A valve bag vacuum filling equipment

A technology of vacuum filling and valve pockets, applied in the directions of packaging, transportation and packaging, types of packaging items, etc., it can solve the problems of reducing beverage filling efficiency, inability to control the outflow speed, quality changes, etc., to improve filling stability and efficiency. Filling efficiency, ensuring filling purity and quality, and the effect of uniform flow speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

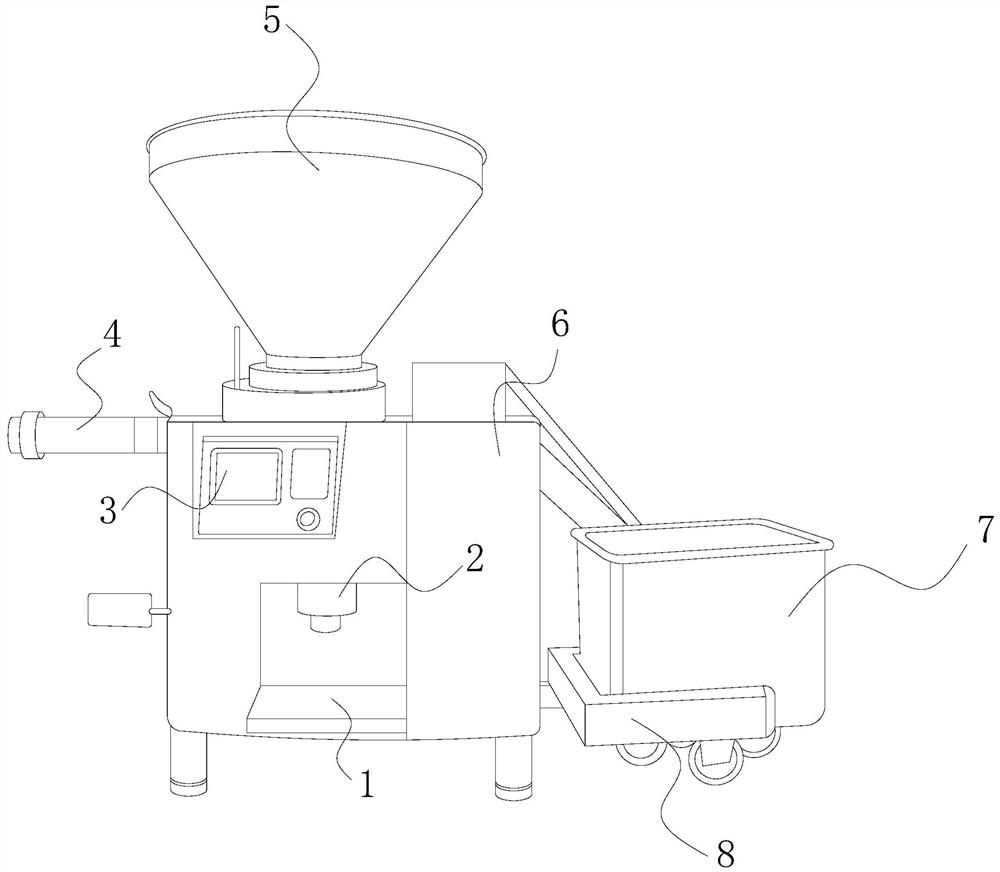

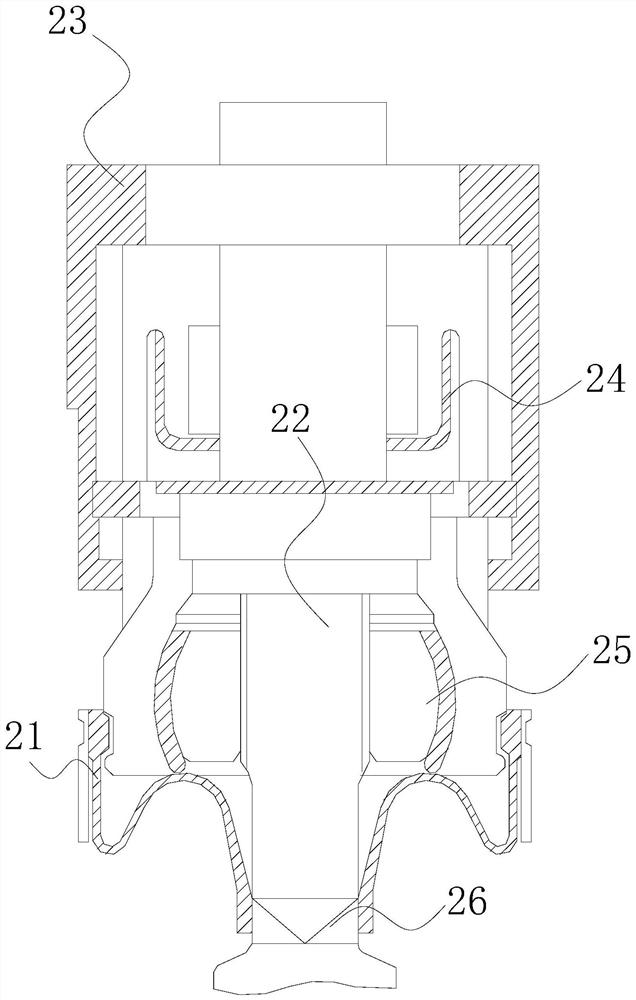

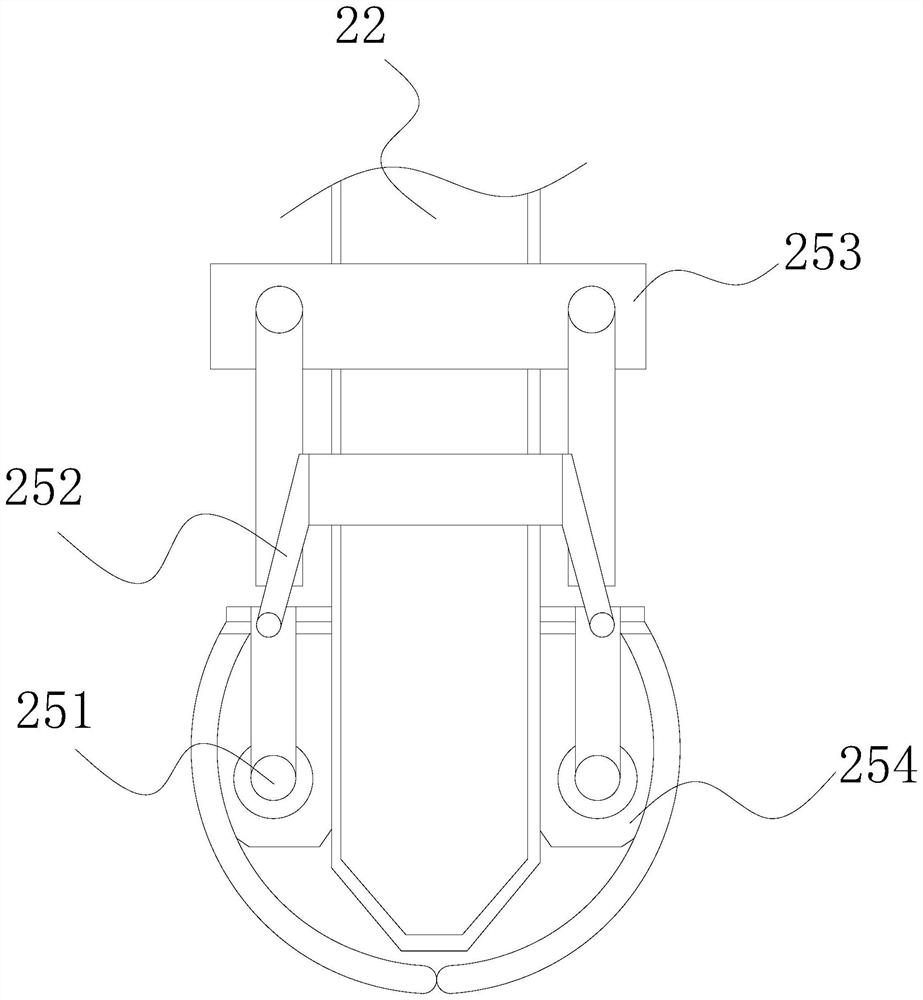

[0033] see figure 1 , the present invention provides a technical solution: a valve bag vacuum filling equipment, the structure of which includes a filling table 1, a protective device 2, a control panel 3, an evacuation valve 4, a hopper 5, a main body 6, a placement chamber 7, and a card holder 8. The filling station 1 is set at the bottom of the main body 6, the top of the filling station 1 is facing the protective device 2, and the protective device 2 is vertically inserted inside the main body 6, and the protective device 2 is connected to the hopper through the main body 6 5, the control panel 3 is installed on one side of the main body 6, the control panel 3 is embedded on the main body 6, the control panel 3 is electrically connected to the inside of the main body 6 through cables, and the top of the main body 6 is provided with There is a hopper 5, the hopper 5 is vertically embedded in the main body 6, the evacuation valve 4 and the card frame 8 are respectively inst...

Embodiment 2

[0045] see figure 1 , the present invention provides a technical solution: a valve bag vacuum filling equipment, the structure of which includes a filling table 1, a protective device 2, a control panel 3, an evacuation valve 4, a hopper 5, a main body 6, a placement chamber 7, and a card holder 8. The filling station 1 is set at the bottom of the main body 6, the top of the filling station 1 is facing the protective device 2, and the protective device 2 is vertically inserted inside the main body 6, and the protective device 2 is connected to the hopper through the main body 6 5, the control panel 3 is installed on one side of the main body 6, the control panel 3 is embedded on the main body 6, the control panel 3 is electrically connected to the inside of the main body 6 through cables, and the top of the main body 6 is provided with There is a hopper 5, the hopper 5 is vertically embedded in the main body 6, the evacuation valve 4 and the card frame 8 are respectively inst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com