Automatic grinding and tabletting press

A tablet press, automatic technology, applied in the field of laboratory inspection equipment, can solve the problems of large sample consistency deviation, long production process, and influence on experimental results, etc., achieve high thickness consistency, improve sample processing efficiency, and guarantee reliability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

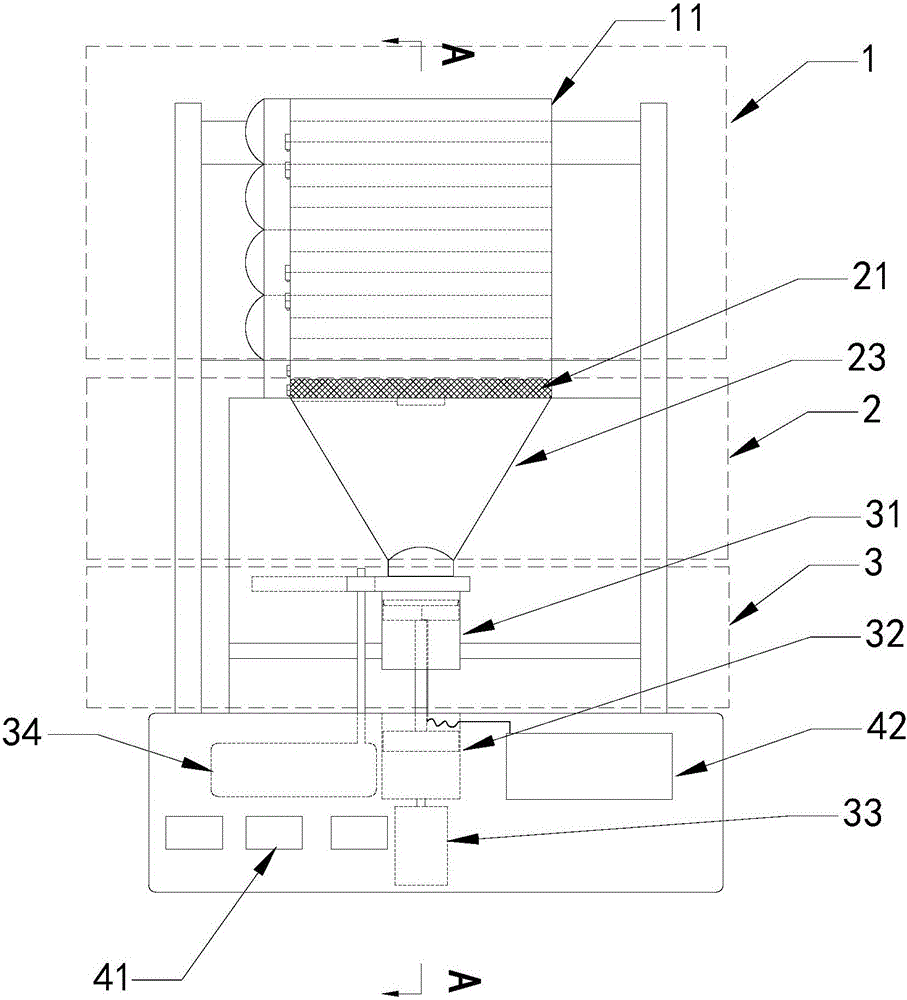

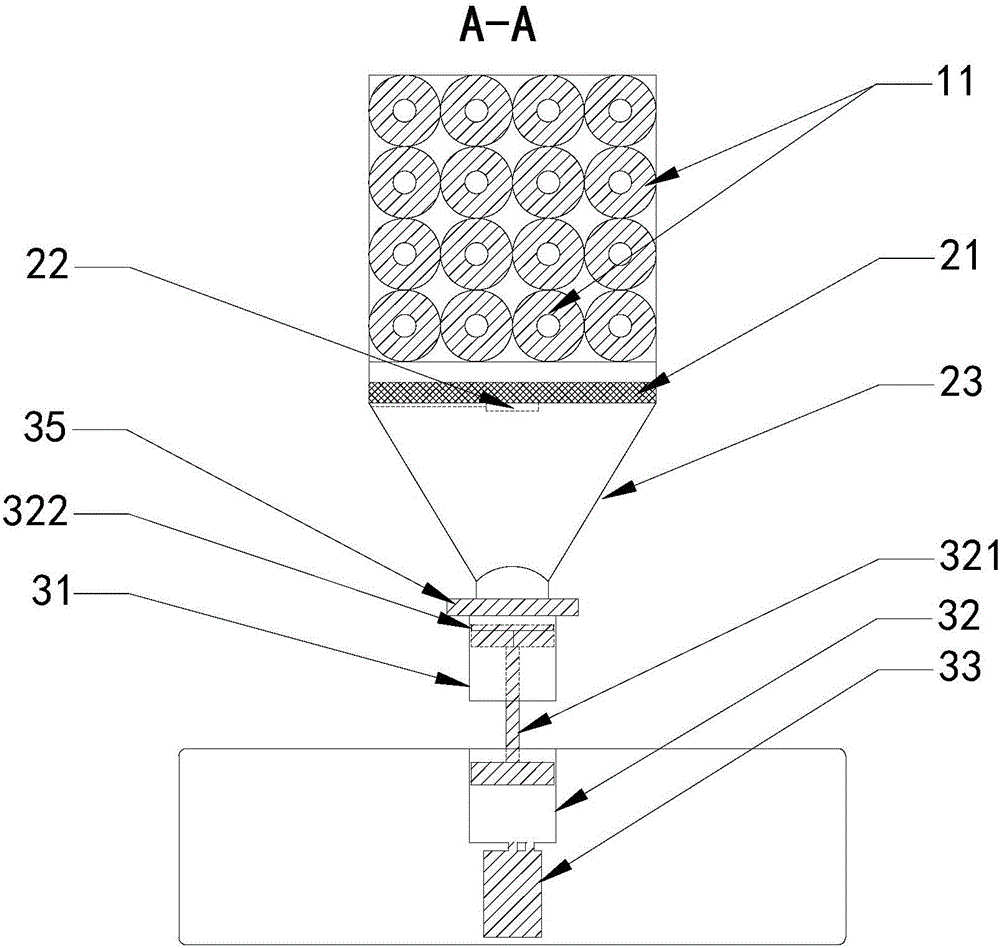

[0032] see Figure 1 to Figure 6 , an embodiment of the present invention is an automatic grinding tablet press for making infrared samples, the automatic grinding tablet