Medicine liquid flow rate controller for infusion set

A technology of flow rate control device and infusion set, which is applied in the directions of flow control, non-electric variable control, control/regulation system, etc., can solve problems such as accurate control of medicinal liquid, and achieve the effects of uniform flow speed, accurate measurement and simple overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

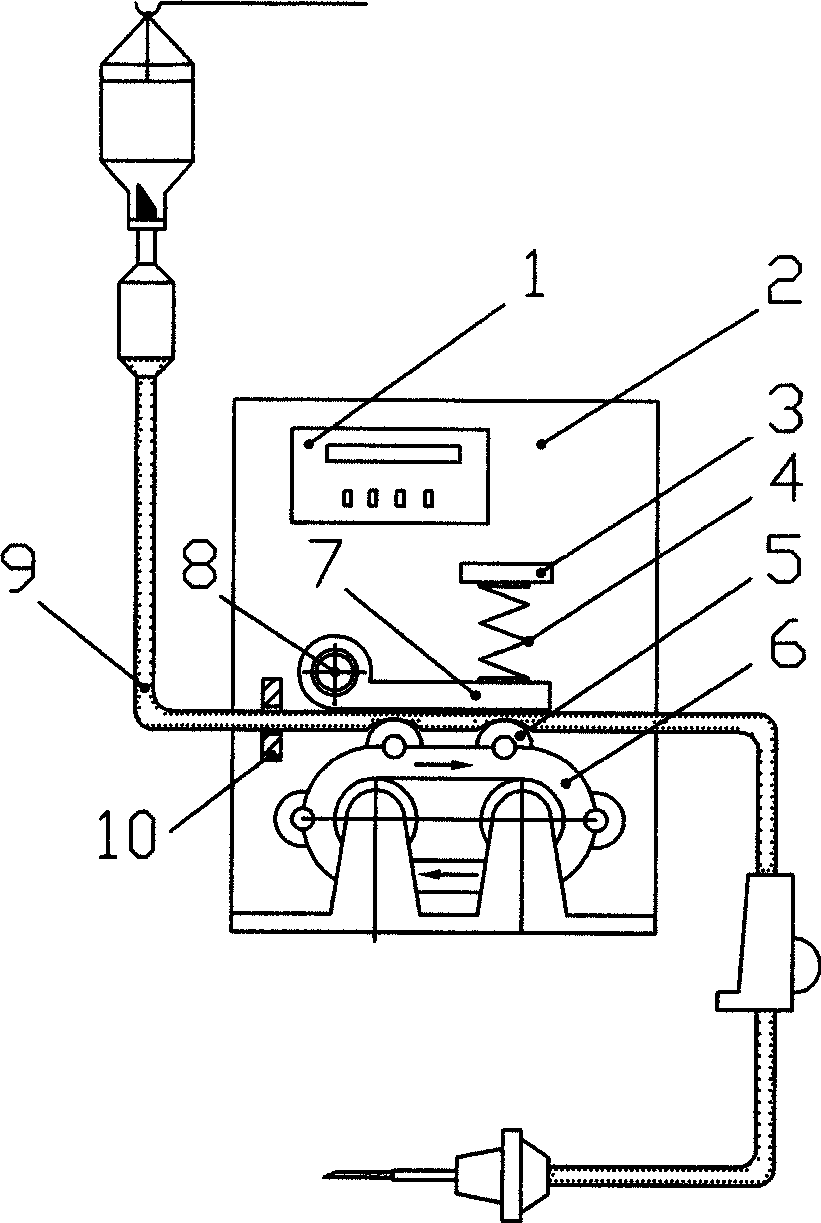

[0024] Such as Figure 1-4 As shown, the present embodiment includes a casing 2, and the casing 2 includes a cavity in which there is a motor 12, and a control instrument 1 connected to the motor 12 through a wire 11 is fixed on the casing 2. There is a bracket on the outside of the cavity, and the flow booster 6 is installed on the bracket. The flow pusher 6 includes two rotating shafts, one of which is connected to the motor 12 . Crawler belts are installed on the rotating shaft, and a group of rollers 5 are installed on the crawler belts through shaft intervals. A pressure plate 7 is installed on the casing 2 on the same side as the two rotating shafts above the pusher 6. One end of the pressing plate 7 is connected with the casing 2 through a positioning shaft 8 parallel to the rotating shaft, and the other end is matched with the lower end of the spring 4. The upper end of the spring 4 It is fixed on the plate body fixedly connected with the casing 2. A tube clip 10 is...

