Defrosting method of multi-split air conditioning system and multi-split air conditioning system

A multi-connected system and air-conditioning technology, applied in refrigerators, mechanical equipment, high-efficiency adjustment technology, etc., can solve problems such as poor defrosting effect, long defrosting time, inconsistent wind speed field of outdoor heat exchanger, etc., to avoid heat exchange Dead angle, rapid defrosting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

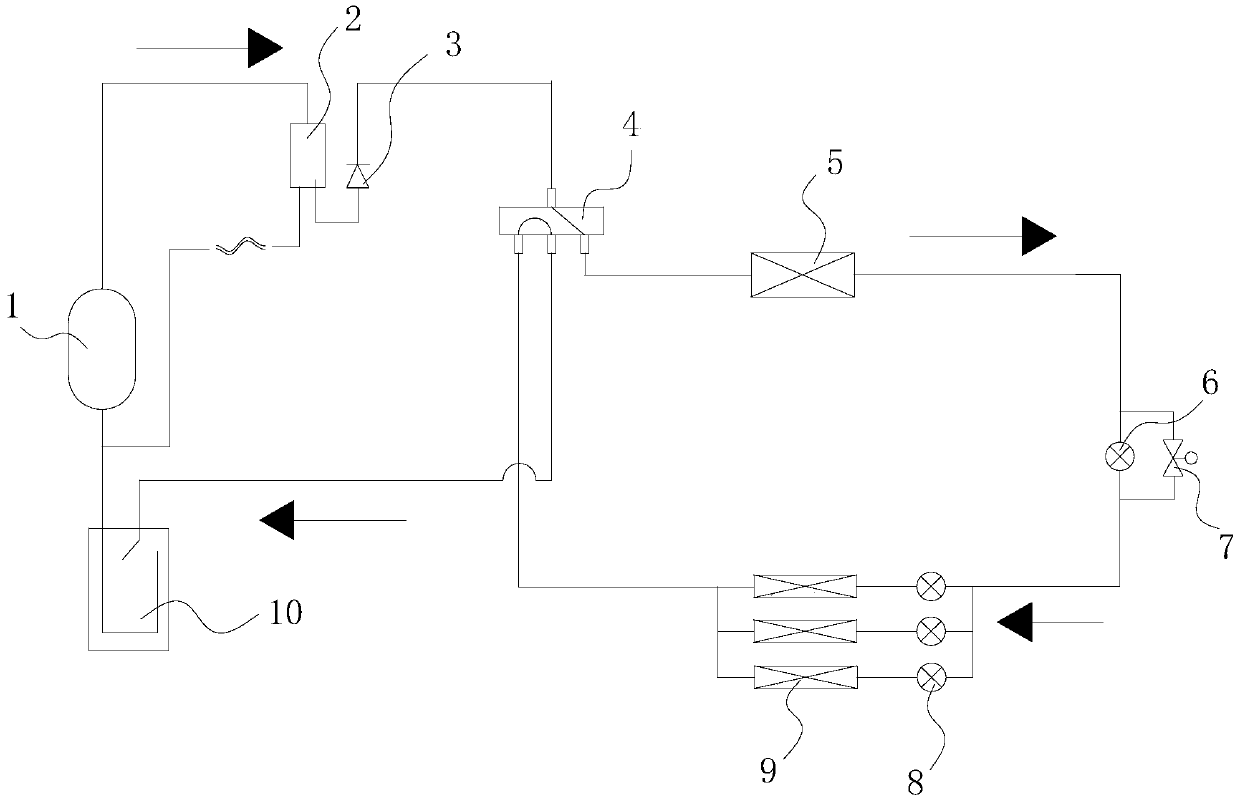

Embodiment 1

[0031] The preferred embodiment discloses a defrosting method for an air conditioner multi-connected system. In this defrosting method, the heating mode is changed to the cooling mode through the reversing of the four-way valve 4, so that the flow speed of the refrigerant in the outdoor heat exchanger 5 and at least part of the pipelines is uneven, resulting in alternating high-speed flow and low-speed flow.

[0032] By changing the flow rate of the refrigerant so that it alternates between high-speed flow and low-speed flow, the disturbance and fluctuation of the high-temperature and high-pressure gaseous refrigerant in the outdoor heat exchanger 5 is strengthened, and the dead angle of the refrigerant in the outdoor heat exchanger 5 is avoided, thereby strengthening the outdoor unit of the multi-connected system defrosting effect.

