Forming mold and forming process for composite material product with complex structure

A composite material and complex structure technology, which is applied in the field of forming molds and forming processes of composite materials products, can solve the problems of pinholes, complex mold manufacturing, uneven heating, etc., so as to save the release time, improve the molding quality, and simplify the mold. effect of structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

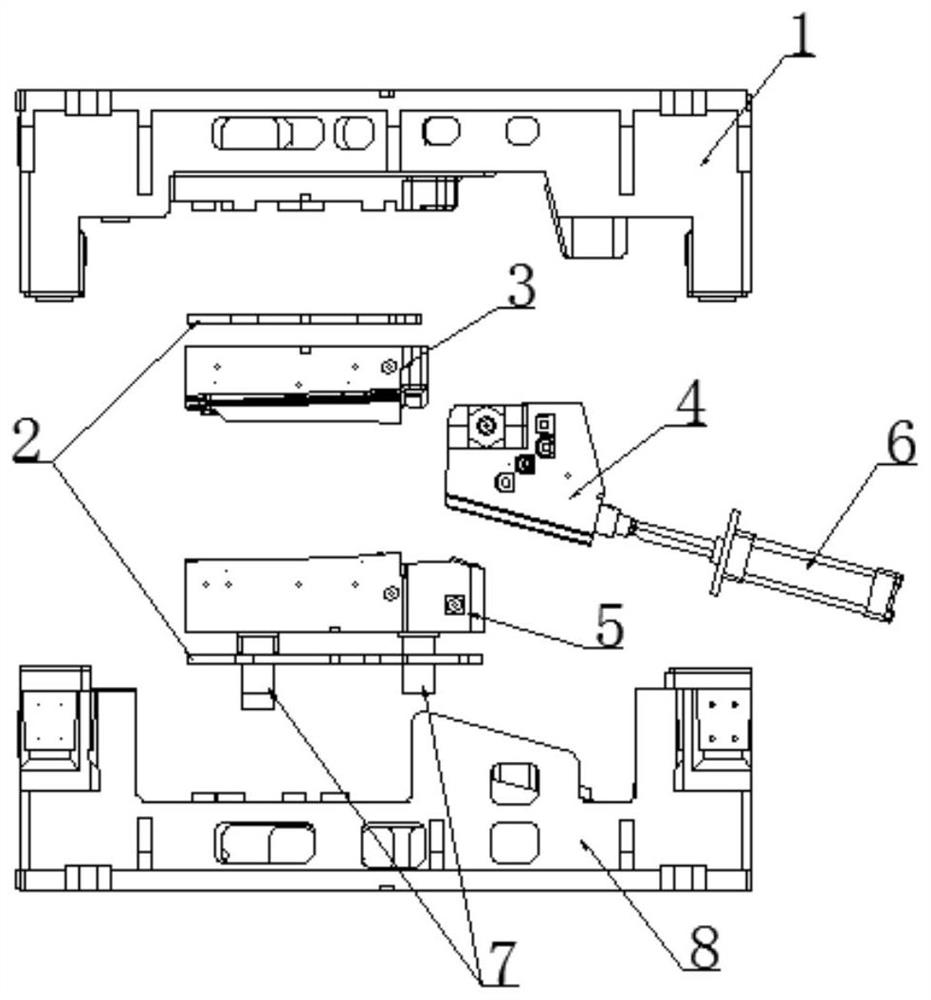

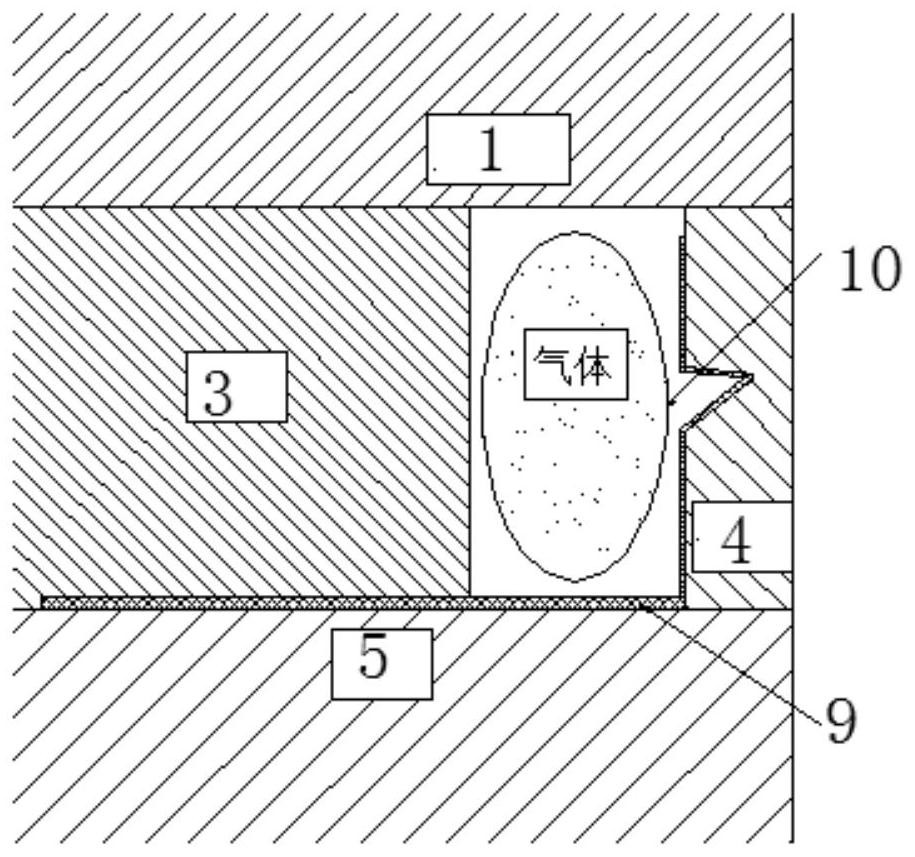

[0050] The first step is to soak the air duct in the release agent solution for 30 minutes, take it out, and let it dry naturally for use;

[0051] In the second step, apply the release agent 3 times in the cavities of the insert 4, the upper mold 3 and the lower mold 5, including the interface of the air duct of the insert 4, and install the air duct to the interface of the insert 4;

[0052] The third step is to cut the 10-layer composite material prepreg according to the specified shape, and lay it on the preform jig to form a preform, and take it out for use;

[0053] The fourth step is to place the preform in the mold cavity and close the mold;

[0054]The fifth step is to blow gas into the air duct to the predetermined pressure and maintain it, then circulate the heating oil to maintain 140°C to heat the mold and product for 4 hours;

[0055] The sixth step, after the product is solidified, release the gas in the air duct, and circulate the cooling oil to cool down;

...

Embodiment 2

[0059] The first step is to soak the air duct in the release agent solution for 30 minutes, take it out, and let it dry naturally for use;

