Precise automatic press for electronic ceramics

A technology for electronic ceramics and printing machines, which is applied to printing machines, rotary printing machines, screen printing machines, etc. It can solve the problems of slurry sagging, inconsistent product coating thickness, and affecting the quality of electronic ceramic products, so as to improve the accuracy , Uniformity and Thickness Consistency Improvement Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

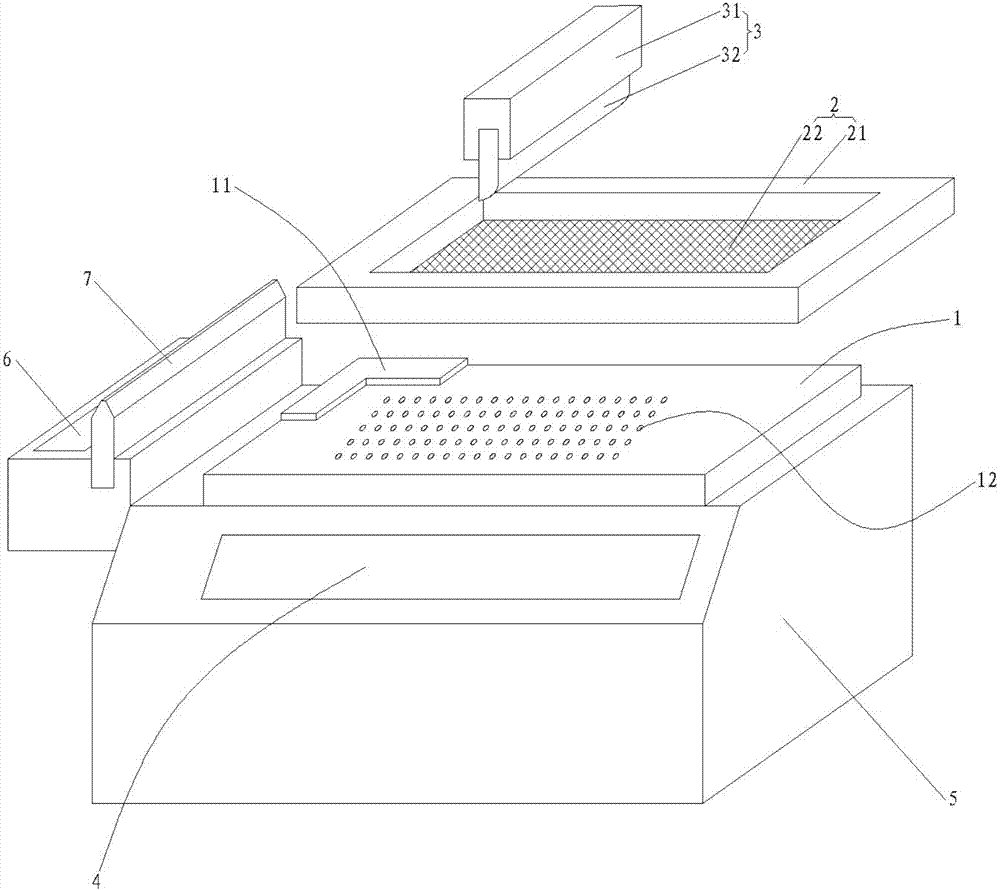

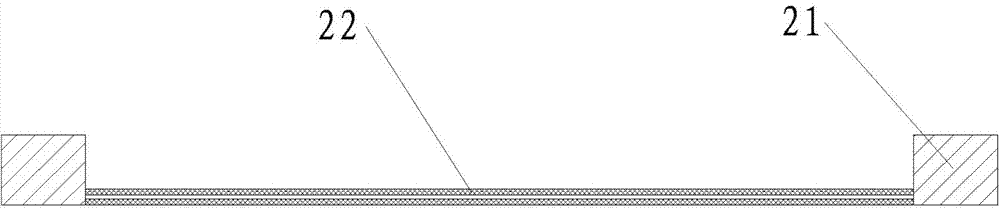

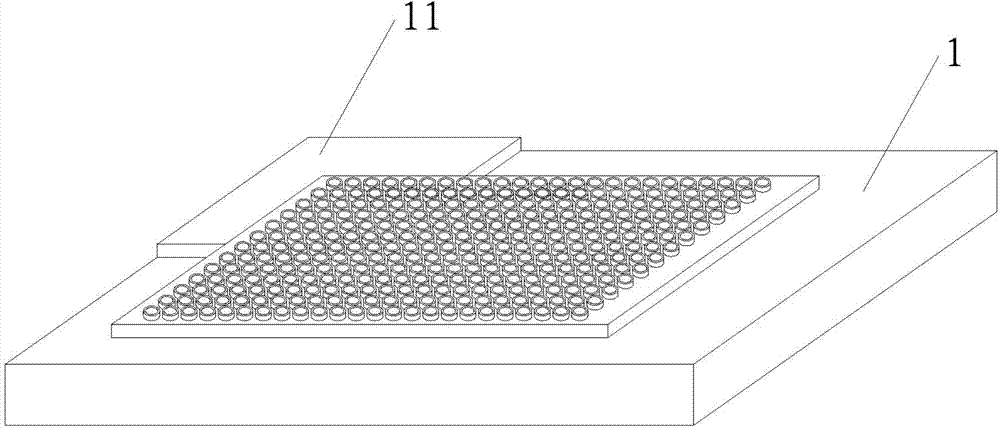

[0028] This embodiment provides a precision automatic printing machine for electronic ceramics, please refer to figure 1 , figure 2 with image 3 , The precision automatic printer includes: the printed electronic ceramic support table 1, the printing screen assembly 2, the slurry scraper assembly 3 and the control mechanism 4. The printed electronic ceramic support table 1, the printing screen assembly 2, the slurry scraper assembly 3 and the control mechanism 4 are all installed on the printer frame 5, wherein the printed electronic ceramic support table 1 and the control mechanism 4 are relatively fixedly installed On the printer frame 5, the printing screen assembly 2 and the slurry scraper assembly 3 are respectively installed on the printer frame 5 through a lifting mechanism and a rail mechanism. When printing conductive layers or other functional layers on electronic ceramic blanks, the regularly arranged printed electronic ceramic blanks are placed on the printed elect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com