Patents

Literature

75results about How to "High thickness consistency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A method of manufacturing a metal-clad laminate with improved thickness uniformity of the insulating layer

InactiveCN102275354APrecise thickness controlAvoid quality control risksLamination ancillary operationsLaminationGlass fiberCooking & baking

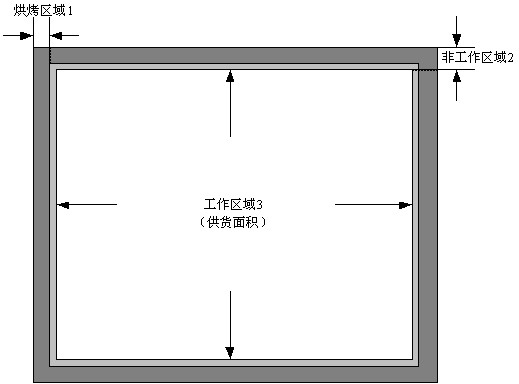

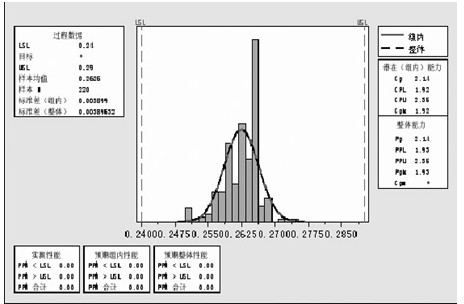

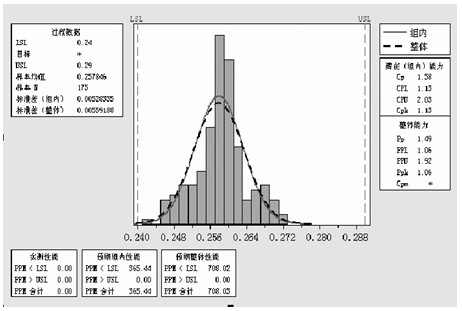

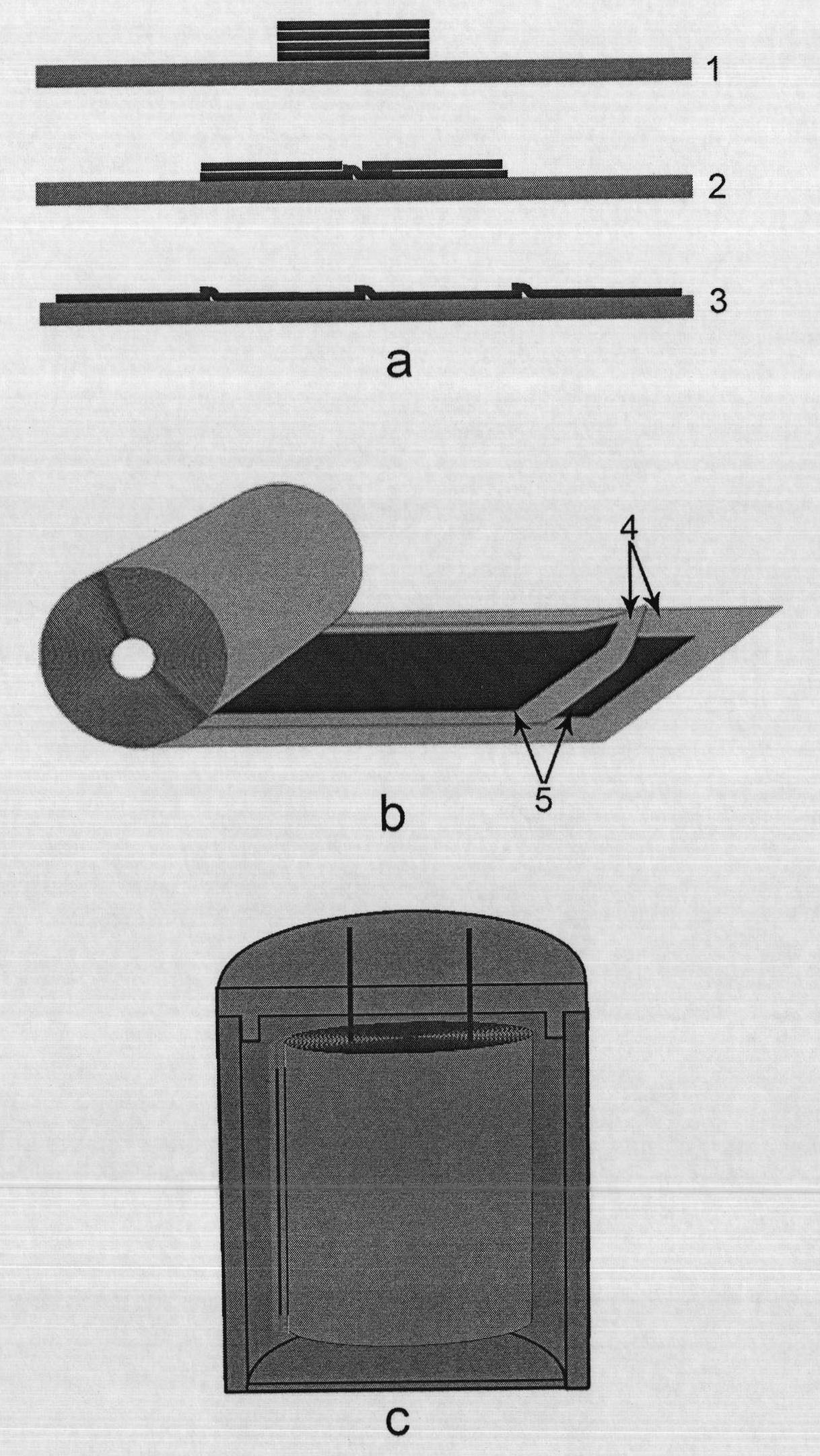

The invention discloses a method for manufacturing a metal foil-clad laminate that improves the thickness uniformity of an insulating layer. The process steps include: putting unrolled glass fiber cloth into a glue tank to soak the glue solution, controlling the glue solution content through metering rollers, After being heated and dried in an oven, cut to obtain prepregs of specified size, stack one or more prepregs, cover one or both sides with copper foil or other metal foils, and send them to the laminator for heating and pressure , press-molded metal foil-clad laminate, characterized in that: before the prepreg is wound and cut, the curing degree of the resin in the edge area around the prepreg is increased to 60% to 80% by setting a heating and baking device for partial baking , the width of the peripheral edge area is 5-30 mm. The invention significantly improves the uniformity and consistency of the thickness of various places in the working area of the plate, and satisfies customers' increasingly stringent requirements for assembly processing accuracy and impedance characteristics of the metal foil-clad laminate.

Owner:SHENGYI TECH SUZHOU

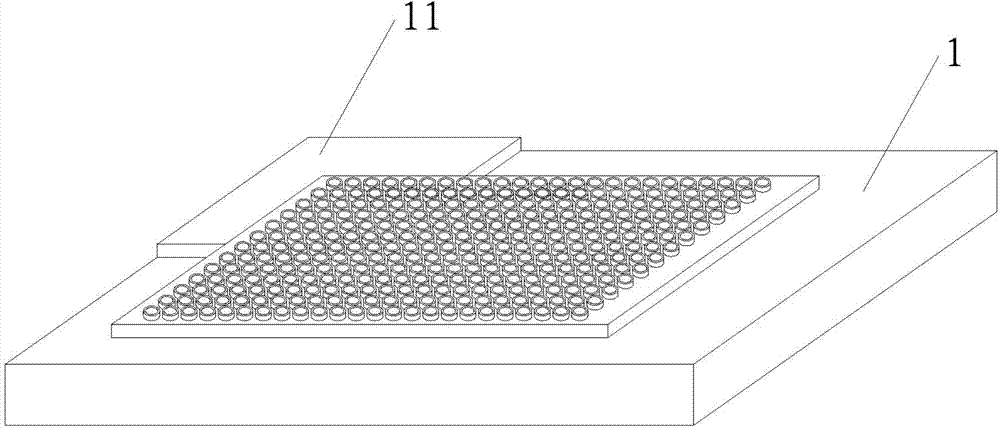

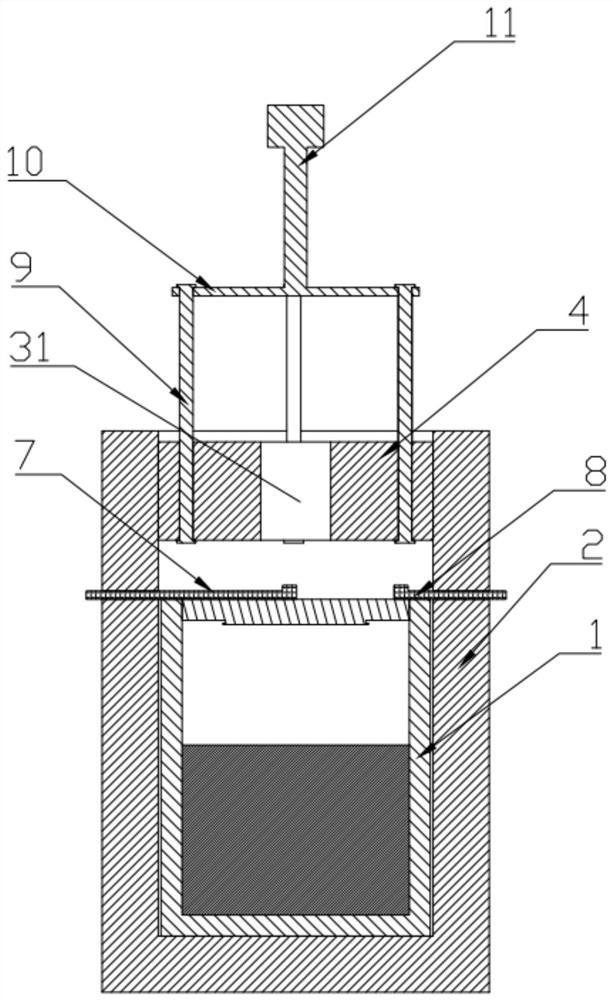

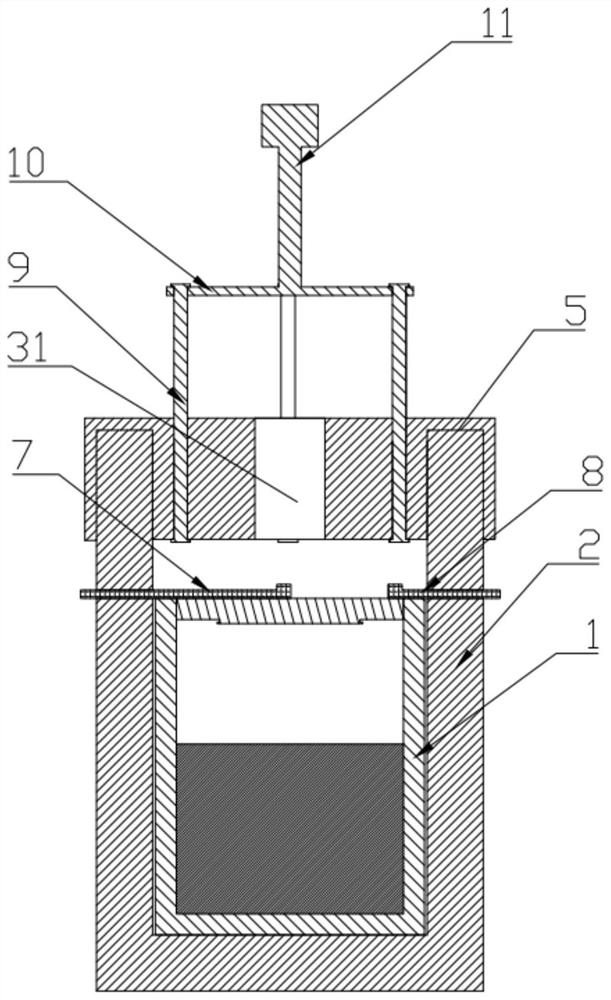

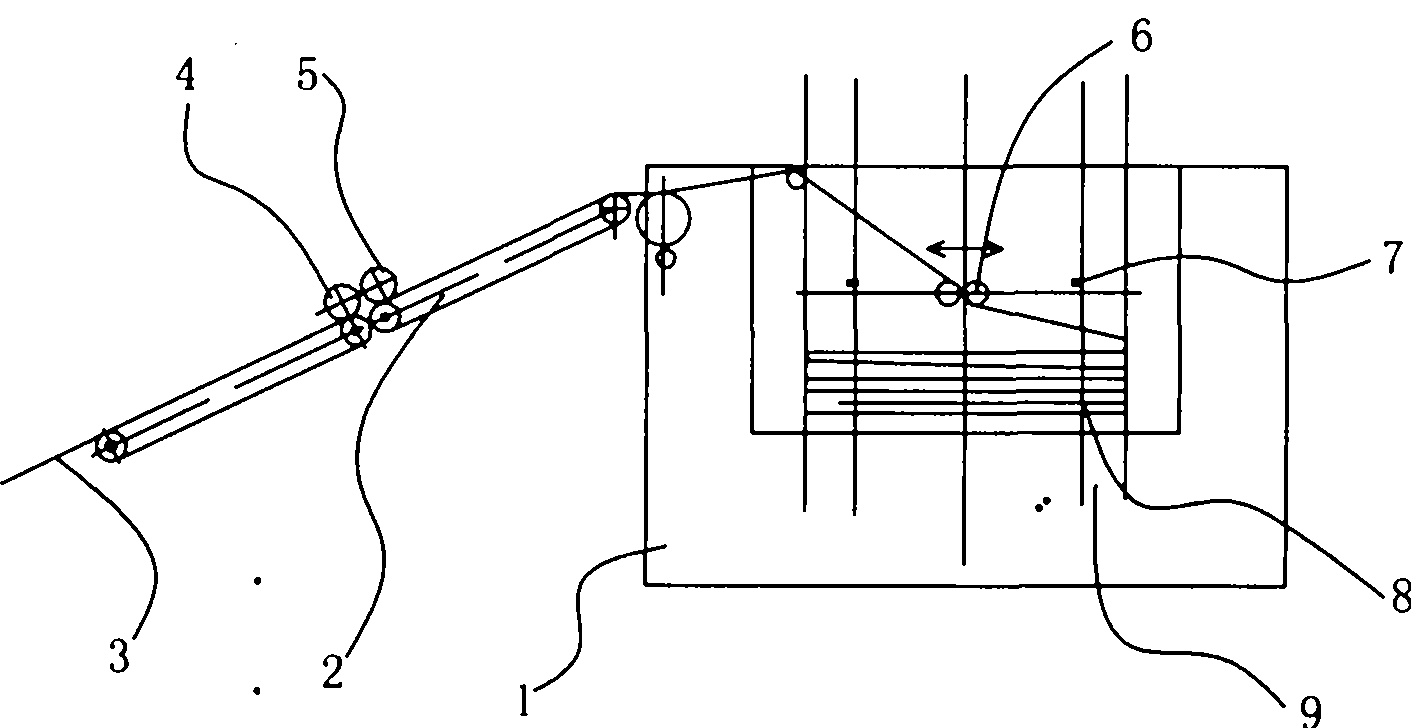

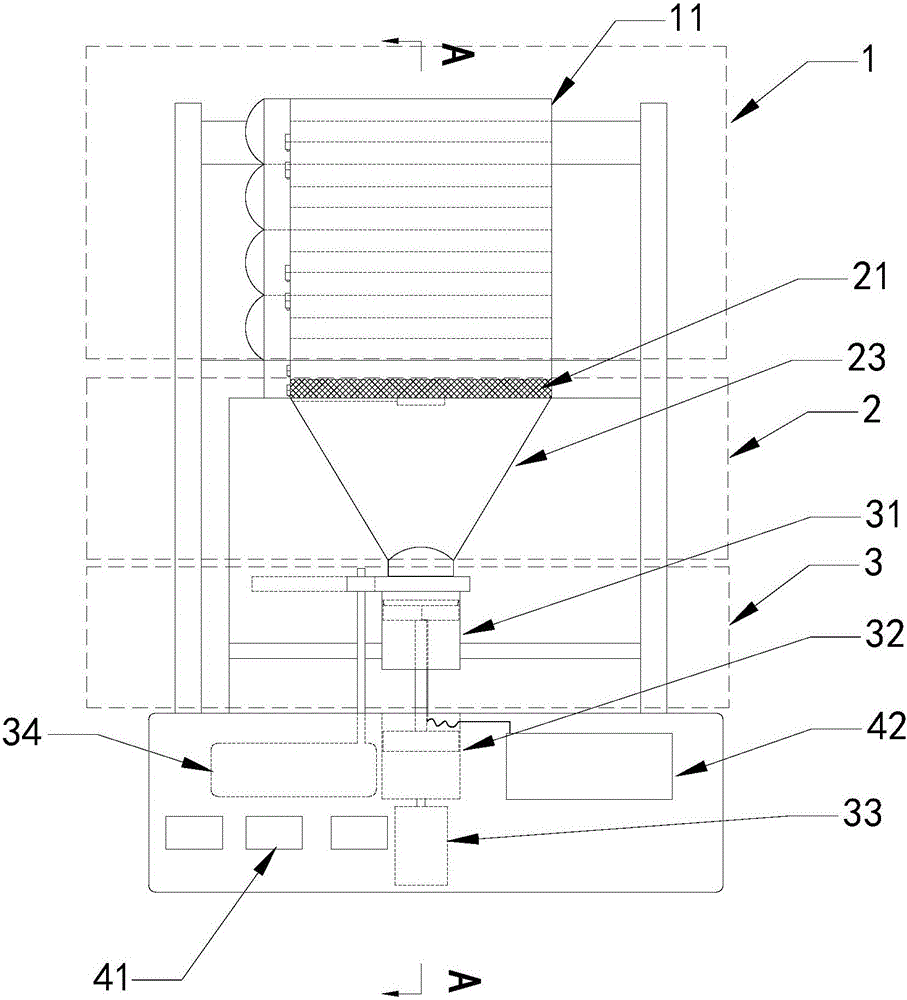

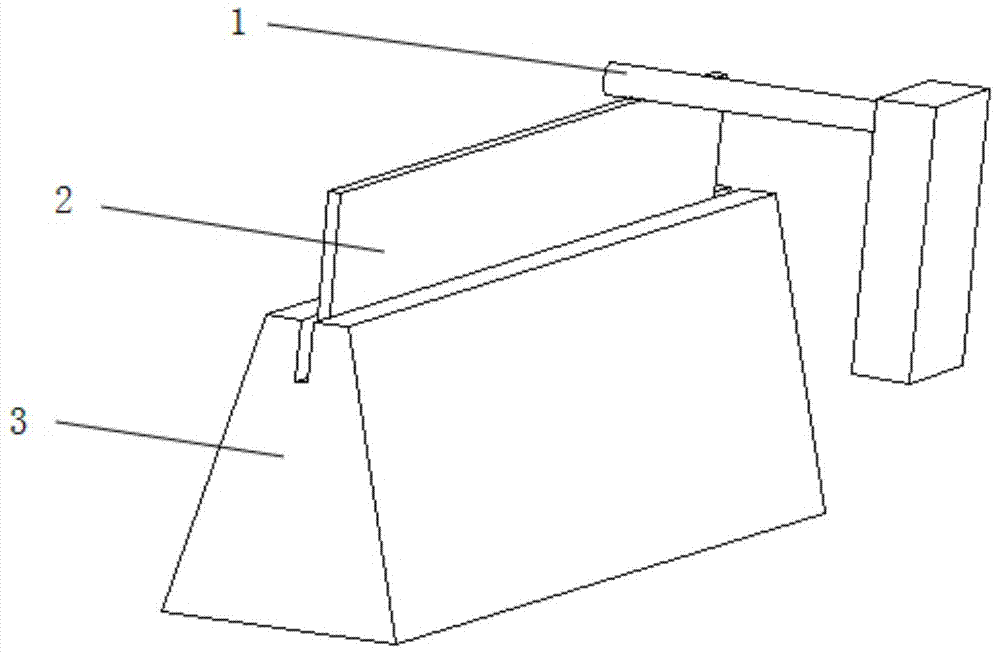

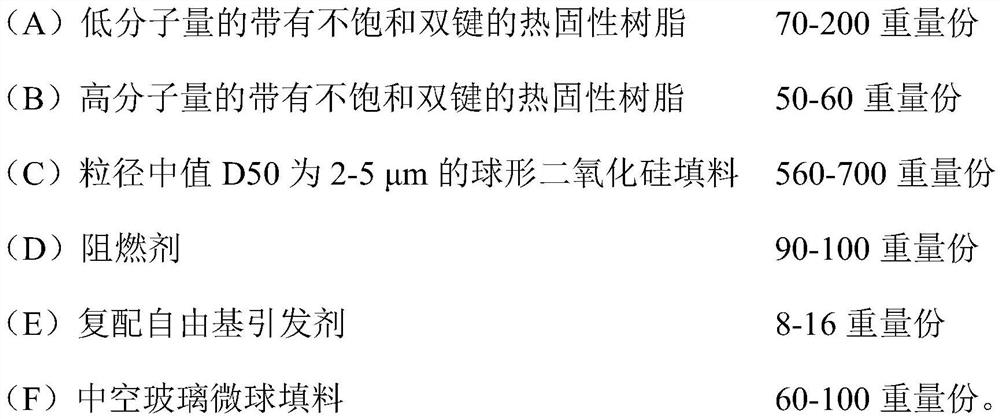

Precise automatic press for electronic ceramics

InactiveCN103481642AHigh precisionImprove uniformityScreen printersPrinting press partsEngineeringPrinting press

