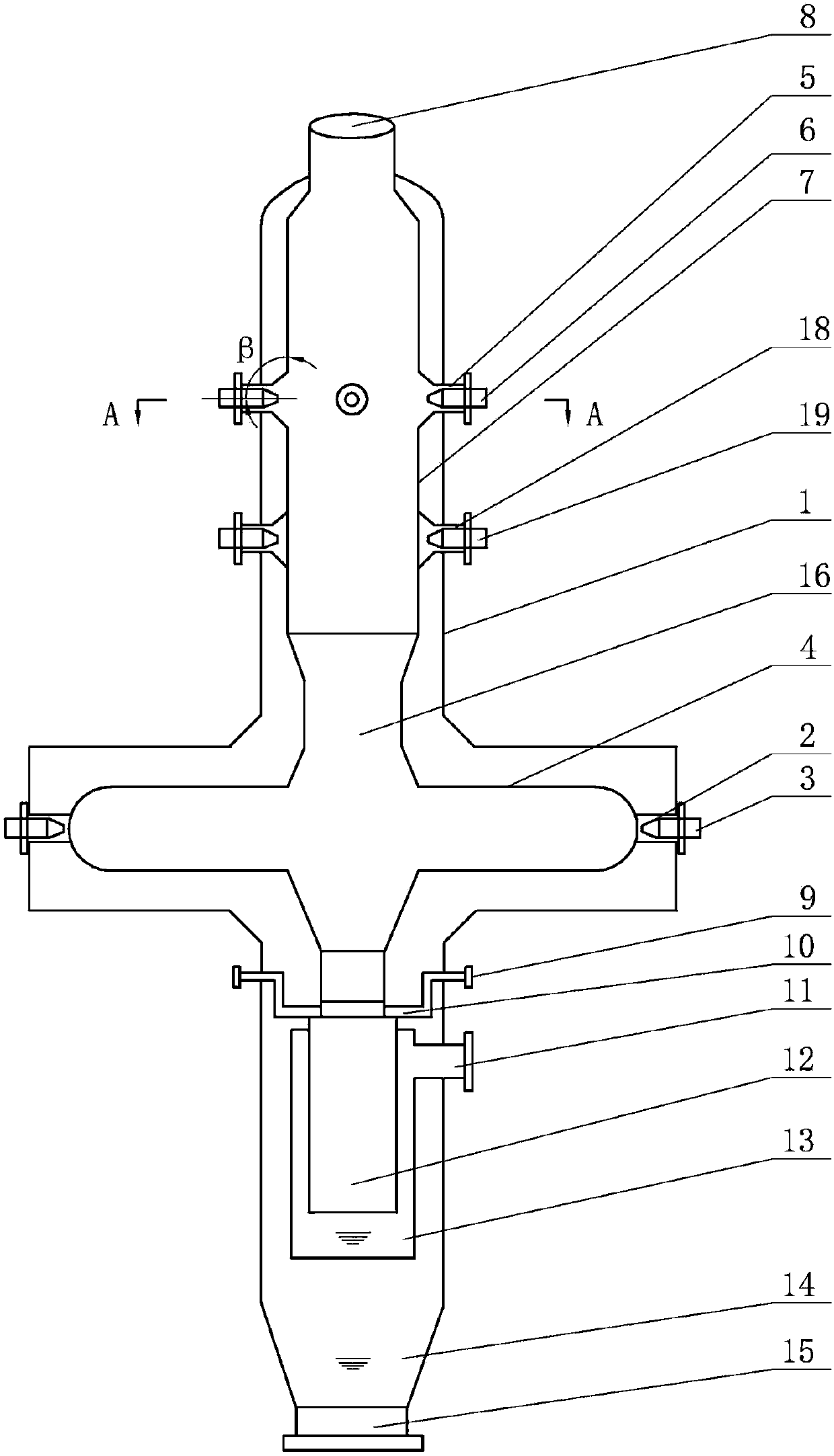

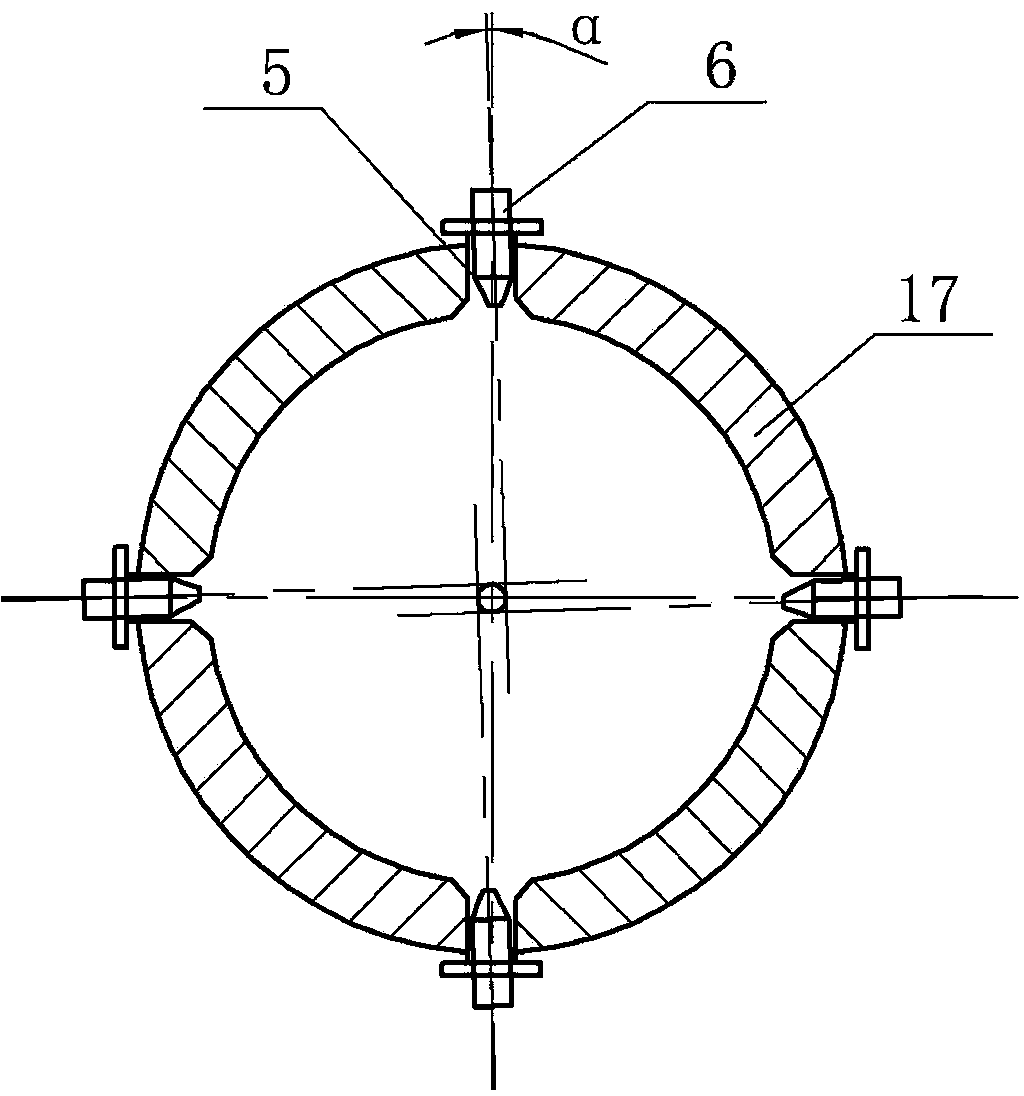

[0019] Example 1: see figure 1 with figure 2 , A biomass two-stage entrained-bed gasification device, comprising a furnace shell, a gasification chamber and a synthesis gas cooling chamber are arranged in the furnace shell, and the gasification chamber is divided into an upper gasification chamber and a lower gasification chamber. The top of the upper gasification chamber is provided with an overhead syngas outlet, the lower gasification chamber is connected to the upper gasification chamber through the middle throat section, and the axes of the upper and lower gasification chambers intersect vertically, and the synthesis gas The gas cooling chamber is arranged below the gasification chamber in the lower section, the conical slag opening of the gasification chamber is arranged at the bottom of the gasification chamber in the lower section, the bottom of the furnace shell is provided with a slag pool, and the bottom of the slag pool is provided with a slag pool slag discharge po...

Embodiment 2

[0024] Example 2: The figure is not drawn. The structure of Example 2 is basically the same as that of Example 1. The similarities are not repeated. The difference is that the axis of the side process burner and the radial direction of the upper gasification chamber The included angle α is 5°, and the included angle β between the side process burner and the axis of the upper gasification chamber is 5.5°.

Embodiment 3

[0025] Example 3: The figure is not drawn. The structure of Example 3 is basically the same as that of Example 1. The similarities are not repeated. The difference is that the axis of the side process burner and the radial direction of the upper gasification chamber The included angle α is 7.5°, and the included angle β between the side process burner and the axis of the upper gasification chamber is 9.5°.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com