Stamping die of notebook computer aluminum alloy housing

A technology for aluminum alloy shells and notebook computers, which is applied to forming tools, manufacturing tools, metal processing equipment, etc., can solve the problems of troublesome removal of stamping parts, affecting stamping efficiency, etc., and achieves convenient operation, improved stamping efficiency, and convenient removal. Material effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

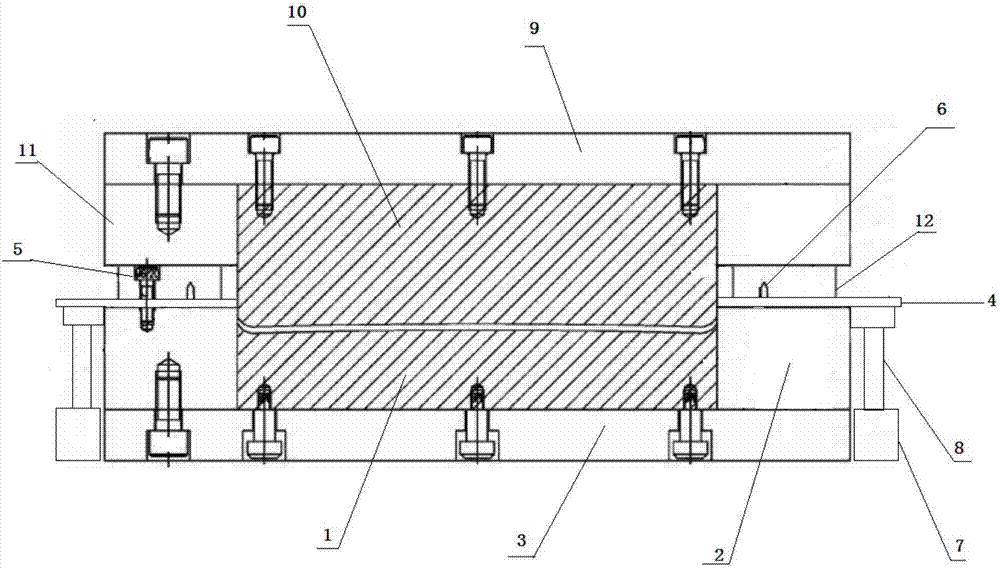

[0015] Embodiment 1: as figure 1 The stamping die for the aluminum alloy casing of the notebook computer shown is used to punch the cut aluminum alloy slab into the shape of the casing, including the forming die 1, the die fixing plate 2, the lower die base 3, the supporting plate 4, the hydraulic pressure Device, limit screw 5, positioning rod 6, upper die base 9, forming punch 10, punch fixing plate 11, blank holder ring 12, guide post (not shown in the figure), die fixing plate 2 is frame-shaped plate, which is fixed on the upper plane of the lower mold base 3 by screws. The forming die 1 is embedded in the frame-shaped cavity of the die fixing plate 2, and is fixed on the upper plane of the lower mold base 3 by screws. The punch fixing plate 11 is a frame plate, which is fixed on the lower plane of the upper die holder 9 by screws. The forming punch 10 is embedded in the frame-shaped cavity of the punch fixing plate 11 . The forming punch 10 is located above the forming...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com