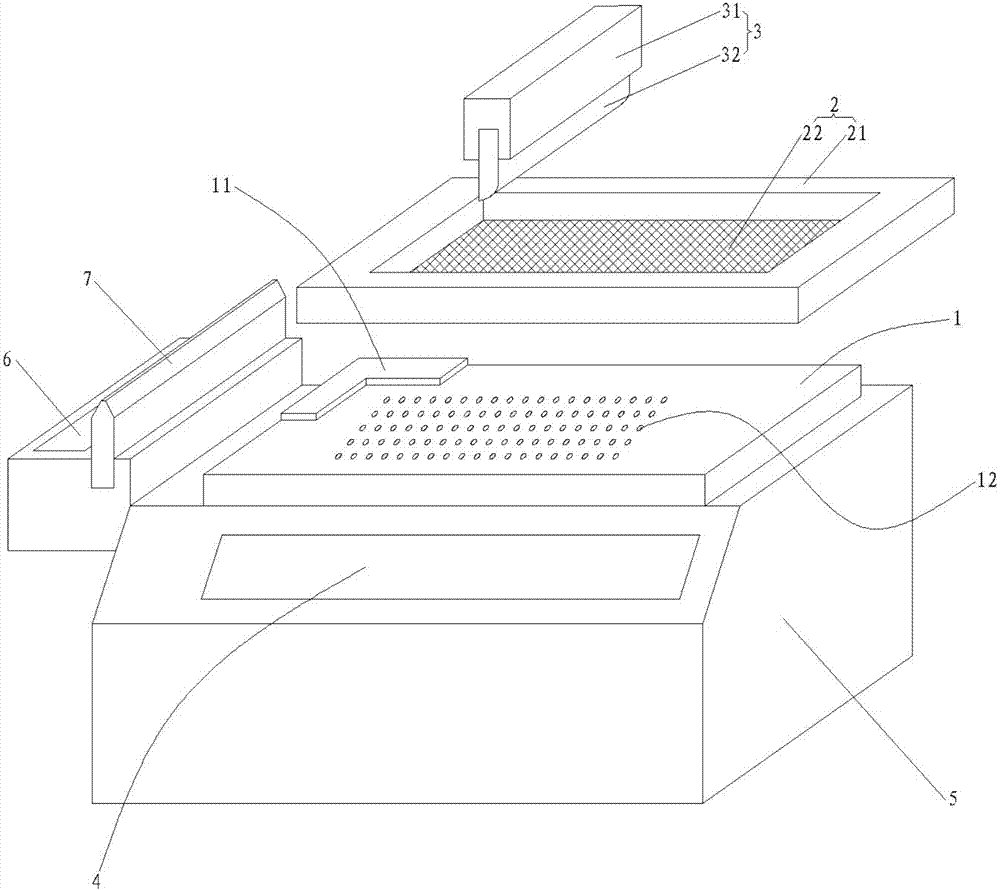

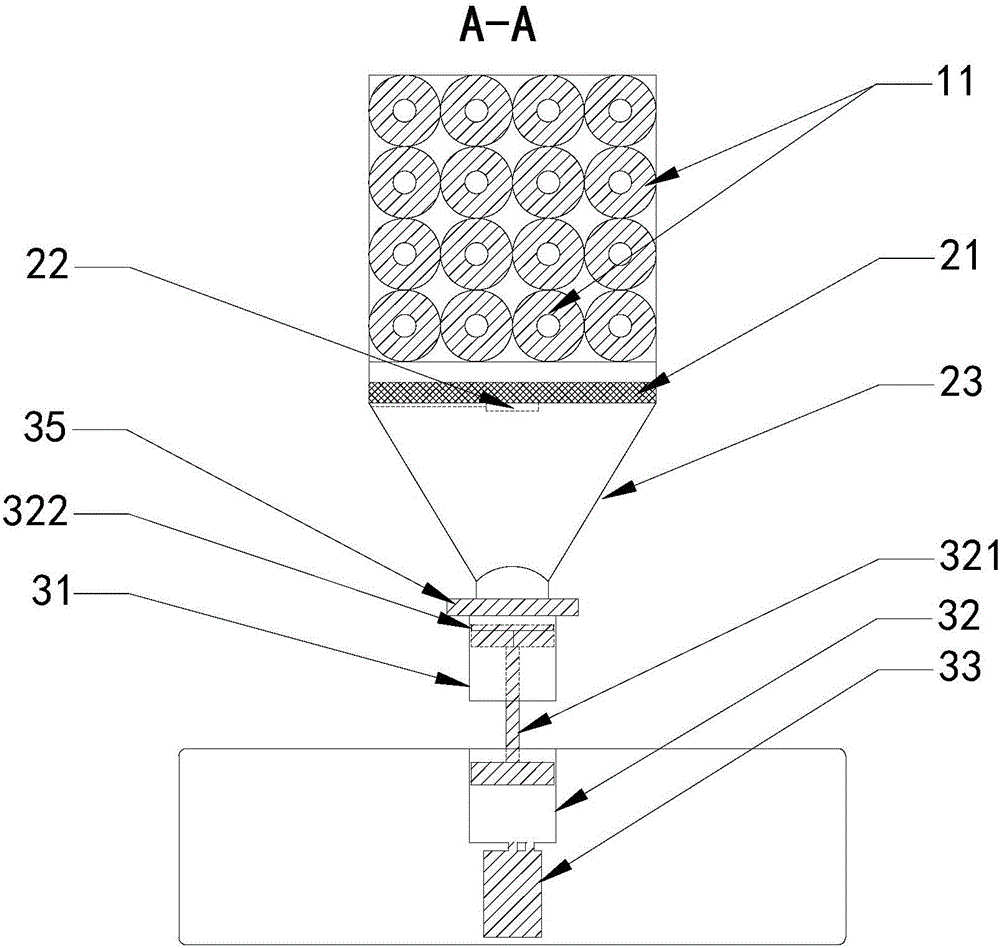

The invention discloses a precise automatic press for electronic ceramics. The precise automatic press comprises a printed electronic-ceramics supporting table face (1), a printing silk screen component (2), a sizing agent scraper component (3) and a control mechanism (4), wherein the printed electronic-ceramics supporting table face (1) and the control mechanism (4) are arranged on a press frame (5), the printing silk screen component (2) is arranged above the printed electronic-ceramics supporting table face (1), the sizing agent scraper component (3) is arranged above the printing silk screen component (2), and the control mechanism (4) controls the printing silk screen component (2) and the sizing agent scraper component (3) to move up and down along a lifting mechanism, and controls the printing silk screen component (2) and the sizing agent scraper component (3) to move left and right along a rail mechanism. The positions and operation of the printed electronic-ceramics supporting table face, the printing silk screen component and the sizing agent scraper component are all controlled through the control mechanism, precision is greatly improved, and printing uniformity and thickness consistency are greatly improved.

Owner:湖南省新化县鑫星电子陶瓷有限责任公司

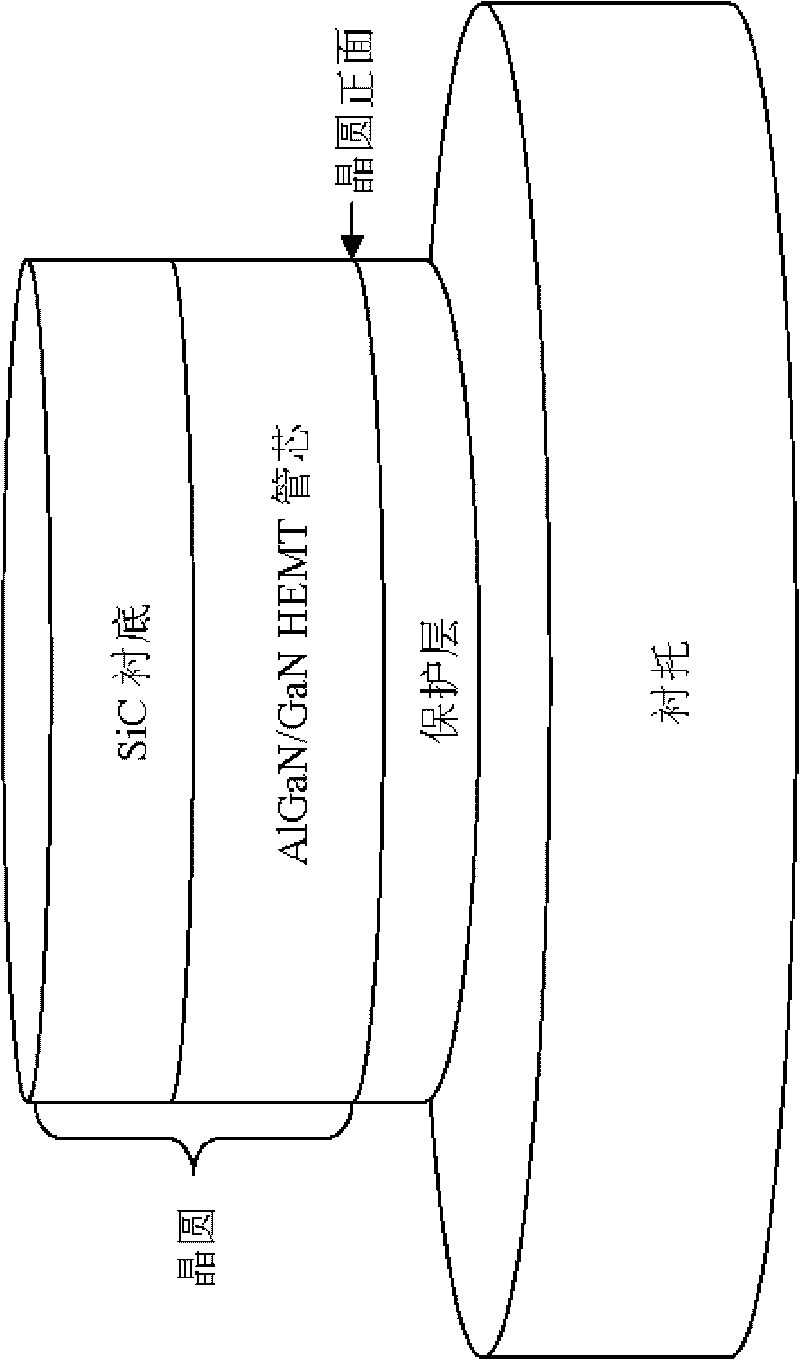

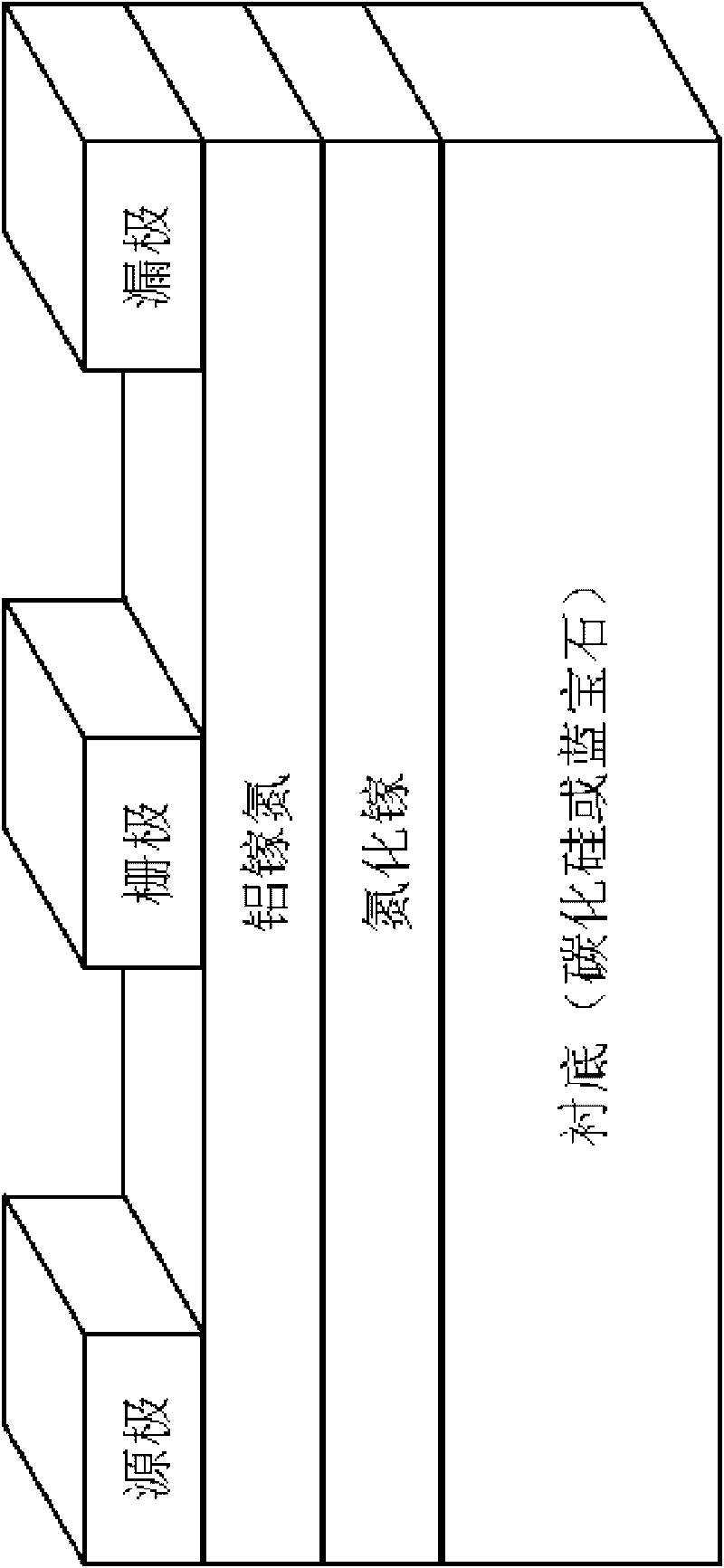

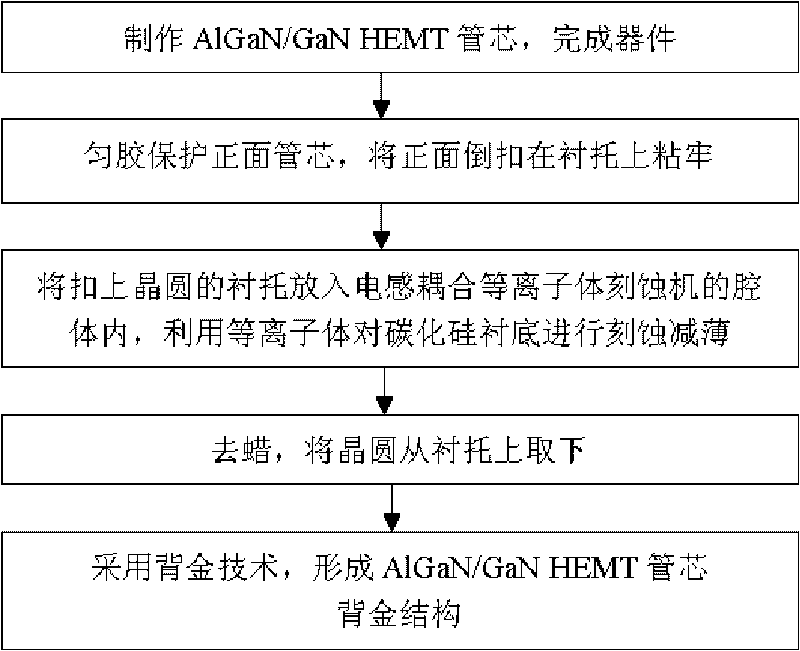

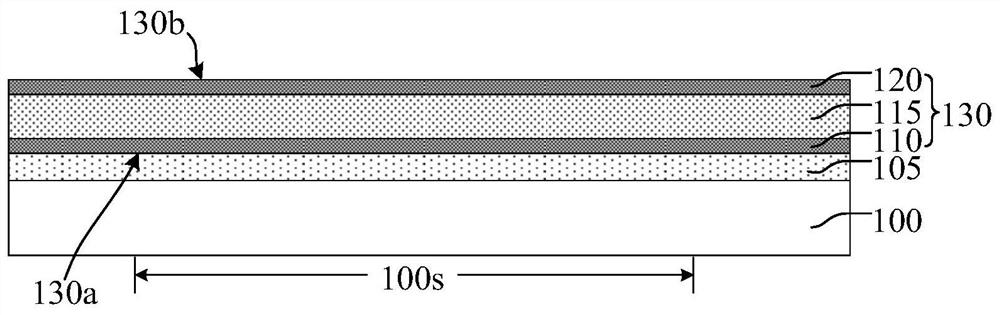

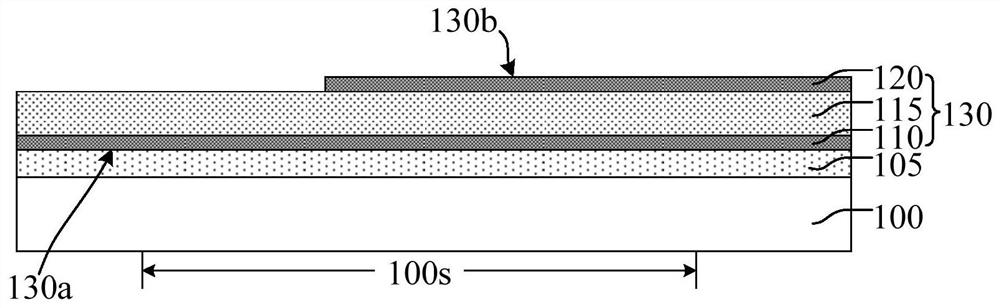

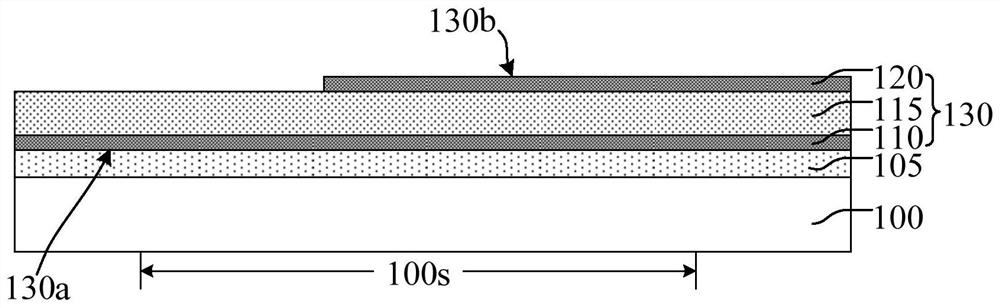

Method for manufacturing field effect transistor

InactiveCN101719471AGuaranteed Stability and ReliabilityUniform rateSemiconductor/solid-state device manufacturingGallium nitrideThinning

The invention relates to a manufacturing technology of a field effect transistor, in particular to a method for thinning a substrate of a gallium nitride-based microwave field effect device. Aiming at the defects of a substrate thinning technology in the method for manufacturing the field effect transistor in the prior art, the invention discloses a method for manufacturing the field effect transistor, improves the substrate thinning technology of the field effect transistor so as to adapt to the thinning of a high-hardness substrate material, and improve the quality of a substrate process technology, the quality of the substrate and the overall performance of the device. By using the method for manufacturing the field effect transistor, in the manufacturing technology process of the field effect transistor, a carborundum substrate and other high-hardness substrates of the field effect transistor can be etched to be thinned by plasma. The invention can avoid the break of wafers and improve the quality of thinned substrates and is particularly suitable for a manufacturing technology of gallium nitride-based field effect transistor devices.

Owner:SICHUAN LONGRUI MICROELECTRONICS

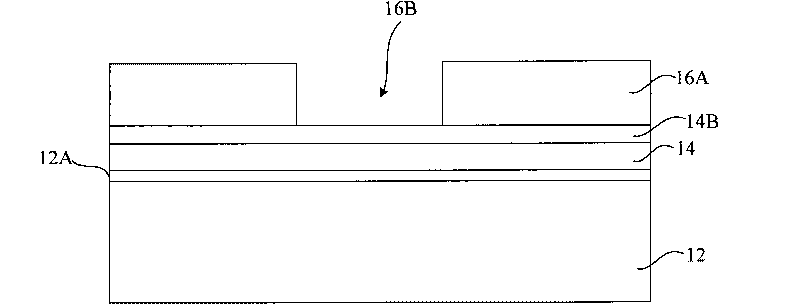

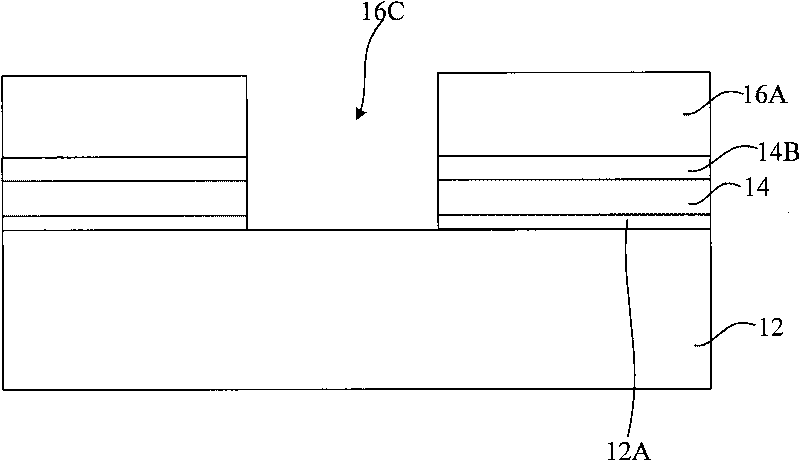

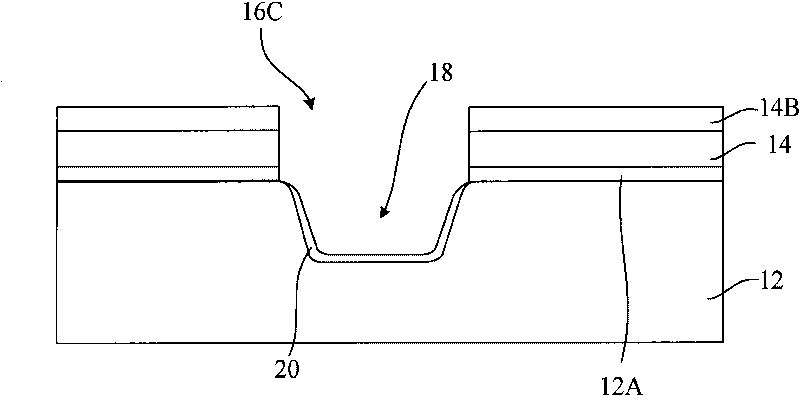

Resonator and forming method thereof

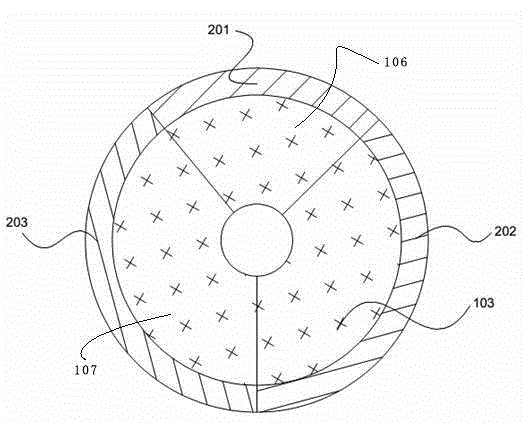

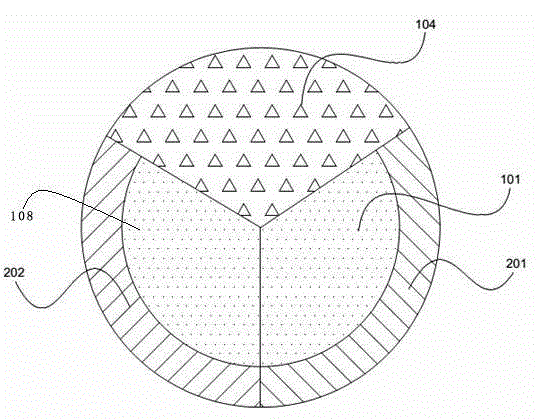

ActiveCN112117987AImprove performanceAchieve sealingImpedence networksEngineeringMechanical engineering

The invention relates to a resonator and a forming method thereof, and the forming method of the resonator comprises the steps: forming a piezoelectric laminated structure on a first substrate, the piezoelectric laminated structure comprises a first region, and the surface, in contact with the first substrate, of the piezoelectric laminated structure is a first front surface; forming a sacrificiallayer covering the piezoelectric laminated structure on the first region; providing a second substrate; forming a bonding layer on the second substrate, the face, making contact with the second substrate, of the bonding layer is a second front face, and the face, opposite to the second front face, of the bonding layer is a second back face; attaching the second back surface of the bonding layer to the sacrificial layer and the piezoelectric laminated structure exposed out of the sacrificial layer, so that the bonding layer covers the side wall of the sacrificial layer and fills between the second substrate and the piezoelectric laminated structure; removing the first substrate to expose the first front surface of the piezoelectric laminated structure; forming a release hole penetrating through the piezoelectric laminated structure or forming a release hole penetrating through the second substrate, wherein the release hole exposes the sacrificial layer; and removing the sacrificial layer through the release hole to form a cavity. The method of the invention is beneficial to improving the performance of the resonator.