press includes a grinding device 1 for grinding infrared samples from top to bottom, and is used to sieve the ground powder A sieving device 2 for sieving, and a tableting device 3 for compressing the sieved sample powder.

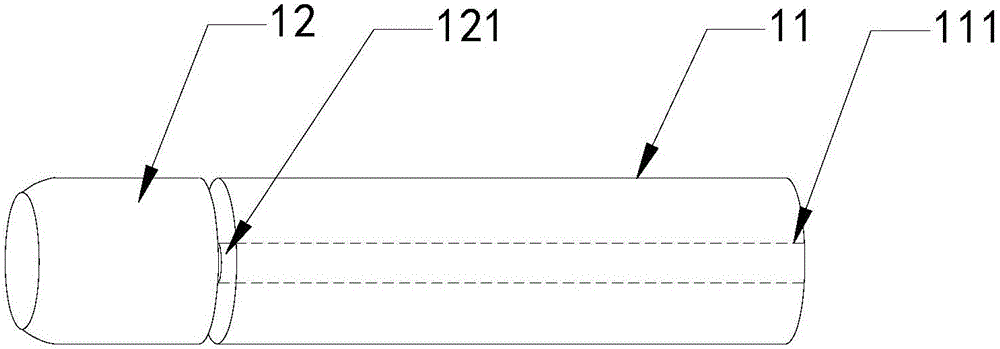

[0033] see figure 1 and figure 2 , the grinding device 1 includes more than two layers of grinding layers stacked, each grinding layer includes more than two pairs of grinding columns 11 arranged horizontally, and the gap between the grinding columns on each grinding layer gradually becomes smaller from top to bottom One end of the grinding column...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com