Semi-solid steel rolling equipment and control method thereof

A semi-solid, equipment technology, applied in the field of semi-solid steel rolling equipment and its control, can solve problems such as consumption, large electricity and gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

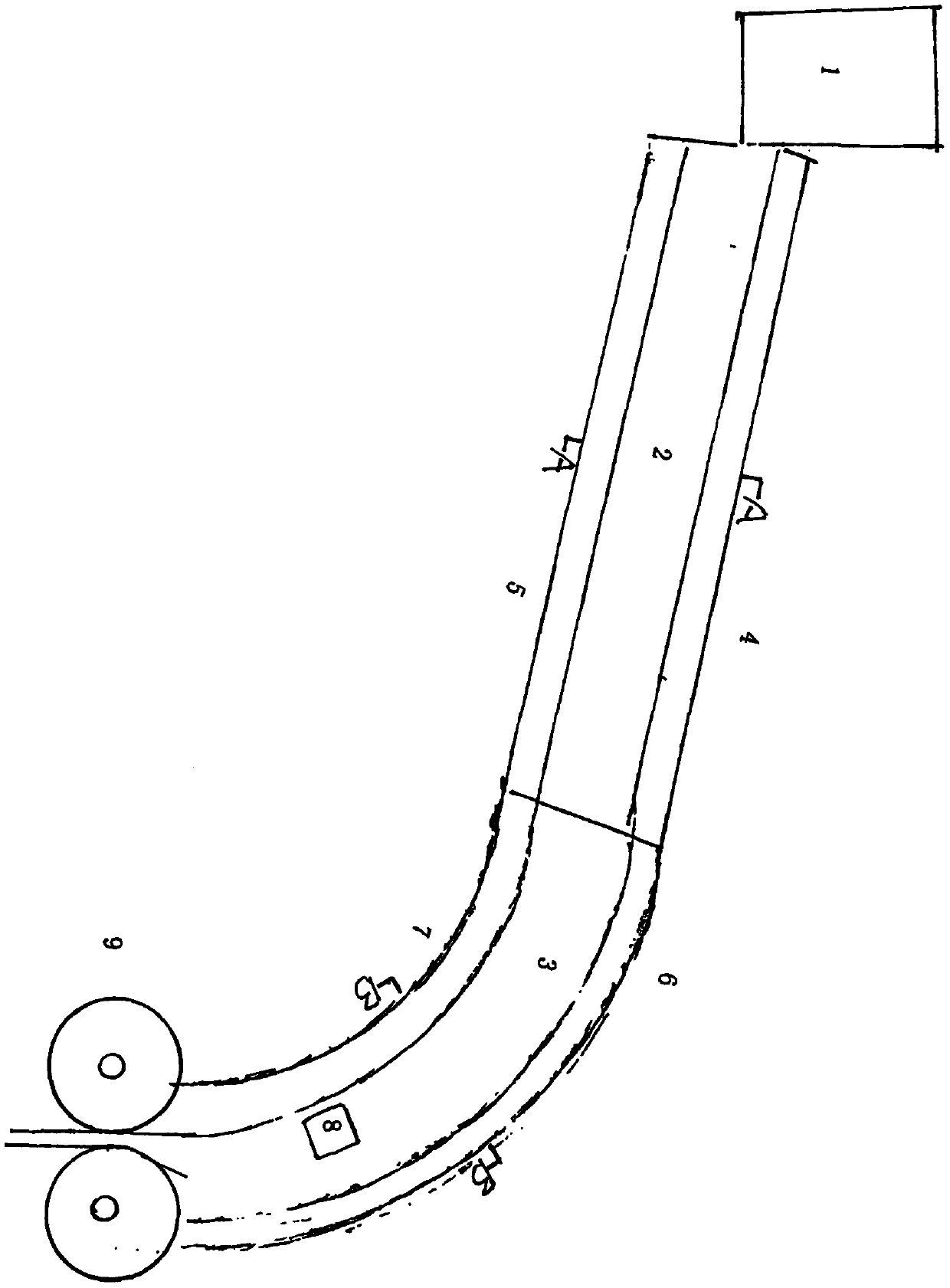

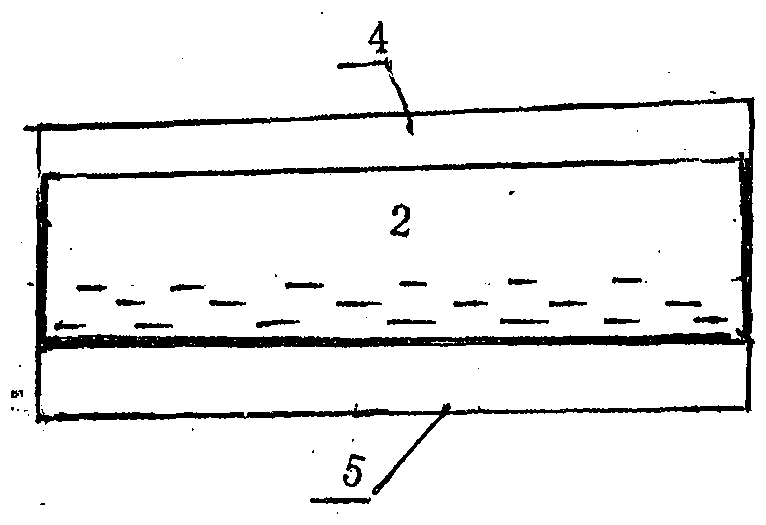

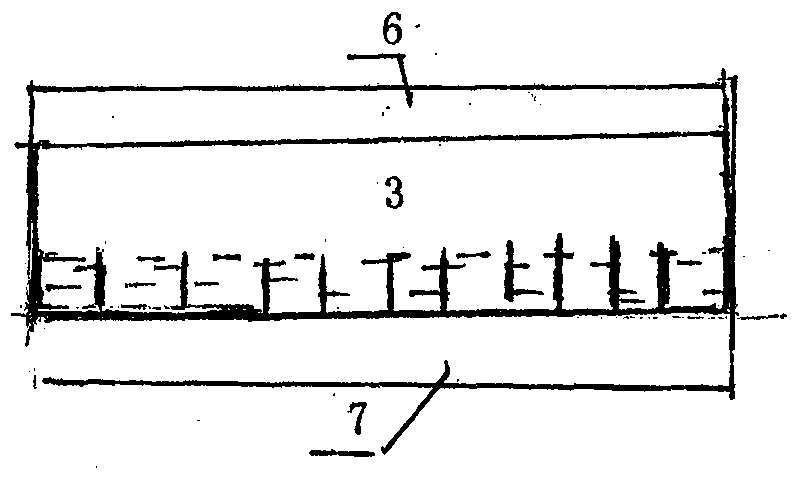

[0014] figure 1 , figure 2 and image 3 Shown, semi-solid steel rolling equipment. The molten steel from the converter or electric furnace flows into the inclined diversion groove made of refractory material. The front of the diversion groove is high and the rear is low. A temperature sensor is installed in the front and rear of the diversion groove, and is controlled by a computer controller. Above the inclined flow guide groove 2 there is an upper cooling flat tube 4 adapted to the flow guide groove 2 , and below the inclined flow guide groove 2 there is a lower cooling flat pipe 5 adapted to the flow guide groove 2 . The rear end of the inclined diversion groove 2 is connected with an uneven arc-shaped groove 3 made of refractory material. The front of the arc-shaped groove 3 is high and the rear is low. The arc-shaped groove 3 is covered with ceramic nails to form a ceramic nail bed. Above the arc-shaped groove 3 there is an upper arc-shaped cooling flat tube 6 matchin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com