Circuit material and printed circuit board

A circuit and reinforcement material technology, which is applied in printed circuits, circuit substrate materials, printed circuit components, etc., can solve problems such as thickness uniformity, dielectric constant uniformity, and PIM problems in low frequency bands.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

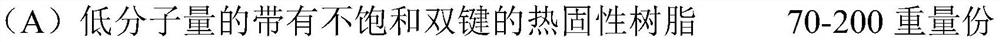

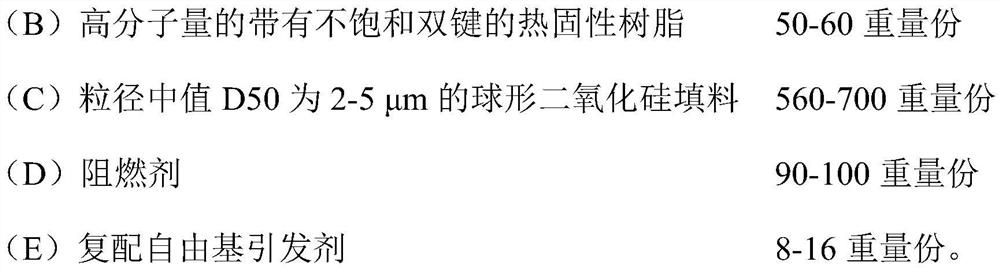

Method used

Image

Examples

Embodiment 1-10

[0072] Prepare the resin composition according to the components shown in Table 2 (the unit of raw material dosage is parts by weight), and make a copper-clad laminate sample according to the following production method:

[0073] (1) Dissolve and mix the components in the formula quantity into the reaction kettle, dilute with toluene to an appropriate viscosity, stir and mix evenly to obtain the resin glue.

[0074] (2) Soak the glass fiber cloth with the resin glue (the unit of the reinforcing material in Table 2 is the number of sheets), remove the solvent and bake to a semi-cured state, then stack multiple sheets, and press a copper foil on the top and bottom (Table 2 The unit of the conductive metal layer in 2 is the number of sheets), put it into a press for curing to obtain a copper clad laminate, the curing temperature is 240 °C, and the curing pressure is 50kg / cm 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com