Owner:NINGBO SEMICON INT CORP

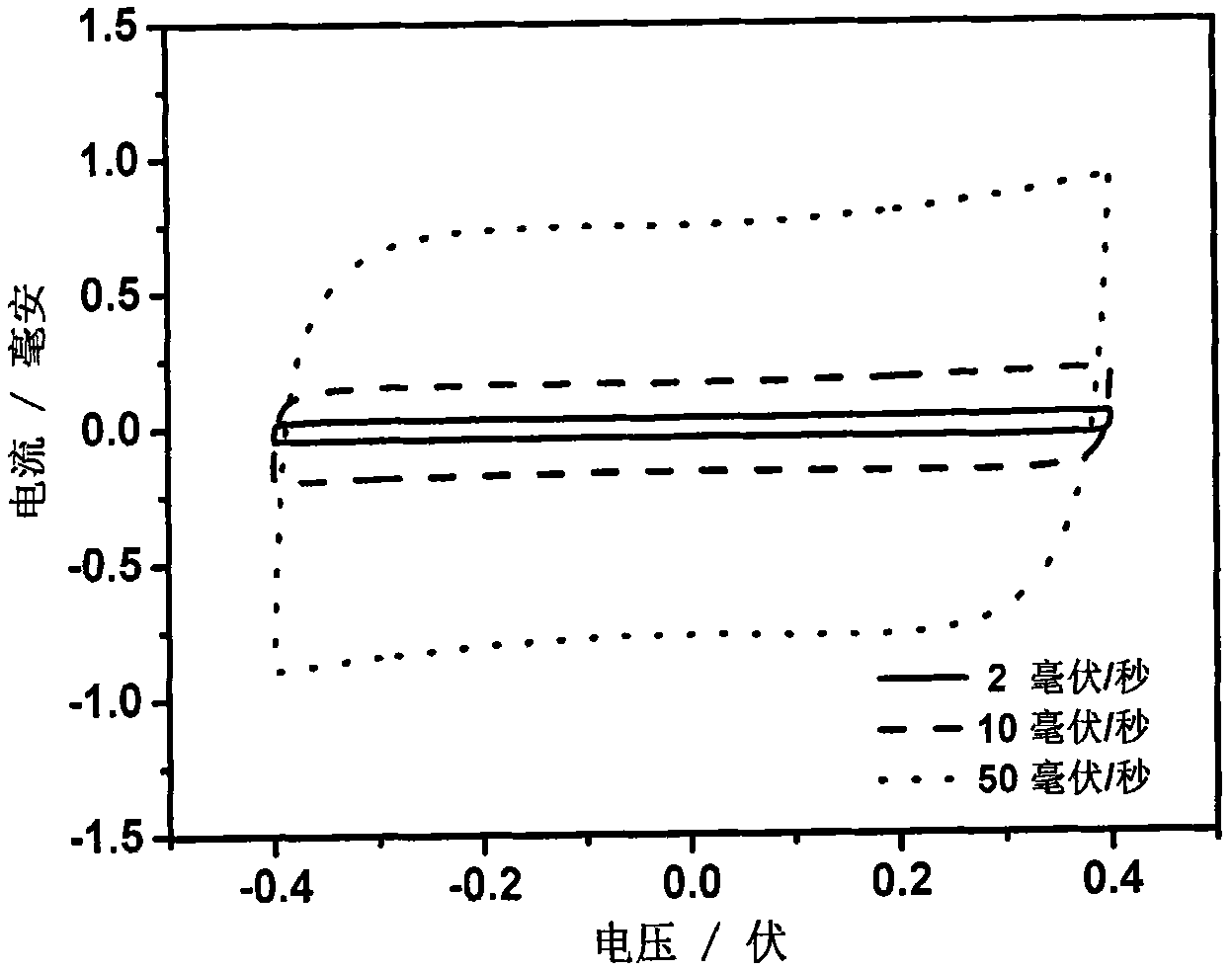

Preparation method of winding type super capacitor

ActiveCN101937774ALower equivalent series resistanceIncrease energy densityCapacitor electrodesPolymer capacitorThin film electrode

The invention provides a preparation method of a winding type super capacitor, which comprises the following steps: 1) selecting the direct growth method for preparing a carbon nanotube thin film as an electrode material; 2) cutting the carbon nanotube thin film into a plurality of carbon nanotube thin film small pieces; 3) flatly laying a long strip-shaped separator film in a volatile organic solvent; 4) sequentially flatly laying the plurality of the carbon nanotube thin film small pieces on the separator film in a head-to-tail connection manner till the organic solvent on the separator film which is laid on the carbon nanotube thin film is completely volatilized; and 5) winding and packaging the separator film and obtaining the winding type super capacitor. The invention firstly successfully prepares the winding type super capacitor with a carbon nanotube thin film electrode and can greatly improve the electrical conductivity of the winding type super capacitor, reduce the equivalent series resistance of the super capacitor, further improve the energy and the power density of the carbon nanotube thin film winding type super capacitor and show good power characteristic and current response.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

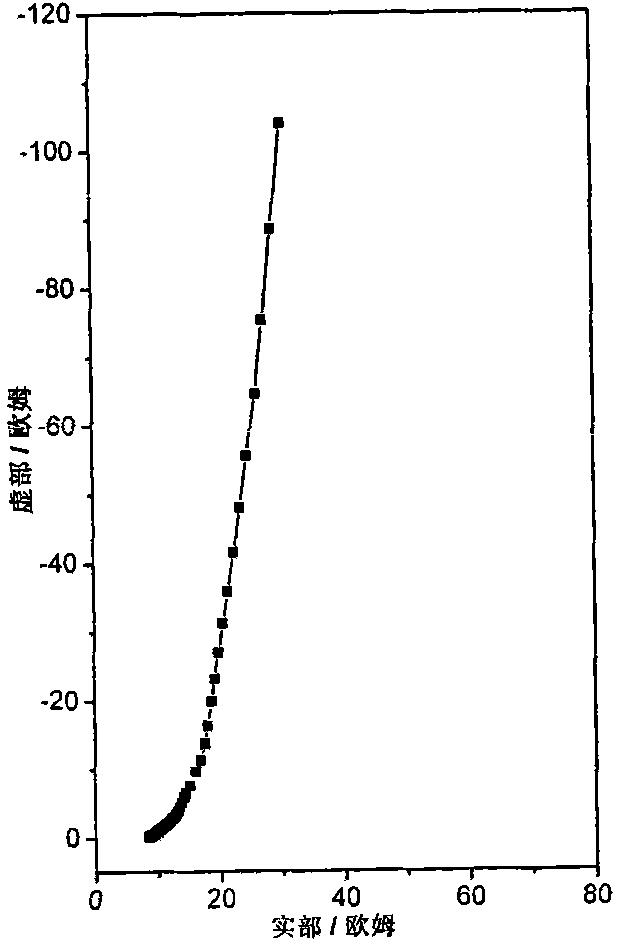

Graphite composite material as well as preparation method and application thereof

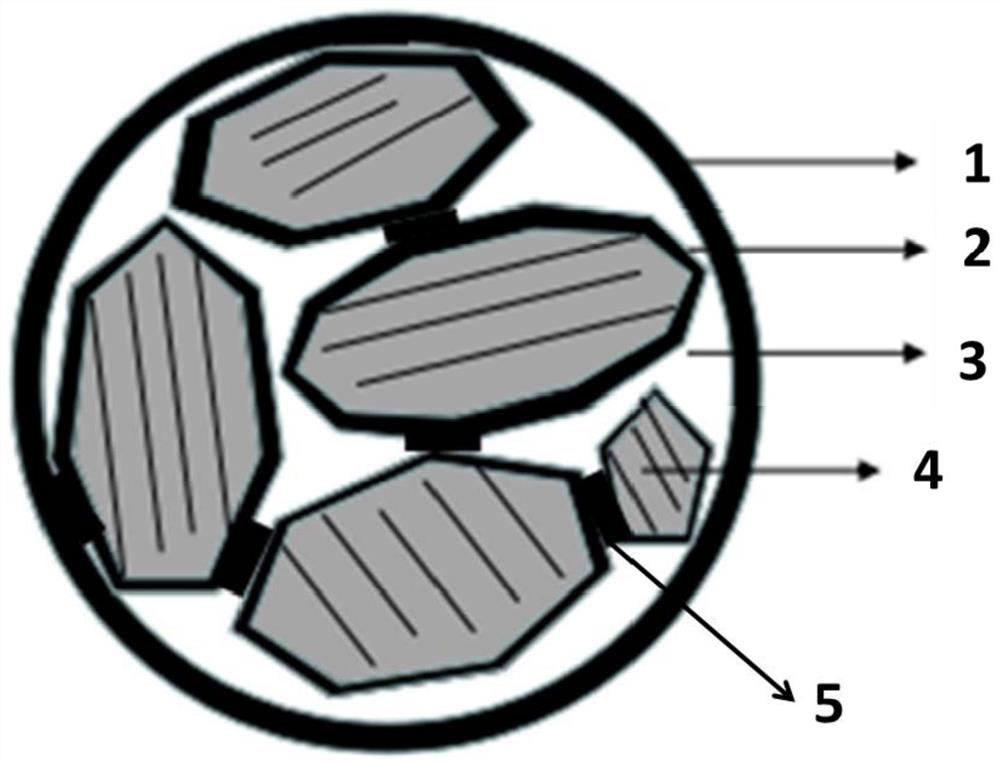

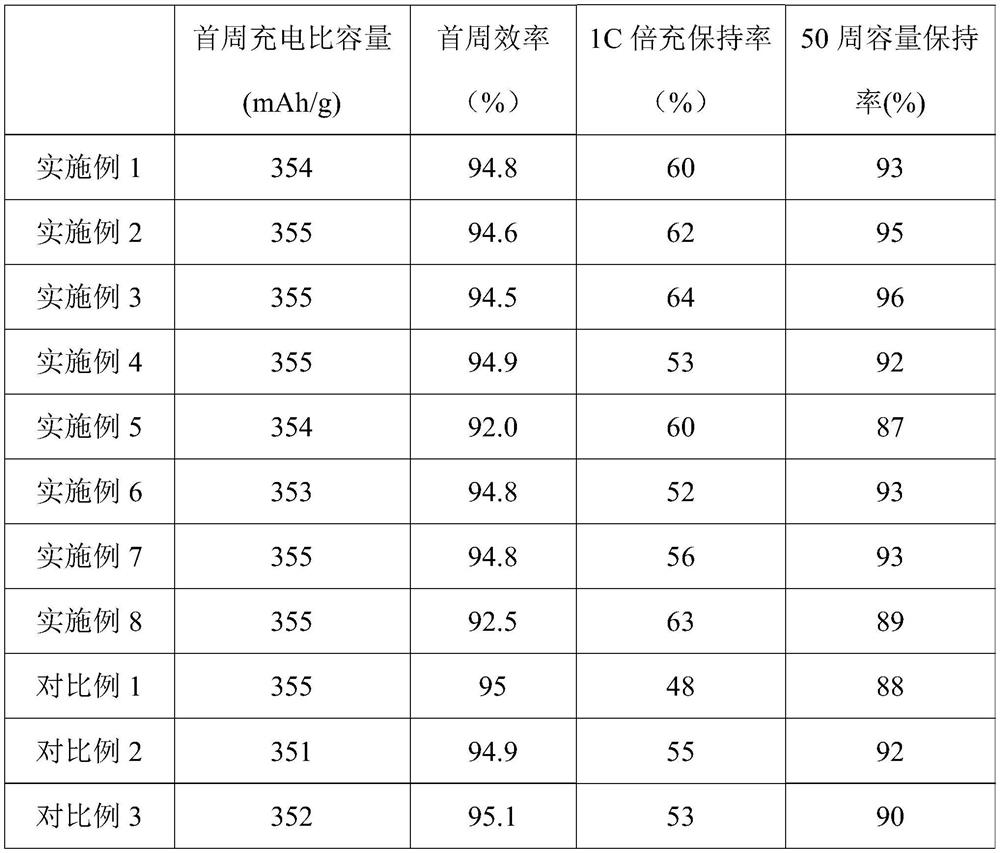

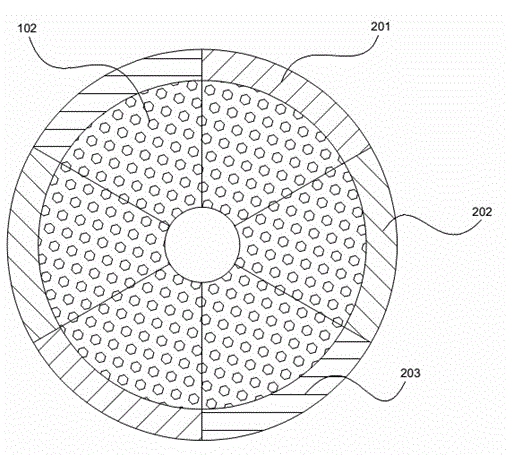

ActiveCN111682177AExcellent long cycle performanceHigh thickness consistencyNon-aqueous electrolyte accumulatorsNegative electrodesCarbon coatingParticle packing

The invention relates to a graphite composite material as well as a preparation method and application thereof. The graphite composite material is of a core-shell structure and comprises a secondary particle inner core and a second hard carbon coating layer on the surface of the secondary particle, wherein the secondary particles comprise a plurality of primary particles, and each primary particlecomprises a first hard carbon coating layer. In the graphite composite material provided by the invention, the hard carbon coating layer formed on the surface layer of the primary particle is tightlybonded with the inner core of the particle, no gap exists between the coating layer and the inner core, and the thickness consistency of the coating layer is high; the hard carbon coating layer of the secondary particle shell is beneficial to stabilizing the primary particle accumulation structure, and is beneficial to the long cycle performance of the material; the first hard carbon coating layer formed on the surface layer of the primary particle and the second hard carbon coating layer formed on the surface layer of the secondary particle can accelerate the desolvation process of lithium ions, so that lithium ions can be inserted into graphite more quickly; and according to the graphite composite material, the capacity can be ensured, and meanwhile, the quick charge and cycle performance can be greatly improved.

Owner:BTR NEW MATERIAL GRP CO LTD

Fluorescent powder color wheel and manufacturing method thereof

ActiveCN103912849AReduce the difficulty of manufacturing processImprove performanceProjectorsSpectral modifiersLaser lightProjection system

Disclosed are a fluorescent powder color wheel and a manufacturing method thereof. A plurality of substrates are assembled to form the fluorescent powder color wheel, and coated substrates and substrates with surfaces coated with fluorescent powder are assembled by the aid of a jig. By the aid of a novel fluorescent powder color wheel structure and the manufacturing method of the fluorescent powder color wheel, multiple functions of a single fluorescent powder color wheel are applied in a combined manner, and the novel fluorescent powder color wheel and a light source using the same are provided to realize flexible combined application of optical path design of a projection system and meet the requirements of an LED (light-emitting diode) light source and a laser light source for exciting light intensity and chromaticity.

Owner:MATERION PRECISION OPTICS SHANGHAI LTD

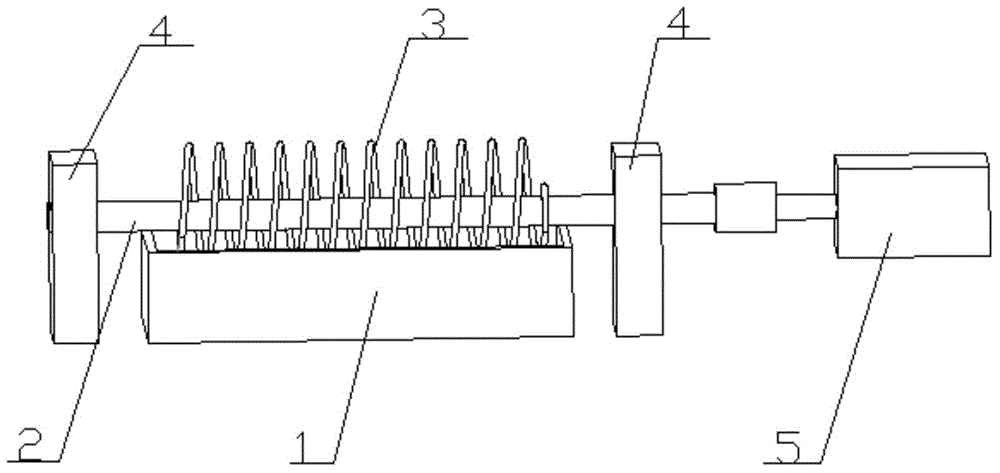

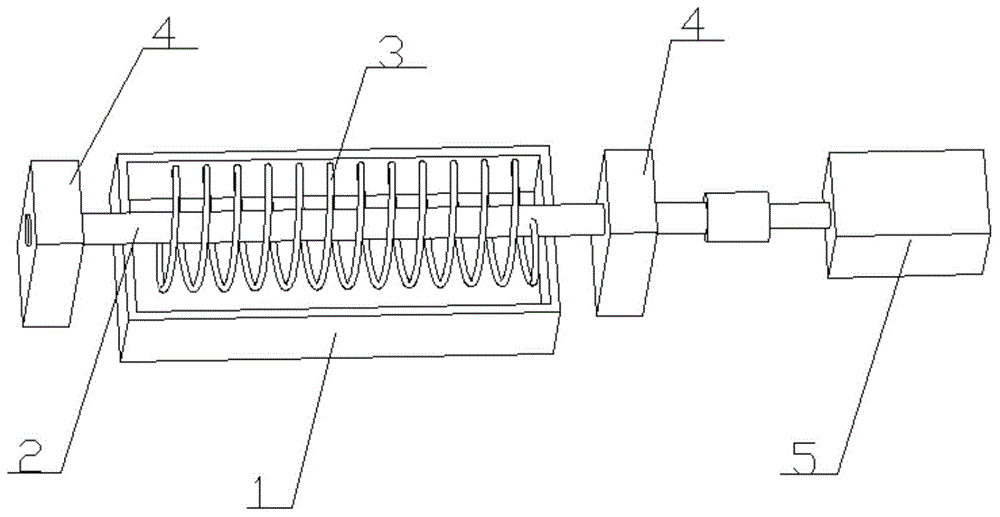

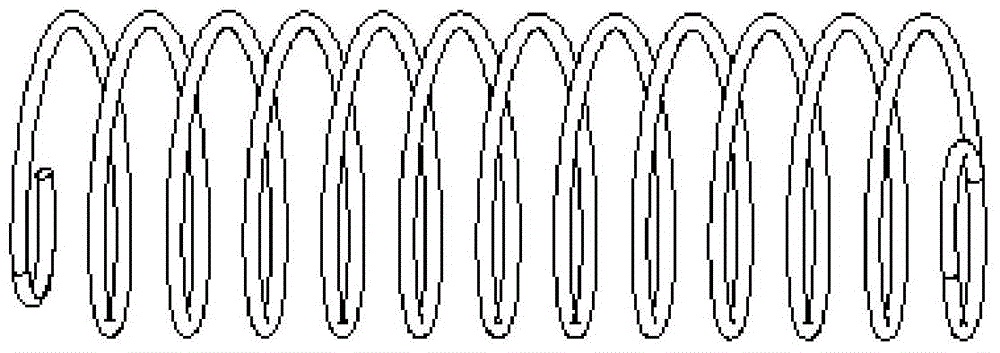

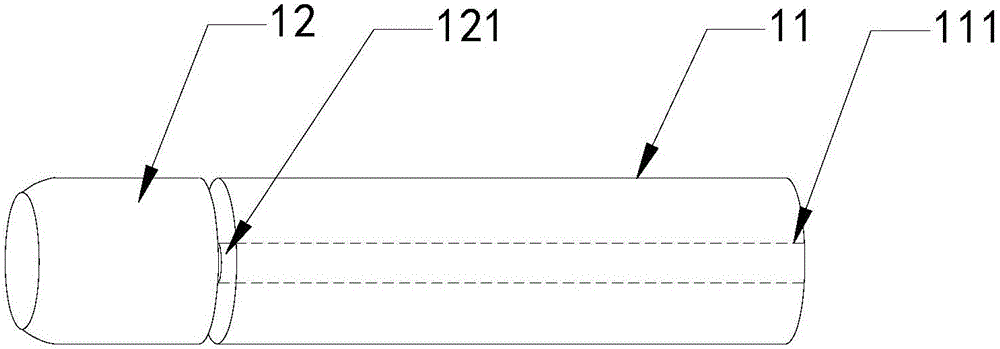

Linear nozzle for electrostatic spinning

The invention relates to an electrostatic spinning nozzle, in particular to a linear nozzle for electrostatic spinning. The linear nozzle is provided with a solution tank, a rotating shaft, a spiral metal ring, supporting bases and a driving device. The upper surface of the solution tank is open. The rotating shaft is arranged above the solution tank, is conductive and is externally connected with a high voltage electrostatic generation device. The two ends of the rotating shaft are connected with the driving device. The left and right sides of the rotating shaft are fixed to the supporting bases respectively. The rotating shaft is fixedly connected with the two ends of the spiral metal ring and located in the axis position of the spiral metal ring. The linear nozzle for electrostatic spinning solves the problems that the yield of an existing electrostatic spinning device is not high enough and the uniformity of thicknesses of spun fiber membranes is low, and can be used for manufacturing nano-fiber membranes on a large scale. The linear nozzle has the advantages of being simple in structure, low in cost, high in efficiency and the like. The spinning yield is greatly improved compared with a traditional needle tip electrostatic spinning nozzle, the problem that the nozzle is blocked does not exist, and the thickness consistency of the spun nano-fiber membranes is high.