[0033] The specific steps of the defrosting method are not limited, as long as the flow rate of the refrigerant can fluctuate. Preferably, the ...

Embodiment 2

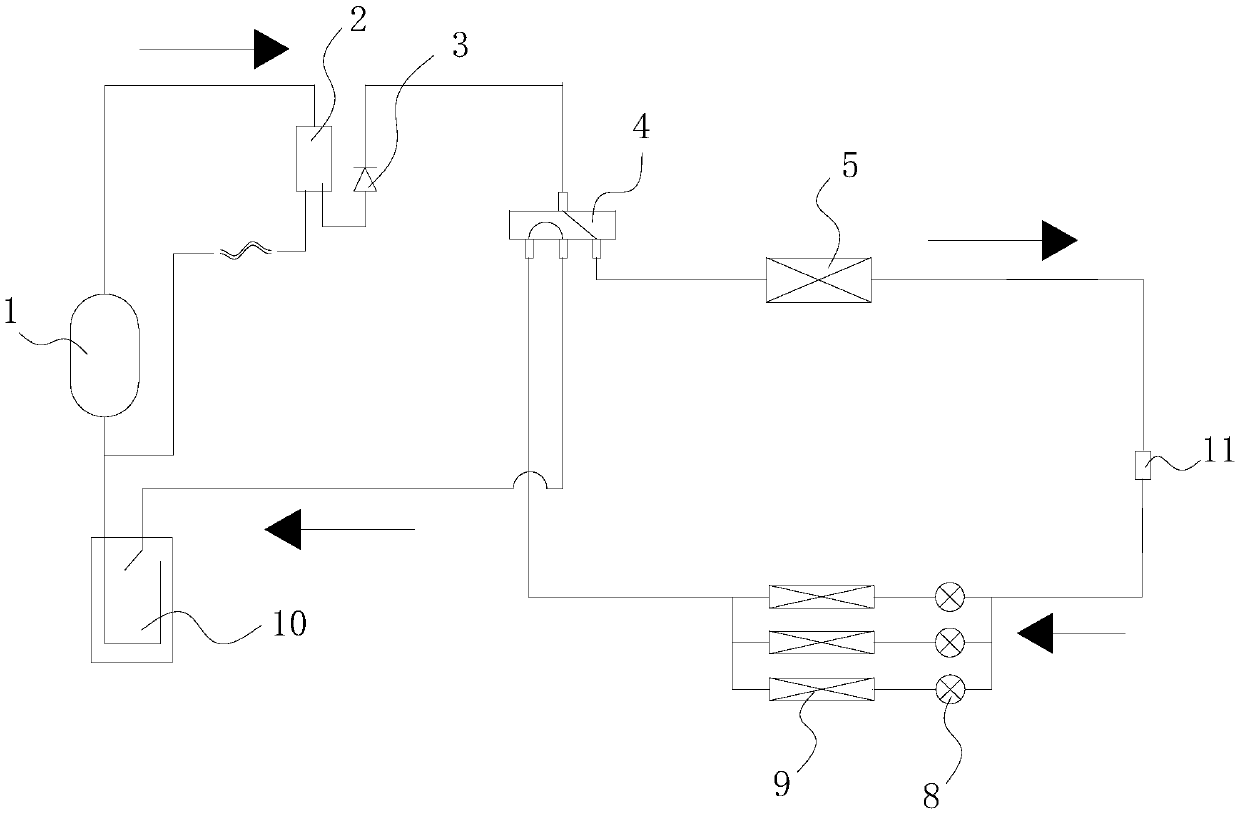

[0045] The preferred embodiment discloses a defrosting method for an air-conditioning multi-connection system and the air-conditioning multi-connection system for realizing the defrosting method. Such as figure 2 As shown, the multi-line air conditioner system used to implement the defrosting method includes a compressor 1 connected through pipelines, an oil separator 2, a four-way valve 4, an outdoor heat exchanger 5, a flow rate control device 11, and an indoor electronic expansion valve 8. Indoor heat exchanger 9 and gas-liquid separator 10. The flow rate control device 11 is in signal communication with the control device.

[0046] The specific structure of the flow rate control device 11 is not limited, as long as it can adjust the flow rate of the refrigerant in the pipeline between the outdoor heat exchanger 5 and the indoor electronic expansion valve 8 . Correspondingly, the details of the defrosting method are slightly changed:

[0047] Step S3, the high-pressure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com