Grinding machine for cereal grains

A technology for grinding machines and grains, applied in the field of grinding machines, which can solve problems such as short slopes, and achieve the effect of uniform air flow speed and constant flow rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

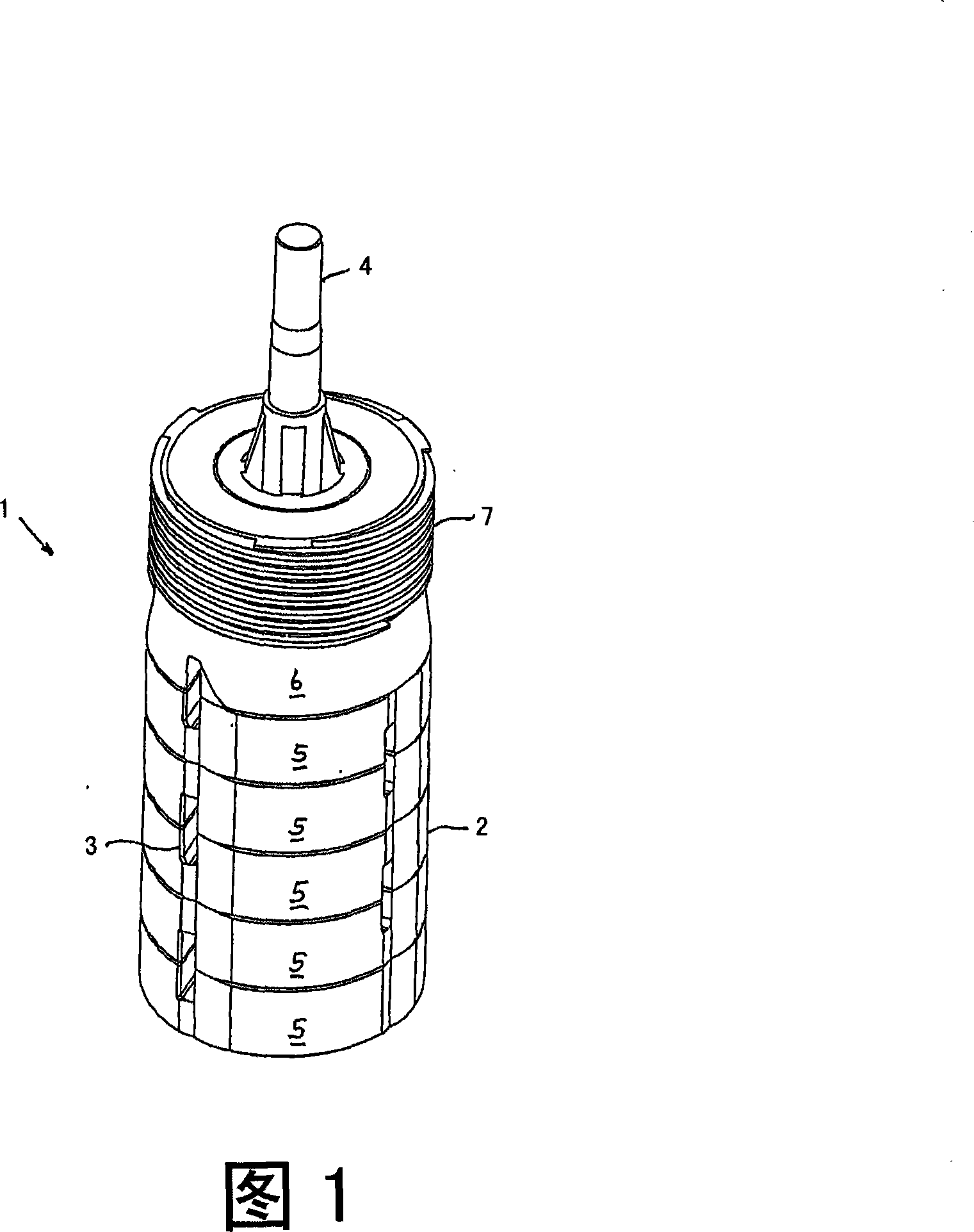

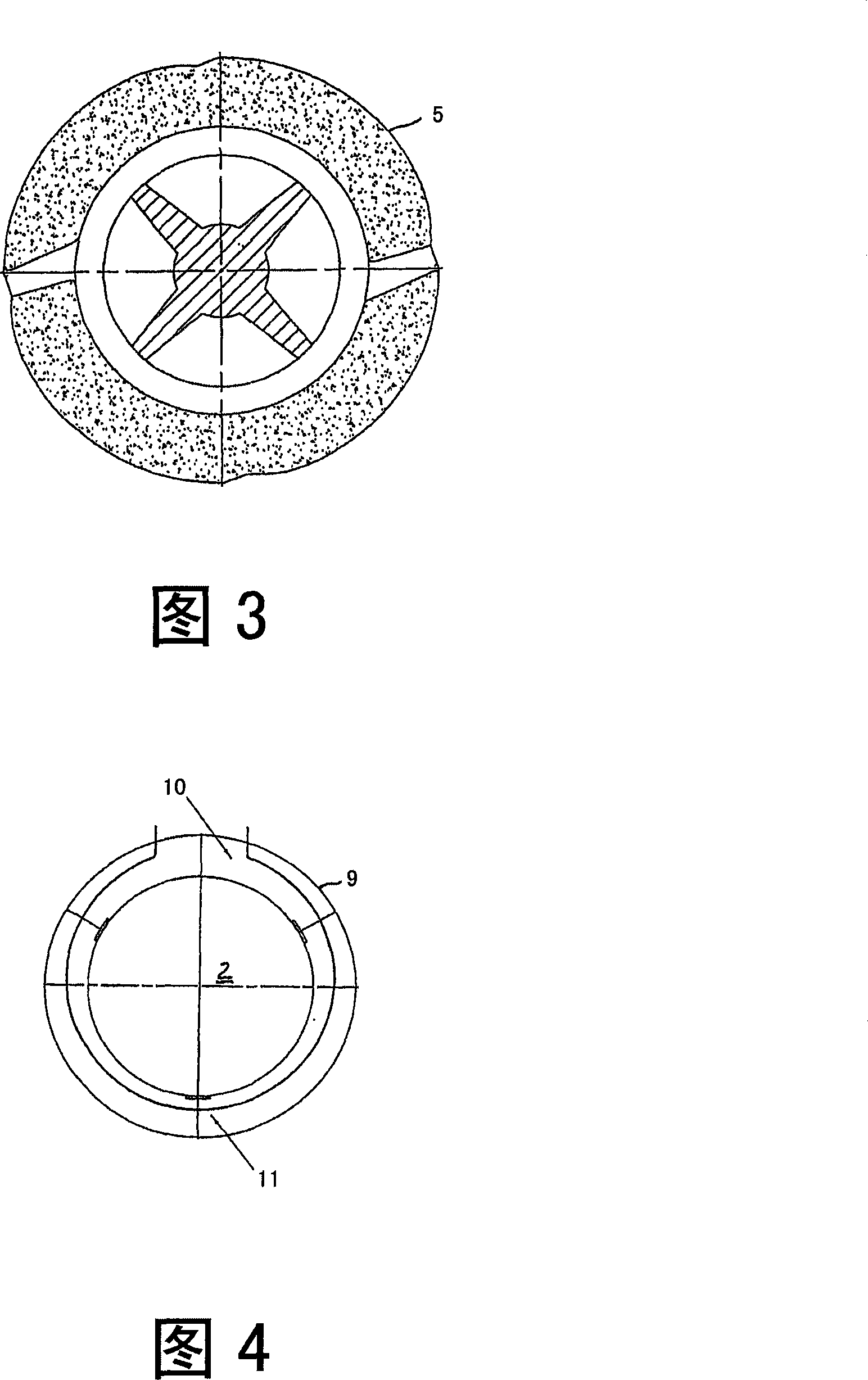

[0018] A grinding machine (not clearly shown), such as the one described in the applicant's patent application document DE-A-10341223, has a vertically arranged grinding rotor 1, whose rotor shaft 4 bears sections 5, 6 and feed screw 7 for grinding tool 2 . The first section 6 after the feed screw 7 is conical. The grinding tool 2 or segments 5 , 6 have vertical vent slots 3 .

[0019] Instead of having sections 5 , 6 , grinding tool 2 can also be designed as one part.