Embodiment 2

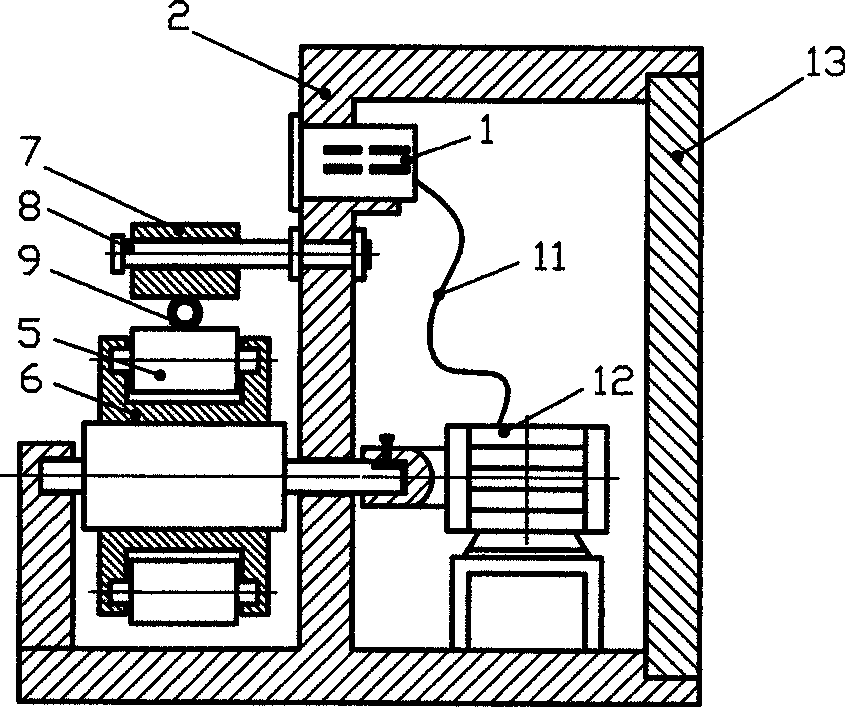

[0027] Such as Figure 5-8 As shown, this embodiment includes a casing 2, and the casing 2 includes a cavity, and a bracket is arranged outside the cavity, and a flow pusher 6 is installed on the bracket. The flow mover 6 includes a circular support with a rotating shaft, a group of rollers 5 are installed at intervals through the shaft in the groove on the side of the support, and a pressing plate 7 is installed on the casing 2 above the flow mover 6 . The part corresponding to the flow booster 6 on the lower surface of the pressing plate 7 is arc-shaped, its curvature is smaller than that of the circular support, and its span is greater than the diameter of the circular support. One end of the pressing plate 7 is connected with the casing 2 through a shaft parallel to the rotating shaft, and the other end cooperates with the lower end of the spring 4 , and the upper end of the spring 4 is fixed on the plate body fixedly connected with the casing 2 . A tube clip 10 is provid...

Embodiment 3

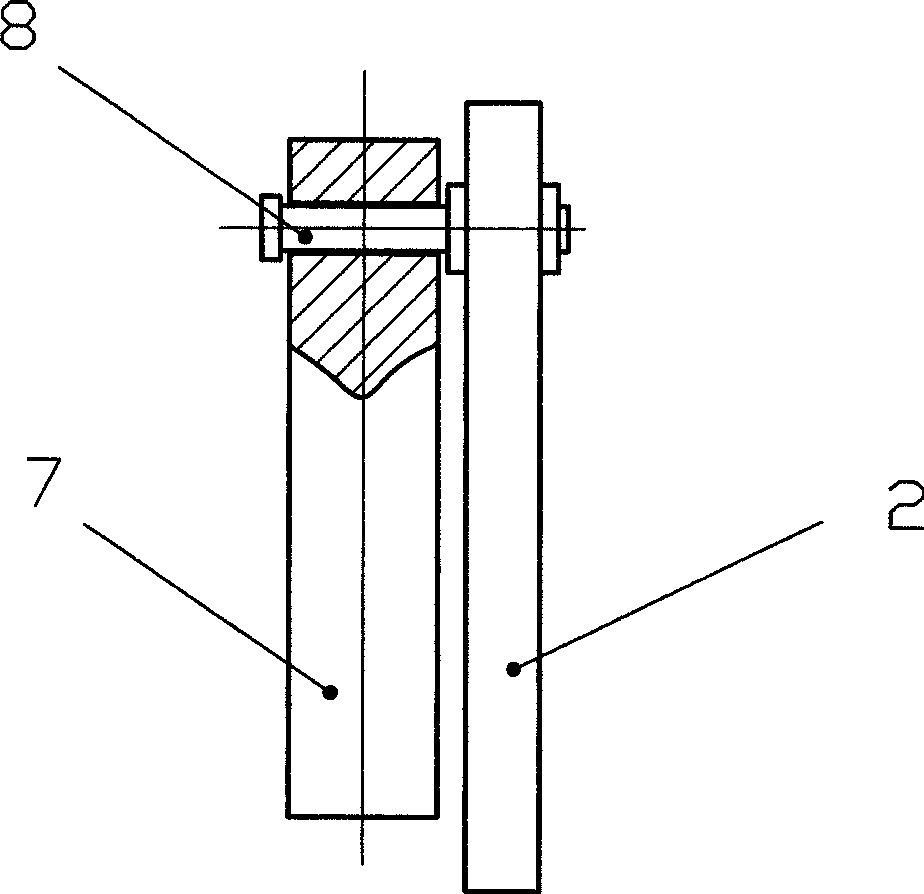

[0029] Such as Figure 9 , 10 As shown, the embodiment includes a casing 2, on which there is a bracket, on which a flow pusher 6 is installed, and the structure of the flow pusher 6 is the same as that of the embodiment 1. Positioning chute 14 is fixed on the casing 2 on flow booster 6 one side, and slide block is housed in the groove, and the slide block top cooperates with spring, and the upper end of spring is connected with the plate body that is fixed on the casing. Other parts of this embodiment are the same as those of Embodiment 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com