Owner:XIAMEN UNIV

Manufacturing method of shallow trench isolation structure

InactiveCN101740462AHigh activityQuick buildSemiconductor/solid-state device manufacturingOptoelectronicsSilicon oxide

The invention relates to a manufacturing method of a shallow trench isolation structure, which comprises the following steps of: providing a substrate and sequentially arranging a pad silicon oxide layer and a hard mask layer on the substrate; arranging a trench in the substrate and respectively arranging an opening at the positions in the pad silicon oxide layer and the hard mask layer corresponding to the trench; executing a wet-oxygen oxidation process and forming a pad silicon oxide layer at the bottom and the side wall of the trench; forming a dielectric layer on the pad silicon oxide layer and the hard mask layer in the trench; and removing the dielectric layer on the hard mask layer and the hard mask layer. The invention can improve the thickness consistency of the pad silicon oxide layer in the shallow trench isolation structure.

Owner:SEMICONDUCTOR MANUFACTURING INTERNATIONAL (BEIJING) CORP

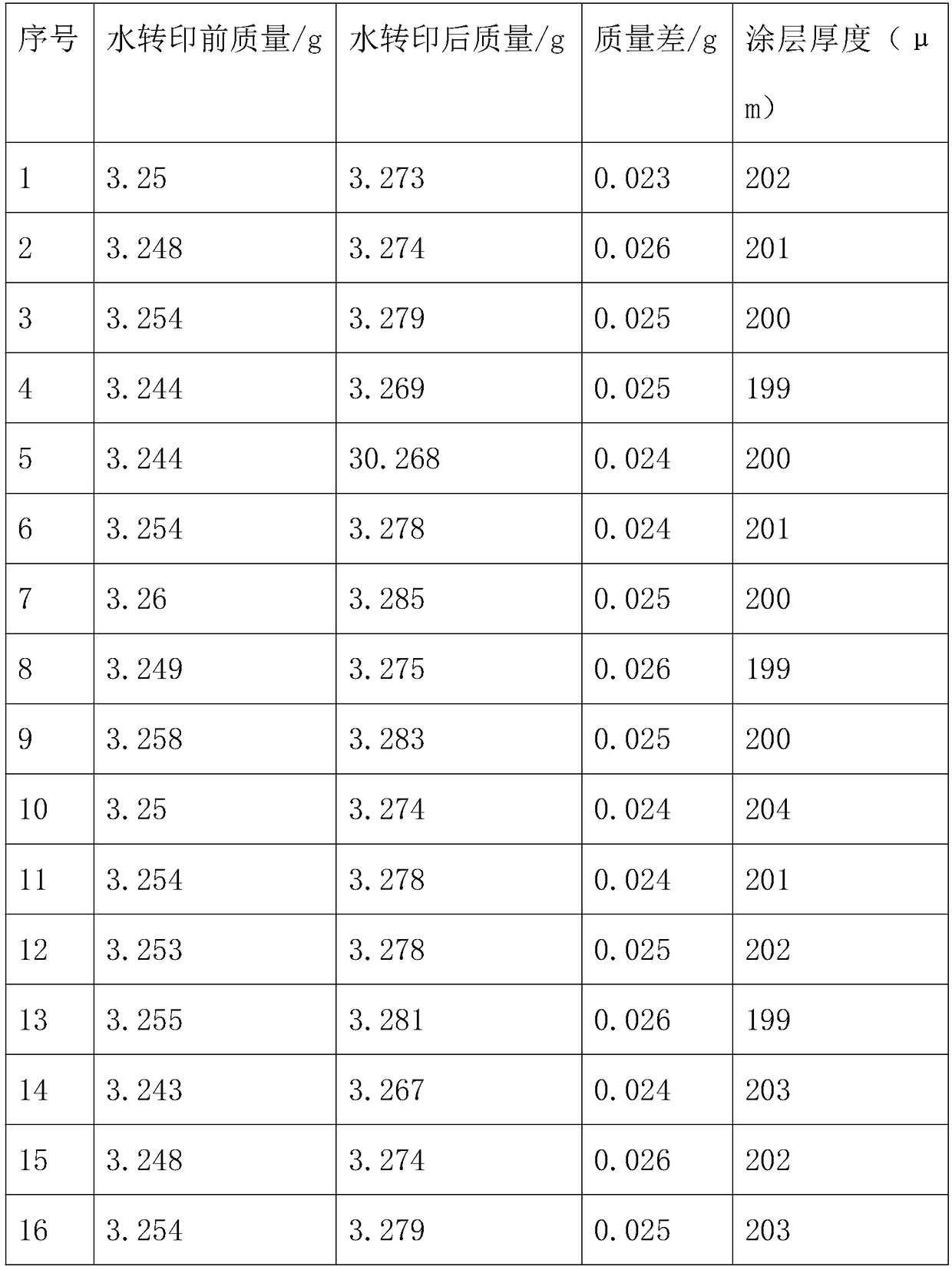

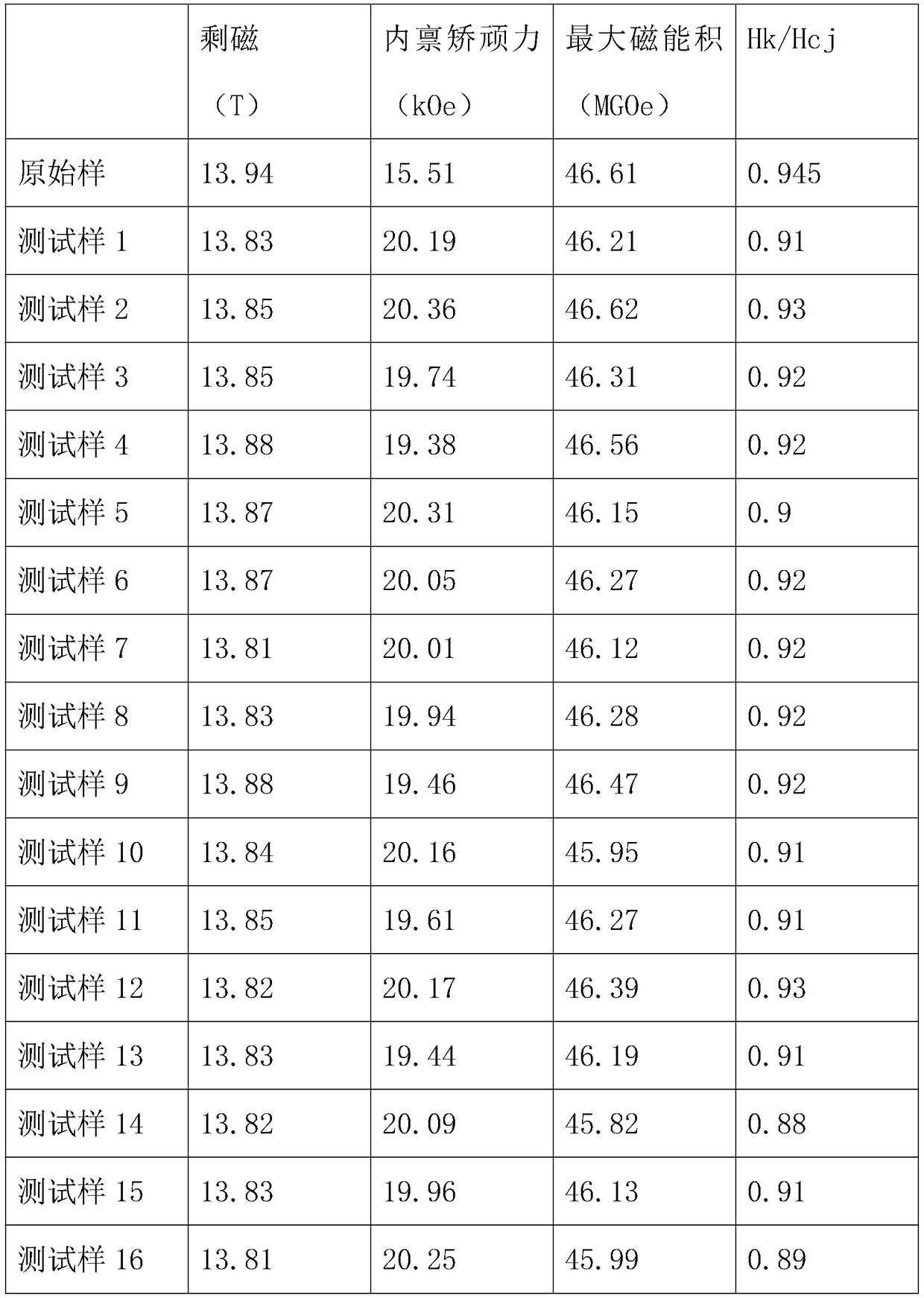

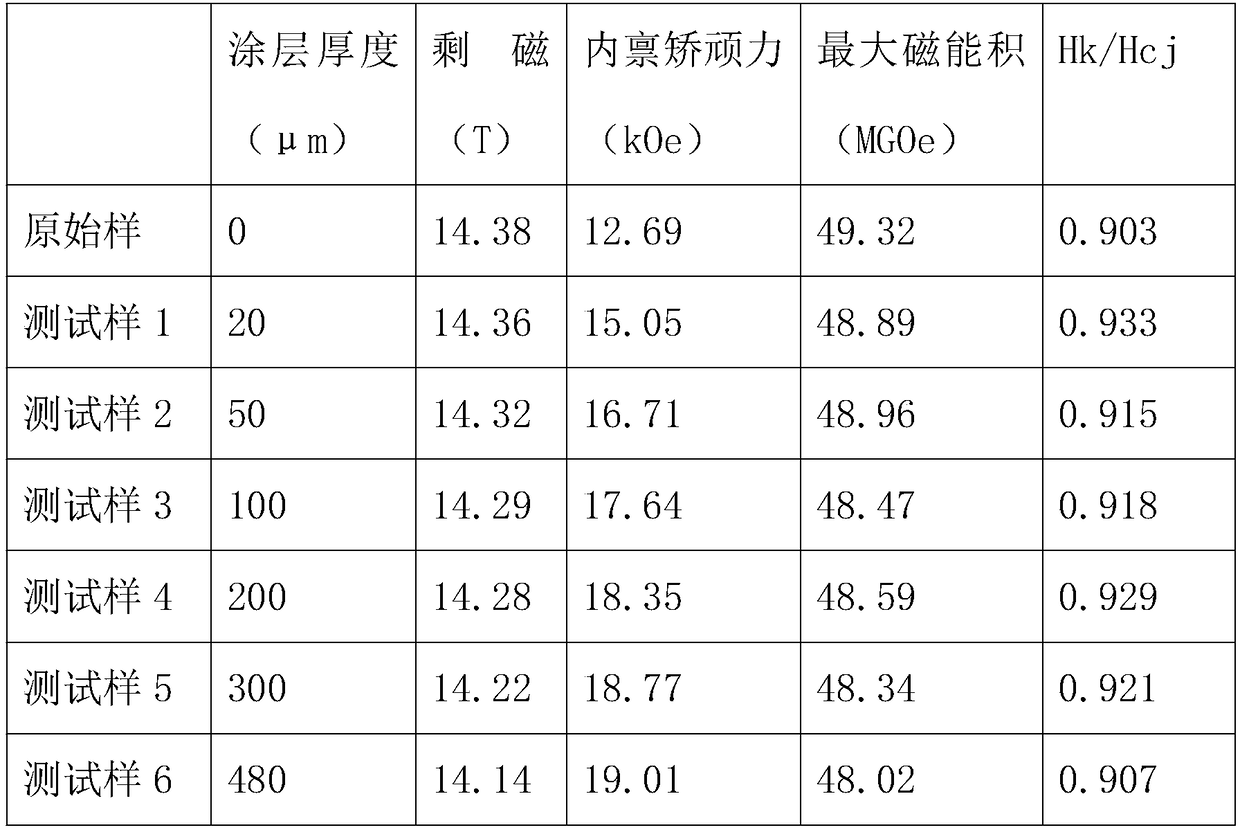

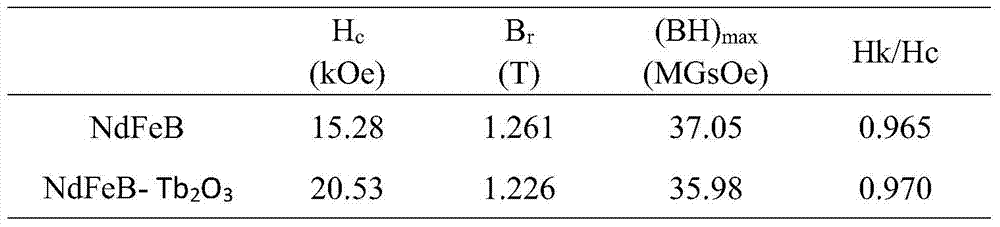

Preparation method of high-performance sintered Nd-Fe-B flake magnets by water transfer printing

ActiveCN108962526AImprove coercive forceImprove distribution uniformityInductances/transformers/magnets manufactureMagnetic materialsRare-earth elementMetal powder

The invention discloses a method for preparing high-performance sintered Nd-Fe-B sheet magnet by water transfer printing, At first, that heavy rare earth metal powder or the heavy rare earth compoundpowder is printed on the decorative paper by the 3D printing technology, Then the pattern paper is immersed in water for 30 seconds, and is affixed to the sintered Nd-Fe-B flake magnet whose surface is pretreated, and then the water is wiped off and dried to obtain the coating containing heavy rare earth elements on the surface of the sintered Nd-Fe-B flake magnet, and then the sintered Nd-Fe-B flake magnet dried by the diffusion treatment and the aging treatment are carried out in an inert gas environment. The method of the invention successfully applies the water transfer technology to the grain boundary diffusion technology, and adopts the water transfer technology to obtain a coating with high uniformity of distribution and consistency of thickness on the surface of the sintered Nd-Fe-B sheet magnet, thereby realizing industrialization of the grain boundary diffusion technology when the magnetic properties of the sintered Nd-Fe-B sheet magnet are improved.

Owner:NINGBO ZHAOBAO MAGNET

Production technology for high-filtering-precision filter cloth

InactiveCN109457393AAvoid the problem of excessive difference in filtering accuracyGuaranteed flatnessFibre treatmentSingeingFiberEngineering

The invention discloses a production technology for a high-filtering-precision filter cloth, and relates to a filter cloth. The aim is to solve the problem that a dust-ward layer is formed with difficulty. In the technical scheme, the production technology for the high-filtering-precision filter cloth is characterized by including fiber opening, carding, net laying, needling, calendaring and singeing, dipping and air blowing, forming of the dust-ward layer and sizing. According to the production technology for the high-filtering-precision filter cloth, the filtering precision of the dust-wardlayer is more uniform, filtering efficiency is higher, the connecting strength of the dust-ward layer and an inner filtering layer is higher, the production efficiency of the filter cloth is higher, and production costs are lower.

Owner:浙江锐捷滤材科技有限公司

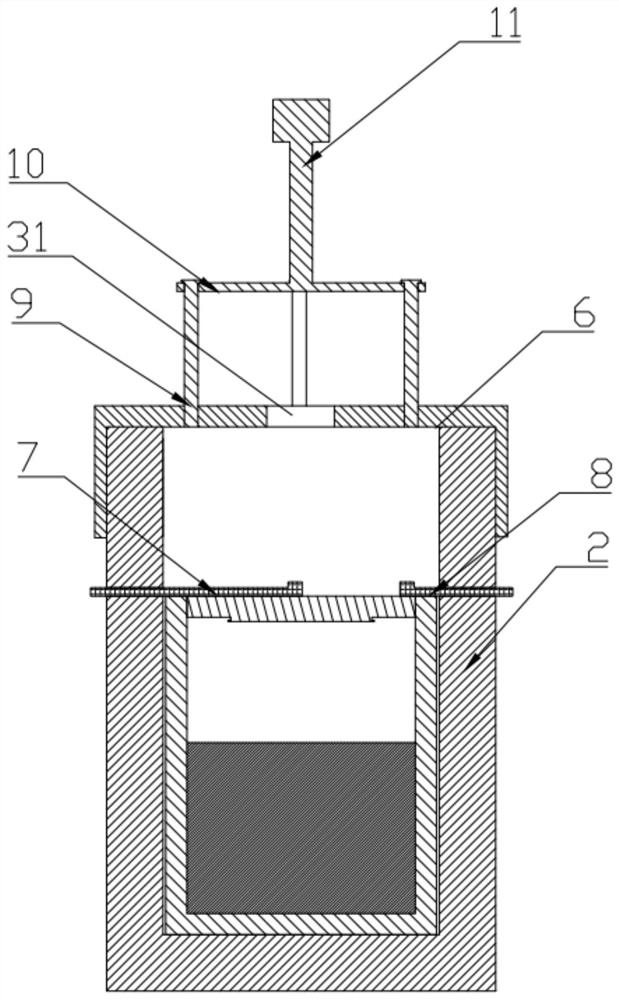

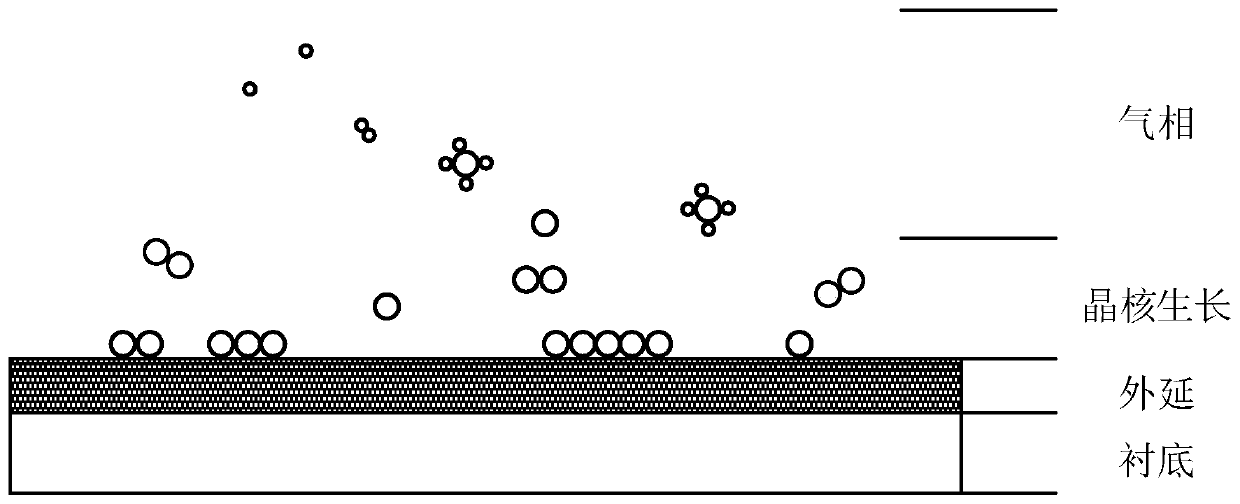

Growth method and device of high-quality silicon carbide crystal

ActiveCN113005511AReduce the chance of occurrenceImprove growth qualityPolycrystalline material growthFrom condensed vaporsCarbide siliconThermal insulation

The invention provides a growth method and device of a high-quality silicon carbide crystal. The method comprises the following steps: (1) an assembling stage; (2) heating stage; (3) nucleation stage: keeping the temperature of the center of the top end of the crucible at T1, controlling the thermal insulation cover to move downwards along the side wall of the thermal insulation cylinder, and controlling the temperature difference between the temperature of the center of the top end of the crucible and the temperature of the edge of the top end of the crucible to be gradually increased to deltaT2 so that the silicon carbide raw material gas phase is transmitted to the seed crystal for nucleation; and (4) growth stage: transmitting the silicon carbide raw material gas phase to the seed crystal for crystal growth. In the nucleation stage, an annular temperature field with the center of the seed crystal as the circle center is formed on the surface of the seed crystal, the heat preservation cover is controlled to move downwards, the annular temperature field is more uniform and stable, the radial temperature gradient is gradually and slowly increased, directional quantitative adjustment of the radial temperature gradient is achieved, the radial temperature gradient at the seed crystal is gradually increased, and multi-core competition and merging in the nucleation stage are promoted through the combined action; uniform and compact growth steps are formed, the generation probability of crystal defects is reduced, and the crystal growth quality is improved.