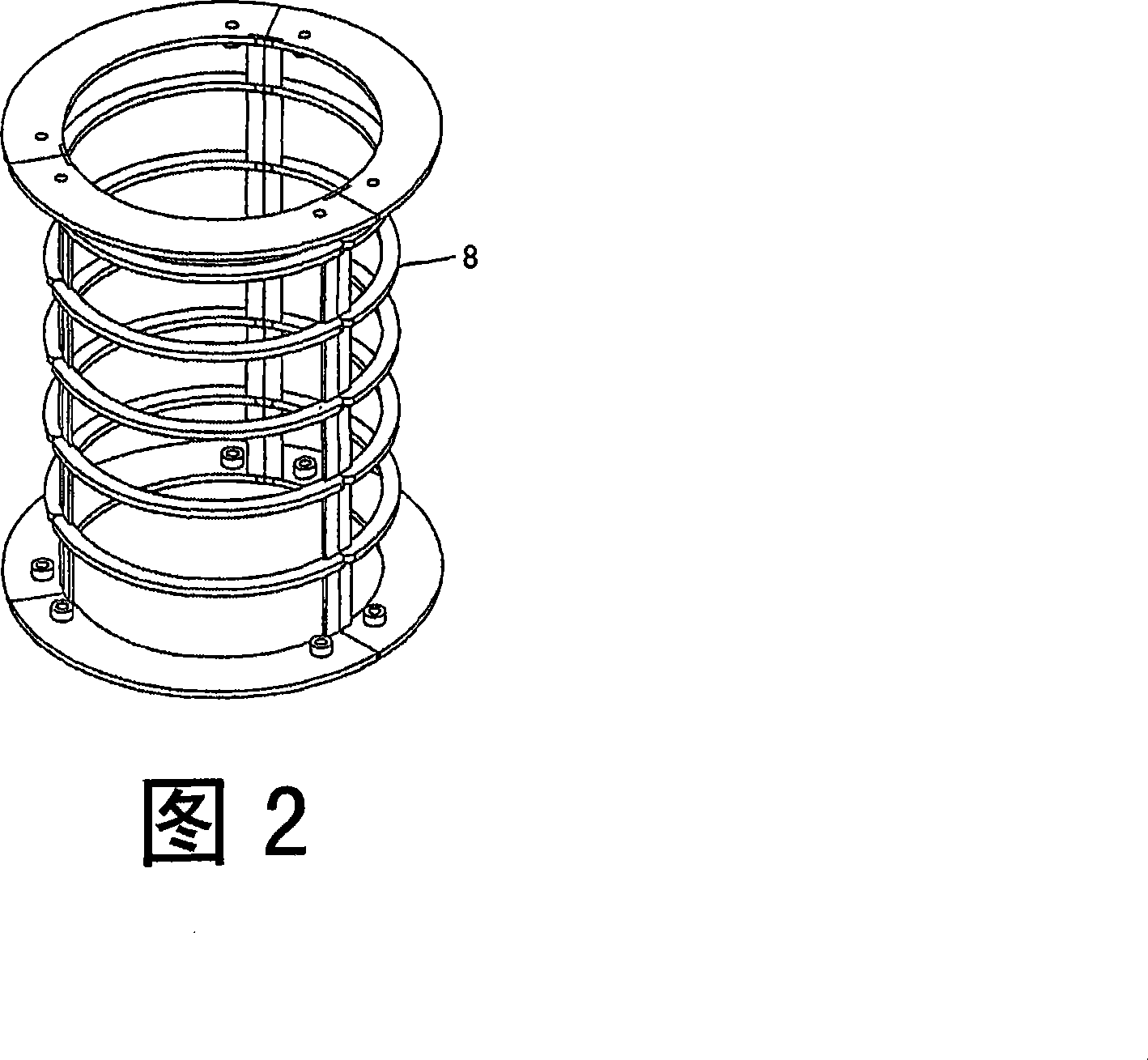

[0020] The grinding tool 2 is enclosed by a perforated basket 8 with a sieve plate (not shown) and which has transverse ribs to facilitate the flow.

[0021] The screen and perforated basket 8 are enclosed by an air enclosure 9 . An area with a wider cross section 9 for a large air volume and an area with a narrower cross section 10 for a small air volume, which results in an eccentric space outside the perforated basket 8 for the discharge of the ground powder .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com