Table chip double side electrophoresis glass passivation technology

A glass passivation and electrophoresis technology, applied in the manufacturing of circuits, electrical components, semiconductor/solid-state devices, etc., can solve the problems of poor electrical properties of devices, glass peeling, poor reliability, etc., and achieve improved thickness consistency and surge resistance. The effect of enhancement, voltage stability improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

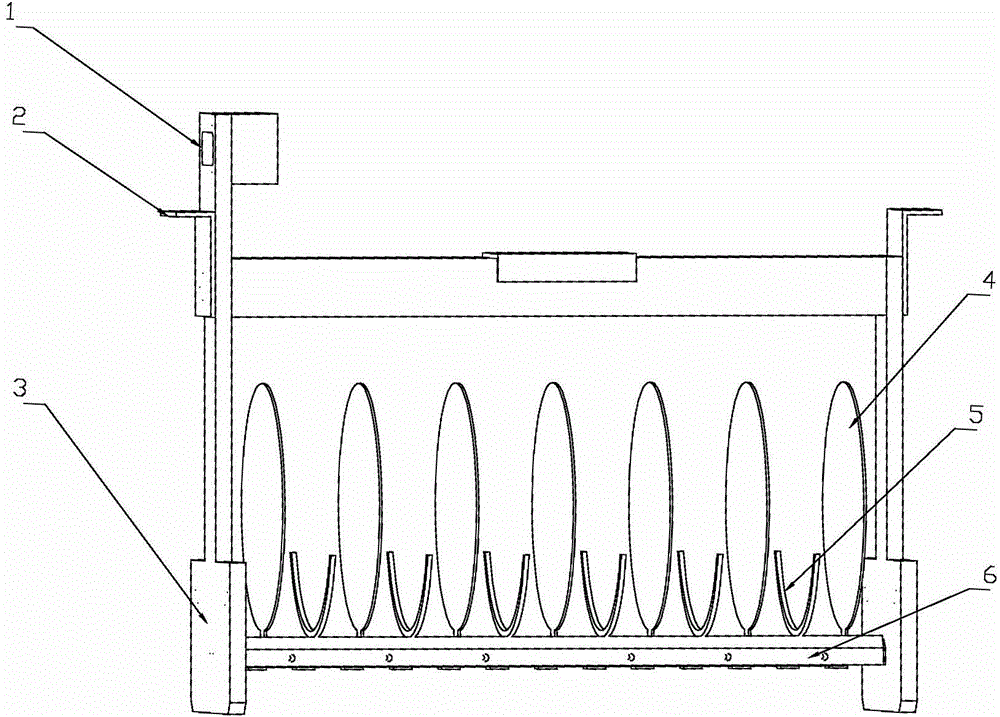

Image

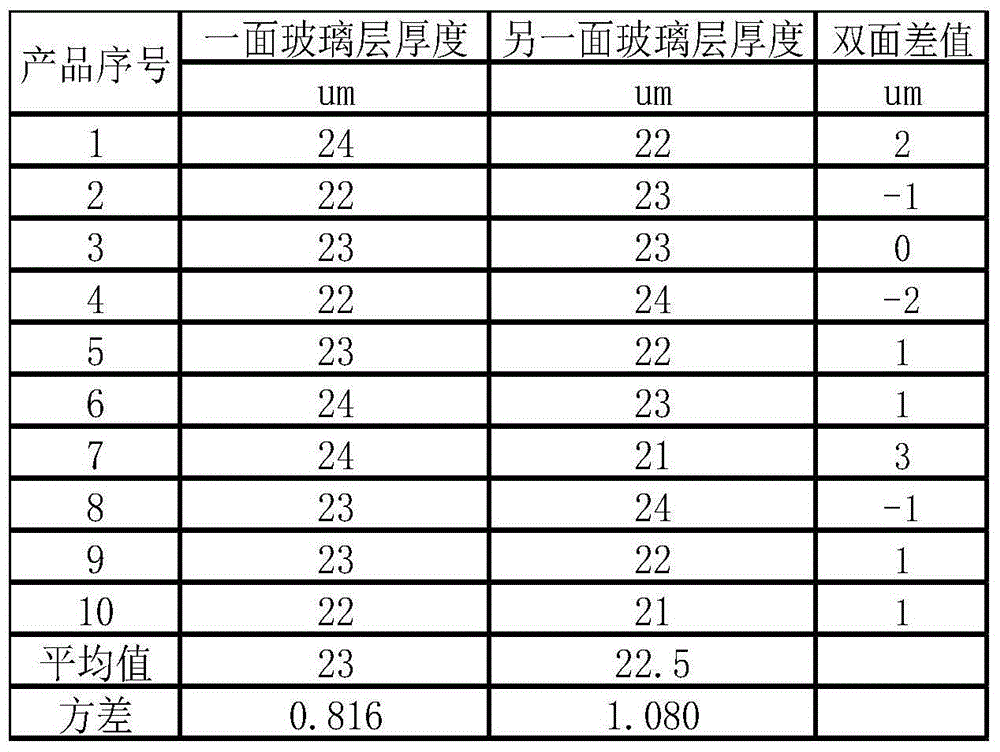

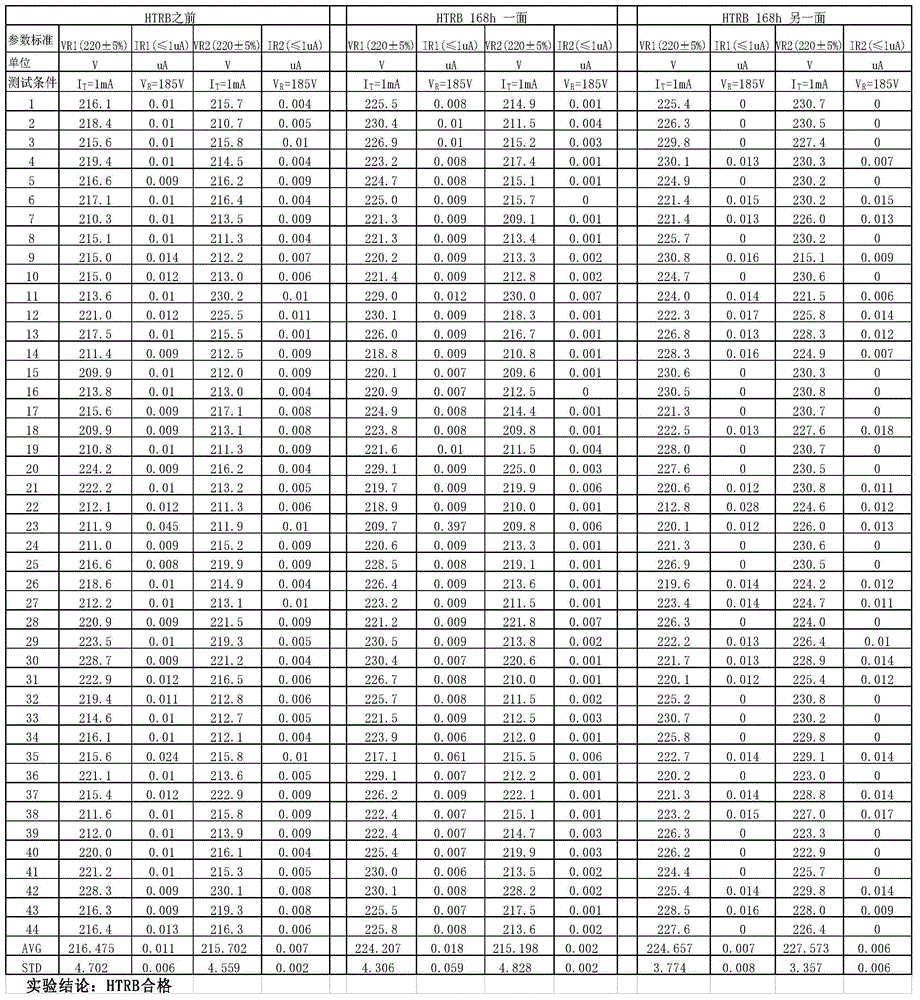

Examples

Embodiment Construction

[0019] The passivation process of a double-sided electrophoretic glass for a mesa chip according to the present invention will be further described in detail through specific examples below.

[0020] A double-sided electrophoretic glass passivation process for mesa chips, comprising the following steps:

[0021] 1) Double-sided photolithography: double-sided gluing, double-sided exposure, and development processes are performed on the diffused and oxidized silicon wafer (4:00 bidirectional mesa device) to form a mesa pattern;

[0022] 2) Double-sided mesa corrosion: use nitric acid, hydrofluoric acid, and glacial acetic acid to corrode the double-sided mesa groove according to the ratio of 5:3.3:1. The temperature of the mixed acid is controlled at -8~-12°C and rinsed with deionized water ;In this embodiment: 5000mL of nitric acid, 3300mL of hydrofluoric acid, and 1000mL of glacial acetic acid are poured into the etching tank in sequence, and the temperature is controlled at -...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com