Owner:SICC CO LTD

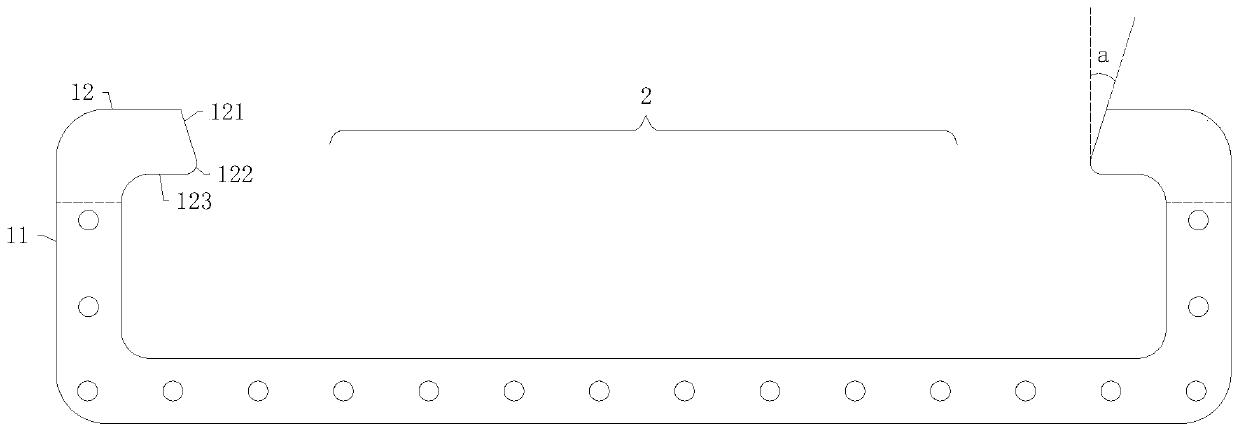

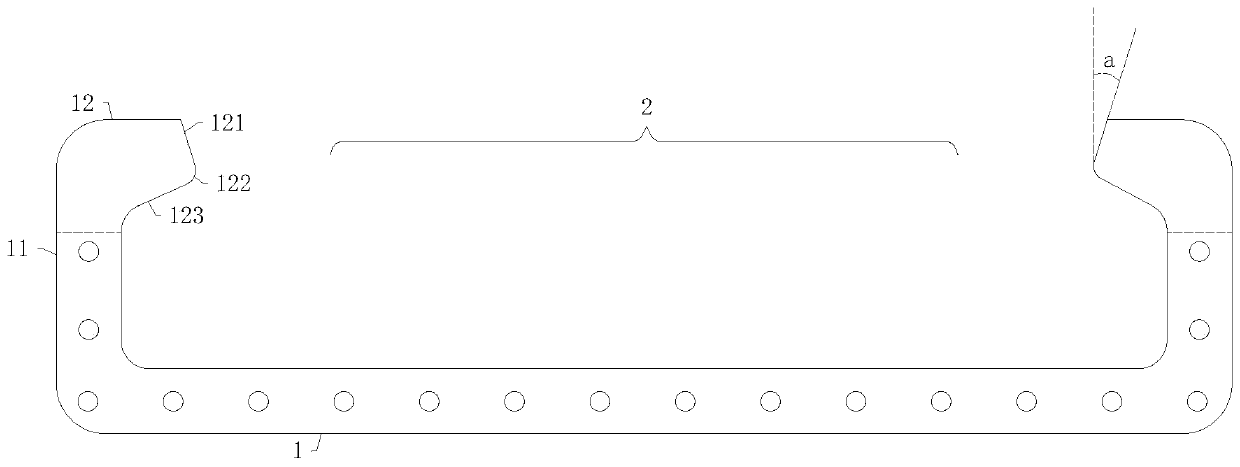

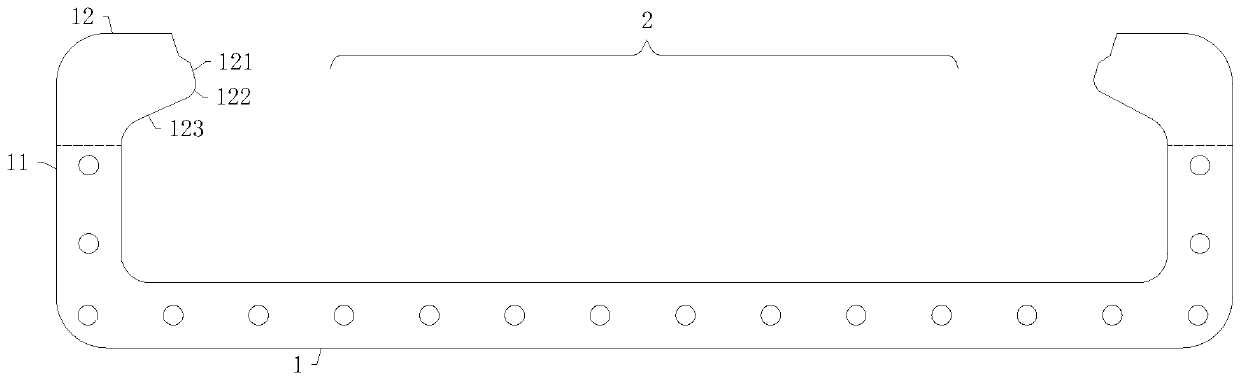

Extruding coating type die head gasket capable of eliminating coating edge effect

ActiveCN111250354AStable fluid pressureHigh thickness consistencyLiquid surface applicatorsElectrode collector coatingEngineeringLithium battery

The invention discloses an extruding coating type die head gasket capable of eliminating the coating edge effect and belongs to the technical field of lithium battery coating. The extruding coating type die head gasket comprises a die head gasket body, wherein a discharging hole is formed in the die head gasket body; the die head gasket body comprises a lower gasket and upper extending gaskets fixedly arranged at the left and right upper ends of the lower gasket; the space between the inner wall of the lower gasket and the two upper extending gaskets forms the discharging hole; and chamferingstructures for improving the fluid pressure when slurry flows to the edges of the upper extending gaskets via the discharging hole are arranged at mutually closed ends of the two upper extending gaskets, so that when the slurry is coated, the fluid pressure at the die head lip edge is stable, the speed of slurry extruded out of a slit is distributed uniformly, the edge thickness consistency of thecoated film surface is high, the coated edge film thickness and the range of the film edge abnormal area can be more effectively controlled to realize continuous coating of multiple films.

Owner:TIANNENG SAFT ENERGY JOINT CO

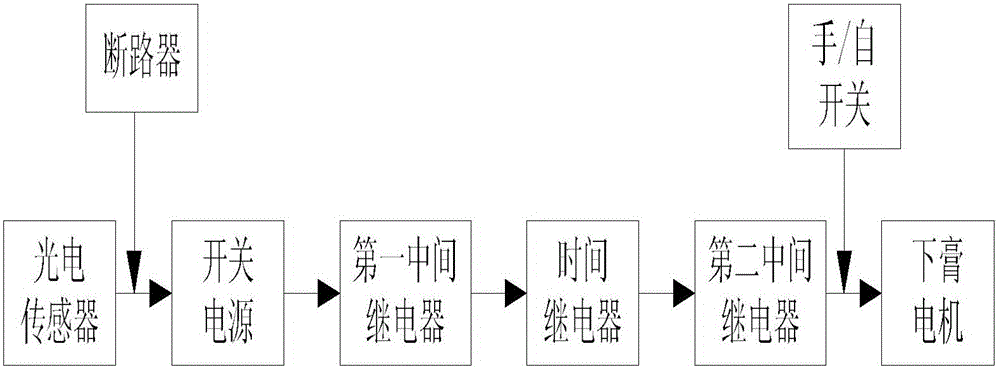

Control device for automatic and quantitative paste feeding to lead storage battery coating plate

PendingCN105870516AAvoid randomnessWeight increaseFinal product manufactureLead-acid accumulator electrodesEngineeringSwitching power

The invention discloses a control device for automatic and quantitative paste feeding to a lead storage battery coating plate. The control device comprises a photoelectric sensor, a switching power supply, a first intermediate relay, a time relay, a second intermediate relay and a paste feeding motor. The photoelectric sensor, the switching power supply, the first intermediate relay, the time relay, the second intermediate relay and the paste feeding motor are connected in sequence. A breaker is connected between the photoelectric sensor and the switching power supply. A switch is connected between the second intermediate relay and the paste feeding motor. The control device controls the paste feeding motor to add lead paste continuously, quantitatively and uniformly through the photoelectric sensor, the switching power supply, the intermediate relays and the time relay, arbitrariness and non-quantization of paste feeding are avoided, the influences imposed by inconsistent pressure of the lead paste in a paste hopper on paste feeding can be eliminated fundamentally, the weight and thickness uniformity of a polar plate is greatly improved, and the service life of a battery is prolonged.

Owner:ANHUI CHAOWEI POWER

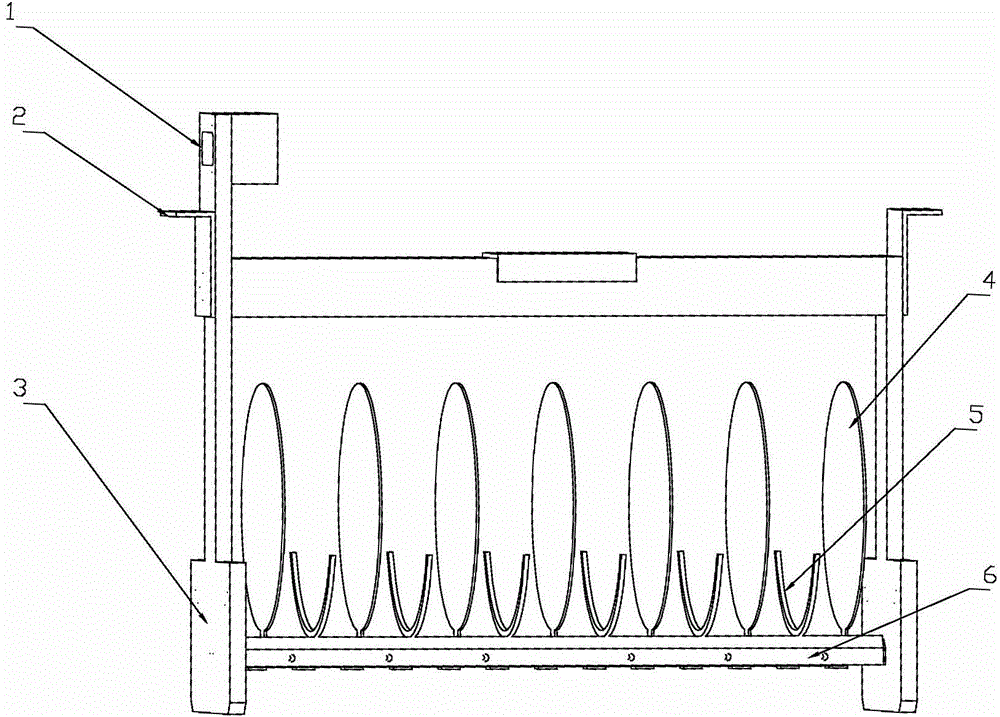

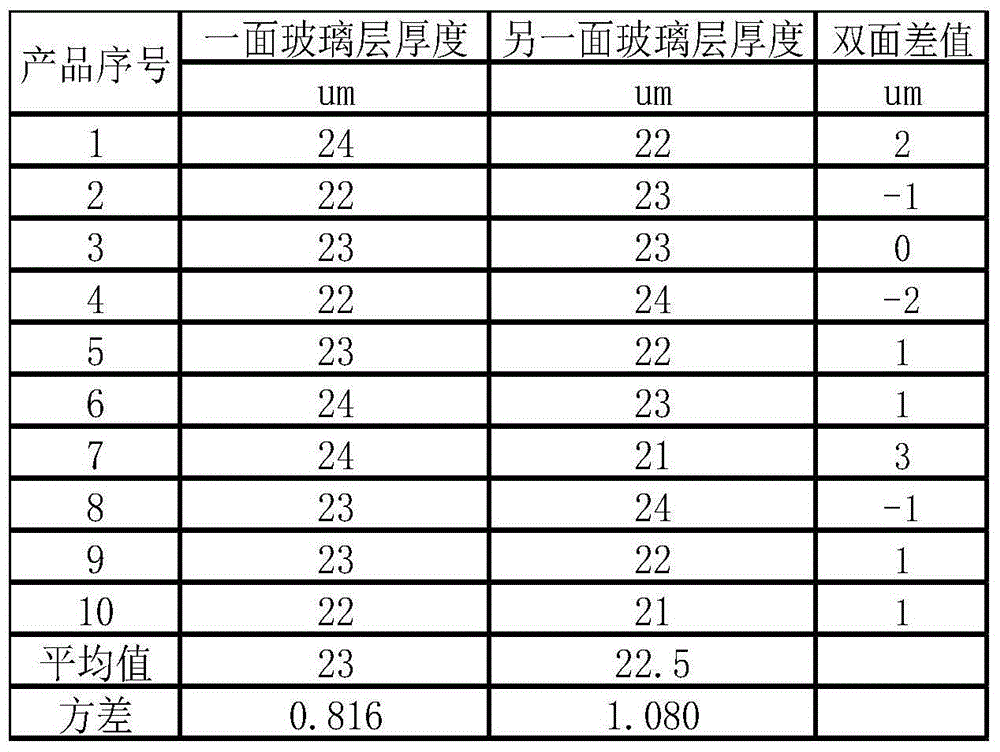

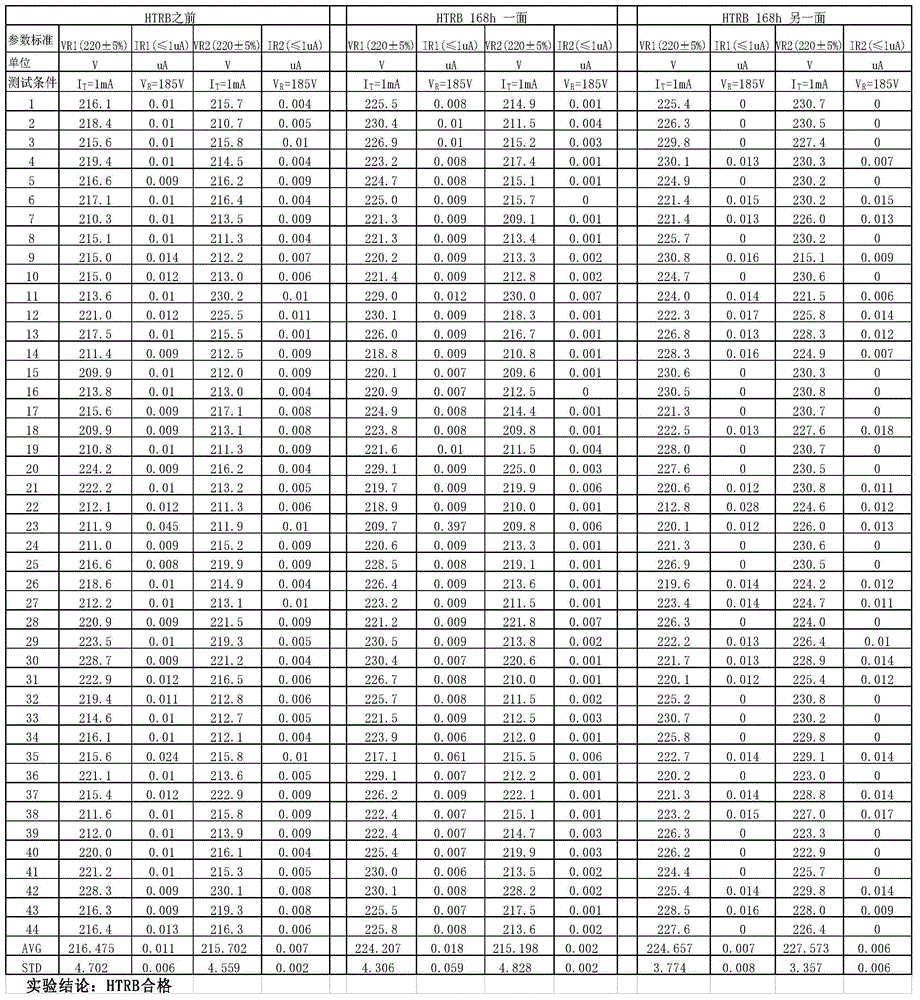

Table chip double side electrophoresis glass passivation technology

ActiveCN104599963AIncreasing the thicknessHigh thickness consistencySemiconductor/solid-state device manufacturingElectric fieldEngineering

The invention relates to the technical field of passivation protection of chips of semiconductor devices, in particular to a table chip double side electrophoresis glass passivation technology. The table chip double side electrophoresis glass passivation technology includes: using a modified electrophoresis frame, directly placing a silicon slice in an anodic metal half ring so as to use the silicon slice as an anodic plate, and placing negative plates on two sides of the anodic plate for electrophoresis. Accordingly, distances from table grooves in two sides of the silicon slice to the negative plates are equal, electric field distribution is even, and glass layers of the same thickness can be formed. Furthermore, an appropriate electrophoresis solution proportion and a glass sintering technology in a wet oxygen atmosphere are used, and therefore consistency of a double face glass passivation layer can be improved, glass is in complete and uniform in modeling, and simultaneously qualified rate and reliability of products can be improved, surge resisting ability of the semiconductor devices is enhanced, and production efficiency can be improved.

Owner:SUZHOU QILAN POWER ELECTRONICS

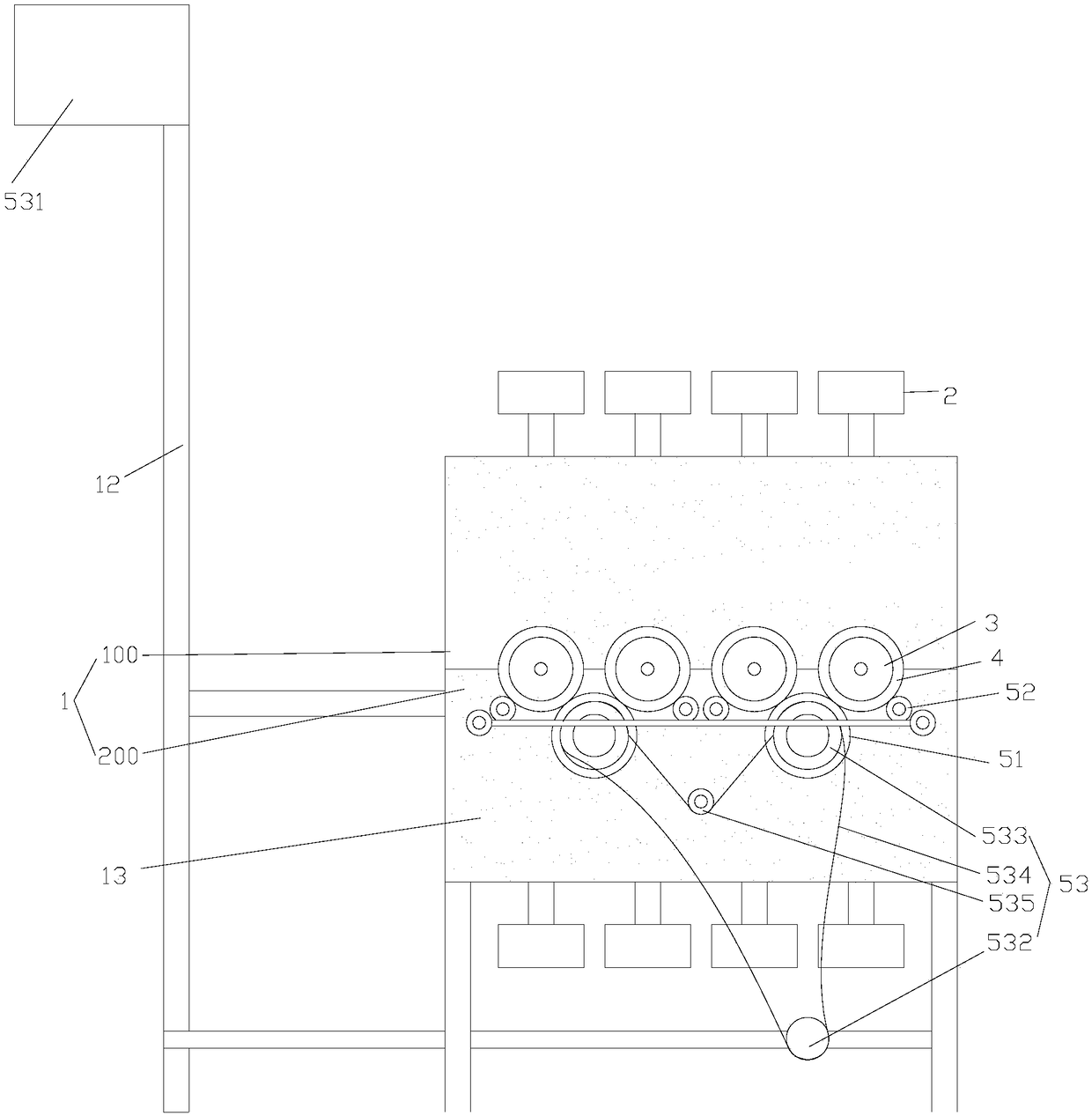

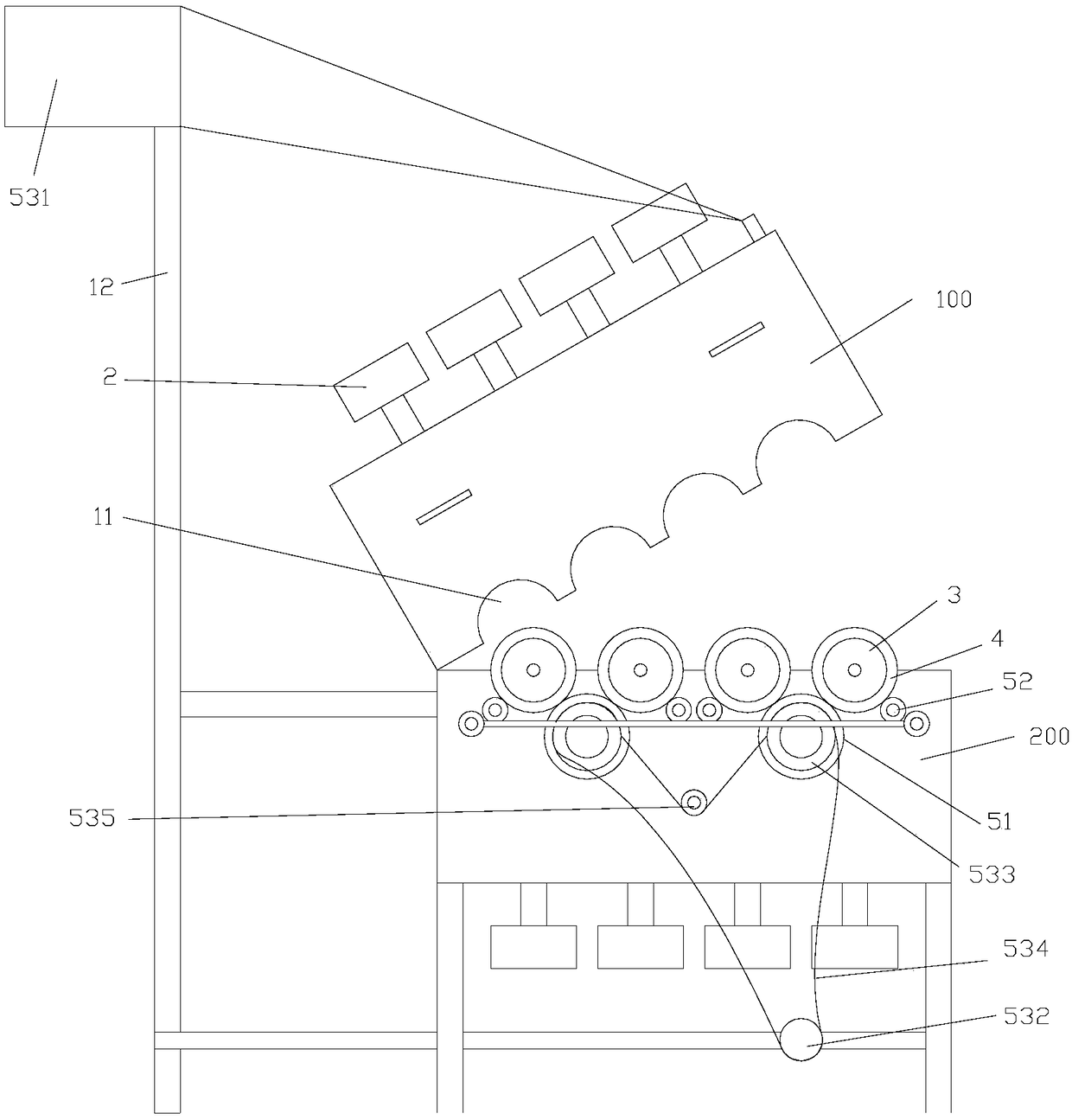

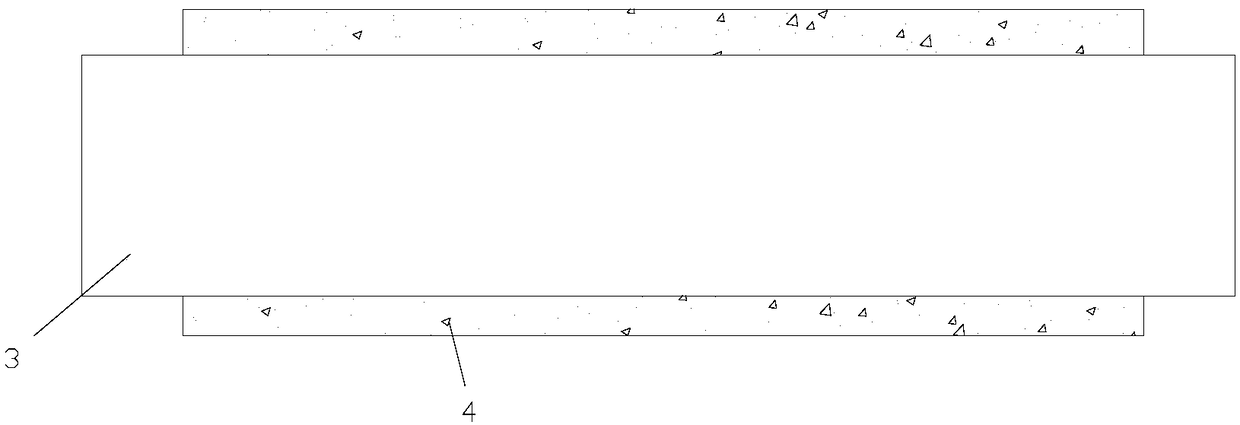

Cross lapping machine

InactiveCN101671919BReduce compactnessOvercoming overfeedingNon-woven fabricsWebs handlingFiberEngineering

