Gas distribution device

A technology of gas distribution device and distribution plate, which is applied in the field of wind and gas exhaust, and can solve problems such as difficult to enlarge design and application, difficult to ensure uniform distribution of gas, complex structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The processing capacity is 1000m 3 The inlet and outlet of the catalytic oxidation device for air exhaust gas / min are respectively equipped with combined gas distribution devices. The cross-sectional size of the oxidation device is 6000mm×6000mm, the catalyst is a monolithic noble metal catalyst loaded with 0.5% Pd, the carrier is a 200-mesh cordierite honeycomb ceramic, and the heat storage ceramic is a corundum-mullite honeycomb ceramic. The data acquisition and control of the device is completed by Siemens S7-300PLC, and the upper computer has a perfect man-machine interface.

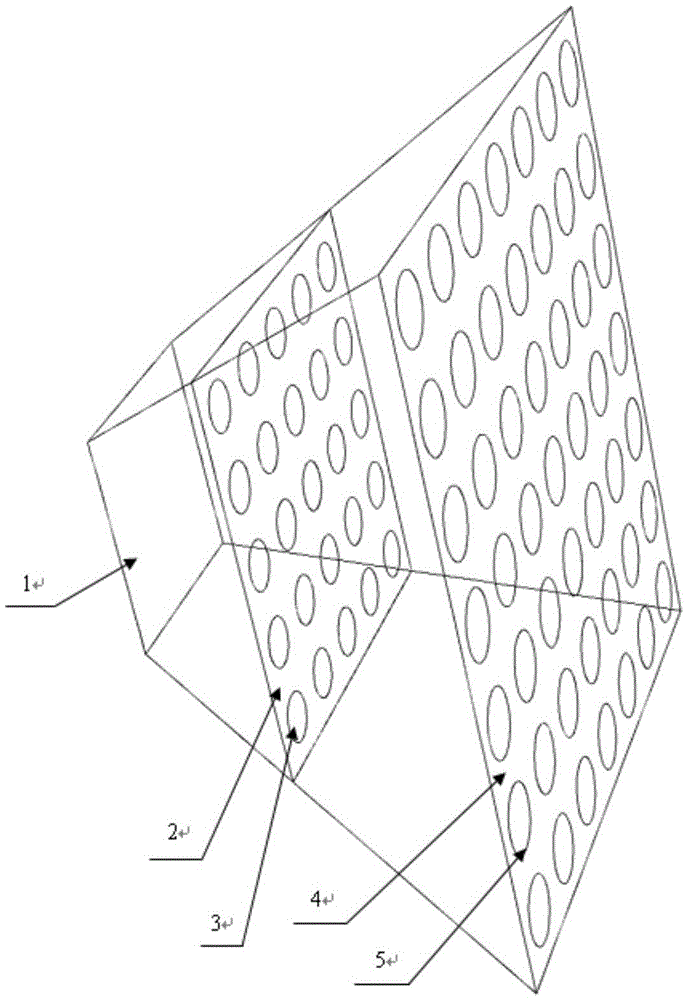

[0029] The structure of the transition section in the gas distribution device in this embodiment is as follows figure 1 As shown, the cross-sectional area of the gas inlet is 2m 2 , the cross-sectional area of the gas outlet is 24m 2, there are two distribution plates in the transition section, the distance between the first distribution plate closest to the inlet of the gas distributio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com