[0060] In the second step, apply the release agent 3 times in the cavities of the insert 4, the upper mold 3 and the lower mold 5, including the interface of the air duct of the insert 4, and install the air duct to the interface of the insert 4;

[0061] The third step is to cut the 8-layer composite material prepreg according to the specified shape, and lay it on the preform jig to form a preform, and take it out for use;

[0062] The fourth step is to place the preform in the mold cavity and close the mold;

[0063] The fifth step is to blow gas into the air duct to the predetermined pressure and maintain it, then circulate the heating oil and maintain 140°C to heat the mold and product for 3 hours;

[0064] The sixth step, after the product is solidified, release the gas in the air duct, and circulate the cooling oil to cool down;

...

Embodiment 3

[0068] The first step is to soak the air duct in the release agent solution for 30 minutes, take it out, and let it dry naturally for use;

[0069] In the second step, apply the release agent 3 times in the cavities of the insert 4, the upper mold 3 and the lower mold 5, including the interface of the air duct of the insert 4, and install the air duct to the interface of the insert 4;

[0070] The third step is to cut the 4-layer composite material prepreg according to the specified shape, and lay it on the preform jig to form a preform, and take it out for use;

[0071] The fourth step is to place the preform in the mold cavity and close the mold;

[0072] The fifth step is to blow gas into the air duct to the predetermined pressure and maintain it, then circulate the heating oil to maintain 140°C to heat the mold and product for 1 hour;

[0073] The sixth step, after the product is solidified, release the gas in the air duct, and circulate the cooling oil to cool down;

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com