The invention provides a cross lapping machine, which relates to a cross lapping machine for fiber webs in non-woven fabric processing. The cross lapping machine comprises a controller, a body, a discharging bench, a lapping trolley and a feeding and conveying curtain for the fiber webs, wherein the feeding and conveying curtain and the discharging bench form an angle of 90 degrees; and the lapping trolley reciprocates to swing in a feeding direction. The cross lapping machine also comprises a lapping trolley position sensing device and a traction mechanism, wherein the lapping trolley position sensing device comprises two sensors which are arranged on the body corresponding to rotation decelerating points at two ends of a lapping trolley stroke respectively; the two sensors are connectedwith the controller respectively; the traction mechanism comprises a first traction roll and a second traction roll which are arranged above the conveying curtain in parallel; the first traction rollis driven by a constant-speed motor; the second traction roll is driven by a variable-speed motor; and the constant-speed motor and the variable-speed motor are connected with the controller respectively. The cross lapping machine greatly improves the transverse thickness consistency of the breadth of a non-woven fabric, avoids the condition that the thickness of both sides is greater than that of the middle part, and greatly improves the quality of products.

Owner:YIZHENG SIFANG LIGHT TEXTILE MACHINERY

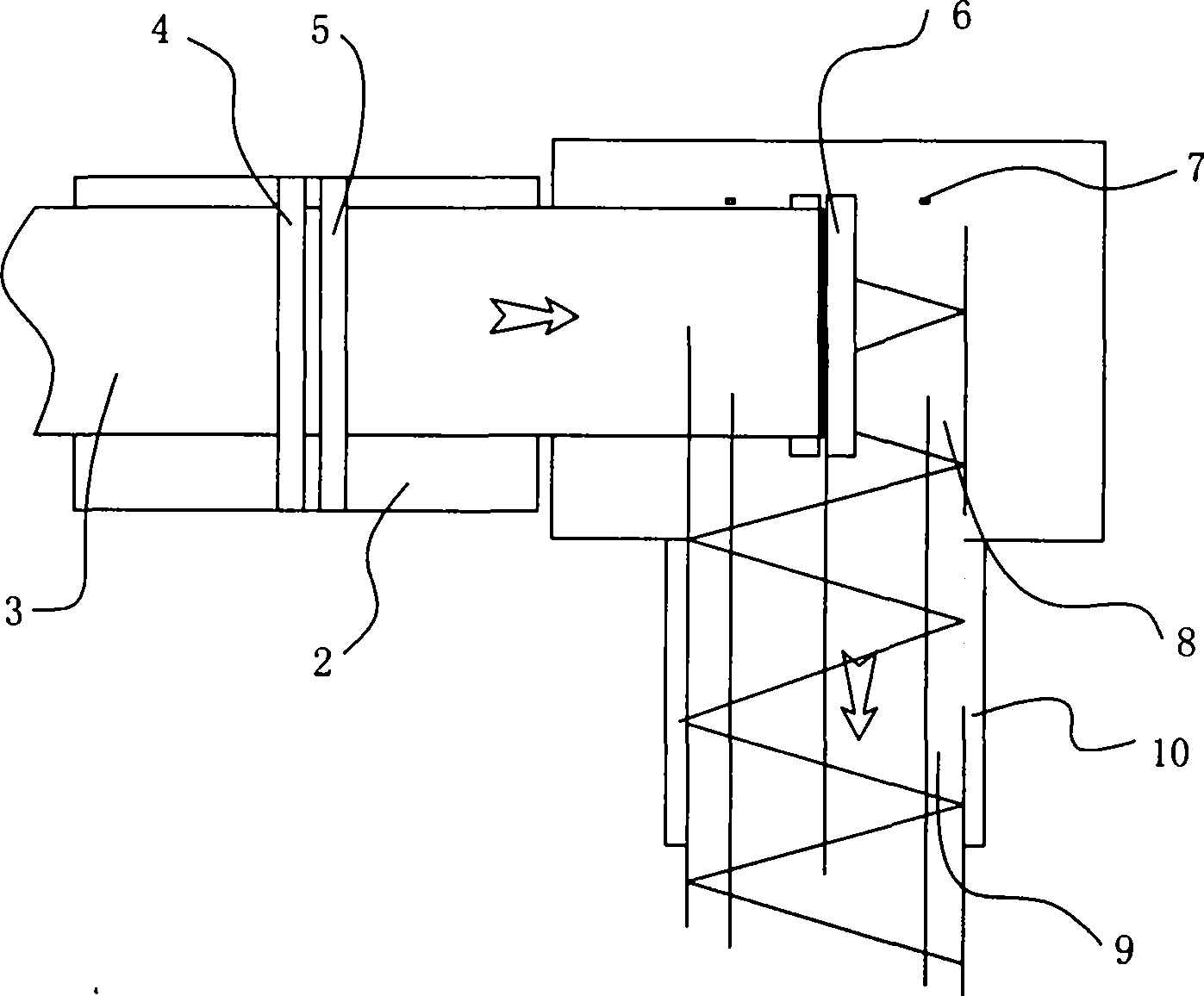

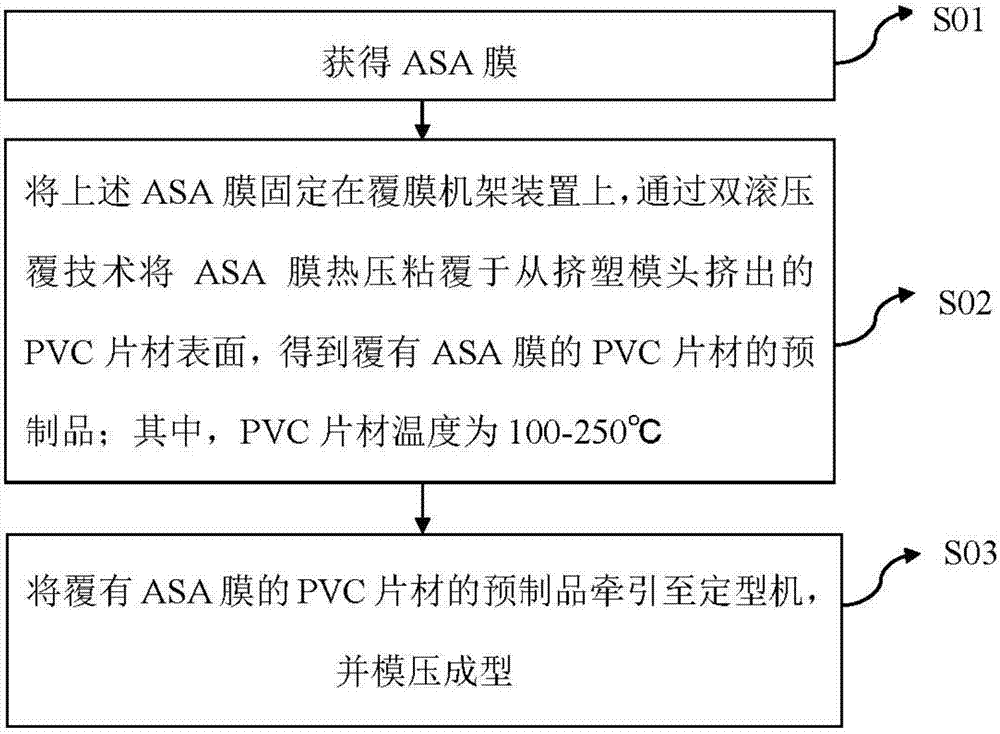

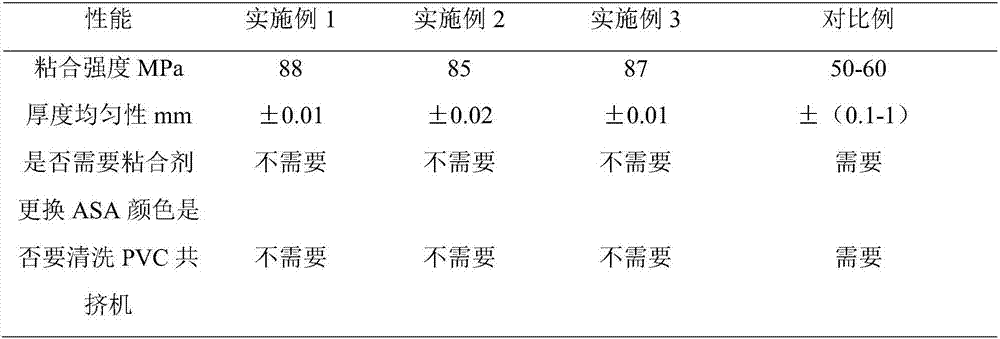

PVC (Polyvinyl Chloride) sheet coated with ASA (Acrylonitile Styrene Acrylate) film and film coating method

InactiveCN107443857AGuaranteed thickness consistencyExtended service lifeSynthetic resin layered productsLaminationAcrylateEngineering

The invention belongs to the technical field of plastic processing and forming, and particularly relates to a PVC (Polyvinyl Chloride) sheet coated with an ASA (Acrylonitile Styrene Acrylate) film and a film coating method. The method comprises the following steps: acquiring the ASA film; fixing the ASA film on a film coating rack device, using the double-roller pressing and coating technique to thermally press and adhere the ASA film to the surface of the PVC sheet extruded from an extruding die head, and obtaining a prefabricated product of the PVC sheet coated with the ASA film, wherein the temperature of the PVC sheet is 100-250 DEG C; and dragging the prefabricated product of the PVC sheet coated with the ASA film to a forming machine, and conducting compression molding. The ASA film is firmly adhered to the PVC sheet through the temperature of the just extruded PVC sheet, the double-roller embossing and the subsequent compression molding pressure, so that the consistency and the evenness of the thickness of the ASA film are guaranteed effectively, the service life of the product is prolonged, and moreover, the time is saved, the production efficiency is improved, and the purposes of saving energies and reducing consumption are fulfilled.

Owner:SHENZHEN YICAIHONGXIANG NEW MATERIALS TECH CO LTD

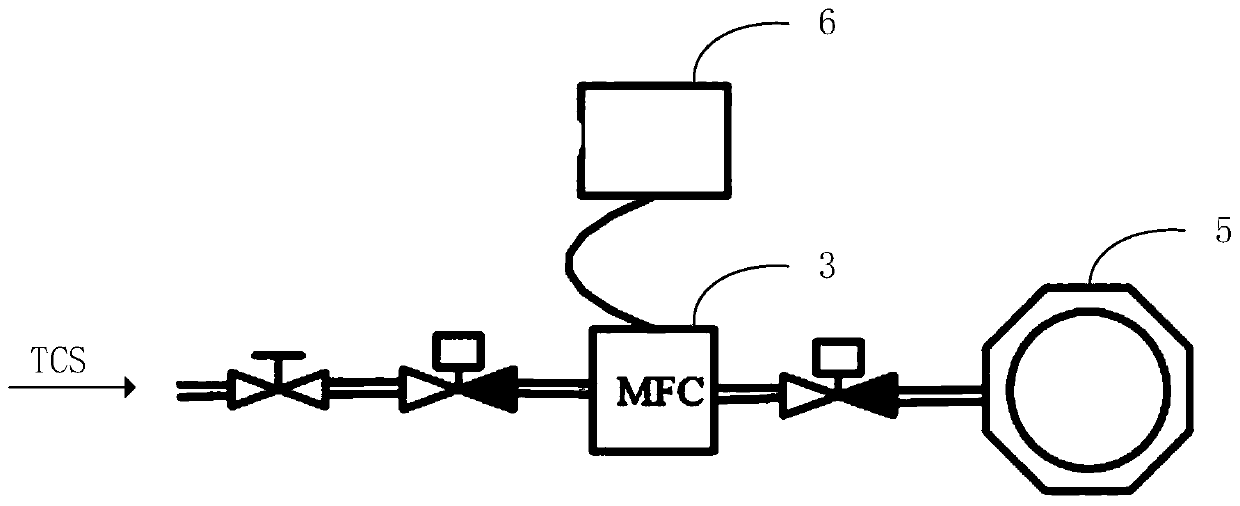

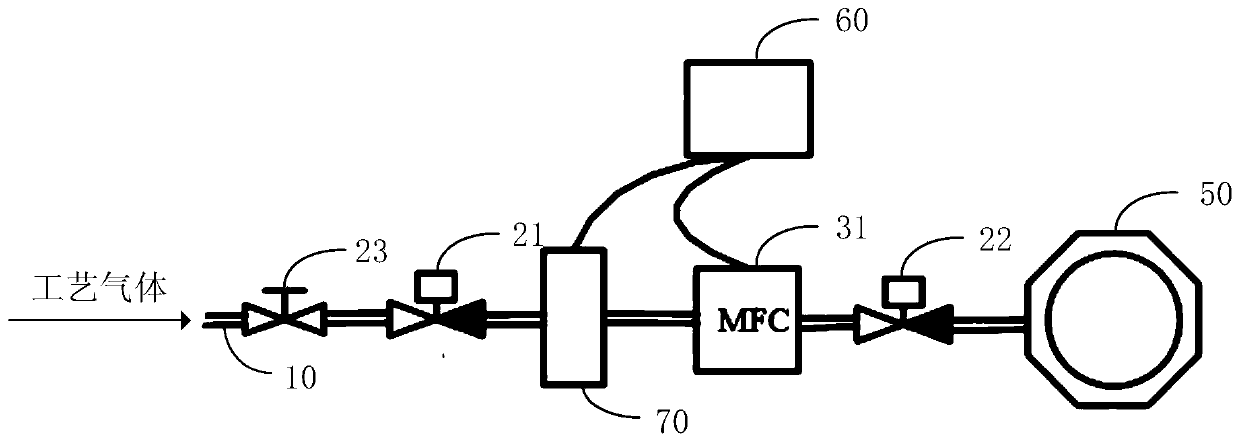

Gas inlet structure and gas inlet method of chemical vapor deposition equipment and equipment

InactiveCN111394789AConsistent qualityEnsure consistencyPolycrystalline material growthFrom chemically reactive gasesPhysical chemistryChemical vapor deposition

The invention provides a technical scheme of a gas inlet structure and a gas inlet method of chemical vapor deposition equipment. A concentration detection unit is used for detecting the current concentration value of source gas on a gas inlet pipeline, and a control unit is utilized to control a flow regulating unit to regulate the flow value of the process gas according to the current concentration value and the target concentration value so that the mass of the process gas in the reaction chamber can be regulated, and the mass of the source gas in the process gas is equal to the target mass. Therefore, the quality of the source gas in the process gas in the reaction chamber can be consistent when the substrate is prepared at different moments, and the consistency of the growth rate of the silicon wafer in the reaction chamber is ensured, the thickness consistency of the silicon wafer is improved and the product yield is further improved. In addition, the invention also provides thechemical vapor deposition equipment.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

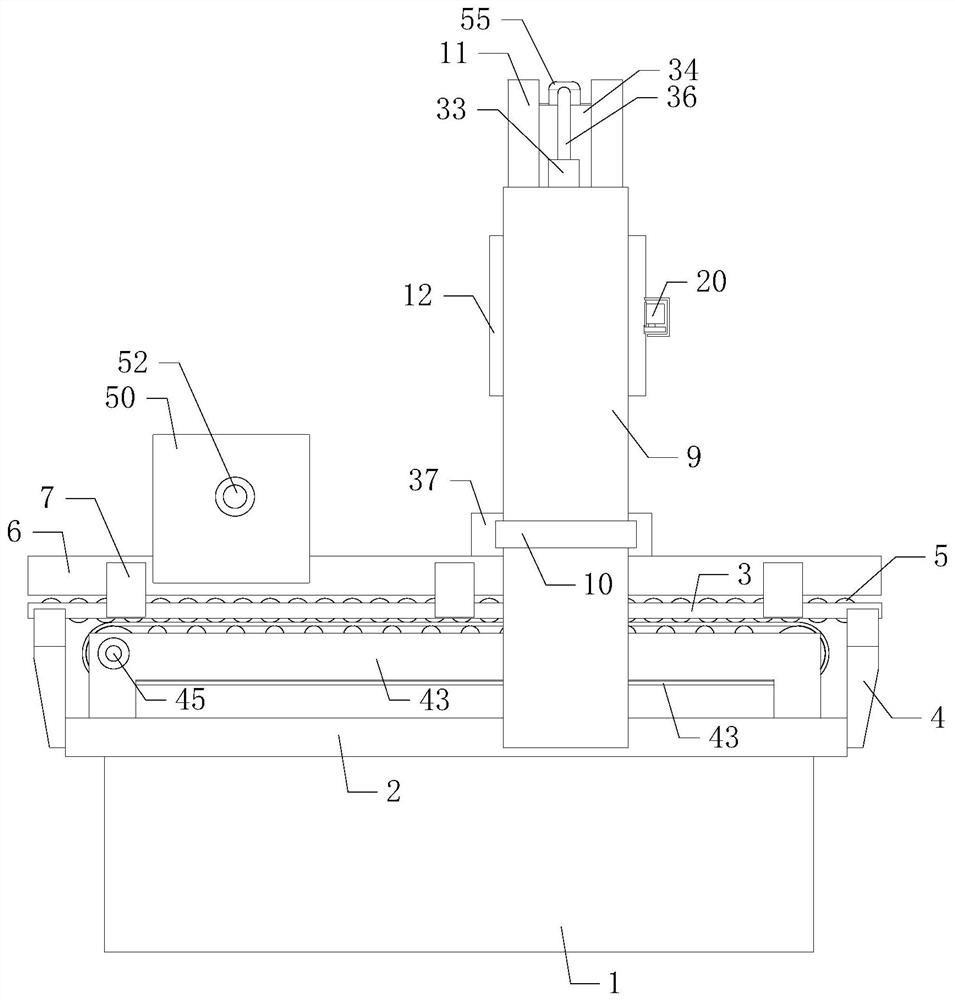

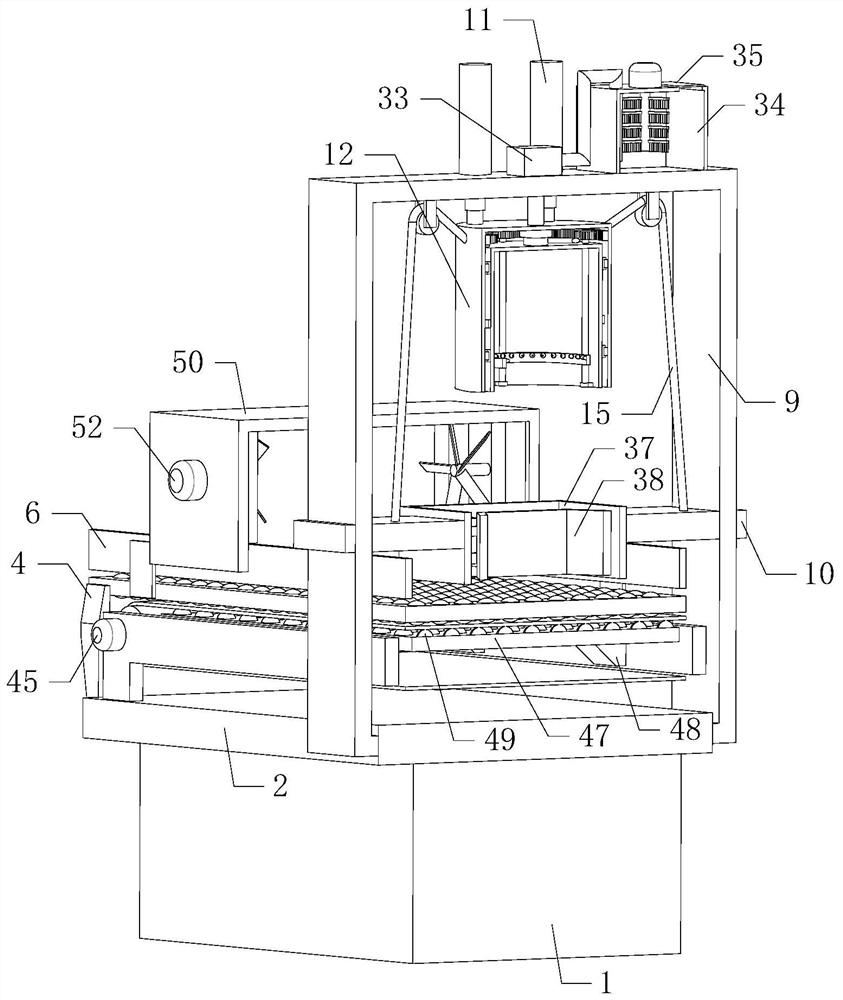

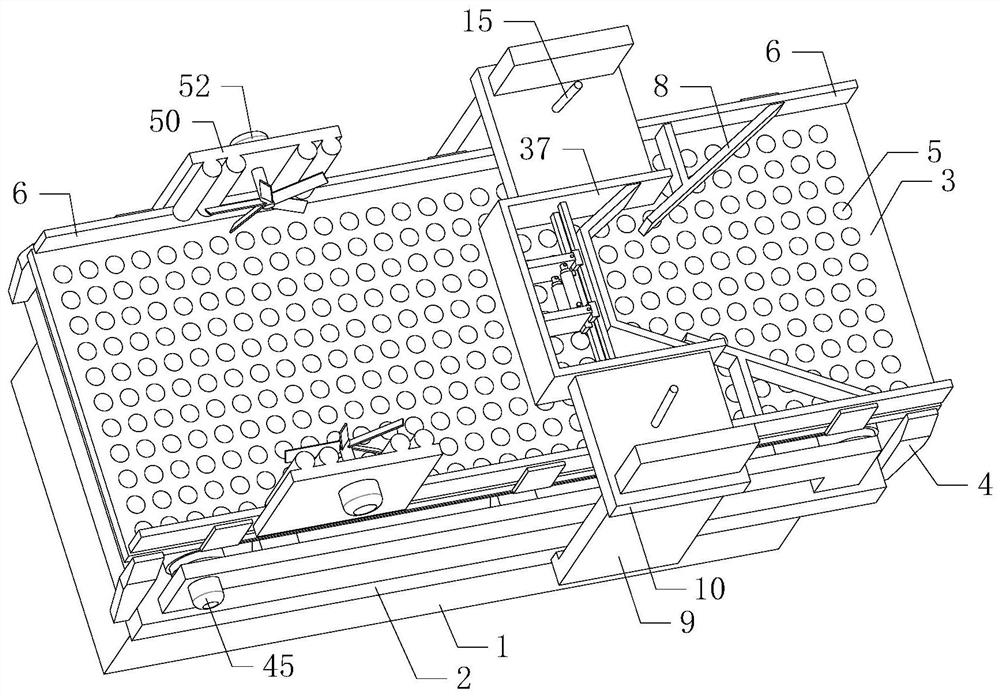

Automatic grinding and tabletting press

InactiveCN105865878AImprove processing efficiencyHigh precisionPreparing sample for investigationEngineeringPatch type

