Preparation method of winding type super capacitor

A supercapacitor, wound technology, applied in the field of electrochemistry, can solve the problems of increasing capacitor weight, poor thickness controllability, large equivalent series resistance, etc., achieve good power characteristics and current response, improve energy and power density, The effect of reducing the equivalent series resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

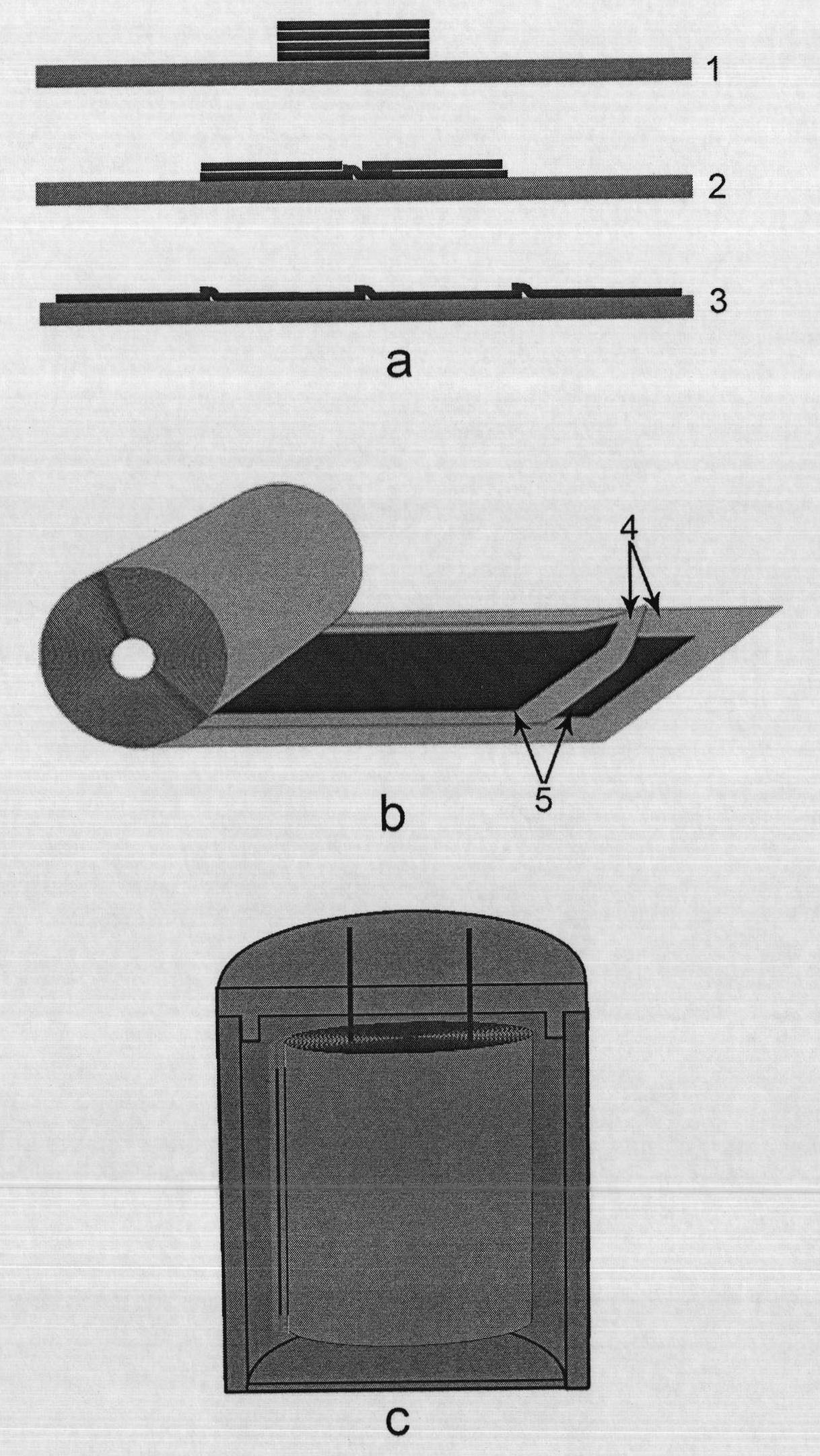

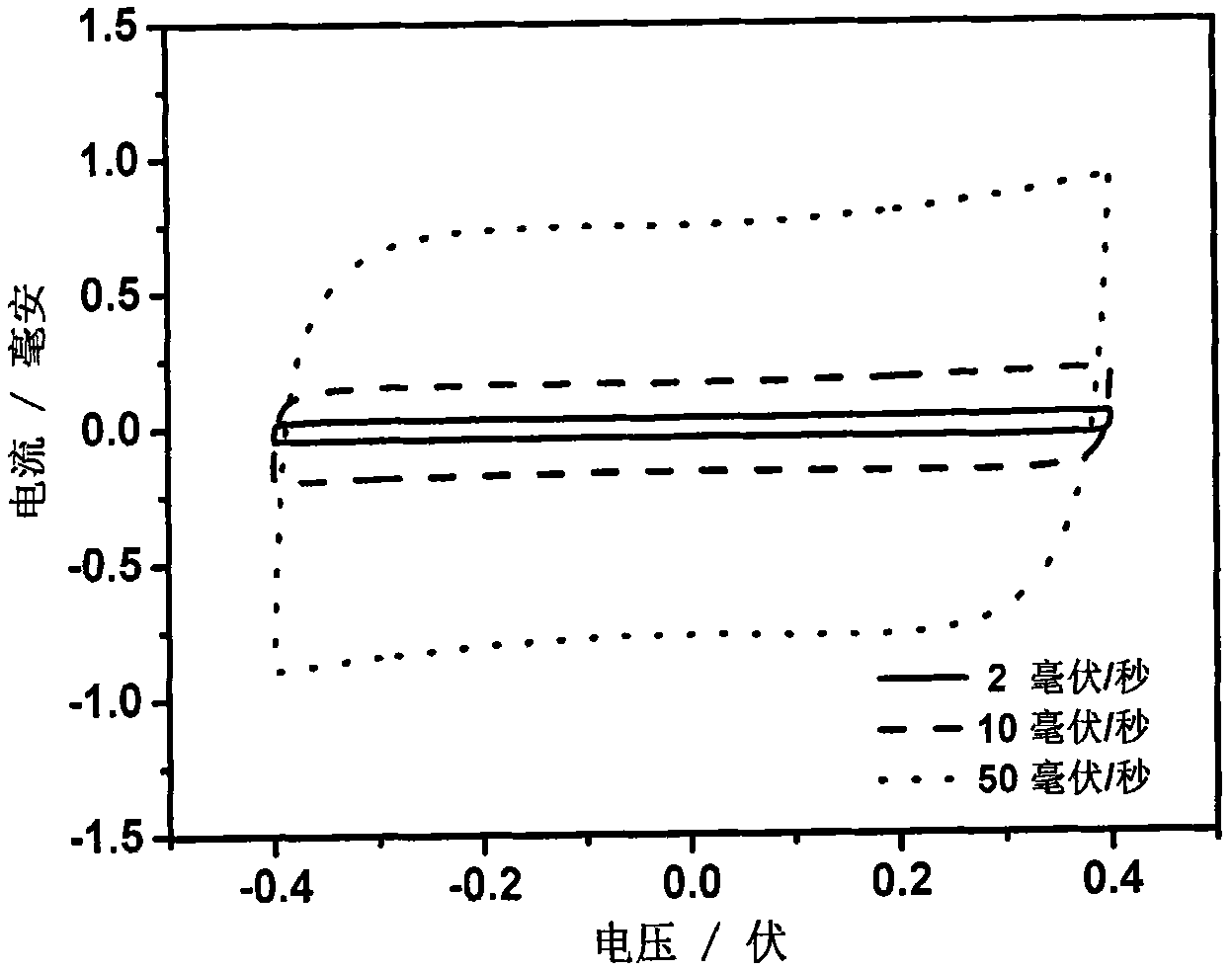

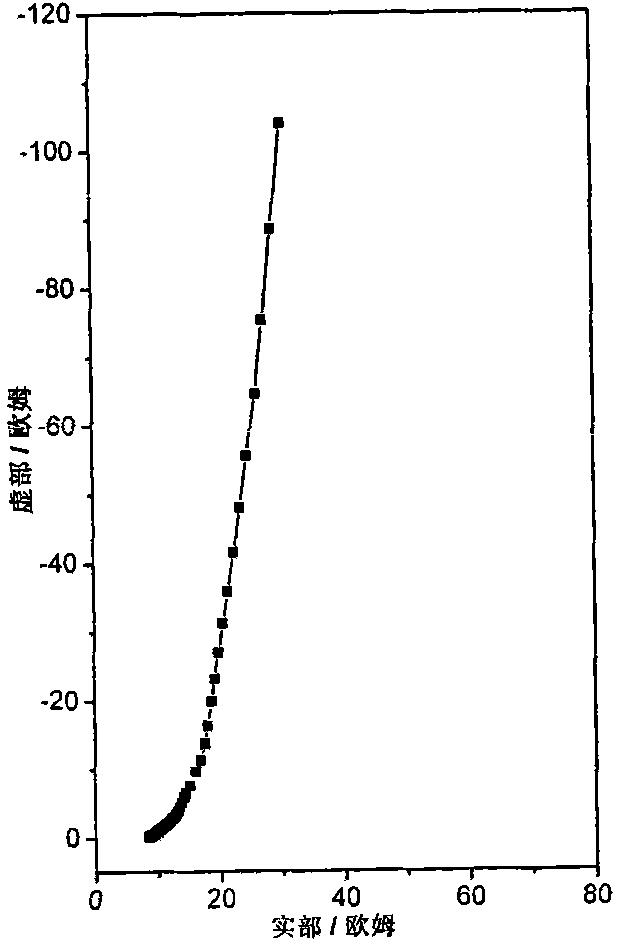

[0038] Below in conjunction with specific embodiment, from the selection of electrode material, the preparation of carbon nanotube film electrode, the assembly of carbon nanotube film wound supercapacitor and the comprehensive performance measured data of carbon nanotube film wound supercapacitor, do the present invention Further explanations and clarifications.

[0039] 1. Selection of electrode materials

[0040] The carbon nanotube thin film used in this embodiment is directly grown by floating catalytic chemical vapor deposition (hereinafter referred to as direct growth method). Unlike the carbon nanotube polymer film, the carbon nanotube film prepared by the direct growth method can be directly tiled on the separator as a positive and negative electrode material without using a metal substrate as a current collector. At the same time, it has strong adsorption. Compared with the carbon nanotube film prepared by the post-deposition method, the carbon nanotube film prepared...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| tensile stress | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com