Air and gas supply structure of gas radiant furnace

An air supply and radiant furnace technology, applied in the field of gas radiant furnace, can solve the problems of reducing the heating efficiency of the heated body, uneven air velocity, uneven flame distribution, etc. The effect of flow speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Next, the structure of the gas radiation furnace of the present invention will be described with reference to the accompanying drawings and examples.

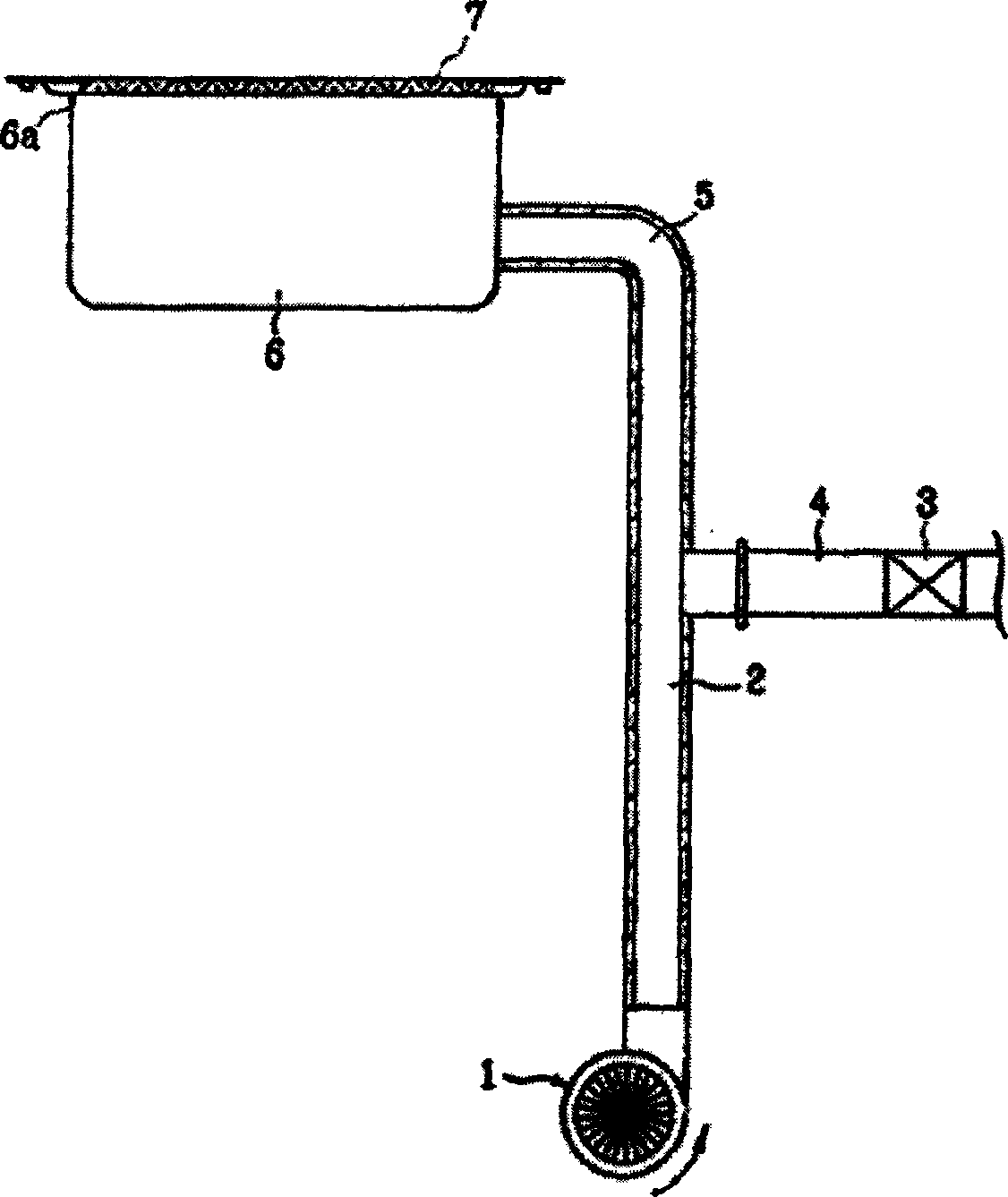

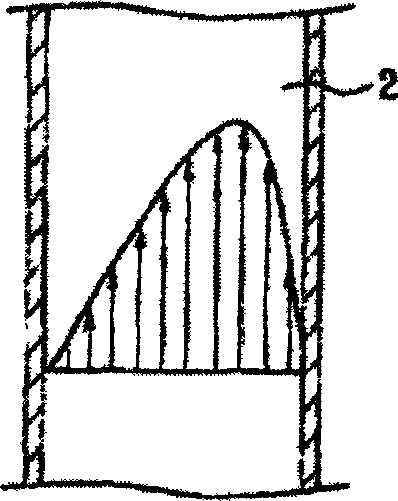

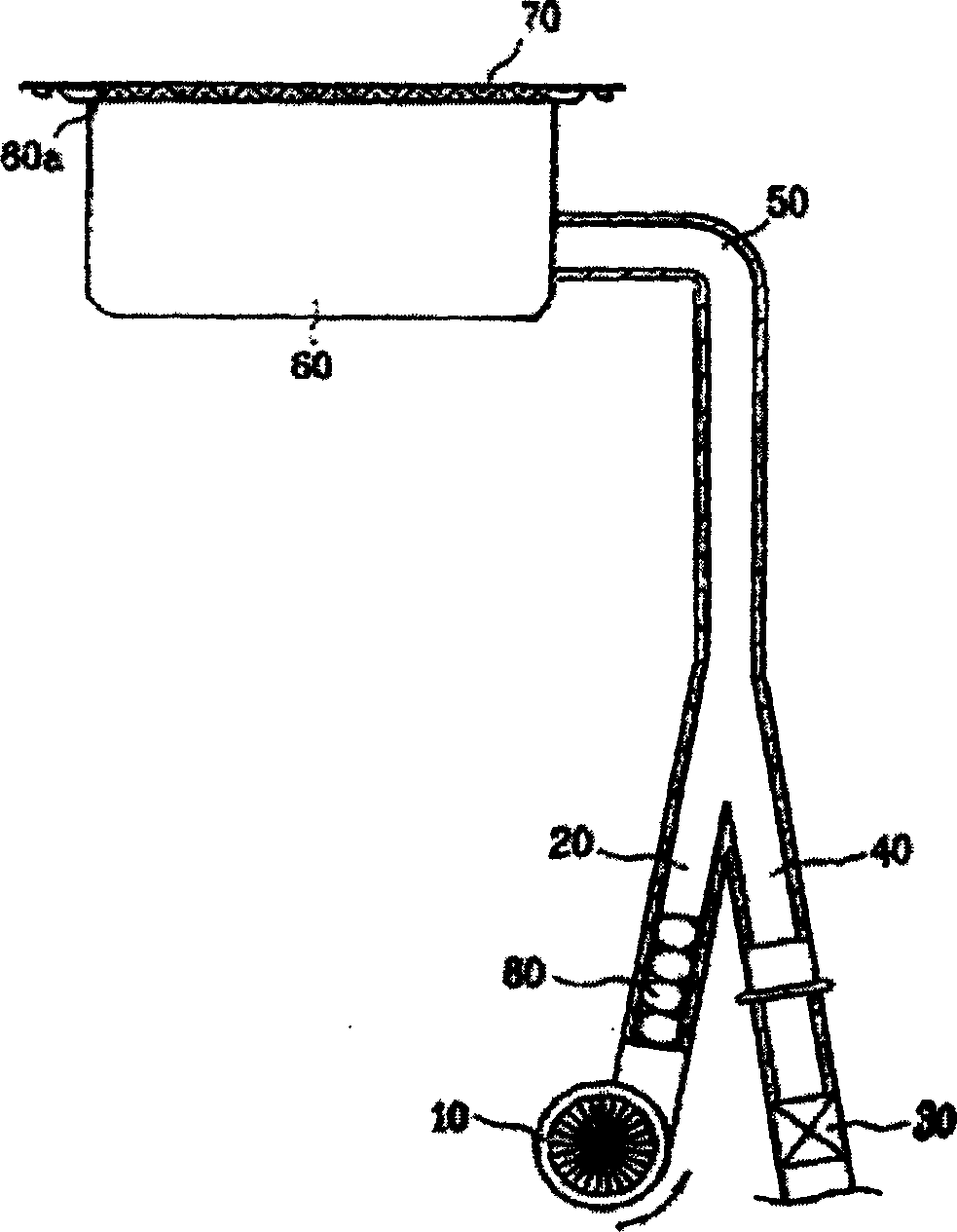

[0035] image 3 It is a brief structural sectional view of a gas radiation furnace in the present invention, Figure 4 yes image 3 Schematic diagram of the structure of the gas stirring device in Figure 5 yes image 3 The profile diagram of the air flow velocity distribution in the air supply pipe.

[0036] Such as image 3 and Figure 4 As shown, the air and gas supply structure of the gas radiant furnace according to the present invention includes the following structures, that is, the mixing tube 50, and the air and gas flow are mixed after they flow into the interior; the air supply tube 20, one side of which is connected to the mixing tube. Pipe 5, the other side is connected to air supply fan 10, so that the air flowing in through air supply fan 10 is supplied to the inside of mixing pipe 50; gas supply pip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com