The invention discloses an automatic grinding and tabletting press. The automatic grinding and tabletting press comprises a grinding device, a sieving device and a tabletting device in sequence from top to bottom, wherein the grinding device comprises more than two layers of grinding layers which are stacked, and each grinding layer comprises more than two pairs of grinding columns which are horizontally arranged; the sieving device comprises a stainless steel screen mesh and a patch type vibrator arranged on the stainless steel screen mesh; the tabletting device comprises a tabletting room, an upper pressing pate, an upper pressing plate driving motor, an air cylinder and an air pump; the air pump is connected with the air cylinder, a piston of the air cylinder is upward and vertically arranged, and the piston of the air cylinder is arranged in the tabletting room in a sliding way; and a sample feeding hole is formed in the top of the tabletting room. According to the automatic grinding and tabletting press, the efficiency of sample grinding and tabletting is greatly improved, and the consistency of sample processing is improved.

Owner:FUJIAN NORMAL UNIV

Strip-shaped spraying head for electrostatic spinning

The invention relates to spraying heads for electrostatic spinning, and provides a strip-shaped spraying head for electrostatic spinning, which can increase the yield of electrostatic spinning equipment and improve the thickness uniformity of spun fiber membranes and cannot be blocked. The strip-shaped spraying head comprises a solution feeding mechanism, a strip-shaped conductive sheet and a conductive sheet bracket, wherein the strip-shaped conductive sheet is fixedly connected with the conductive sheet bracket; the solution feeding mechanism is used for uniformly coating the surface of one side of the long edge of the strip-shaped conductive sheet with a spinning solution. During spinning, the strip-shaped conductive sheet is connected with the anode of a high-voltage direct-current power supply, a spinning collection plate is connected with the cathode of the high-voltage direct-current power supply, the solution is uniformly applied to the surface of one side of the long edge of the conductive sheet through the solution feeding mechanism, the solution on the strip-shaped conductive sheet forms electro-spinning under the action of an electrostatic force, and the solution feeding mechanism continuously coats the strip-shaped conductive sheet with the solution. The strip-shaped spraying head is simple in structure, the yield is greatly increased in comparison with that of a conventional spraying head for needle electro-spinning, no problem of spraying head blockage is caused, and the thickness uniformity of the spun nano fiber membranes is relatively high.

Owner:XIAMEN UNIV

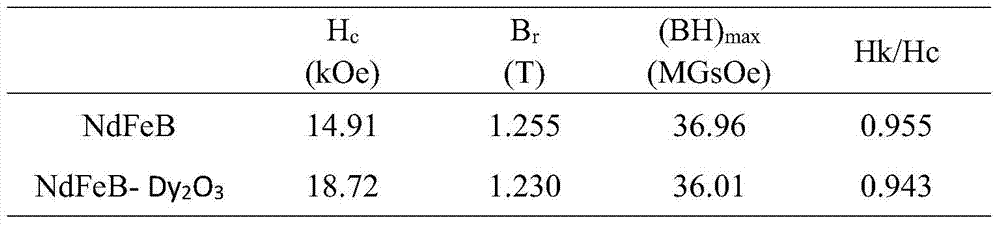

A method for improving the magnetic properties of sintered NdFeB by grain boundary diffusion

ActiveCN105489335BAvoid damageImprove adhesionInorganic material magnetismRare-earth elementVacuum drying

The invention discloses a method for improving the magnetic performance of sintered NdFeB through grain boundary diffusion, and belongs to the technical field of rare earth magnetic materials. The method comprises the steps that sintered NdFeB magnetic powder is subjected to semi-densification sintering, wherein the density is 90-95%; the periphery of the semi-densification sintered NdFeB is coated with turbid liquid, with the viscosity of 100-500 mpa.s, containing heavy rare earth compounds, the vacuum drying is carried out, coatings with heavy rare earth elements areobtained on the surface of a semi-densification sintered NdFeB magnet, then sintering at 1040-1080 DEG C is carried out for 2-3 h, primary tempering at 900-940 DEG C is carried out for 1-3 h, secondary tempering at 480-550 DEG C is carried out for 2-4 h, and the high-magnetism sintered NdFeB material is obtained. Certain adhesive force is formed between the semi-densification sintered NdFeB magnet and the coatings such as Dy2O3, Tb2O3, DyF3 and DyH3, the heavy rare earth elements enter the NdFeB magnet in the sintering process, the organizational structure and components at the combined position of a grain boundary and a main phase are improved, the heavy rare earth elements can be more easily diffused into the NdFeB magnet, the distribution uniformity and thickness consistency are high, and the depth of the diffusion layer is greatly increased.

Owner:UNIV OF SCI & TECH BEIJING

Surface rust-proof treatment equipment for metal shell of wind power generation equipment

InactiveCN112403773AEasy to liftPrevent looseningPretreated surfacesCoatingsStructural engineeringMechanical equipment

The invention relates to the technical field of mechanical equipment, in particular to surface rust-proof treatment equipment for a metal shell of wind power generation equipment. The surface rust-proof treatment equipment has the advantages that paint is continuously and automatically sprayed onto the metal shell, so that the physical strength during manual operation can be effectively saved, thepaint spraying speed can be increased, the working efficiency can be improved, meanwhile, the equipment automatically sprays the paint, the uniformity of the paint attached to the metal shell is improved, the paint thickness consistency is improved, the paint spraying quality is effectively improved, and the practicability and the reliability are improved. The surface rust-proof treatment equipment comprises a base, a workbench, a first flat plate and four groups of first fixing plates, the workbench is arranged at the top of the base, a power device is arranged at the top of the workbench, the first flat plate is located above the power device, the four groups of first fixing plates are evenly arranged on the outer side of the first flat plate, the bottoms of the four groups of first fixing plates are all fixed to the workbench, and multiple groups of conveying balls are evenly arranged on the first flat plate in a penetrating and inserted mode.

Owner:苏州立科工业设计有限公司

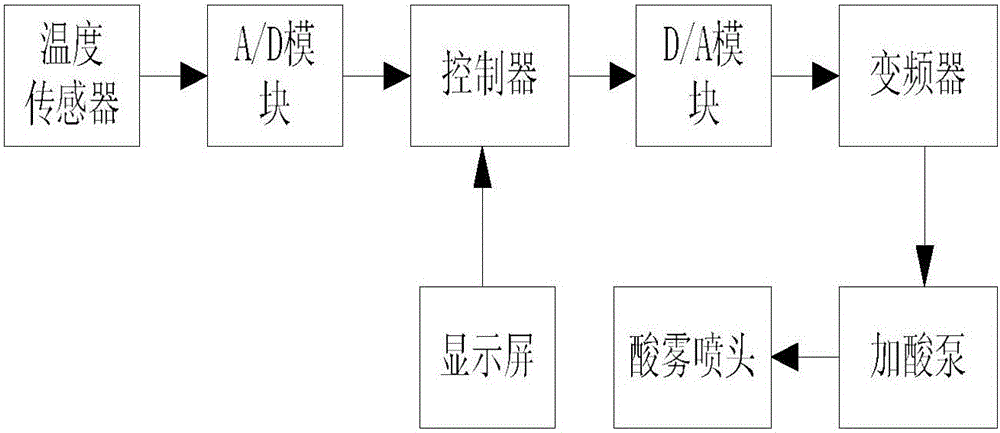

Paste mixing temperature and automatic acid-adding controlling device

PendingCN105845990AControlling uneven mixingWeight increaseFinal product manufactureLead-acid accumulator electrodesFrequency changerTemperature control

The invention discloses a paste mixing temperature and automatic acid-adding controlling device, which comprises a temperature control part and a pressurized acid spray control part, wherein the temperature control part comprises a temperature sensor, an A / D module, a controller and a D / A module; the temperature sensor, the A / D module, the controller and the D / A module are sequentially connected; the pressurized acid spray control part comprises a frequency converter, an acid adding pump and an acid mist spray head; the frequency converter, the acid adding pump and the acid mist spray head are sequentially connected; and the D / A module is connected with the frequency converter. By the control device, the lead paste temperature in the paste mixing process and the condition that an acid and a solution are mixed unevenly are effectively controlled through temperature control and pressurized acid spray control; the weight and thickness uniformity of the pole plates is greatly improved; and the service lifetime of a battery is prolonged.

Owner:ANHUI CHAOWEI POWER

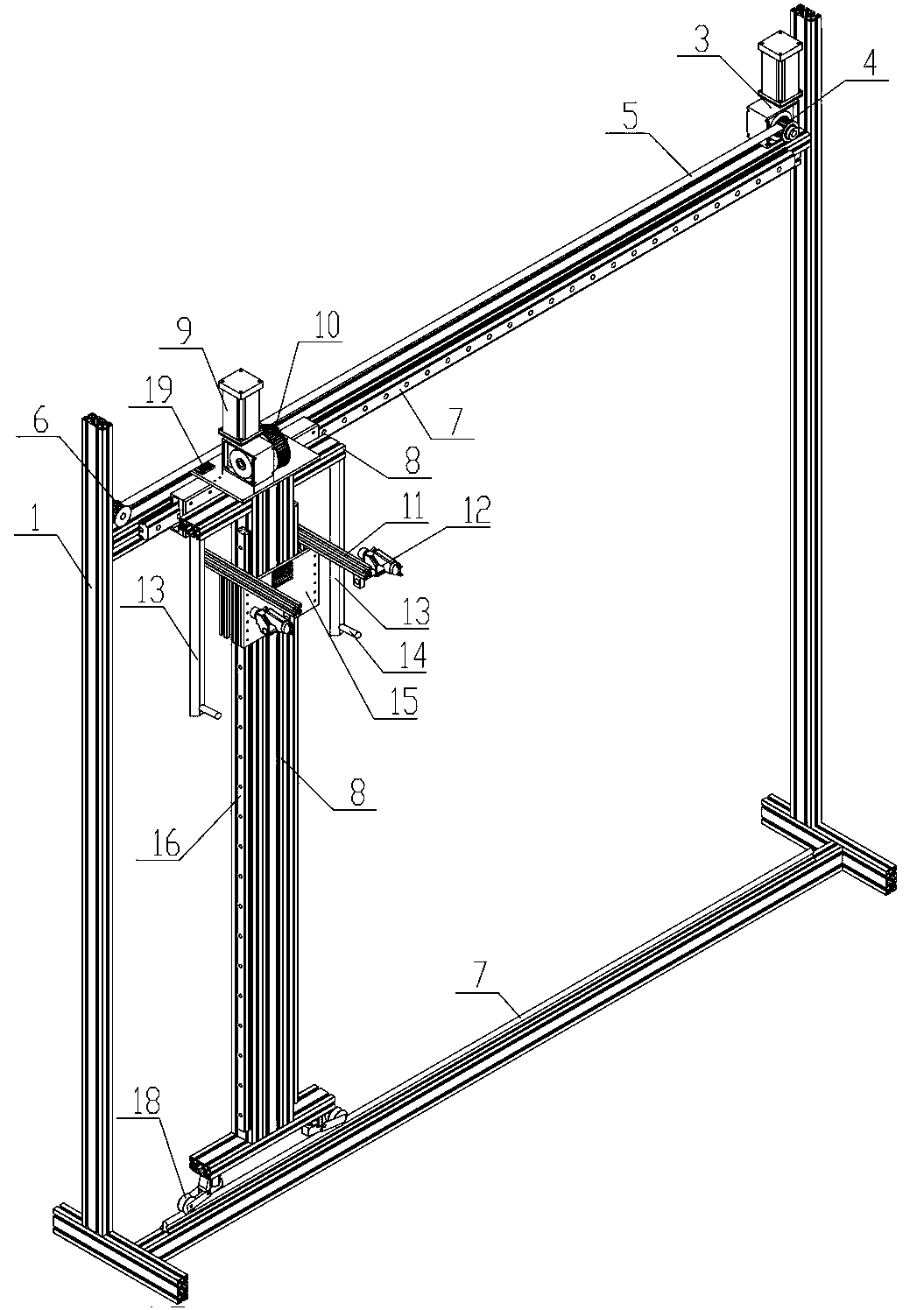

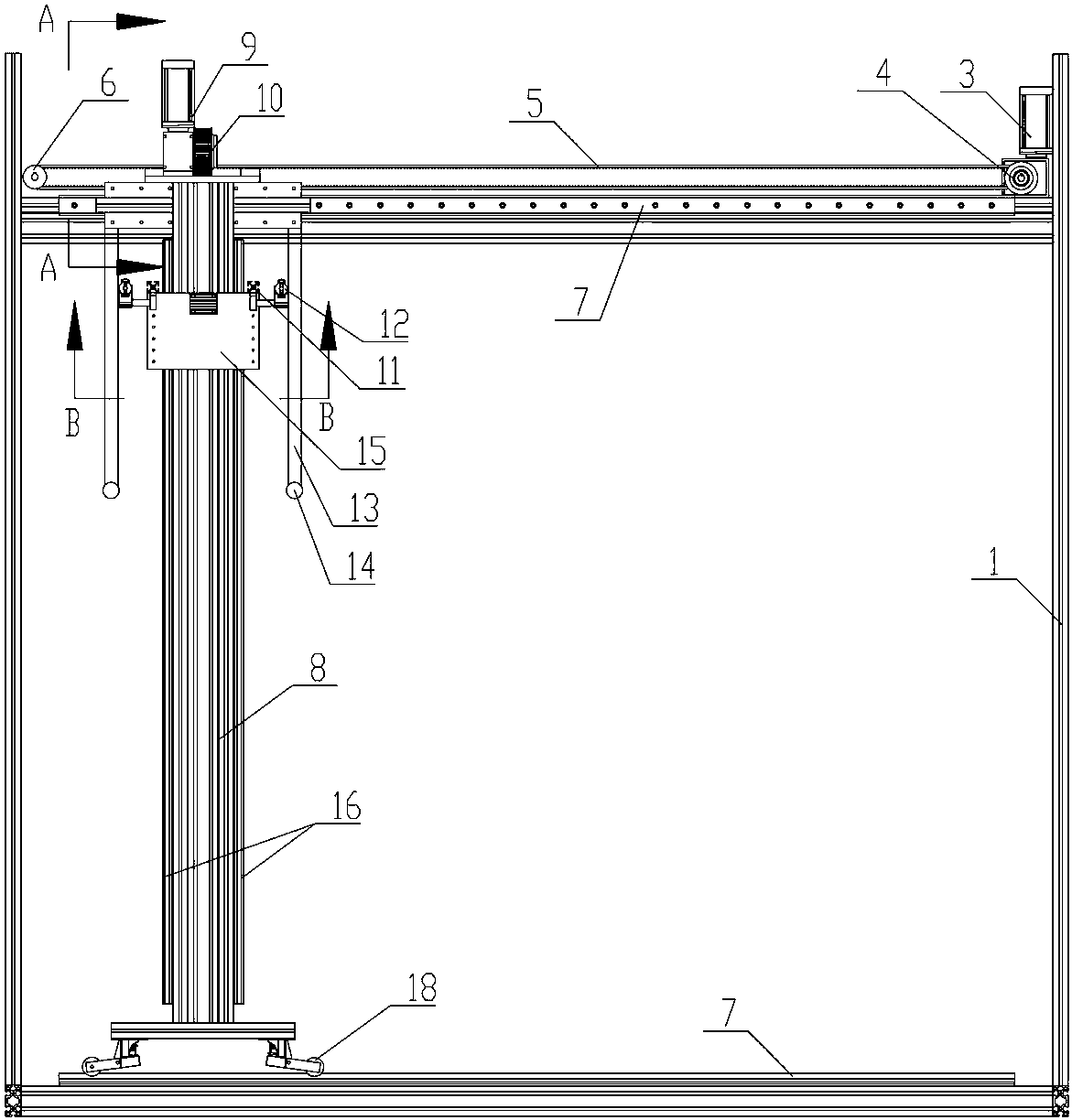

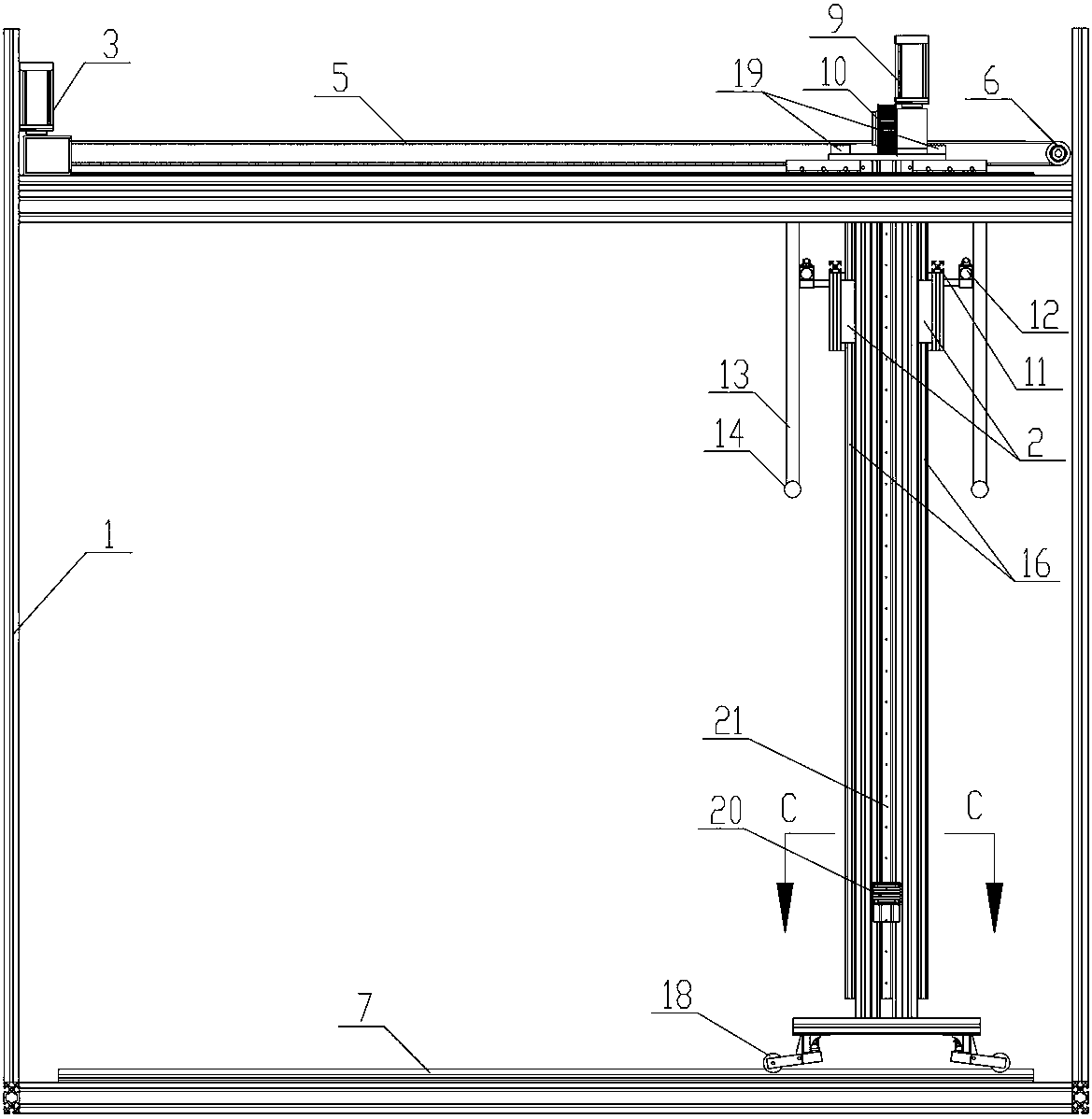

Automatic spraying machine for enamelled pressed steel

The invention relates to the field of decoration building materials, in particular to an automatic spraying machine for enamelled pressed steel. The automatic spraying machine comprises a rack. The bottom and top of the rack are provided with two horizontal guide rails respectively, the two horizontal guide rails are provided with a horizontally-moved support, the top of the rack is provided witha driving device A for driving the support to move horizontally, and the top of the support is provided with a driving device B. The two sides of the support are provided with two vertical guide railsrespectively, the two vertical guide rails are provided with two slide bases respectively, the portions, of the front end of the support, of the two slide bases are provided with a slide plate, and the rear end of the support is provided with a vertical rail. The rail is provided with a balance weight device capable of moving along the rail, a gear is connected to an output end of the driving device B and provided with a chain, one end of the chain is connected with the slide plate, the other end of the chain is connected with the balance weight device, and the two sides of the slide plate are provided with two spray guns respectively. According to the automatic spraying machine, the production efficiency is greatly improved, and the spraying quality is better.

Owner:HUBEI SANXING TECH CO LTD

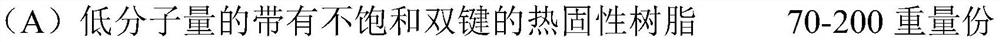

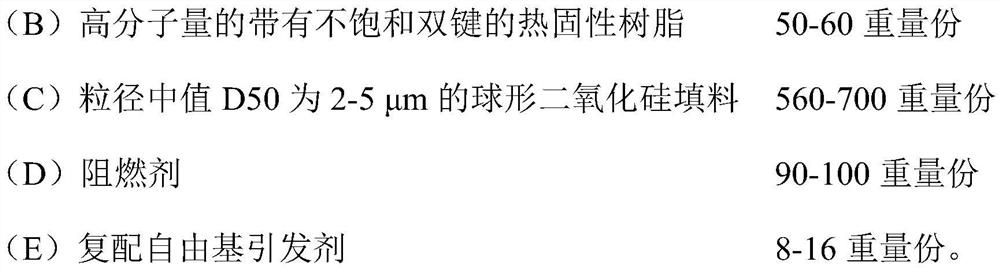

Circuit material and printed circuit board

ActiveCN112592554ASolve the PIM problemHigh thickness consistencyLaminationLamination apparatusDielectric substrateHemt circuits

The invention relates to a circuit material and a printed circuit board. The circuit material comprises a dielectric substrate layer and conductive metal layers, wherein the conductive metal layers are laminated on one side or two sides of the dielectric substrate layer, and the rough surface roughness Rz of the conductive metal layers is less than or equal to 3 microns; and the dielectric substrate layer comprises a reinforcing material and a resin composition covering the reinforcing material. The resin composition comprises the following components: thermosetting resin with unsaturated double bonds, of which the number-average molecular weight Mn is less than or equal to 5000g / mol, thermosetting resin with unsaturated double bonds and number-average molecular weight Mn greater than or equal to 50000 g / mol, a spherical silica filler having a median particle diameter D50 of 2-5 [mu] m, a flame retardant, and a compound radical initiator. The circuit material provided by the inventioncan meet the requirements of a high-frequency electronic circuit substrate on comprehensive properties such as thickness uniformity, stable low dielectric constant, low dielectric loss, full-band lowPIM value, low insertion loss and the like.

Owner:GUANGDONG SHENGYI SCI TECH

A kind of manufacturing method of ceramic core free end wax cap

ActiveCN109622883BHigh thickness consistencyUniform and controllable gapFoundry mouldsFoundry coresCastingCeramic materials

The invention discloses a method for manufacturing a wax cap at the free end of a ceramic core, comprising the following steps: designing the free end of the ceramic core; At the wax cap, process the space required by the size of the wax cap; put the ceramic core into the casting wax mold, inject wax into the mold and keep the pressure; take out the wax mold with the ceramic core. The invention replaces the previous method of pressing the wax mold and then manually brushing the wax to make the free-end wax cap. The method of the invention reduces production time. At the wax cap at the free end of the ceramic core corresponding to the inner cavity of the casting wax mold, process the space required by the size of the wax cap, put the ceramic core into the casting wax mold, inject wax into the mold and keep the pressure, and the mold is pressed The wax cap is more regular, the size of the wax cap and the thickness of the wax layer are more consistent, and the gap between the corresponding ceramic core and the mold shell is uniform and controllable, which can reduce the core breaking rate during pouring.

Owner:AECC AVIATION POWER CO LTD

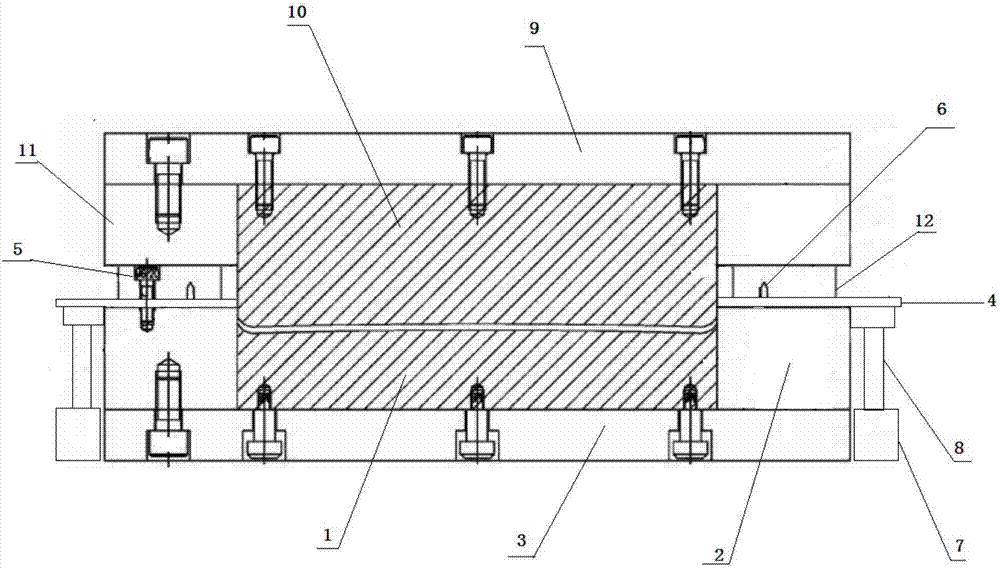

Stamping die of notebook computer aluminum alloy housing

InactiveCN107398503ASave stripping timeEasy to remove stripping materialShaping toolsMaterials scienceAluminium alloy

The invention discloses a stamping die for an aluminum alloy shell of a notebook computer, which comprises a forming die, a die fixing plate, and a lower die base, and the die fixing plate is a frame-shaped plate, which is fixed on the lower die base plane, the forming die is embedded in the frame-shaped cavity of the die fixing plate, and in this technical solution, it also includes a supporting plate and a hydraulic device, and the supporting plate is arranged between the die fixing plate and the Between the stamping parts of the aluminum alloy shell, the output end of the hydraulic device is connected to the support plate to drive the support plate to move up and down. The stamping die sets a supporting plate between the aluminum alloy slab stamping part and the die fixing plate. After the stamping is completed, the punch rises, and the hydraulic device drives the supporting plate to lift the stamping part away from the plane of the groove fixing plate. Therefore, it is convenient to remove the stripping material, the device structure is simple, and the operation is convenient, which effectively saves the stripping time of the stamping parts and improves the stamping efficiency.

Owner:KUNSHAN YULI METAL PROD

Vacuum tube type microwave heating carbon furnace

PendingCN108172354AShort sintering timeUniform temperatureOhmic-resistance heatingMicrowave heatingCarbon filmHigh rate

The invention provides a vacuum tube type microwave heating carbon furnace, relates to the technical field of high temperature vacuum coating equipment, and solves the technical problems that a heating temperature field inside the furnace is non-uniform and the resistance value of a resistor carbon film is not inconsistent. The vacuum tube type microwave heating carbon furnace comprises a furnacebody, a magnetron, a double-layer vacuum quartz tube with a jacket, and a microwave absorbing heating material, wherein the magnetron is arranged on a furnace body, and the magnetron can emit microwaves inside an inner cavity of the furnace body after being electrified; the vacuum quartz tube is arranged inside the furnace body in a rotating manner, and treated workpieces are placed inside the vacuum quartz tube for carbon coating film treatment; and the microwave absorbing heating material inside the jacket of the vacuum quartz tube can emit heat after absorbing microwaves, and the furnace body is further internally provided with a heat insulation layer made of a microwave-transmitting material. A novel material sintering method has the characteristics of high heating rate, high energy utilization rate, high heating efficiency, uniform material temperature field, good technological controllability, short technological period, good product uniformity and high rate of finished products.

Owner:宁波拓源新材料科技有限公司

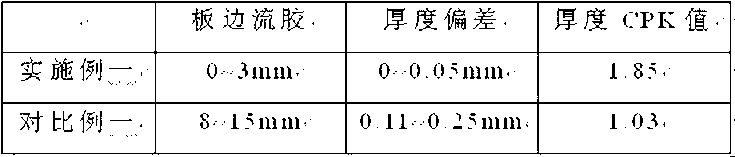

Preparation method of copper-clad plate

ActiveCN103101280AImprove the problem of thin thicknessImprove thickness uniformityLaminationLamination apparatusCopper foilEngineering

The invention discloses a preparation method of a copper-clad plate, which comprises the following steps: (1) taking at least one prepreg, and stacking copper foils on the single side or double sides of the prepreg so as to obtain prepreg combinations; (2) taking at least one set of the prepreg combination, and placing the at least one set of the prepreg combination between upper and lower heating plates of a laminating machine to carry out laminated pressing; (3) in the stage of glue solution melting in the process of laminating, heating the periphery of the prepreg, so that a glue solution at the periphery of the prepreg achieves a high elastic state prior to a glue solution in the middle of the prepreg, wherein the relative curing degree of the glue solution in the high elastic state is over 60%; and (4) carrying out conventional laminating operation, so that the copper-clad plate can be obtained. According to the invention, a novel copper-clad plate preparation method is developed, so that the glue flowing problem in the process of laminating is prevented, and the problem that the thicknesses of four edges of the copper-clad plate are thin is effectively improved, thereby significantly improving the thickness uniformity and consistency of each part of the plate.

Owner:SHENGYI TECH SUZHOU

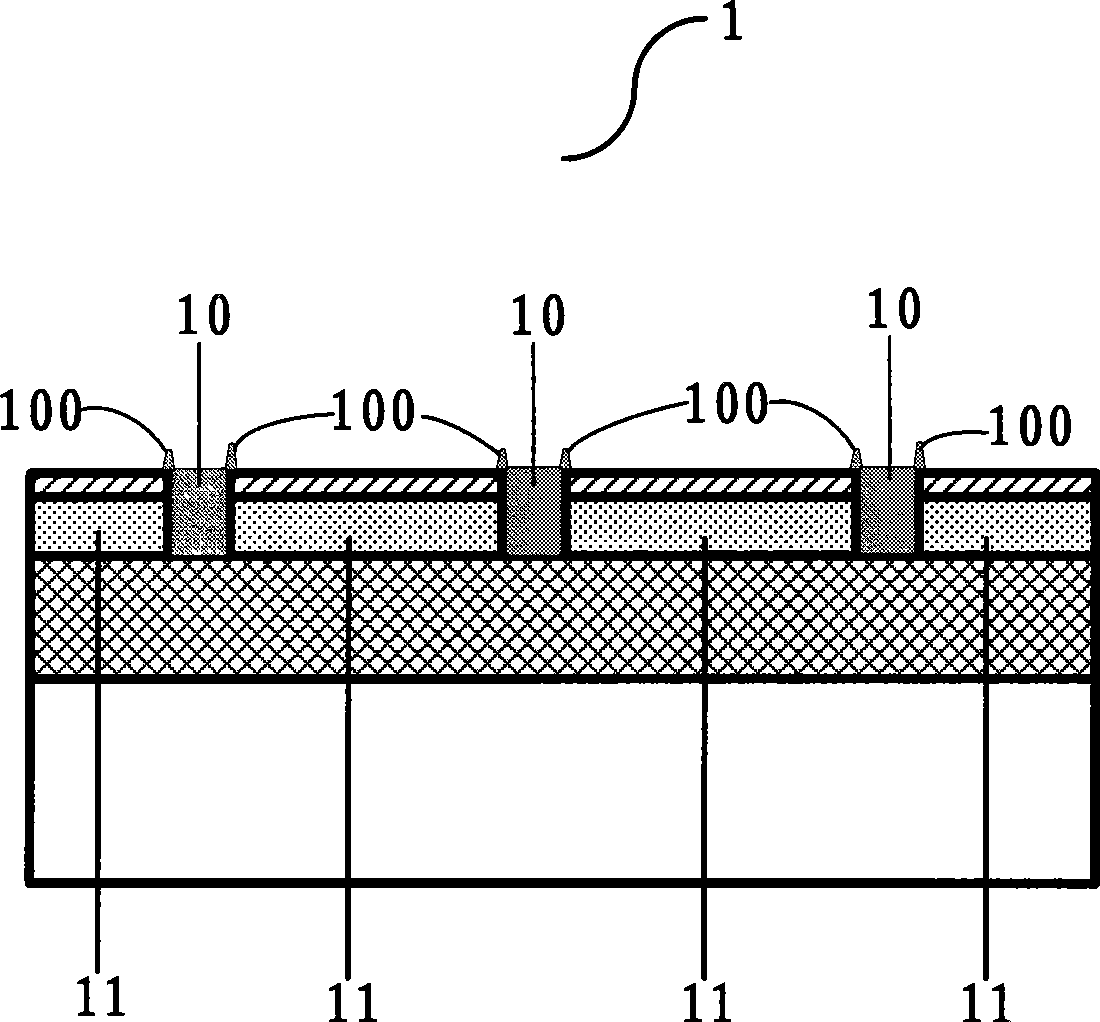

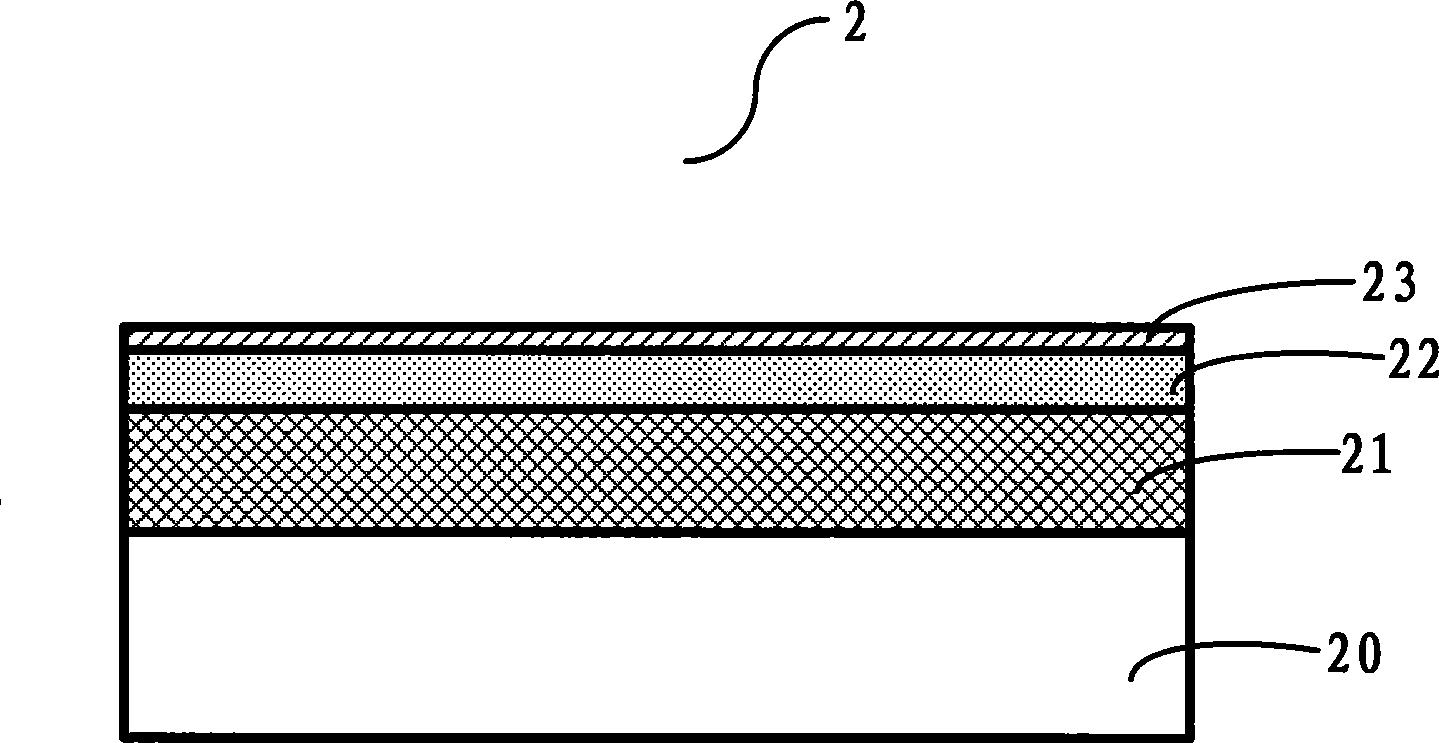

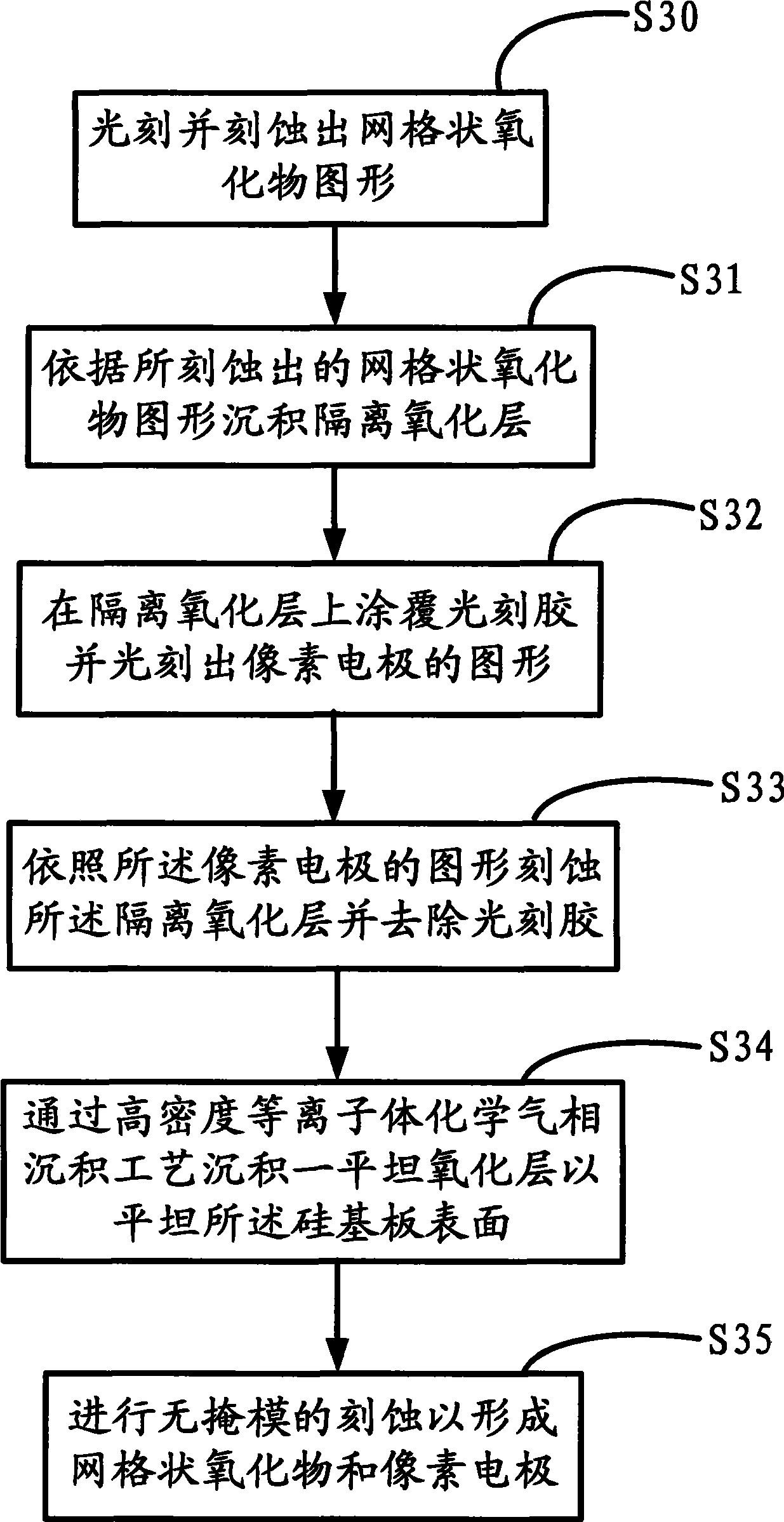

Flatness-raised pixel electrode manufacture method

ActiveCN101399224AImprove flatnessHigh thickness consistencySemiconductor/solid-state device manufacturingNon-linear opticsResistDisplay contrast

The invention provides a pixel electrode preparation method which can improve the flatness, and the pixel electrode is manufactured on a silicon substrate which is provided with a control circuit, as well as top metal and a protective oxide layer which are stacked on the control circuit. In the prior art, when the pixel electrode is manufactured, latticed oxide is prone to be facilitated to generate a convex, thus affecting the flatness of the pixel electrode, and further affecting the performance of liquid crystal on the silicon substrate. In the pixel electrode preparation method, firstly, a latticed oxide pattern used for dividing the top metal into a plurality of pixel electrodes is prepared by lithography and etching; then, an isolation oxide layer is deposited; after that, optical resist is coated on the isolation oxide layer and a pattern of pixel electrodes is prepared by lithography; then, the isolation oxide layer is etched according to the pattern of pixel electrodes and the optical resist is removed; after that, a flat oxide layer is deposited on the flat surface of the silicon substrate; finally, maskless etching is carried out to form the latticed oxide and the pixel electrodes. The invention has the advantage that the flatness of the pixel electrode can be greatly improved, and then the performance, especially the display contrast, of the liquid crystal on the silicon substrate is improved.

Owner:SEMICON MFG INT (SHANGHAI) CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com